Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

273 results about "Beryllium copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze and spring copper, is a copper alloy with 0.5—3% beryllium and sometimes other elements. Beryllium copper combines high strength with non-magnetic and non-sparking qualities. It has excellent metalworking, forming and machining properties. It has many specialized applications in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and aerospace. Beryllium alloys present a toxic inhalation hazard during manufacture.

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

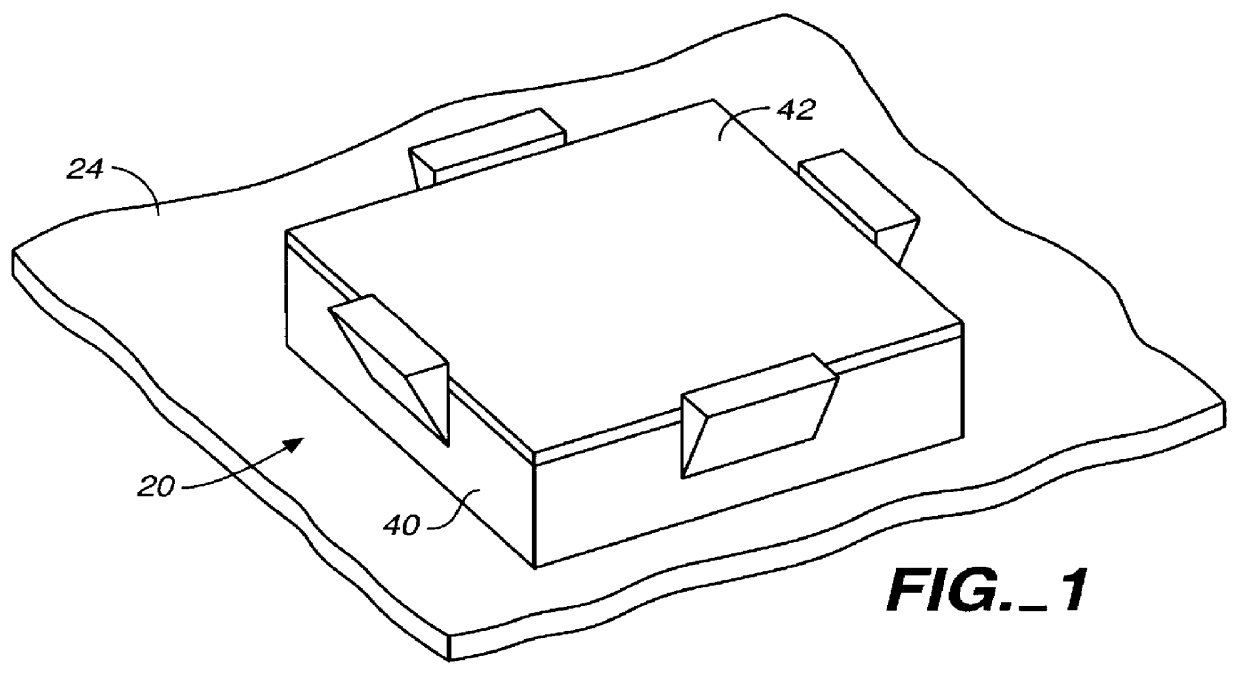

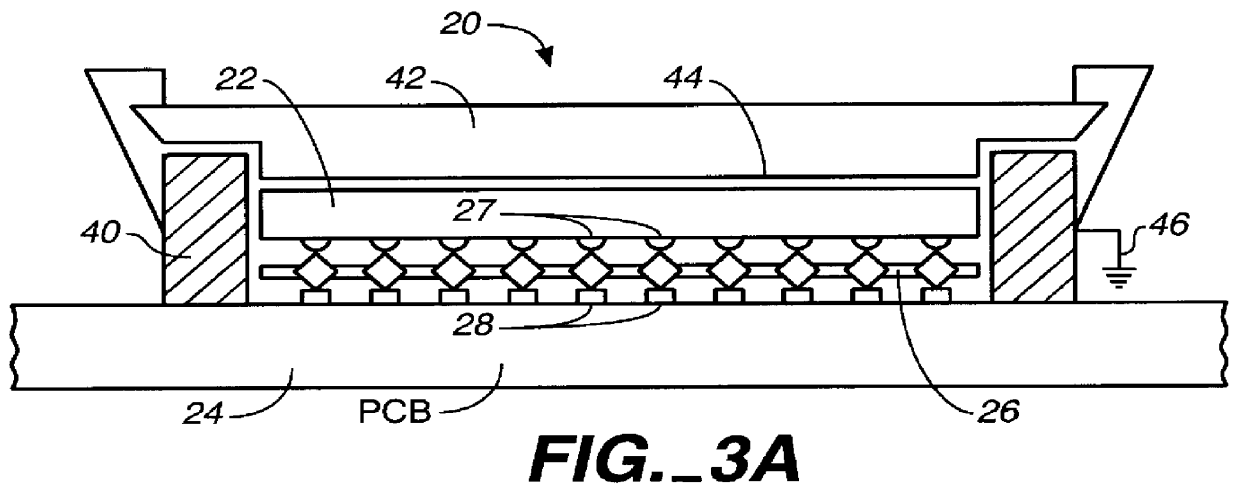

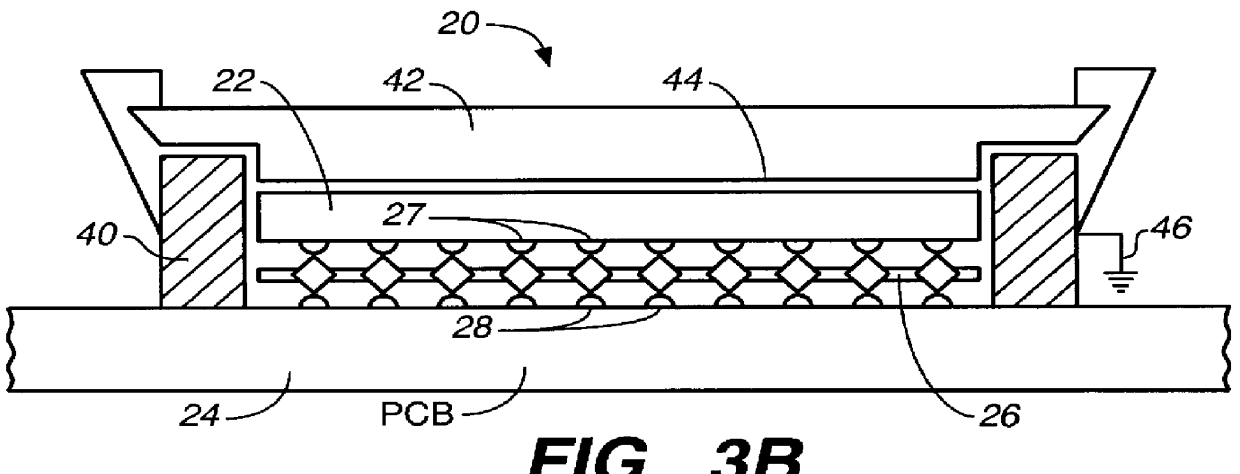

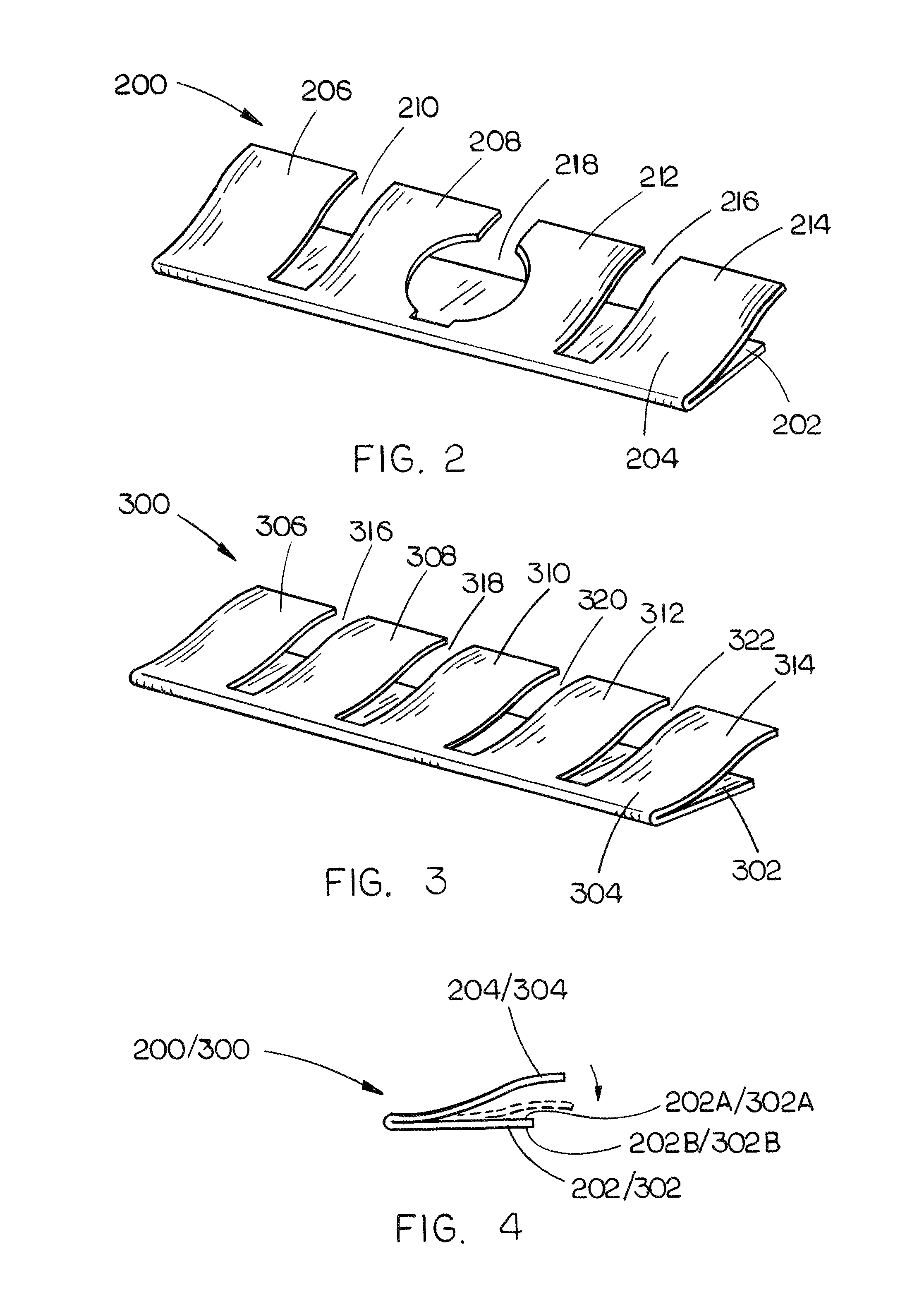

Connector, connector system and method of making a connector

InactiveUS6042387AMass productionLow costElectrically conductive connectionsCoupling contact membersConductive materialsContact element

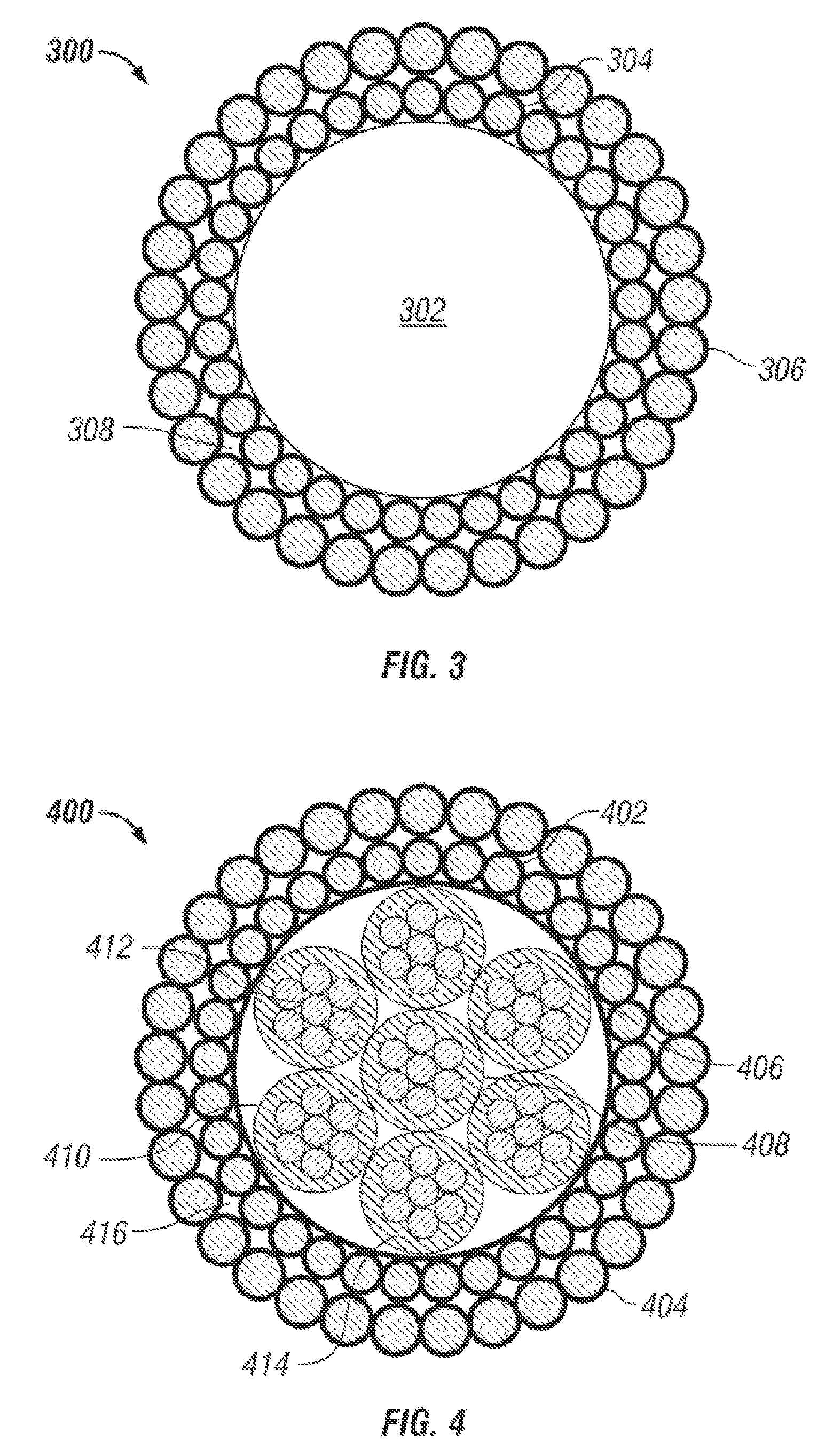

A connector system (20) connects a leadless integrated circuit (IC) device (22) to a printed circuit (PC) board (24) by means of a contact array (26). The contact array (26) connects input-output (I / O) contacts on the IC device (22) to corresponding circuit contacts (28) on PC board (24). The contact array (26) is a generally thin, flexible and rectangular shaped element that is sandwiched between the PC board (24) and the IC device (22). The contact array (26) has a plurality of square cells (30) that are each a portion of the array (26) and are formed from a planar body (32) of a suitable conductive material, such as beryllium copper, sandwiched between suitable insulating films, formed from polyimide. Each cell is divided into a first pair (34) of contact elements (36) extending above the plane of the body (32) and a second pair (38) of contact elements (36) extending below the plane of the body (32).

Owner:SMITHS INTERCONNECT AMERICAS INC

Copper or copper alloy target/copper alloy backing plate assembly

Owner:JX NIPPON MINING& METALS CORP

Lightweight armor wires for electrical cables

ActiveUS20070158095A1Simple designHigh strengthNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorTitanium alloy

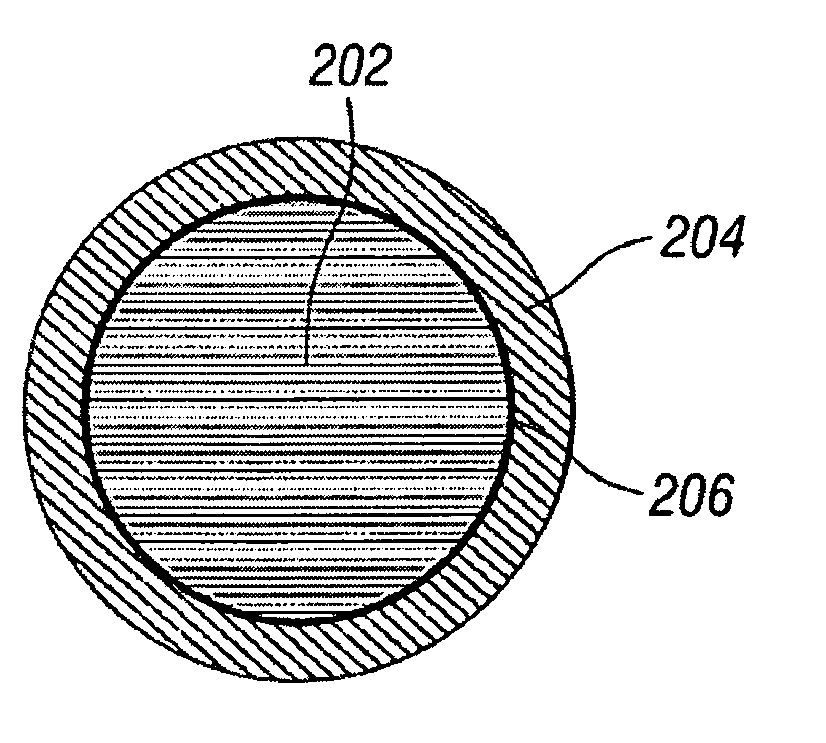

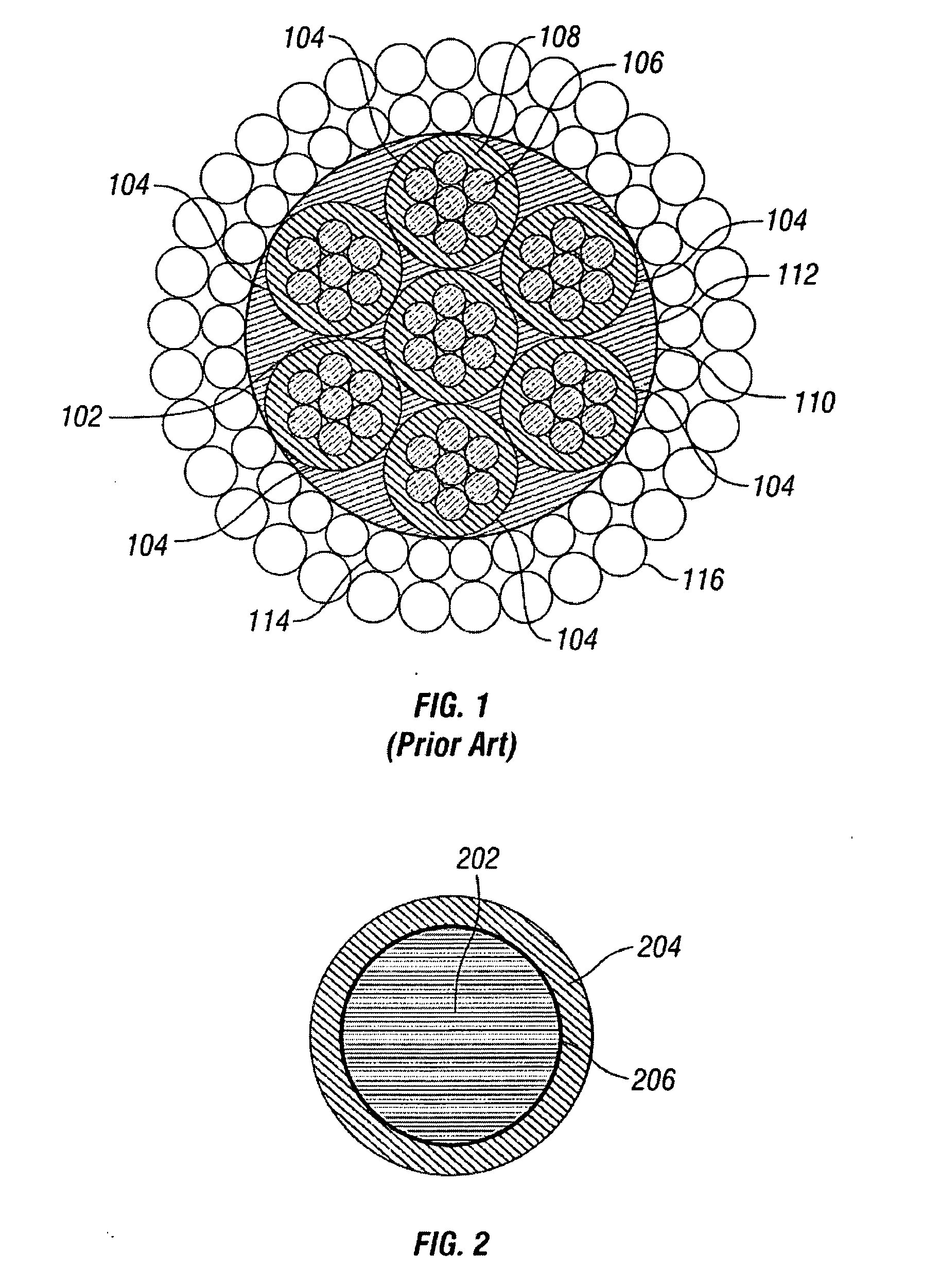

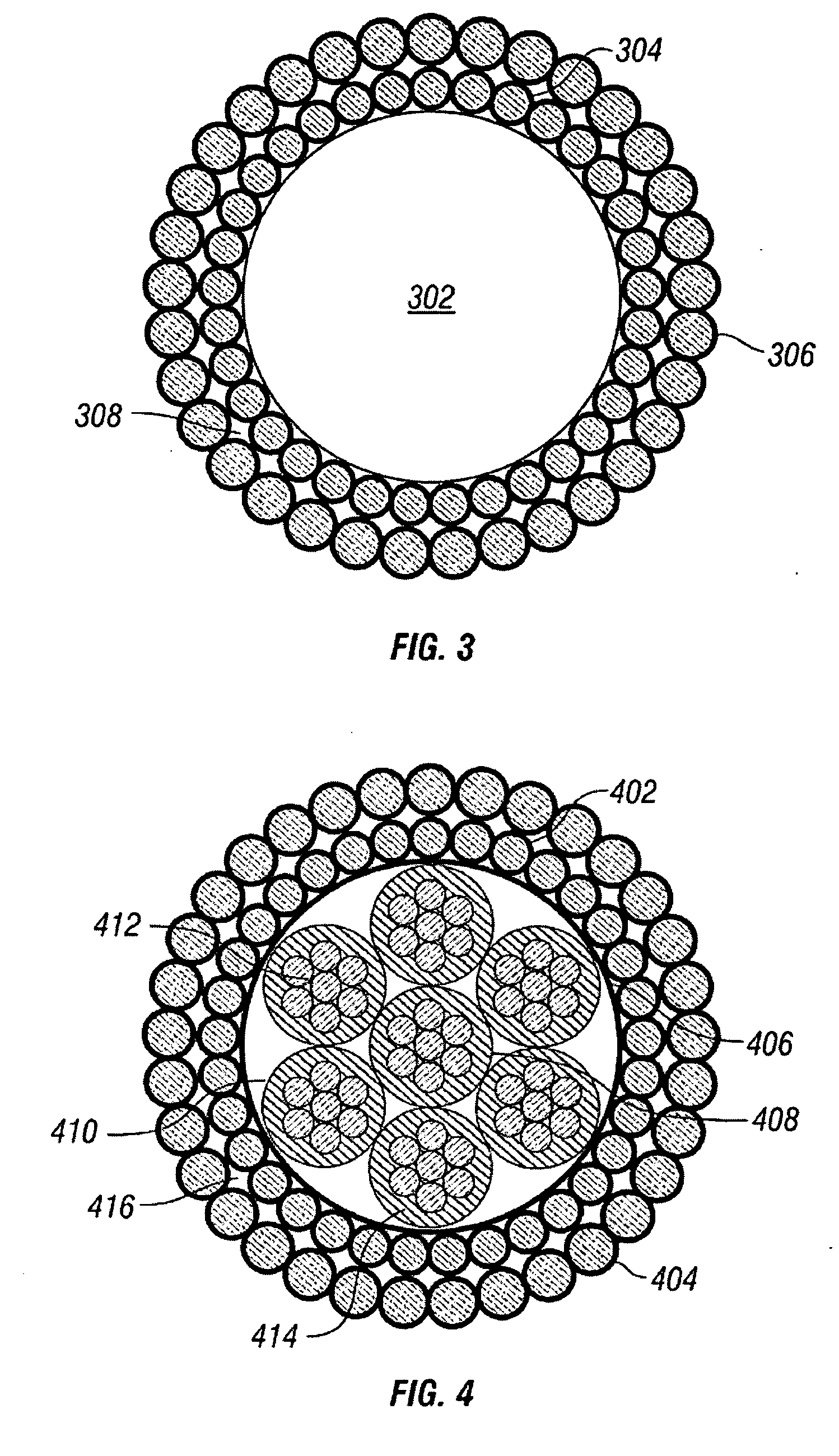

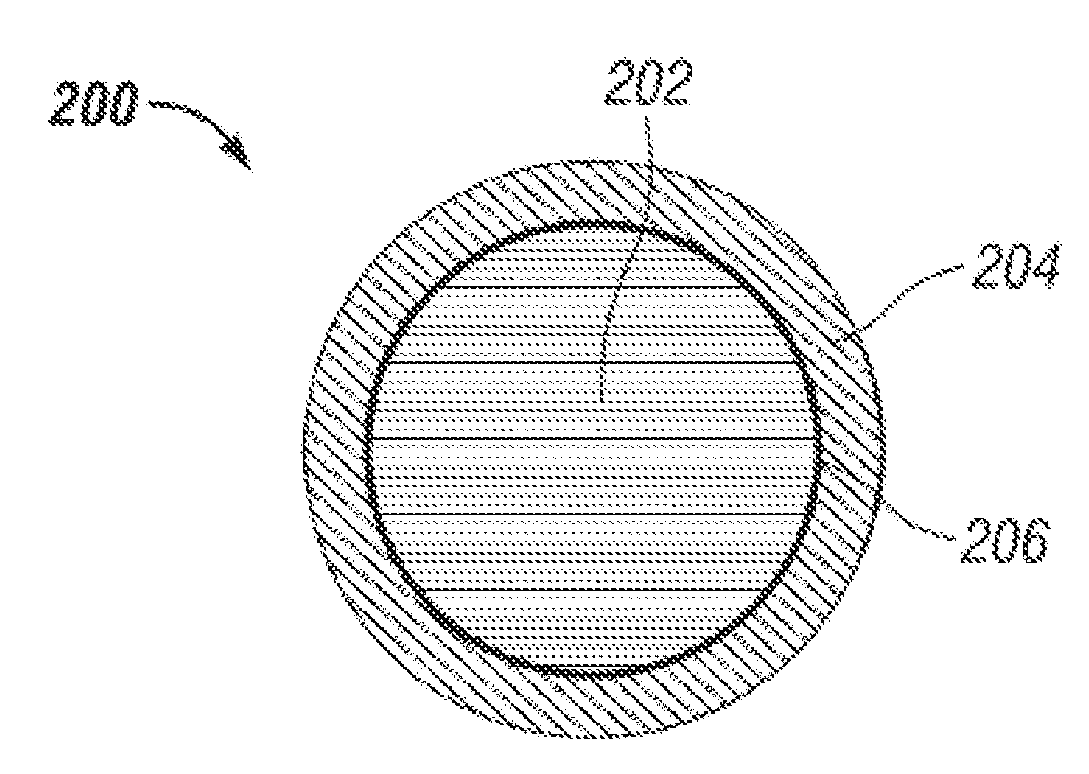

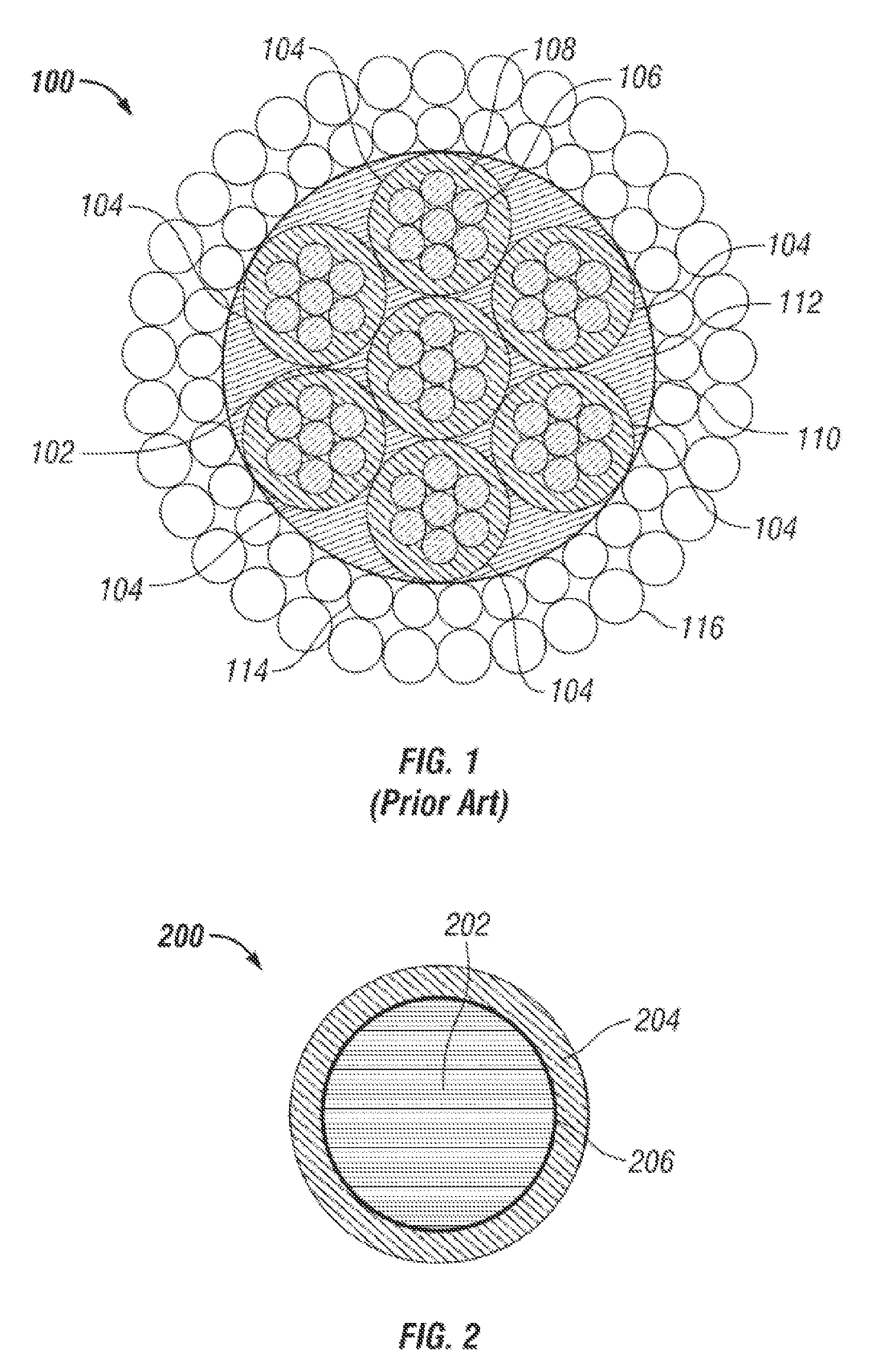

Disclosed are electric cables with improved armor wires used with wellbore devices to analyze geologic formations adjacent a wellbore. The cables include at least one insulated conductor, and one or more armor wires surrounding the insulated conductor. The armor wires include a low density core surrounded by a corrosion resistant alloy clad, where the alloy clad includes such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The low density core may be based upon titanium or titanium alloys. The cables of the invention may be any useful electric cable design, including monocables, quadcables, heptacables, quadcables, slickline cables, multiline cables, coaxial cables, or seismic cables.

Owner:SCHLUMBERGER TECH CORP

Bimetallic materials for oilfield applications

Corrosion resistant and / or lightweight bimetallic cylinders used in tools and electric cables, including core surrounded by corrosion resistant alloy outer cladding materials, where the alloy clad may include such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The core may be a low density core based substantially upon titanium or titanium alloys.

Owner:SCHLUMBERGER TECH CORP

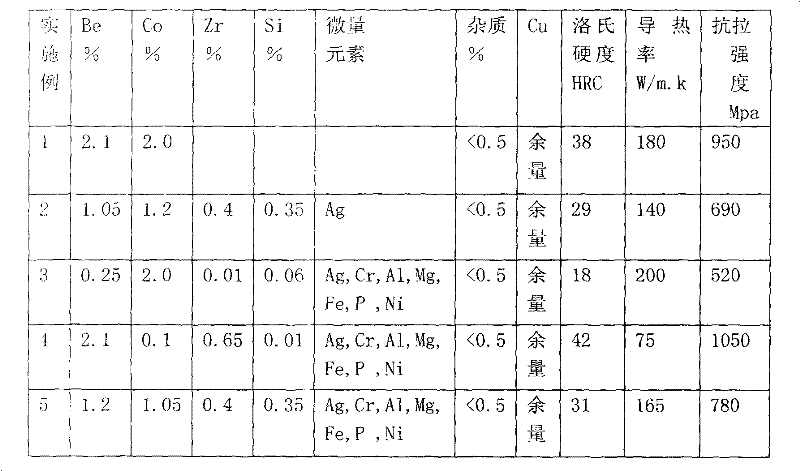

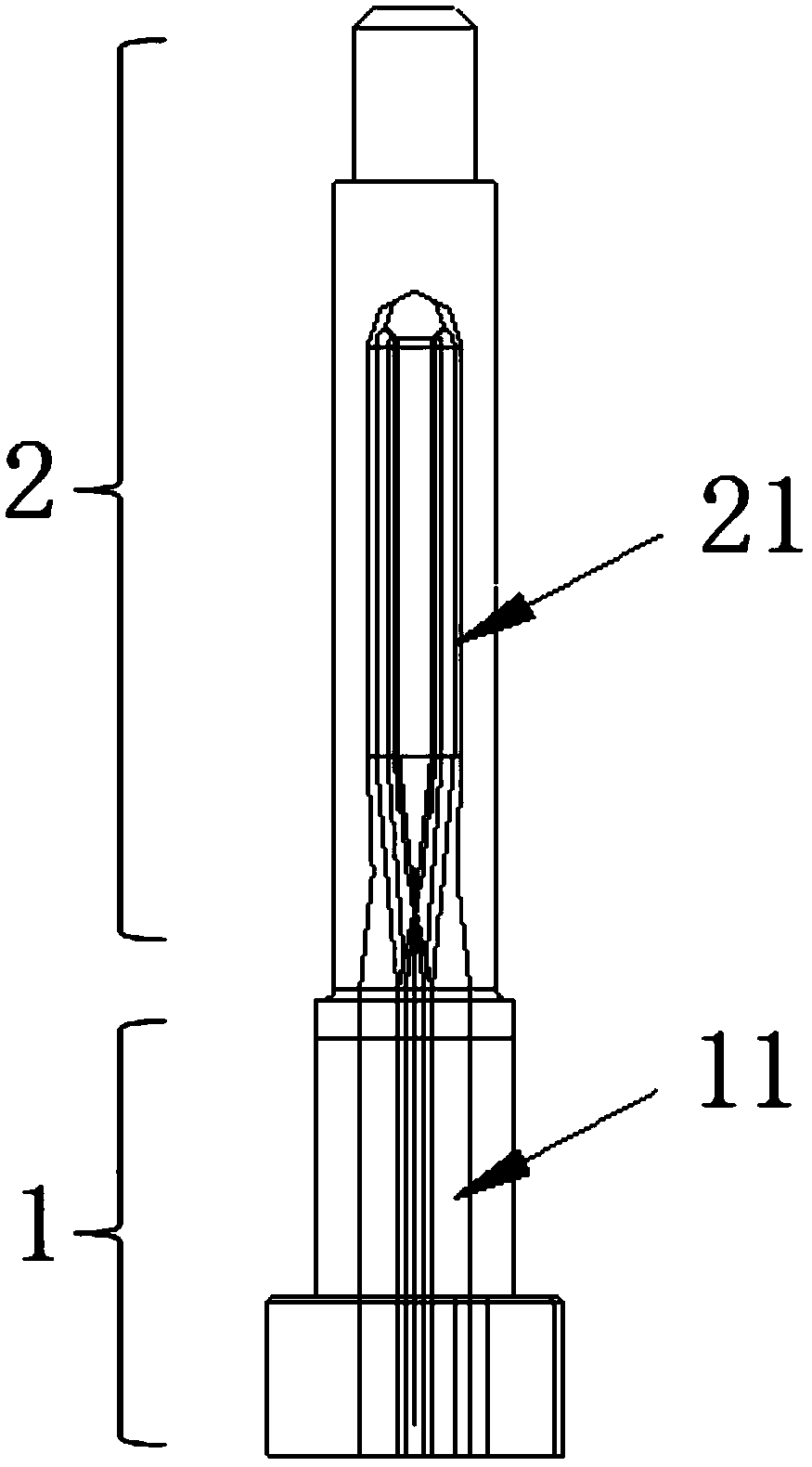

Inner-condensing diamond anvil cell pressing machine

InactiveCN104596835ATo overcome the disadvantage of partial loss of pressureOvercoming the disadvantage of lossPreparing sample for investigationHigh intensityWater cooling

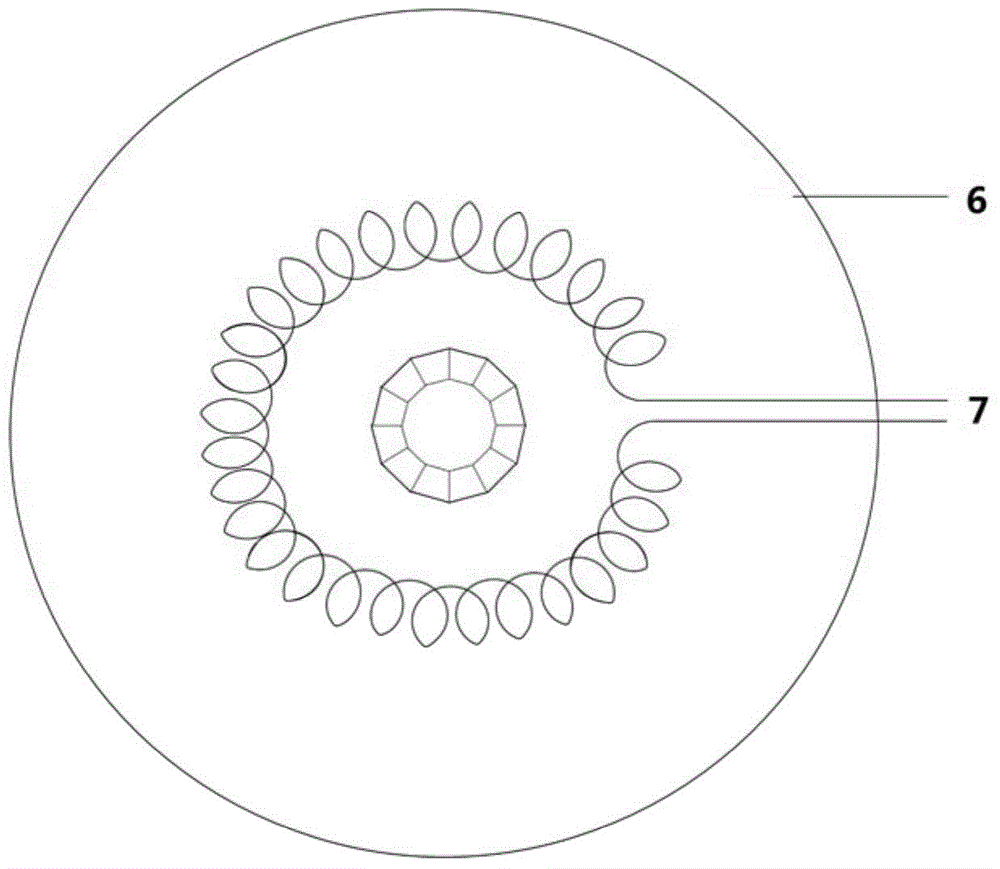

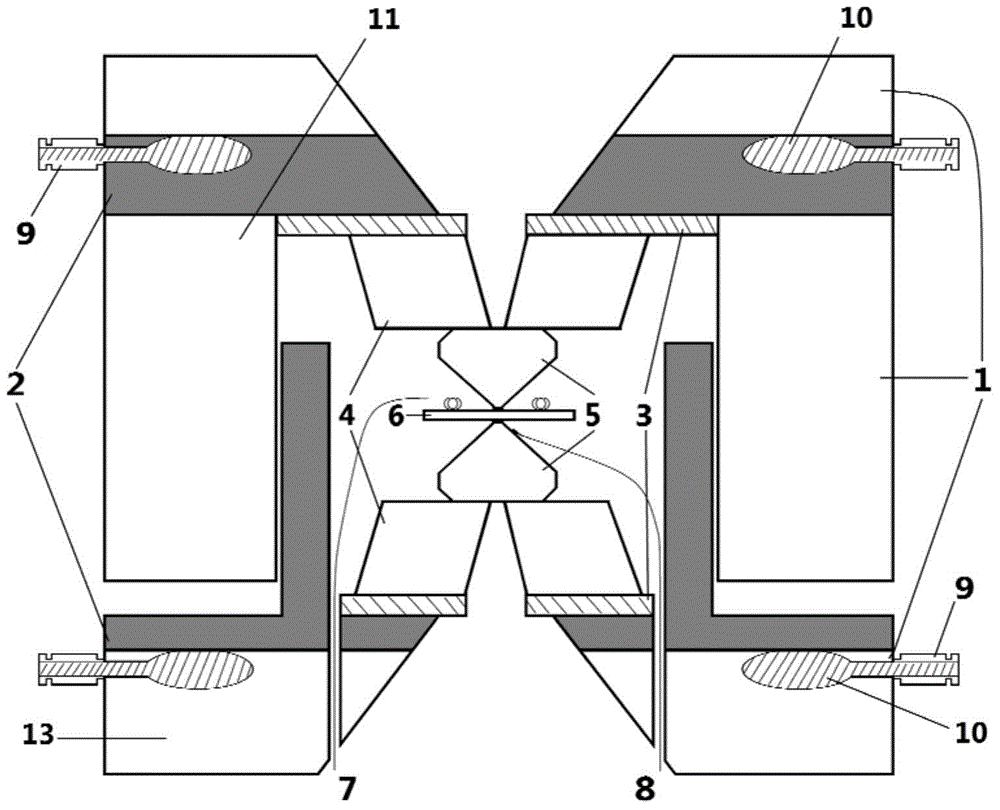

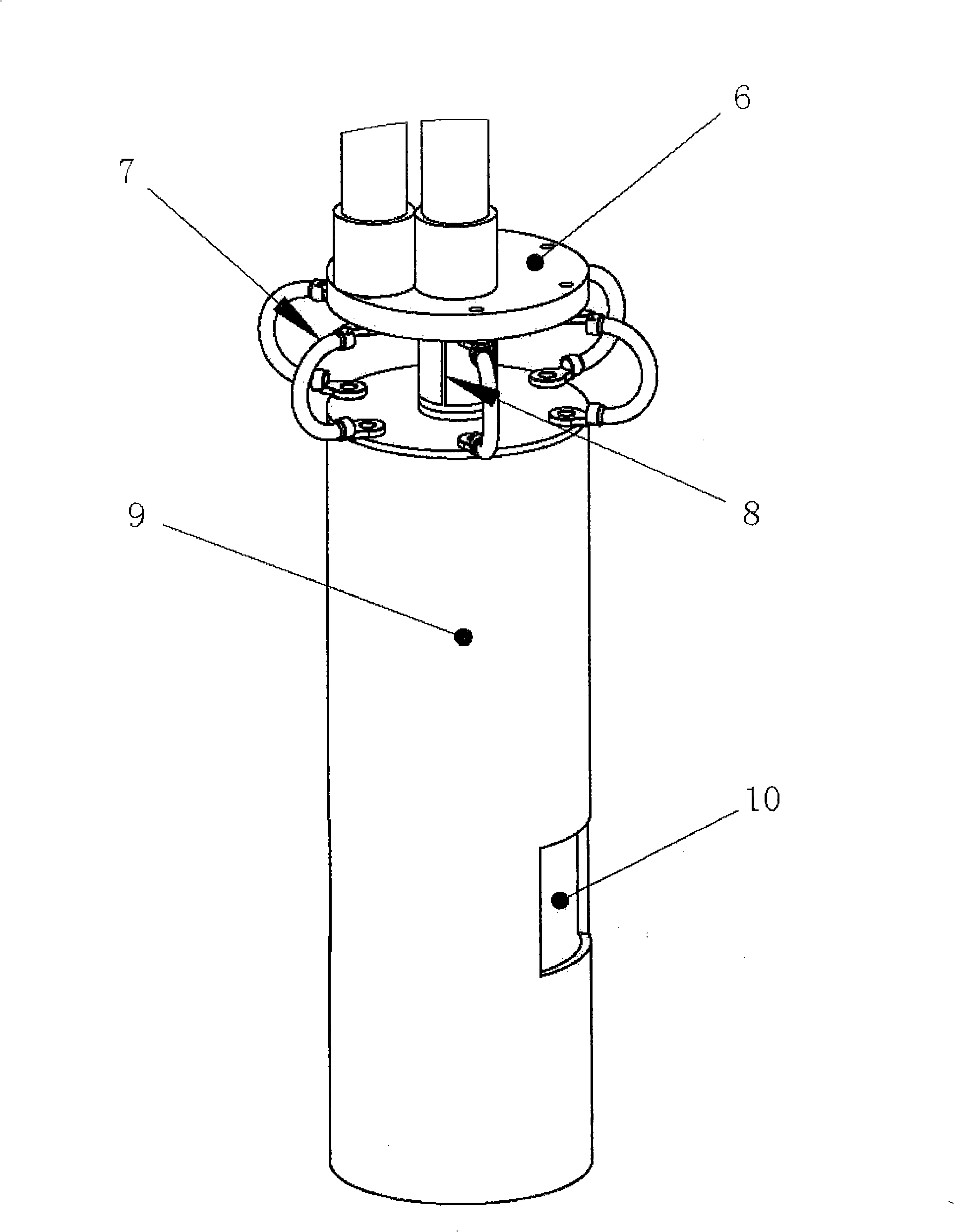

The invention discloses an inner-condensing diamond anvil cell pressing machine and belongs to the technical field of an in-situ physical quantity measurement device at high temperature and high pressure. The device comprises a pressing machine made of high-strength alloy steel (1) and beryllium copper (2), one pair of diamond anvil cells (5), a rocking bed (4) among the pressing machine and the diamond anvil cells (5), a mica sheet (3) between the pressing machine and the rocking bed (4), a spacer (6) between the two diamond anvil cells (5), spiral heater strips (7) wound on the spacer (6), a thermoelectric coupler (8), pneumatic fast joints (9) connected with a circulating water cavity (10) and a water pipe in the pressing machine, an external water-cooling machine and a water pump. The pressing machine is heated by the spiral heater strips and cooled by circulating water so that the high-temperature environment can be provided for the sample, and the pressing machine can be retained at a normal temperature status without pressure loss; a testing device for in-site measurement of multiple physical quantities at a high-temperature and high-pressure extreme condition and a testing method for the in-site measurement are established.

Owner:JILIN UNIV

Preparation method of high-strength and high-conductivity beryllium copper alloy

ActiveCN102383078AConductivity has little effectLittle tensile strengthNiobium alloyComposite structure

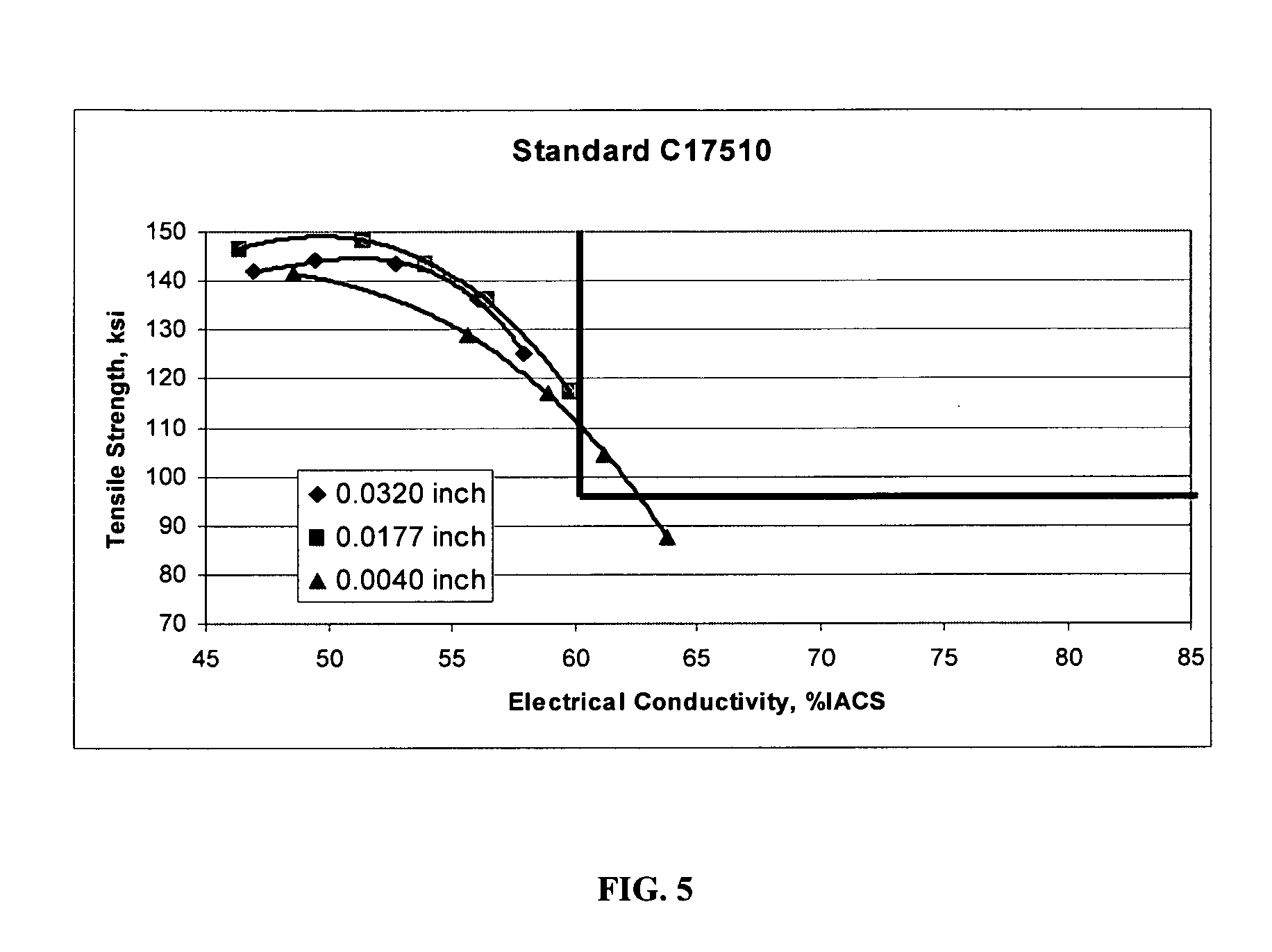

The invention relates to a preparation method of a high-strength and high-conductivity beryllium copper alloy. In the method, the high-strength and high-conductivity beryllium copper alloy is obtained through hot working, high-working rate cold working, solution treatment, finish rolling or product drawing and aging treatment after smelting the low-beryllium alloy and copper-niobium composite materials together and casting into an ingot. The dispersively distributed copper-niobium composite materials are added into the high-conductivity low-beryllium alloy, the dispersively distributed niobium particles form an ordered composite structure in the low-beryllium alloy after one-time hot working and multiple high-working rate cold working, so that the strength and hardness of the low-beryllium alloy are greatly improved, the conductivity of the low-beryllium alloy is not influenced, and the beryllium copper alloy with the tensile strength sigma b equal to 1200-1400Mpa, hardness HB equal to 334-374 and conductivity g equal to 45-60% IAC is finally obtained. The beryllium niobium alloy prepared by the invention has high strength, high hardness, high elasticity and high wear resistance of the high-beryllium alloy and high conductivity and thermal conductivity of the low-beryllium alloy at the same time, and the comprehensive property of the beryllium copper alloy is greatly improved.

Owner:CNMC NINGXIA ORIENT GRP

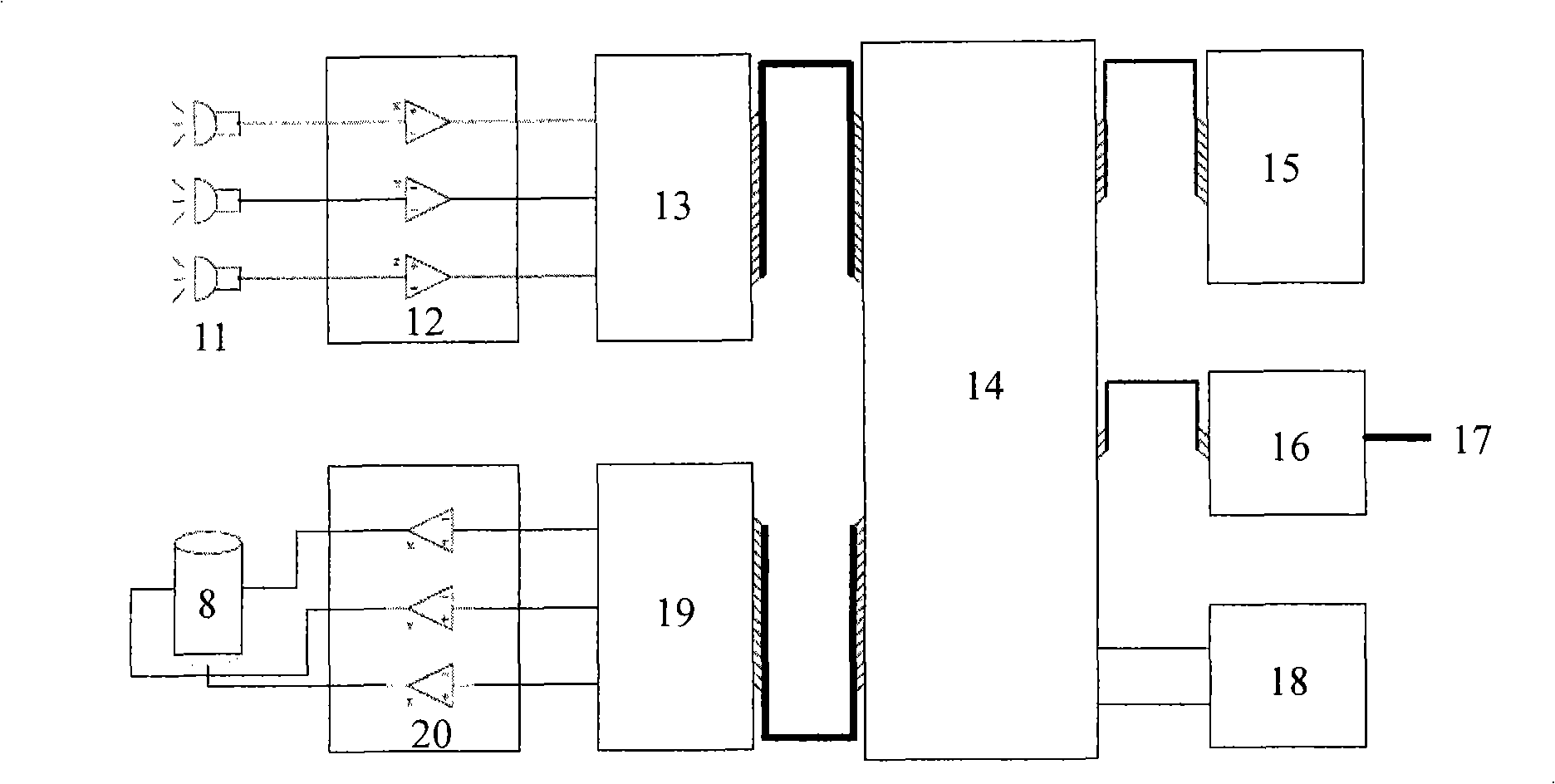

Low temperature scanning probe microscope system based on pulsatron refrigeration technology

ActiveCN101294889ALow running costEliminate vibrationSurface/boundary effectInstrumental componentsRetention timeDigital signal processor

The invention relates to a low temperature scanning probe microscope system based on pulse tube refrigeration technology. Aimed at vibration source and characteristics, a multistage active / passive damping device, including a sylphon bellowss, a piezoelectric ceramic tube and a spring are adopted. The sylphon bellowss is used for connecting a main system cavity and a refrigeration head of the pulse tube to realize vibration isolation of the whole system. As for low frequency vibration unique to a pulse tube refrigerator, an active damping device with a piezoelectric ceramic tube and a digital signal processor as the core is adopted. A beryllium copper spring and a damping magnet form a first stage passive damping device to isolate vibration. The system eliminates the vibration from the pulse tube refrigerator and the refrigeration head to the scanning probe, applies to other vibration sensitive occasions that require low temperature, saves a large amount of liquid helium refrigerant, simplifies equipment operation and maintenance, and significantly prolongs the retention time at low temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Tellurium berylco alloy and preparation method thereof

The invention discloses a tellurium berylco alloy; the tellurium berylco alloy is prepared from 0.2-2.1 wt.% of Be, 0.1-0.7 wt.% of Te, and others including Co, Ni, Ti, rare-earth elements and impurity elements of which total is not more than 4% wt; the rest is Cu; the preparation method includes steps of a, dosing, feeding, smelting and casting raw materials to acquire an ingot blank according to weight percent; b, orderly performing homogenizing heat treatment, heat processing technique, cold processing technique and annealing, solid dissolving, and aging heat treatment on the ingot blank acquired in step a orderly; and preparing the tellurium berylco alloy. Through adding tellurium in the berylco alloy, tellurium and a copper base can form Cu2Te; the tellurium berylco alloy is good in high-temperature stability, remains the excellent physical performance and corrosive resistance of tellurium beryllium copper, and greatly improves the material cutting performance on the basis of environmental protection, and also performs the plasticity performance.

Owner:KINKOU SUZHOU COPPER IND CO LTD

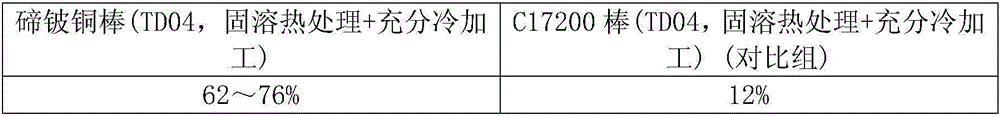

Beryllium copper alloy, copper bush for amorphous and/or nano crystal strip production equipment and preparation method

The invention discloses a beryllium copper alloy, a copper bush for amorphous and / or nano crystal strip production equipment and a preparation method. The copper contains the following elements in percentage by mass: 0.25 to 2.1 percent of Be, and 0.1 to 2.0 percent of Co. By adding the elements such as Co and the like into the beryllium copper alloy, the advantage of interaction of the alloy elements is exerted; and the smelted alloy is cast into a cast ingot or a cast blank, and the cast blank is subjected to the processes of hot forging, heat preservation, ageing treatment and the like to prepare the beryllium copper alloy with high strength and high thermal conductivity and in accordance with the copper bush for the amorphous or nano crystal strip production equipment. When the beryllium copper bush is applied in the strip production link, the appearance quality and the actual performance of amorphous or nano crystal strips can be effectively promoted.

Owner:李希涛

Acoustic ear tube retainer spring

A metal retainer spring bent into a U-shape retains an acoustic ear tube for use with behind-the-ear devices. The tube is held by a tube retaining opening in a tapered mid portion, forming the curved portion of the bent spring, and end slots bent together with the slots holding the tube. The retainer spring fits into the human ear canal for securing a narrow acoustic ear tube within a user's ear canal. The spring is manufactured from beryllium copper, or other material with excellent strength and great elasticity, and is then gold plated for the hypoallergenic properties. The top and bottom ear canal-contacting surfaces of each spring have a pebbled or rippled finish to limit slippage without causing abrasions.

Owner:DAVIS JOHN W

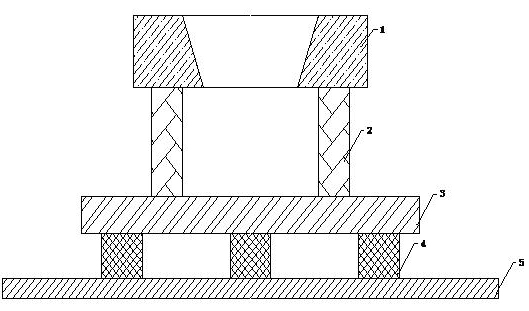

Injection mold core with air suction, discharge and rapid cooling functional structure

The invention provides an injection mold core with an air suction, discharge and rapid cooling functional structure. The injection mold core consists of a core body (1), a ventilated surface (2), an air suction and discharge channel (3) and a heat-conductive pin (4). In the injection mold core, the technical scheme that: the core body is made from a beryllium copper material with high heat conductivity; the ventilated surface which is made of porous ventilated steel is fixedly inlaid at the top of the core body; the air suction and discharge channel which is connected with a mold is reserved in the core body; and the heat-conductive pin which is directly inserted into a mold cooling water pipe is arranged at the bottom of the core body is adopted, so that the problems of low qualification rate, high cost and poor quality consistency of products in the molding of small-diameter deep-cavity injection products in the prior art are solved. The injection mold core with the air suction, discharge and rapid cooling functional structure provided by the invention fulfills the aims of improving the qualification rate, reducing the cost and ensuring the quality consistency of the products of the molding of the small-diameter deep-cavity injection products by increasing cooling rate and improving air suction and discharging conditions of the core body structurally.

Owner:NINGBO RUIYUAN MOLD & PLASTICS

High-performance beryllium-copper alloy and preparation method thereof

The invention discloses a high-performance beryllium-copper alloy and a preparation method thereof. The high-performance beryllium copper comprises 1.6-2.2% of beryllium, 0.35-0.65% of cobalt and nickel, 0.03-0.1% of yttrium, 0.03-0.1% of titanium, 0.1-0.3% of boron, 0.1-0.3% of magnesium and the balance of copper in percentage by weight, wherein the beryllium is added in the form of a beryllium-copper immediate alloy and accounts for 3.8-4.2% of the beryllium-copper alloy; the cobalt and the nickel are also respectively added in the form of immediate alloys of a cobalt-copper alloy and a nickel-copper alloy and respectively account for 8-12% of the alloy; the titanium is added in the form of a titanium-copper immediate alloy and accounts for 4-6% of the alloy; and the yttrium is added in the form of a yttrium-copper immediate alloy and accounts for 8-12% of the alloy. By using the invention, the mechanical comprehensive performance is improved, the service life of the material is largely prolonged, and the service life of a beryllium-copper injection plunger head applied to a die casting machine is increased to more than 20000 mold times from the original 8000-12000 mold times.

Owner:DONGGUAN JIASHENG COPPER

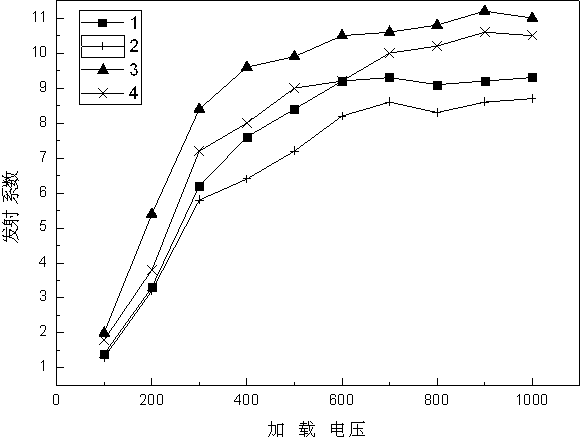

Method for processing Beryllium copper plate strip for secondary electronic emission

The invention provides a method for processing beryllium copper plate strips for secondary electronic emission. The composition proportion of the sheet material comprises: by weight, 2.7-3.0 % of beryllium, 0.31% or less than 0.31% of nickel, 0.058% or less than 0.058% of ferrum, 0.013% or less than 0.013% of aluminum, 0.028 % or less than 0.028 % of silicon, 0.0020 % or less than 0.0020 % of plumbum, 0.0020 % or less than 0.0020 % of cadmium, 0.0020 % or less than 0.0020 % of zinc, and 0.43 % or less than 0.43 % of the sum of other impurity elements, and the balance copper. The particular rolling technology includes the steps: using methods of plasticization and extrusion to manufacture blanks; heating the blanks and preserving heat; matching with the middle annealing technology and acid-washing, conducting multi-pass rolling on a rolling machine; and after rolling is conducted, conducting corresponding heat treatment to obtain the sheet materials with corresponding standards. A secondary electronic emission peak value of beryllium copper plate and strip emitting can reach more than 10 which is far more than a level of a peak value which is 6.

Owner:CENT SOUTH UNIV +1

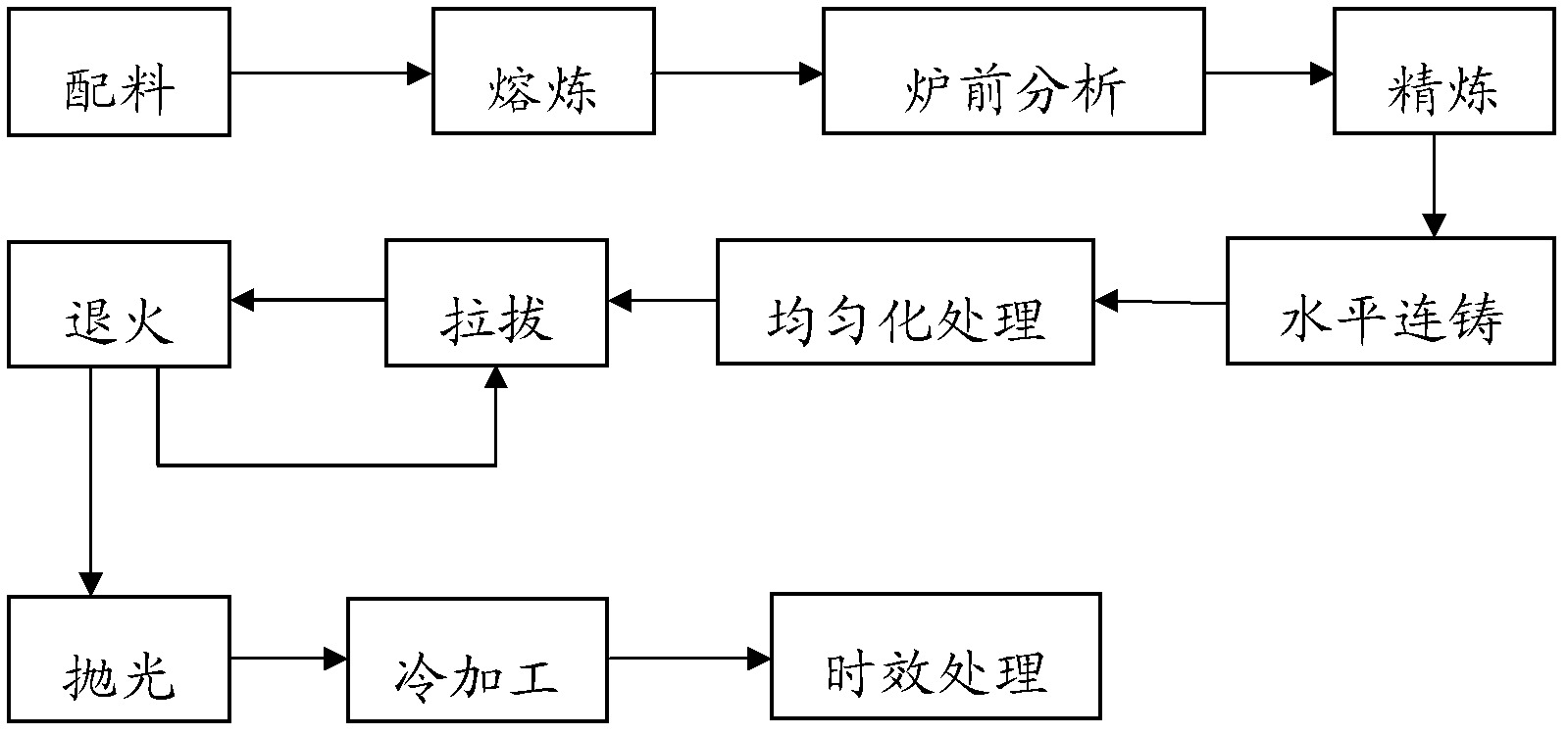

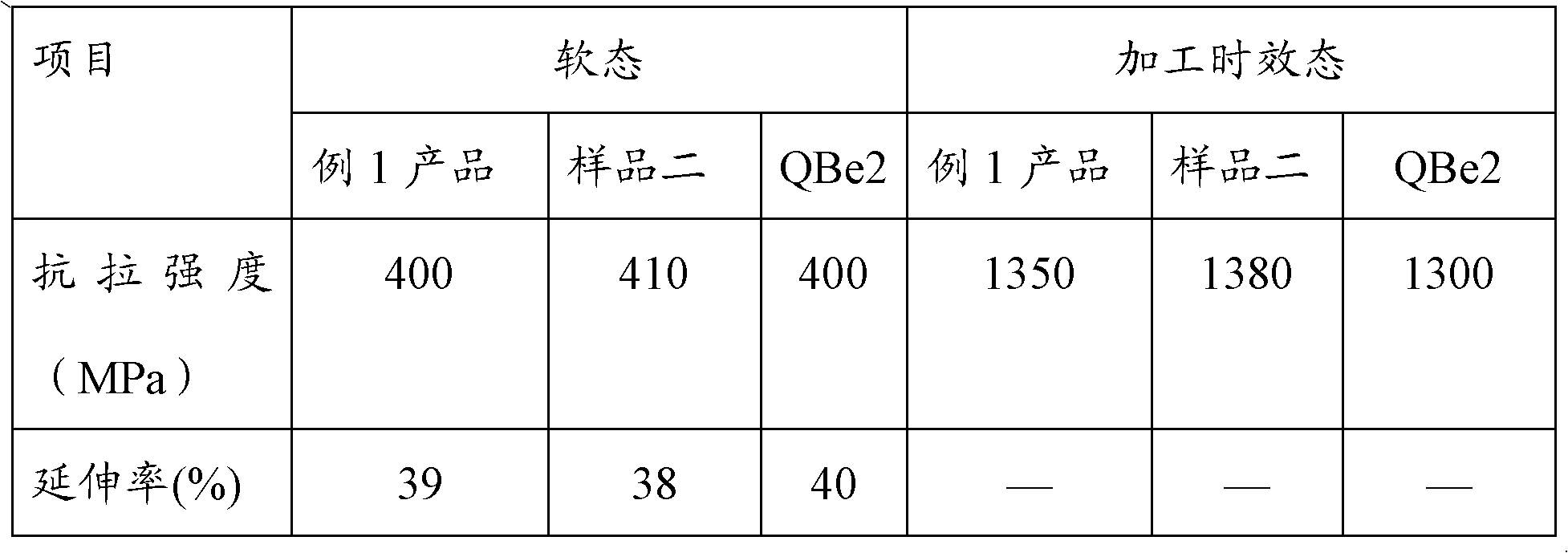

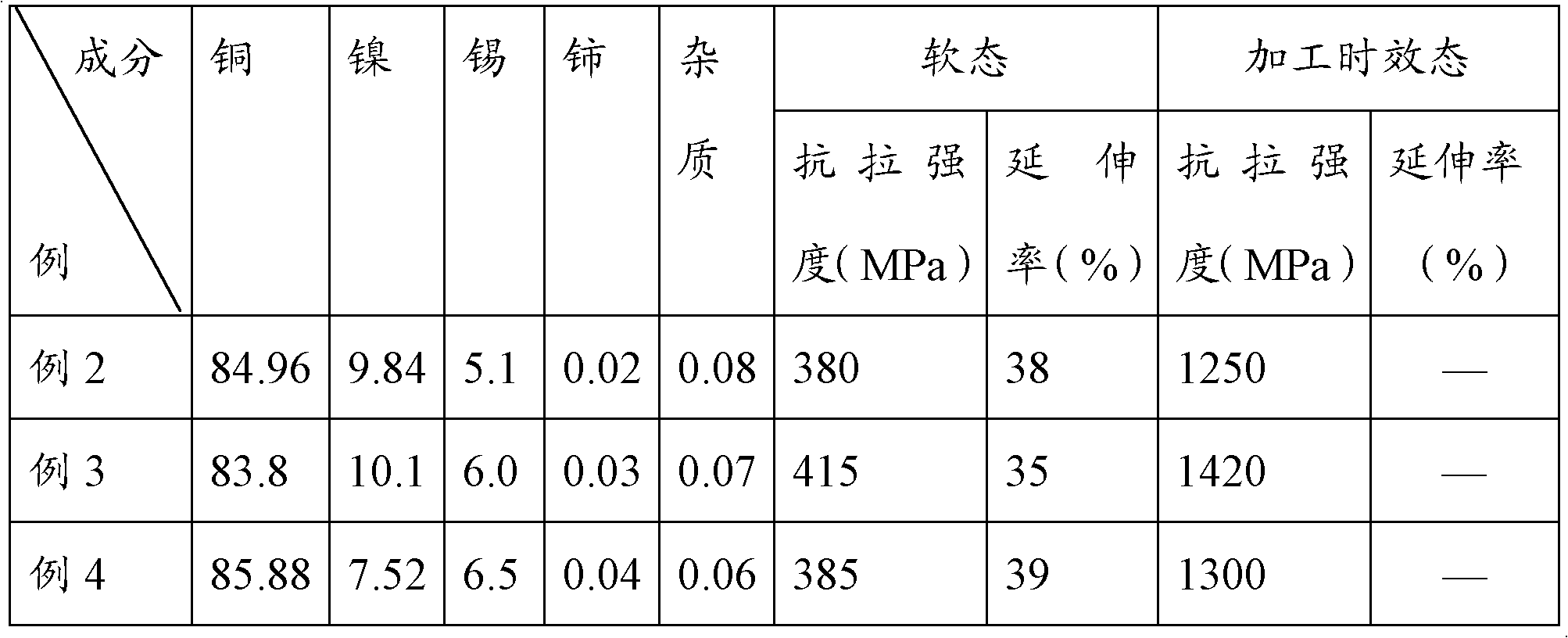

Copper-nickel-tin alloy and preparation method for wires thereof

The invention discloses copper-nickel-tin alloy and a preparation method for wires thereof. The copper-nickel-tin alloy comprises, by weight, 7 to 11% of nickel, 4 to 8% of tin and 0.02 to 0.04% of cerium, with the balance being copper and unavoidable impurities; the alloy has same performance as beryllium-copper alloy does. Horizontal continuous casting is used in the preparation method for wires of the copper-nickel-tin alloy; compared to vacuum melting commonly used at home and abroad, the method provided in the invention has the advantages of high rolling yield, simple processing equipment, small investment, short process flow and capacity of obtaining wire products with same excellent performance.

Owner:厦门火炬特种金属材料有限公司

Low-beryllium elastic copper alloy and preparation and manufacture method thereof

InactiveCN102676878AReduce the difficulty of productionSimple preparation processSolution treatmentStress relaxation

The invention relates to low-beryllium elastic copper alloy and a preparation and manufacture method thereof. The low-beryllium elastic copper alloy comprises by mass: 0.2-0.4% of Be, 1.3-2.6 % of Ni and the balance Cu, wherein the mass ratio of the Ni to the Be in the beryllium copper alloy is larger than or equal to 5.5 and smaller than or equal to 6.5. The alloy can further contain Cr and Zr. The preparation method of the low-beryllium elastic copper alloy comprises alloy component design, casting, hot rolling, solution treatment, rolling deformation and ageing treatment. The alloy is low in Be content (smaller than 0.5%) and can effectively save metal beryllium, the tensile strength of the alloy after deformation ageing treatment can reach 968MPa, conductivity is larger than 55% according to the international annealed copper standard (IACS), and the rate of resistance to stress relaxation is larger than 85%. Therefore, the low-beryllium elastic copper alloy can serve as a conductive elastic material which has high elasticity, high strength and excellent resistance to stress relaxation, can be applied to electrical contact components, connectors, relays and the like, and has wide application prospects.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

Rapid Direct-current deicing short circuit device of electric transmission line

ActiveCN103490363AQuick hookEasy to mountOverhead installationElectrical resistance and conductanceBeryllium copper

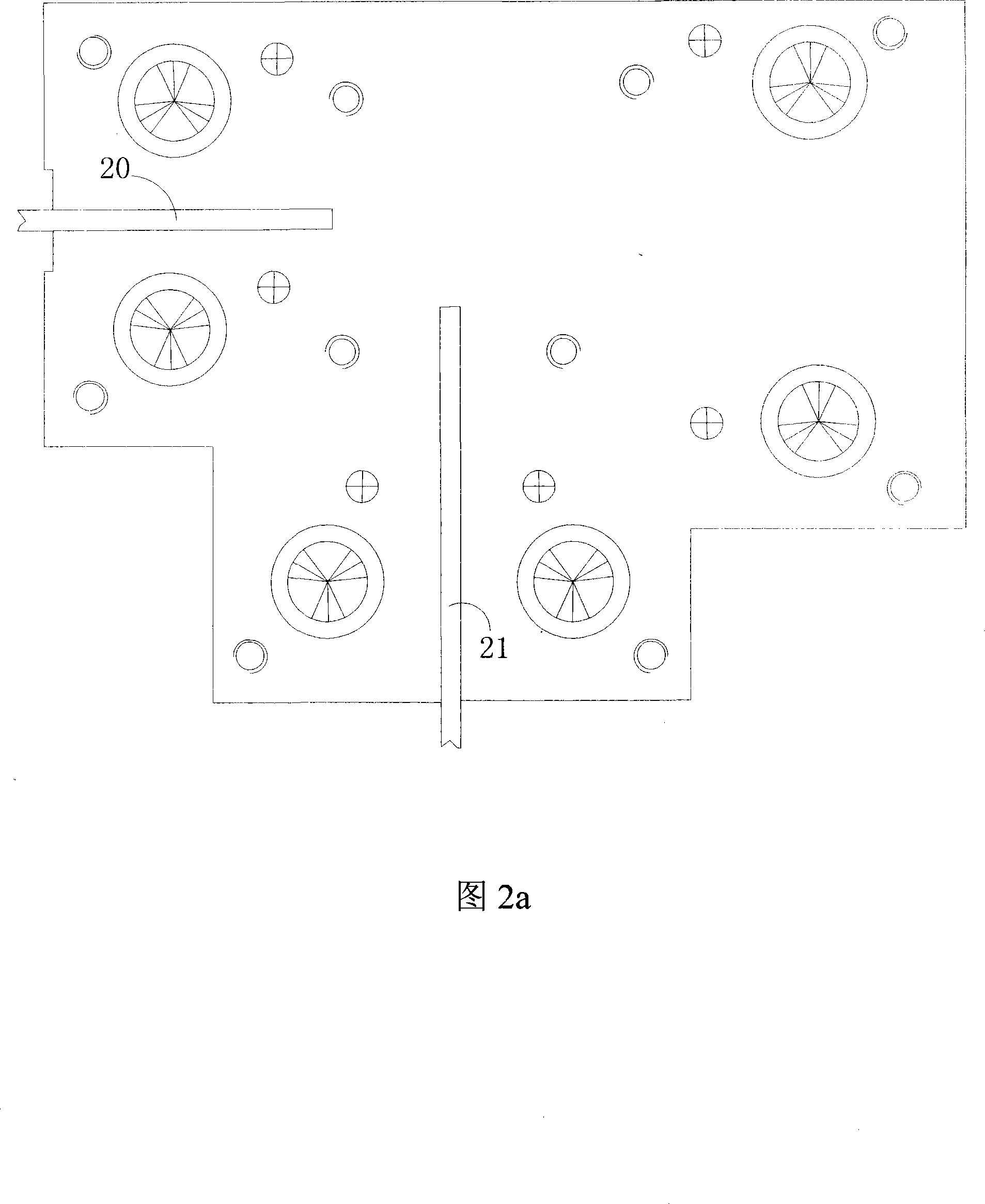

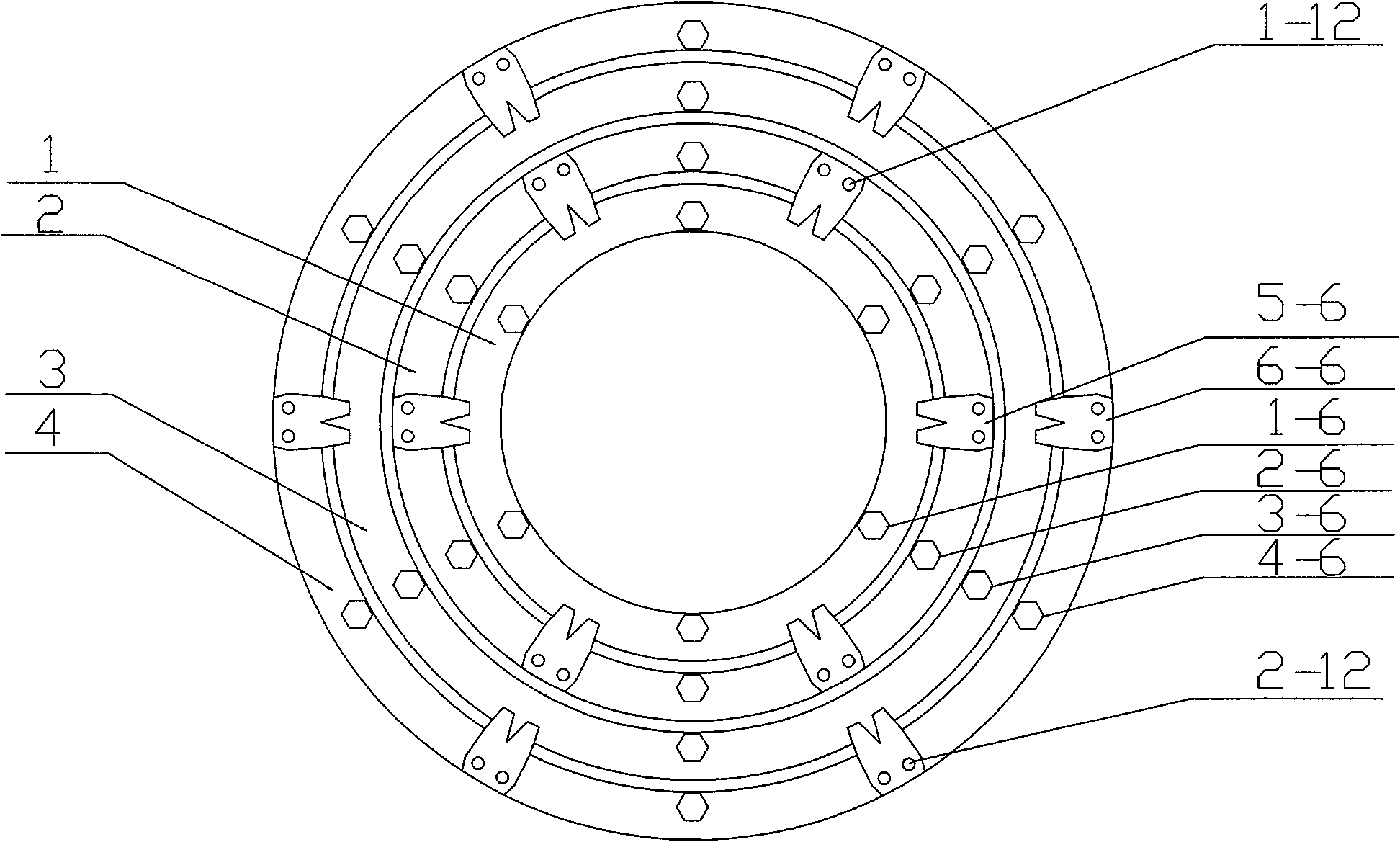

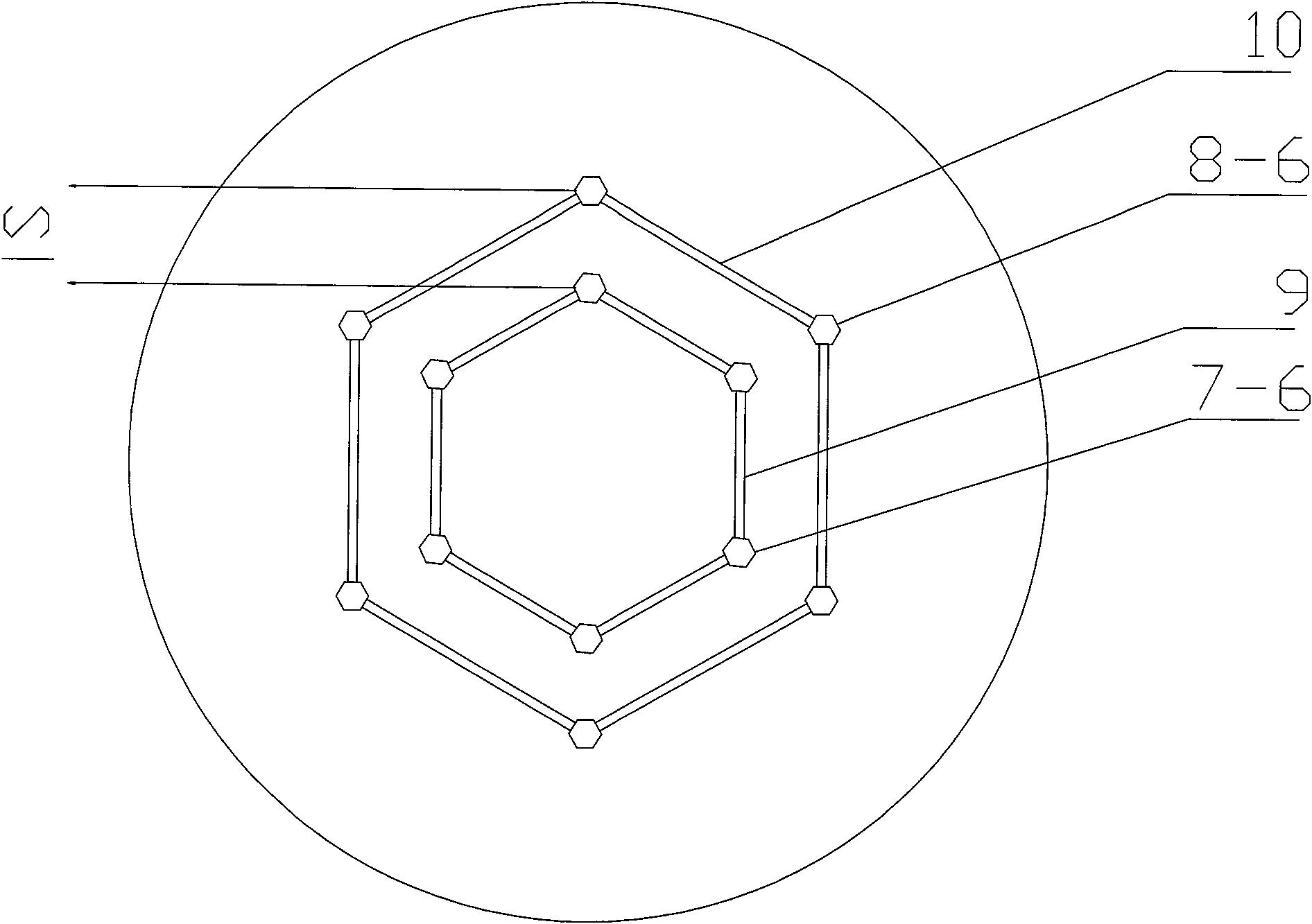

The invention relates to a rapid direct-current deicing short circuit device of an electric transmission line and belongs to the technical field of electric power line device fittings. According to the structure, the rapid direct-current deicing short circuit device of the electric transmission line comprises a short circuit cable (1). The two ends of the short circuit cable (1) are respectively connected with one line hanging connection clamp. One end of an upper clamping block (2) of each line hanging connection clamp and one end of a lower clamping block (3) of the line hanging connection clamp are movably connected through a hinge, the other end of each upper clamping block (2) is provided with an upper semi-tile combined beryllium copper sleeve (5), and the other end of each lower clamping block (3) is provided with a lower semi-tile combined beryllium copper sleeve (6), wherein the upper semi-tile combined beryllium copper sleeve (5) and the lower semi-tile combined beryllium copper sleeve (6) are matched with the overhead line in diameter. The two ends of the short circuit cable (1) are respectively connected with a downward-convex conductive block (7) in a rapid screwing mode through an internal-thread clamping connector (8). The lower end of each pull rod (4) is square and is connected with the middle of one lower clamping block (3) through a shotpin mechanism. According to the rapid direct-current deicing short circuit device of the electric transmission line, the line hanging connection clamps are connected to two overhead lines which are erected in parallel, a large current power source is loaded between adjacent phases of the overhead lines, heat generated through a resistor of the overhead aluminum conductors is utilized, so that attached ice is rapidly deiced and eliminated, and adjacent phase connection can be rapidly and conveniently conducted. The rapid direct-current deicing short circuit device of the electric transmission line has the advantages of being capable of saving labor, short in time, rapid in installation, convenient to install, and firm.

Owner:郴州市东晟科技有限公司

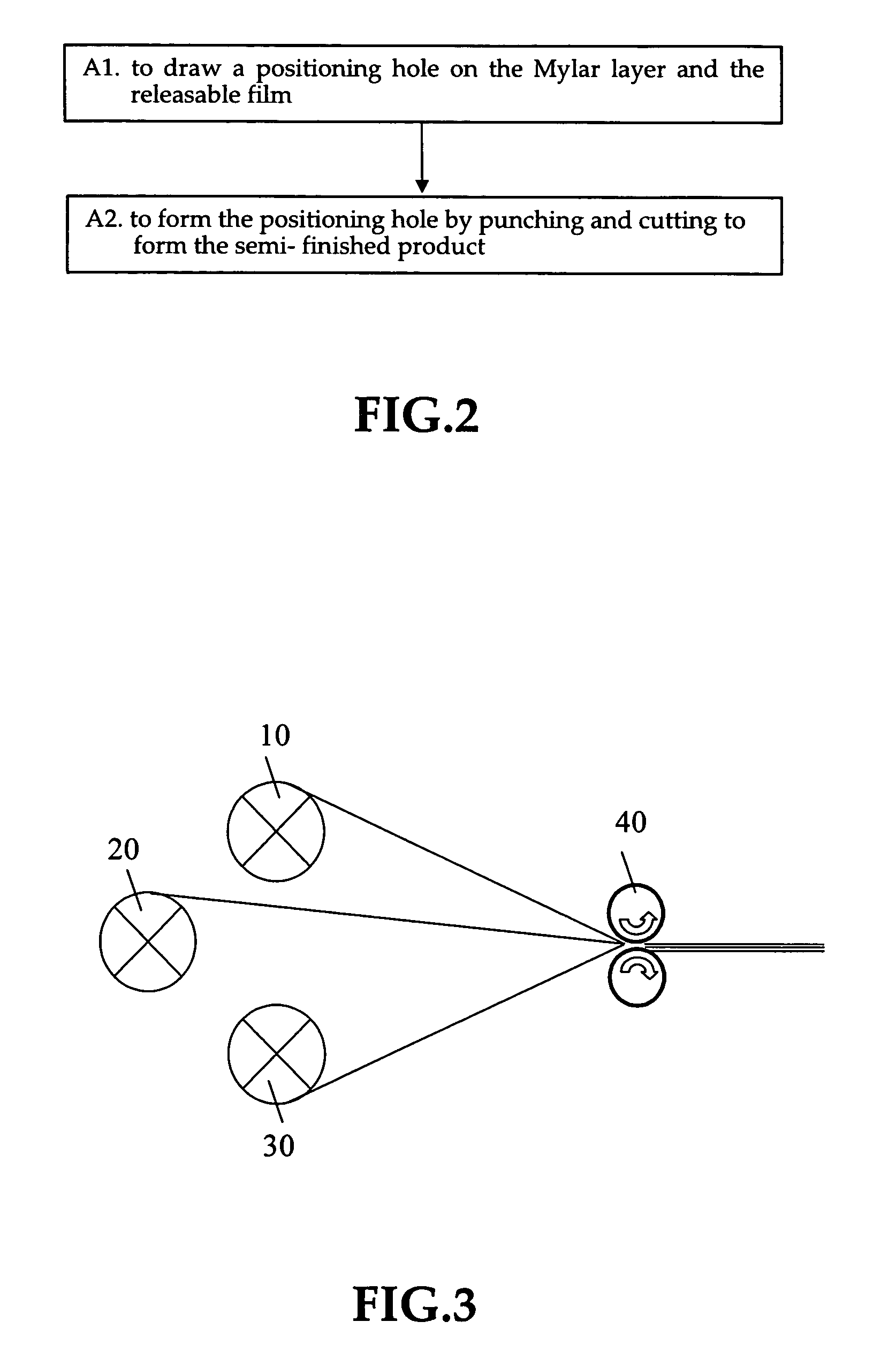

Method of manufacturing a sticker type antenna

InactiveUS20080010809A1Save consumption of manpowerImprove stabilityPrinted circuit aspectsConductive pattern formationPolyesterPunching

A method of manufacturing a sticker type antenna, in which a copper foil of 0.017 mm by thickness is stuck to a layer of releasable film in advance, in order that the copper foil can bear the pulling force in a brush electroplating process to thereby substitute the conventional beryllium copper of a larger thickness. The copper foil after brush electroplating undergoes punching and cutting for forming a pattern and is stuck to a semi-finished product of Mylar, hence the copper foil is stuck onto the back side of the Mylar layer; then the Mylar layer with the copper foil is separated from the releasable film, then the back side of the Mylar layer is applied with adhesive and again is stuck to the releasable film; after punching and cutting the Mylar layer for patterning and edging, a sticker type antenna is made.

Owner:AUDEN TECHNO

Miniature surface mount technology electromagnetic interference shielding device

ActiveUS8933346B1Screening gaskets/sealsDigital data processing detailsElectromagnetic interferenceEngineering

The present invention is directed to an electromagnetic interference (EMI) shielding device. The EMI shielding device may be formed of a material (ex.—Beryllium Copper) having a thickness which allows the shielding device to provide a desired range of compression. Further, the EMI shielding device may be constructed for accommodating tolerances and compression forces which may be encountered in various implementation environments. Further, the EMI shielding device may be sized and shaped for promoting compatibility of the EMI shielding device with Surface Mount Technology (SMT) processes.

Owner:ROCKWELL COLLINS INC

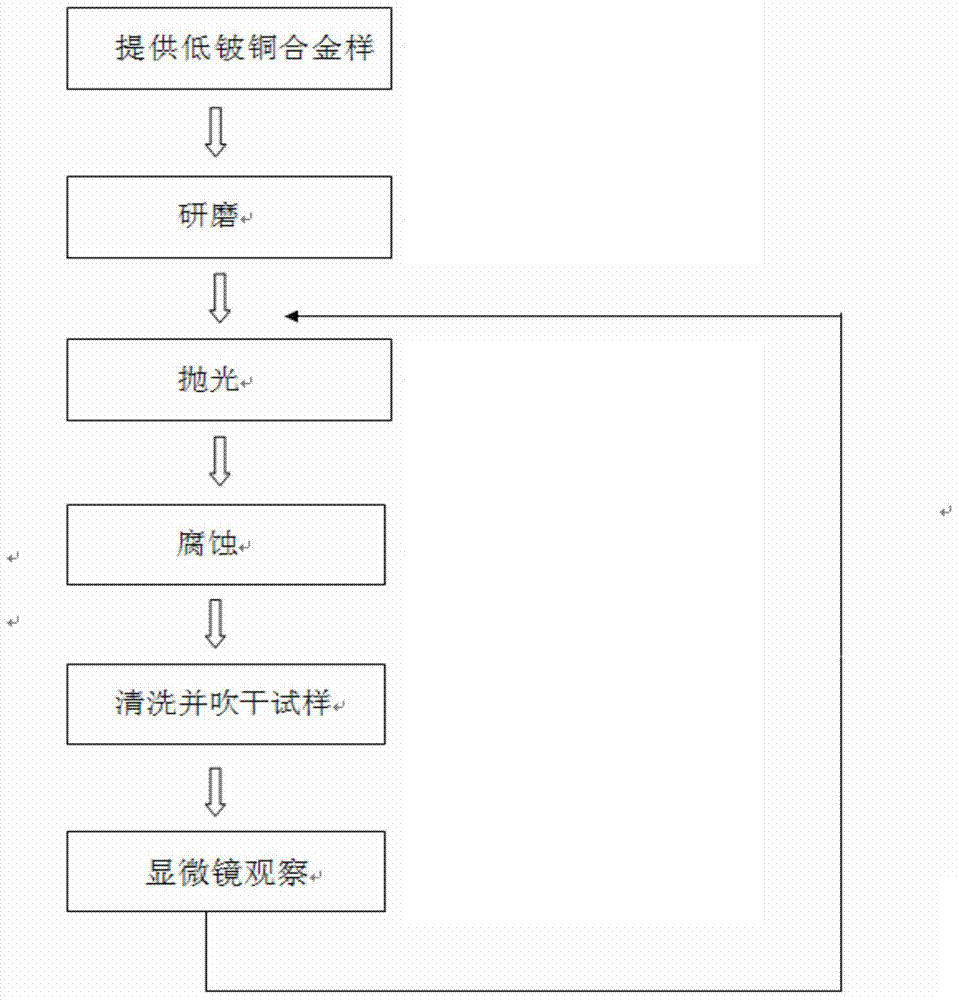

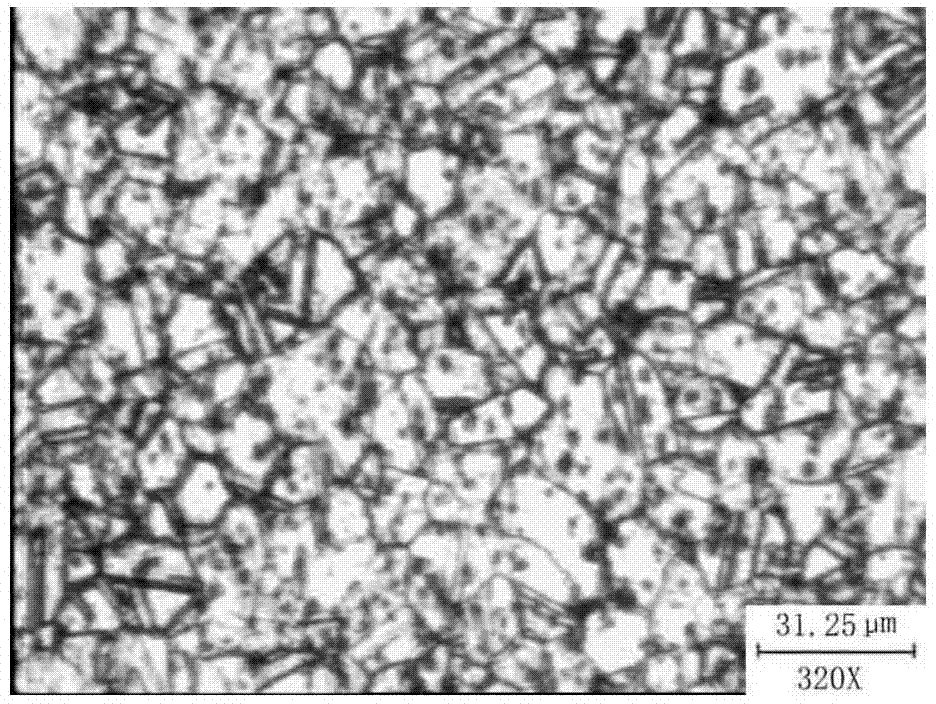

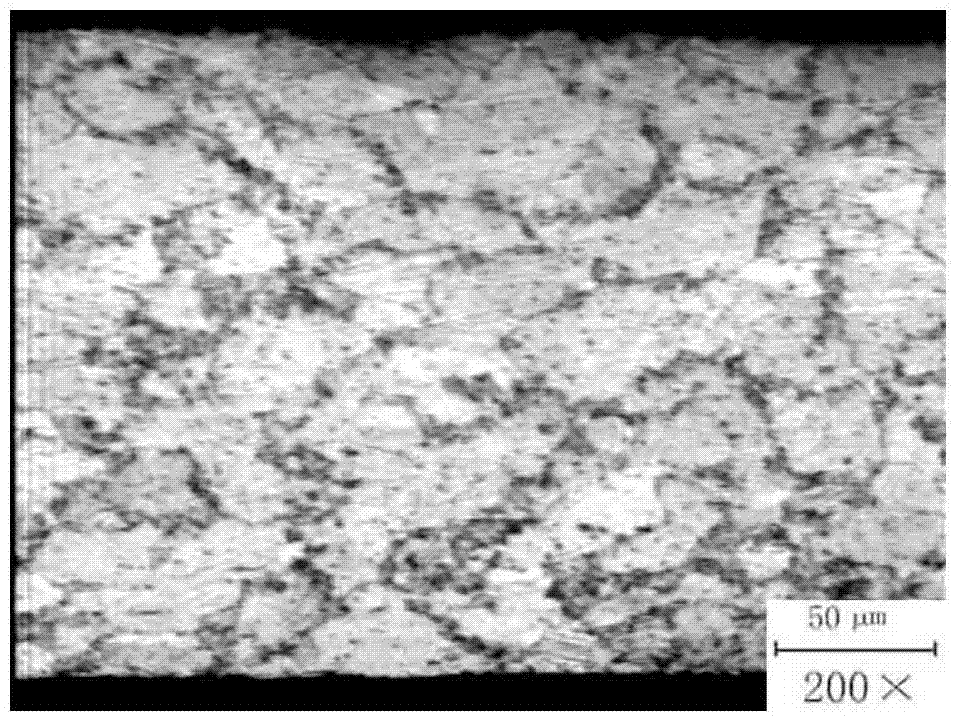

Low-beryllium copper alloy metallographic corrosive agent and display method of metallographic structure of low-beryllium copper alloy

ActiveCN103575585AImplement testSimple processPreparing sample for investigationBeryllium-Copper AlloyBeryllium copper

The invention relates to a low-beryllium copper alloy metallographic corrosive agent and a display method of metallographic structure of low-beryllium copper alloy. The method comprises the following steps of: orderly burnishing a low-beryllium copper alloy sample with 180-mesh, 400-mesh, 800-mesh and 1500-mesh silicon carbide waterproof abrasive papers or aluminum oxide waterproof abrasive paper by virtue of using water as a wetting agent, then, polishing the alloy with aluminum oxide polishing solutions of different particle sizes, finally, performing corrosion treatment by using one or any combination of three types of low-beryllium copper alloy metallographic corrosive agents prepared by the invention, and further washing and observing the sample. According to the invention, with the prepared corrosive agent effective to the metallographic structure of the low-beryllium copper alloy, the metallographic structure of the low-beryllium copper alloy can be displayed clearly, so that inspection on the low-beryllium copper alloy is realized. The technology is simple, and is simple and convenient to operate.

Owner:西北稀有金属材料研究院宁夏有限公司

Manufacturing method of injection mold and 3D printing injection mold

PendingCN109016272AGuaranteed cooling effectShort timeAdditive manufacturing apparatusBeryllium copperMaterials science

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +1

Production of beryllium copper pipe

A technology for manufacturing the beryllium-copper pipe includes such steps as providing a beryllium-copper alloy ingot prepared from Be, P and Cu and with 50-90 mm for diameter, 30-50 mm for internal hole diameter and 210-300 mm for length, extruding at 750-800 deg.C by (600-800)-ton press, annealing in H2 at 500-600 deg.C, forced cooling to 0-50 deg.C, and rolling.

Owner:上海威嘉金属材料有限公司

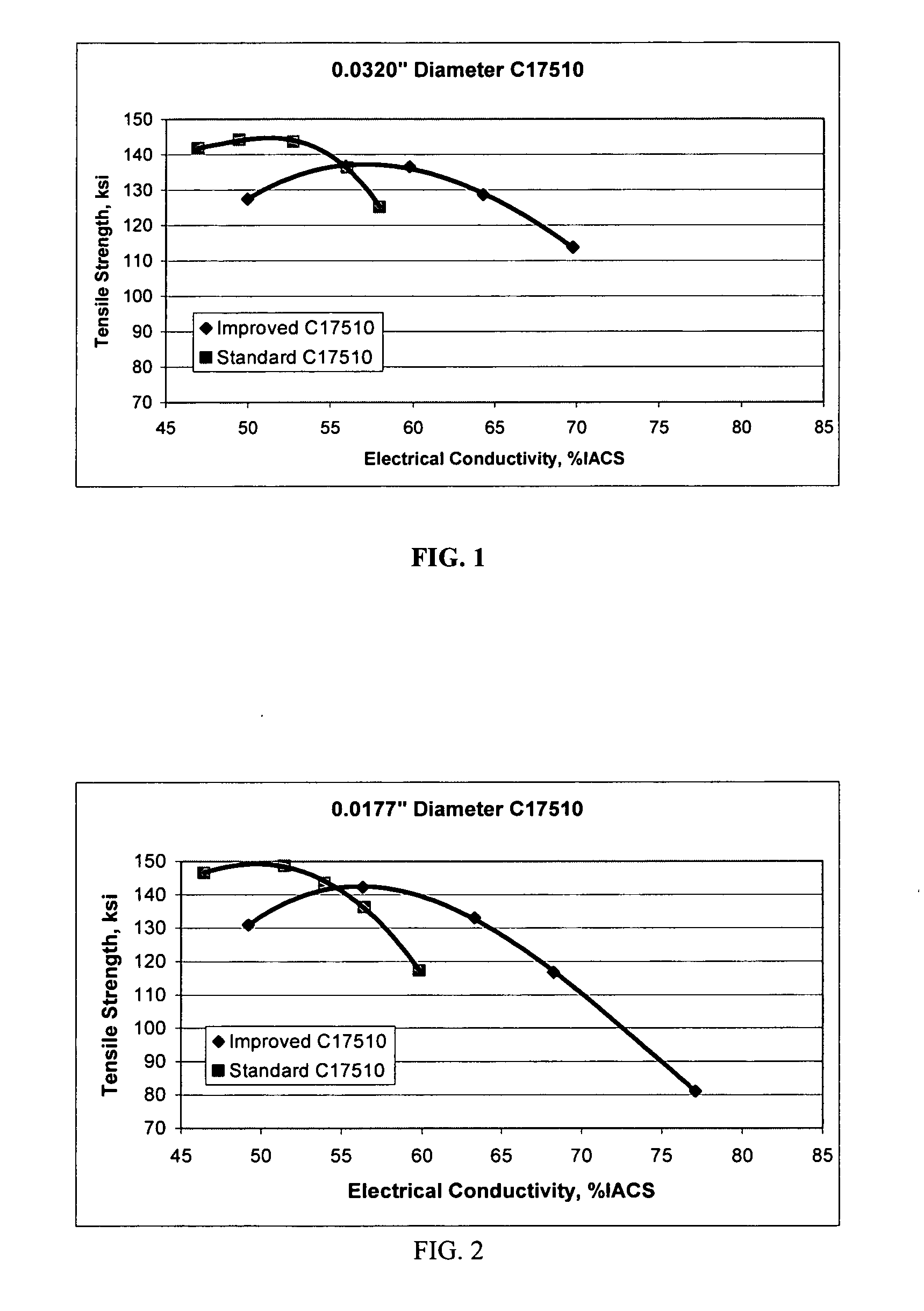

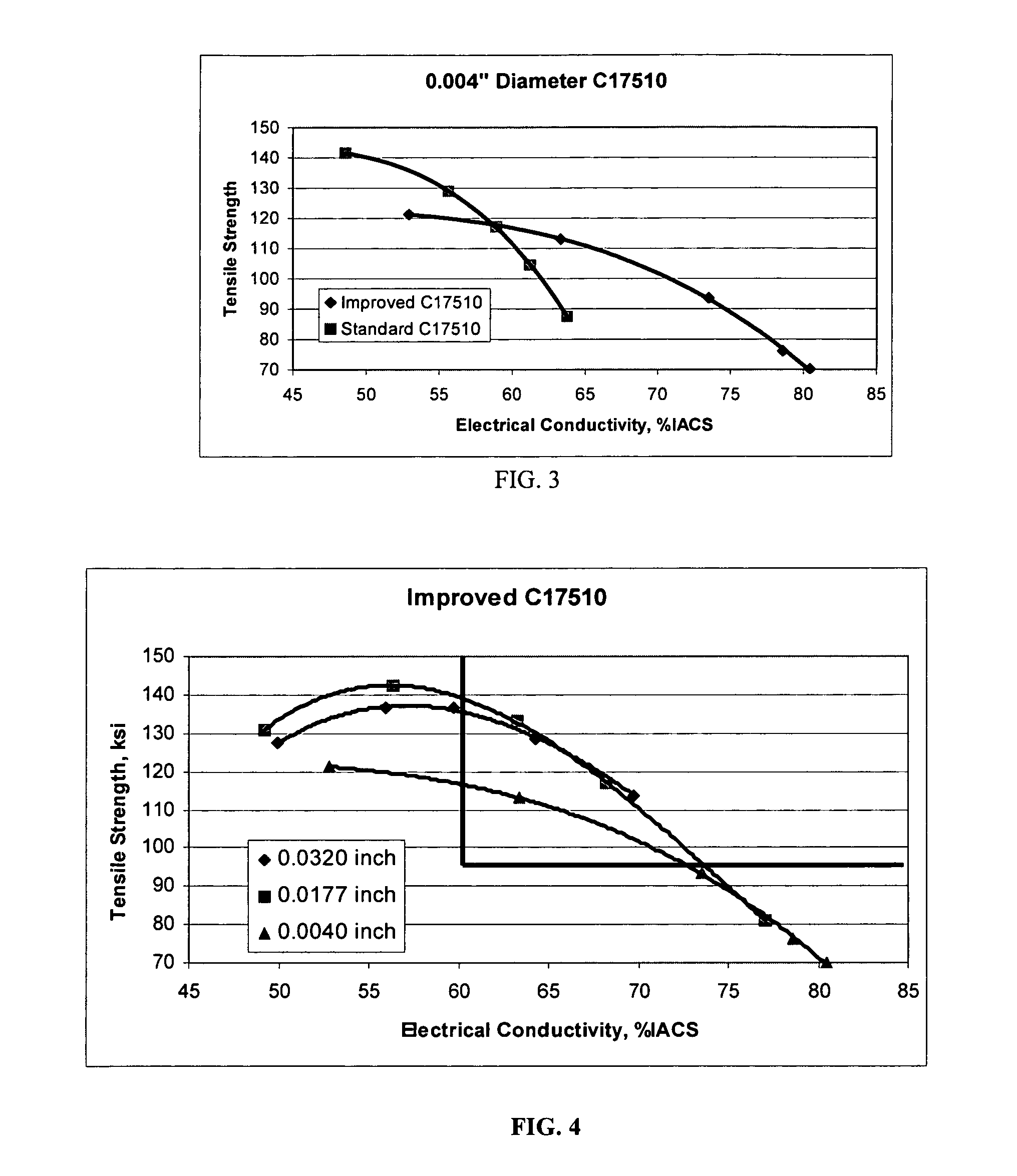

Beryllium-copper conductor

InactiveUS20080202643A1Improve conductivityHigh surface brightnessConductive materialElectrical conductorAlloy

A process is provided for forming an age hardened wire for use as an electrical conductor, which wire is formed from a copper base alloy consisting of from 1.25 to 3.6 wt % nickel, from 0.25 to 0.45 beryllium, and the balance copper and impurities which do not affect the properties of said alloy, with the nickel and beryllium being present in the copper base alloy in a ratio of nickel to beryllium from 5.0 to 8.0. The process comprises the steps of providing a copper base alloy material consisting of from 1.25 to 3.6 wt % nickel, from 0.25 to 0.45 beryllium, and the balance copper and impurities which do not affect the properties of said alloy, which nickel and beryllium are present in the copper base alloy in a ratio of nickel to beryllium from 5.0 to 8.0, cold working the material in a single step; and age hardening the cold worked material in a single step to form a wire in a cold worked and aged hardened condition having an electrical conductivity of at least about 60% IACS.

Owner:FISK ALLOY WIRE

Manufacturing method of DC electric machine carbon brush holder

ActiveCN101162820AIncrease productivityImprove bindingLine/current collector detailsRotary current collectorState of artPunching

The present invention discloses a producing method for a direct current motor carbon brush rack, which adopts the producing method combined the automatic feeding of a brass material belt and a beryllium copper material belt and automatic punching of a terminator produced by the brass material belt and an elastic arm produced by the beryllium copper material belt, thereby replacing the separate molding of the terminator and the elastic arm, manual riveting and further completing molding, falling and other working sequences for the riveted terminator and the elastic arm in the prior art. The present invention has the advantages of high producing efficiency, stable combination of the terminator and the elastic arm, guaranteed quality, reduction of corner material and improved operation factor of raw material.

Owner:东莞市林远实业有限公司

Rotary power supply converter

InactiveCN101635421AReduce volumeEnhances the conductivity of active electrical connectionsRotary current collectorElectricityElectrical connection

The invention relates to a rotary power supply converter, popularly an electric turntable. The electric turntable mainly uses strong-elasticity beryllium copper to produce conductive connecting pieces, and in a round platform shaped insulating shell, two flaky conducting rings fixed on an upper insulating supporting plate and connected with an electric load are in double-sided occlusion rotary sliding friction active electrical connection with two flaky conducting slip rings fixed on a lower insulating supporting plate and connected with a power supply through six groups of dual-conductive connecting pieces respectively. Because the conductive connecting pieces, the conducting rings and the conducting slip rings are flaky and are hung in the air and horizontally placed on a middle horizontal line between the upper insulating supporting plate and the lower insulating supporting plate, and together with an ultra-thin center positioning turntable and an pressure-bearing steel ball in an R groove, the rotary power supply converter strides forward into the ultra-thin field in design. Thus, the product is portable and convenient, and can be matched with a dining table in use independently to form a rotary electric hot pot table. Simultaneously, the rotary power supply converter can be widely applied to theatrical stages and industrial and agricultural productions so that the rotary power supply conversion steps into a new step.

Owner:汪文捷 +1

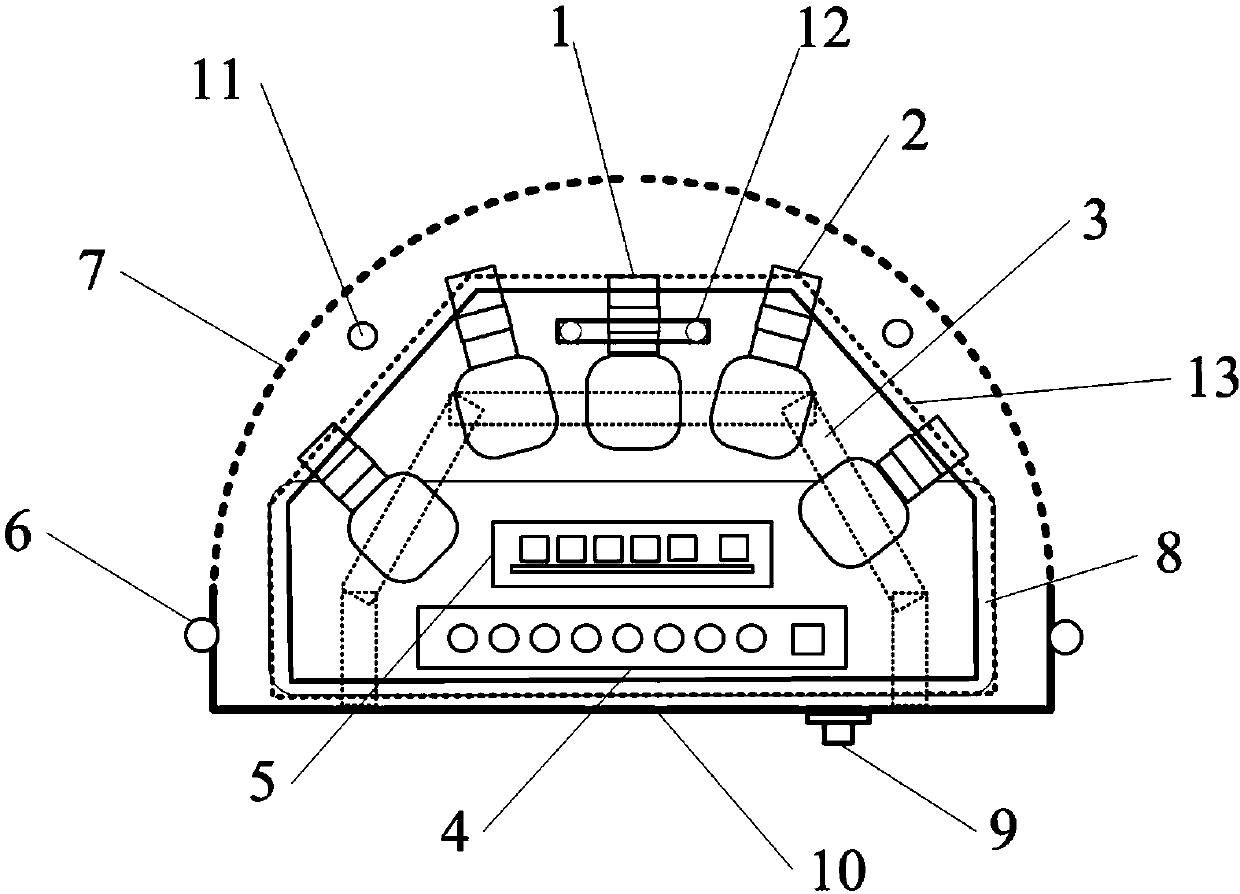

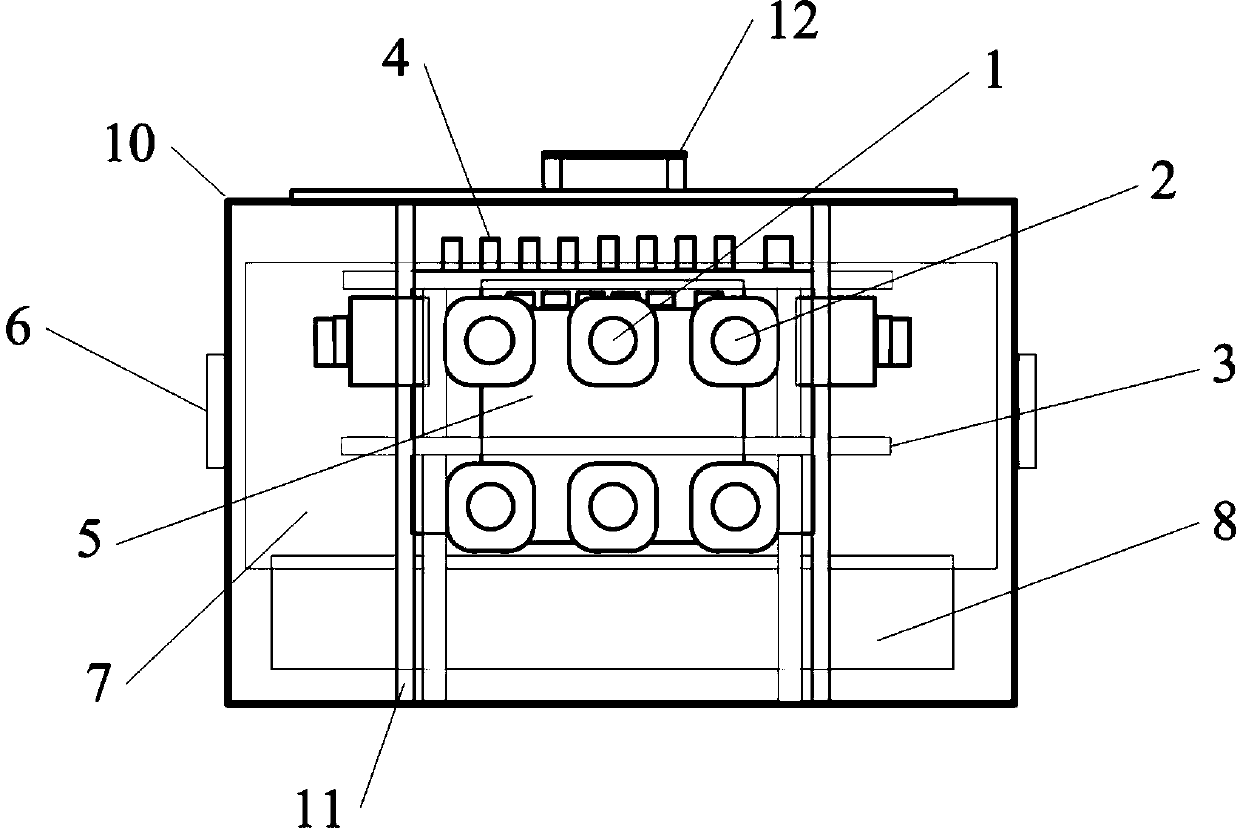

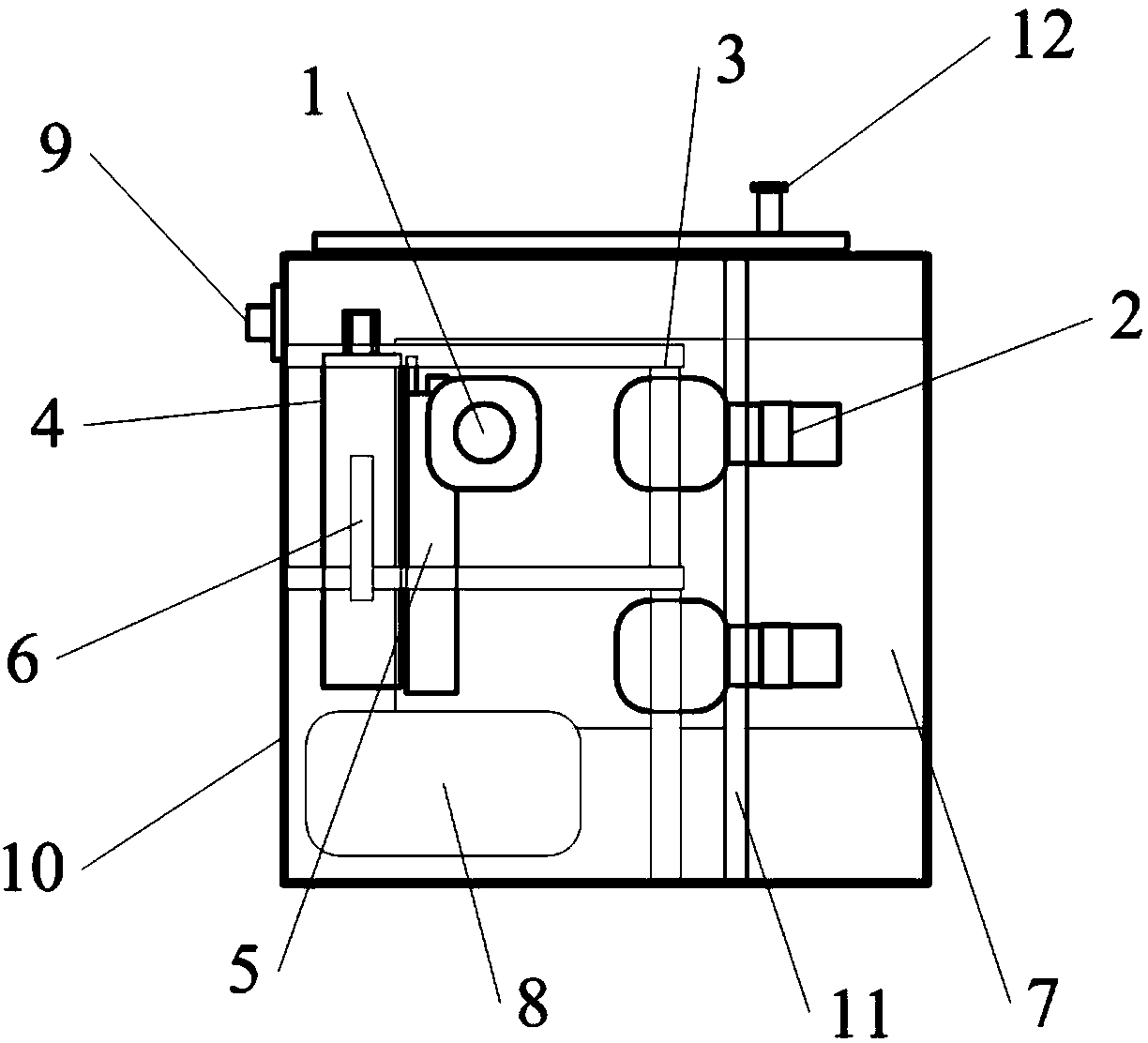

Panoramic surveillance camera shooting system of cockpit

ActiveCN104219499AAvoid enteringWork lessOptical transmission adaptationsClosed circuit television systemsSurveillance cameraElectromagnetic shielding

A panoramic surveillance camera shooting system of a cockpit is characterized by comprising a video capture sub system and a wireless optical transmission sub system. The video capture sub system comprises wide-range camera shooting modules (1), long-focus local camera shooting modules (2), a fixing support (3), a lightware-terminal-equipment transmitting module (4), an integrated power supply module (5), external fixed handles (6), an arc-shaped light-transmitting material and metal mesh composite structure (7), a high-capacity battery pack (8), a fiber interface (9), an electromagnetic shielding shell (10), a shielding door (12) and a beryllium copper spring (13). The wireless optical transmission sub system comprises a wireless transmission module shell (14), rubber cushions (15), an optical antenna (16), fixed magnet sets (17), a fiber interface (18) and a communication optical fiber (19). By the panoramic surveillance camera shooting system, normal operation of the whole video capture system is guaranteed while circuits are protected from influences of high-radio-frequency electromagnetic radiation.

Owner:沈阳飞机设计研究所扬州协同创新研究院有限公司

Low-leakage host case

InactiveCN104298325ALow ejaculation capabilityAvoid major hidden dangersInternal/peripheral component protectionDigital processing power distributionLow leakageBeryllium copper

The invention provides a low-leakage host case. A shielding door connected by use of a hinge is arranged on one side of the case and an embedded body embedded into a door frame is arranged on the inner side of the shielding door; a beryllium copper leaf spring is arranged on at least one of the outer walls of the four sides of the embedded body and used for reducing a gap between the embedded body and the frame. As the gap between the shielding door and the door frame is reduced, the low-leakage capacity of the case is effectively guaranteed, and therefore, the problem of heavy hidden trouble due to electromagnetic information leakage can be avoided.

Owner:ANFANG HI TECH ELECTROMAGNETIC SAFETY TECHN BEIJING

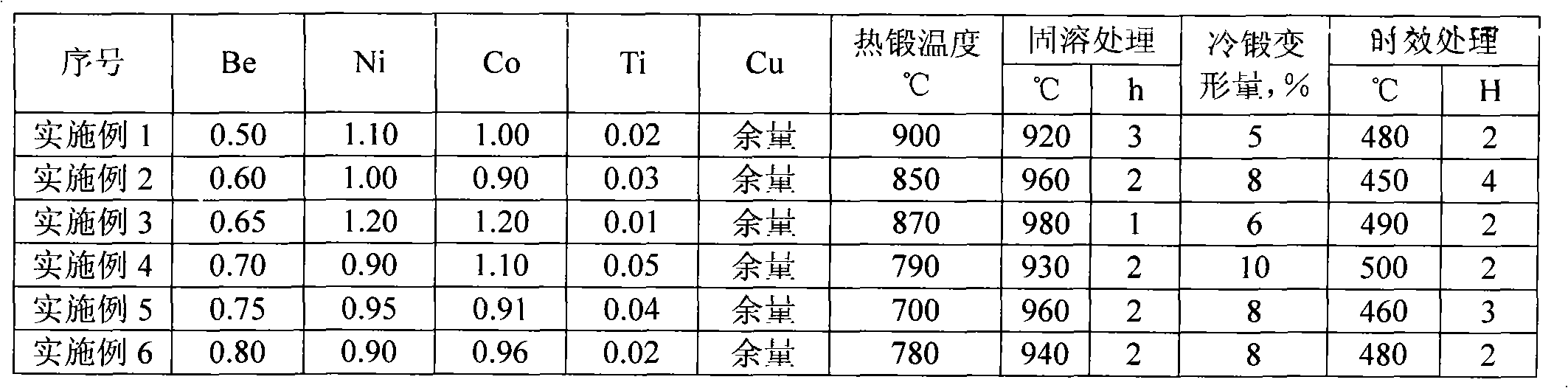

Low copper beryllium mold material for gravitation and low-pressure casting and production process thereof

The invention provides a low beryllium copper alloy mold material used for gravity and low pressure casting as well as a production process, comprising: adding Ni, Co and Ti elements on the basis of a low beryllium copper alloy, giving full play to advantages of the interaction of alloying elements, carrying out processing steps of cold deformation and time effect treatment after the hot forging, solution treatment and water quenching to a cast ingot, and obtaining the special low beryllium copper alloy mold material used in the gravity and low pressure casting industry and having high strength, good toughness and high heat conductivity, and products of the invention are equivalent to ASTM B534 C17500 materials and can fully replace imported goods.

Owner:周水军

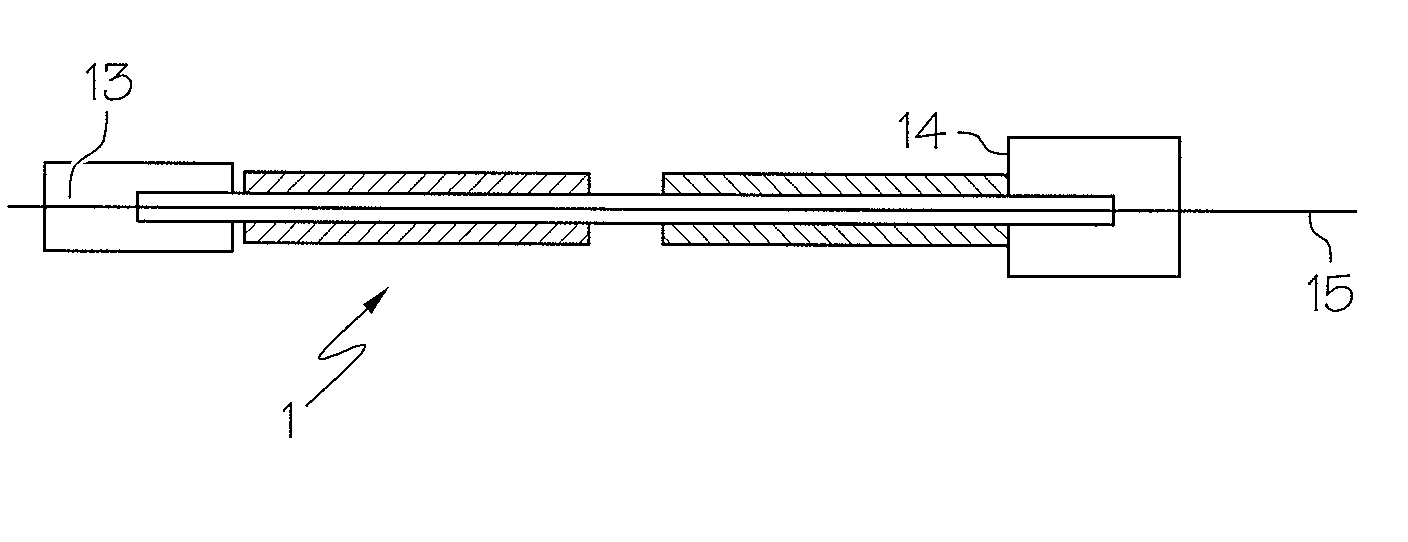

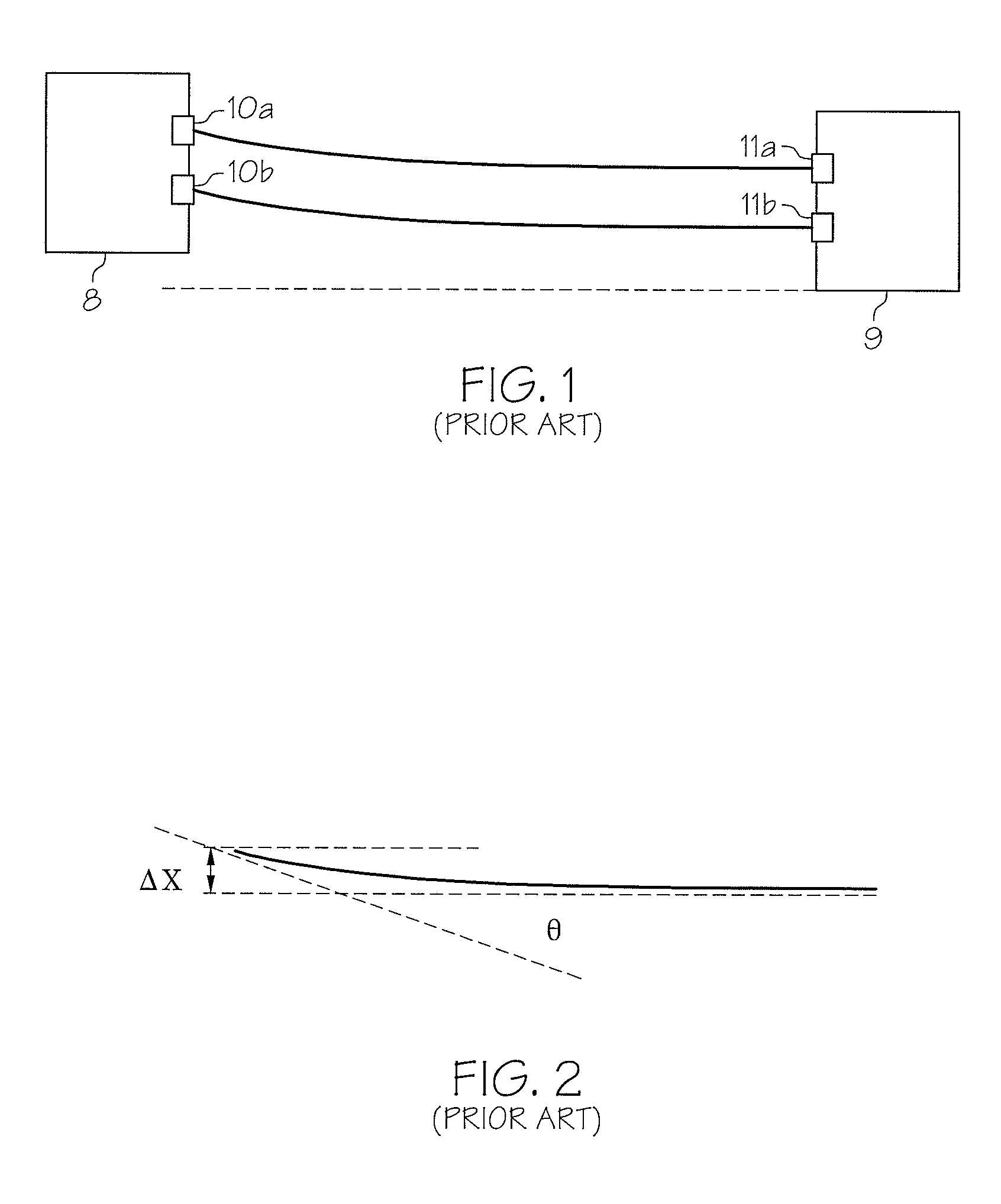

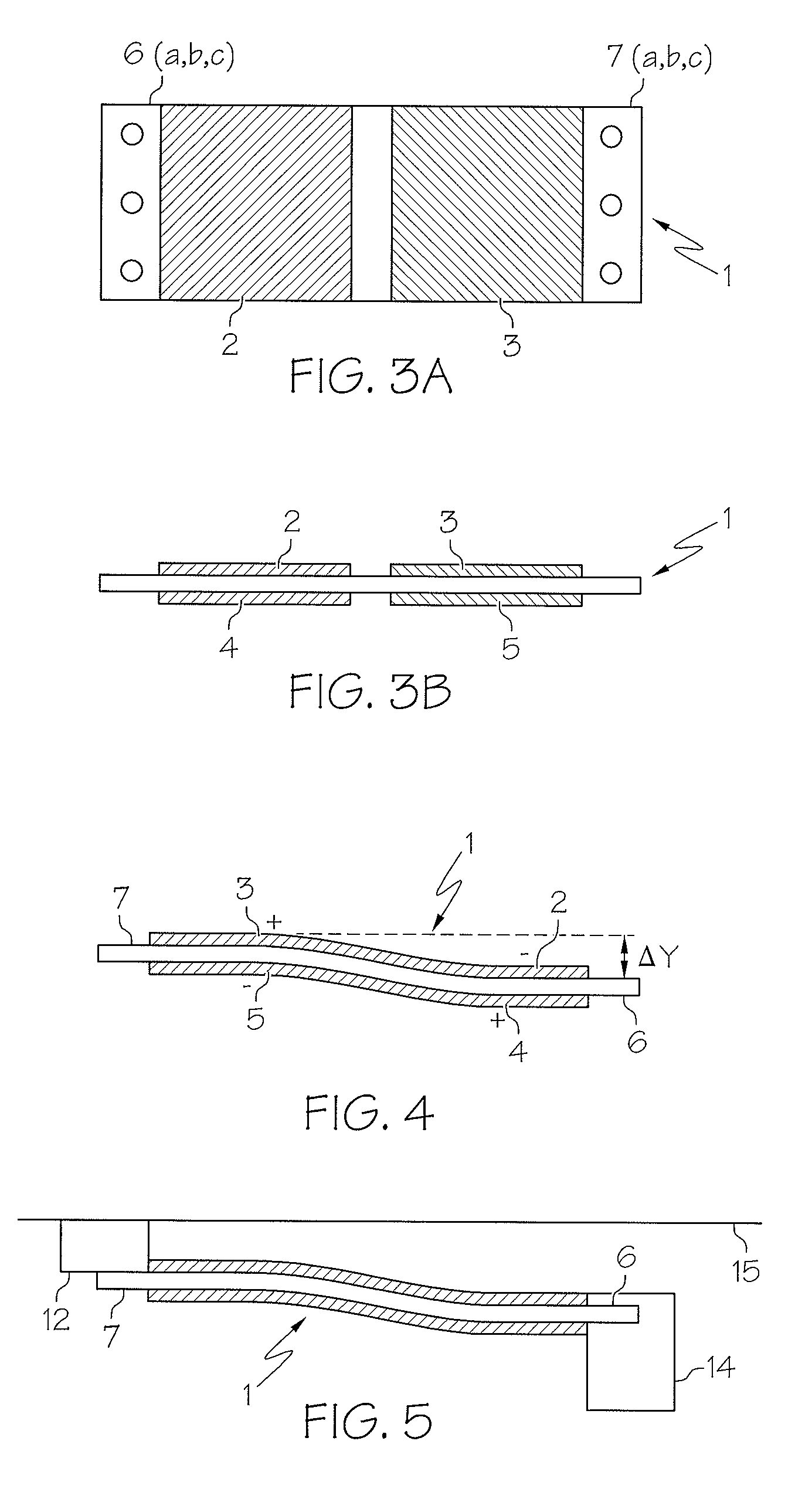

Compact, active alignment fusion splicer with automatic view-angle compensation

InactiveUS20090046982A1Compact and simple and cost-effective alignmentCoupling light guidesElectricityBarium titanate

In accordance with various aspects of the present invention, provided is an extremely compact, simple, and cost-effective approach for aligning optical fibers in an optical fiber fusion splicer. The basis of this alignment method is an “S”-Curve Piezo Bending Actuator. The device comprises a thin strip of elastically flexible material (such as spring steel, beryllium copper, or fiber reinforced polymer) that is coated in four areas with a piezoelectric material (such as barium titanate or other known compounds).

Owner:3SAE TECH

Repair method of bores of blast furnace tuyere small sleeve

The invention discloses a repair method of bores of a blast furnace tuyere small sleeve, comprising the following steps: a. carrying out oil and rust removal treatment to the blast furnace tuyere small sleeve; b. placing the blast furnace tuyere small sleeve into a heating furnace, heating the blast furnace tuyere small sleeve to the temperature of 450 DEG C to 500 DEG C at the speed of 130 DEG Cto 160 DEG C every hour and keeping the temperature for 3 hours; c. carrying out build-up welding to the bores of the blast furnace tuyere small sleeve by a beryllium copper welding rod at the temperature of 450 DEG C to 480 DEG C, wherein the preheating temperature of the beryllium copper welding rod ranges from 300 DEG C to 350 DEG C; and d. placing the blast furnace tuyere small sleeve into theheating furnace again, keeping the blast furnace tuyere small sleeve at the temperature of 320 DEG C to 350 DEG C for 4 hours and then cooling. The repair method of the bores of the blast furnace tuyere small sleeve adopts the beryllium copper welding rod for welding and metallurgical bonding by welding fusion; the blast furnace tuyere small sleeve can not be separated and deform after welding, the service life of the repaired blast furnace tuyere small sleeve is closed to or longer than that of a new blast furnace tuyere small sleeve, and the consumption of spare parts of the blast furnace tuyere small sleeve is reduced.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com