Preparation method for TiN/Ti composite permeable layer on surface of beryllium-copper alloy

A beryllium-copper alloy and composite infiltration technology, which is applied in metal material coating process, coating, solid-state diffusion coating and other directions, can solve the problems of insignificant improvement of wear resistance and limited increase in hardness of beryllium-copper alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the TiN / Ti compound infiltration layer on the beryllium-copper alloy surface provided by the present embodiment comprises the following steps:

[0035] (1) Pretreatment of the beryllium-copper alloy workpiece: the surface of the beryllium-copper alloy workpiece is polished with SiC water washing sandpaper → diamond powder polishing → acetone cleaning, and then dried for later use;

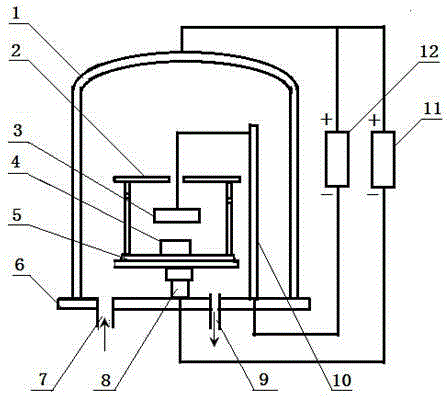

[0036] (2) Place the pretreated beryllium-copper alloy workpiece 4 on the cathode backing plate 5 in the plasma metallization furnace, and add an auxiliary cathode 2 around it, and process holes on the auxiliary cathode to facilitate the passage of working gas; The pure titanium plate 3 is placed above the beryllium-copper alloy workpiece through the target cathode frame 10, and the pure titanium plate 3 is located in the auxiliary cathode, with a distance of 18mm from the beryllium-copper alloy workpiece;

[0037] The target material is pure titanium plate with a p...

Embodiment 2

[0045] The preparation method of the TiN / Ti compound infiltration layer on the beryllium-copper alloy surface provided by the present embodiment comprises the following steps:

[0046] (1) Pretreatment of the beryllium-copper alloy workpiece: the surface of the beryllium-copper alloy workpiece is polished with SiC water washing sandpaper → diamond powder polishing → acetone cleaning, and then dried for later use;

[0047] (2) Place the pretreated beryllium-copper alloy workpiece 4 on the cathode backing plate 5 in the plasma metallization furnace, and add an auxiliary cathode 2 around it, and process holes on the auxiliary cathode to facilitate the passage of working gas; The pure titanium plate 3 is placed above the beryllium copper alloy workpiece through the target cathode frame 10, the pure titanium plate 3 is located in the auxiliary cathode, and the distance between the beryllium copper alloy workpiece and the beryllium copper alloy workpiece is 25mm;

[0048] (3) The be...

Embodiment 3

[0055] The preparation method of the TiN / Ti compound infiltration layer on the beryllium-copper alloy surface provided by the present embodiment comprises the following steps:

[0056] (1) Pretreatment of the beryllium-copper alloy workpiece: the surface of the beryllium-copper alloy workpiece is polished with SiC water washing sandpaper → diamond powder polishing → acetone cleaning, and then dried for later use;

[0057] (2) Place the pretreated beryllium-copper alloy workpiece 4 on the cathode backing plate 5 in the plasma metallization furnace, and add an auxiliary cathode 2 around it, and process holes on the auxiliary cathode to facilitate the passage of working gas; The pure titanium plate 3 is placed above the beryllium-copper alloy workpiece through the target cathode frame 10, and the pure titanium plate 3 is located in the auxiliary cathode, with a distance of 15mm from the beryllium-copper alloy workpiece;

[0058] (3) The beryllium copper alloy workpiece is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com