Hub bearing lubricating grease for electric automobile as well as preparation method thereof

A wheel bearing and electric vehicle technology, applied in the field of lubricating grease, can solve the problems that the performance cannot meet the high temperature resistance requirements of electric vehicles, and the service life is short, so as to achieve good anti-wear performance, prolong the oil change cycle, and good high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

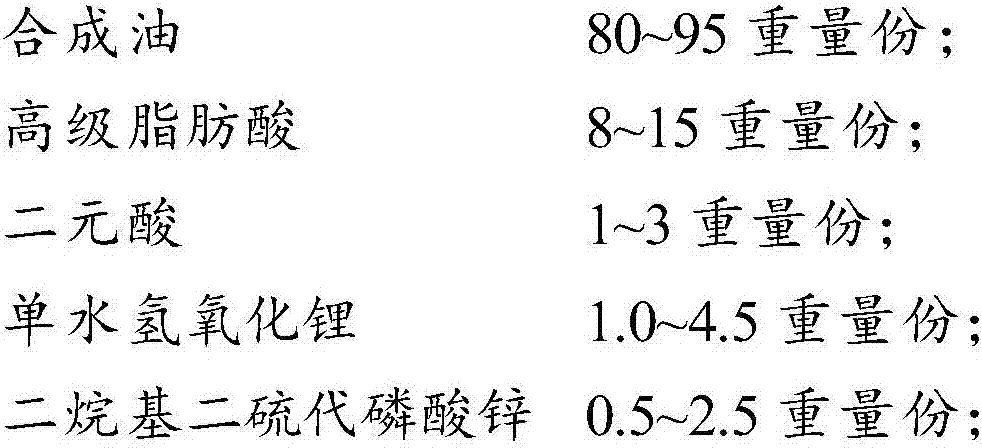

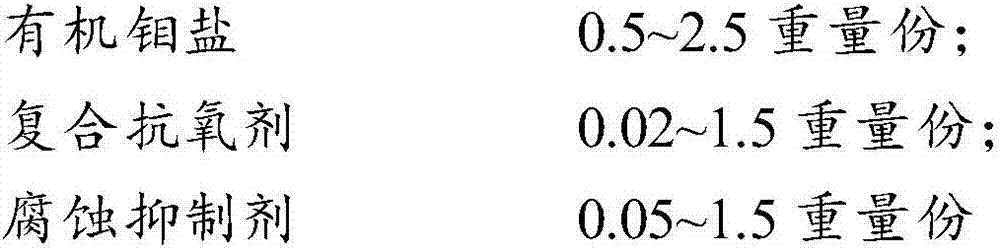

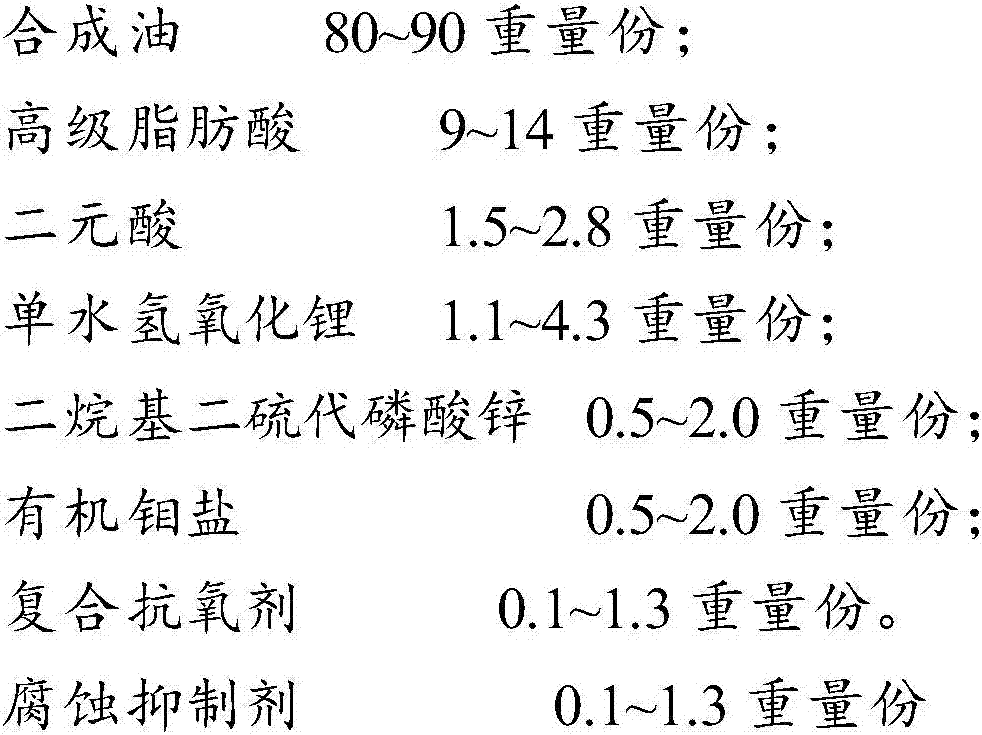

[0061] The present invention provides a method for preparing the hub bearing grease for electric vehicles described in any one of the above technical solutions, comprising:

[0062] The present invention provides a preparation method of the hub bearing lubricating grease for electric vehicles described in the above technical solution, comprising:

[0063] A) Mix part of the synthetic oil with higher fatty acid, dibasic acid, and lithium hydroxide monohydrate, and react at 100°C to 120°C to obtain a reaction solution;

[0064] B) The temperature of the reaction solution is raised to 230°C-240°C, kept for 5-10 minutes, mixed with the remaining synthetic oil and cooled to 90°C-110°C, and then mixed with composite antioxidant, zinc dialkyldithiophosphate, organic Molybdenum salt and corrosion inhibitor are mixed to obtain hub bearing lubricating grease for electric vehicles.

[0065] The preparation method of the hub bearing lubricating grease for electric vehicles provided by th...

Embodiment 1~3、 comparative example 1

[0079] Process requirements: Take 1 / 2 synthetic oil and add 12-hydroxystearic acid / sebacic acid / lithium hydroxide monohydrate into the open reaction cup, keep the temperature at 110±5°C, react the soap for 2 to 3 hours, and replenish during the process Appropriate amount of water, continue to heat up to the highest refining temperature of 230±5°C, keep the temperature for 5 minutes, add the remaining synthetic oil and cool to 100±5°C, add p-diisooctyldiphenylamine and bis(3,5-tertiary butyl The compound antioxidant, ZDDP, organic molybdenum salt and corrosion inhibitor compounded with 4-hydroxyphenyl) sulfide in a ratio of 1:1 are stirred evenly and passed through a grinder to obtain the finished product. The components and proportions are shown in Table 1, and the test results are shown in Table 2. Table 2 shows the performance results of the lubricating grease for wheel hub bearings for electric vehicles prepared in the examples and comparative examples of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com