High-strength and high softening temperature low beryllium-copper alloy and preparation method thereof

A technology of beryllium copper alloy and softening temperature, which is applied in the field of alloy materials, can solve the problems of thermal stability and high temperature softening resistance not evaluated, Be content control range is large, and electrical conductivity is not mentioned, so as to improve the recrystallization temperature and Good thermal stability, comprehensive mechanical properties, and the effect of solving the contradiction between high electrical conductivity and high softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

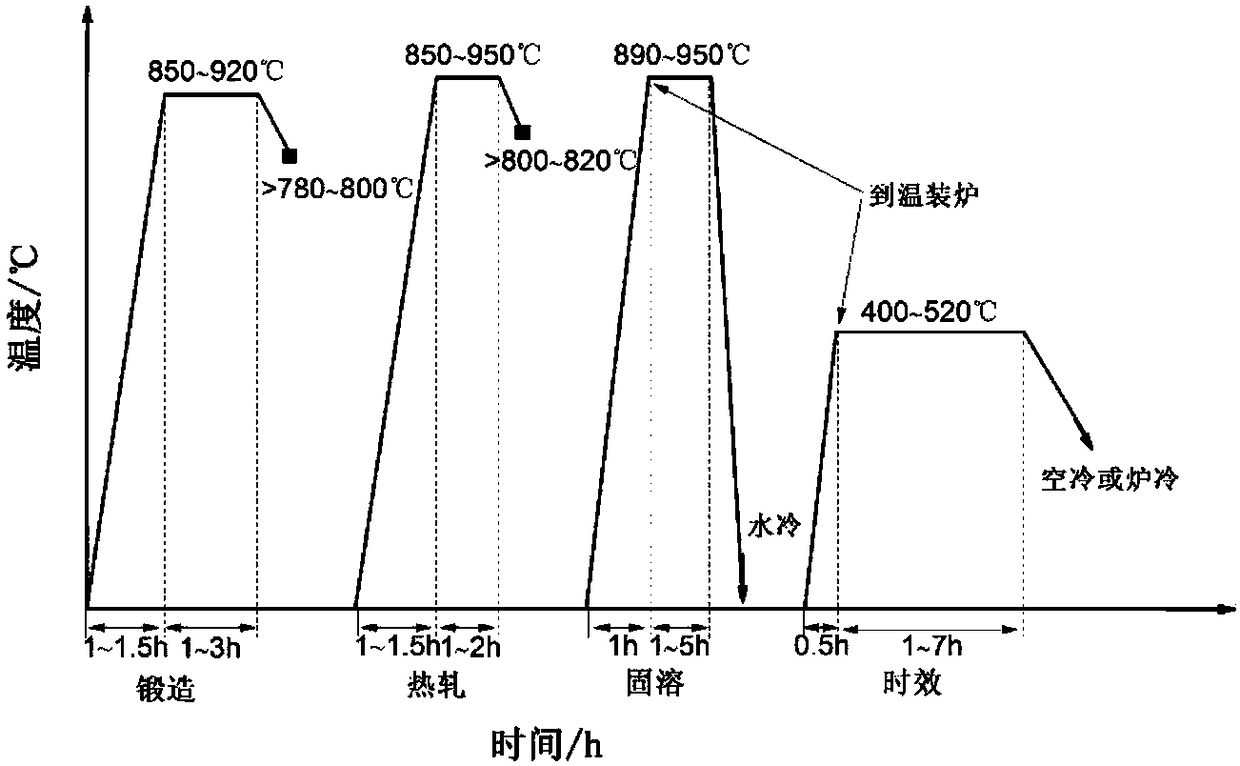

Method used

Image

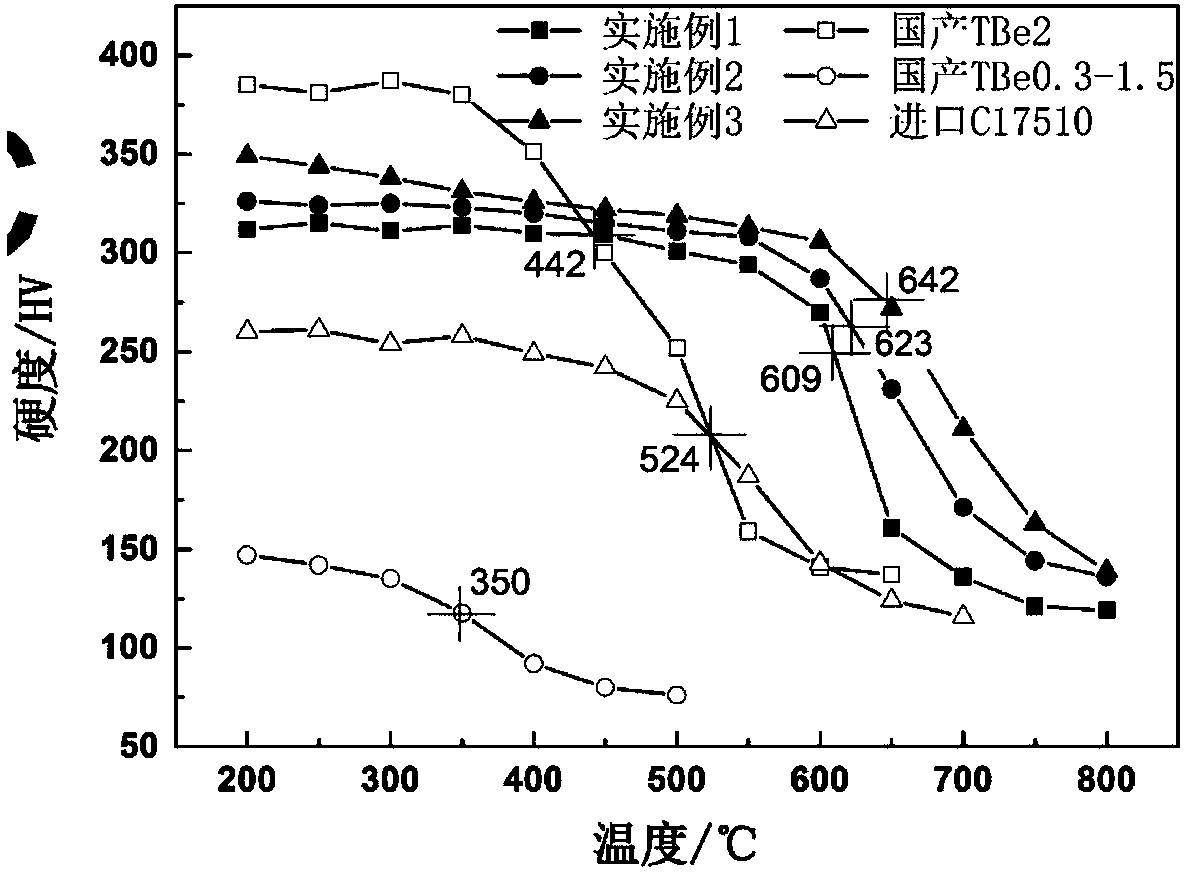

Examples

Embodiment 1

[0053] 1. Ingredients

[0054] Take No. 2 oxygen-free copper, electrolytic nickel, electrolytic cobalt, beryllium beads, high-purity silver, CuZr 14 , MgNi 20 As a raw material, remove the rust product on the surface of the raw material, remove oil stains, floating liquid, etc., and dry it for use. According to the mass ratio Be: 0.3%, Ni: 1.4%, Co: 0.3%, Ag: 0.6, Zr: 0.07%, Mg: 0.04%.

[0055] 2. Melting and casting

[0056] No. 2 oxygen-free copper, electrolytic nickel and electrolytic cobalt are placed in the crucible, among which, electrolytic nickel and electrolytic cobalt are installed in the middle and lower part of the crucible, small materials are placed between large materials, and the bottom is tight and the top is loose to prevent "bridging" when the metal is melted. "Phenomenon. Beads, High Purity Silver, CuZr 14 and MgNi 20 The master alloy is placed in the hopper. Vacuumize, when the vacuum degree in the furnace is 14 For the intermediate alloy, after eac...

Embodiment 2

[0071] 1. Ingredients

[0072] Take No. 2 oxygen-free copper, electrolytic nickel, electrolytic cobalt, beryllium beads, high-purity silver, CuZr 14 , MgNi 20 As a raw material, remove the rust product on the surface of the raw material, remove oil stains, floating liquid, etc., and dry it for use. According to mass ratio Be: 0.4%, Ni: 1.5%, Co: 0.35%, Ag: 0.7, Zr: 0.08%, Mg: 0.04%.

[0073] 2. Melting and casting

[0074] No. 2 oxygen-free copper, electrolytic nickel and electrolytic cobalt are placed in the crucible, and the electrolytic nickel and electrolytic cobalt are installed in the lower part of the crucible. Small materials are placed between large materials, and the bottom is tightened and the top is loosened to prevent "bridging" when the metal is melted. Beads, High Purity Silver, CuZr 14 and MgNi 20 The master alloy is placed in the hopper. Vacuumize, when the vacuum degree in the furnace is 14 For the intermediate alloy, after each element is added, the po...

Embodiment 3

[0089] 1. Ingredients

[0090] Take No. 2 oxygen-free copper, electrolytic nickel, electrolytic cobalt, beryllium beads, high-purity silver, CuZr 14 , MgNi 20 As a raw material, remove the rust product on the surface of the raw material, remove oil stains, floating liquid, etc., and dry it for use. According to the mass ratio Be: 0.44%, Ni: 1.6%, Co: 0.4%, Ag: 0.8, Zr: 0.1%, Mg: 0.05%.

[0091] 2. Melting and casting

[0092] No. 2 oxygen-free copper, electrolytic nickel and electrolytic cobalt are placed in the crucible, and the electrolytic nickel and electrolytic cobalt are installed in the lower part of the crucible. Small materials are placed between large materials, and the bottom is tightened and the top is loosened to prevent "bridging" when the metal is melted. Beads, High Purity Silver, CuZr 14 and MgNi 20 The master alloy is placed in the hopper. Vacuumize, when the vacuum degree in the furnace is 14 For the intermediate alloy, after each element is added, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com