Manufacturing method for tantalum composite board equipment

A manufacturing method and composite board technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult quality control, difficult preparation of tantalum composite board equipment, etc., and achieve the effect of solving connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

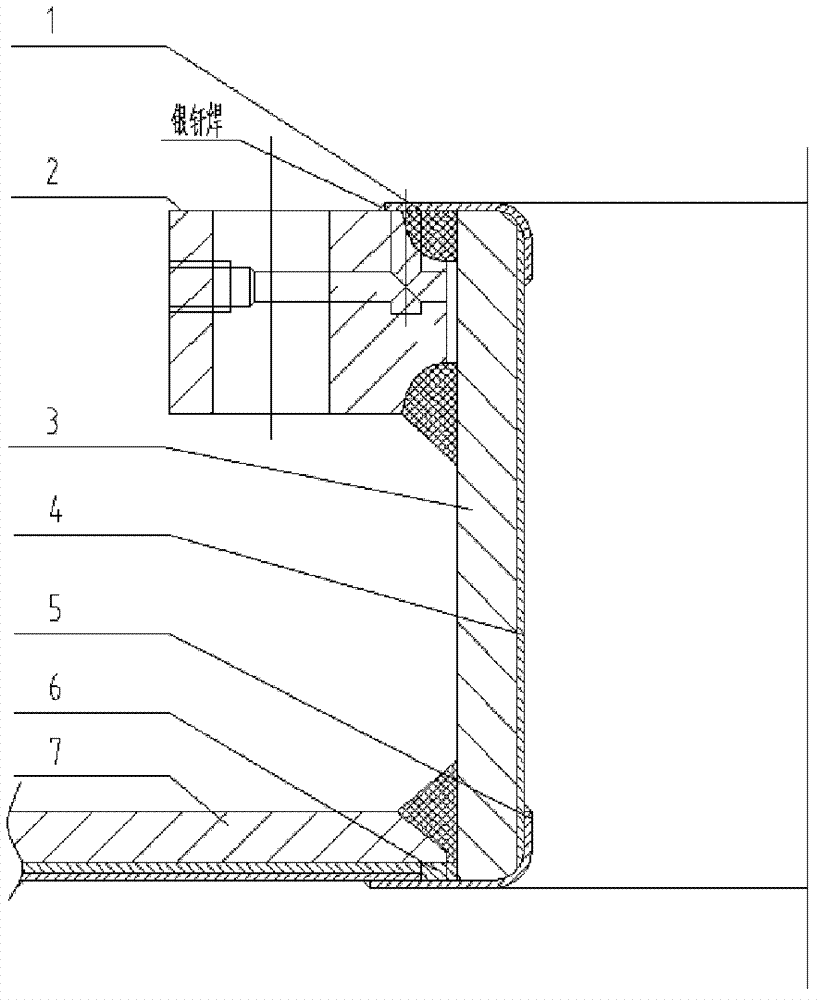

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be specifically described below.

[0019] The welding procedure qualification of steel shall be carried out in accordance with the provisions of JB4708-2000≤Welding procedure qualification of steel pressure vessels≥. The welding method of tantalum clad plate welding cannot weaken the mechanical properties and corrosion resistance of the material.

[0020] The base layer is welded first by argon arc welding, manual arc welding is used between the connecting pipe and the base layer of the shell or head, and the base layer of the longitudinal circumferential weld of the shell and head is submerged arc welding. In order to avoid the reduction of the bonding strength of the base layer near the weld joint due to the influence of the welding heat cycle, the welding on the inner side of the cylinder should adopt a small heat input process, multi-layer and multi-pass welding, and control the temperature between layers; the groove size an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com