Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

249results about How to "Solve scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser cladding composite repair manufacturing method and application thereof

InactiveCN109385631AEnsure safetyReduce volumeMetallic material coating processesCleaning processes and apparatusOptoelectronicsMachining

The invention relates to a laser cladding composite repair manufacturing method. The method comprises the steps as follows: step 1, laser cleaning; step 2, laser preheating: continuously irradiating the surface of a to-be-repaired workpiece by a laser unit to preheat the to-be-repaired workpiece, marking emergent laser of the laser unit as preheating laser, wherein the spot shape of the preheatinglaser is round or rectangular, the area of preheating spots is 6 mm<2>-20 mm<2> and the scanning speed of the preheating laser spots is 8 mm / s-20 mm / s; step 3, laser cladding: irradiating the preheated to-be-repaired workpiece by cladding laser, wherein the spot shape, spot area and scanning speed of cladding laser are identical with those of the preheating laser; step 4, machining. The inventionalso relates to an application of the laser cladding composite repair manufacturing method. The method can be applied to repair manufacturing of high-carbon steel workpieces and high-alloy steel workpieces; laser is used as machining means, so that the method is clean, efficient, green and environmentally friendly.

Owner:山东泰利先进制造研究院有限公司

Machining method for symmetrically split thin-wall aluminum cylinder part

ActiveCN112077542AGuaranteed machining accuracyImprove machining accuracyEngineeringMechanical engineering

The invention relates to a machining method for a symmetrically split thin-wall aluminum cylinder part. The machining method is characterized by comprising the following steps of: blanking or formingan aluminum cylinder blank; roughly machining the length of the aluminum cylinder blank, splitting the roughly machined aluminum cylinder blank from a symmetrical center line, and finely turning positioning steps at the two ends of the symmetrically split aluminum cylinder; finely turning the outer diameter of the residual part of the symmetrically split aluminum cylinder to the size of a finishedproduct; and turning the inner diameter of the finished product of the symmetrically split aluminum cylinder. By the machining method, the machining accuracy of the symmetrically split precise thin-wall aluminum cylinder is ensured; in different machining stages, machining procedures are creatively adjusted; and by adopting various clamps, central symmetry adjustment and positioning clamping of the symmetrically split precise thin-wall aluminum cylinder are realized, and the problem of part scrapping caused by deformation due to internal stress release after the precise thin-wall aluminum cylinder is split in product production is solved. The machining method is high in positioning accuracy and easy to operate, workpieces are convenient to assemble and disassemble, and clamping force canuniformly act on the clamped workpieces.

Owner:齐齐哈尔建华机械有限公司

Method for improving gain of microchannel plate

ActiveCN106847649AHigh gainImprove yield rateMutiple dynode arrangementsPhoto-emissive cathodes manufactureSilicon dioxideMetal

The invention discloses a method for improving gain of a microchannnel plate. A dielectric film layer is evaporated on the input end of the microchannel plate by means of a vacuum evaporating method, thereby covering a metal input electrode. The dielectric film layer covers an input electrode at a chananel inlet of the microchannel plate and furthermore covers an input electrode on the input-end surface of the microchannel plate. The dielectric film layer is made of silicon dioxide (SiO2), titanium dioxide (TiO2) and aluminum oxide (Al203). After the method of the invention is utilized, the gain of the microchannel plate is improved by more than one time without characteristic change of the original microchannel plate, such as parameters of plate resistance, dark current, resolution, etc. The method settles a problem of image intensifier discard caused by incapability of satisfying the requirement by partial MCPs in the manufacture process of the image intensifier, and furthermore improves yield rate of super-second-generation image intensifiers in manufacture.

Owner:NORTH NIGHT VISION TECH

Intelligent full-automatic perforating machine with good clamping effect

InactiveCN107363895AImprove clamping effectAchieve the effect of the first clampingMetal working apparatusEngineeringMaterial Perforation

The invention provides an intelligent automatic punching machine with good clamping effect, which relates to the technical field of punching. The intelligent automatic punching machine with good clamping effect includes a workbench, the bottom of the inner wall of the workbench is fixedly connected with a shock-absorbing pad, the top of the shock-absorbing pad is fixedly connected with a placing plate, and the workbench is A rotating seat is fixedly connected to one side of the top, and a support arm is sleeved inside the rotating seat. The intelligent automatic punching machine with good clamping effect is driven by the central axis and hinged through the fixed box arranged on the top of the worktable and the action of the second electric telescopic rod inside the fixed box, driven by the second electric telescopic rod. The lever principle between the rod, the support rod and the connecting rod will make the anti-skid clamping plate on the clamping box approach the punching material and clamp it, which achieves the effect of clamping the punching material for the first time and solves the problem when punching. Due to the poor clamping effect, the quality of the punching holes will be reduced, and in severe cases, the material will be scrapped.

Owner:扬州市中福商业管理有限公司

Solid rocket engine fiber-wound shell inner heat insulation layer cold bonding repairing method

ActiveCN108638544ASolve the failure to use or scrapSolve the problem of bonding strength at room temperatureDomestic articlesPre treatmentEngineering

The invention discloses a solid rocket engine fiber-wound shell inner heat insulation layer cold bonding repairing method. The method comprises pre-treatment, repairing mature rubber sheet preparing,heat insulation layer defect treatment, repairing mature rubber sheet treatment, adhesive preparing and repairing. It is guaranteed that the surface defect of an inner heat insulation layer of a solidengine is repaired in a normal-temperature curing manner, it is guaranteed that the engine with the inner heat insulation layer defect can be continuously normally used, and the problem that due to the defect of the inner heat insulation layer, the engine cannot be normally used or is scrapped is solved; the thickness and the bonding face intensity of the repaired inner heat insulation layer meetthe requirements for the solid rocket engine fiber-wound shell inner heat insulation layer, meanwhile, the airtight performance and ablation performance of a repaired fiber-wound shell are guaranteed, and the solid rocket engine fiber-wound shell inner heat insulation layer cold bonding repairing method is suitable for repairing in the aspects that the defect depth is smaller than 5 mm, and the defect area is smaller than 5,000 mm<2>.

Owner:湖北三江航天江北机械工程有限公司

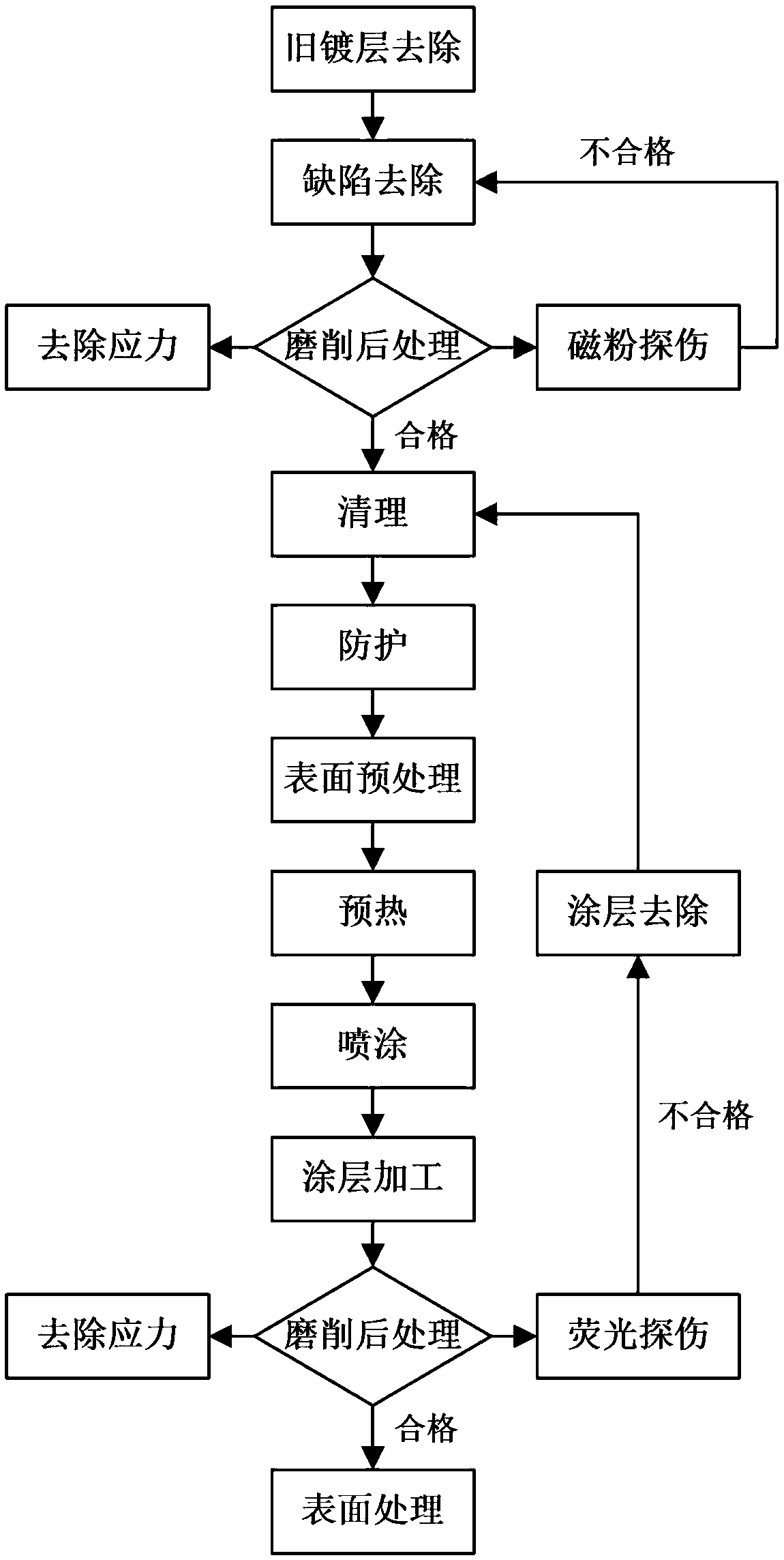

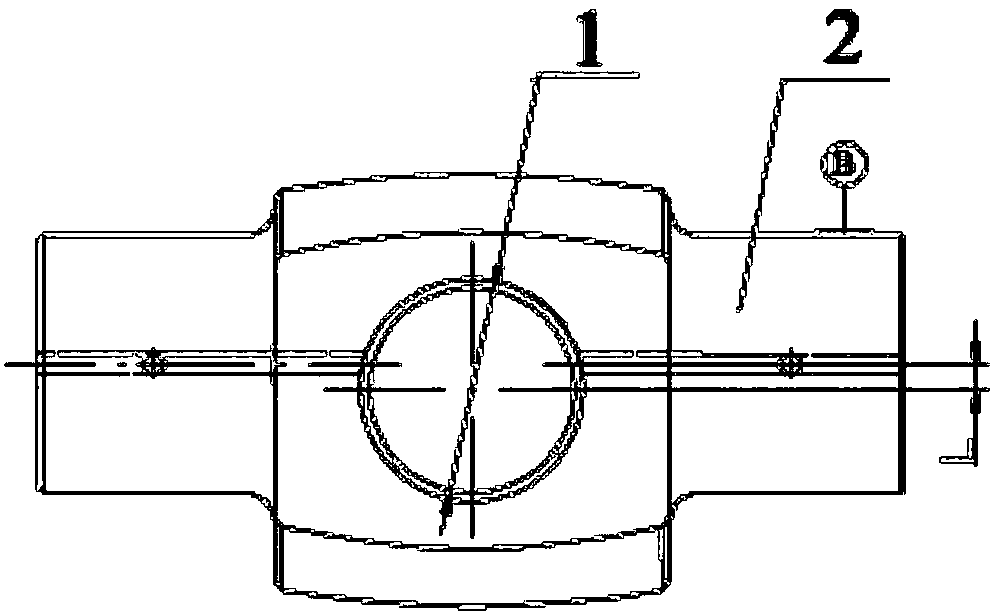

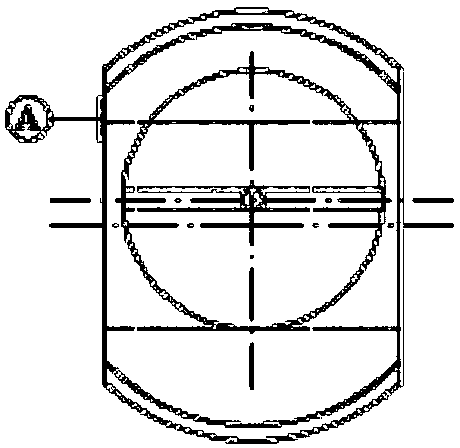

An aircraft cardan shaft remanufacturing and repairing process

The invention relates to the technical field of repairing cardan shafts of aircraft horizontal tail control systems, and particularly relates to an aircraft cardan shaft remanufacturing and repairingprocess. The process includes (1) removal of an original plating, (2) hydrogen removal, (3) measurement, (4) defect removal, (5) grinding after-treatment, (6) cleaning, (7) protection, (8) surface pretreatment, (9) preheating before spraying, (10) component spraying, (11) coating processing, (12) grinding after-treatment and (13) surface treatment. The process solves a problem that a high number of components are scrapped because aircraft cardan shafts cannot be repaired due to inner pore abrasion and scratches. Through selection and preparation of a wear-resistant coating, inner pore wear resistance after a cardan shaft is repaired is greatly improved and service lifetime of components is prolonged.

Owner:国营芜湖机械厂

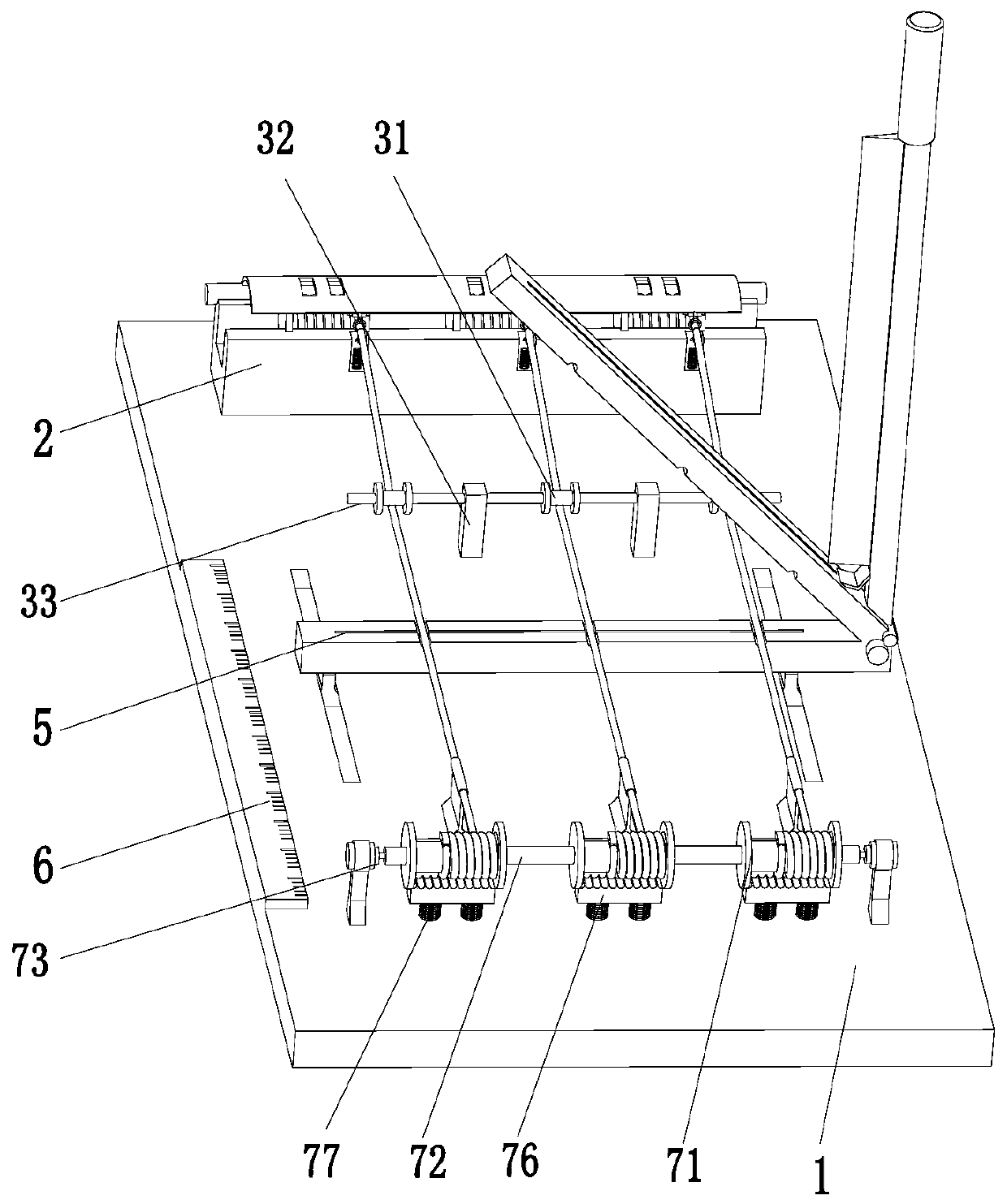

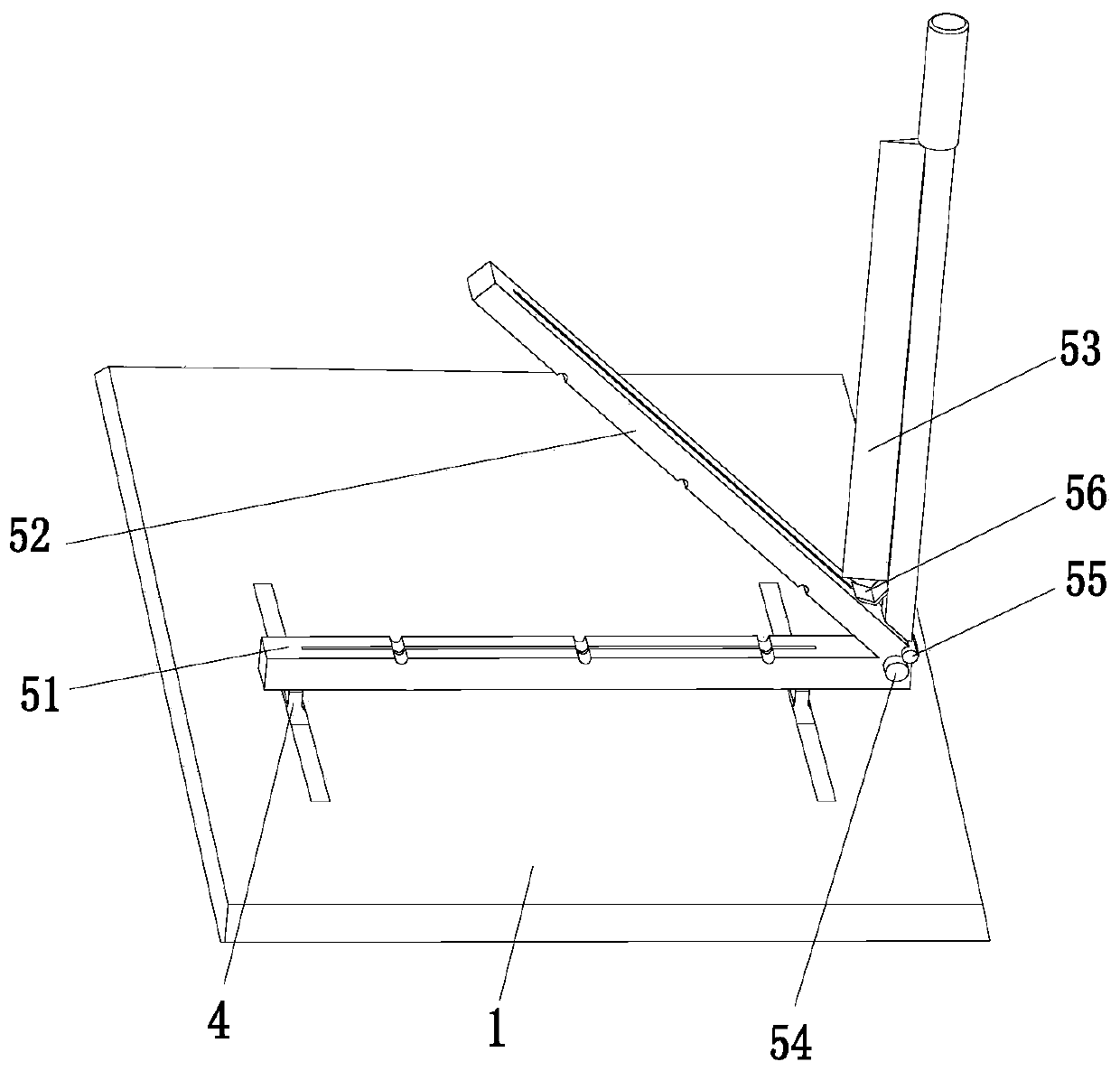

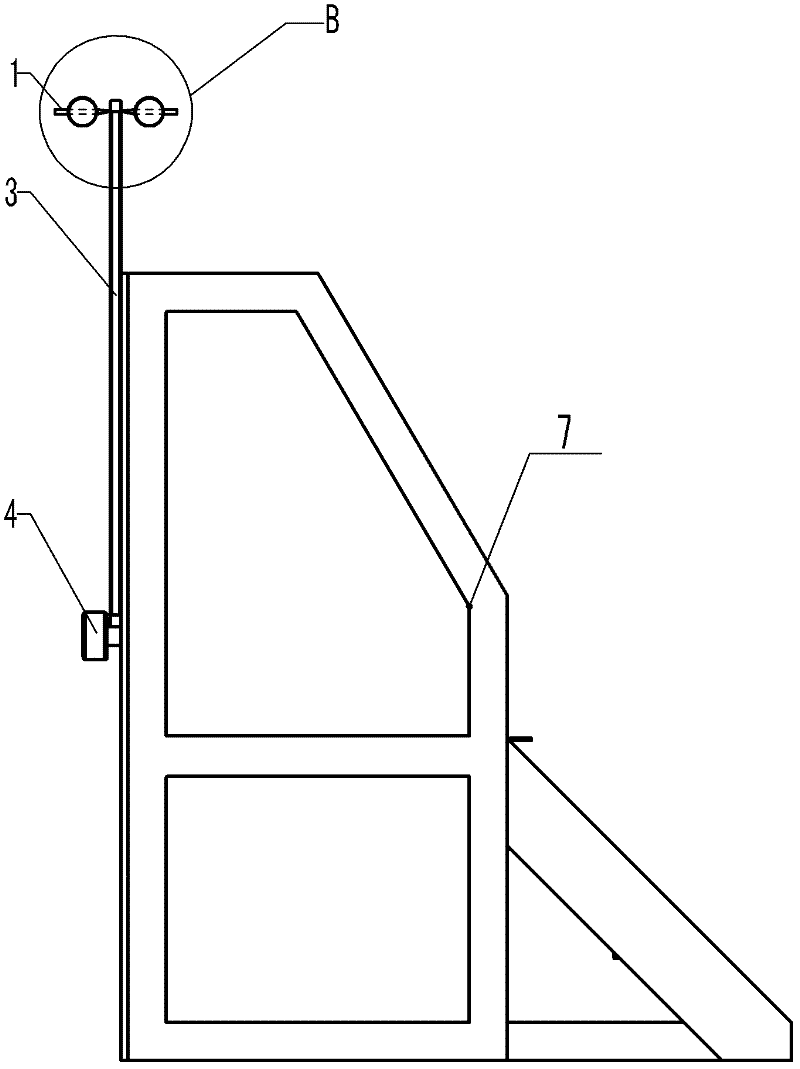

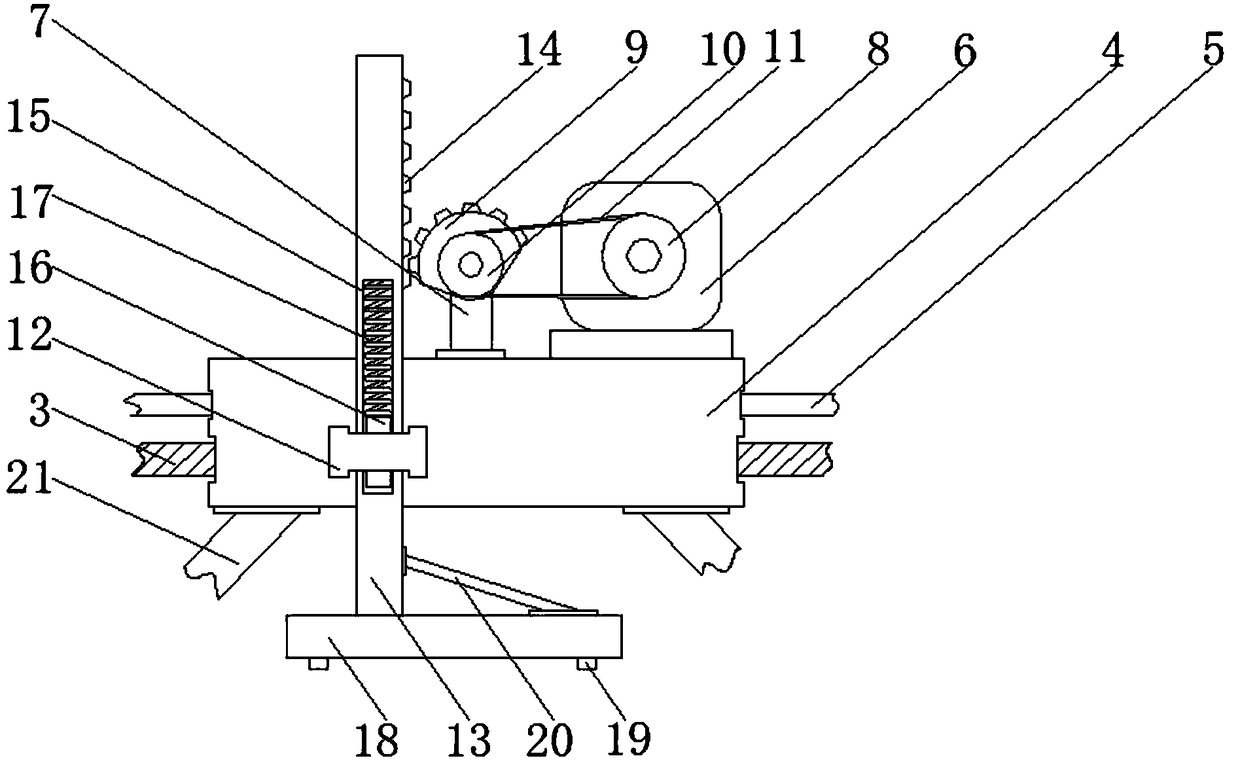

Fixed length shearing machine for wire harnesses and wire cables of new energy automobile

ActiveCN110508722AGuaranteed smooth releaseImprove clippingMetal working apparatusEngineeringCable harness

The invention relates to a fixed length shearing machine for wire harnesses and wire cables of a new energy automobile. The fixed length shearing machine comprises a bottom plate, a pay-off mechanism,a limiting mechanism, electric slide blocks, a shearing mechanism, a dividing rule and a fixed length mechanism. Chutes are symmetrically formed front and back in the middle part of the top end of the bottom plate, the pay-off mechanism is mounted on the left side of the top end of the bottom plate, the limiting mechanism is located on the right side of the pay-off mechanism, two ends of the limiting mechanism are mounted at the top end of the bottom plate, the electric slide blocks are connected in the chutes of the bottom plate in a sliding fit manner, the shearing mechanism is arranged onthe right side of the limiting mechanism, two ends of the shearing mechanism are mounted at the top ends of the electric slide blocks, the dividing rule is mounted on the front side of the middle partof the top end of the bottom plate, the fixed length mechanism is located on the right side of the shearing mechanism, and the fixed length mechanism is mounted on the right side of the top end of the bottom plate. The fixed length shearing machine can solve the problems that the shearing precision is low as the measuring length has a relatively large error when the wire harnesses are sheared manually, and the cutting effect is poor as a pair of cutting pliers is manually held to cut the wire harnesses and the like.

Owner:博锐腾新能源科技(淮安)有限公司

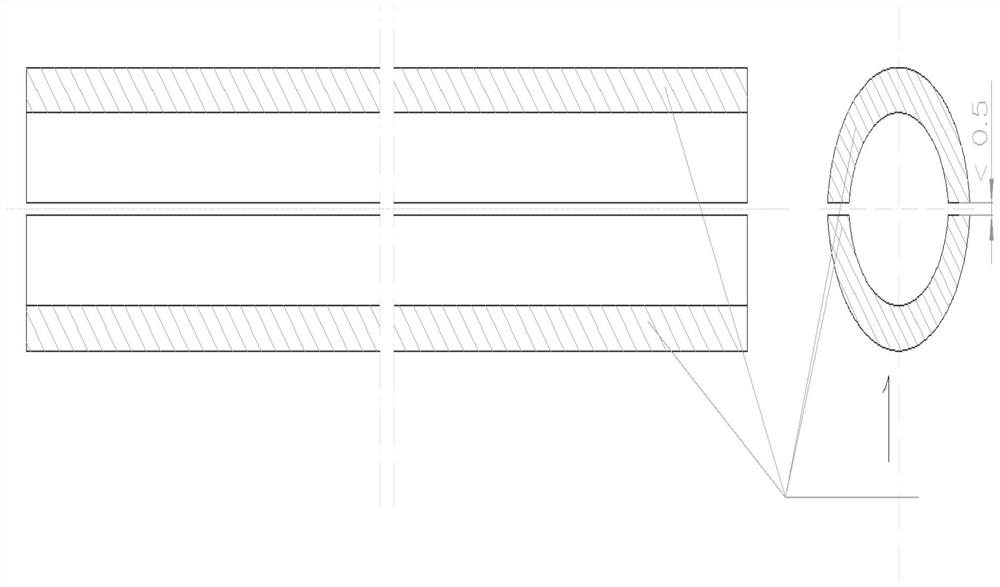

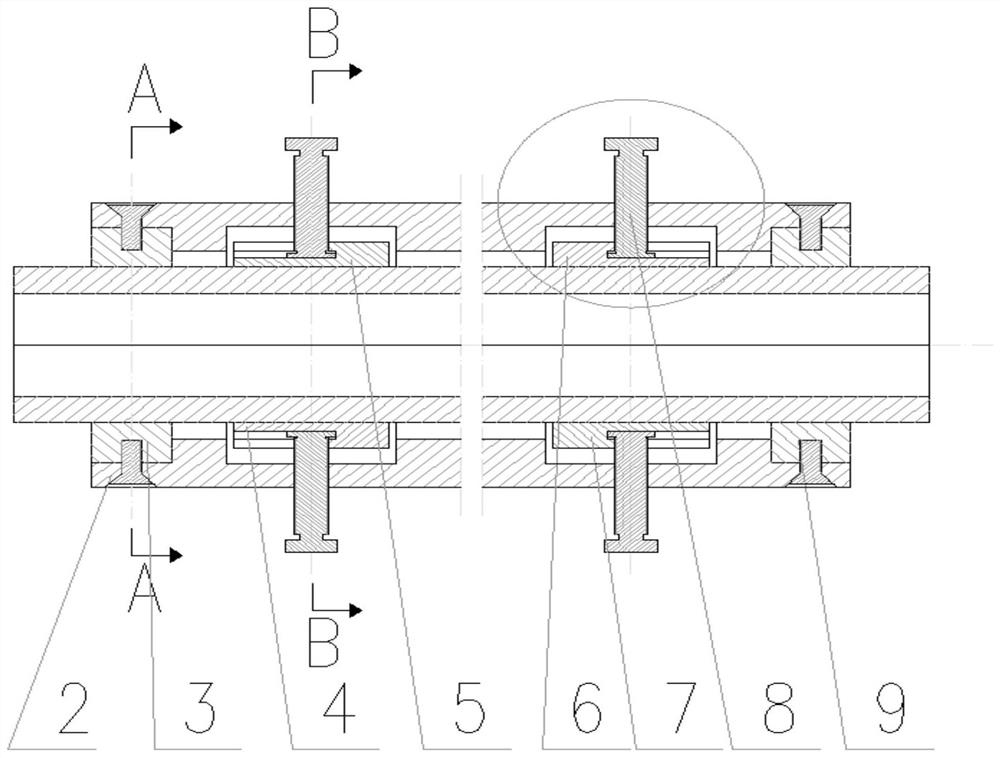

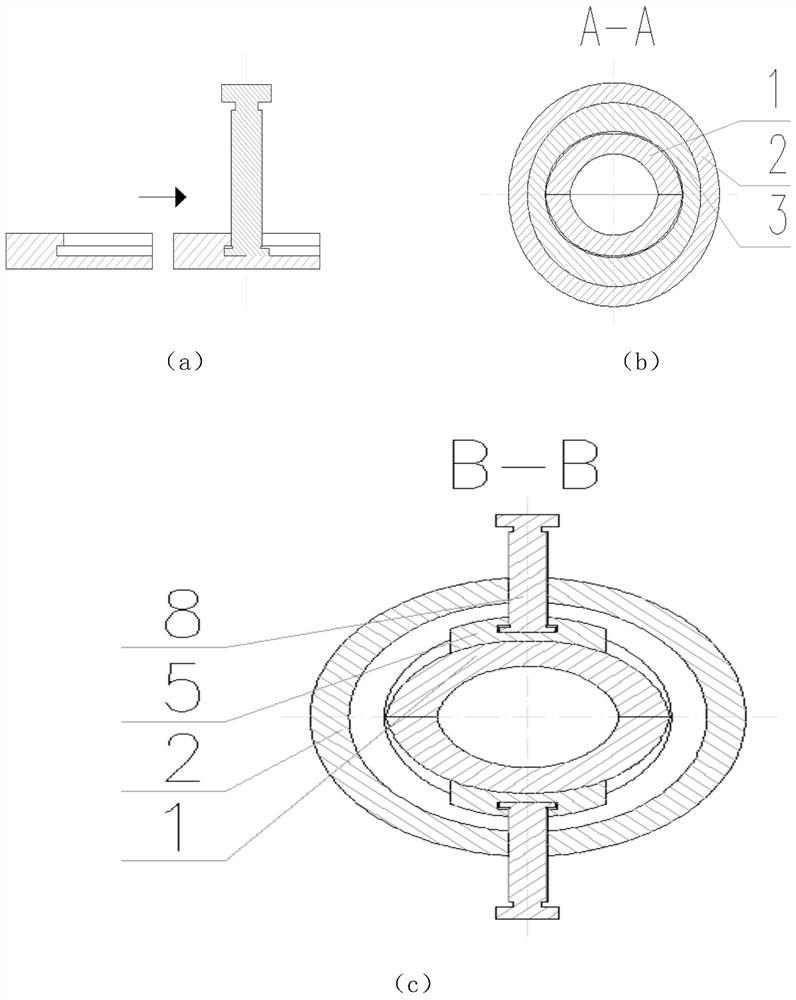

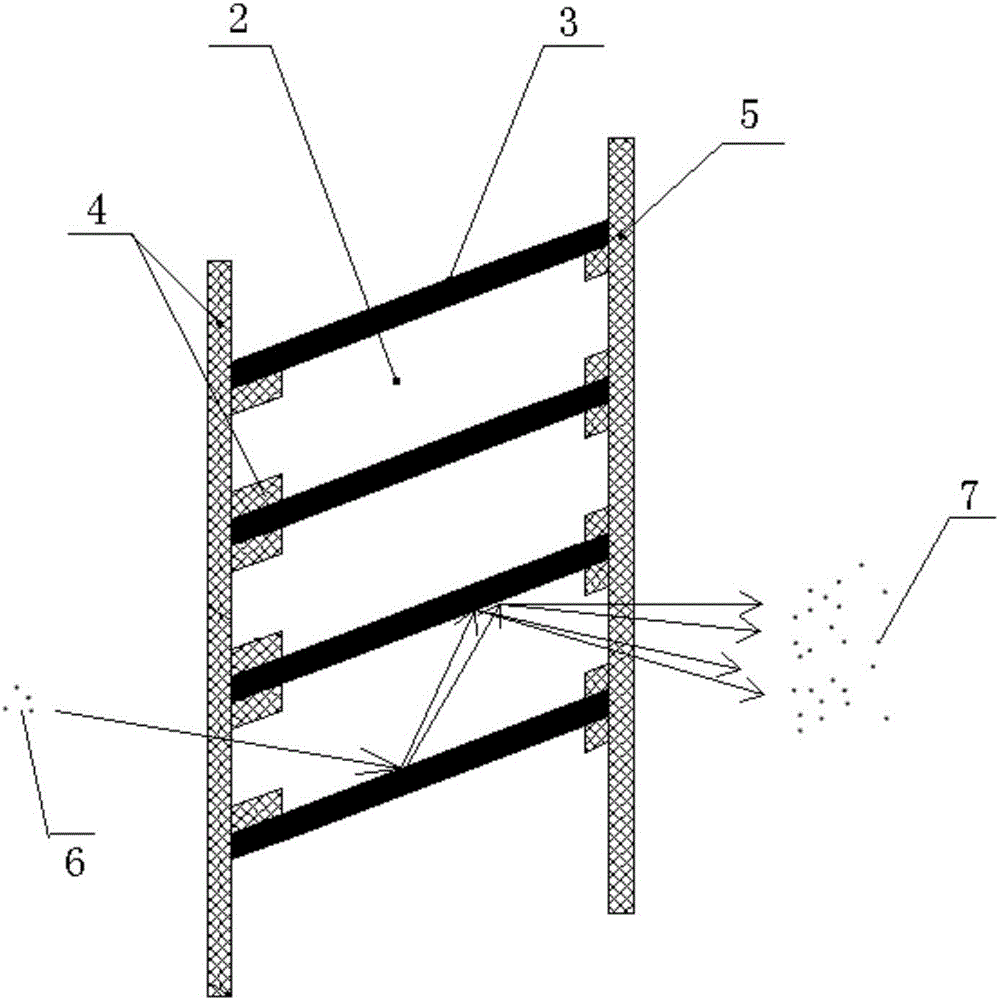

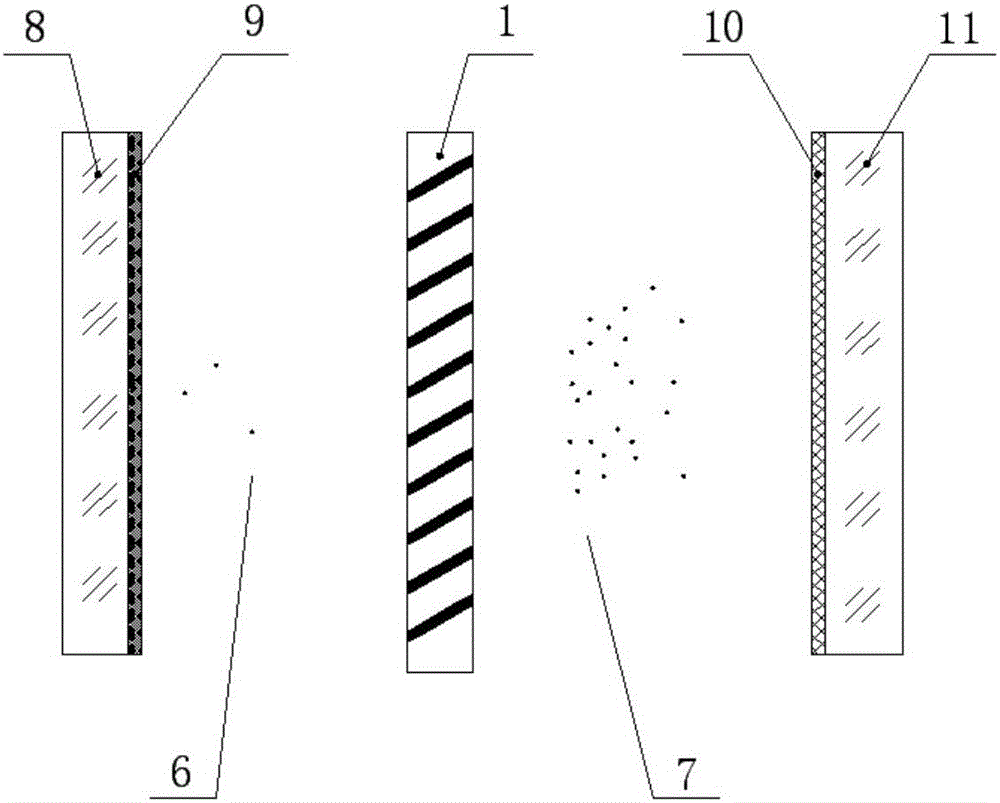

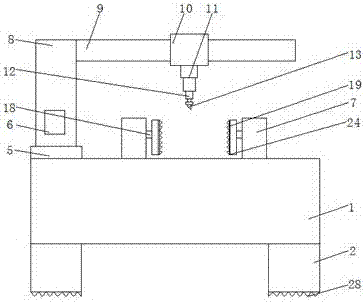

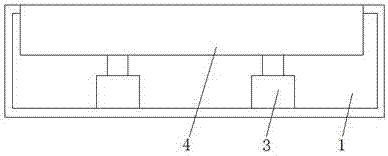

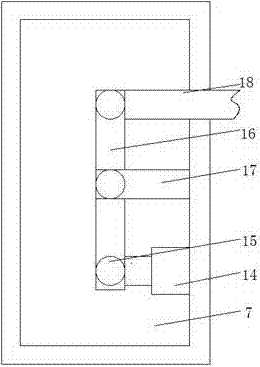

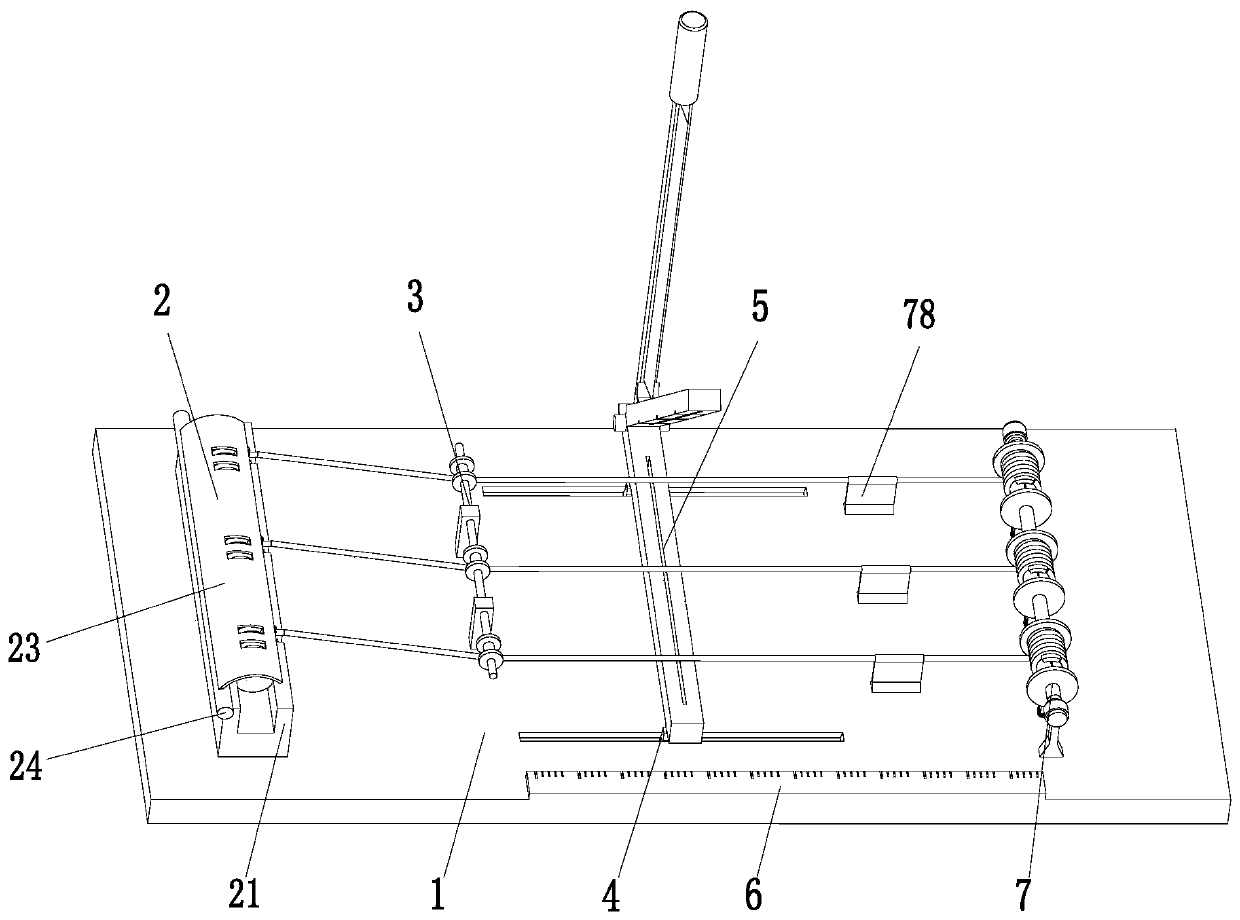

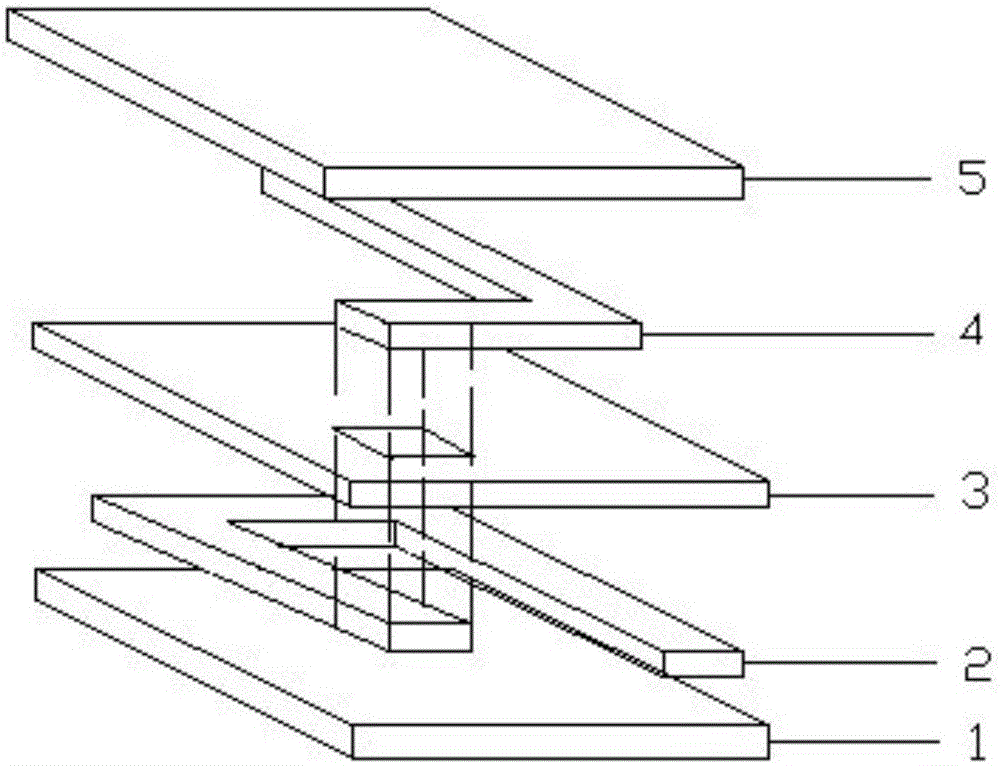

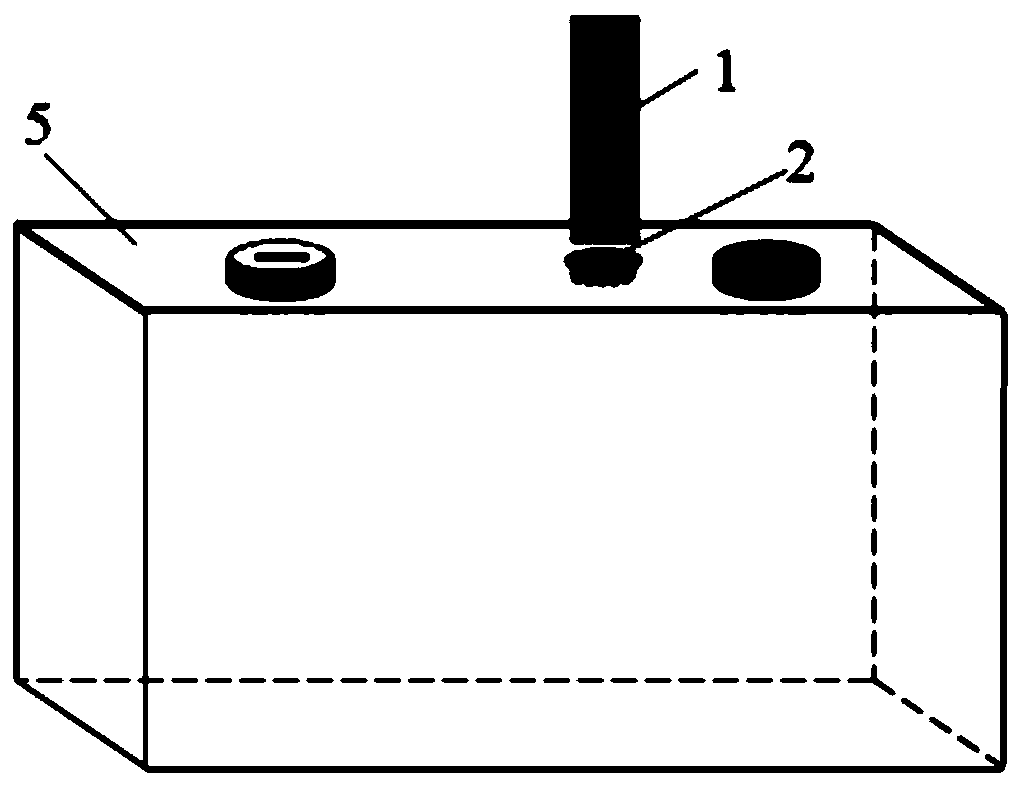

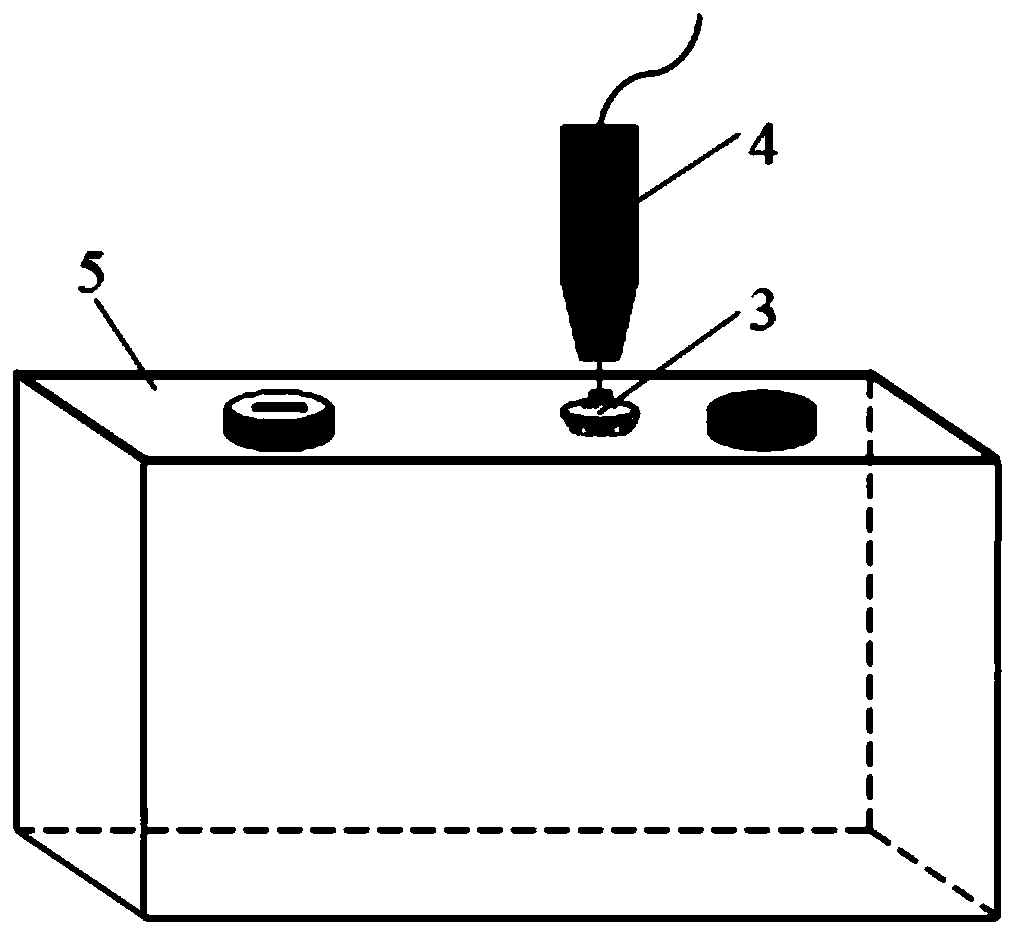

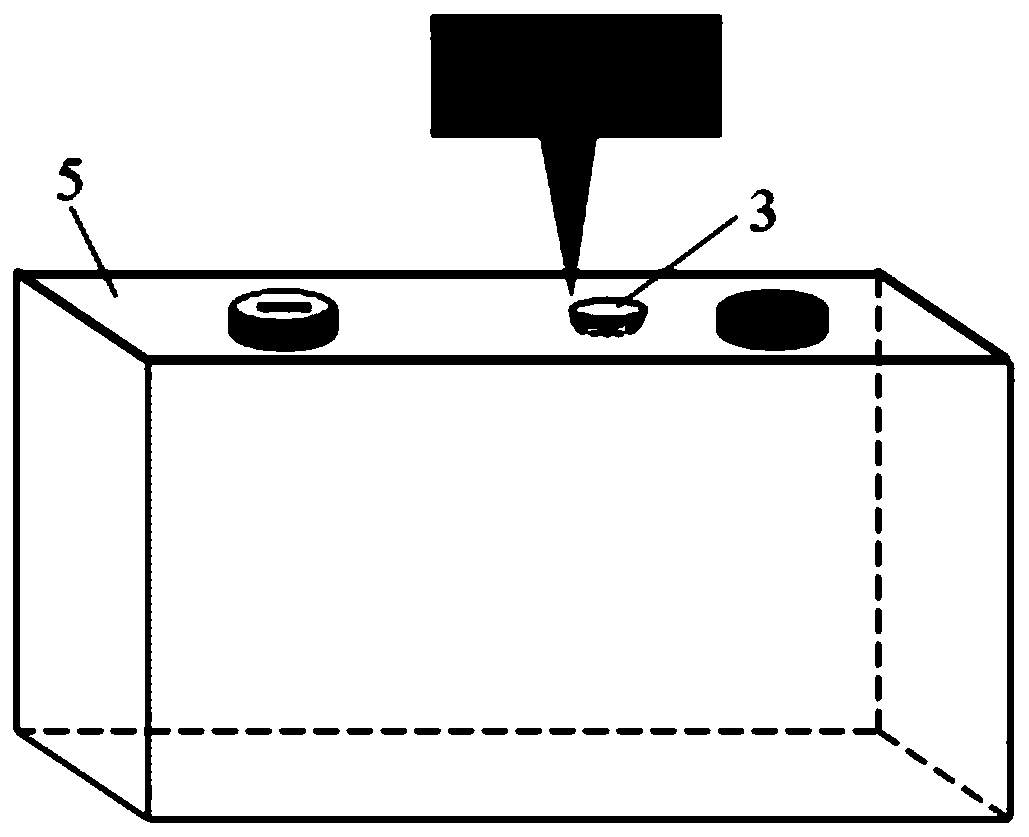

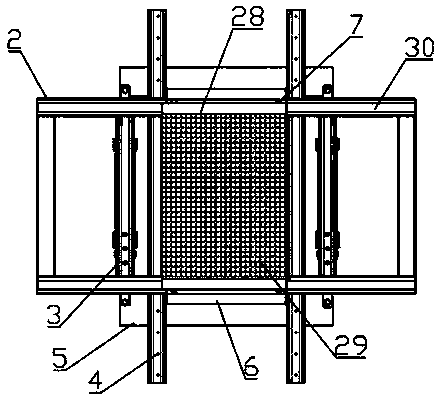

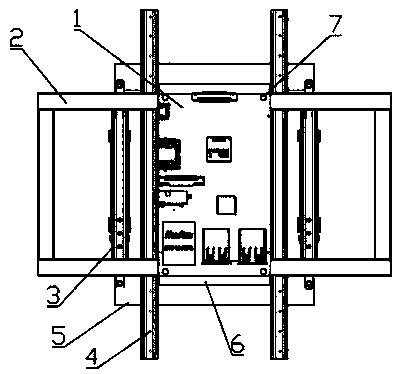

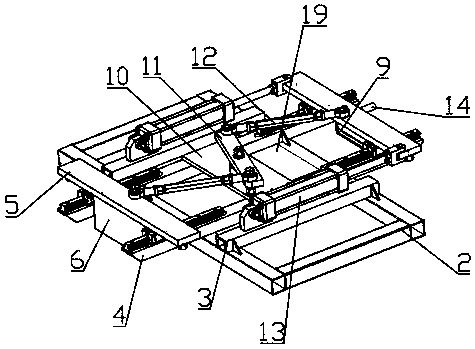

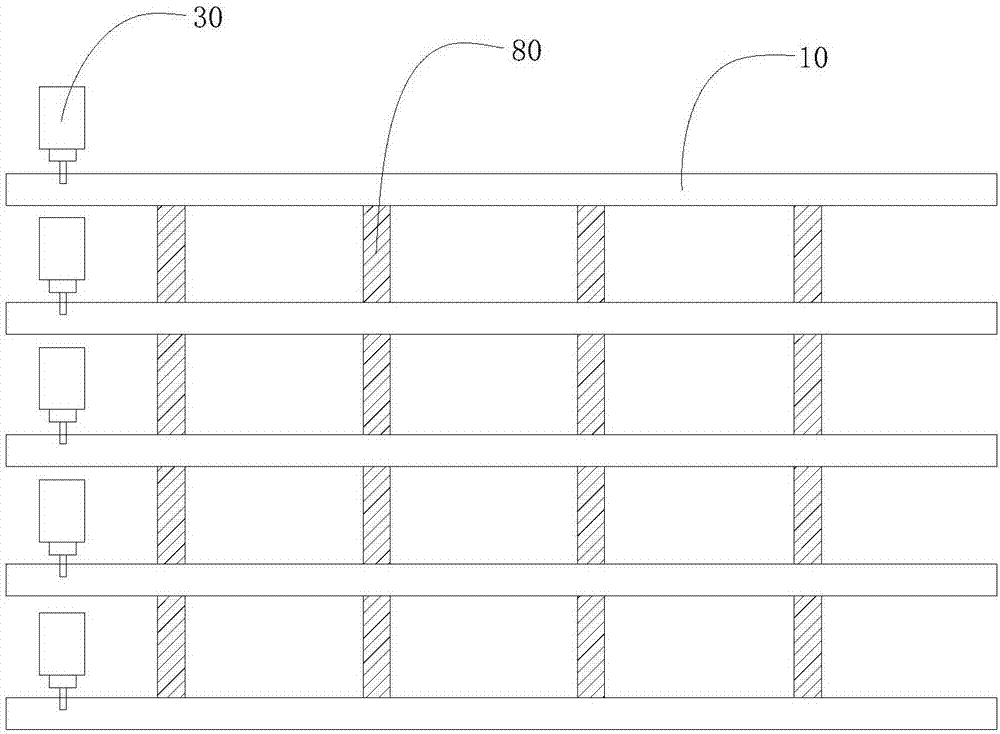

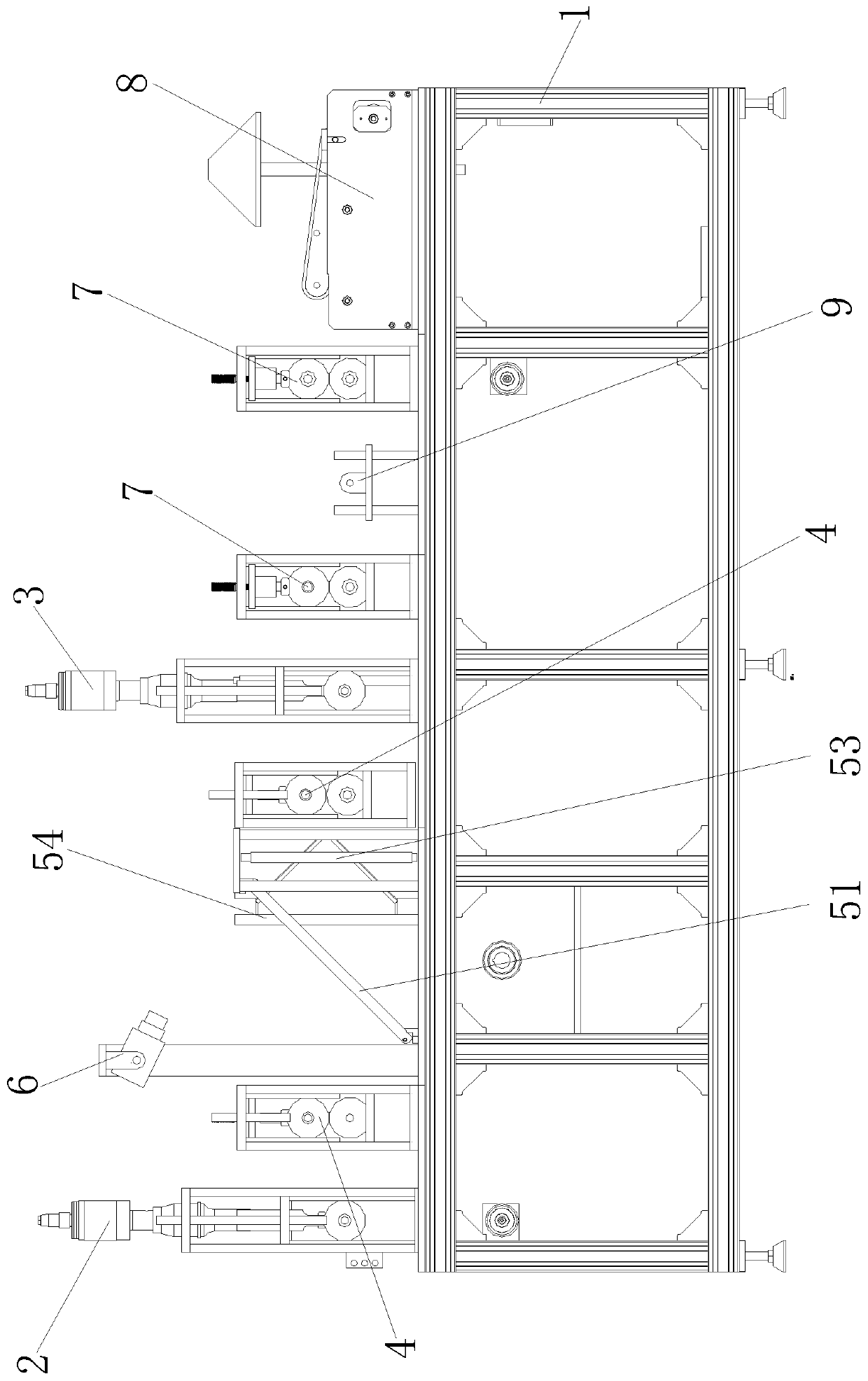

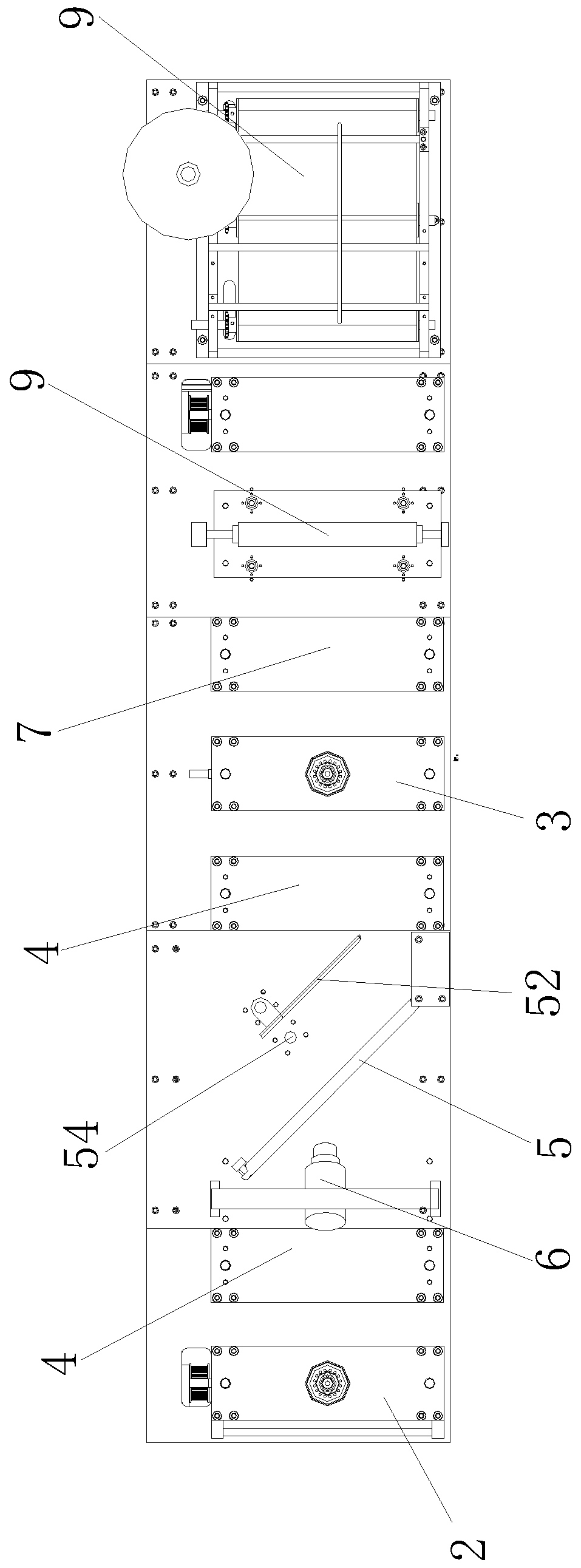

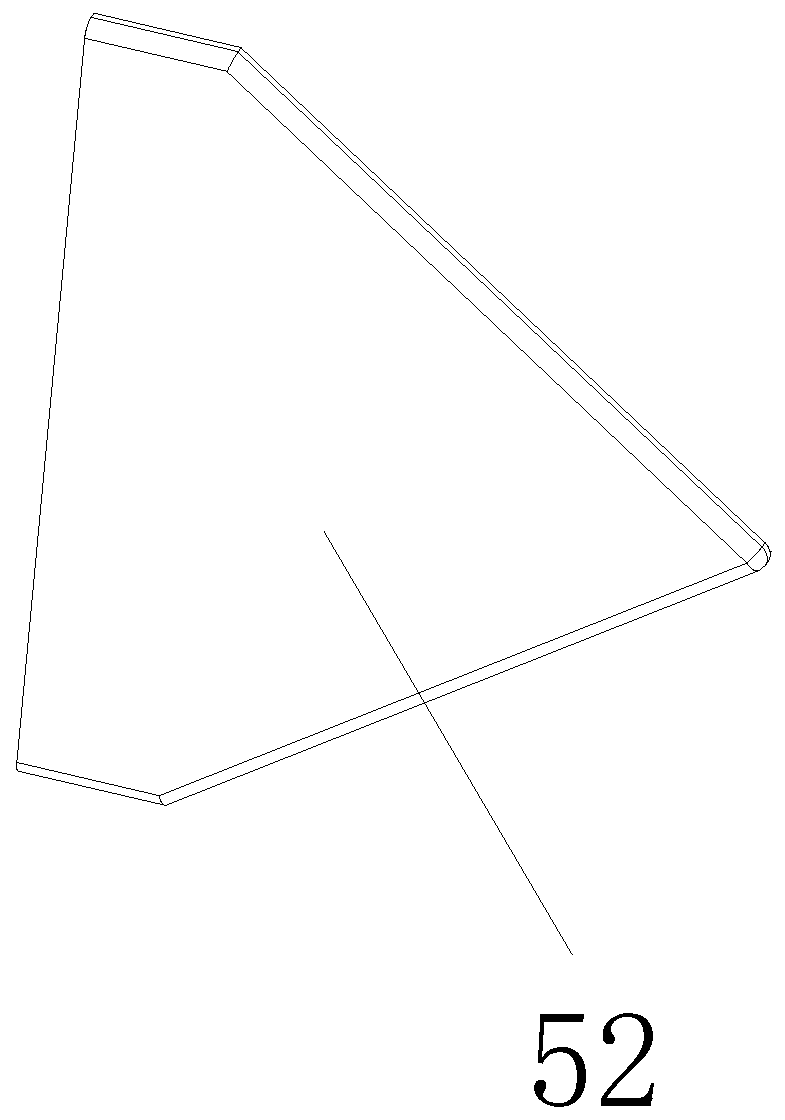

Technology and device for welding periphery of plate layer of vacuum freeze dryer

ActiveCN102357743APracticalSolve scrapWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a technology and a device for welding the periphery of a plate layer of a vacuum freeze dryer, belonging to the technical field of pharmaceutical machinery welding. The technology comprises the following steps of: 1.1, welding and fixing a plate layer (3) and edge steel (2) by using an argon arc point welding mode; 1.2, moving a movable workbench (7) to a proper position, and tightly pressing the plate layer (3) through a pressing mechanism (11); 1.3, carrying out fine-adjusting on the height of welding guns (1), and moving the welding guns (1) to the outside of the plate layer (3) through a welding gun moving unit (9); 1.4, igniting the two welding guns (1) arranged at two sides of the plate layer (3) at the same time, carrying out self-fusing welding at first andthen carrying out wire filling welding; 1.5, hoisting the plate layer (3) again, and welding another welded wire in the same way; and 1.6, repeating the welding process in step 1.3 for a plurality oftimes until gradual welding is completed. The invention has the advantages that the technology process is simple, the plate layer is not easy to deform, the welded wire is even, the technology and the device are suitable for welding different specifications and sizes of plate layers and the like.

Owner:山东浩器生物装备技术有限公司

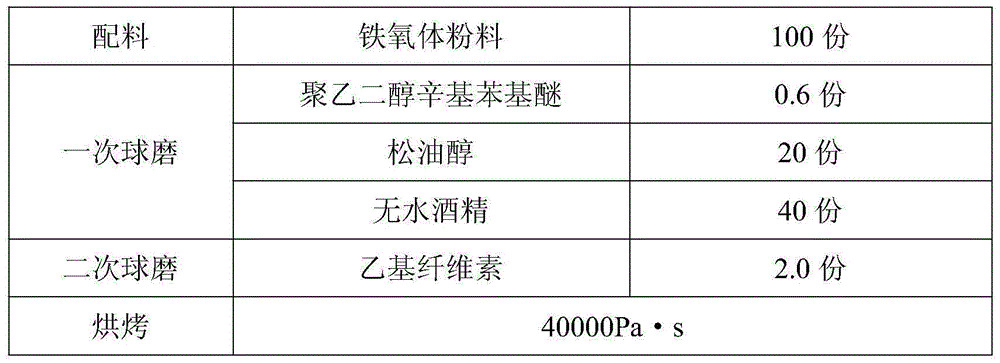

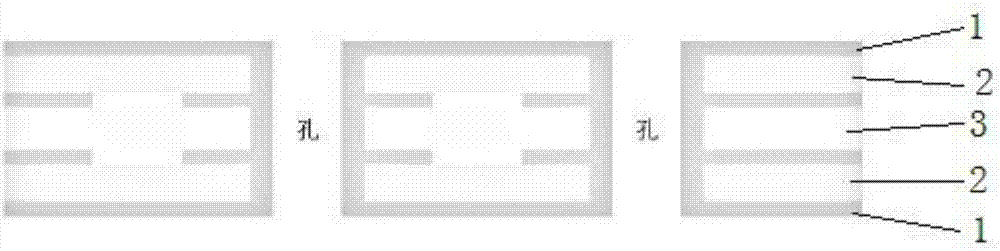

Ferrite slurry used for wet process stacked inductor printing and manufacturing method thereof

ActiveCN105000875ACause uneven sizePrevent openingInductances/transformers/magnets manufactureConductive pattern formationCombustionInductor

The invention provides ferrite slurry used for wet process stacked inductor printing and a manufacturing method thereof. The main constituent of the ferrite slurry used for the wet process stacked inductor printing is NiCuZn ferrite, Ni in the main constituent takes up 15mol%-25 mol% when being converted into NiO, copper takes up 8mol%-13mol% when being converted into CuO, Zn takes up 18mol%-25mol% when being converted into ZnO, and the balance iron takes up 46.5mol%-49.5mol% when being converted into Fe<2>O<3>; auxiliary agents comprise a combustion auxiliary agent and an addition agent, and the combustion auxiliary agent is Bi<2>O<3> and / or B<2>O<3> and takes up 1-4wt% of the main constituent; the addition agent is Co<2>O<3> and takes up 0.1-0.5wt% of the main constituent. The manufacturing method of the ferrite slurry used for the wet process stacked inductor printing comprises the steps of material compounding, first ball-milling, secondary ball-milling and baking. By means of the ferrite slurry used for the wet process stacked inductor printing, electric conduction among conductive circuit layers is good.

Owner:SHENZHEN GUDIAN ELECTRONICS

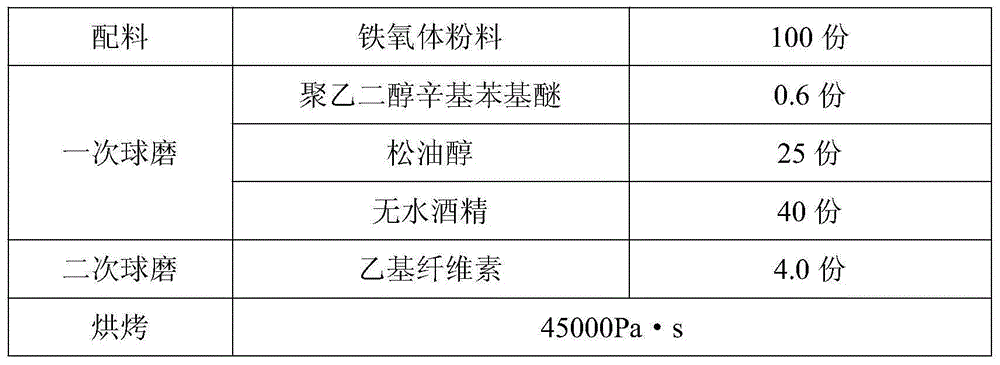

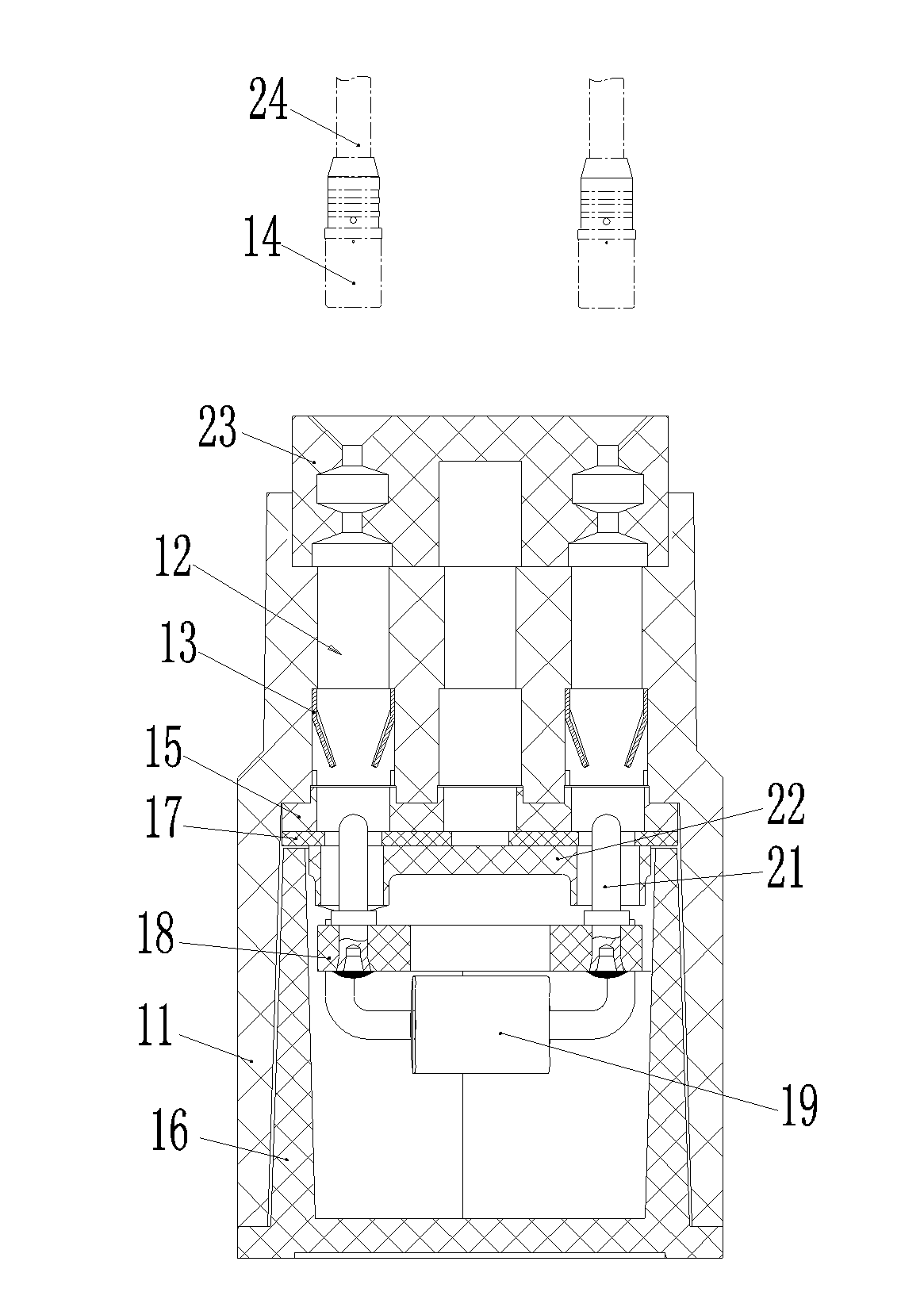

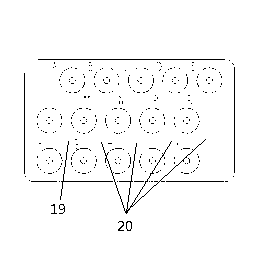

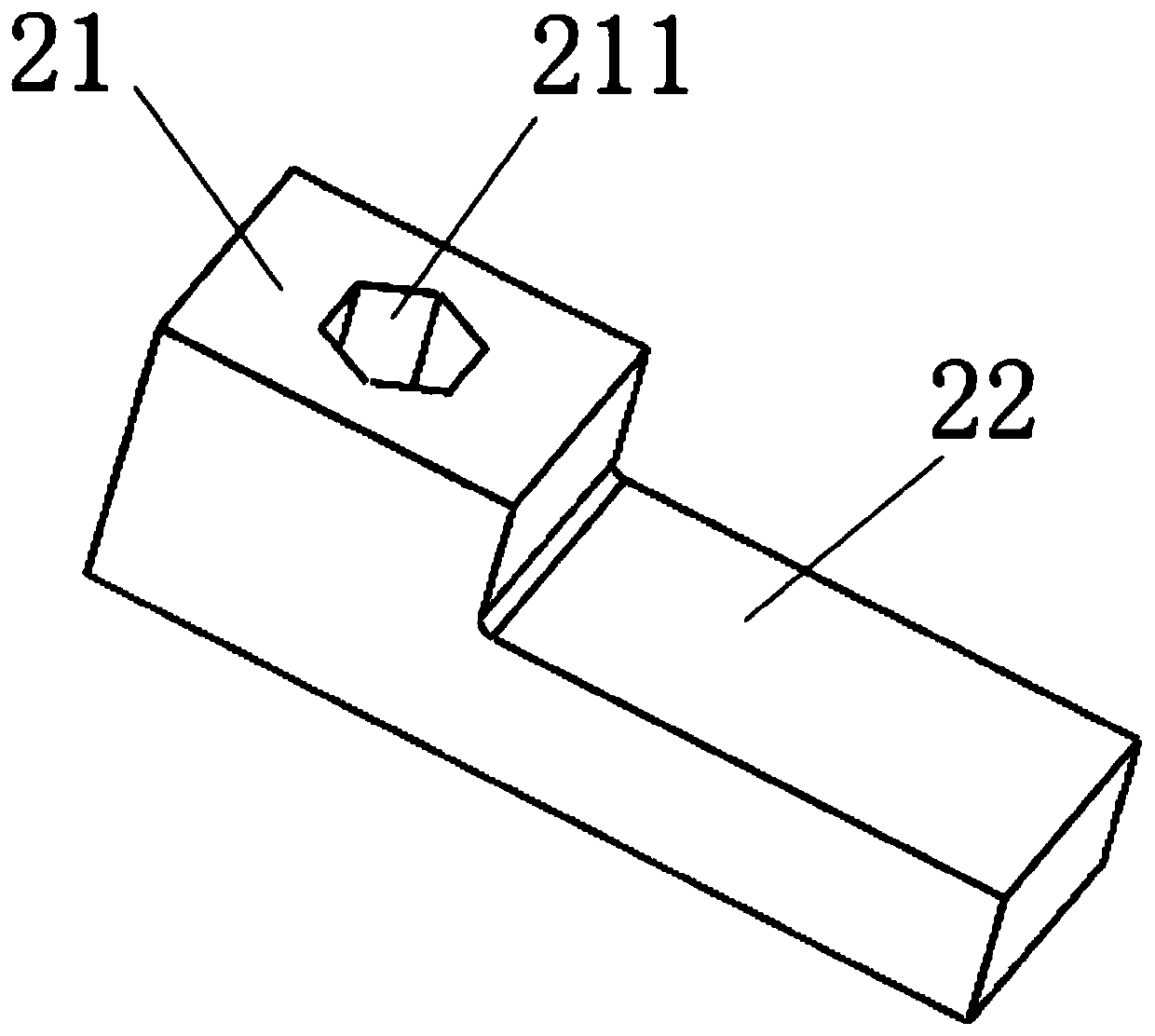

Module connector

ActiveCN103066457ACause scrapSolve scrapCoupling contact membersCouplings bases/casesElectricityComputer module

The invention relates to the field of electric connectors, in particular to a module connector. The front end of the module connector is a plug end. The module connector comprises a shell body. A printed plate is arranged in the shell body in a fixed mode. At least one kind of functional module is arranged on the printed plate. Each functional module is provided with at least one substitute module. The each functional module and the substitute module thereof are respectively provided with respective external contact element. When in use, fracture places of corresponding circuit are respectively connected with the corresponding contact elements. The corresponding functional module is enabled to be in use through that the contact element is connected with the external contact element of the module connector in an inserted mode. When one of the functional modules is damaged, due to the fact that the external contact element of the damaged functional module is separated from the contact element of the circuit, the contact element of the circuit is connected with the corresponding substitute module in an inserted mode, and therefore the corresponding device can continue to work. The whole scrap of the printed plate caused by any damaged element is avoided. The problem that the existing printed plated scraps when any element is damaged is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

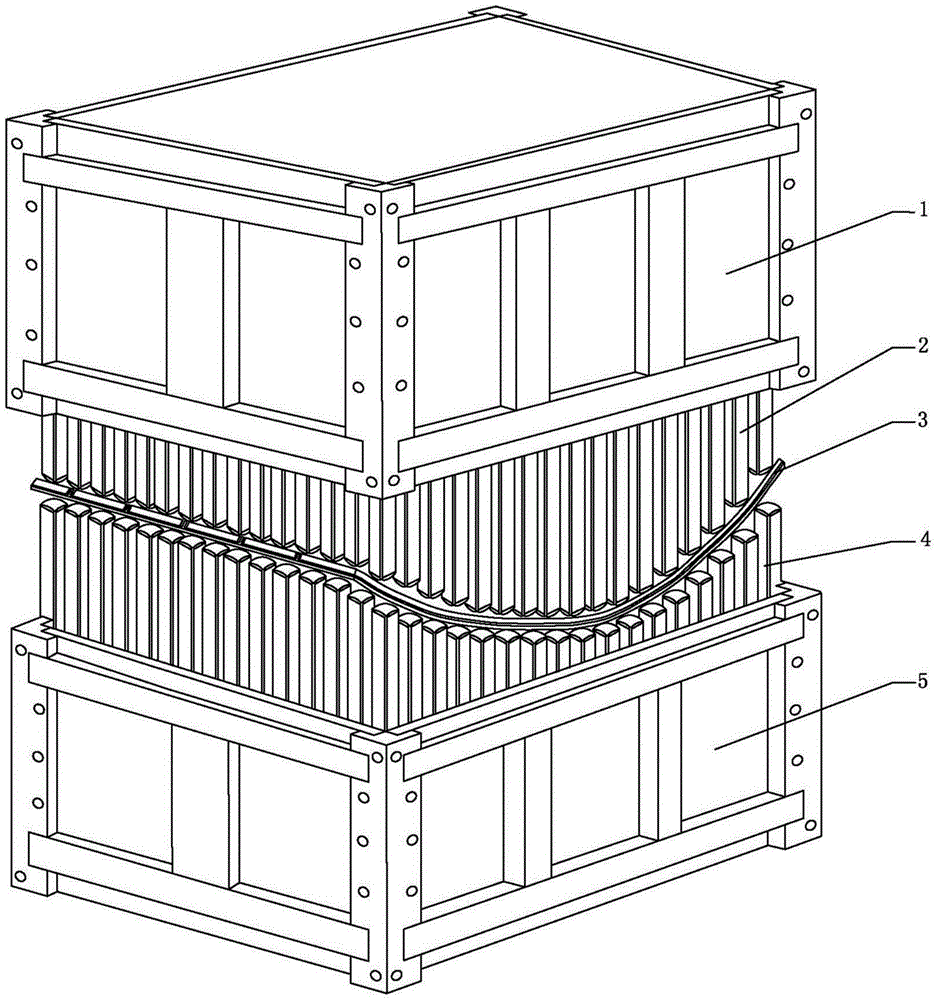

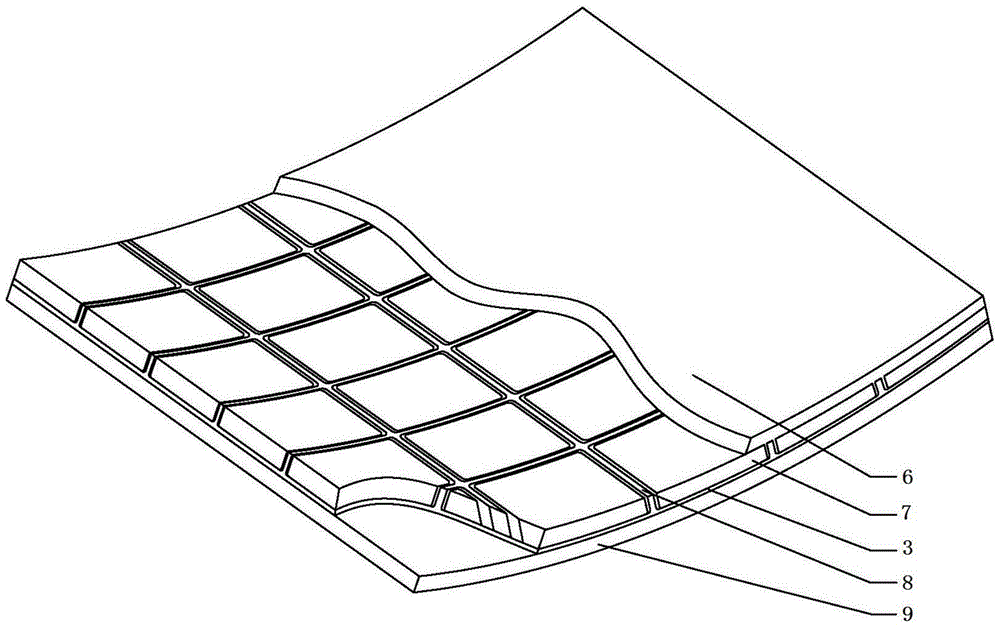

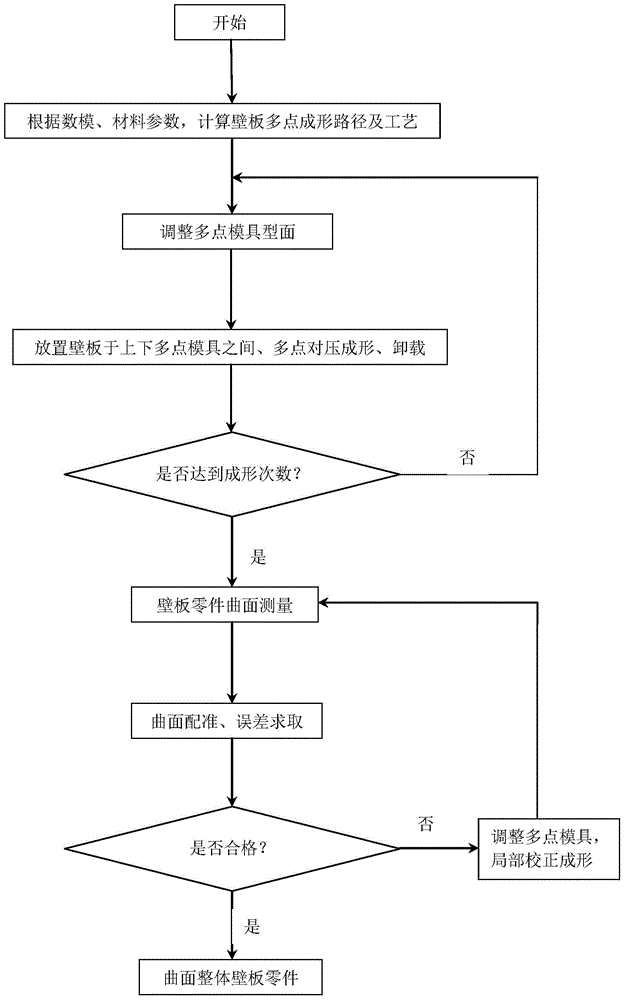

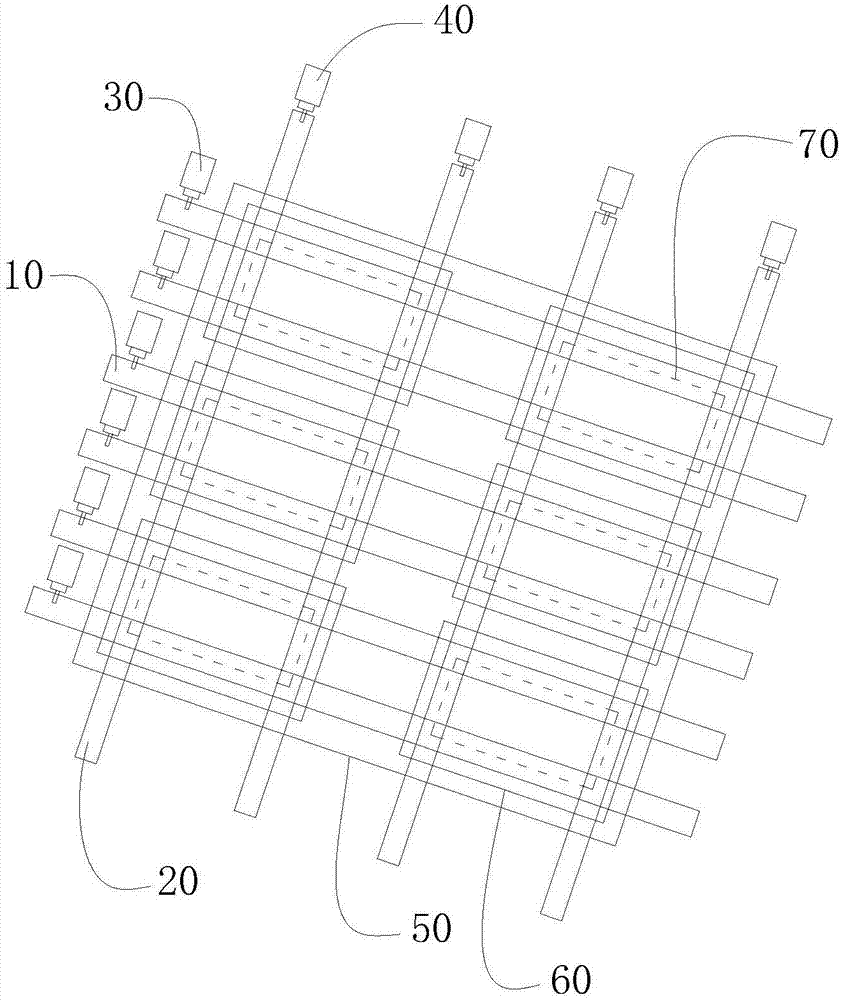

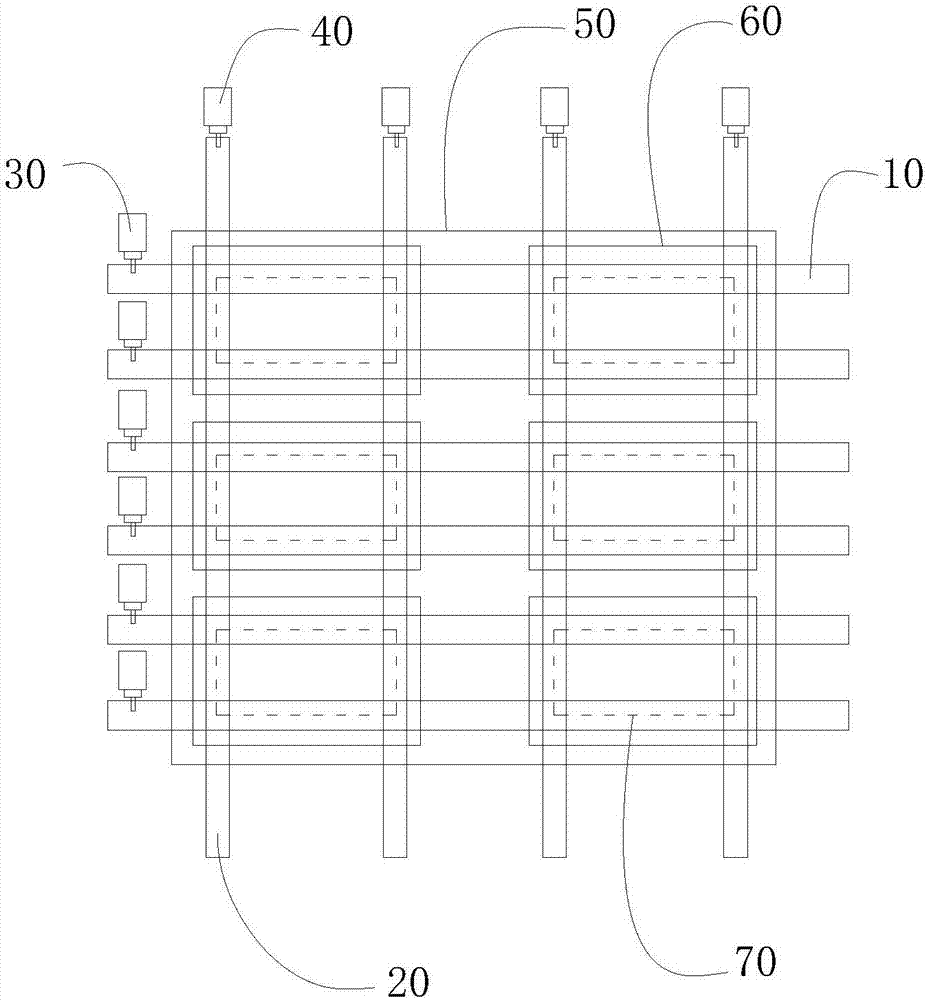

Multi-point forming method of aluminum alloy aircraft integral wall panel

InactiveCN104646475BSolve scrapHigh forming precisionShaping toolsMetal working apparatusDouble curvatureRocket

The invention discloses a multi-point forming method for a whole aluminum alloy wall plate of an aircraft. The multi-point forming method comprises the following steps of arranging the whole aluminum alloy wall plate with ribs between an upper multi-point die and a lower multi-point die of a quick reconstructing die surface, filling a filling material between the ribs, arranging an elastic cushion between the wall plate and the multi-point die, and gradually forming a whole aluminum alloy wall plate part with ribs by a die pressing method along a controllable deformation path. The multi-point forming method has the advantages that by utilizing the quick and adjustable characteristic of the reconstructing multi-point die surface, the wall plate parts with different geometric shapes and double curvatures can be processed by one set of equipment; compared with the traditional rolling and bending forming method and the pressing and bending forming method, the stress of the wall plate is uniform, and the forming quality can be guaranteed; compared with the shot peen forming method and the aging forming method, the deformation amount is large, and the forming efficiency is high; the method can be used for forming the whole aircraft wall plate with different rib structures and the double curvatures, the problems of large size and high rib in the whole wall plate forming process are solved, and the method can be applied to the manufacturing of other large ribbed curvature parts of aircrafts, rockets and the like.

Owner:JILIN UNIV

Expendable seawater measurement device

InactiveCN106840114AEfficient transmissionSimple structureOpen water surveySeawaterMeasurement device

The invention discloses an expendable seawater measurement device which comprises a measuring probe and a launcher, wherein the launcher comprises a fixing plate, a supporting plate, a spindle, a pull rod and a junction box; a handle, a rolling bearing and an eccentric wheel are mounted on the spindle; the rolling bearing is contacted with the supporting plate; one end of the pull rod is mounted on the fixing plate, and the other end of the pull rod penetrates through a pull rod guide slot of the supporting plate and is connected with an eccentric shaft of the eccentric wheel; the junction box is positioned between the fixing plate and the supporting plate; a contact pin used for being contacted with a metal contact on the measuring probe is arranged on a side face, which faces the fixing plate, of the junction box; a tightening spring is arranged on a side face, which faces the supporting plate, of the junction box; and the junction box is connected with the supporting plate through the tightening spring. According to the expendable seawater measurement device disclosed by the invention, the acquired data can be effectively transmitted in real time when the measuring probe is reliably put in, and the expendable seawater measurement device is simple in structure, light and reliable and is conveniently operated and used on deck by scientific research personnel.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

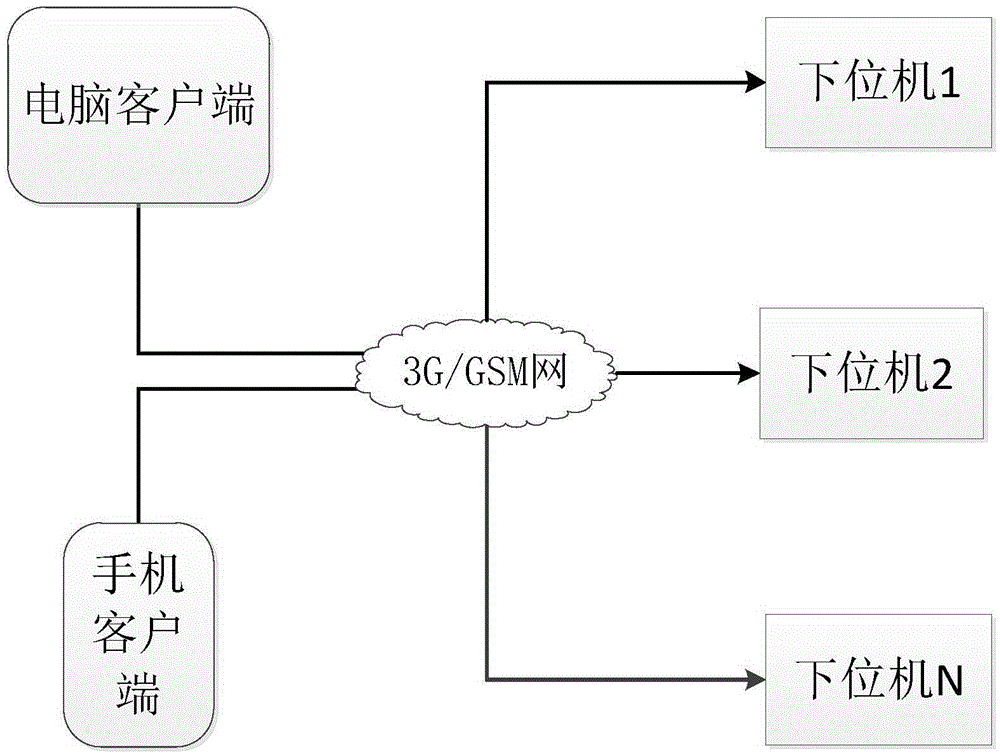

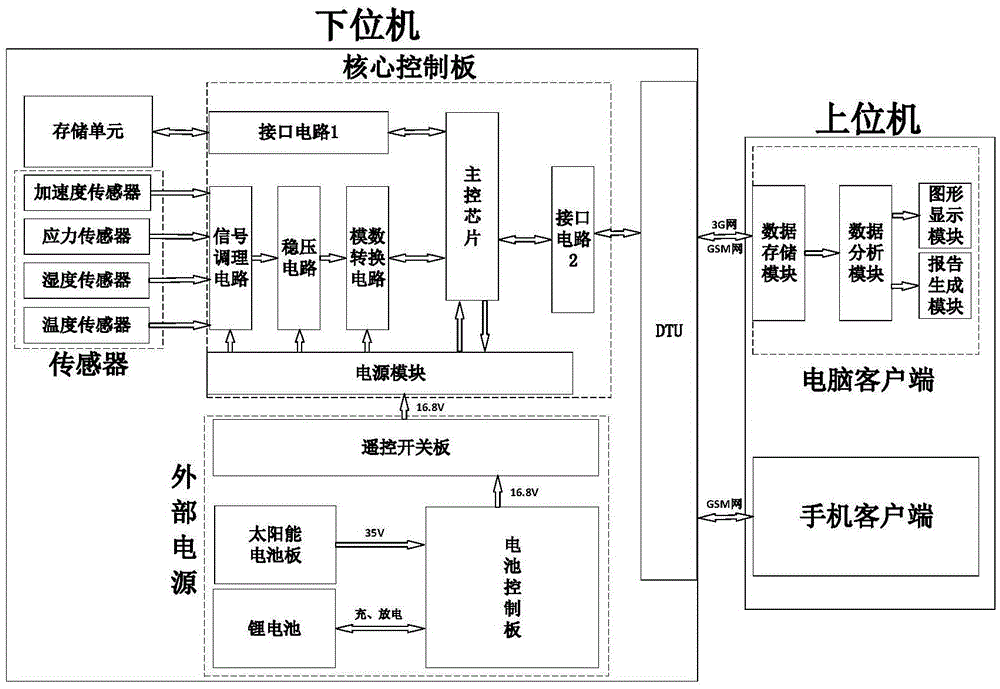

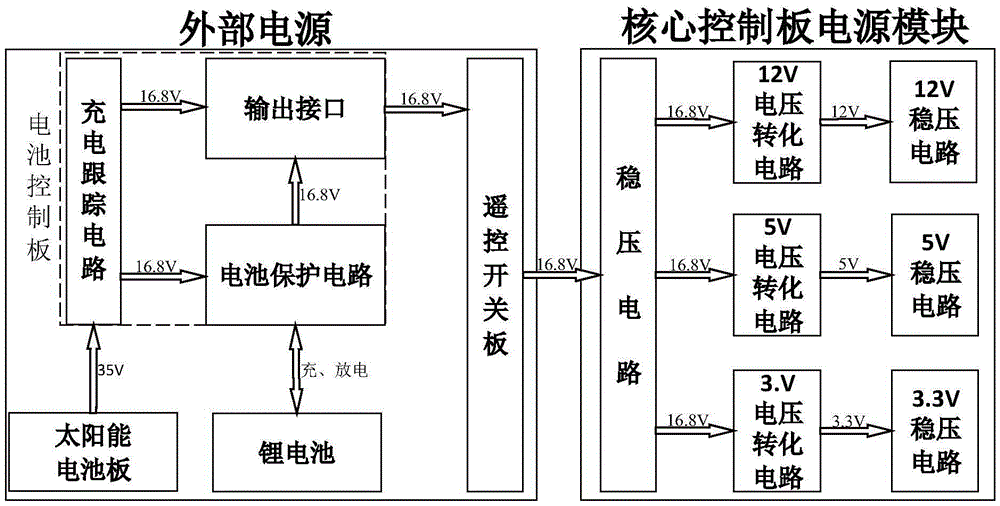

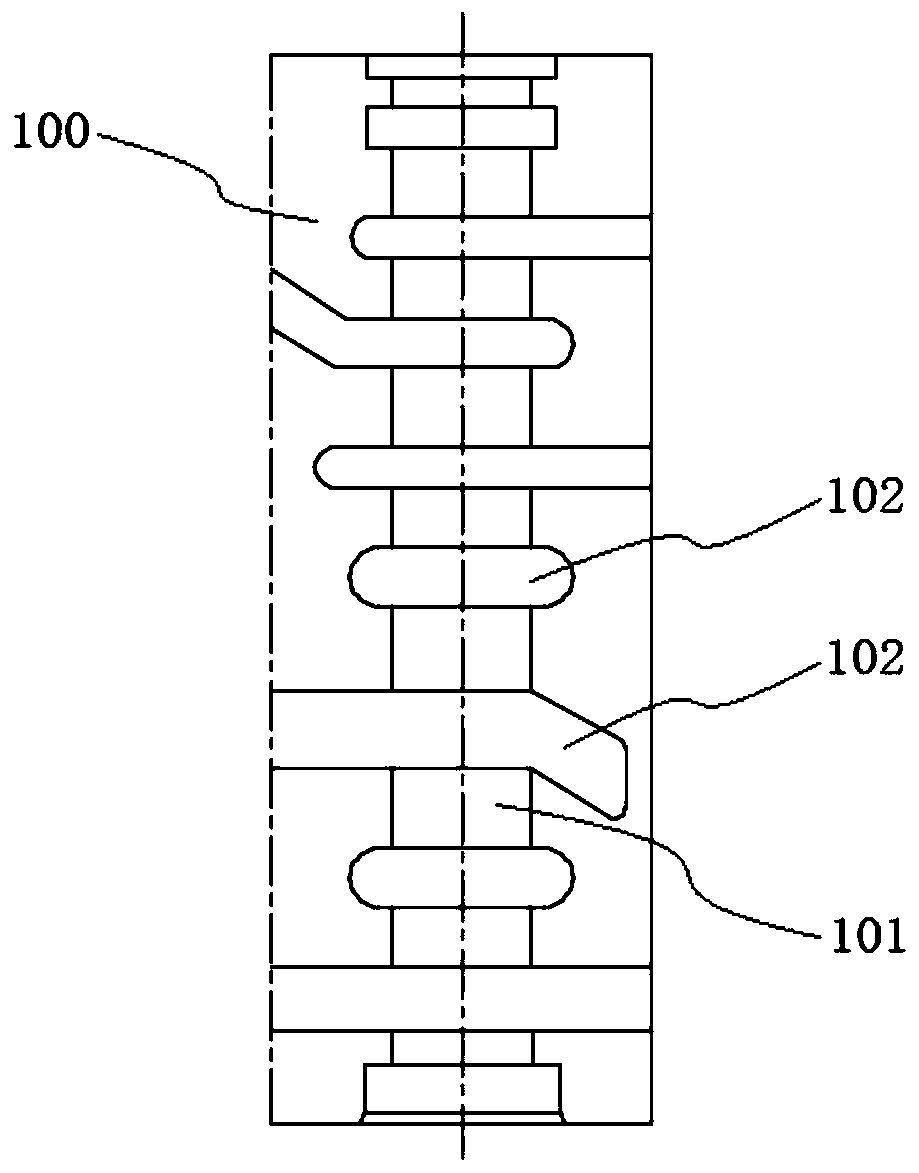

Self-powered multivariate distributed online monitoring system and method based on 3G/GSM network

InactiveCN105469583ARealize real-time monitoringReserved time domainMeasurement devicesTransmission systemsVibration accelerationThird generation

The invention discloses a self-powered multivariate distributed online monitoring system and method based on a 3G / GSM network. The system comprises a lower computer and an upper computer. The lower computer comprises a core control board, a DTU (a GSM module and a 3G module), various sensors, an external power source and a storage unit. An acceleration sensor, a stress sensor, a humidity sensor and a temperature sensor adopted by the lower computer are distributed at different monitoring points of an object to be monitored for monitoring the vibration acceleration, the stress surface stress, the surface humidity and the environment temperature of the object to be monitored. The external power source is used for supplying power to the units of the lower computer. The upper computer comprises a computer client and a mobile phone client, wherein the computer client can store and analyze information transmitted back by the lower computer and generate real-time graphs and monitoring reports, and the mobile phone client can control the lower computer at any time and any place. The self-powered multivariate distributed online monitoring system and method have the advantages that debugging is convenient, the working time is long, electricity and energy are saved, mobile control is achieved, and data can be intelligently processed.

Owner:WUHAN UNIV

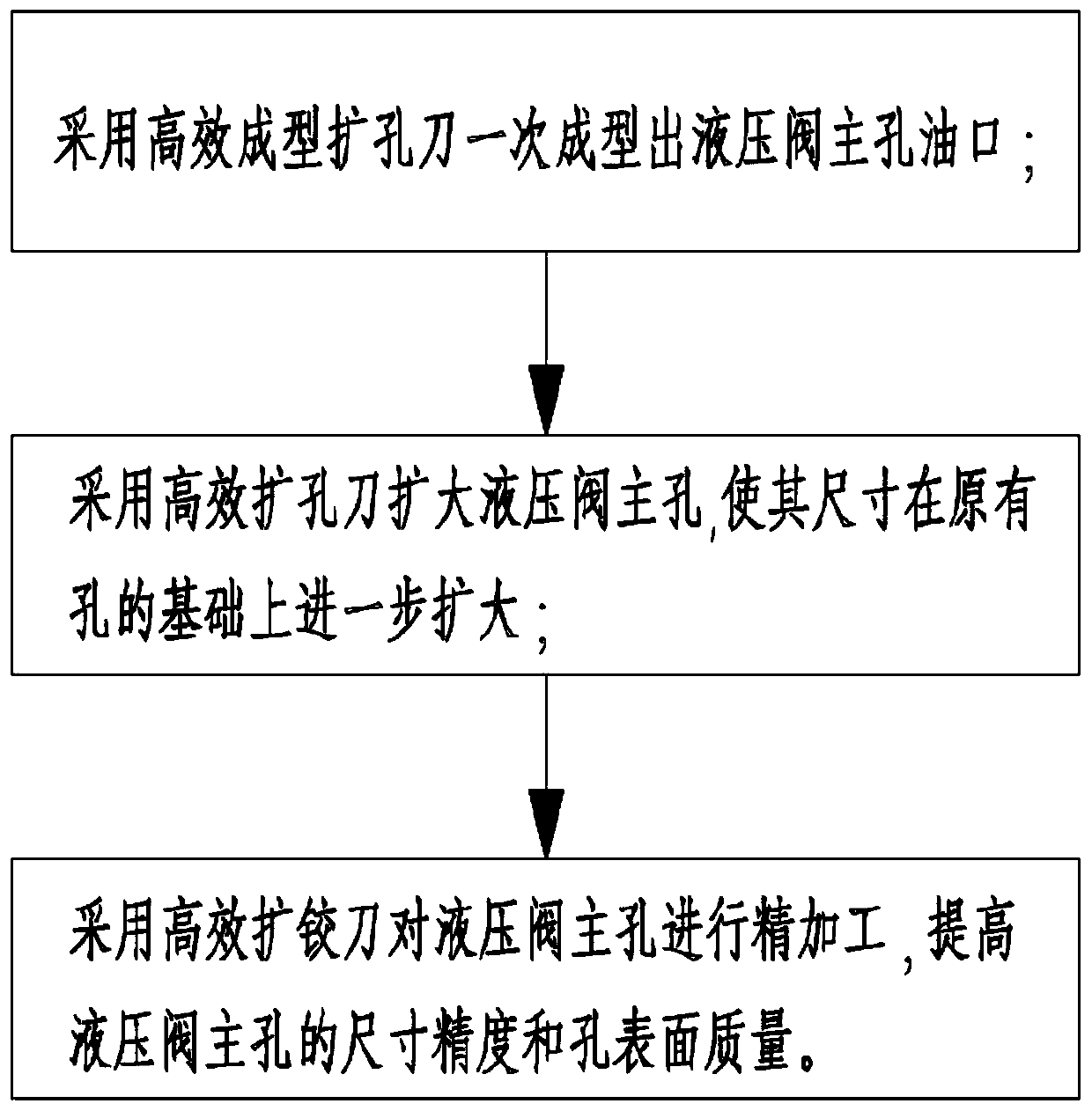

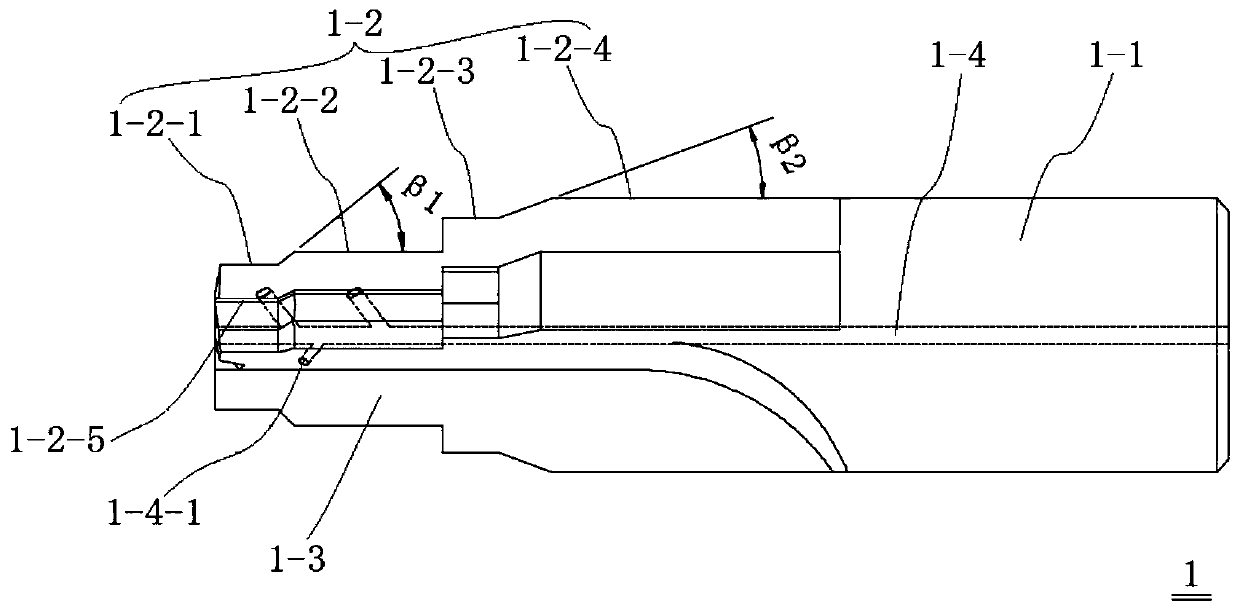

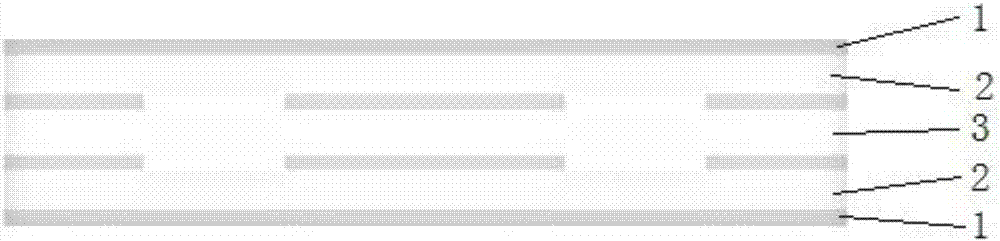

Efficient and long-service-life hydraulic valve main hole machining method

ActiveCN111002003AGood concentricityHigh surface finishCutting insertsWorkpiecesReamerStructural engineering

The invention discloses an efficient and long-service-life hydraulic valve main hole machining method, and belongs to the hole machining technology field. In the machining method, an oil port three-blade forming cutter, a three-blade chambering cutter and an eight-blade expanding reamer are sequentially used for machining a main hole of a hydraulic valve. One-time forming of a forming hole is guaranteed through the oil port three-blade forming cutter, a service life is long, and cutting efficiency is high. An unequal design of the three-blade chambering cutter is matched with a layered structure design so that chambering cutting vibration is reduced, a chambering machining allowance is large, concentricity of the main hole of an intermittent hydraulic valve is ensured, and machining precision and machining efficiency are high. Unequal parts of the eight-blade expanding reamer are combined with unequal teeth so that vibration of a cutter of expanding and reaming is greatly reduced, andsurface roughness and cylindricity of the main hole of the hydraulic valve, the reaming processing allowance and the cutting efficiency are improved; and the method has the advantages of high machining efficiency, good machining precision, a long service life of the cutter and the like, and a problem that hydraulic valves are scrapped due to blockage of ducts by residual cuttings is effectively solved.

Owner:CHANGZHOU LEAD CUTTING TECH CO LTD

Machining process of PCB

InactiveCN107124827ASolve the problem of high cost and repair causing product scrapSolve scrapMultilayer circuit manufactureNon-metallic protective coating applicationSolderingCopper

The invention discloses a machining process of a PCB. The machining process comprises the following steps: laminating, drilling, electrodeless plating copper, resistance-soldering plughole, resistance-soldering baking, ceramic plate grinding, imaging by virtue of external light, resistance-soldering silk printing, and resistance-soldering baking, wherein the resistance-soldering plughole process is advanced to the step subsequent to the electrodeless plating copper from the normal machining step behind the external-light imaging, so that the problems that the resin plughole is high in cost, and the product is scraped when in repairing can be solved.

Owner:珠海杰赛科技有限公司 +1

Method for repairing various welding seam defects of laser welding of power battery sealing nails

InactiveCN111037098ARepair Weld DefectsSolve scrapCell component detailsMetal working apparatusPower batteryMilling cutter

The invention discloses a method for repairing various welding seam defects of laser welding of power battery sealing nails, which comprises the steps of firstly, milling a groove in a welding seam ofan original sealing nail on a battery cell top cover by using a milling cutter, and removing the defect position of welding; secondly, comprehensively cleaning the milled groove by using alcohol andan electric brush, wherein the specific operation process is as follows: the groove is cleaned after being milled, the milled groove is cleaned by using the electric brush firstly, and then the grooveis wiped by using alcohol; thirdly, conducting laser cleaning on the cleaned groove; and fourthly, putting a new sealing nail made of the same material in the milled groove, and conducting laser sealing welding again. According to the invention, the nail is placed and welded again after groove milling, and groove milling is conducted through the milling cutter to integrally remove the defect position of welding; and the state before welding is restored, the sealing welding is completed again so as to achieve the effect of effectively repairing the welding seam defect.

Owner:WUHU ETC BATTERY LTD

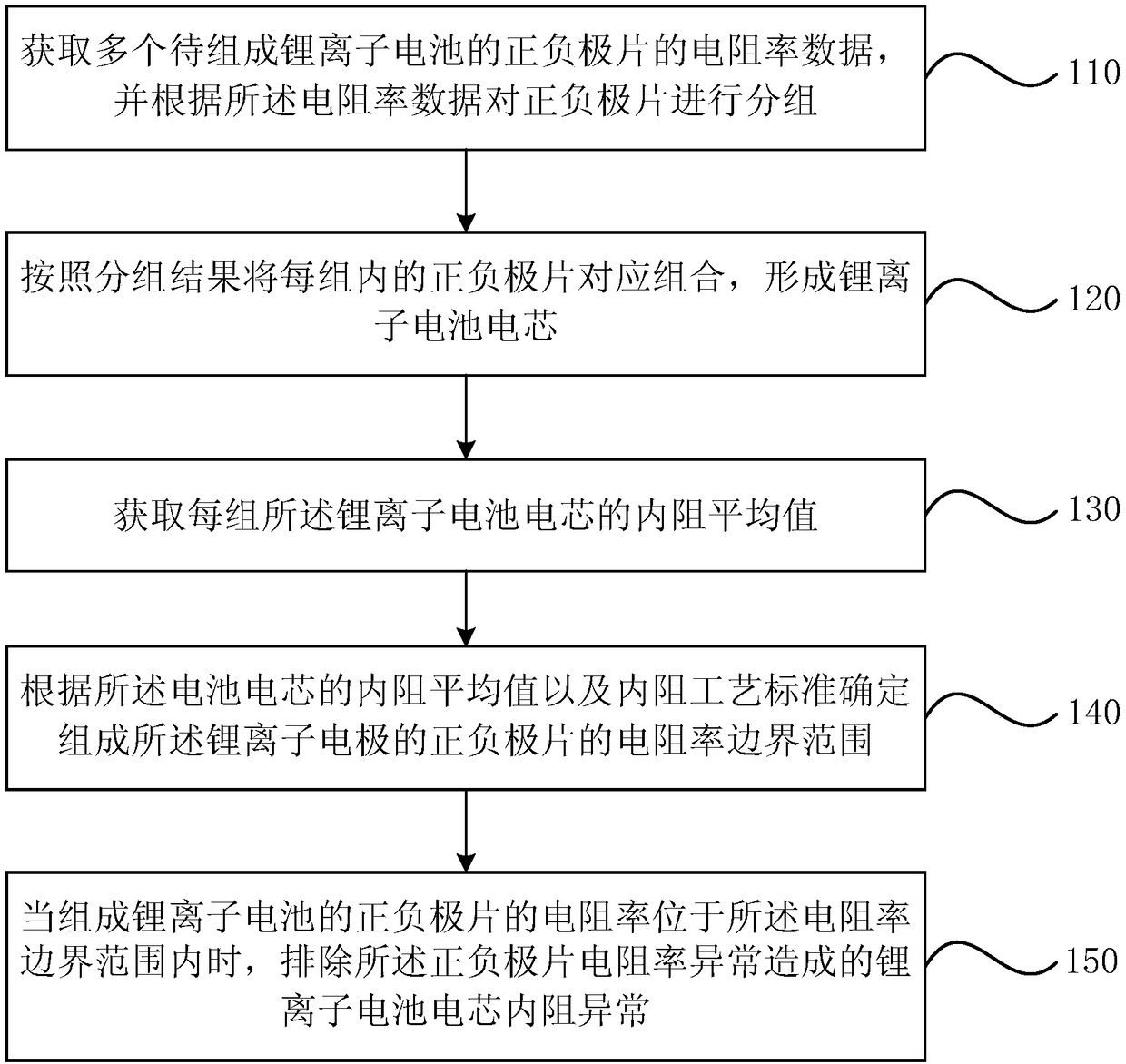

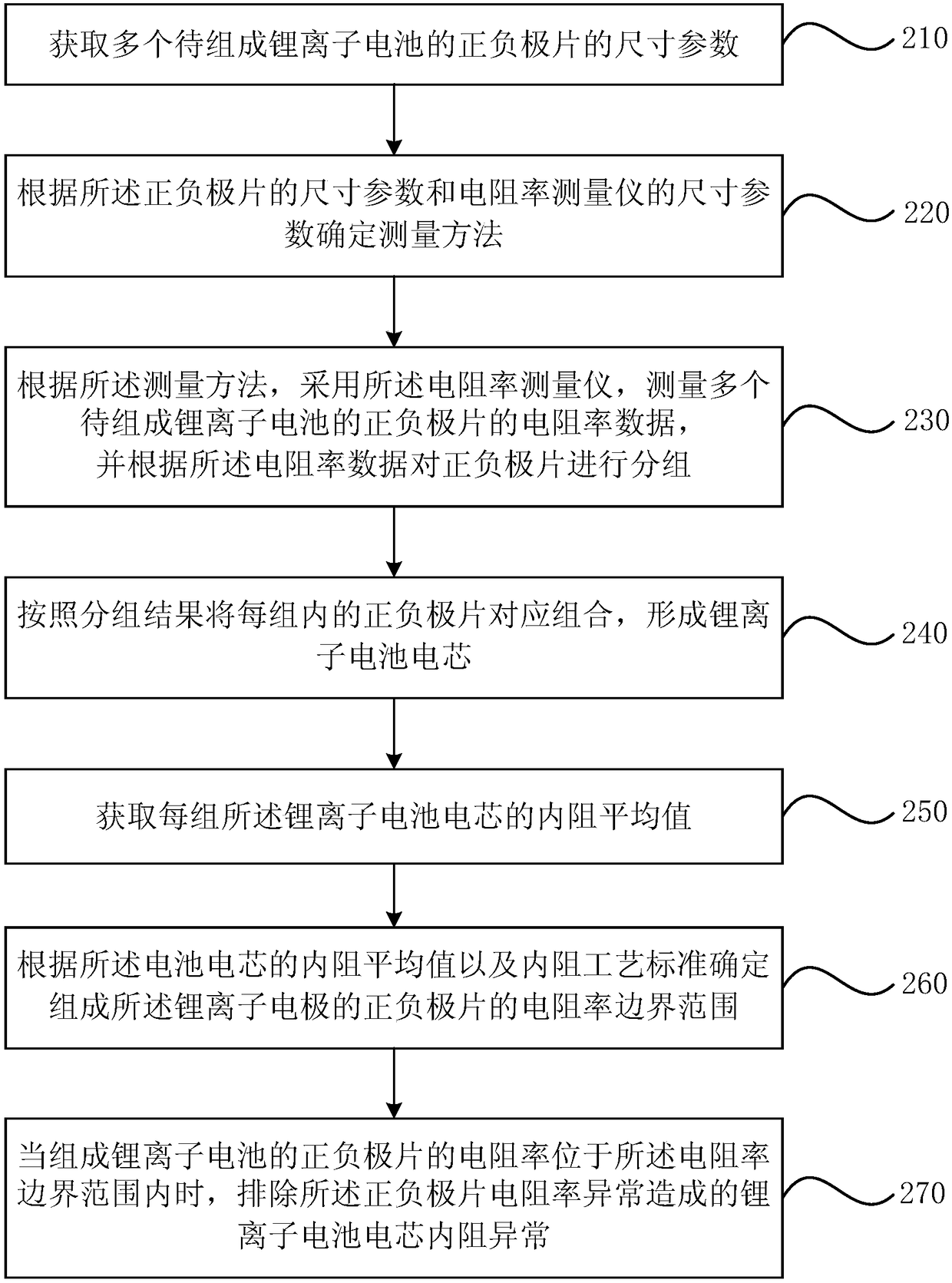

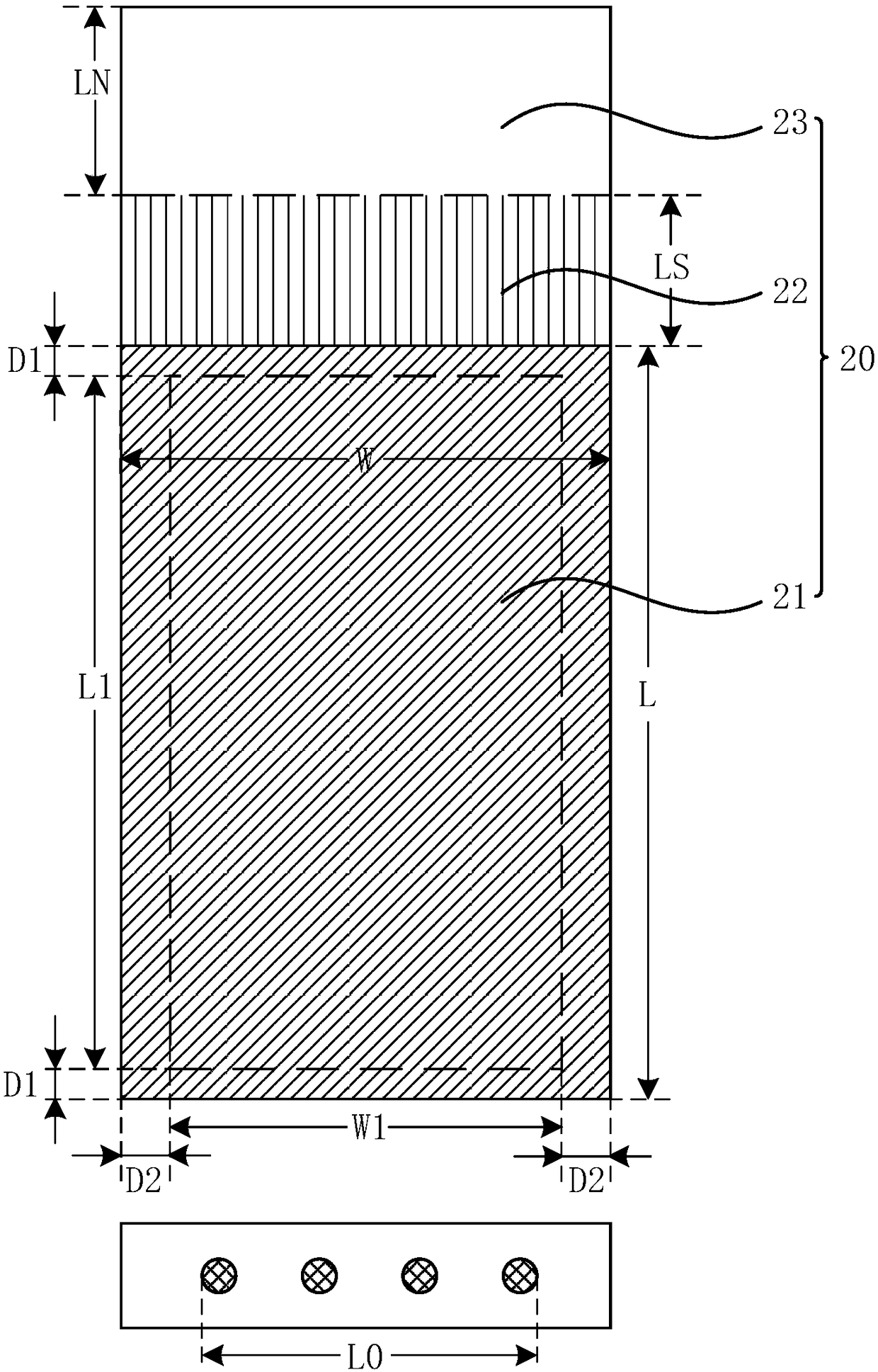

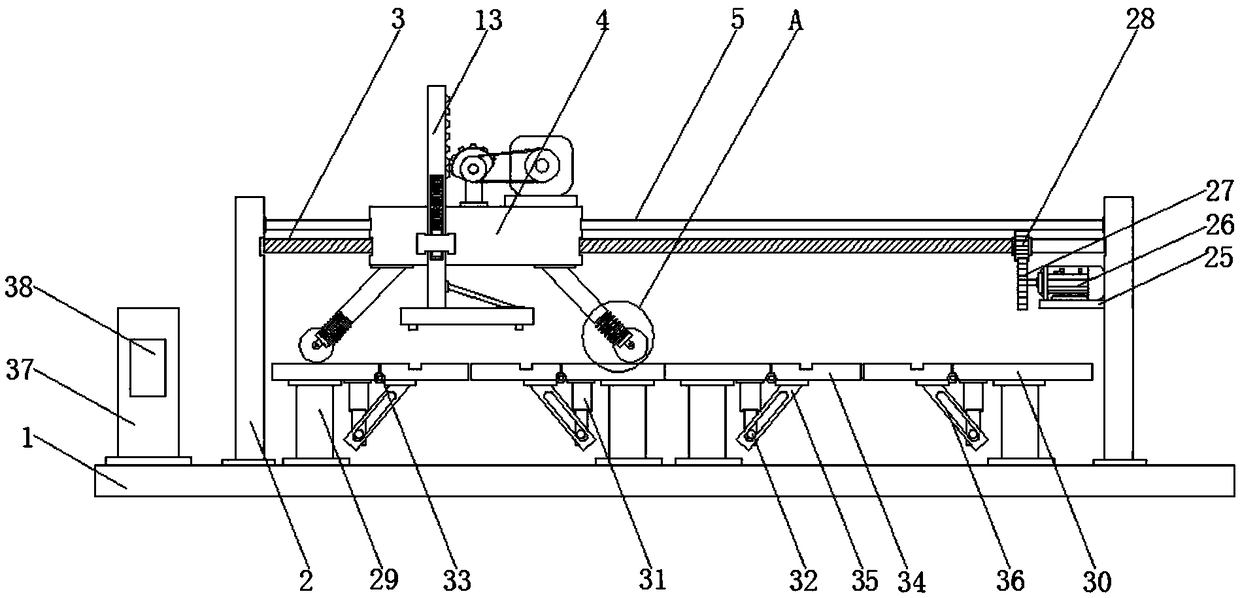

Method for judging lithium-ion-battery cell internal resistance abnormity

ActiveCN108196123ASolve scrapIncrease the detection method of electrical qualityResistance/reactance/impedenceFinal product manufactureElectrical batteryInternal resistance

The invention discloses a method for judging lithium-ion-battery cell internal resistance abnormity. The method includes: acquiring the resistivity data of a plurality of positive and negative electrode plates for forming a lithium ion battery, and grouping the positive and negative electrode plates according to the resistivity data; corresponding combining the positive and negative electrode plates in each group according to the grouping result to form lithium-ion-battery cells; acquiring the average value of the internal resistance of each group of lithium-ion-battery cells; determining theresistivity boundary range of the positive and negative electrode plates forming the electrodes of the lithium ion battery according to the average value of the internal resistance of the lithium-ion-battery cells and internal resistance process standards; when the resistivity of the positive and negative electrode plates for forming the lithium ion battery is located in the resistivity boundary range, eliminating lithium-ion-battery cell internal resistance abnormity caused by positive and negative electrode plate resistivity abnormity. The method has the advantages that whether cell internalresistance is abnormal or not is prejudged by measuring the resistivity of the positive and negative electrode plates, the monitoring method for the cell internal resistance is provided, and processscrappage probability is lowered.

Owner:EVE ENERGY CO LTD

Carton crimping device for logistics packaging

InactiveCN108115981AChange a single structureImprove functionalityBox making operationsPaper-makingCardboardCoupling

The invention discloses a carton crimping device for logistics packaging and relates to the technical field of logistics. The carton crimping device comprises a base, the top of the base is fixedly connected with a supporting rod, and opposite sides of the two supporting rods are rotatably connected with rotating rods, the surface of each rotating rod is in threaded connection with a movable block, a sliding rod is slidably connected inside the movable block, the two ends of the sliding rod are fixedly connected with the surface of the supporting rod, the top of the movable block is respectively fixedly connected with a first motor and a supporting block, an output shaft of the first motor is fixedly connected with a first belt pulley through a coupling, and the front surface of the supporting block is rotatably connected with a semicircular gear. According to the carton crimping device for logistics packaging, the problem that in the paperboard crimping process, crimping unevenness occurs easily, which leads to product scrapping is solved, the product quality is ensured, the working efficiency is greatly improved, functionality is enhanced, the production cost is reduced, and thecorporate profits are increased.

Owner:界首市果子林电子商务有限公司

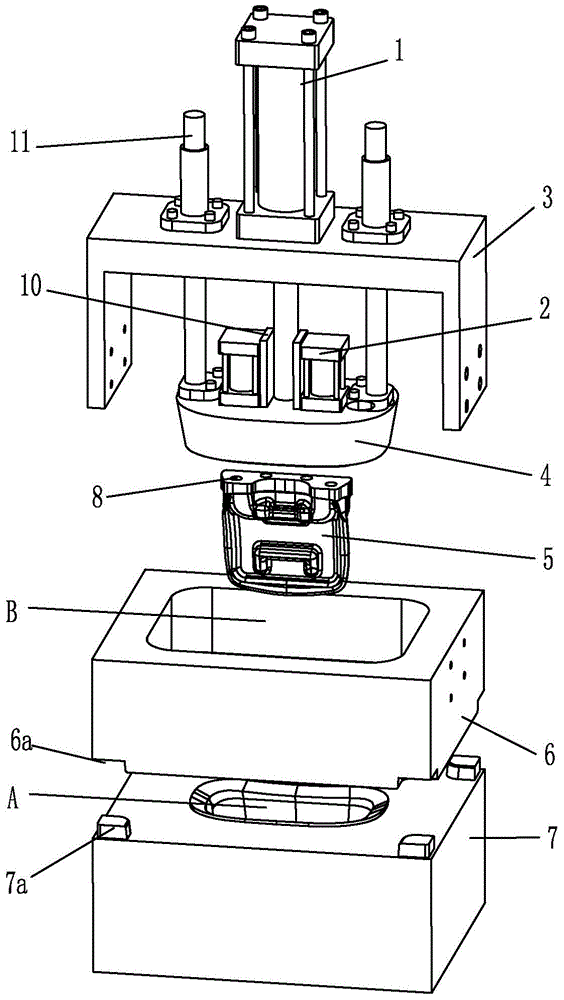

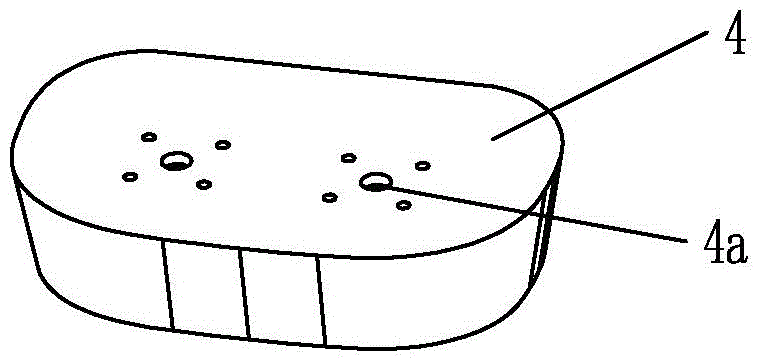

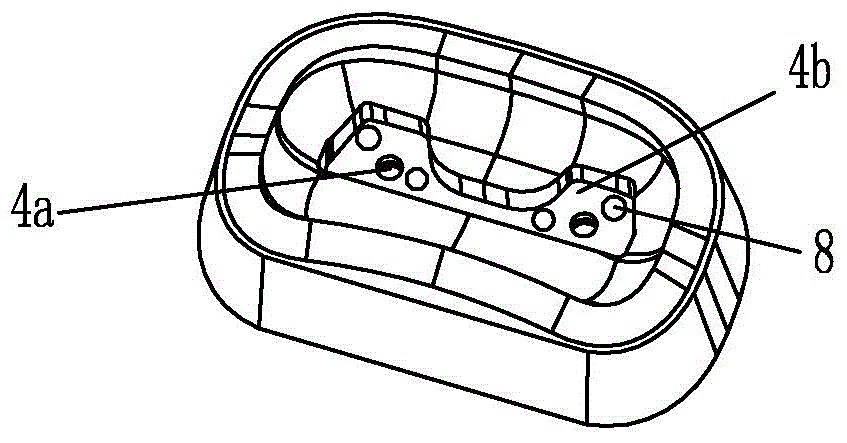

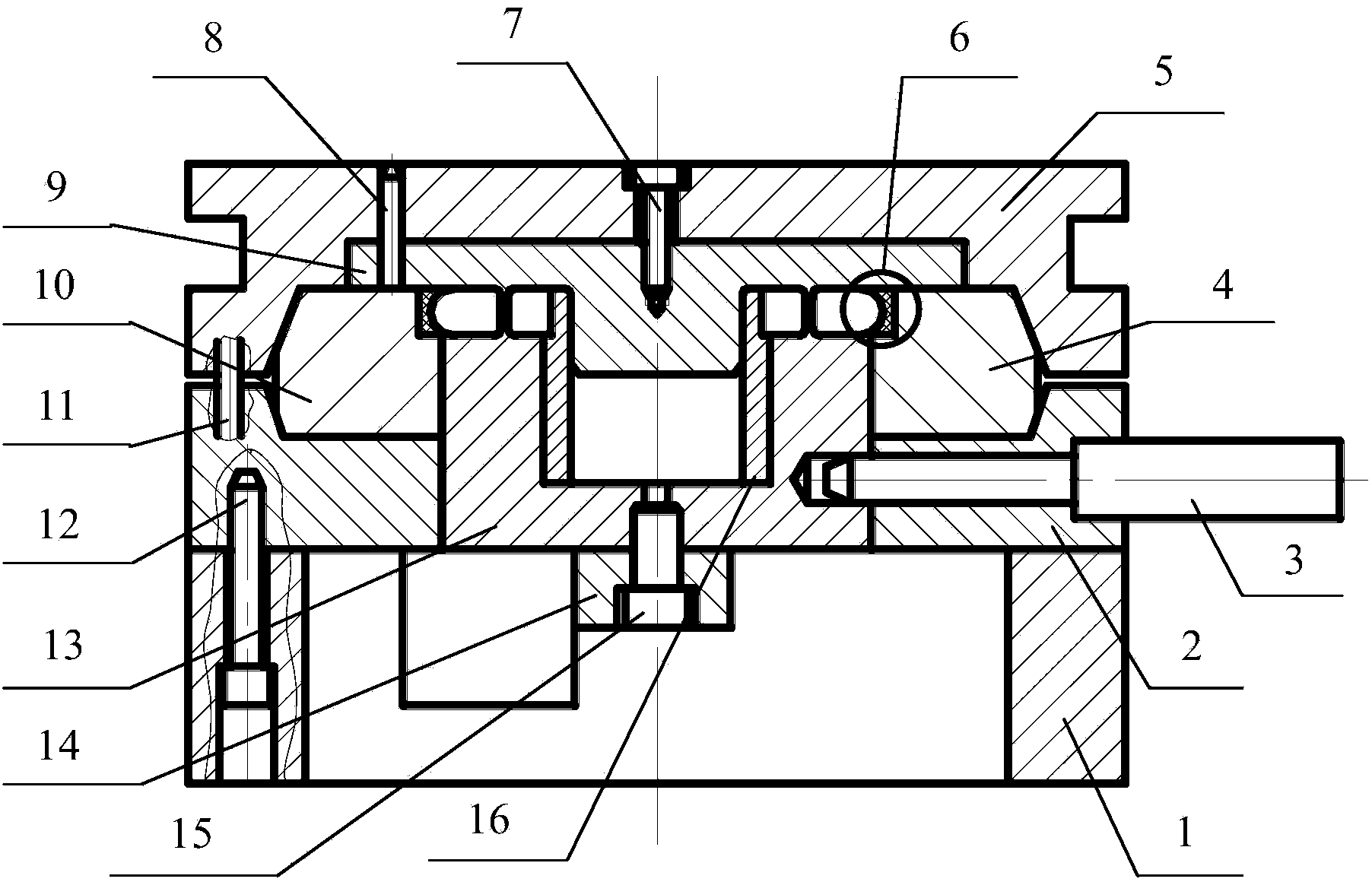

Seat headrest vertical foaming mold

The invention discloses a seat headrest vertical foaming mold. An upper mold and a lower mold are buckled together to form a headrest foaming cavity; a large cylinder is arranged at the top of a cylinder bracket, a small cylinder is arranged at the top of an upper mold insert, the left end and right end of the cylinder bracket extends downwards vertically so as to be fixedly connected with the left side wall and right side wall of the upper mold, the lower end of a piston rod of the large cylinder is connected with the upper mold insert which is internally provided with a vertically-through round hole, and the piston rod passes through the round hole; the top of a movable inserting block extends into a groove matched with the bottom of the upper mold insert, and the top of the movable inserting block and the top of the groove are fixed together by virtue of the magnetic force of a magnet; the upper mold insert drives the movable inserting block to move from top to bottom together; the upper mold insert extends into the top cavity of the upper mold, and the movable inserting block extends into the headrest foaming cavity. According to the seat headrest vertical foaming mold, material overflow and hard edges are avoided, the product stability is improved and the workload of operators is reduced.

Owner:CHONGQING ZONGSHEN HONGLI CUSHION MFG

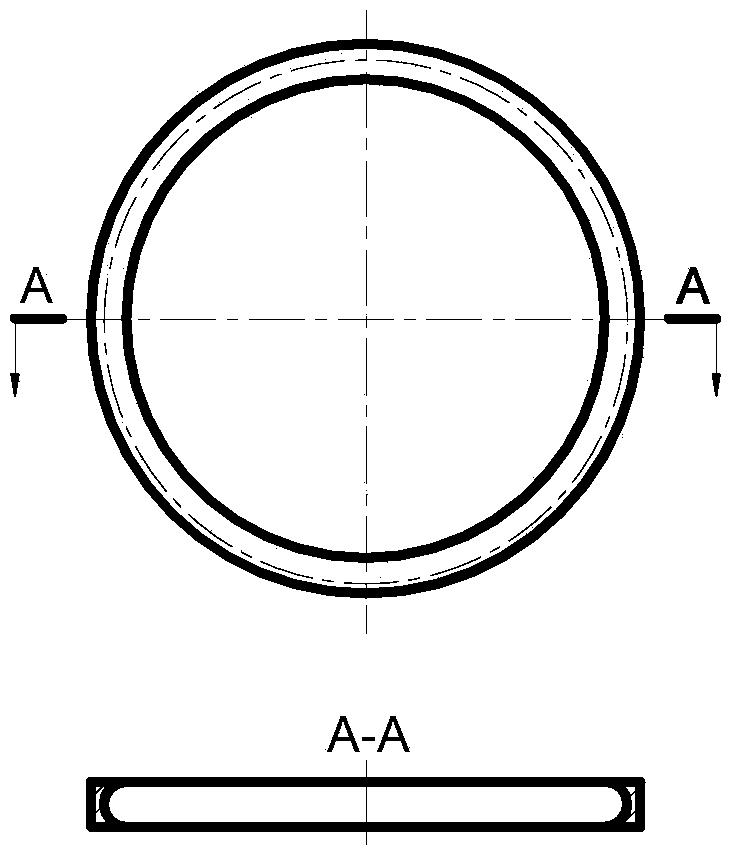

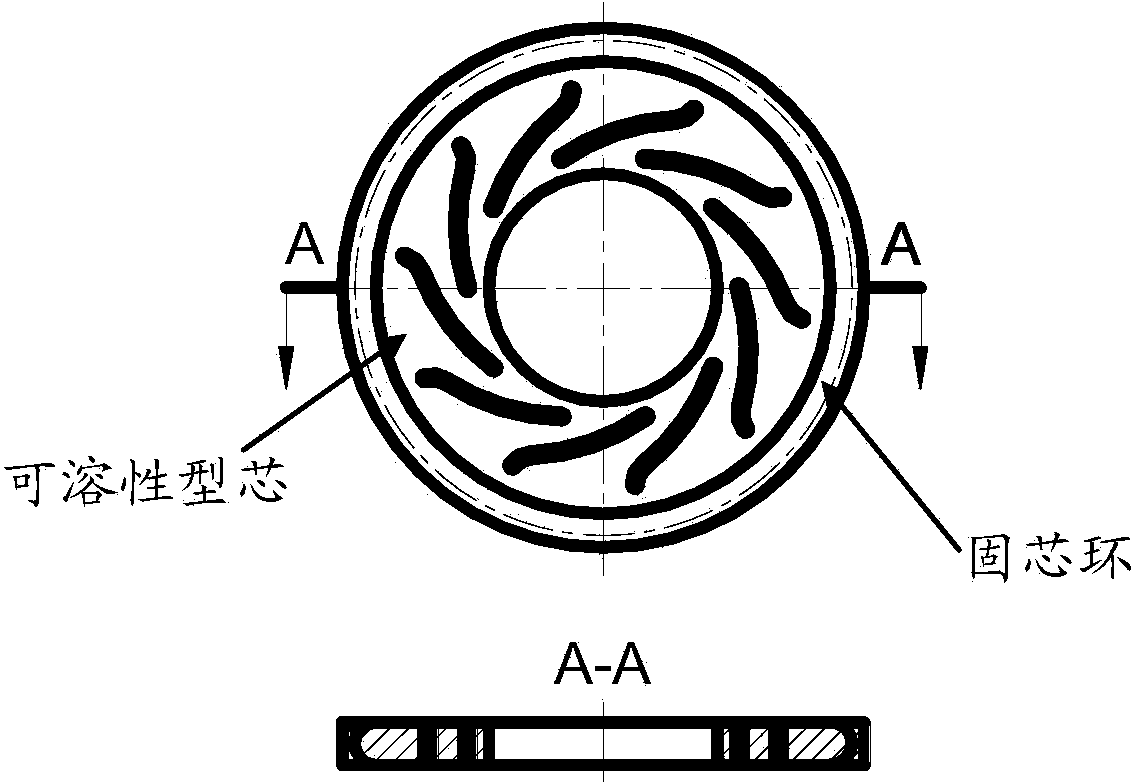

Core fixing ring and method for making soluble core of swirler

The invention relates to a tool for a making preciously cast soluble core, and a method thereof, and especially relates to a tool for making the soluble core of a swirler, and a method thereof. The method for making the soluble core of the swirler comprises the following steps: 1, placing a core fixing ring in a soluble core die, compacting according to technological parameters to form the soluble core, slightly wholly taking out the soluble core and the core fixing ring, and allowing the soluble core and the core fixing ring to stand on a flat sponge for a period of time; 2, placing the soluble core with the core fixing ring in a wax die, compacting according to technological parameters to form a wax mold, and allowing the wax mold to stand on the flat sponge for a period of time; and 3, putting the wax mold in a core removing pool, removing the core, taking out the ring fixing ring after the core is completely removed, cleaning, and air-drying the core fixing ring. The fracture phenomenon of the soluble core obviously decreases by adopting the tool, the method and the core fixing ring.

Owner:AECC AVIATION POWER CO LTD

Reinforced computer board card with pulling assisting and heat dissipation functions

ActiveCN111562828AAvoid damageGuaranteed firmnessDispersed particle filtrationDigital processing power distributionMechanical engineeringPhysics

Owner:AVIC POWER SCI & TECH ENG

Sealing frame glue coating device

ActiveCN106862011ASolve scrapImprove process capabilityLiquid surface applicatorsCoatingsProcess capabilityEngineering

The invention provides a sealing frame glue coating device. The sealing frame glue coating device comprises a glue frame coating mechanism used for spraying sealing frame glue in a set coating area of a to-be-coated base plate, and a track control mechanism used for controlling the frame glue coating mechanism to coat the set coating area with sealing frame glue, wherein the to-be-coated base plate is located below the frame glue coating mechanism. The frame glue coating mechanism synchronously moves along with movement of the track control mechanism, the track control mechanism can synchronously obtain the movement track of the to-be-coated base plate and conduct synchronous alignment with the to-be-coated base plate, and therefore the coating track of the frame glue coating mechanism can pass through the set coating area. According to the sealing frame glue coating device, the problem of abnormal frame glue coating caused by deflection of glass base plate incoming materials is solved, the frame glue coating track can be adjusted in time in the deflection direction of the glass incoming materials, the frame glue can be accurately sprayed to the set coating area, and the panel process capability is improved from the aspect of equipment.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Visual detection system in mask folding process and detection method thereof

PendingCN111336922ASolve scrapOvercome the shortcomings of high cost and complicated production processUsing optical meansDomestic articlesUltrasonic weldingVisual inspection

The invention relates to a visual inspection system in a mask folding process and an inspection method of the visual inspection system. The visual inspection system comprises a support, a first ultrasonic welding device, a second ultrasonic welding device and a pair of first hydraulic pressing devices, and the first ultrasonic welding device cuts folding seams at equal intervals along the center line of mask cloth; a folding mechanism for turning over and folding the mask cloth is arranged between the pair of first hydraulic pressing devices, and visual detection instruments for detecting themask cloth are distributed above the folding mechanism; the folding mechanism enables the folding seams in the mask cloth to be aligned with the visual detection instrument so as to shoot and detect the mask cloth through the visual detection instrument. The mask cloth is detected through cooperation of the folding mechanism and the visual detection instrument, production automation is achieved, and the defect that production equipment is high in cost is overcome; whether the mask cloth can be folded neatly or not is detected by comparing the tracks of the folding seams through a computer, andthe problem that the whole batch of masks are scrapped due to the fact that the masks are not folded in place at a time in the mask production process is solved.

Owner:安徽天航机电有限公司

TPE door seal granular material for refrigerator door

The invention discloses a TPE door seal granular material for a refrigerator door. The TPE door seal granular material is prepared from the following components in parts by weight: 40-50 parts of POE plastic, 30-50 parts of PP elastomer, 15-20 parts of SEBS, 5-15 parts of naphthenic oil, 0.2-0.6 part of an antioxygen, 0.2-0.6 part of a lubricant, 10-20 parts of a filler, and 0-5 parts of paint. The TPE door seal granular material has the characteristics of low temperature resistance, ageing resistance, better welding effect, high product yield, good sealing effect and the like, improves a sealing property of refrigerators and freezers, and prolongs the self service life per se.

Owner:ANHUI HIGASKET PLASTICS CO LTD

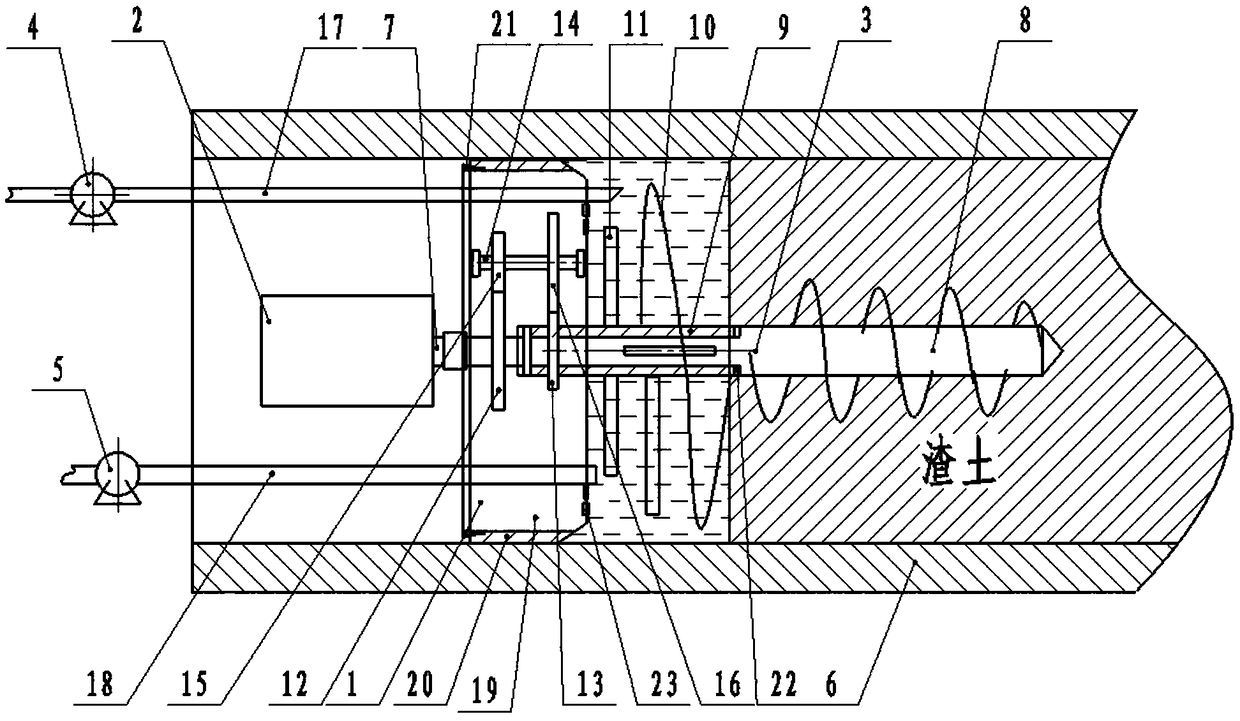

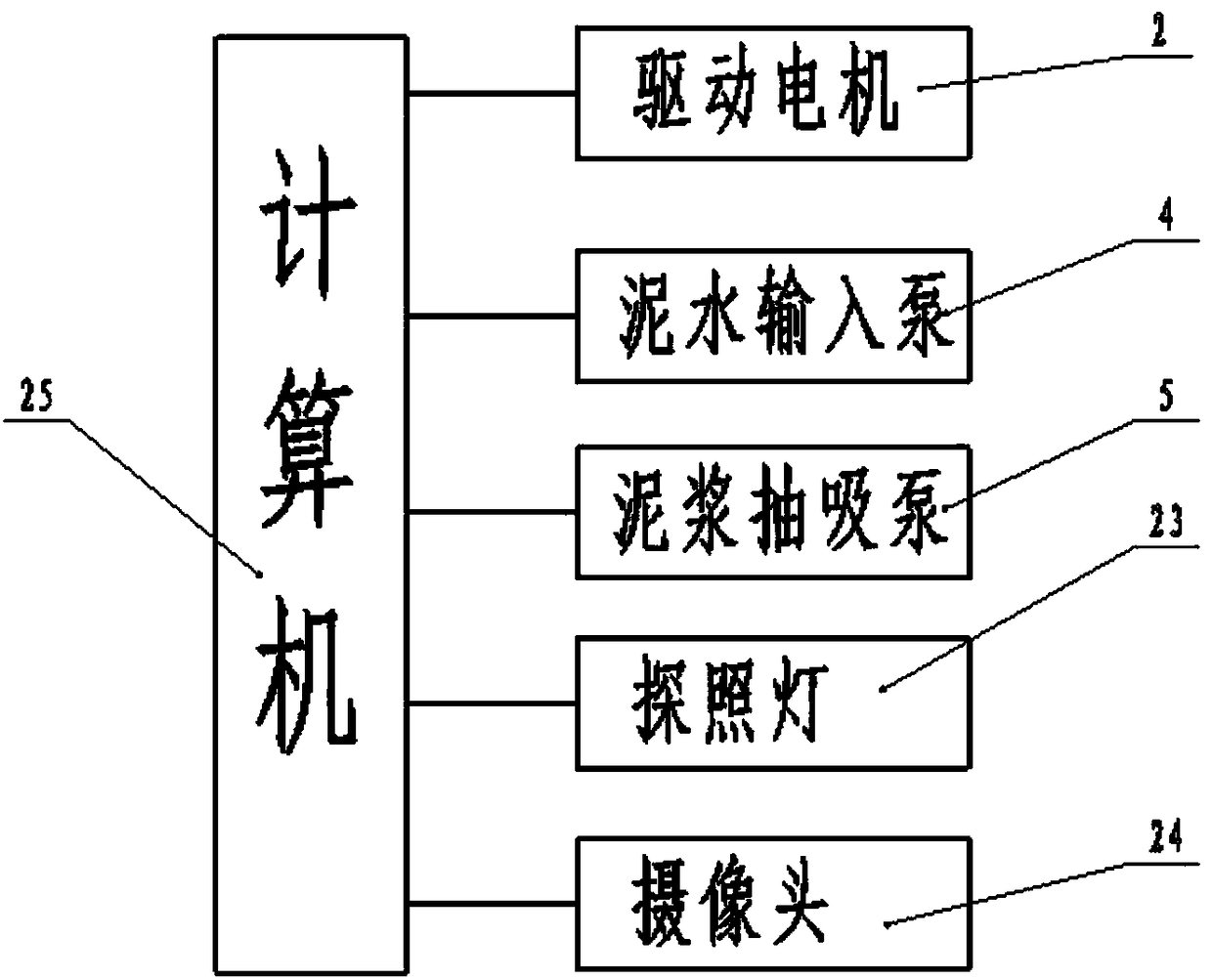

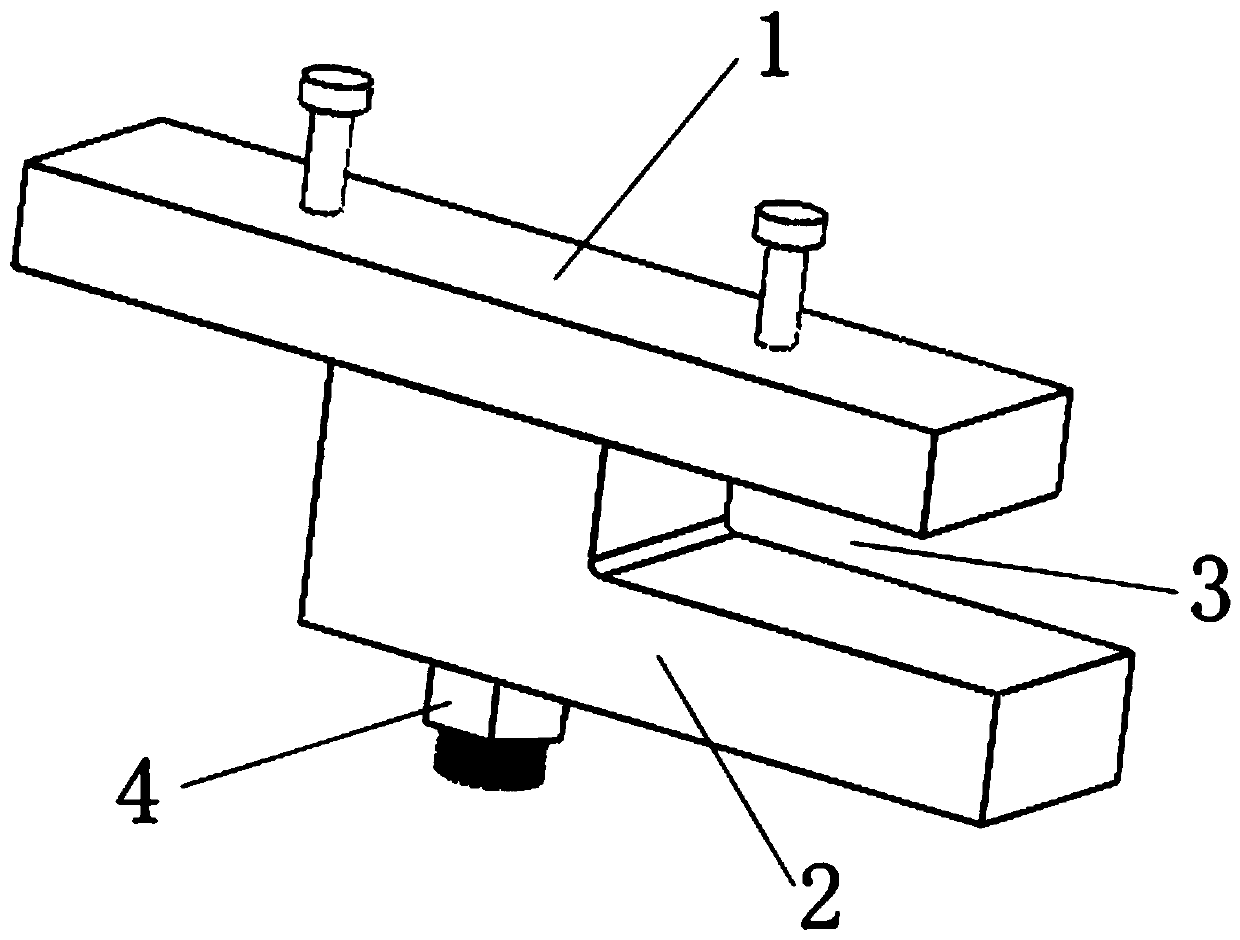

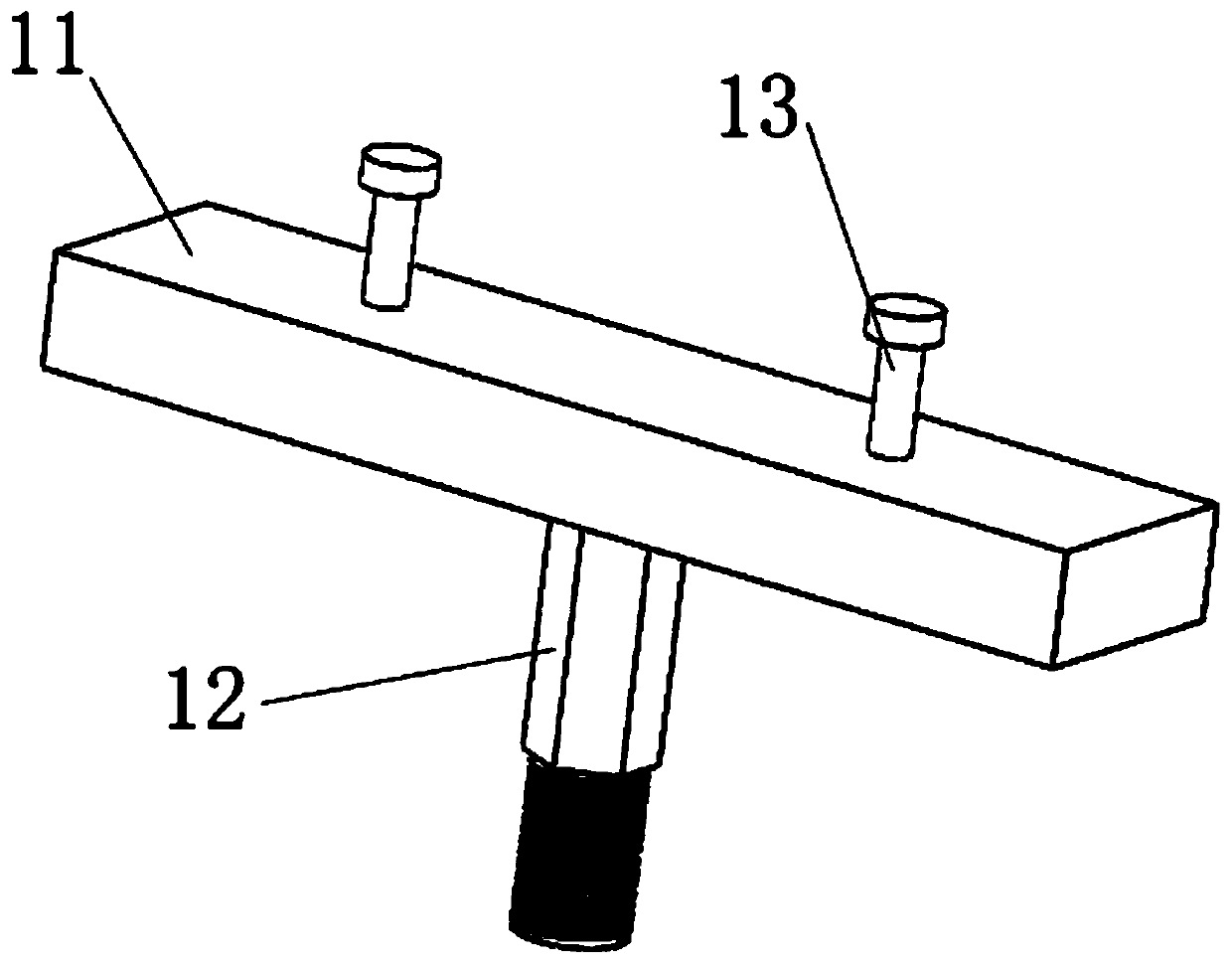

In-pipe waste soil transferring device and method after underground artificial pipe jacking for municipal environmental protection construction

ActiveCN108517910AImprove efficiencySave human effortSoil-shifting machines/dredgersSpiral bladeEngineering

The invention discloses an in-pipe waste soil transferring device and method after underground artificial pipe jacking for municipal environmental protection construction. The in-pipe waste soil transferring device comprises an annular sealing body, a driving motor, a rotating main shaft, a muddy water input pump and a mud slurry suction pump, wherein the annular sealing body is arranged in a jacking pipe; an annular surface of the annular sealing body is hermetically connected with an inner wall of the jacking pipe; the driving motor is arranged in the middle of the outer side of the annularsealing body; the outer end of the rotating main shaft hermetically penetrates through the center of the annular sealing body and is connected with an output rotating shaft of the driving motor; a feeding drill bit is arranged on an inner end shaft of the rotating main shaft; a rotating sleeve is arranged in the middle of the rotating main shaft in a sleeving manner; a soil loosening spiral bladeis arranged at the inner end of the rotating sleeve; a soil crushing block is arranged on the rotating sleeve positioned on the rear side of the soil loosening spiral blade; the rear end part of the rotating sleeve is arranged in the annular sealing body; a first speed change gear is arranged on the rotating main shaft positioned in the annular sealing body; a second speed change gear is arrangedon the rotating sleeve positioned in the annular sealing body; and a variable speed wheel shaft is arranged on one side, parallel to the rotating main shaft, in the annular sealing body.

Owner:重庆伯颜建筑工程有限公司

Steel-concrete composite beam connecting piece, steel-concrete composite beam and manufacturing method thereof

ActiveCN110469052AImprove crack resistanceIncreased durabilityLoad-supporting elementsBuilding material handlingEngineeringFlange

The invention relates to the technical field of steel-concrete composite beams, and discloses a steel-concrete composite beam connecting piece, a steel-concrete composite beam and a manufacturing method thereof. The steel-concrete composite beam connecting piece comprises a built-in fitting and a clamping member, thebuilt-in fitting and the clamping member are detachably connected, and a flange plate clamping cavity is formed between the built-in fitting and the clamping member. According to the steel-concrete composite beam connecting piece, the steel-concrete composite beam and the manufacturing method thereof, cracking performance and durability of a concrete plate in a negative bending moment area can be greatly improved, and maintenance and replacement of the structure can be facilitated.

Owner:BEIJING MUNICIPAL BRIDGE MAINTENANCE MANAGEMENT +1

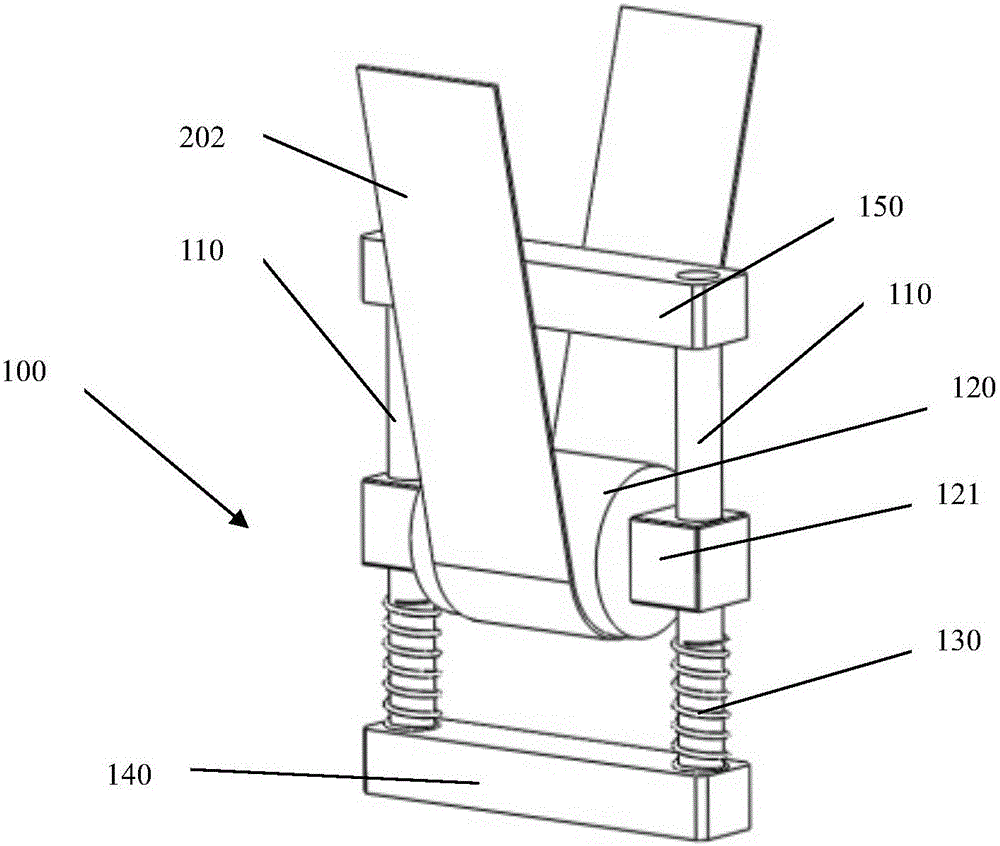

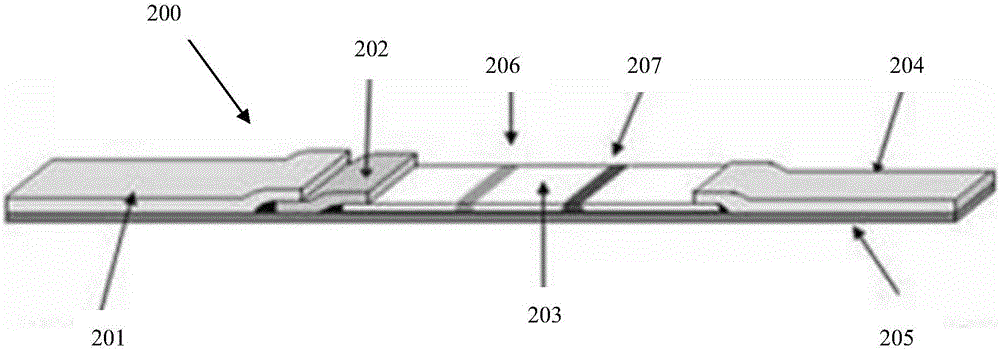

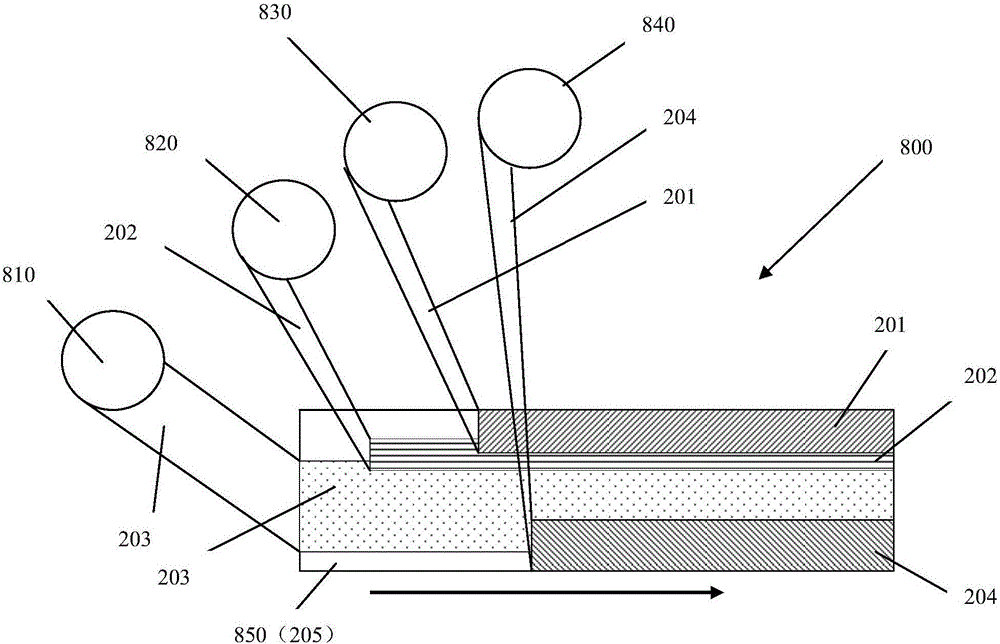

Stretching apparatus as well as equipment and method for assembling test strips

The invention relates to a stretching apparatus. The stretching apparatus is used for adjusting flexible sheet materials, and is used in a test strip assembling operation, the apparatus comprises two symmetrical columns and a roller which is positioned between two columns. The roller can move up and down relative to the column. The invention also relates to a piece of equipment including the stretching apparatus for assembling test strips and a method for assembling the test strips. The stretching apparatus ensures tight state of the flexible sheet materials which pass through, so that the phenomenon that partial flexible sheet materials have creases in the assembling production of the test strips is effectively prevented, abandonment of test strip products is prevented, and cost is saved. At the same time, assembling equipment with the apparatus and method for assembling test strips are the same, efficiency is high, and cost is saved.

Owner:ABON BIOPHARM HANGZHOU

Preparation method of vinyl silicone oil with low hydroxyl content

The invention discloses a preparation method of vinyl silicone oil with low hydroxyl content, which comprises the following steps: (1) adding a dimethyl siloxane ring body and an end capping agent into a reaction kettle with stirring and heating functions; (2) adding a catalyst, and reacting for 25 hours at the temperature of 80-110 DEG C; (3) adding a silicon hydroxyl eliminating agent, and reacting for 0.5-1.5 h; (4) breaking enzyme for 30-60 minutes; and (5) at the temperature of 160-180 DEG C and the vacuum degree of greater than 0.095, removing the solvent for 3-5 hours, cooling and filtering to obtain a finished product. Silicon hydroxyl in the vinyl silicone oil is eliminated by adopting the silicon hydroxyl eliminating agent, so that the process is simplified, the energy is saved, the efficiency is improved, the content of silicon hydroxyl in the vinyl silicone oil is reduced, and the quality of the vinyl silicone oil is improved.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Vibrating piezoelectric spray head system

PendingCN107097409AEasy to disassemble and repairSolve scrap3D object support structuresApplying layer meansFluid viscosityEngineering

The invention discloses a vibrating piezoelectric spray head system. The vibrating piezoelectric spray head system comprises a liquid storage cavity. A liquid supply connector is arranged above the liquid storage cavity. A liquid outlet is formed in the bottom of the liquid storage cavity. A piezoelectric ceramic vibrating mechanism used for vibrating so as to spray fluid is arranged at the bottom of the liquid storage cavity. The piezoelectric ceramic vibrating mechanism comprises an annular piezoelectric ceramic vibrating piece and a metal piece, wherein the annular piezoelectric ceramic vibrating piece and the metal piece are bonded together, convex conical holes communicating with the liquid outlet are formed in the annular piezoelectric ceramic vibrating piece and the metal piece, and a vibrating signal of the piezoelectric ceramic vibrating mechanism is guided in through an electrode on one side of the annular piezoelectric ceramic vibrating piece and an electrode on one side of the metal piece. Compared with the prior art, the vibrating piezoelectric spray head system is large in vibrating amplitude, and the problems that an existing printer spray head is prone to being blocked due to the fact that the fluid viscosity is large and is scrapped when severely blocked can be effectively solved.

Owner:GUIZHOU UNIV

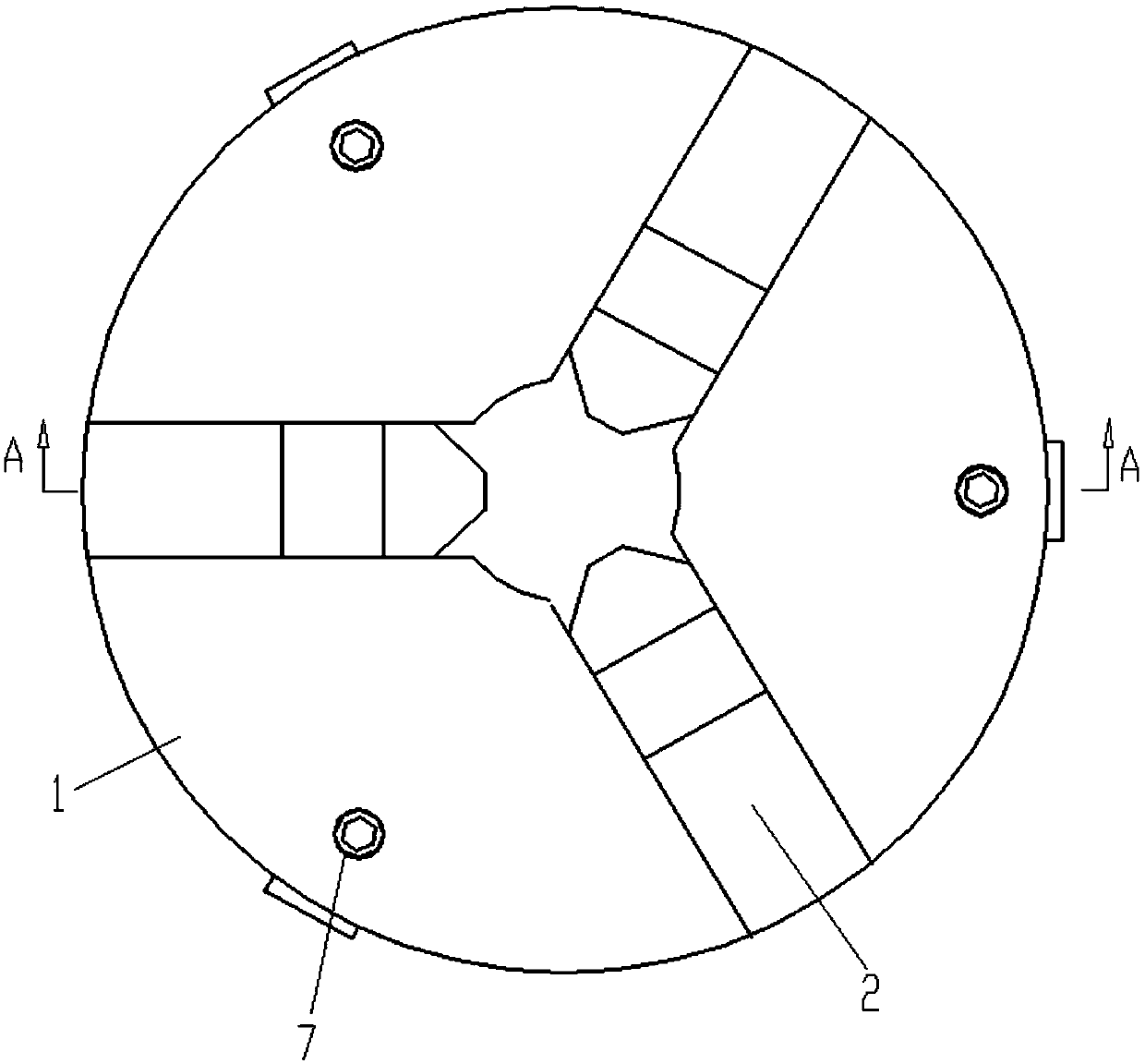

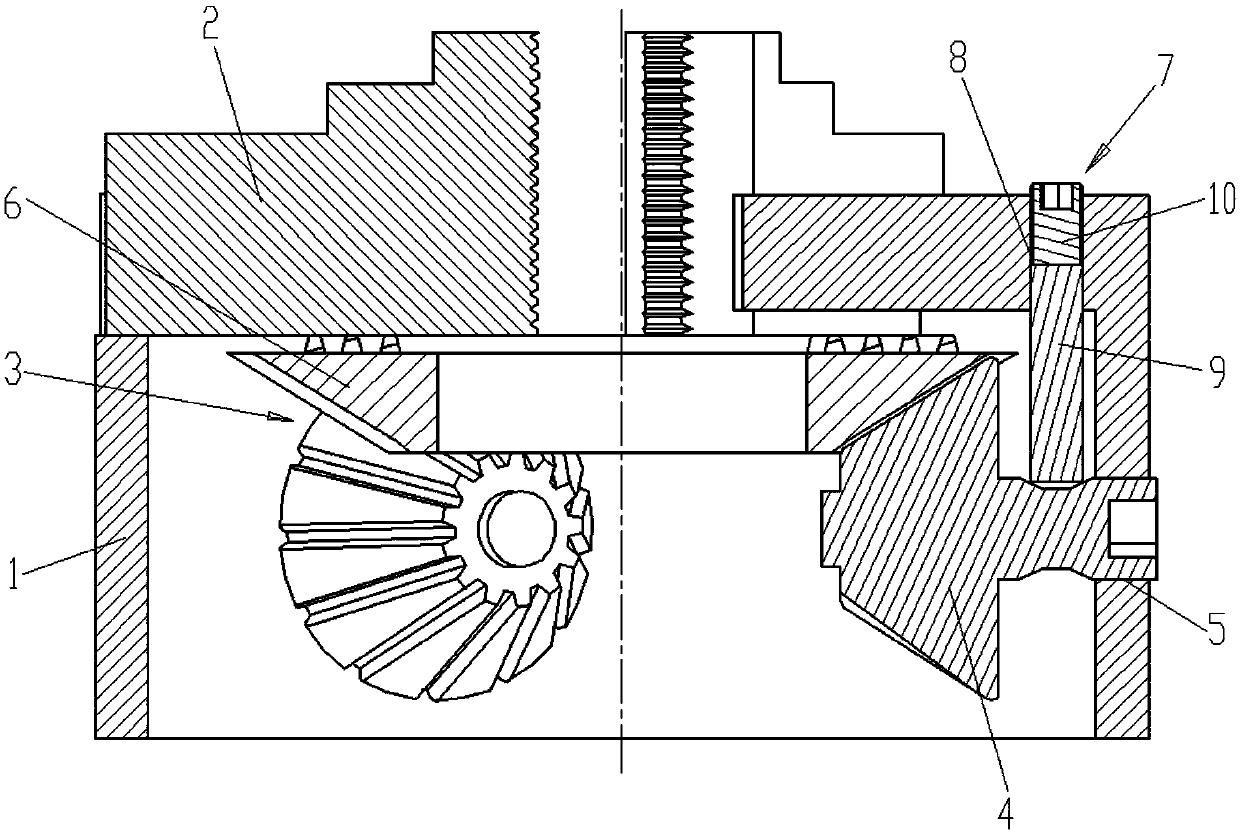

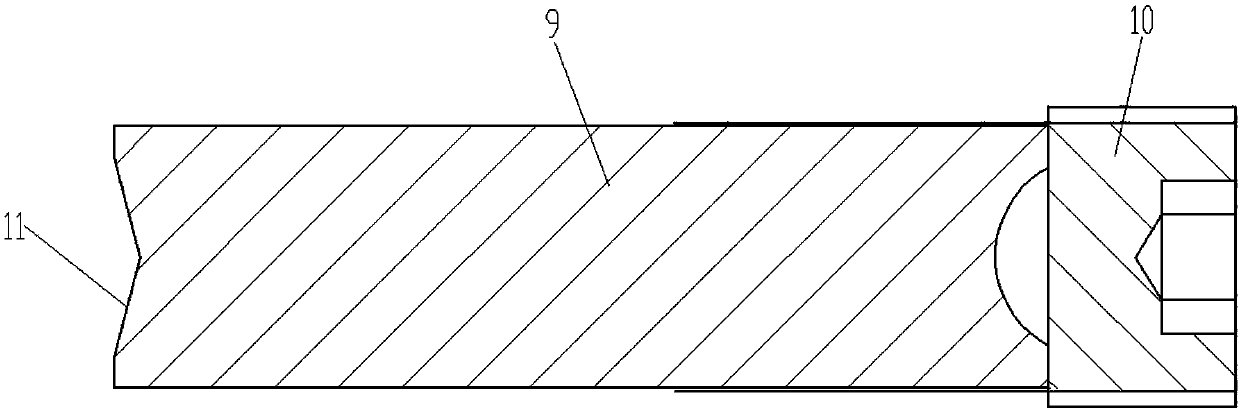

Manual three-jaw chuck with three-jaw micro-movement locking devices

The invention provides a manual three-jaw chuck with three-jaw micro-movement locking devices. The manual three-jaw chuck comprises a chuck body. Three movable jaws are uniformly arranged on the uppercircumference of the chuck body. A jaw driving mechanism for driving the three movable jaws to move is arranged in the chuck body. The jaw driving mechanism comprises a butterfly bevel gear arrangedin the chuck body to drive the movable jaws to move and three bevel pinions, wherein the three bevel pinions are uniformly supported in the chuck body in the circumferential direction and engaged withthe butterfly bevel gear to drive the butterfly bevel gear to rotate. The three-jaw micro-movement locking devices are uniformly arranged on the circumference of the upper end surface of the chuck body. The three-jaw micro-movement locking devices correspond to the three bevel pinions and lock the rotation of the bevel pinions to limit the micro-movement of the three movable jaws relative to thecenter of the chuck. The manual three-jaw chuck solves the problems that the three movable jaws move outwards relative to the center of the chuck due to various factors, and the clamping force is continuously reduced, so that the workpiece clamping is not tight and the three jaws withdraw, and the problems of scrapping and flying out of the chuck caused by the untight workpiece clamping are avoided.

Owner:SHAANXI BAOCHENG AVIATION INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com