Rigid connection method for steel beam and concrete pier

A rigid connection, reinforced concrete technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low rigidity and bearing capacity, complicated construction, complicated construction process, etc., to improve strength and ductility, construction convenience, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

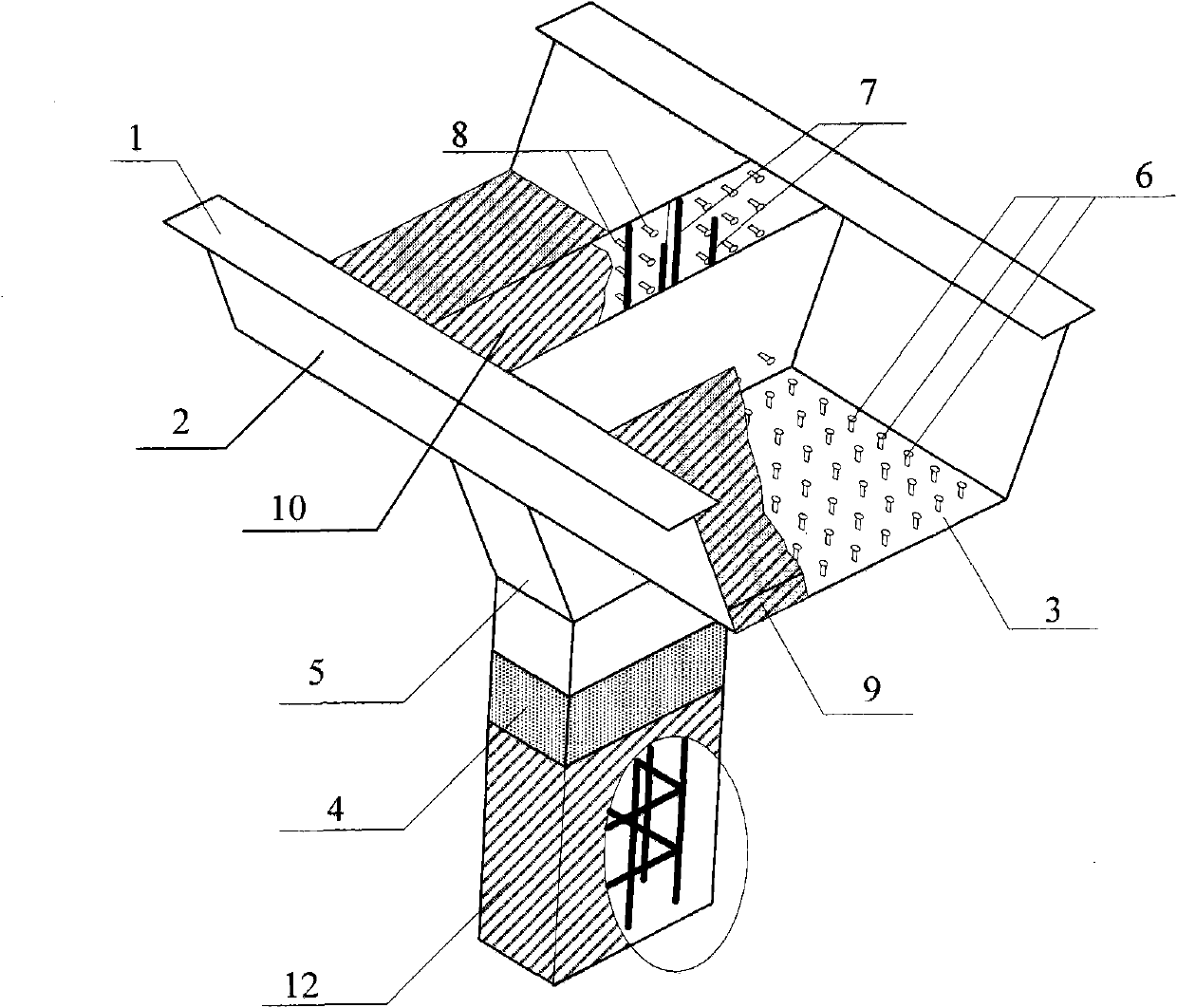

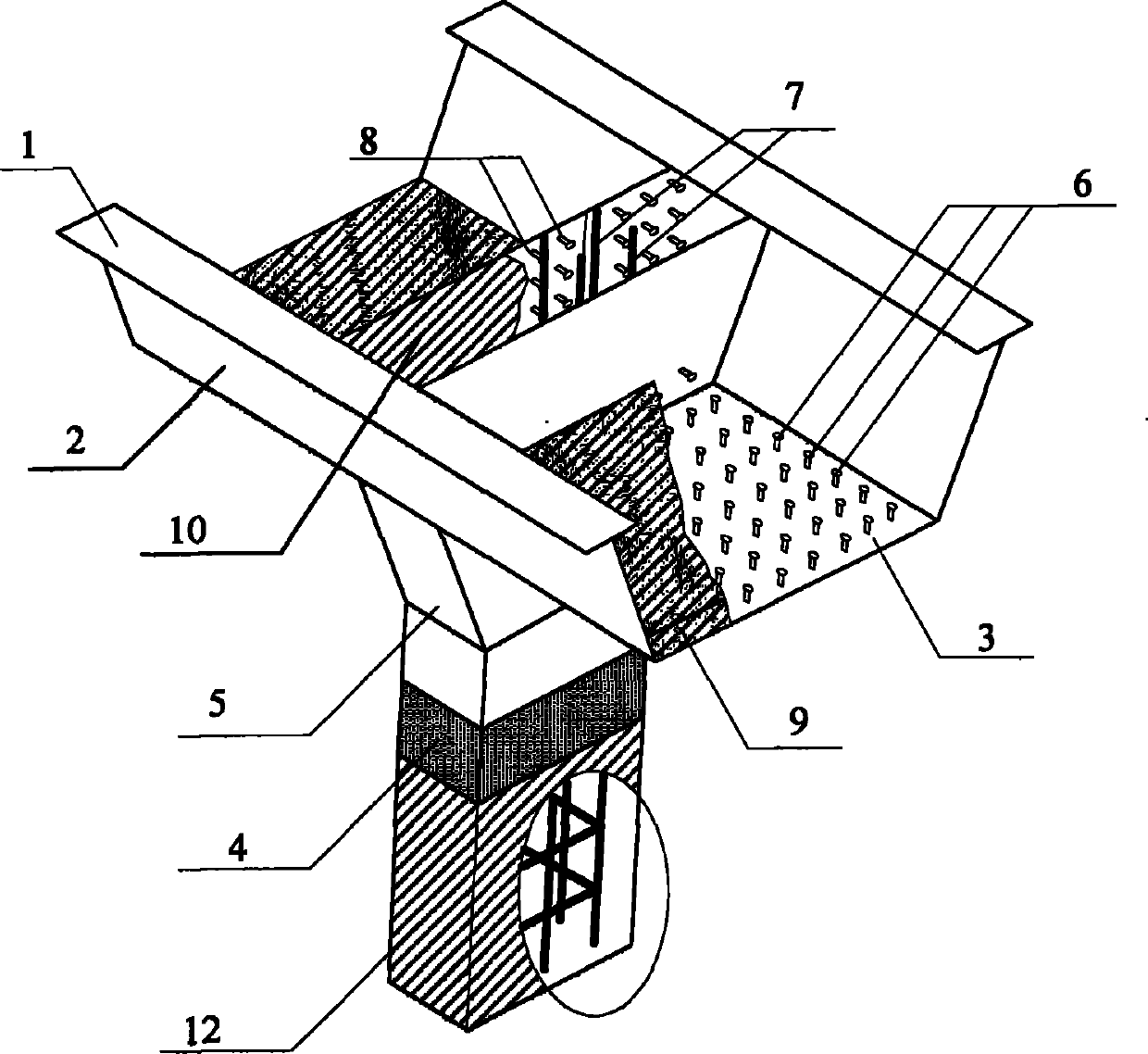

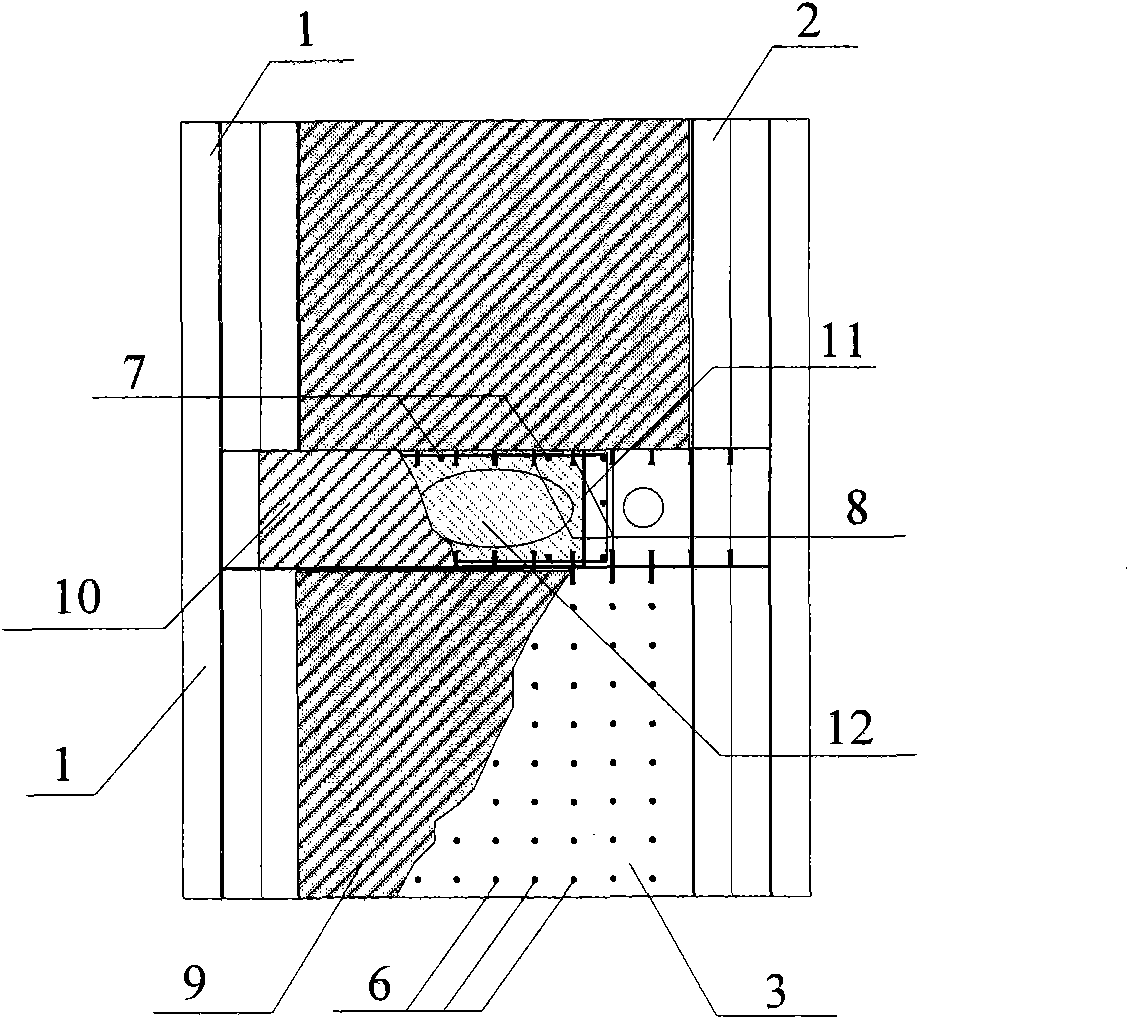

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Construction procedure of the present invention is:

[0019] 1) Weld the steel girder upper flange (1), steel girder bottom plate (3) and steel girder web (2) into a whole, wherein the steel girder bottom plate (3) has holes in the joint area, and a sleeve is extended under the steel girder bottom plate Tube (5) is welded together with steel beam bottom plate (3). Weld the studs (6) on the steel beam bottom plate (3), weld the studs (8) on the inside of the steel beam overhanging sleeve (5), and weld the studs (8) on the inside of the steel beam overhanging sleeve (5) and the steel beam bottom plate (3) Weld the inner partition steel plate (11) of the opening at the equal height opening;

[0020] 2) Install the steel sleeve (4) at the top of the reinforced concrete pier to the top of the pier, and pour the pier concrete (12) so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com