Solid-liquid phase composite internal combustion engine oil

An internal combustion engine oil, solid-liquid phase technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as increased oil viscosity, affecting normal use, and failing to meet the requirements of equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

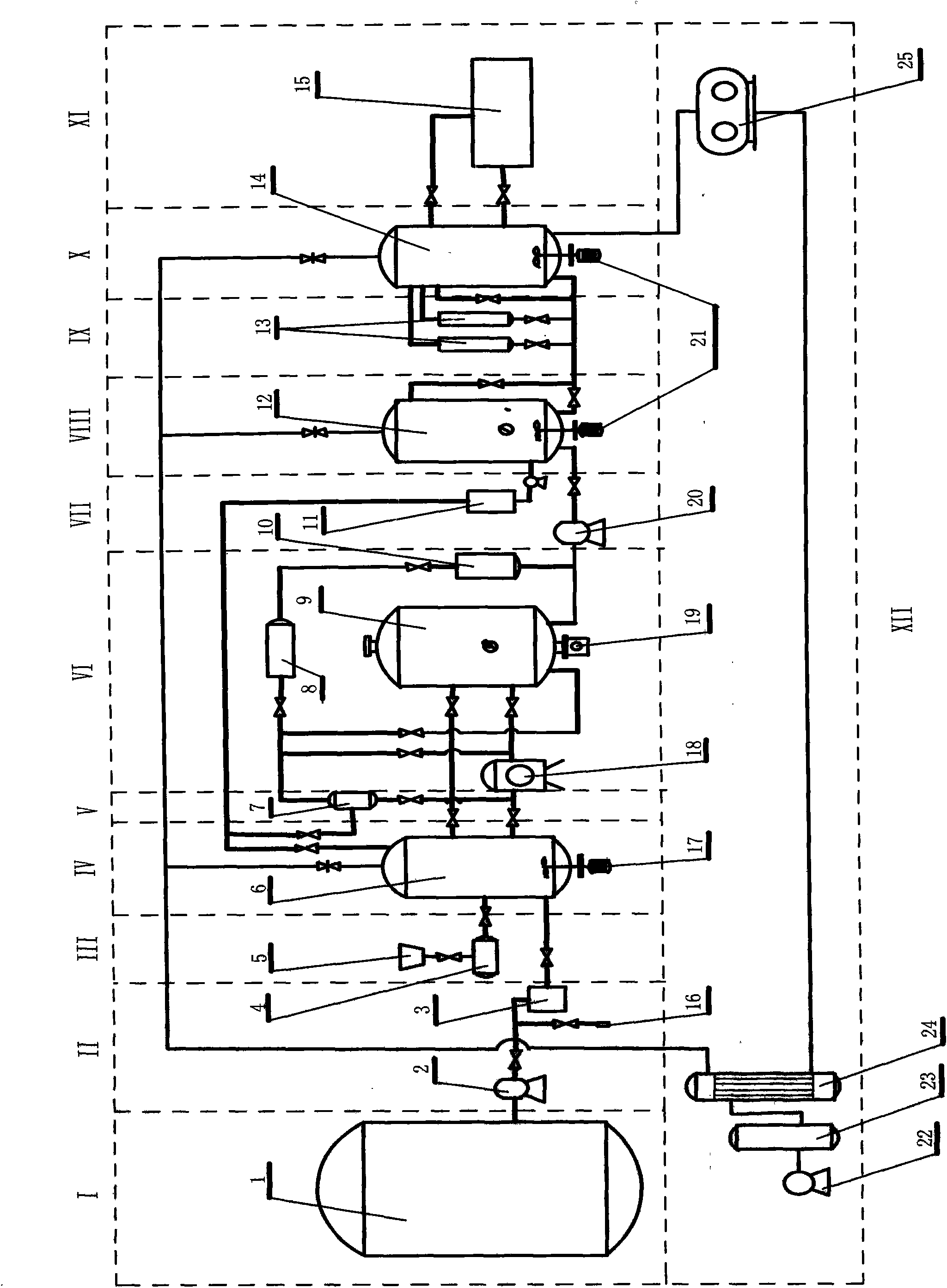

Image

Examples

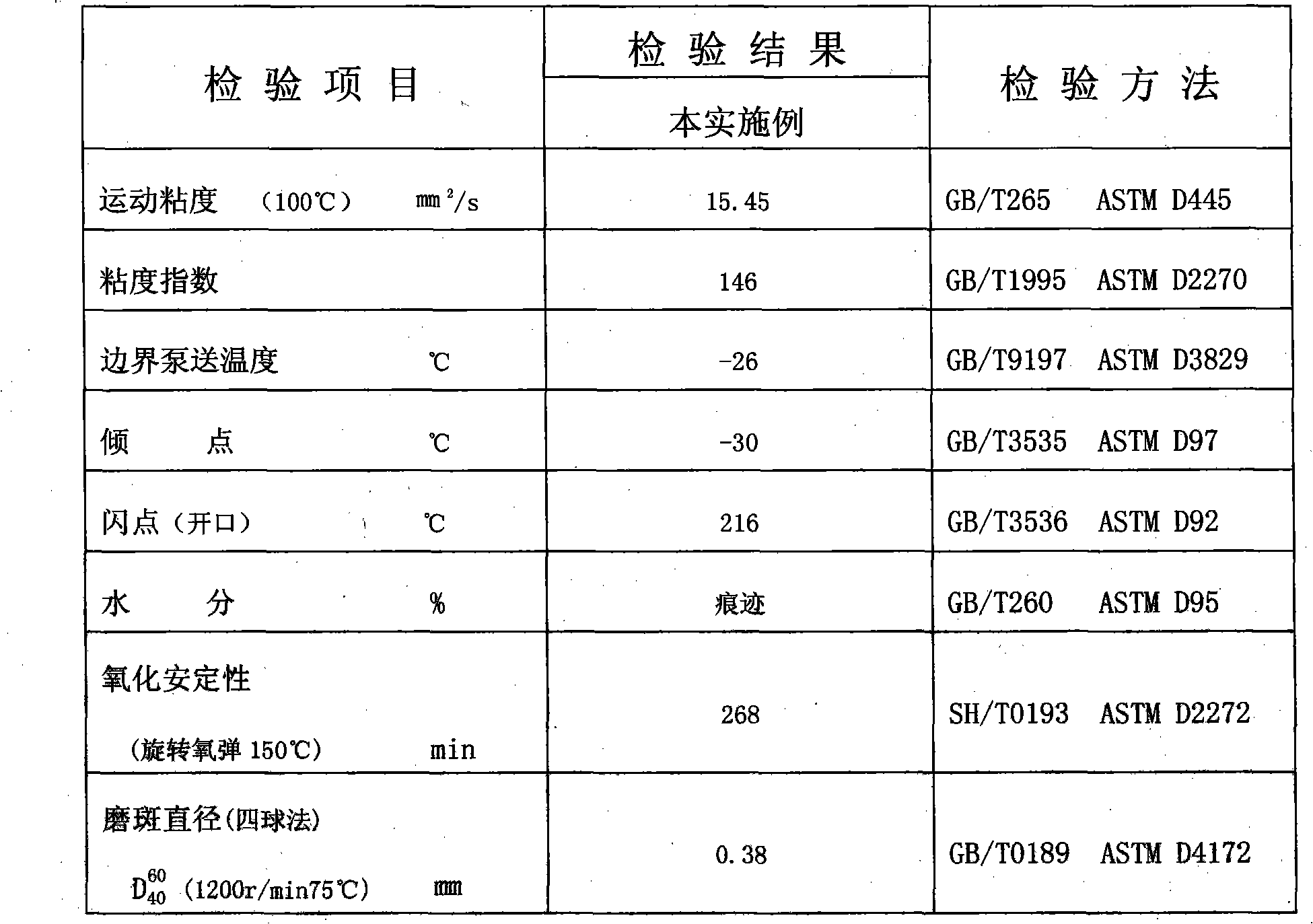

Embodiment 1

[0200] An internal combustion engine oil suitable for land vehicles and construction machinery engines, its components include solid lubricating materials, liquid media, dispersants, detergents, anti-oxidant and anti-corrosion agents, compounding agents, defoamers, stable dispersants, etc.

[0201] The parts by weight that each component occupies are as follows:

[0202] ●Solid lubricating material: 0.35 parts;

[0203] Among them: 0.245 parts of graphite; 0.0525 parts of molybdenum disulfide; 0.0525 parts of boron nitride;

[0204] Graphite: molybdenum disulfide: boron nitride = 0.245: 0.0525: 0.0525

[0205] ●Liquid medium: 87.08 parts;

[0206]Among them: 67.08 parts of 150N hydrodewaxed base oil; 10 parts of 500N; 10 parts of 150BS;

[0207] ●Dispersant: polysuccinimide (T155) 0.35 parts;

[0208] ●Detergent: 0.21 parts of synthetic calcium sulfonate with high base value (Hitec611);

[0209] Antioxidant and anticorrosion agent: 0.70 parts of ...

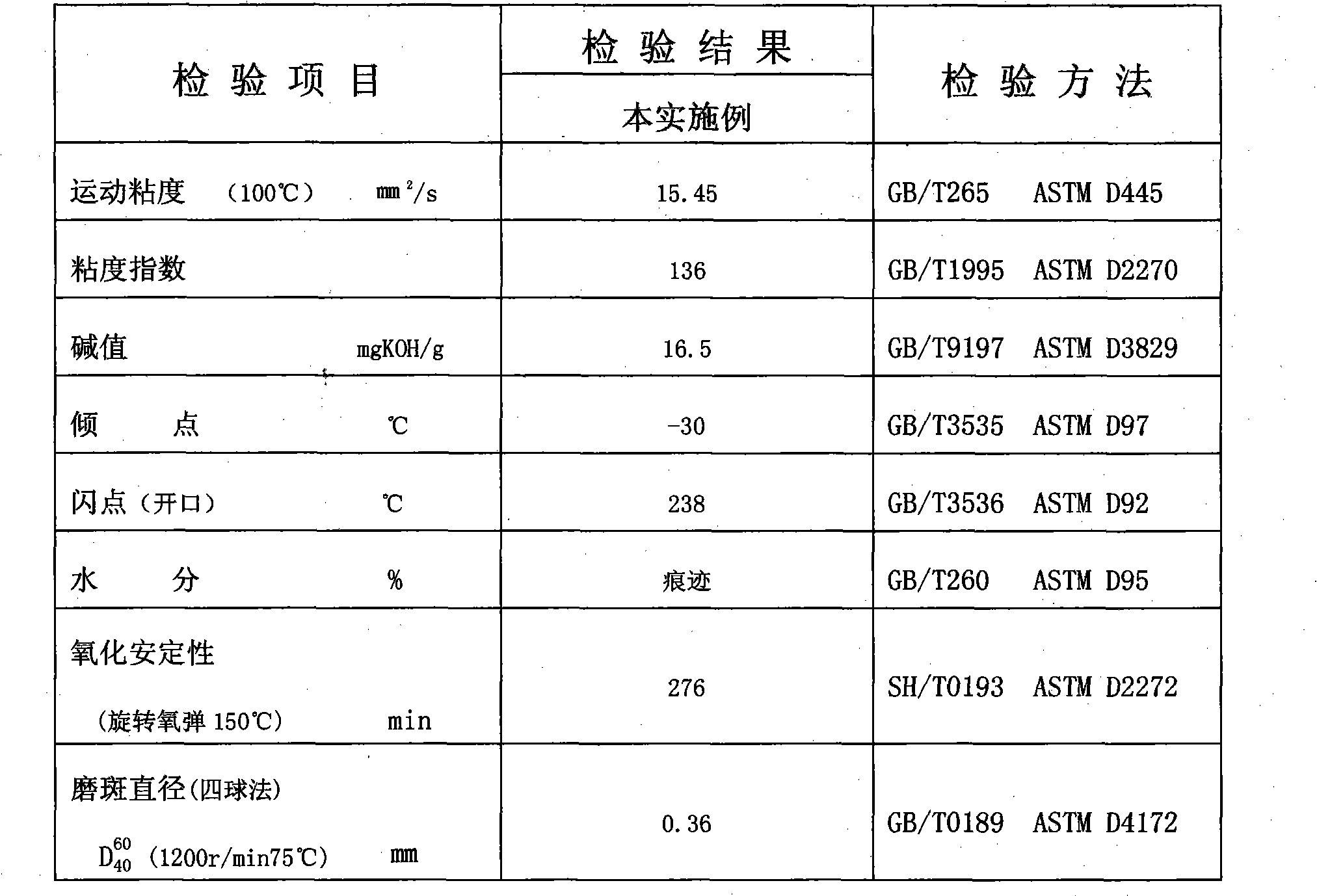

Embodiment 3

[0297] An internal combustion engine oil additive suitable for locomotive engines, its components include solid lubricating materials, liquid media, dispersants, detergents, anti-oxidant and anti-corrosion agents, compounding agents, defoamers, stable dispersants, etc.

[0298] The parts by weight that each component occupies are as follows:

[0299] ●Solid lubricating material: 0.45 parts;

[0300] Among them: 0.2925 parts of graphite; 0.0540 parts of molybdenum disulfide; 0.1035 parts of boron nitride;

[0301] Graphite: molybdenum disulfide: boron nitride = 0.2925: 0.0540: 0.1035;

[0302] ●Liquid medium: 84.55 parts;

[0303] Among them: 1.44 parts of 50N hydrodewaxed base oil; 150N63.62 parts; 150BS15 parts;

[0304] ●Dispersant: boronated succinimide (Hitec 648) 0.45 parts;

[0305] ●Detergent: 0.675 parts of high alkali value sulfurized calcium alkylphenate (OLOA219);

[0306] Antioxidant and anticorrosion agent: 1.125 parts of zinc diamyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com