Sliding guide rail plastic-pasting process method

A process method and sliding guide rail technology, applied in the field of sliding guide rail plastic laminating technology, can solve the problems of reducing the cost of high-precision sliding guide rails, inconsistent oil groove depth, time-consuming and labor-intensive problems, and achieve good market application prospects and promotion value, and good accuracy consistency , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

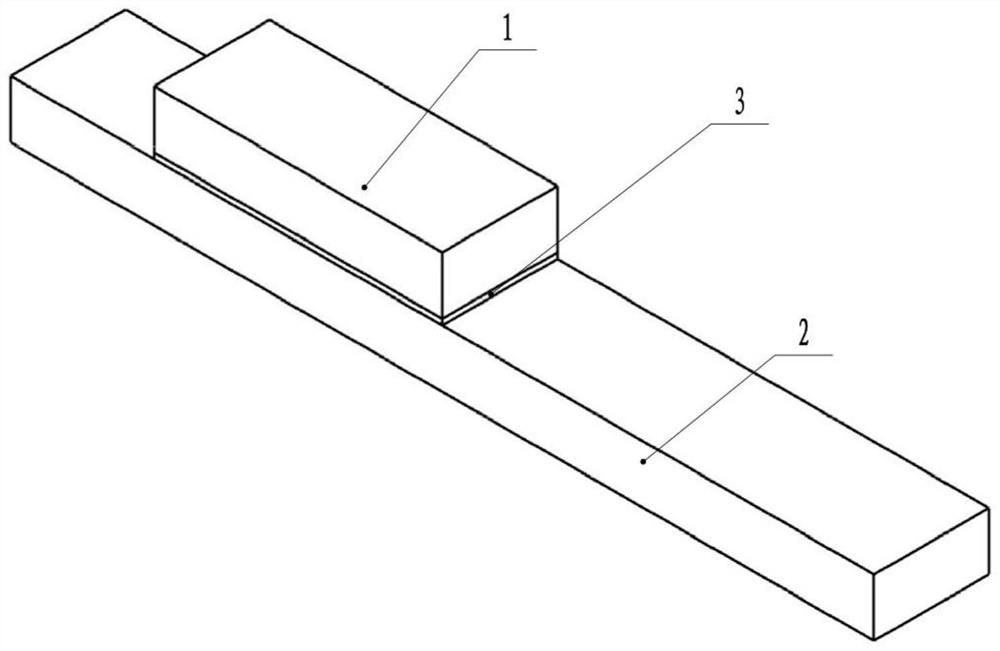

[0022] Taking a linear sliding pair as an example, the specific implementation of the invention is described;

[0023] The upper guide rail 1 slides linearly on the lower guide rail 2, and plastic is pasted on the upper guide rail 1. The size of the guide rail base of the upper guide rail 1 is 50mm×20mm, and the long side direction is parallel to the movement direction of the sliding pair. The upper guide rail 1 and the lower guide rail 2 are both GCr15 material;

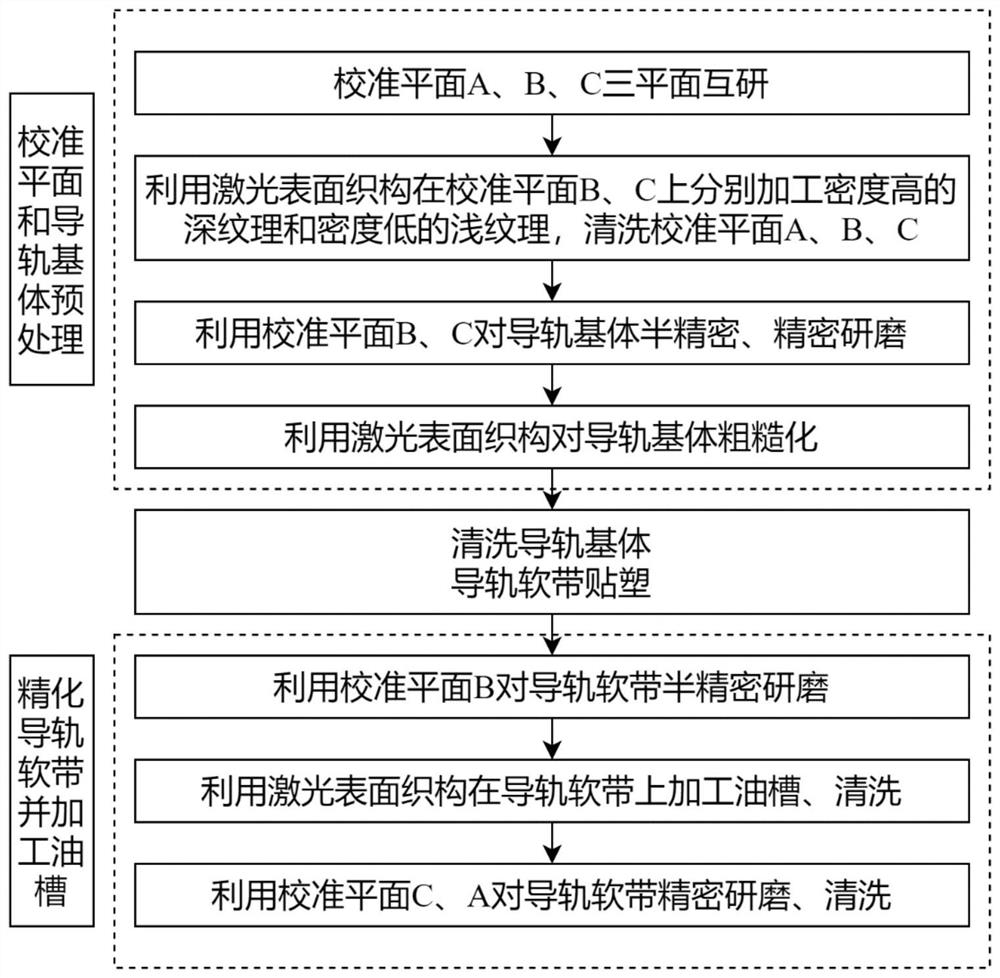

[0024] The first step is to preprocess the guide rail substrate and calibration plane;

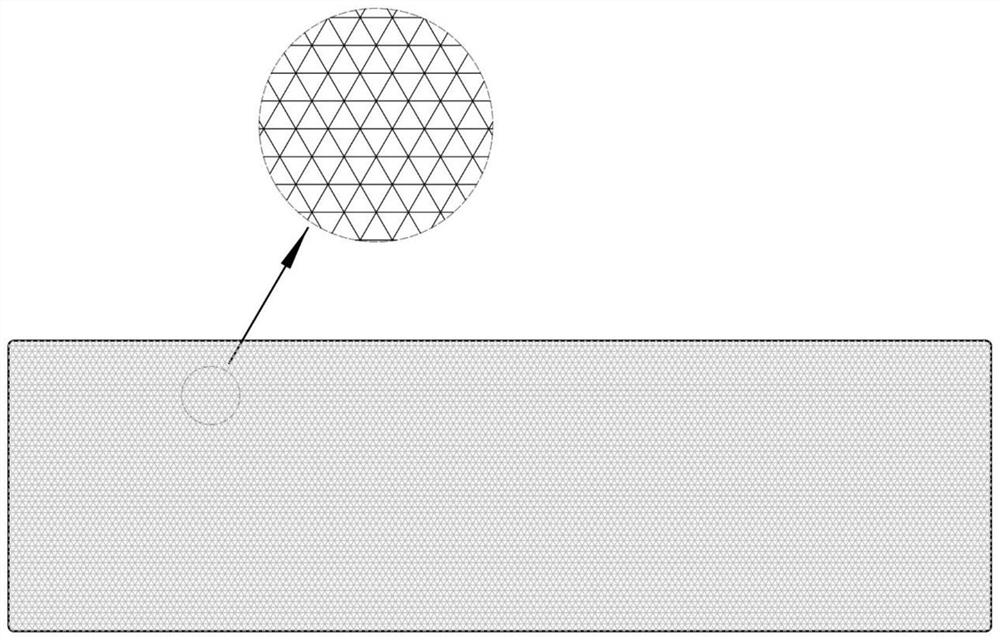

[0025] First, the calibration planes A, B, and C are processed by the three-plane mutual research method. The substrates of the calibration planes A, B, and C are all flat plates of 200mm×200mm×50mm sintered by boron carbide; after the three-plane mutual research, the calibration planes A, B, and C The flatness error should not be greater than 1 μm; laser surface texture is performed on the calibration planes B and C, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com