Lower shell of steel-aluminum hybrid battery pack

A technology of mixing battery packs and casings, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of poor connection strength of the lower casing of the battery pack, decreased mechanical structural performance, and easy aging of structural adhesives. The effect of high connection strength, small welding deformation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

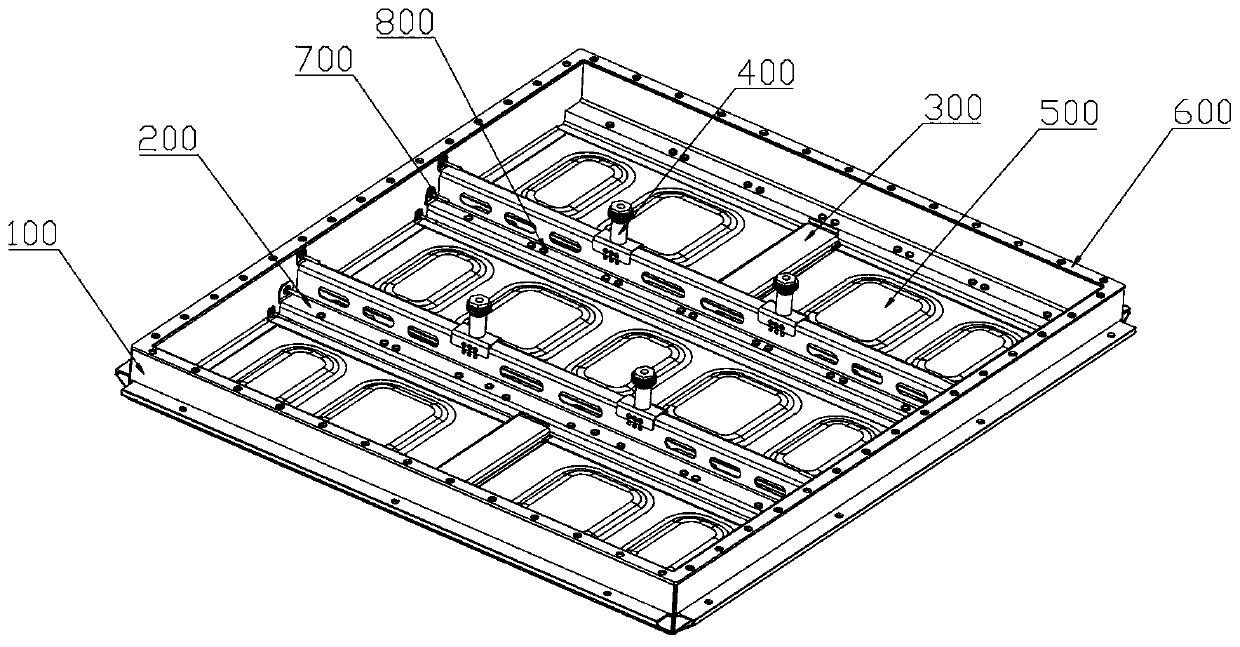

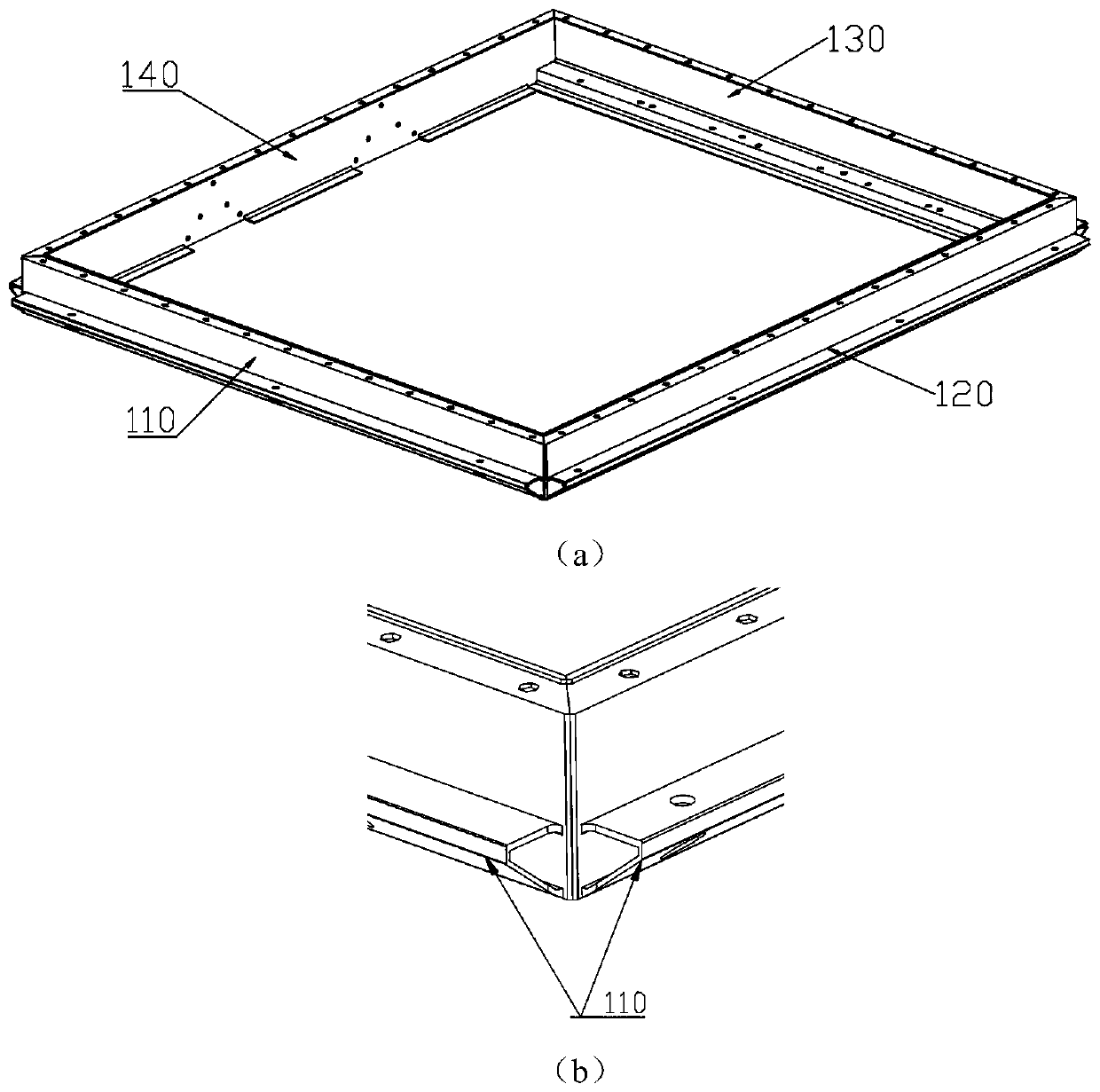

[0032] figure 1 It is an axonometric view of the lower casing of the steel-aluminum hybrid battery pack of the present invention, including five parts: frame structure 100, crossbeam 200, longitudinal beam 300, middle lug 400 and bottom plate 500. 500 connected, the frame structure 100 is connected with the flanging at both ends of the beam 200 through the rivet mounting hole 126 on the inner wall, the flange at the bottom of the beam 200 is connected with the bottom plate 500 by resistance spot welding, and the flanging at one end of the longitudinal beam 300 is connected with the frame structure 100 by bonding Glue connection, the flange at the other end is connected to the beam 200 by MIG welding, the flange at the bottom of the longitudinal beam 300 is connected to the bottom plate 500 by resistance spot welding, the middle lug 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com