Preparation method of Mo-V-C-N composite coating

A composite coating, mo-v-c-n technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of difficult to meet the needs of lubrication, long service life, difficult to obtain, etc., to avoid cracking And peeling, good wear resistance, uniform and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

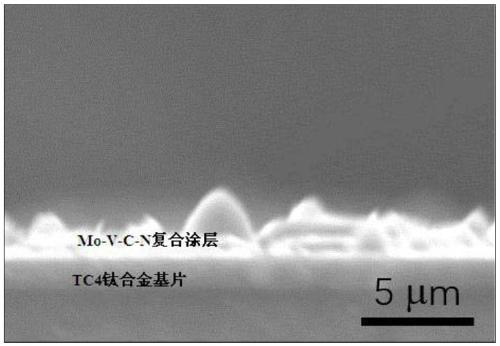

[0037] This embodiment includes the following steps:

[0038] Step 1. Use 80 in sequence # 、280 # 、400 # 、600 # , 800 # 、1000 # , 1500 # , 2000 # The surface of the TC4 titanium alloy substrate was ground and polished with metallographic sandpaper, and then the ground and polished substrate was placed in analytically pure acetone and analytically pure ethanol for ultrasonic cleaning, and then ultrasonically cleaned in deionized water. Air blower drying to obtain a clean TC4 titanium alloy substrate;

[0039] Step 2. Fix the Mo target and the V arc target with a mass purity of 99.99% on the position of the magnetron sputtering source of the magnetron sputtering equipment, and put the clean TC4 titanium alloy substrate obtained in step 1 into the magnetron sputtering In the vacuum chamber of the injection equipment and fixed on the rotatable sample holder, then close the door of the vacuum chamber, turn on the mechanical pump and the molecular pump in turn to evacuate th...

Embodiment 2

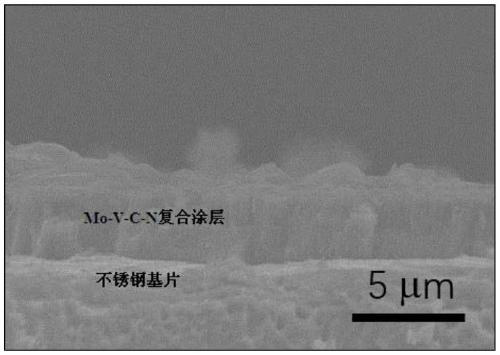

[0050] This embodiment includes the following steps:

[0051] Step 1. Use 80 in sequence # 、280 # 、400 # 、600 # , 800 # 、1000 # , 1500 # , 2000 # The surface of the stainless steel substrate is ground and polished with metallographic sandpaper, and then the ground and polished substrate is placed in analytically pure acetone and analytically pure ethanol for ultrasonic cleaning, and then ultrasonically cleaned in deionized water, and blown by a hot air blower. Dry to get a clean stainless steel substrate;

[0052] Step 2: Fix the Mo target and the V-arc target with a mass purity of 99.99% on the position of the magnetron sputtering source of the magnetron sputtering equipment, and load the clean stainless steel substrate obtained in step 1 into the magnetron sputtering equipment and fixed on the rotatable sample holder, then close the door of the vacuum chamber, turn on the mechanical pump and the molecular pump in turn to evacuate the vacuum chamber to a vacuum degree...

Embodiment 3

[0063] This embodiment includes the following steps:

[0064] Step 1. Use 80 in sequence # 、280 # 、400 # 、600 # , 800 # 、1000 # , 1500 # , 2000 # The surface of the superalloy substrate is ground and polished with metallographic sandpaper, and then the ground and polished substrate is placed in analytically pure acetone and analytically pure ethanol for ultrasonic cleaning, and then ultrasonically cleaned in deionized water. Blow dry to obtain a clean superalloy substrate;

[0065] Step 2. Fix the Mo target and the V arc target with a mass purity of 99.99% on the position of the magnetron sputtering source of the magnetron sputtering equipment, and put the clean superalloy substrate obtained in step 1 into the magnetron sputtering The vacuum chamber of the equipment is fixed on the rotatable sample holder, then the door of the vacuum chamber is closed, and the mechanical pump and the molecular pump are turned on in turn to evacuate the vacuum chamber to a vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com