Subway train special gear oil and preparation method

A technology for gear oil and trains, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of shortening the service life of friction parts, affecting the safe operation of subway trains, and carbon deposition on friction parts of gear boxes, etc., to reduce noise, reduce Subway operating costs and the effect of extending the oil change interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

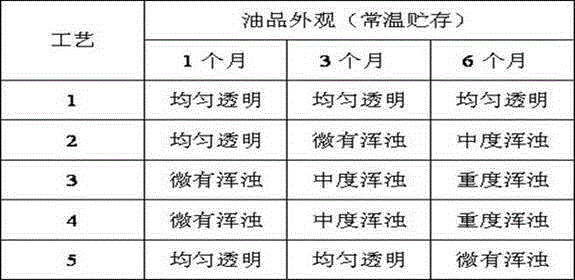

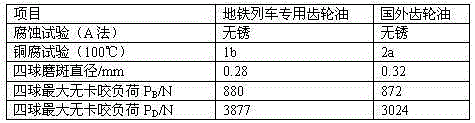

Method used

Image

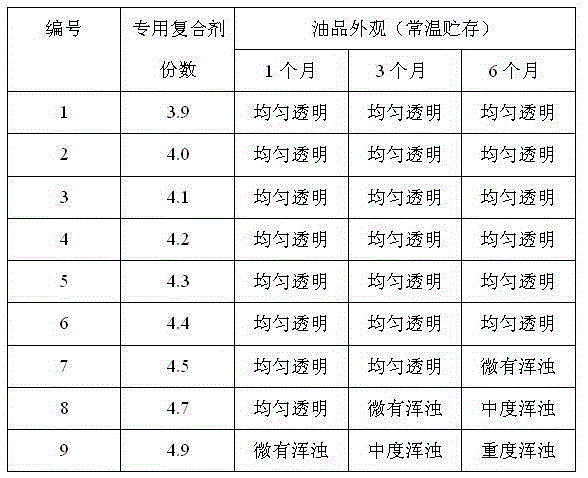

Examples

Embodiment 1

[0025] A special gear oil for subway trains is composed of the following components in parts by weight: 93 parts of base oil, 1 part of thickener, 0.4 part of pour point depressant, 3.9 parts of special compounding agent, and 0.0015 parts of antifoaming agent.

[0026] The base oil is composed of 650SN, 500N, 150BS base oil, and its weight ratio is: 650SN47 parts, 500N16 parts, 150BS30 parts.

[0027] The tackifier is polyisobutylene.

[0028] The pour point depressant is polymethacrylate.

[0029] The special compounding agent, in parts by weight, includes: 12 parts of extreme pressure antiwear agent, 11 parts of oily agent, 0.1 part of antioxidant, 0.12 part of friction modifier, and 0.1 part of rust inhibitor. Among them, the extreme pressure antiwear agent is a mixture of 3 parts of acidic dibutyl phosphite and 9 parts of vulcanized cottonseed oil, the oiliness agent is benzotriazole fatty acid ammonium salt, and the antioxidant is dialkyl dithiocarbamate. The improver is molybde...

Embodiment 2

[0033] A special gear oil for subway trains is composed of the following components in parts by weight: 93 parts of base oil, 1 part of thickener, 0.4 part of pour point depressant, 4.1 parts of special compounding agent, and 0.0015 parts of antifoaming agent.

[0034] The base oil is composed of 650SN, 500N, 150BS base oil, and its weight ratio is: 650SN47 parts, 500N16 parts, 150BS30 parts.

[0035] The tackifier is polyisobutylene.

[0036] The pour point depressant is polymethacrylate.

[0037] The special compounding agent, in parts by weight, includes: 12 parts of extreme pressure antiwear agent, 12 parts of oily agent, 0.2 part of antioxidant, 0.18 part of friction modifier, and 0.14 part of rust inhibitor. Among them, the extreme pressure antiwear agent is a mixture of 3 parts of acidic dibutyl phosphite and 9 parts of vulcanized cottonseed oil, the oiliness agent is benzotriazole fatty acid ammonium salt, and the antioxidant is dialkyl dithiocarbamate. The improver is molybd...

Embodiment 3

[0041] A special gear oil for subway trains is composed of the following components in parts by weight: 93 parts of base oil, 1 part of thickener, 0.4 part of pour point depressant, 4.4 parts of special compounding agent, and 0.0015 parts of antifoaming agent.

[0042] The base oil is composed of 650SN, 500N, 150BS base oil, and its weight ratio is: 650SN47 parts, 500N16 parts, 150BS30 parts.

[0043] The tackifier is polyisobutylene.

[0044] The pour point depressant is polymethacrylate.

[0045] The special compounding agent, in parts by weight, includes: 12 parts of extreme pressure antiwear agent, 14 parts of oily agent, 0.3 part of antioxidant, 0.24 part of friction modifier, and 0.18 part of rust inhibitor. Among them, the extreme pressure antiwear agent is a mixture of 3 parts of acidic dibutyl phosphite and 9 parts of vulcanized cottonseed oil, the oiliness agent is benzotriazole fatty acid ammonium salt, and the antioxidant is dialkyl dithiocarbamate. The improver is molybd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com