Core fixing ring and method for making soluble core of swirler

A soluble and vortex technology, applied in the direction of core, casting mold, casting mold composition, etc., can solve the problems of vortexer wax mold throat size out of tolerance, soluble core cracks, wax mold casting scrap, etc., to achieve suitable Effects of promotional use, reduction of breakage phenomenon, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

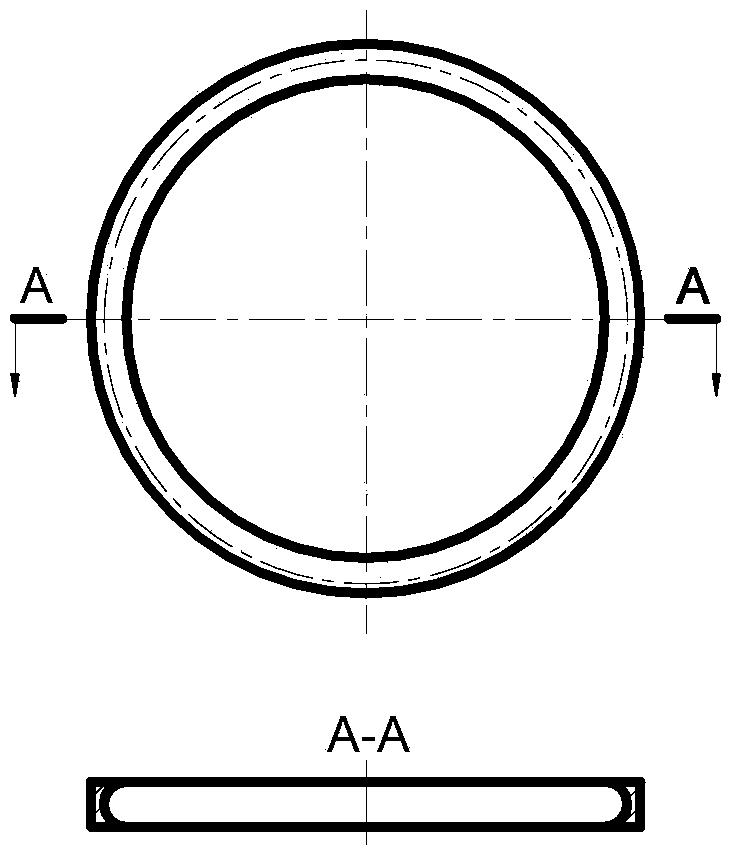

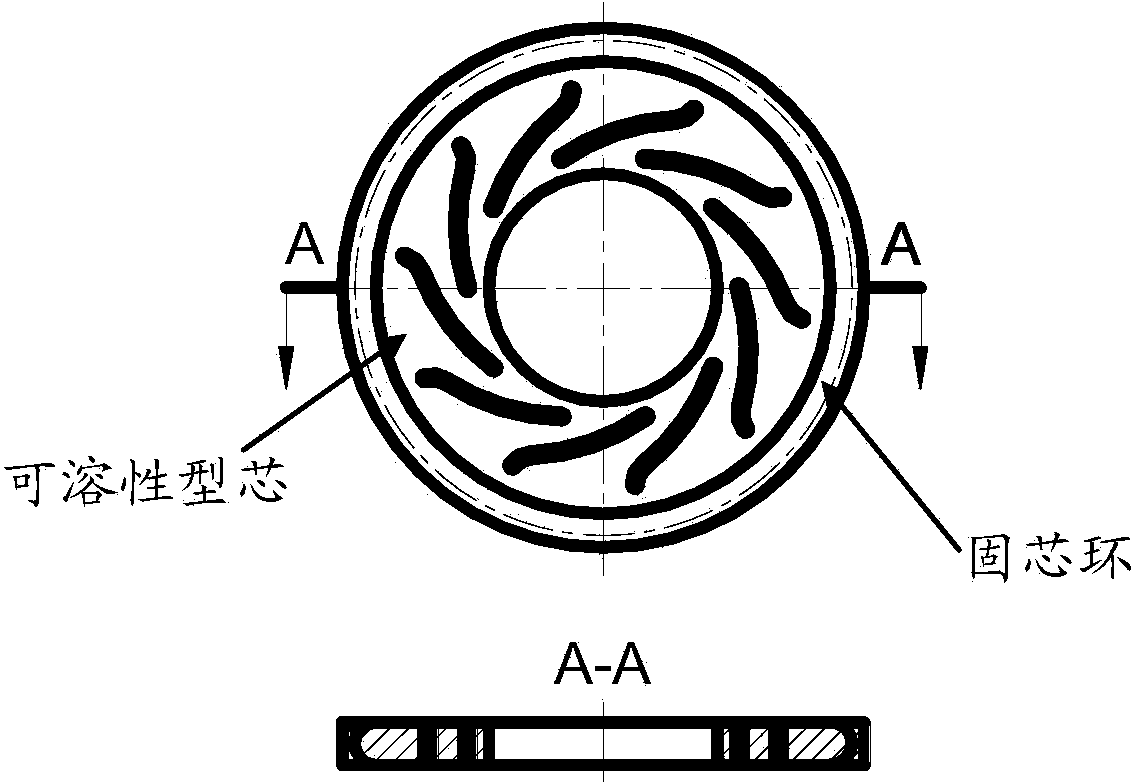

[0021] The specific implementation method: on the basis of the soluble core mold of the main vortex device of a certain machine, a solid core ring is added (such as figure 1 ). The solid core ring is made of corrosion-resistant 2Cr13, and its section thickness is the same as that of the soluble core mold cavity. The radius of the ring is 3mm larger than that of the inner ring and must match the inner cavity of the soluble core mold and the wax mold.

Embodiment approach

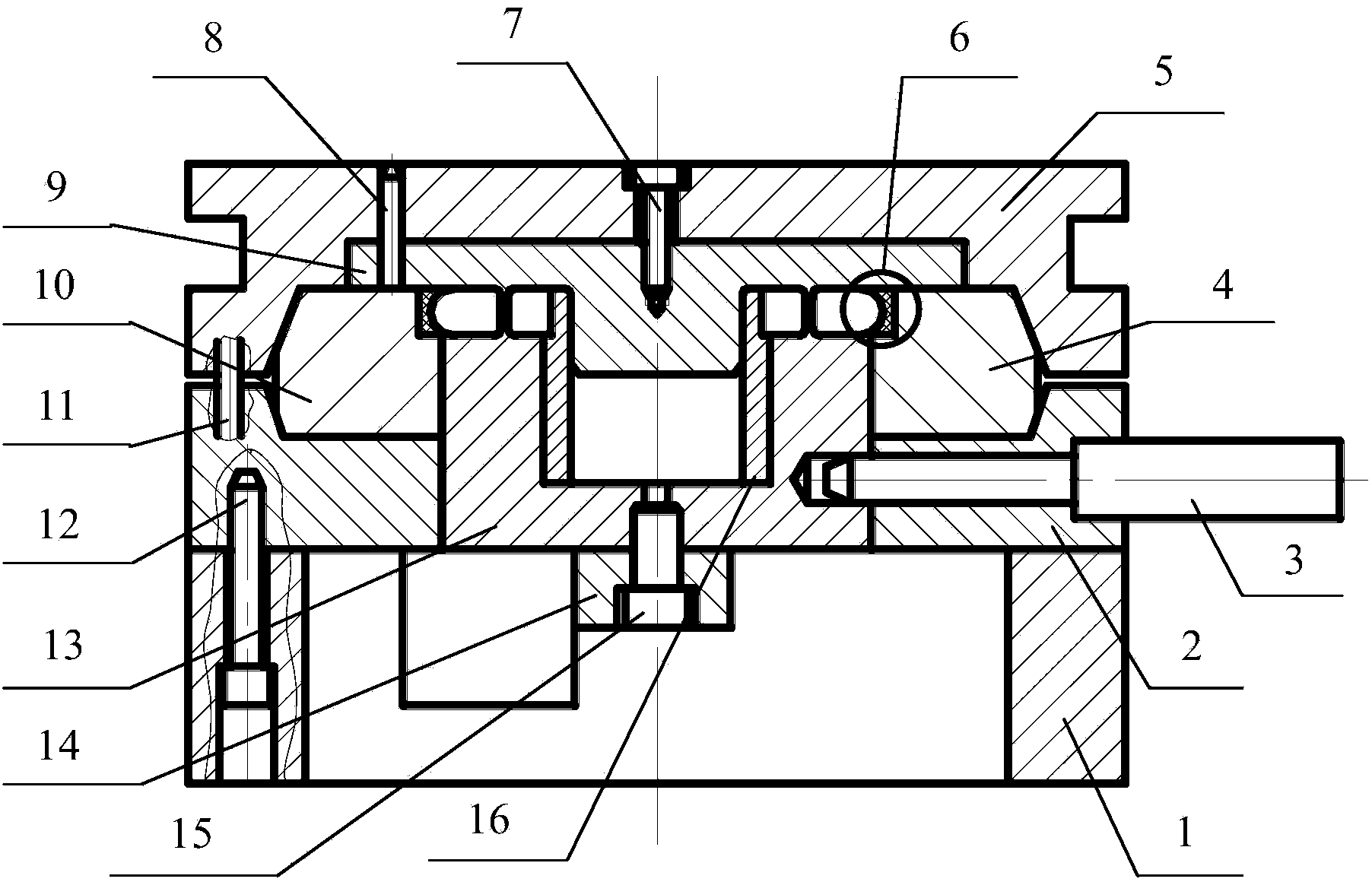

[0022] Implementation method: 1. The solid core ring is placed in the soluble core mold (such as figure 2 ), during installation, first the base 1 is connected with the lower mold 2 through the hexagonal screw 12, the pressure plate 14 is connected with the core 13 through the hexagonal screw 15, and the core 13 and the lower mold 2 are matched through the positioning pin 3 to form the lower mold core core mechanism , then the upper mold 5 and the core 9 are connected through the positioning pin 8 and the hexagonal screw 7 to form the upper mold core mechanism, the left half mold 10 and the right half mold 4 are placed in the lower mold core mechanism, and then the solid core ring is placed in the corresponding position (attached figure 2 ). Finally, the upper model core mechanism and the lower model core mechanism carry out mold matching through the positioning pin 11 . After pressing the soluble core according to the process parameters, the soluble core and the solid cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com