Inner-condensing diamond anvil cell pressing machine

A technology of diamond countertop and diamond anvil, which is applied in the field of in-situ measurement devices for physical quantities under high temperature and high pressure conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Embodiment 1 The structure of the diamond counter-anvil press of the present invention will be described with reference to the accompanying drawings.

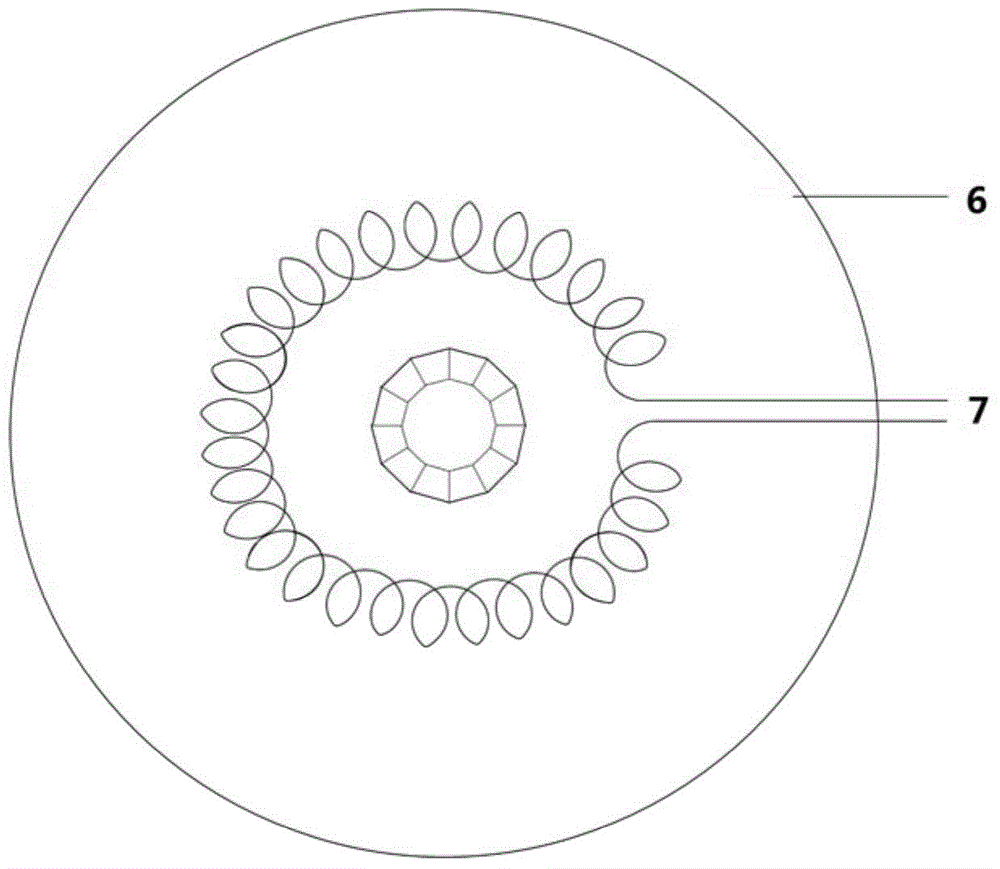

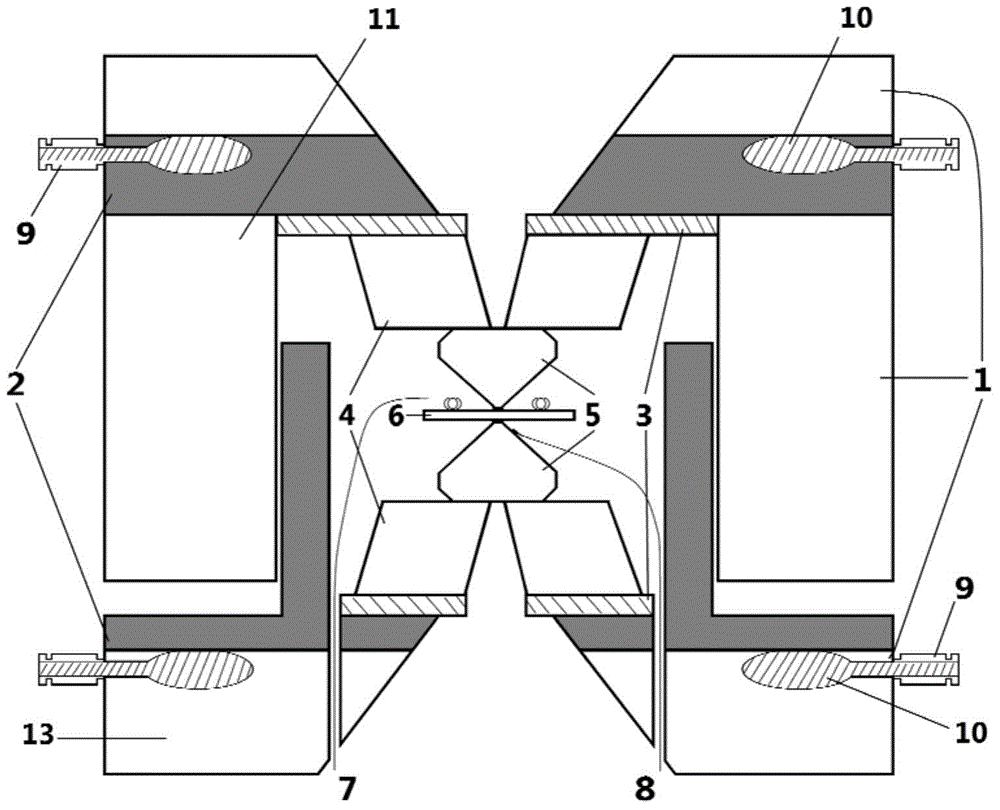

[0025] The structure of the diamond anvil press of the present invention is as figure 1 , 2 , 3, 4 shown. figure 1 , 2 , 3, 4, 1 is alloy steel, 2 is beryllium copper, 3 is mica sheet, 4 is shaking table, 5 is diamond anvil, 6 is gasket, 7 is spiral heating wire, 8 is thermocouple, 9 is Pneumatic quick connector, 10 is the circulating water chamber, 11 is the upper mold of the press, 12 is the inner wall of the upper mold cylinder, 13 is the lower mold of the press, 14 is the cylindrical piston, 15 is the cylindrical piston holder, and the cylindrical piston 14 and cylindrical piston holder 15 form an integral body to form press lower die 13, and 16 is the lower die piston outer wall.

[0026] The diamond anvil press of the present invention has the same structure as the prior art: a press consisting of a press upper ...

Embodiment 2

[0028] Embodiment 2 The assembly process of the internal cooling diamond anvil press of the present invention

[0029] First clean the two diamond anvils 5, then fix the diamond anvils 5 on the shaker 4 with a high-temperature repair agent, put the shaker 4 into the press, and place a layer between the shaker 4 and the press The mica sheet 3 with a hole in the center is balanced and centered so that the anvil surfaces of the upper and lower diamond anvils 5 are completely coincident. The sample to be tested is packaged between two diamond anvils 5 and sealed with a pre-pressed gasket 6 on which a spiral heating wire 7 has been pre-arranged. The heating wire 7 and the thermocouple 8 are led out through the small hole of the lower die 13 of the press for heating and temperature measurement. Utilize the pneumatic quick plug 9 to connect the water pipe and the circulating water cavity 10 of the upper and lower parts of the press, and connect the water chiller and the water pump i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com