Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Cause scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

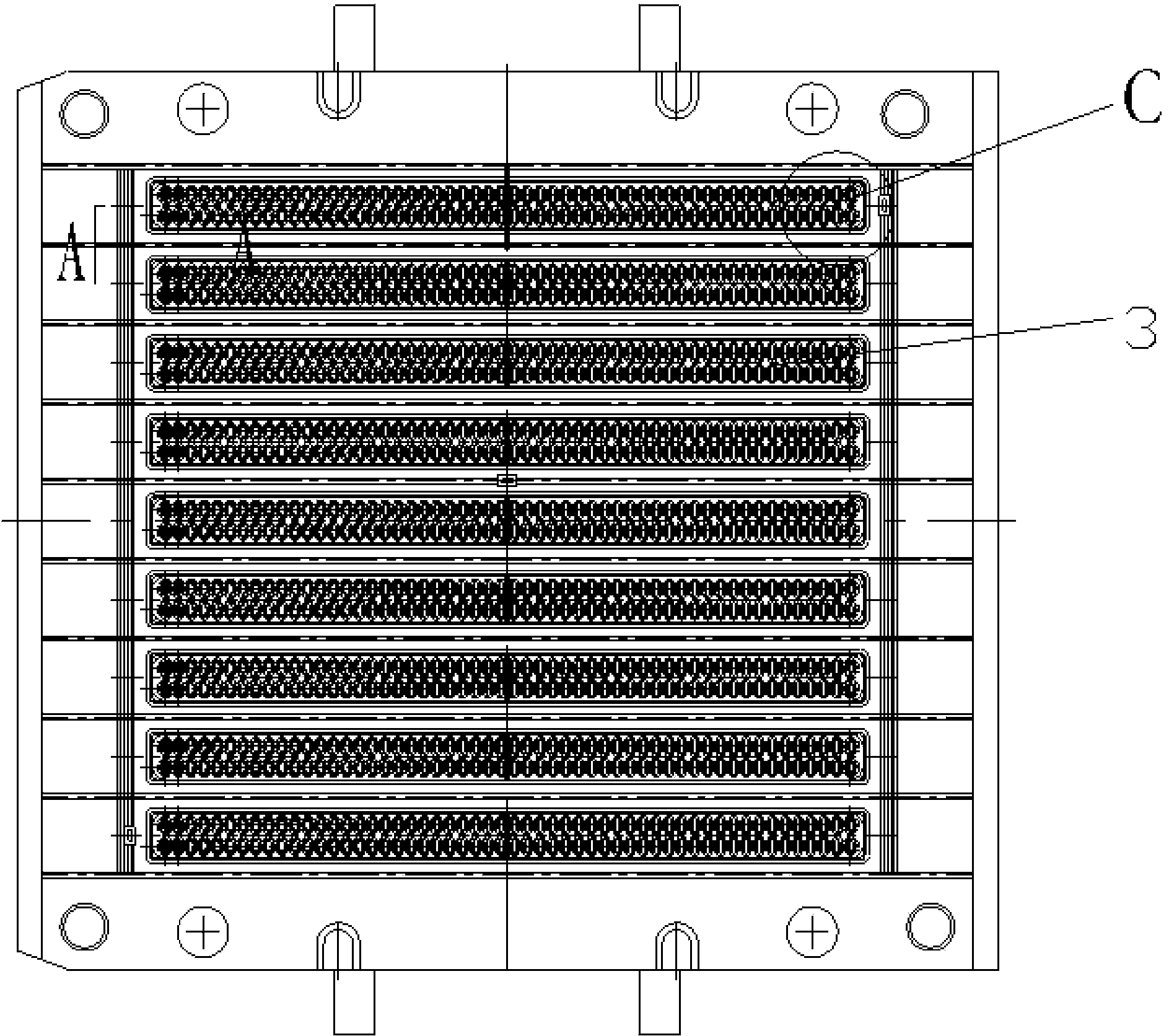

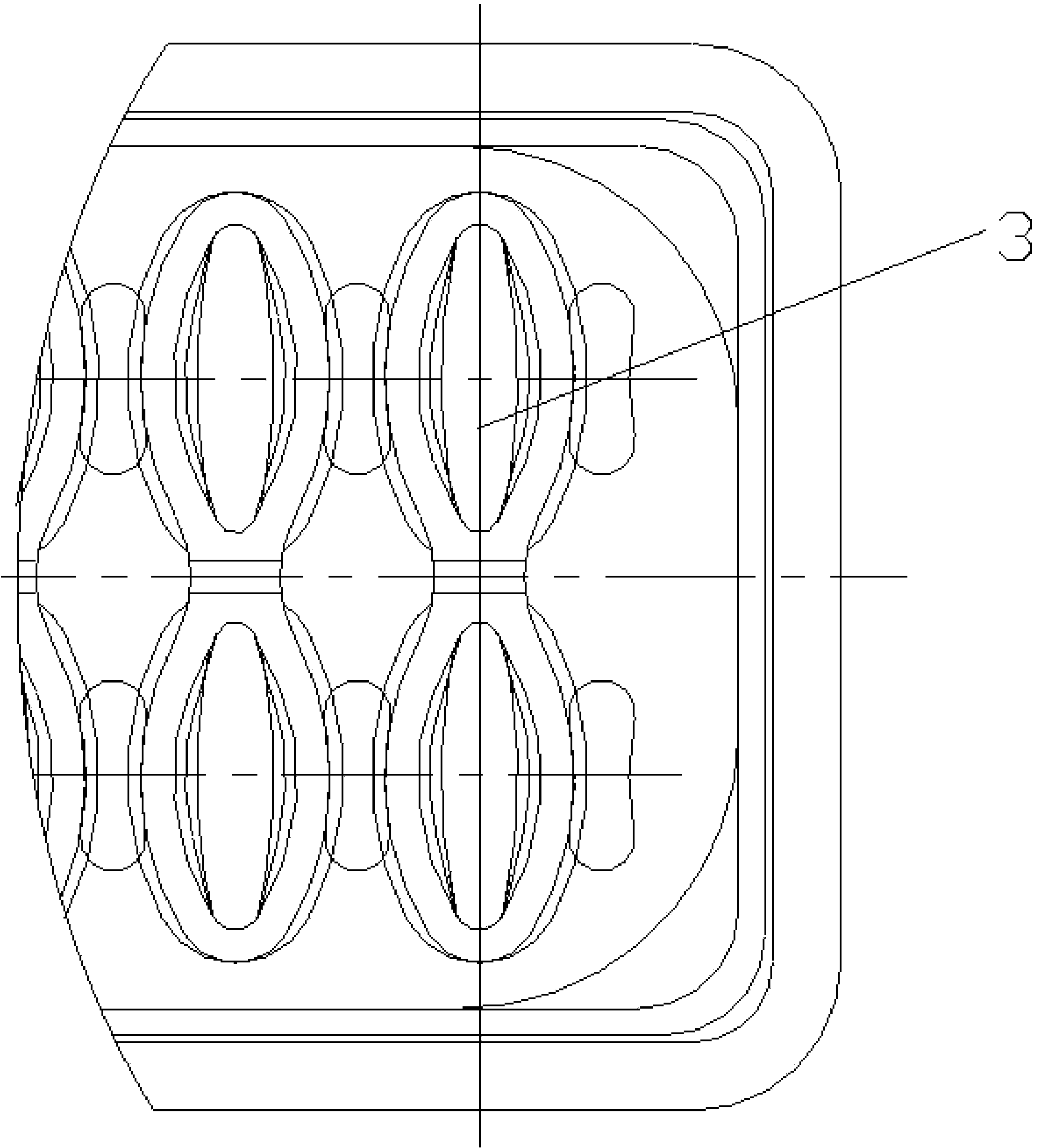

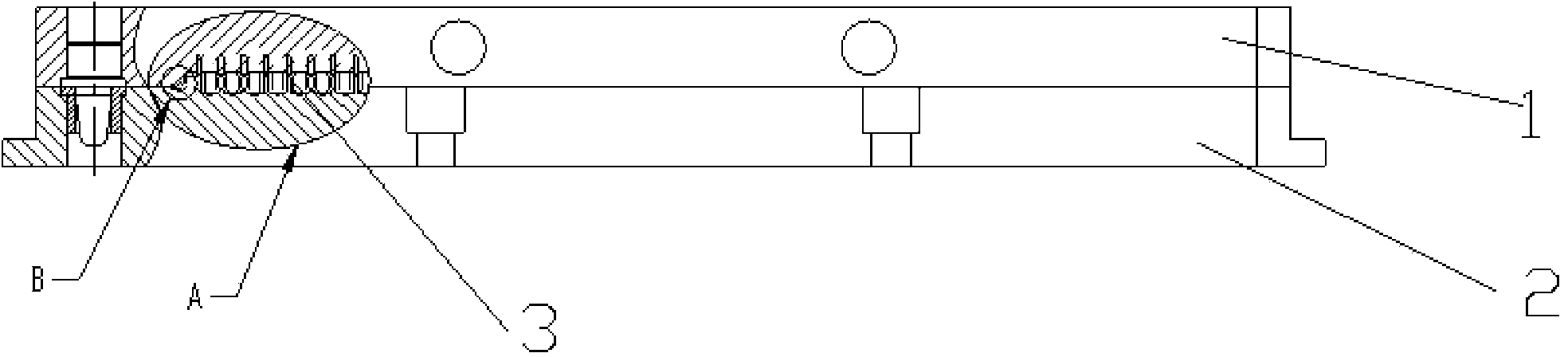

Sealing strip mold and mold machining process

The invention discloses a sealing strip mold and a mold machining process, belonging to the technical field of mold machining and structural design and designed for solving the problems of an existing mold that an edge tearing groove is not reasonable to machine so that the mold is abandoned and the like. The sealing strip mold comprises a first template and a second template which are arranged in an overlapped manner, and a plurality of cavities which are formed between the first template and the second template and are arrayed in parallel; a circular-arc-shaped edge tearing groove with the depth being 0.7mm-0.9mm is arranged at the outer part of each cavity between the first template and the second template. The suitable edge tearing groove is machined on the mold so that flashes can be removed well and the abandoning risk of the mold is reduced. The sealing strip mold is simple in machining process and the accuracy of the machined edge tearing groove is high.

Owner:安徽宁国中鼎模具制造有限公司

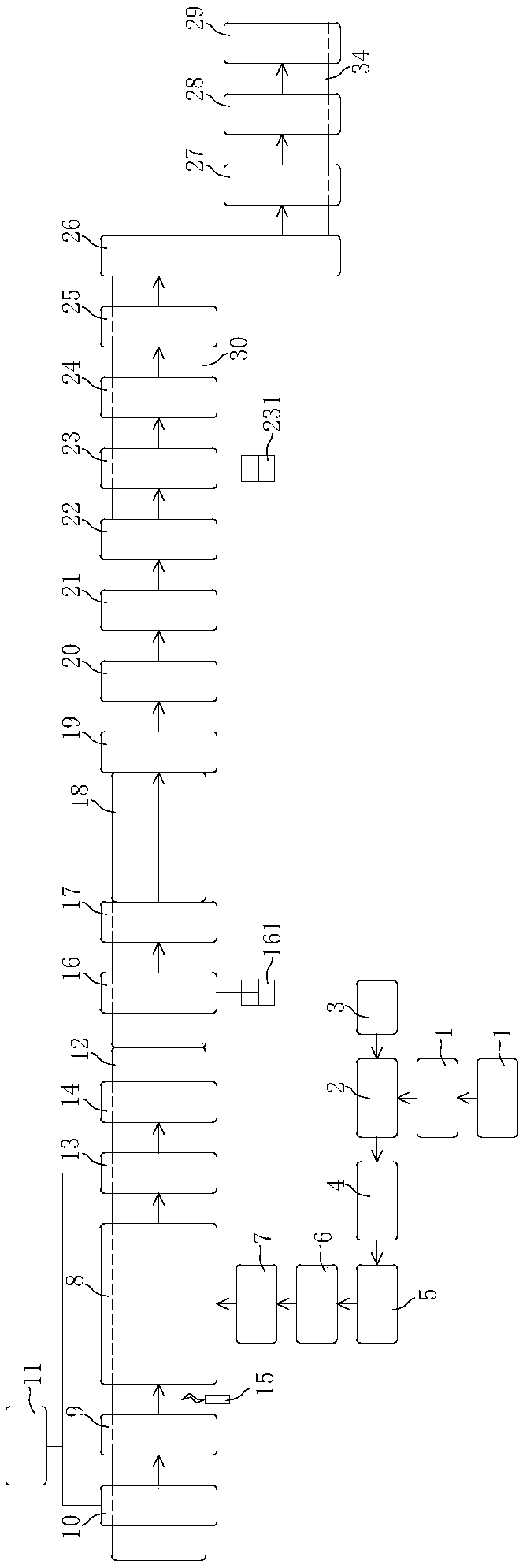

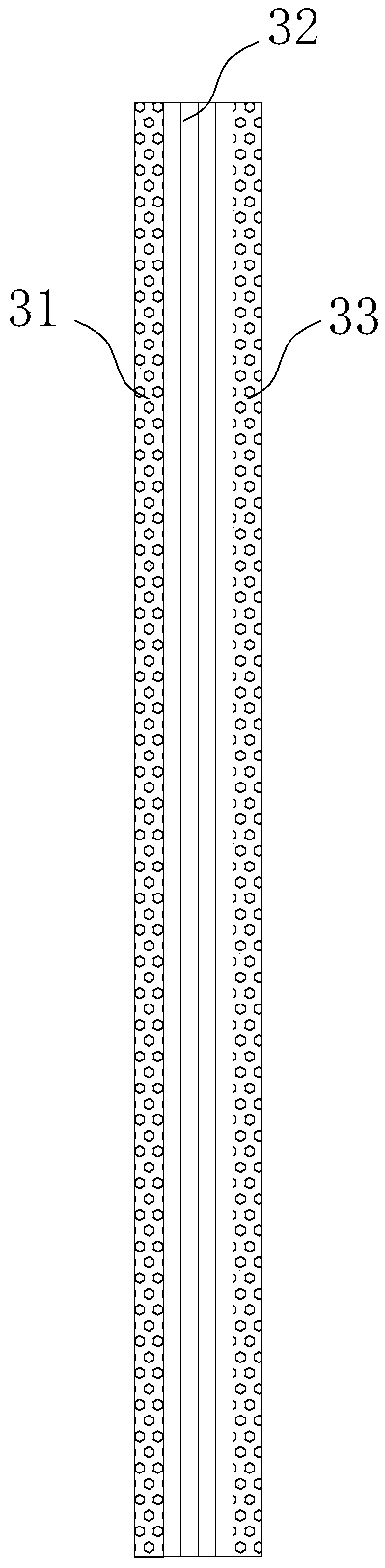

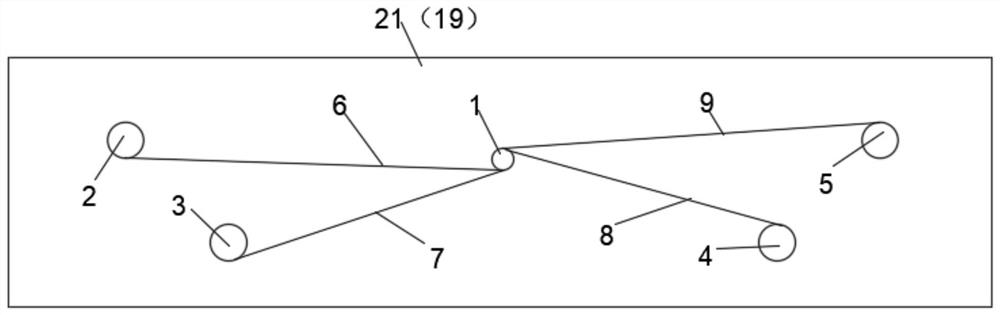

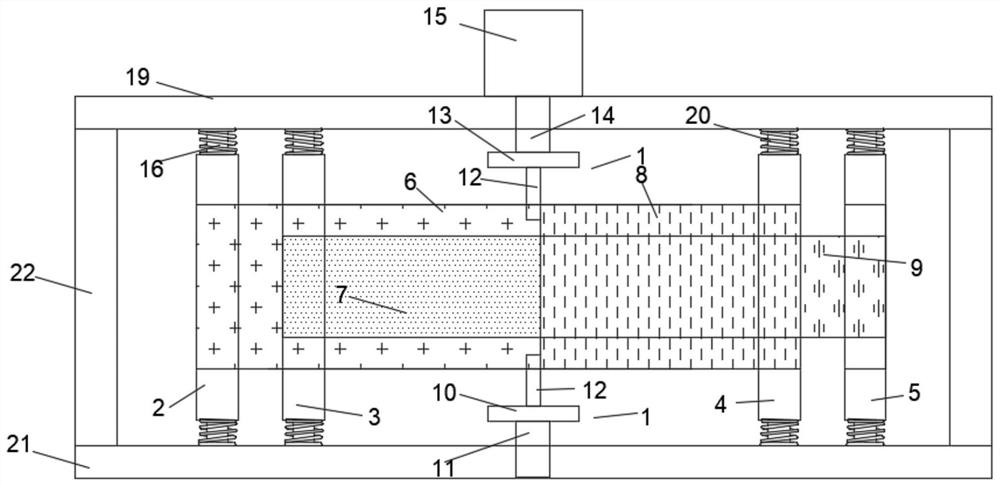

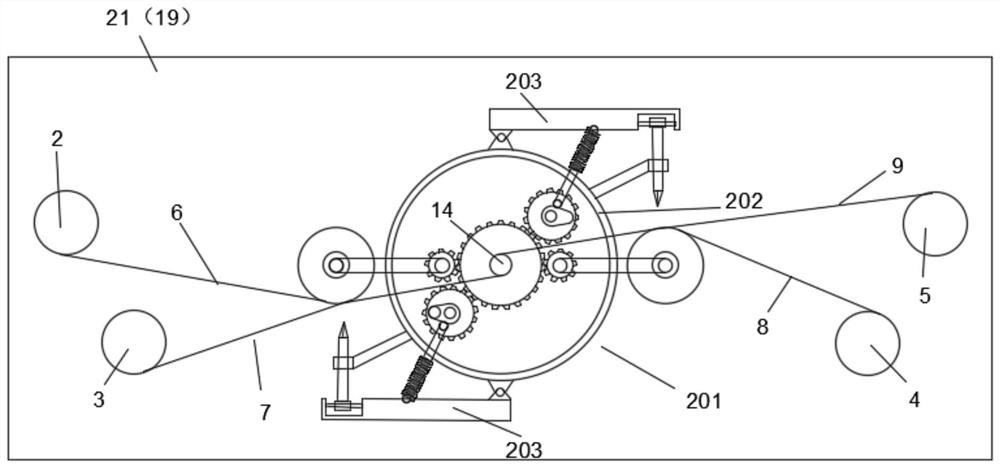

Manufacturing method and production line of composite panels

PendingCN108943210AFlat surfaceConducive to the subsequent veneer processOther plywood/veneer working apparatusProduction lineSurface layer

The invention belongs to the technical field of wood panel production and discloses a production line of composite panels. The production line comprises a lower surface layer paving working position,a first prepressing working position, a bonding working position, an upper surface layer paving working position, a second prepressing working position and a hot pressing working position, and furthercomprises a conveying device. The lower surface layer paving working position, the first prepressing working position, the bonding working position, the upper surface layer paving working position, the second prepressing working position and the hot pressing working position are sequentially arranged. The conveying device is used for conveying materials to each working position. The bonding working position is provided with two material inlets, wherein one material inlet of the bonding working position is connected with a material outlet of the first prepressing working position, and the other material inlet is provided with a glue applying working position. A manufacturing method comprises the following steps of: manufacturing raw materials for surface layers, gluing plywood, manufacturing the lower surface layer, bonding the lower surface layer, manufacturing the upper surface layer, hot pressing and stacking. The manufacturing method enables the production efficiency to be high through a specially designed one-time hot pressing molding, reciprocating plate feeding and paving process, and enables a plywood layer and the surface layers to be more tightly combined and protected against easy degumming and cracking.

Owner:成都市荣胜木业有限公司

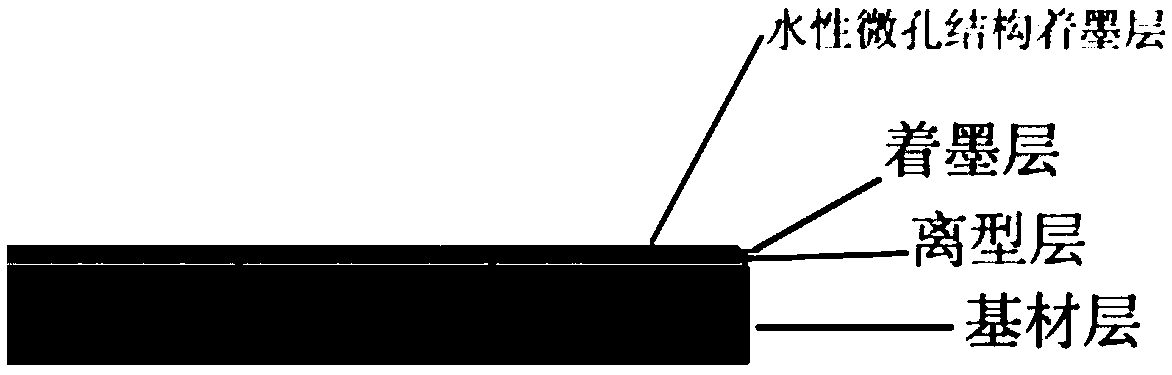

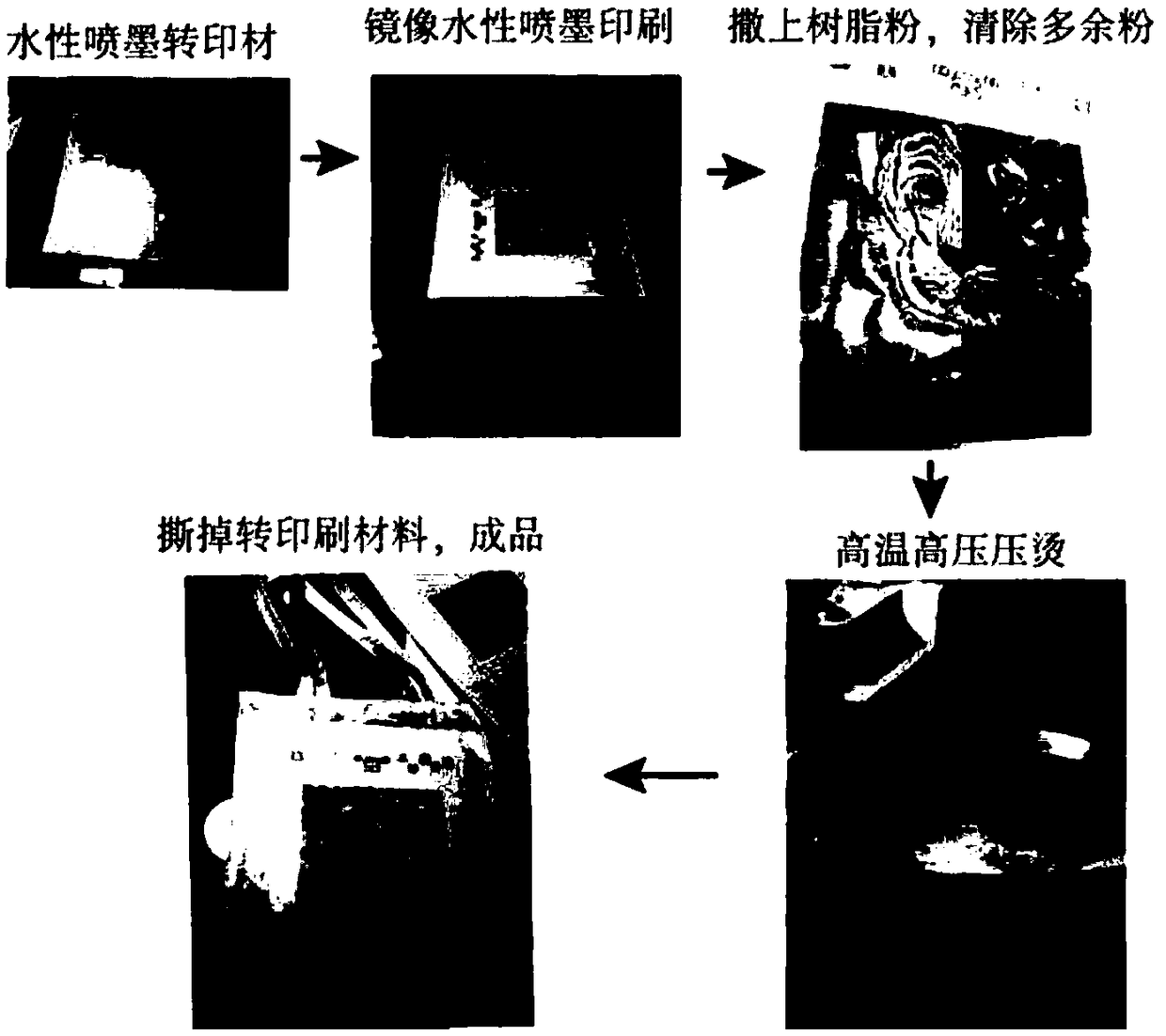

Water-based ink jet transfer printing method for textile personalized printing

ActiveCN109334292ASoft touchColorfulPrinting after-treatmentInk transfer from master sheetIonColor printing

The invention discloses a water-based ink jet transfer printing method for textile personalized printing. A water-based ink jet transfer printing material sequentially comprises a base material layer,a release layer and an inking layer; the release layer is a PP release layer; the inking layer is formed by mixing 50-85 parts of deionized water, 1-30 parts of nano SiO2 emulsion of which the solidcontent is 20-48%, 0.1-10 parts of sodium alginate and 0.1-3 parts of butynediol ethoxylate and / or butynediol, ink jet printing is conducted on one side of the inking layer to form a mirror image, powdered resin is uniformly spread on the surface of the mirror image, the surfaces of the non-mirror-image positions are cleaned, one side of the image covered with the powdered resin is put on a textile at the temperature of 120-160 DEG C and subjected to high-temperature high-pressure pressing for 8-240 s, cooling is conducted, and a printed textile is obtained by peeling off the transfer printingmaterial; and color printing of textiles of various materials can be achieved, the obtained textile is soft in hand feel, bright in color, resistant to water washing, high in weather resistance and breathable, color restore is better compared with that of direct spraying, the fastness is far higher than that of a direct spraying textile, and the rejection rate is greatly reduced.

Owner:上海嵩阳印刷科技有限公司

Quick-drying type environmental protection water epoxy floor paint and preparation method thereof

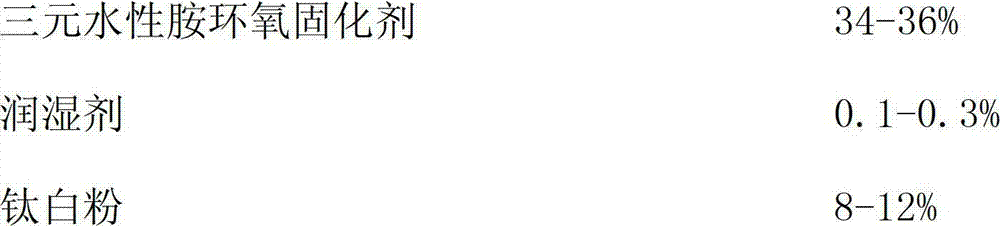

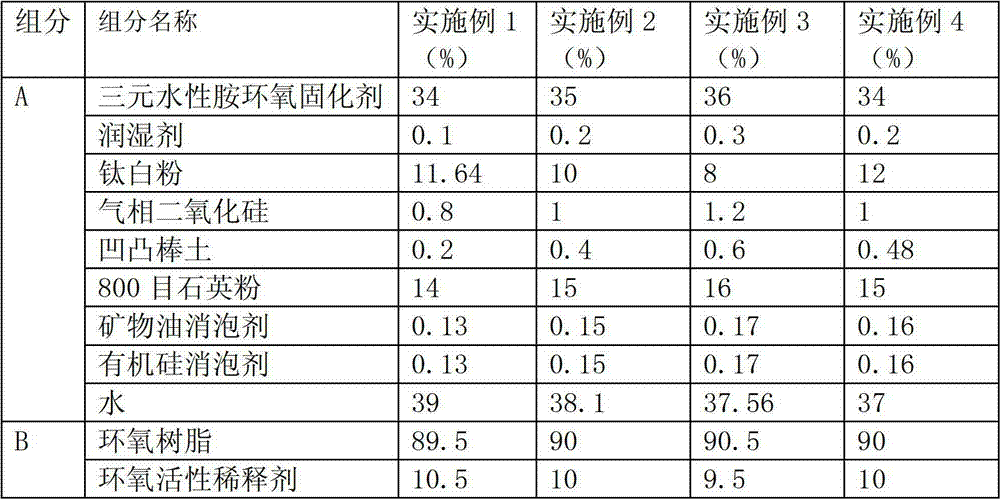

The invention discloses quick-drying type environmental protection water epoxy floor paint and a preparation method thereof. The floor paint consists of the following components in percentage by weight: component A: 34-36 percent of ternary water amine epoxy hardener, 0.1-0.3 percent of moistening agent, 8-12 percent of titanium pigment, 0.8-1.2 percent of gaseous phase silica, 0.2-0.6 percent of palygorskite, 14-16 percent of 800-porous silicon powder, 0.13-0.17 percent of mineral oil defoaming agent, 0.13-0.17 percent of organic silicon defoaming agent, and 37-39 percent of water, and the summation of weight ratios of the component A is one hundred percent; component B: 89.5-90.5 percent of epoxy resin, and 9.5-10.5 percent of epoxy activated diluent, and the summation of weight ratios of the component B is one hundred percent; and the component A and the component B are uniformly mixed according to a weight ratio of 4:1. The preparation method comprises the following three steps of preparing the component A, preparing the component B and preparing epoxy floor paint. According to the epoxy floor paint and the preparation method thereof, excellent property of the coating layer is obtained, the time of surface drying and actual drying is greatly shortened, the uniformity of the paint is better, the epoxy floor paint is environment-friendly, and has good compatibility with water color paste.

Owner:中山蓝海洋水性涂料有限公司

Quick-drying type water-borne mental corrosive-resistant paint and preparation method thereof

InactiveCN106867362AImprove anti-corrosion performanceLong activation periodAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention provides quick-drying type water-borne mental corrosive-resistant paint and a preparation method thereof. The quick-drying type water-borne mental corrosive-resistant paint is prepared from an ingredient A and an ingredient B, wherein the ingredient A is prepared from water-borne acrylic resin emulsion and water-borne modified fatty amine curing agent blended resin; the ingredient B is epoxy resin. A water-borne epoxy technology and a water-borne acrylic technology are creatively compounded and applied, so that a product has a long activation period and fast drying speed; the construction is convenient; healthy and environment-friendly effects are achieved; a paint film has the performance advantages such as high hardness, high impact resistance and excellent adhesive force; the quick-drying type water-borne mental corrosive-resistant paint can be widely applied to decoration and protection of metal substrates such as galvanized plates, tinplate, stainless steel and aluminum-plastic plates.

Owner:中山蓝海洋水性涂料有限公司

Module connector

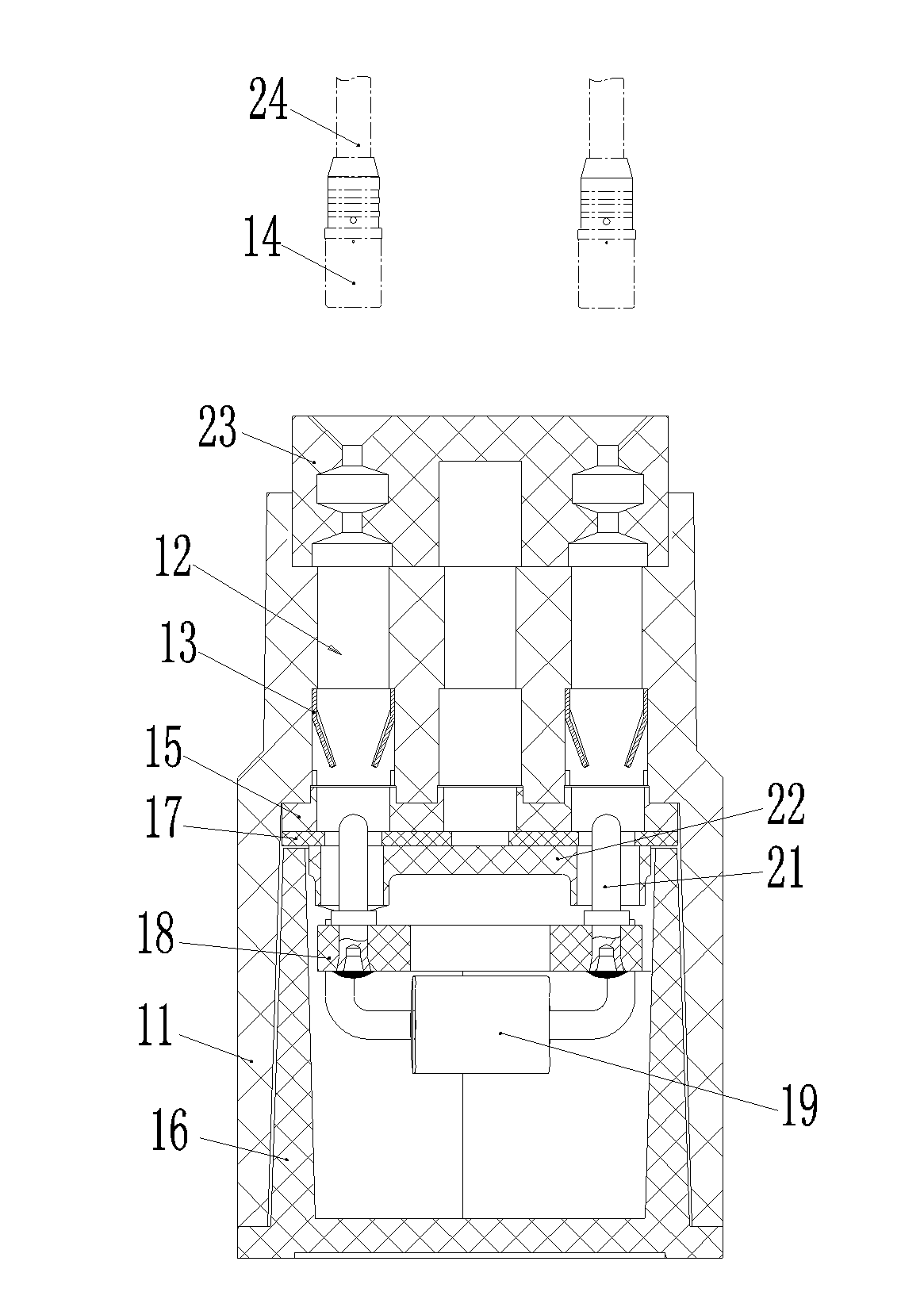

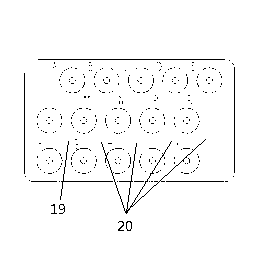

ActiveCN103066457ACause scrapSolve scrapCoupling contact membersCouplings bases/casesElectricityComputer module

The invention relates to the field of electric connectors, in particular to a module connector. The front end of the module connector is a plug end. The module connector comprises a shell body. A printed plate is arranged in the shell body in a fixed mode. At least one kind of functional module is arranged on the printed plate. Each functional module is provided with at least one substitute module. The each functional module and the substitute module thereof are respectively provided with respective external contact element. When in use, fracture places of corresponding circuit are respectively connected with the corresponding contact elements. The corresponding functional module is enabled to be in use through that the contact element is connected with the external contact element of the module connector in an inserted mode. When one of the functional modules is damaged, due to the fact that the external contact element of the damaged functional module is separated from the contact element of the circuit, the contact element of the circuit is connected with the corresponding substitute module in an inserted mode, and therefore the corresponding device can continue to work. The whole scrap of the printed plate caused by any damaged element is avoided. The problem that the existing printed plated scraps when any element is damaged is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

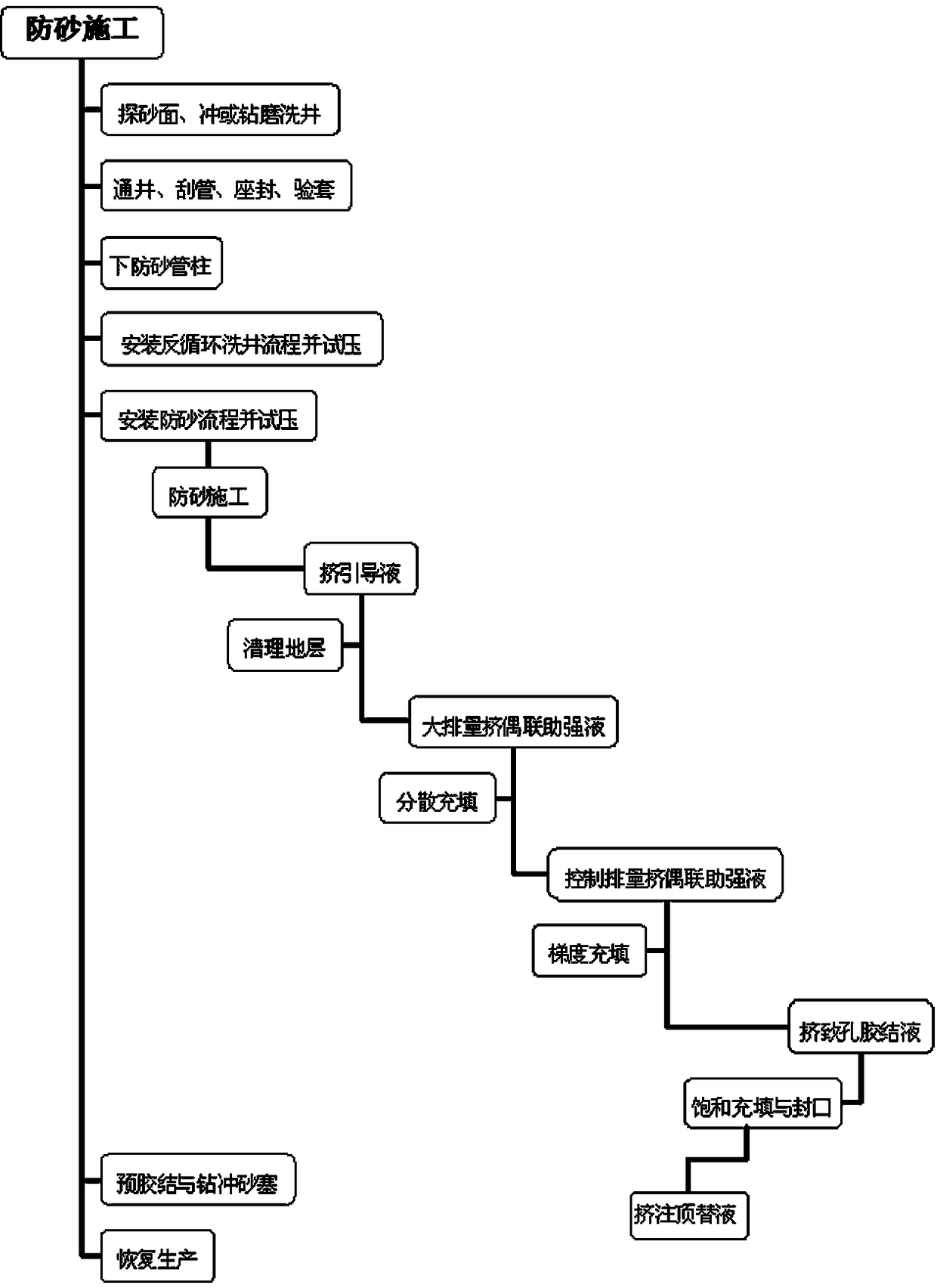

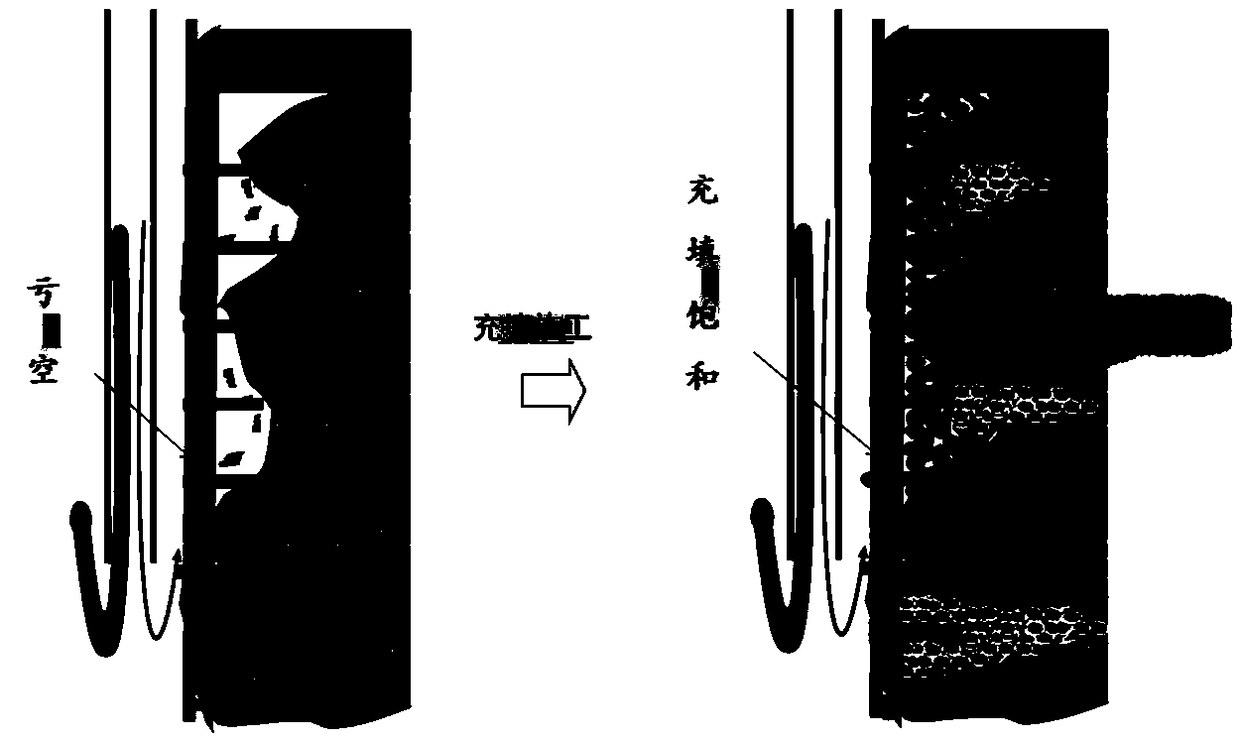

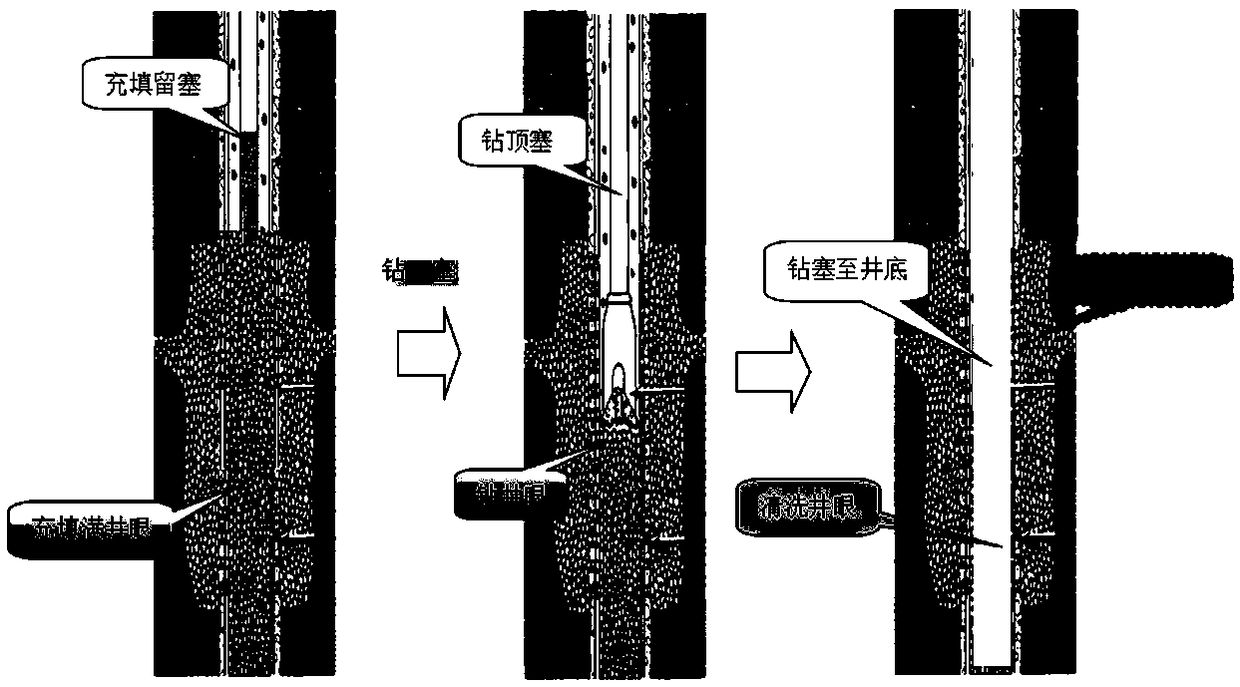

Method for manufacturing artificial borehole wall by saturated filling of bondable gravel around wellbore

ActiveCN109209299ADoes not cause problems with re-fishing toolsSubsequent maintenance costs are lowFluid removalDrilling compositionHigh densityCarrier fluid

The invention discloses a method for manufacturing an artificial borehole wall by saturated filling of bondable gravel around the wellbore, which is a new special sand control and collapse preventiontechnology for supporting the rock face and stabilizing the sand body through implementing saturated filling of the bondable gravel around the wellbore by adopting a high-flow-rate and high-pump-pressure end screening-out filling mode. The method comprises the steps of firstly effectively cleaning a flow guide channel by using a prepad fluid, relieving the resistance imposed on construction drainage by a micro-solid and high-density fluid, then conveying the bondable gravel to the end parts of deficit zone rocks by a low-flow-resistance carrier fluid, enabling the fluid to be drained on the rock surface to perform filter pressing on the bondable gravel so as to form an artificial sand belt, continuously filling until all deficits are filled, thus achieving saturated filling to form the artificial sand wall. The strength of the artificial sand wall is improved by thermal solidification so as to achieve a purpose of repairing and prolonging the service life of the production well.

Owner:韩阳 +1

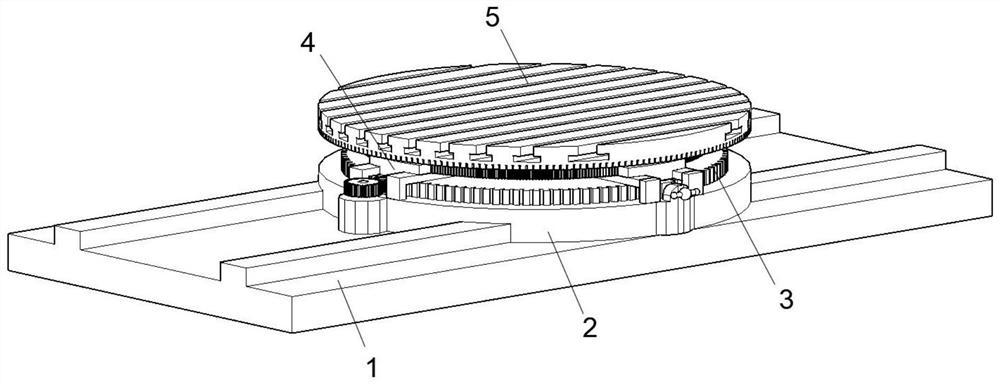

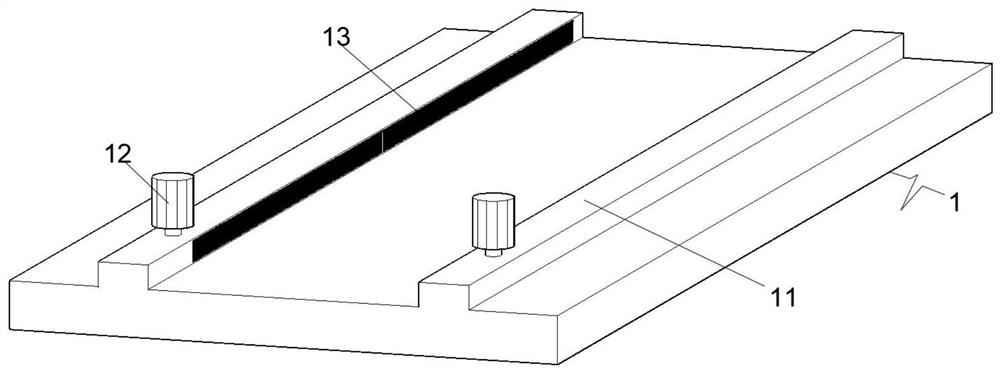

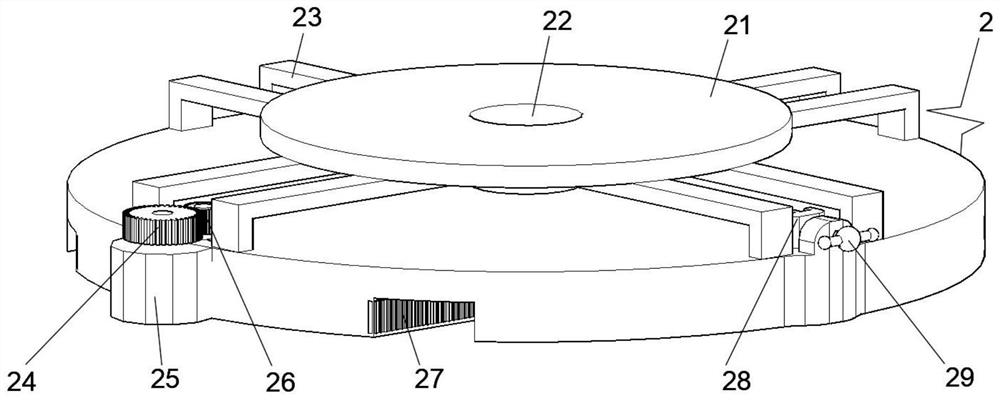

Automatic horizontal milling and boring machine

PendingCN111823053ASmooth lateral movementPlay a restrictive rolePrecision positioning equipmentBoring/drilling machinesElectric machineryEngineering

The invention relates to the technical field of milling and boring machine equipment, in particular to an automatic horizontal milling and boring machine. The automatic horizontal milling and boring machine comprises a base, a baes plate, an adjusting plate, positioning blocks and a machining table, wherein the base plate is movably engaged with the top face of the base, the adjusting plate is movably clamped to the center of the top of the base plate, and the positioning blocks are movably clamped to the edge of the top face of the base plate; and the machining table is rotationally installedin the center of the top face of the base plate, guide rails are symmetrically arranged on the top face of the base, chains are movably installed in the side faces of the guide rails, and a first driving motor is fixedly installed on the edge of one end of the top of each guide rail. By controlling rotation of the adjusting plate, the four sets of positioning blocks can position the machining table, so that the machining table is conveniently rotated to change the machining angle of a workpiece, repeated mounting and dismounting of a clamp are avoided, and the machining efficiency of the workpiece is improved.

Owner:杨安龙

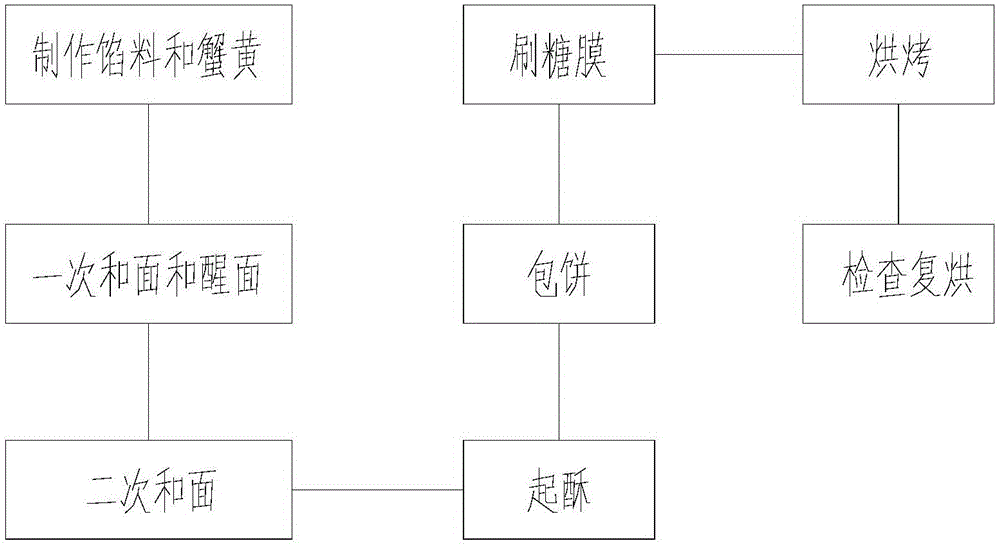

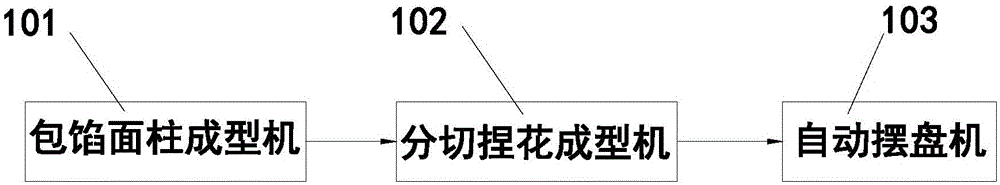

Method for making crabshell yellow sesame seed cake

InactiveCN105145743AReduce distanceAvoid scrappingDough treatmentBakery productsPreservativeEngineering

The invention discloses a method for making a crabshell yellow sesame seed cake. The method includes the seven steps of stuffing and crab cream making, primary dough kneading and leavening, secondary dough kneading and leavening, puffing, cake covering, sugar film brushing and baking. The temperature in a material barrel is controlled in the primary dough kneading and leavening process, the amount of required water is adjusted according to specific seasons, and dough leavening efficiency is greatly improved. Besides, the crisp degree and chewiness of the cake are remarkably improved. The making method is unique and low in cost. No pigment or preservative is added in the making process. The requirements for nutrients, health care and fresh taste of people are met. The bottleneck that standard, industrial and large-scale production of a crabshell yellow sesame seed cake is difficult to achieve is broken through. The cake made through the method is in the color of crab cream, crisp, layering, scorched outside but tender inside, oily but not greasy and popular with mass customers.

Owner:HUANGSHAN HANBAIQI FOOD CO LTD

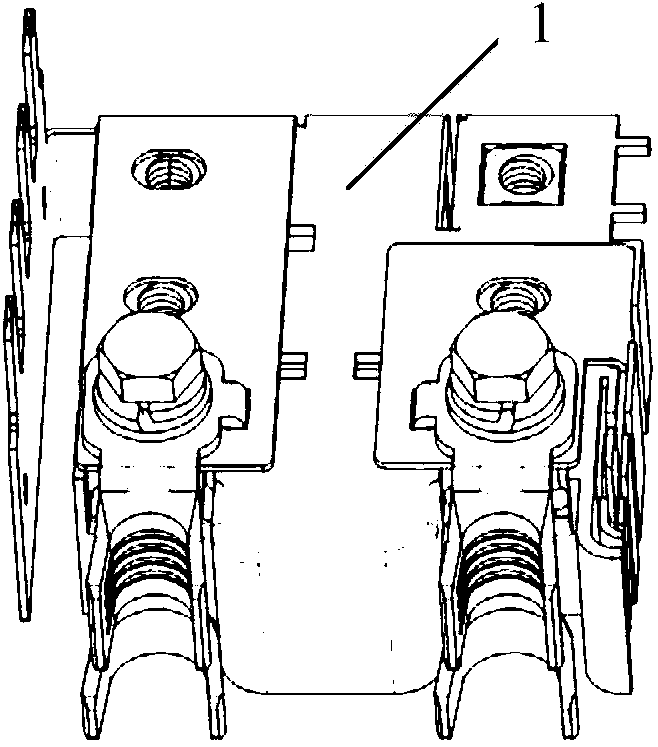

Detachable fixing structure for high-current terminals of automotive electric box

ActiveCN103635055AImplement error-proofing in assemblyImplement anti-following designCasings/cabinets/drawers detailsEngineeringCable harness

The invention relates to a detachable fixing structure for high-current terminals of an automotive electric box. The structure comprises an electric box body, fixing nuts, convergence sheets and the high-current terminals, wherein the electric box body is provided with two fixing nut positions; the convergence sheet is arranged above each fixing nut position; the high-current terminals are fixed on the electric box body through bolts after being matched with the convergence sheets. According to the structure, the fixing nuts for the high-current terminals in the electric box are replaceable, so that the scrapping of the electric box and wire harnesses due to the problems of the nuts in processes of assembly and the like is avoided, and the electric box is repairable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Polishing roll shaft based on ceramic home decoration polishing

InactiveCN112059905AAvoid damageCause damageGrinding machine componentsPolishing machinesRubber ringPolishing

The invention relates to the technical field of home decorations, and discloses a polishing roll shaft based on ceramic home decoration polishing. The polishing roll shaft based on ceramic home decoration polishing comprises a roll shaft body, the inner wall of the roll shaft body is fixedly connected with a ferromagnetic ring, the inner side of the ferromagnetic ring is movably connected with a rubber ring, the inner wall of the rubber ring is movably connected with a fastening ring, and the inner wall of the fastening ring is fixedly connected with a closed wire magnetic ring. According to the polishing roll shaft based on ceramic home decoration polishing, a power source is switched on by the closed wire magnetic ring to drive the roll shaft body to rotate, efficient utilization of energy is achieved, the use of a motor is avoided, the production rate is increased, the power source is cut off, an ejected limiting block can be clamped into a clamping groove in the inner wall of the ferromagnetic ring to prevent the ferromagnetic ring from rotating, and therefore, rotation of the roller shaft is prevented, the roller shaft can stop rotating at the moment when a worker finds that amachine has errors and operation of the worker is improper and cuts off a power supply, damage and scrapping of ceramics are avoided, and resources are saved.

Owner:广州梦柯贸易有限公司

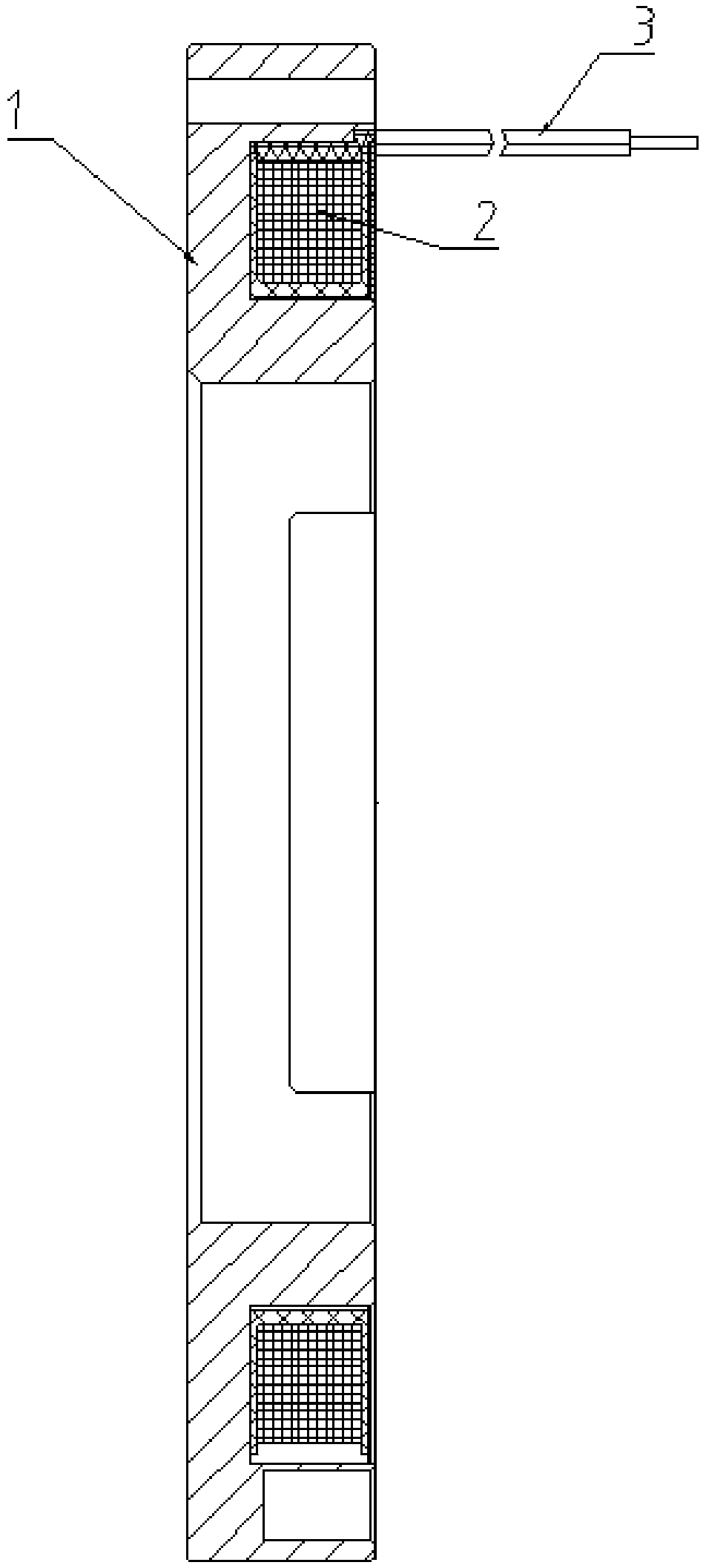

Intelligent film capacitor full-automatic winding machine based on Internet of Things

ActiveCN113470994ACause scrapEasy to monitor remotelyWinding capacitor machinesInformation processingThe Internet

The invention discloses an intelligent film capacitor full-automatic winding machine based on the Internet of thing. A side plate is fixed on a bottom plate, a top plate is fixed to the bottom plate through the side plate, a winding mechanism, a film roller and an aluminum foil roller are arranged between the bottom plate and the top plate, and a monitoring device is fixed to the top plate. The monitoring device comprises a data acquisition module, a data processing module, a gateway and a cloud service center; when the cloud service center receives that the comprehensive information about the current operation of the winding machine, which is transmitted by the data processing module through the gateway, has an abnormal state, performing abnormal matching according to the information pre-stored by the cloud service center, so that the solution of the current abnormal state is matched with the current abnormal state; and the cloud service center sends the abnormal state information, the processing scheme and the processing result to a worker through the gateway for confirmation, so that production safety is ensured, and the problem that an existing winding device does not have the remote monitoring function and the self-adaptive problem processing capacity is solved.

Owner:东莞市纬迪实业有限公司

Method for controlling speed of hot continuous rolling strip steel loop at low loop position

ActiveCN104384200AGuaranteed to be normalCause scrapFlexible work arrangmentsMetal rolling arrangementsAutomatic controlInverter

The invention discloses a method for controlling speed of a hot continuous rolling strip steel loop at the low loop position, and belongs to the field of automatic control of hot rolled steel of a metallurgy industry. When time of loop rising of the strip steel biting loop, located between every two adjacent racks of a finishing mill set, of a rear rack is delayed by 1 to 1.2 seconds, the angle of the loop is smaller than or equal to 13 degrees, and meanwhile the torque deviation of the loop is larger than 500, a loop system speed compensation value obtained through calculation of a first-class computer is superimposed to a host speed control reference value; the superimposed value is transmitted to a main transmission system-Siemens inverter SM150 through a PROFIBUS, and the main transmission system carries out automatic speed adjustment and control based on the superimposed value; and the aims of speed adjustment of a finishing mill host and control stability of the loop are achieved. According to the method, rolled strip steel is stably controlled, and meanwhile the influence of instability like loop strip steel loop loosening caused by mismatching of the host speed and loop system adjustment when the loop is located at the low loop position on rolling is avoided; the failure time is shortened; the strip steel product quality is ensured; and the good benefits are obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

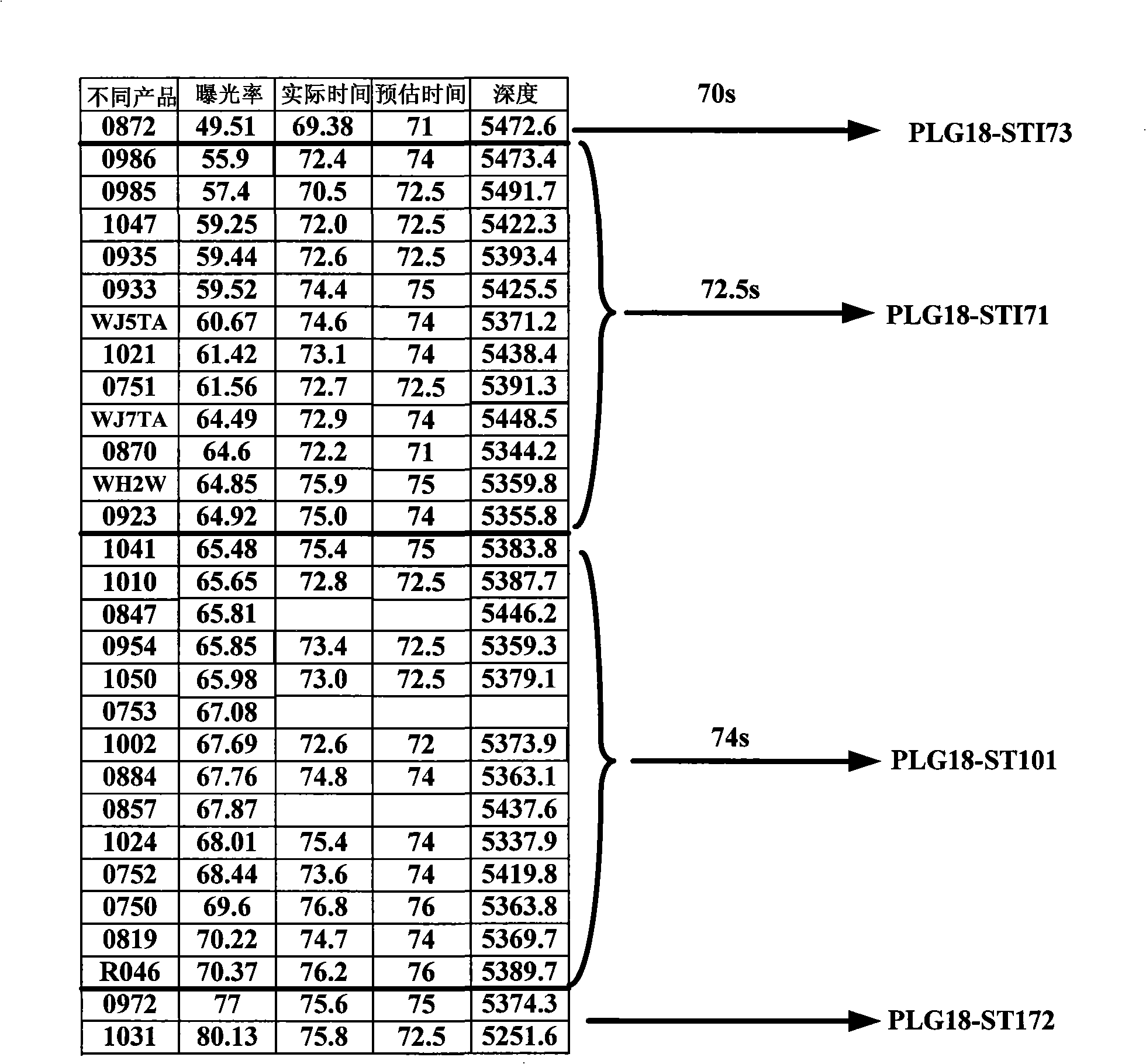

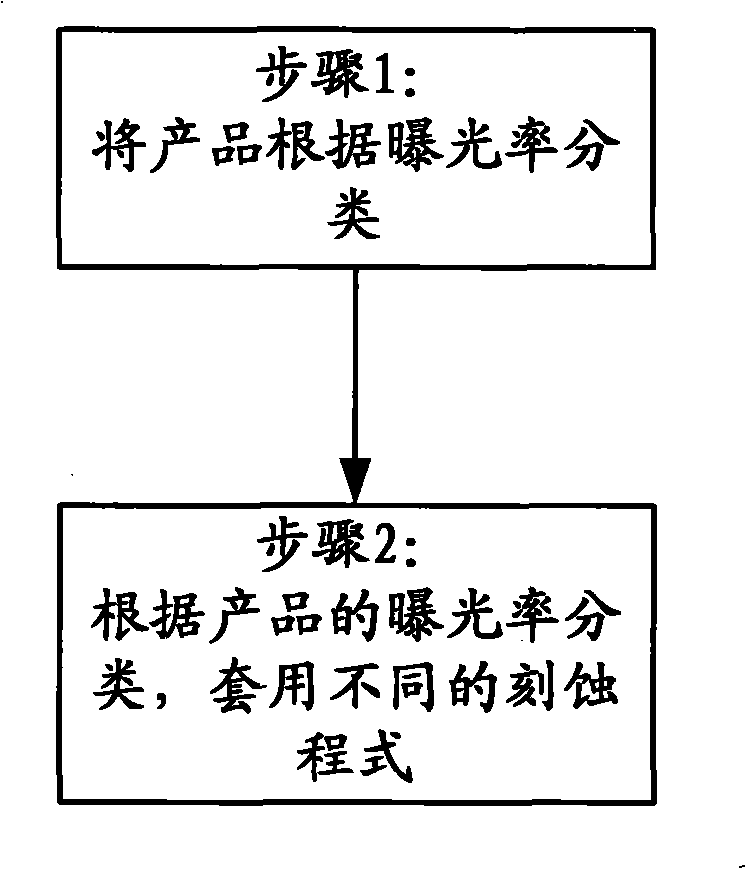

Method for improving etching depth accuracy

InactiveCN101350289AImprove performanceAvoid scrappingSemiconductor/solid-state device manufacturingEtchingMaterial resources

A method for improving the deepness and the accuracy of etching, which belongs to the field of the technical process of a semi-conductor and comprises the following steps: firstly, classifying products according to the exposure rate, secondly, applying different etching formulas according to the classification of the exposure rate of the products. The method of the invention guarantees the exposure rate of products, improves the performances of a chip and the production efficiency, and saves human and material resources.

Owner:SEMICON MFG INT (SHANGHAI) CORP

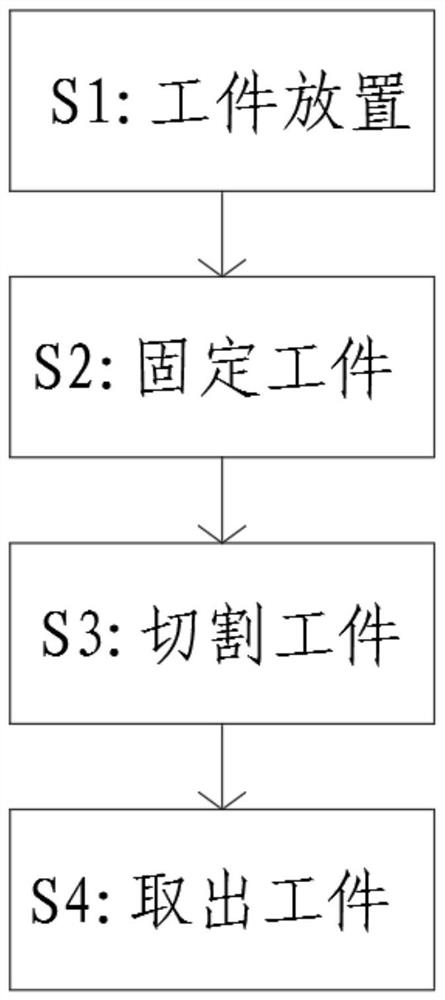

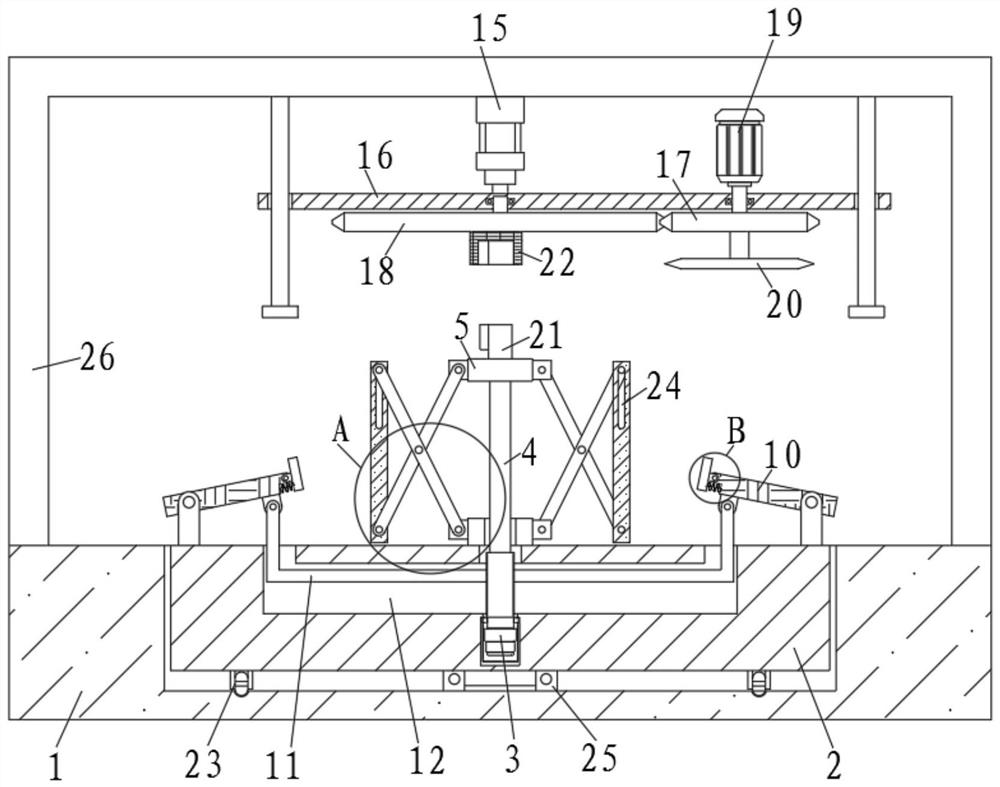

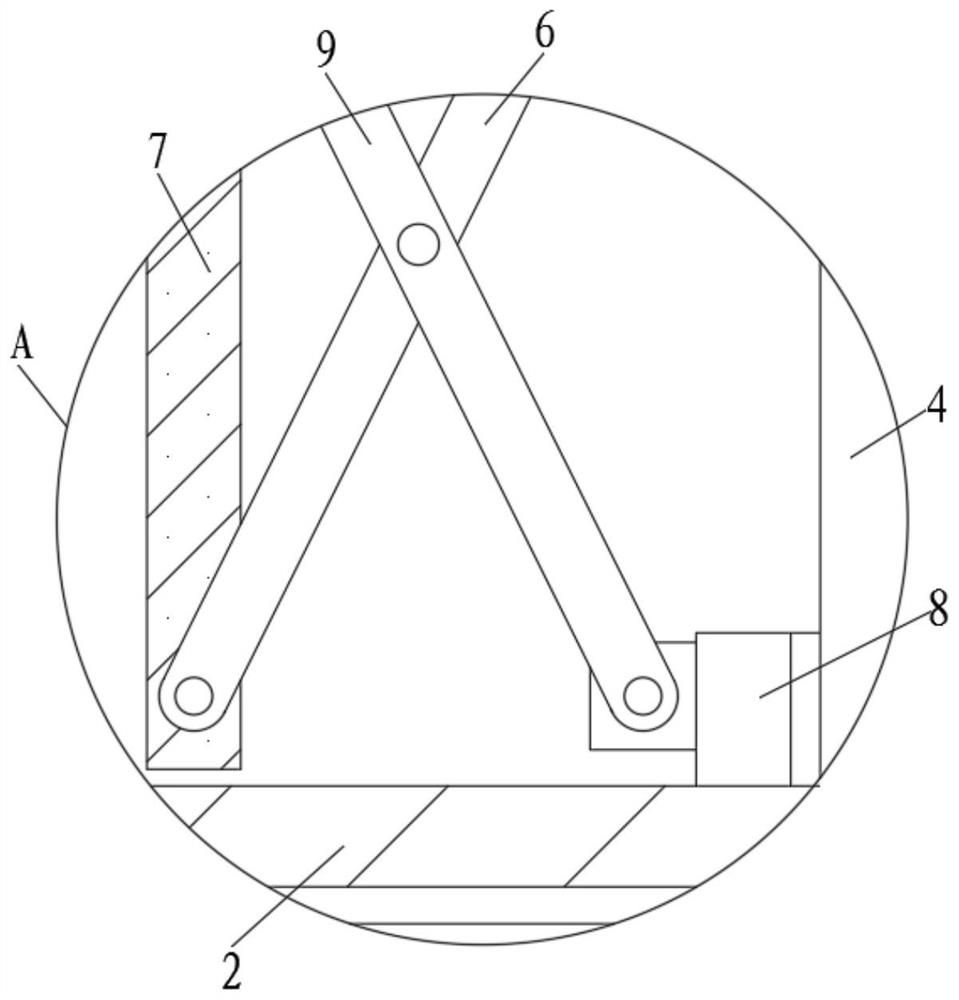

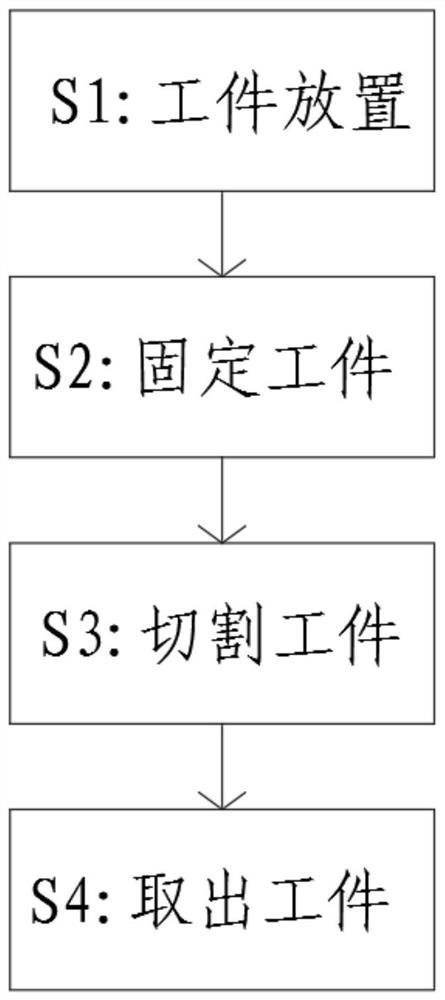

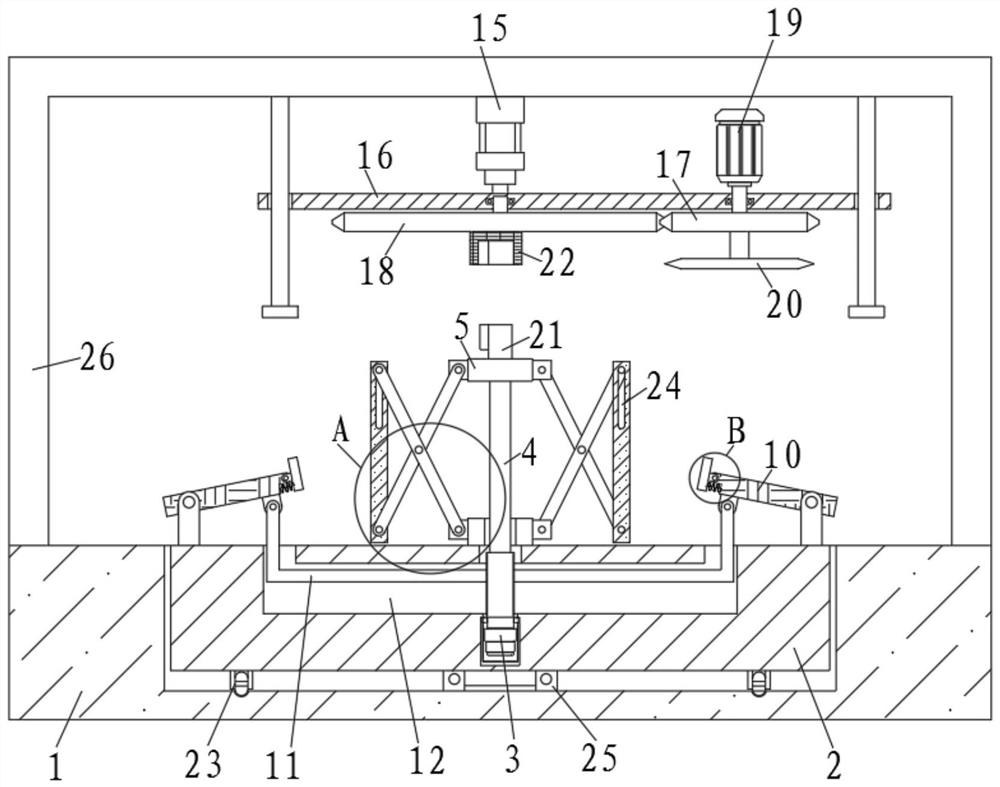

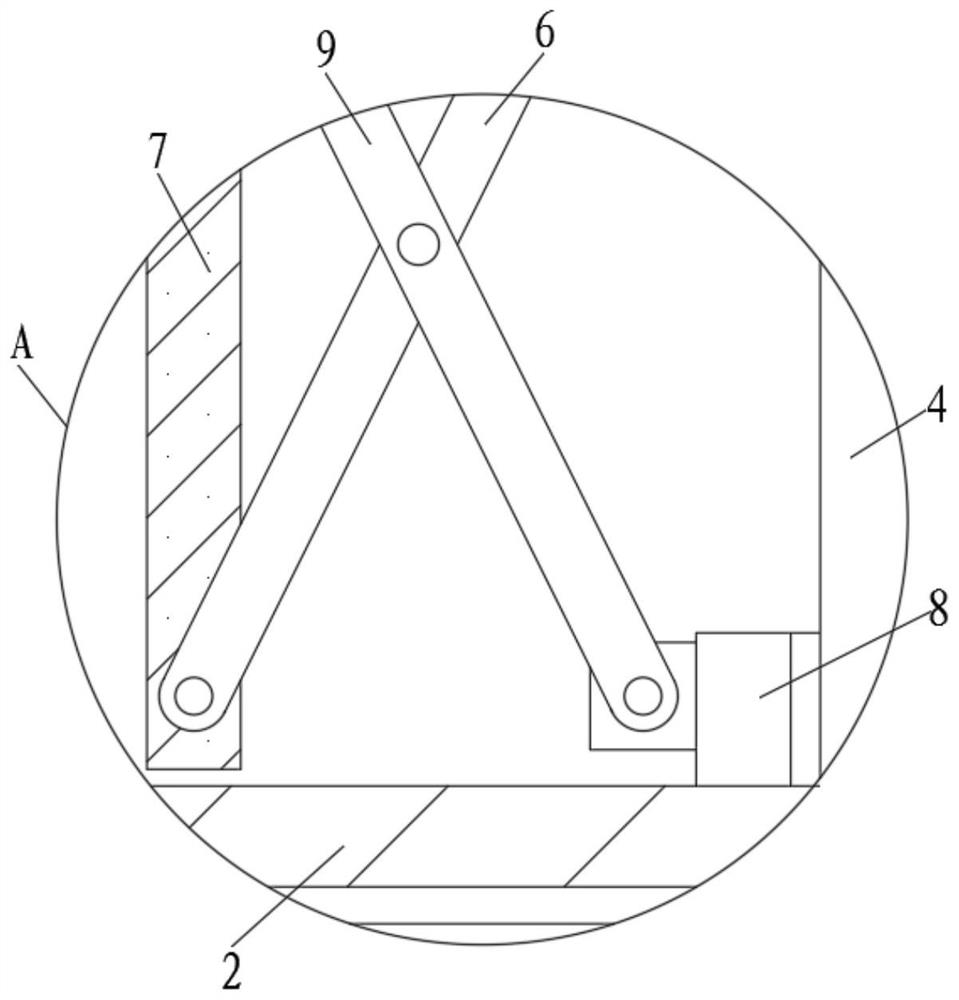

Thin-wall part cutting machining technology

ActiveCN113042803AEasy to fixAvoid scrappingShearing machinesMetal working apparatusEngineeringMachining process

The invention relates to the technical field of thin-wall part machining, in particular to a thin-wall part cutting machining technology. A cutting device is used in the technology. According to the technology, a fixing air cylinder drives a fixing rod to move downwards, so that a first rotating rod and a second rotating rod rotate; one end of the second rotating rod is glidingly connected with a pressing plate, so that the pressing plate moves horizontally to abut against the inner wall of the workpiece; the fixing air cylinder drives the fixing rod and synchronously drives a connecting rod to slide down, the connecting rod drives a rotating plate to rotate, and an arc-shaped plate presses the outer side of the workpiece, so that the inside and the outside of the workpiece are fixed through synchronous pressing of the arc-shaped plate and the pressing plate, the workpiece is fixed more firmly, material scrapping caused by movement of the workpiece during machining is avoided, and the working efficiency is improved.

Owner:苏州莱易精密机电有限公司

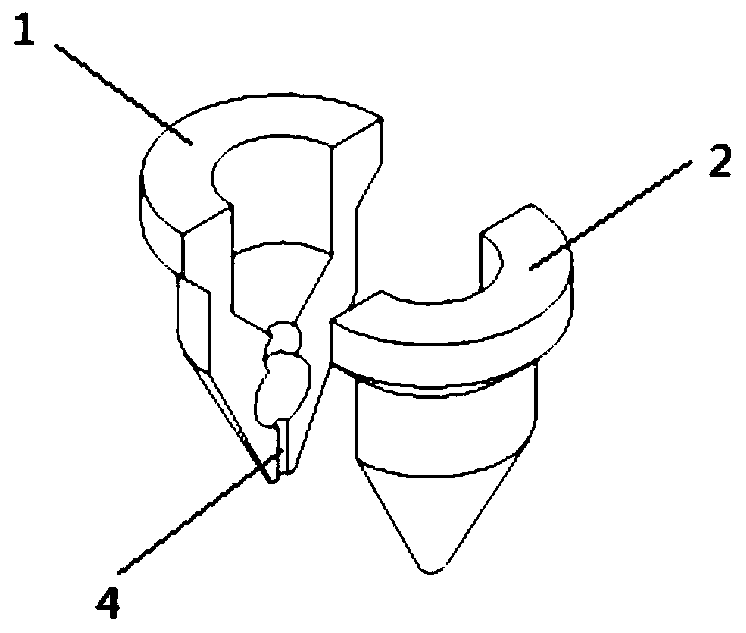

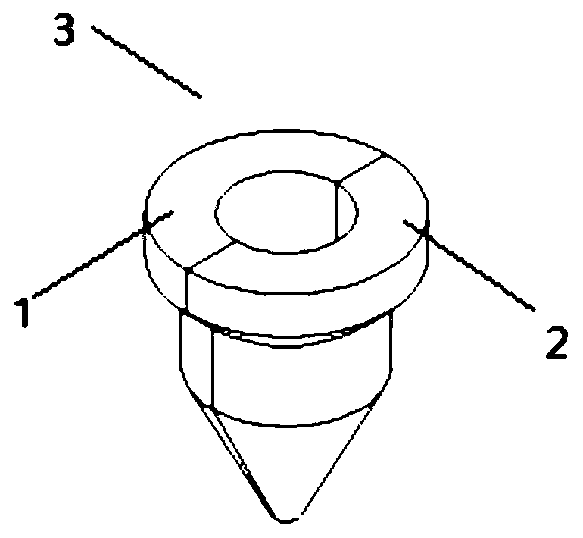

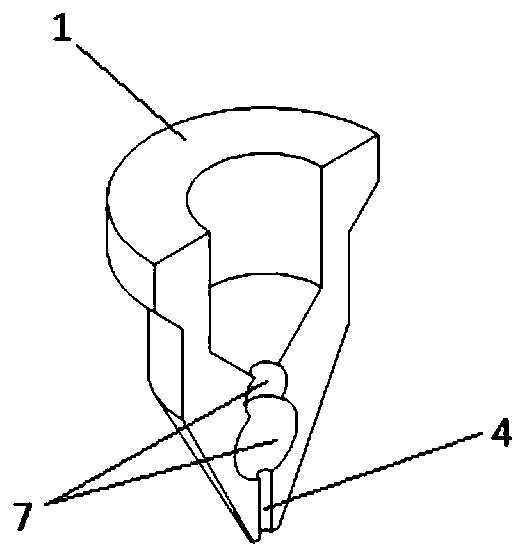

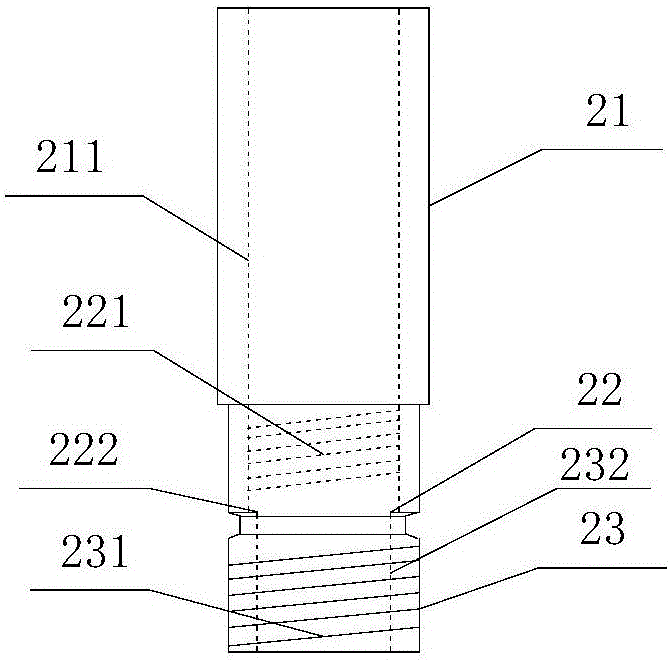

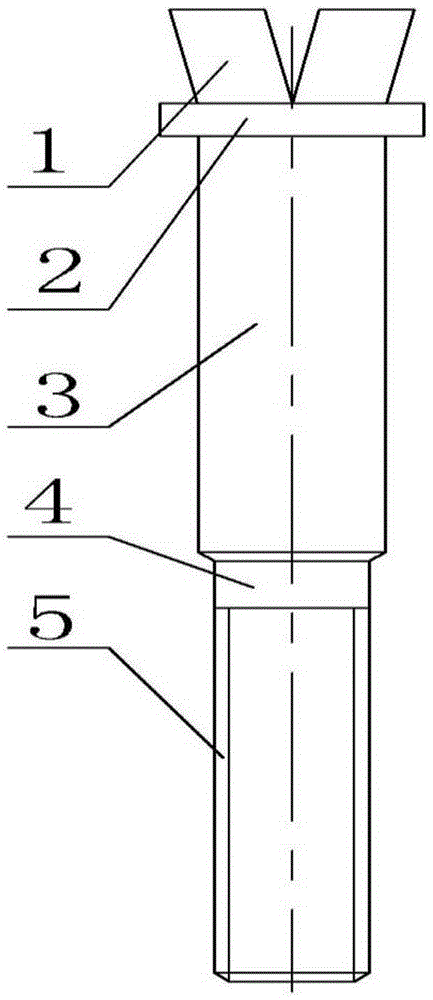

Separated type nozzle and dispensing valve adopting separated type nozzle

InactiveCN110052365AAvoid processing difficultiesSolve the inconvenient processingLiquid surface applicatorsCoatingsSpray nozzleAgricultural engineering

The invention relates to the technical field of dispensing equipment, and aims to provide a separated type nozzle and a dispensing valve adopting the separated type nozzle. The nozzle adopts a separated type structure design, an internal flow channel structure is easy to process, the convenience in cleaning is realized, and the manufacturing and use cost is reduced. The separated type nozzle comprises a left nozzle component and a right nozzle component, wherein the two nozzle components are connected through combination so as to form the separated type nozzle (3); a partial flow channel (7) is molded on the combined surface of each nozzle component; and after combination, the inner part of the separated type nozzle (3) forms a complete flow channel. The separated type nozzle provided by the invention solves the problems that an existing integrated nozzle is difficult to process an internal flow channel structure, difficult to clean and repair, and high in manufacturing and use cost.

Owner:PAIHE SCI & TECH HLDG CO LTD BEIJING

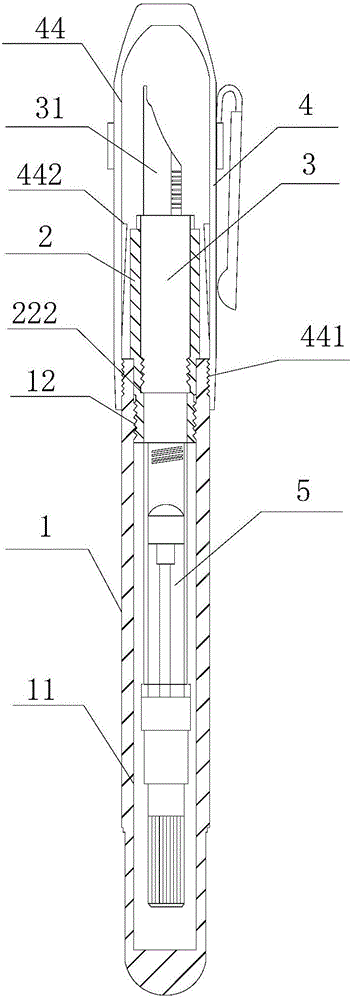

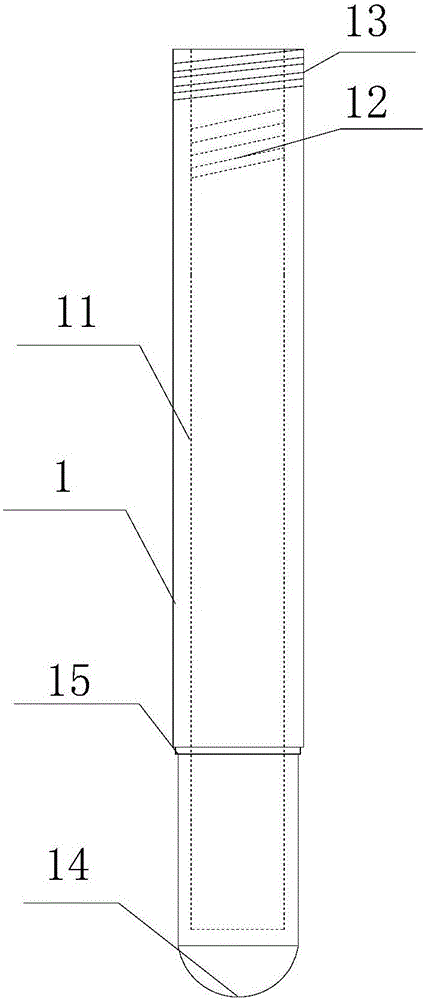

Improved dip pen with replaceable point

The invention discloses an improved dip pen with a replaceable point. The improved dip pen comprises a pen rod, a clamping sleeve, a pen point set, a pen cap and an ink suction device. A first installation cavity is formed in the pen rod and matched with the clamping sleeve. The clamping sleeve is provided with a handhold part, a second installation cavity is formed in the handhold part in a penetrating mode, a first connecting part is arranged below the handhold part and matched with the pen point set, and a second connecting part is arranged below the first connecting part and matched with the first installation cavity. The pen point set is provided with an ink guide assembly, the pen point is arranged above the ink guide assembly, an ink guide tube is arranged below the ink guide assembly and matched with the ink suction device, and a sealing sleeve is arranged at the connecting end of the ink suction device and the pen point set. The pen cap is matched with the pen rod. Due to the detachable pen point, it is avoided that a whole pen is scrapped once a pen point is fractured or damaged, and resources are saved; the ink suction device supplies ink, and thus it is not needed to dip the pen with ink frequently in the writing process.

Owner:JIAXING DELI KESI TECH CO LTD

Injection molding bolt for automobile spare tire and production process of injection molding bolt

InactiveCN105351320AExtended service lifeAdd depthBoltsScrewsPulp and paper industryThermal treatment

The invention discloses an injection molding bolt for an automobile spare tire and a production process of the injection molding bolt and relates to the technical field of injection molding bolts. The injection molding bolt comprises a bolt body. A bolt tail is arranged on the lower portion of the bolt body, a thread is arranged at the bolt tail, a bolt head is arranged on the upper portion of the bolt body, and a cross head is machined on the upper portion of the bolt head. The production process includes the following steps of firstly, material selection and preliminary machining, secondly stamping forming, thirdly, finish machining and thread machining, fourthly, thermal treatment and fifthly polishing treatment.

Owner:舒城县博力非标异型紧固件厂

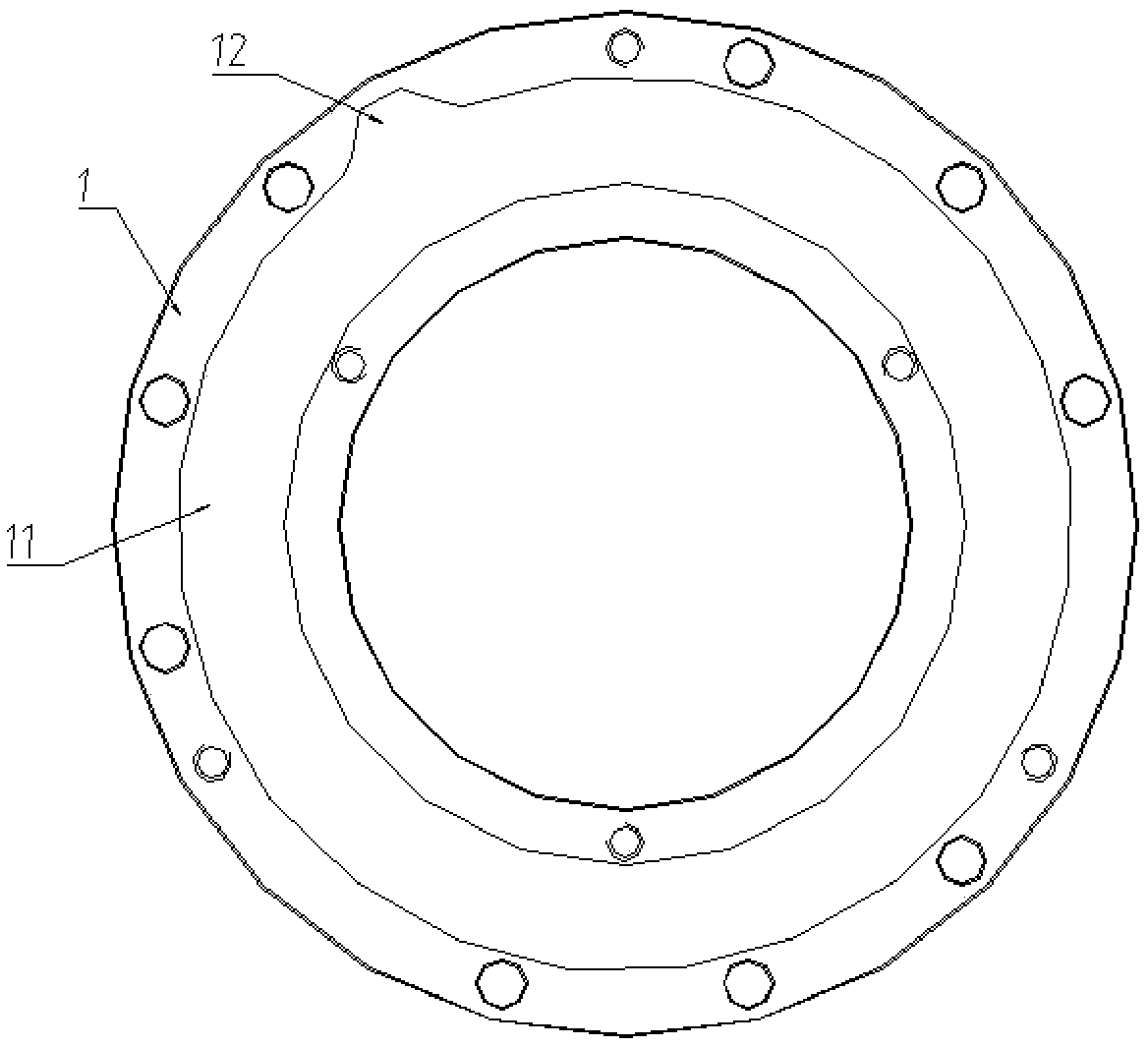

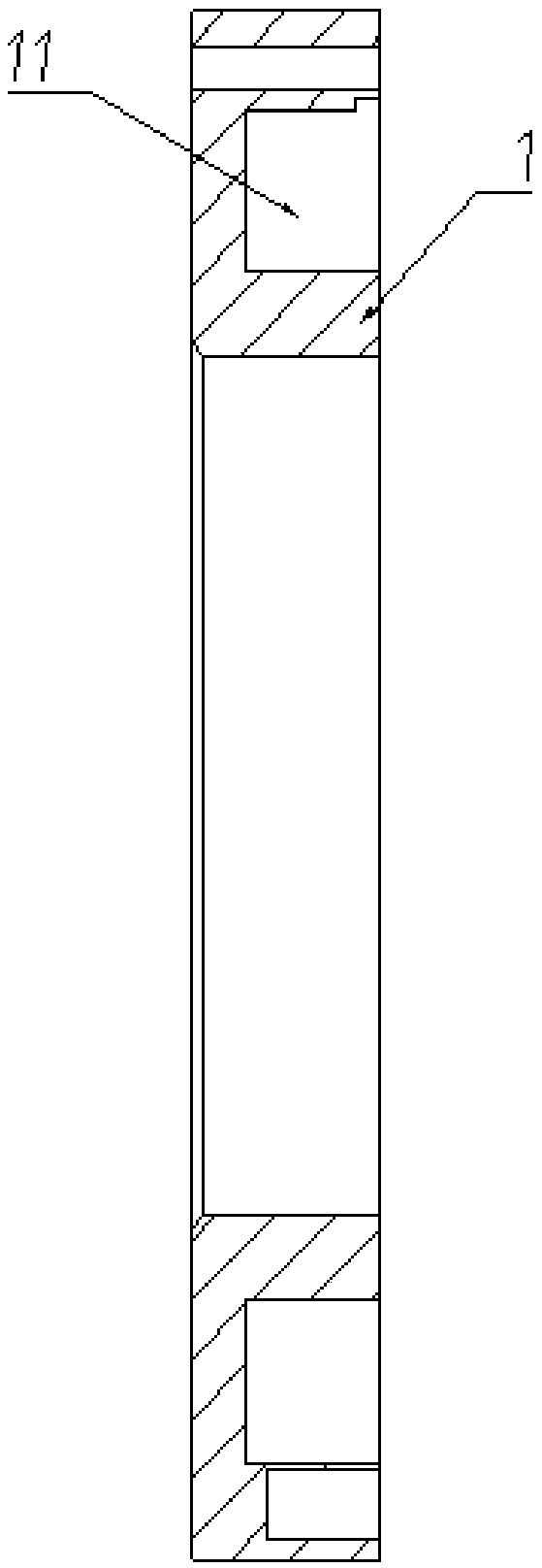

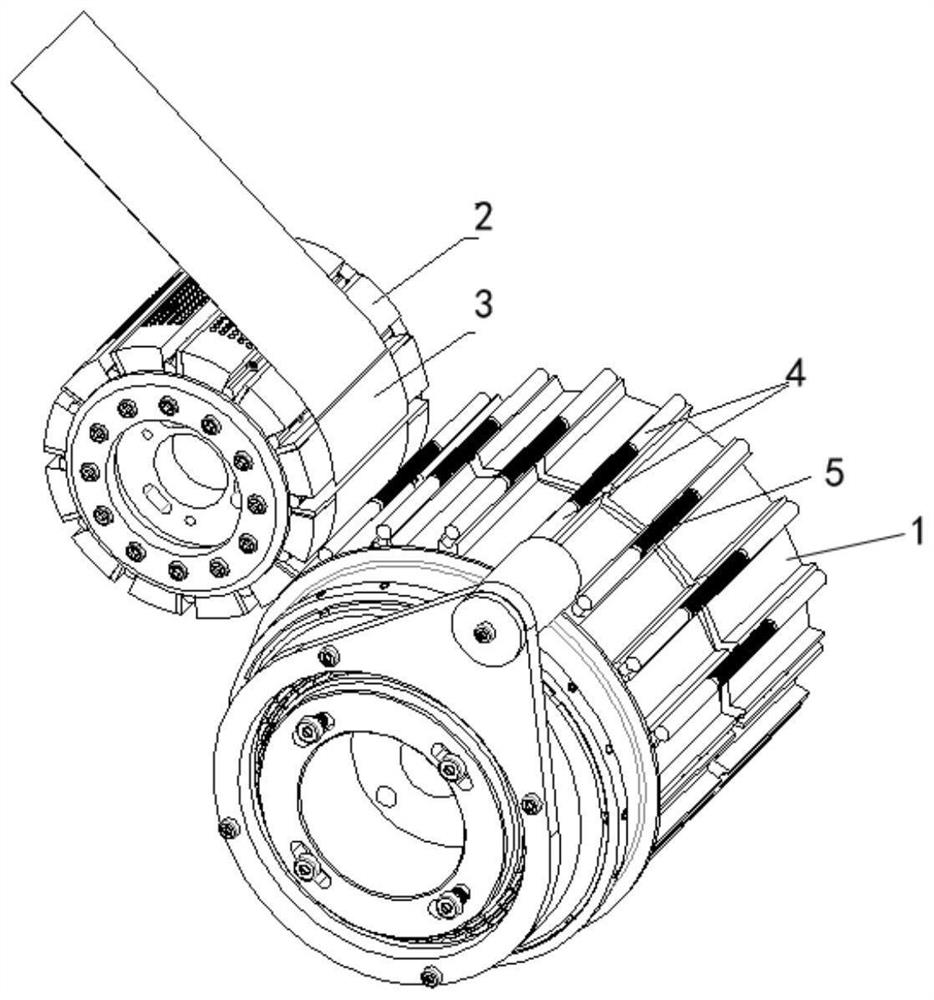

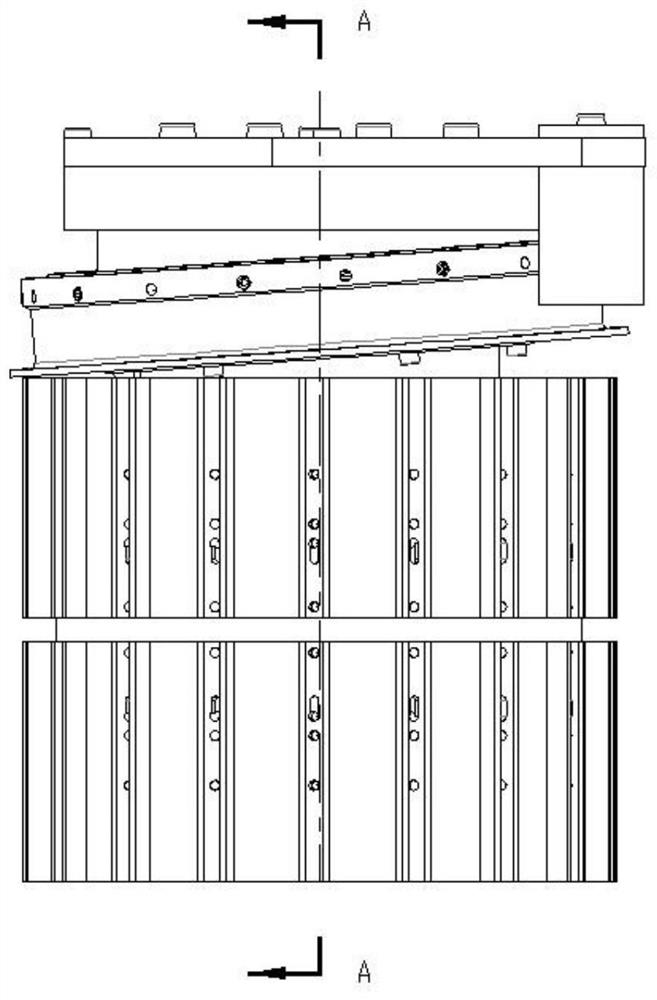

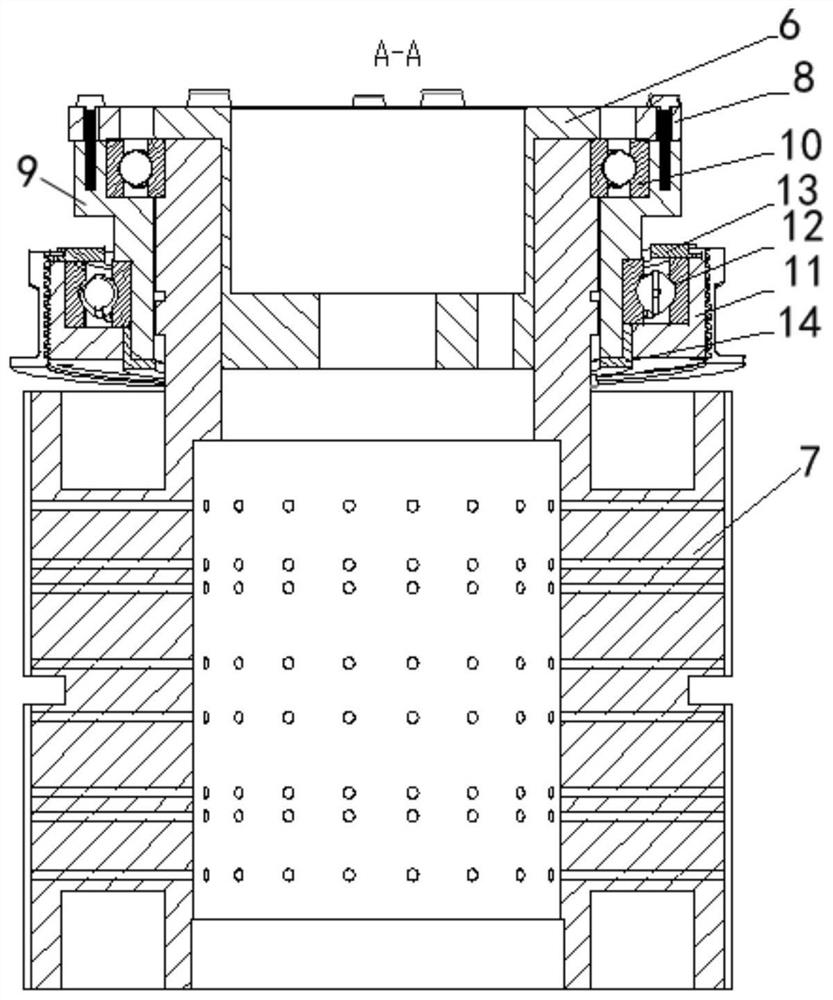

Brake stator structure of servo motor and servo motor

ActiveCN108880011AEasy to locateReduce the possibilityWindingsMagnetic circuit stationary partsPhysicsStator

The invention relates to a brake stator structure of a servo motor, comprising a stator core and a stator placed in the stator core. The stator iron core is of an annular structure, and a stator slotused for placing the stator is arranged on the stator core. The stator slot is an annular slot, and the stator slot is opened along one side of the axial direction of the stator core. The stator comprises a coil and a lead connected with the coil at one end, and an injection molding housing is formed on the outer surface of the stator through injection molding. In injection molding, the stator andat least one parts of the lead connected to one end of the stator are integrally formed through the injection molding housing. According to the stator structure, the stator and a part of the lead areintegrally formed, so that the lead can be effectively prevented from being disconnected from the stator during installation.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

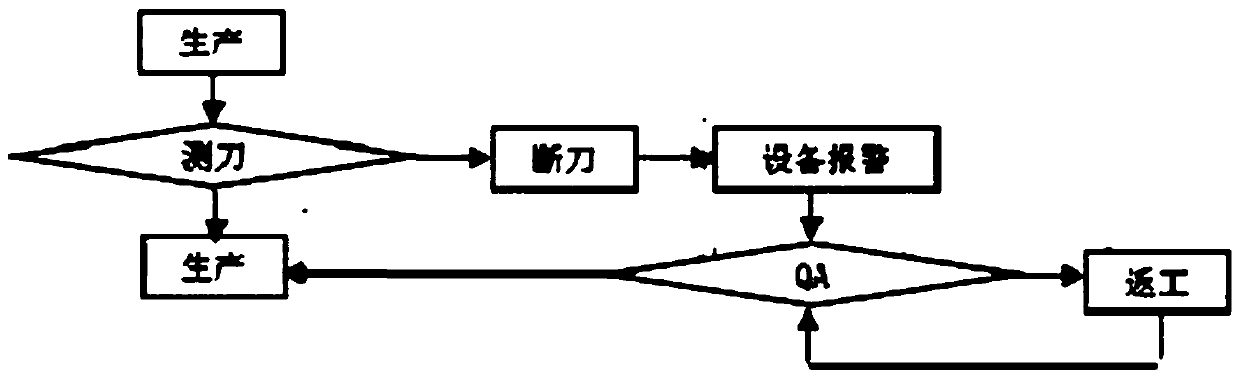

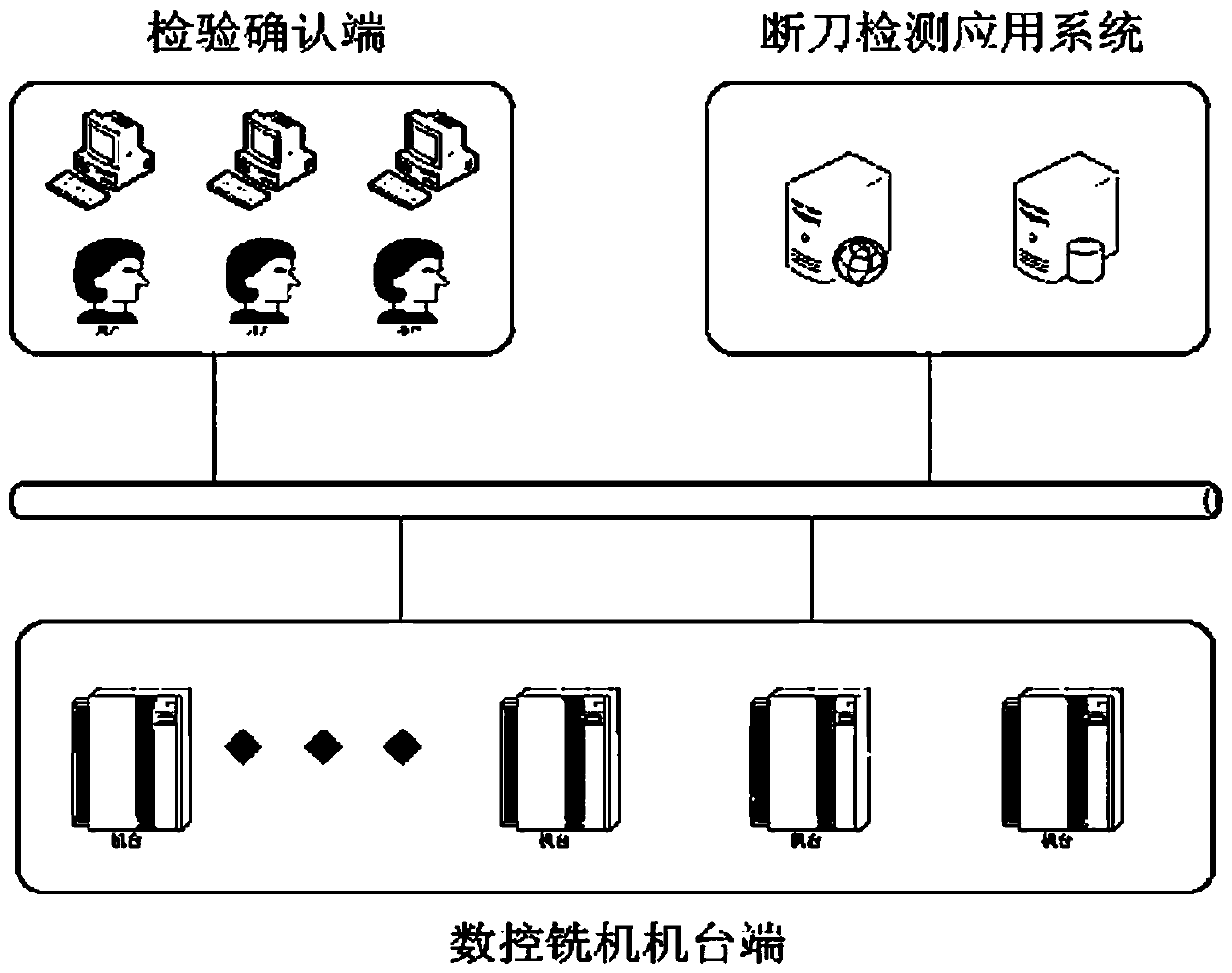

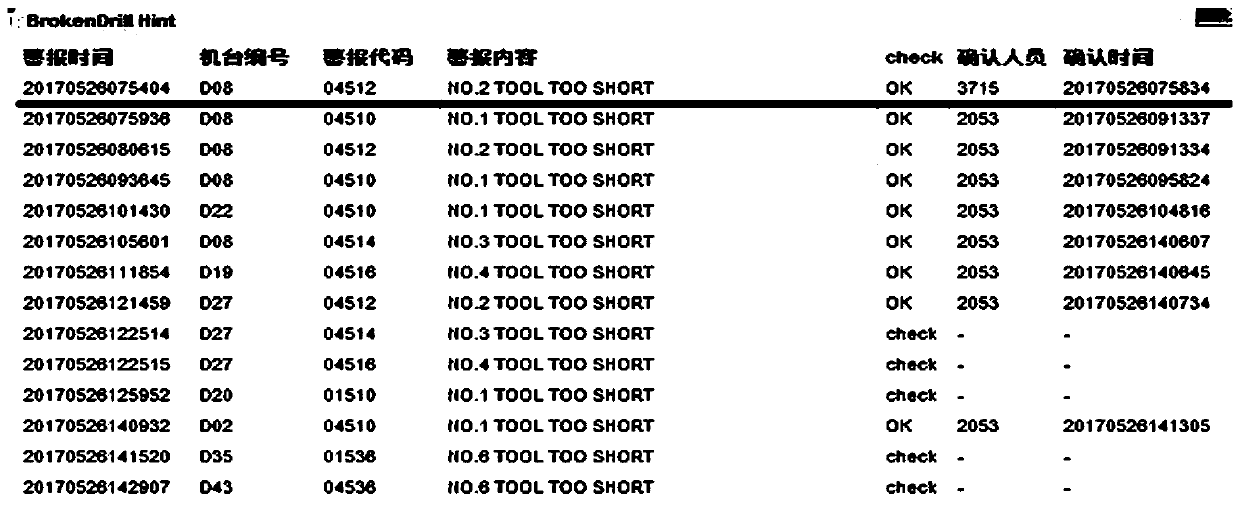

Numerical control milling machine cutter breaking monitoring method

InactiveCN107621807ACause customer complaintsCause scrapProgramme controlComputer controlNumerical controlMaterial resources

The invention provides a numerical control milling machine cutter breaking monitoring method comprising the following steps that S1: a cutter measurer is installed on the cutter shaft of a milling machine, and the cutter measurer is corresponding to the cutter shaft in a one-to-one way; S2: a cutter measurement circuit is connected, and the situation of cutter breaking is judged by one signal given by on / off of the cutter measurement circuit; S3: if a power supply signal appears, the judgment result indicates the situation of cutter breaking; or the judgment result indicates no situation of cutter breaking; S4: the power supply signal is tracked and recorded and machine alarm prompting is given; S5: the record is searched for every period of time and the cutter breaking alarm signal is analyzed and identified; S6: the identified information is transmitted to the monitoring computer side; S7: the quality inspection personnel receives the information and performs on-site processing; andS8: the quality inspection personnel completes processing and then returns to the computer side for confirmation so that processing is completed. According to the numerical control milling machine cutter breaking monitoring method, the quality of the product and the customer satisfaction can be enhanced and the manpower and material resources for handling the customer complaint can be saved.

Owner:SHANGHAI KAISER ELECTRONICS

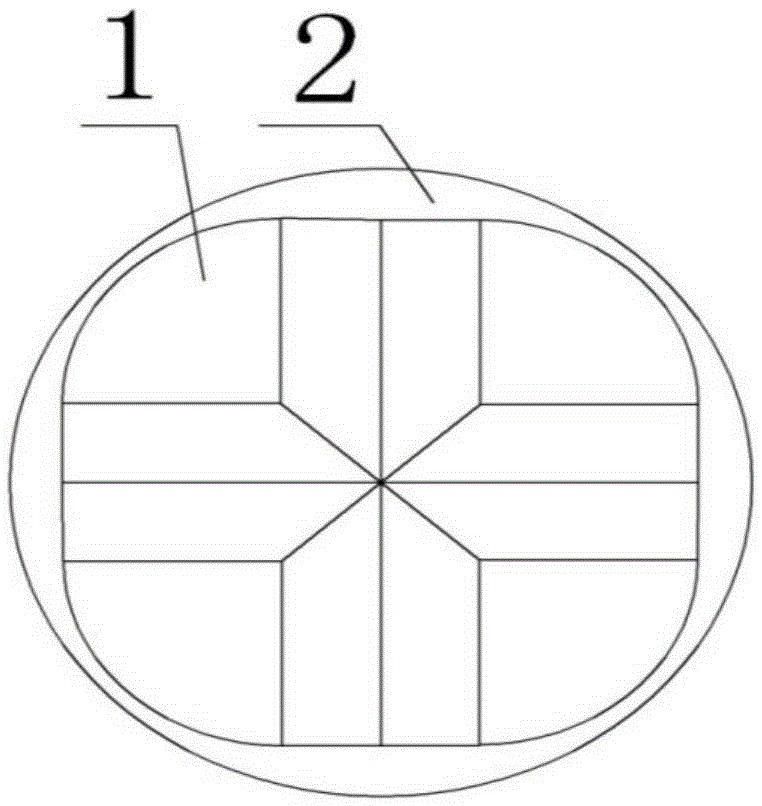

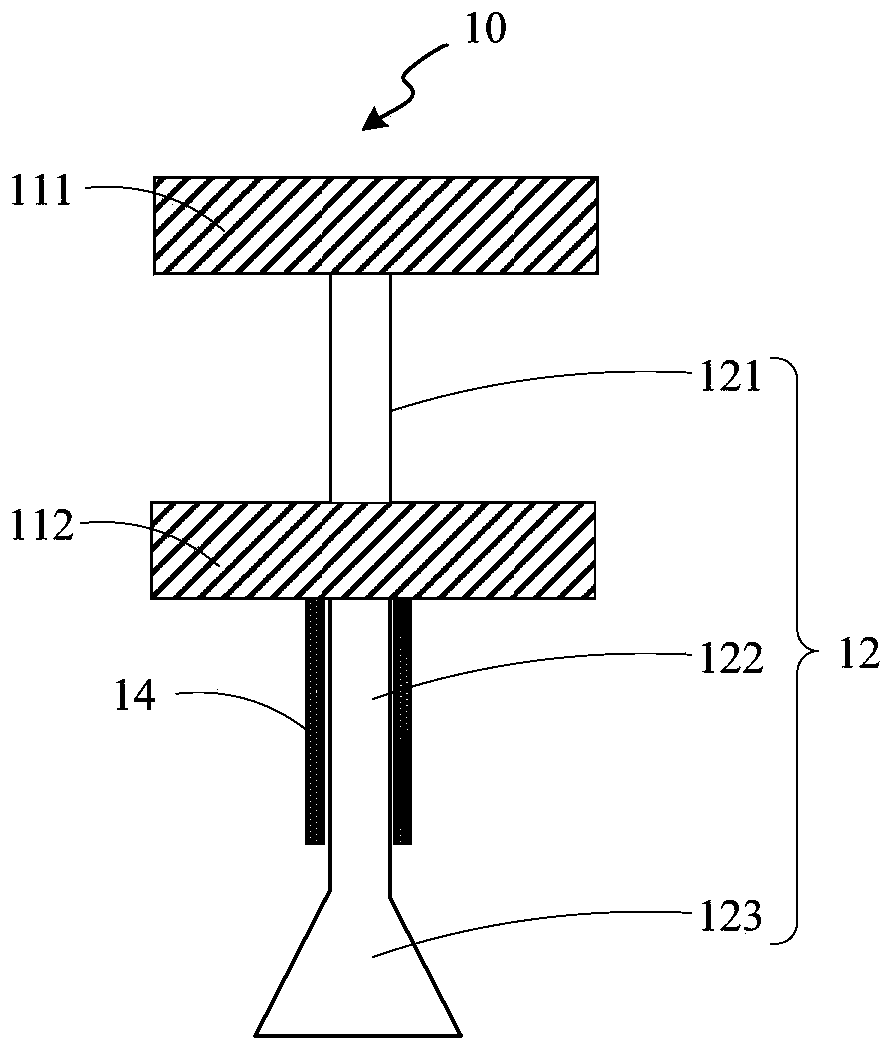

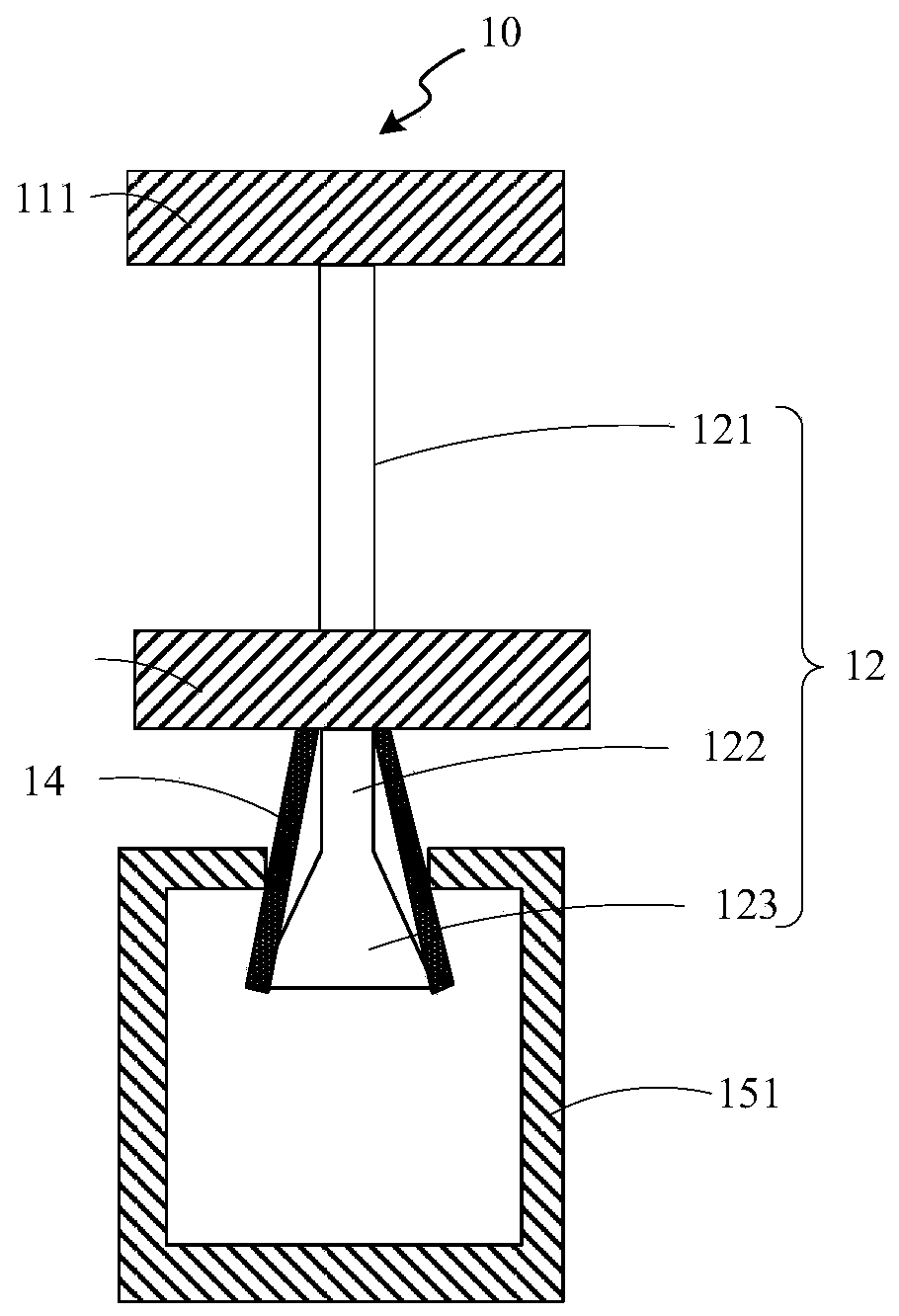

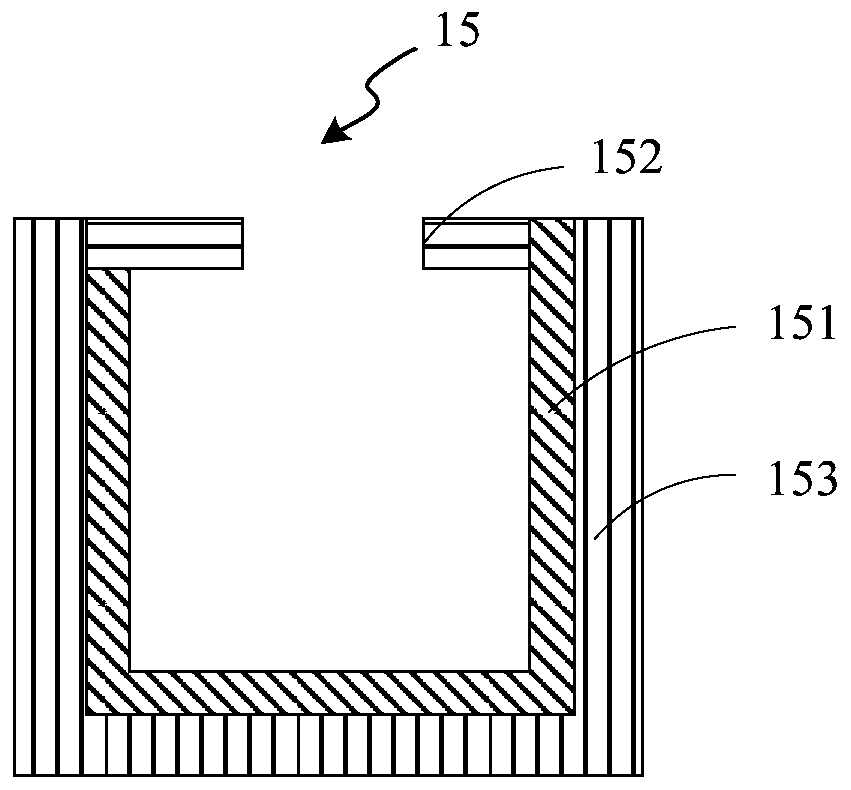

Evaporation crucible supporter

ActiveCN110029312ACause scrapAvoid pollutionVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses an evaporation crucible supporter which comprises a shell, a shaft rod, a first elastic piece and a support component. The shaft rod is axially arranged in the shell; the firstelastic piece is configured to be used for enabling the shaft rod to move up and down relative to the shell; the support component comprises multiple first connecting rods, multiple second connectingrods and multiple connecting pieces; and the support component can be switched between a closed state and an opened state.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

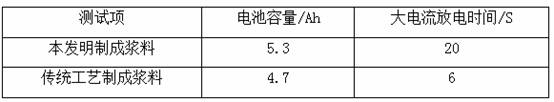

A kind of negative electrode slurry of nickel-metal hydride battery and preparation method thereof

ActiveCN110993914BGood dispersionImprove uniformityCell electrodesNickel accumulatorsCarboxymethyl celluloseElectrical battery

The invention discloses nickel-metal hydride battery negative electrode slurry and a preparation method thereof. The nickel-metal hydride battery negative electrode slurry comprises the following components in parts by weight: 60-70 parts of hydrogen storage alloy powder, 0.3-0.5 part of carbon black, 0.1-0.15 part of sodium carboxymethyl cellulose, 1 part of a polytetrafluoroethylene aqueous solution, 0.2 part of yttrium oxide, 5 parts of a thickener PAS and 25-35 parts of deionized water. According to the invention, preparation of a CMC aqueous solution is used as an intermediate step, the CMC aqueous solution is controlled within a certain viscosity range, metal, non-metal materials and non-hydrophilic materials with large specific gravity differences are uniformly mixed together in a short time, the preparation period is short, the operation is simple and convenient, the dispersity and uniformity of the slurry are improved, the prepared slurry is good in stability, the high-temperature resistance is improved, and a battery prepared from the slurry has good electrochemical performance. The method is suitable for preparing the nickel-metal hydride battery negative electrode slurry.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

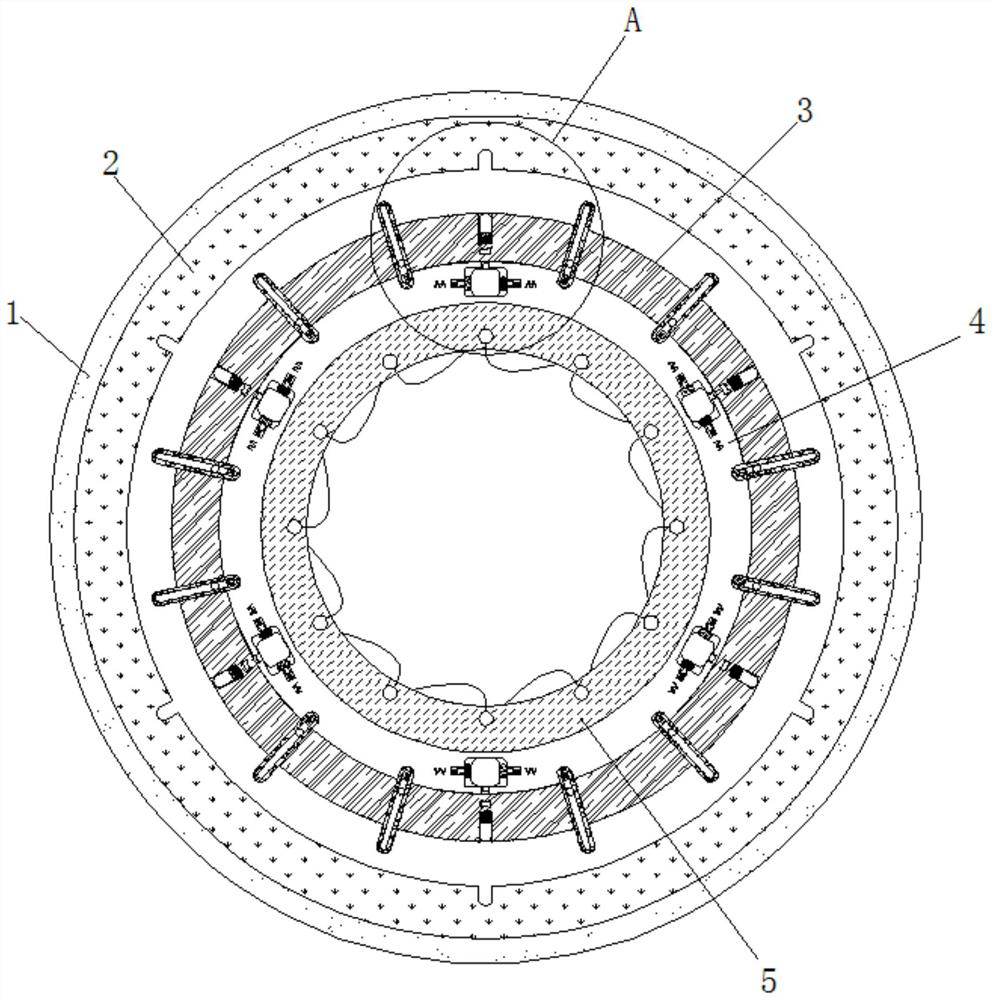

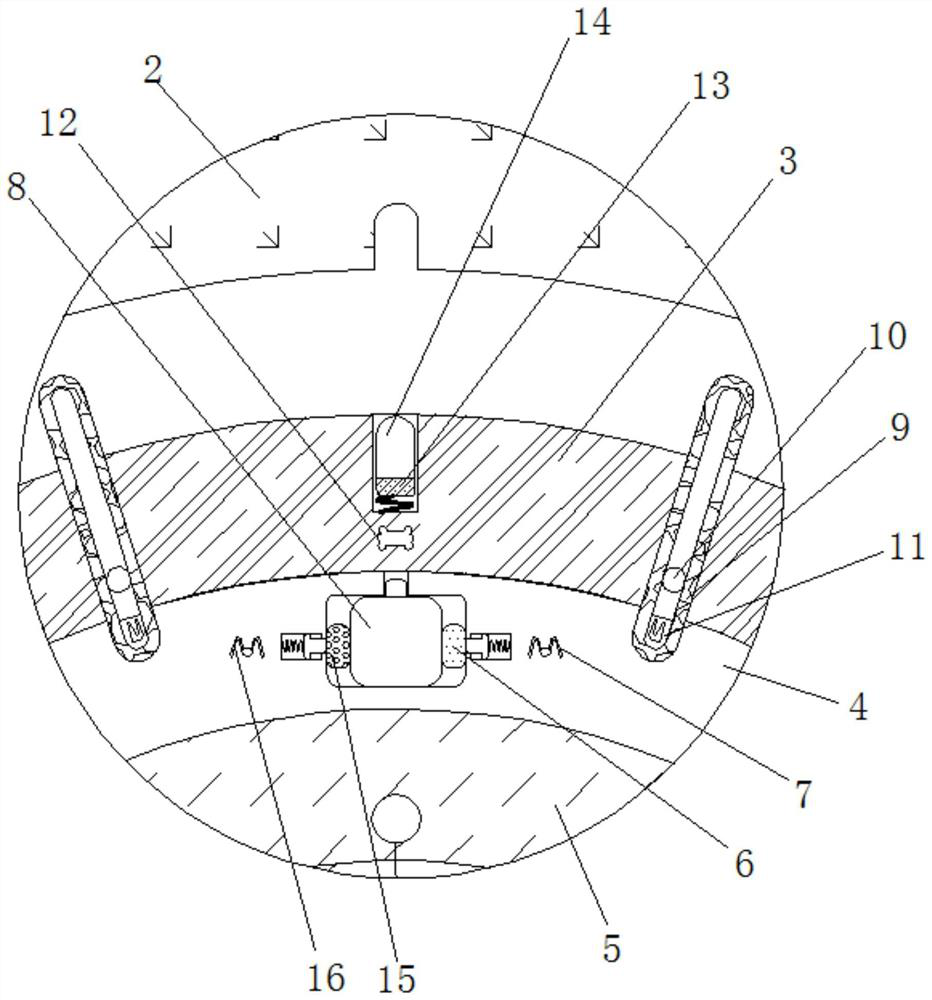

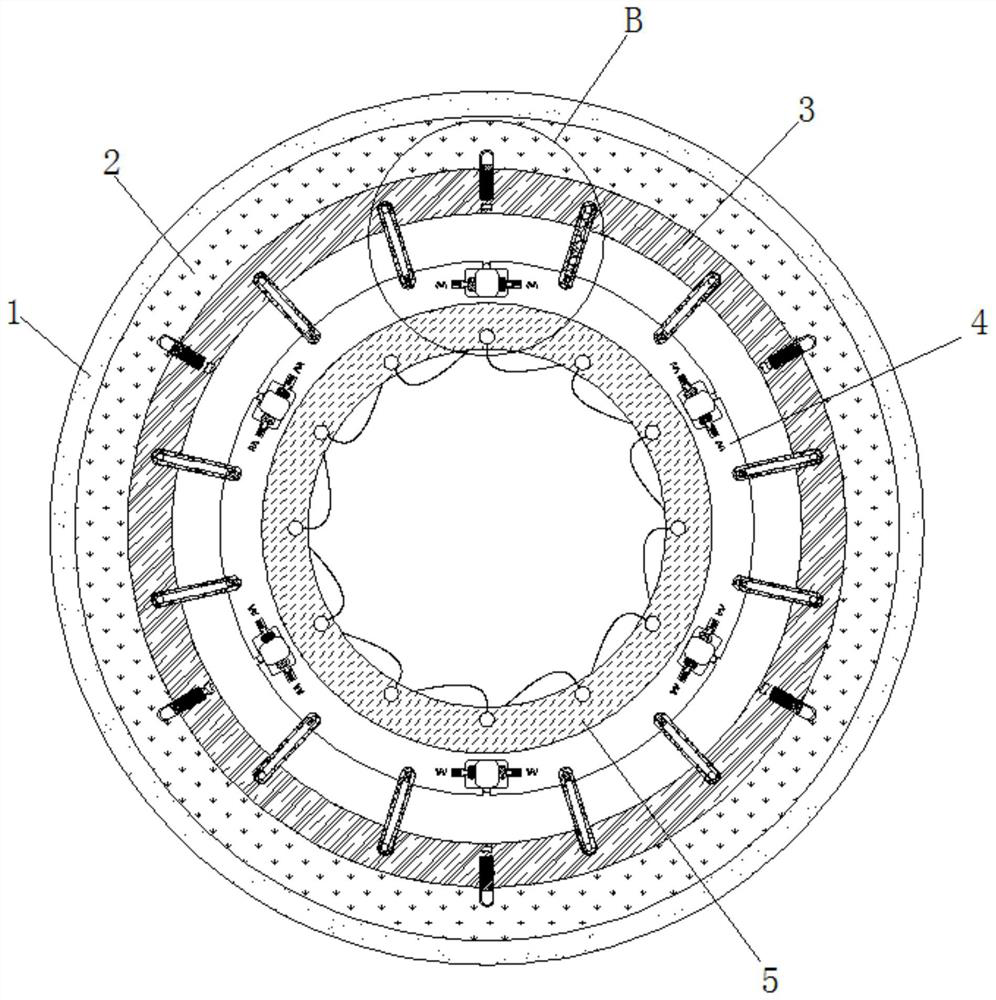

Method for repairing screw hole of normal-pressure cutterhead and cutterhead cylinder of slurry balance shield tunneling machine

ActiveCN113756826ACause scrapAvoid causing re-damage repairsMining devicesTunnelsStructural engineeringDamage repair

The invention discloses a method for repairing a screw hole of a normal-pressure cutterhead and a cutterhead cylinder of a slurry balance shield machine. The method comprises the following steps: 1, cleaning and fixing a cutter cylinder to be repaired; 2, mounting a positioning tool; 3, drilling and dismounting the positioning tool; 4, repairing the screw hole to be repaired; and 5, plugging the repaired screw hole. The to-be-repaired cutterhead cylinder is reversely fixed on the drilling machine, the to-be-repaired screw hole is repaired from the reverse side of the fixed end of the cutterhead holder, the repair process is simple, the possibility of re-damage repair and even cutterhead cylinder scrapping caused by an old repair process is avoided, and a large amount of time cost and capital cost can be saved; and meanwhile, the positioning tool is used for determining the position of the screw hole from the reverse side of the fixed end of the tool apron, so that the repairability of the cutterhead cylinder is improved on the premise that the cutterhead cylinder to be repaired is not damaged, the reliability of the cutterhead cylinder is further improved, the service life of the cutterhead cylinder is further prolonged, and the later construction risk is reduced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

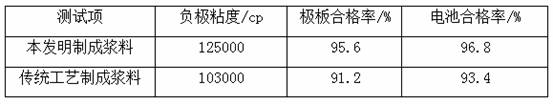

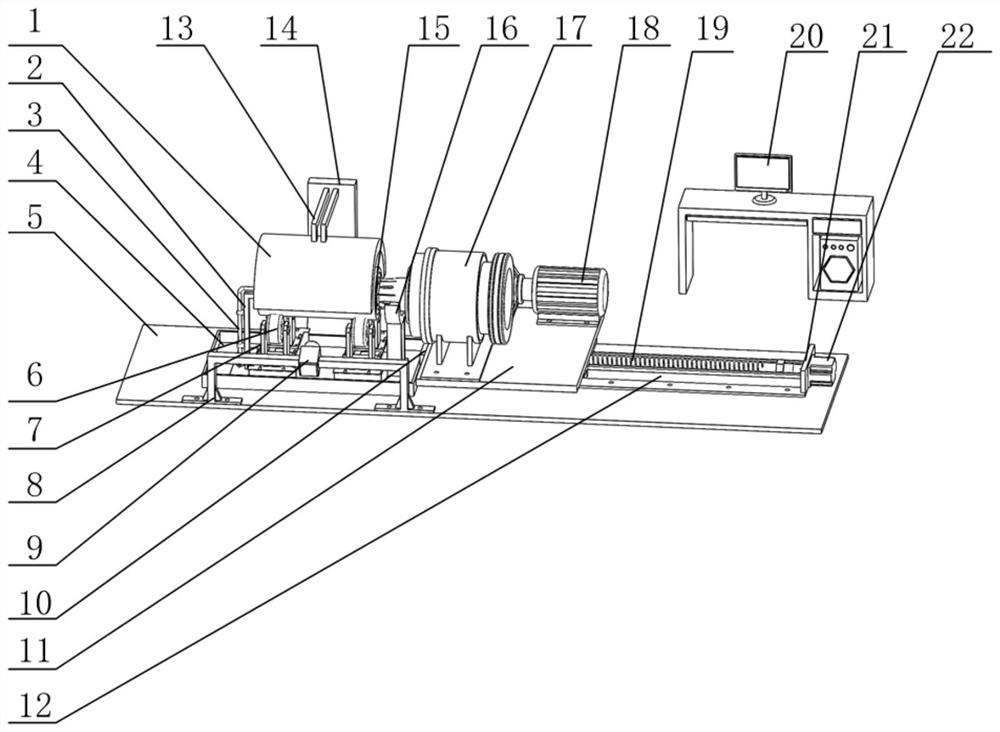

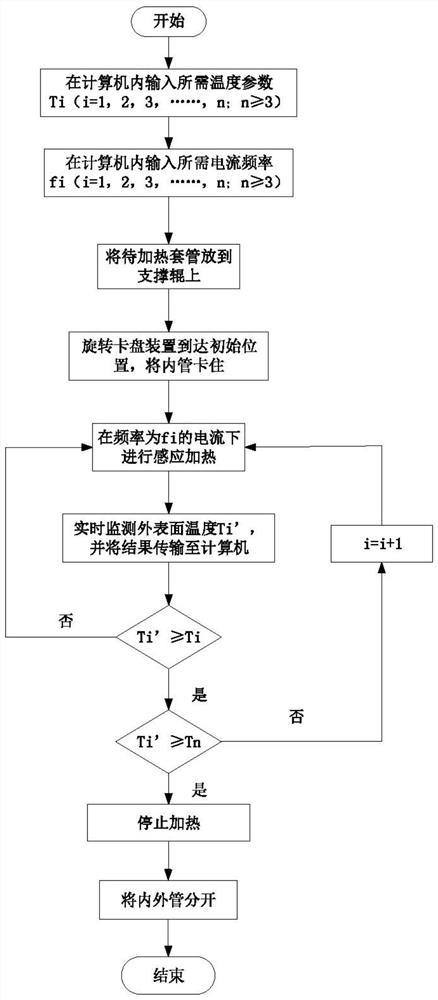

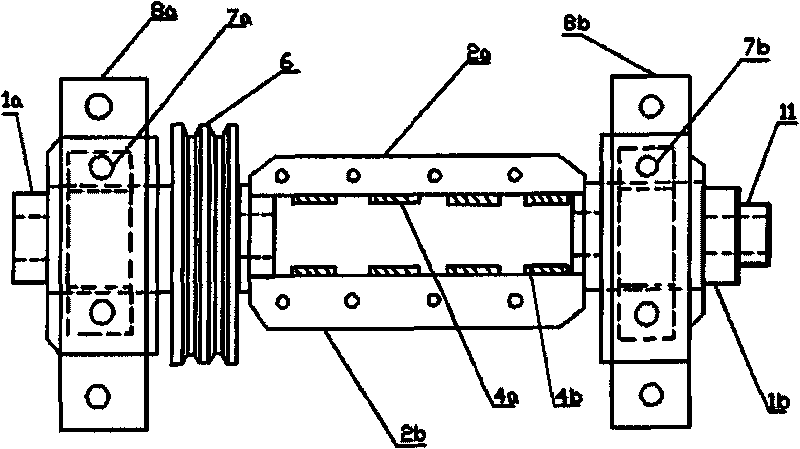

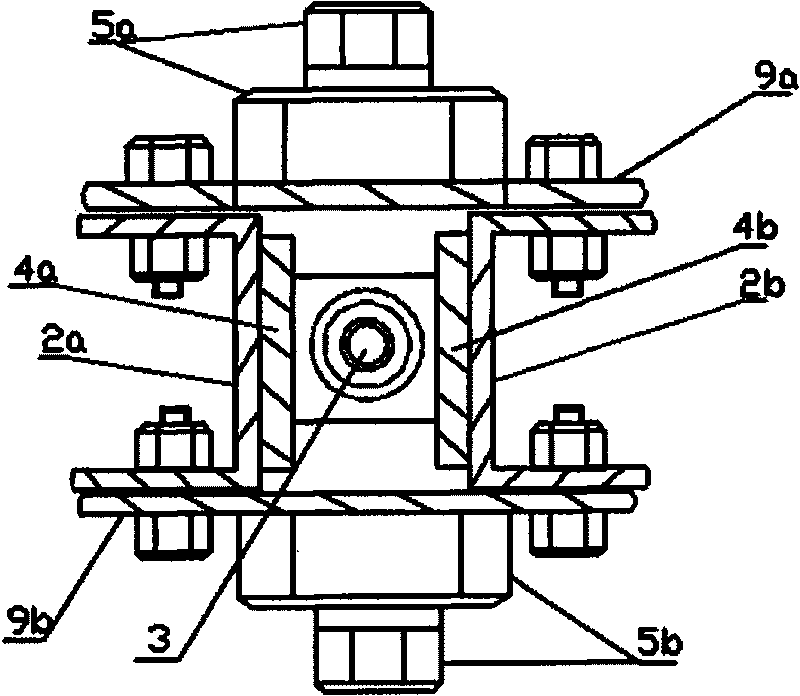

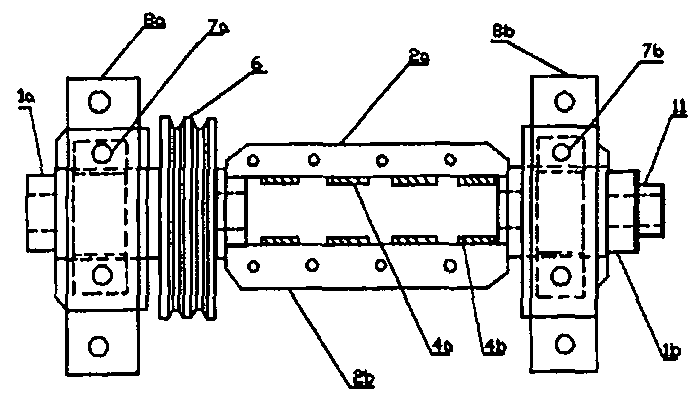

Sleeve dismounting device and method based on asynchronous multi-frequency induction heating

The invention relates to a sleeve dismounting device and method based on asynchronous multi-frequency induction heating, and belongs to the technical field of heat treatment. The device comprises a computer, a platform, a cooling device arranged on the platform, a water tank, a rack fixed to the platform, a supporting roller arranged on the rack, a vertical power table fixed to the side face of the platform, a multi-frequency induction heating device, a rotary chuck device, a horizontal moving device, a semicircular baffle and a temperature measuring device. According to the principle that the penetration depths of currents at different frequencies are different, an inner pipe and an outer pipe of a sleeve are made to have a large temperature difference, so that the inner pipe and the outer pipe deform to different degrees after being heated, the original interference fit between the inner pipe and the outer pipe is changed into clearance fit, and finally the inner pipe and the outer pipe are separated through pushing force provided by an inner jaw chuck and the semicircular baffle. Therefore, the waste of materials is reduced.

Owner:东北大学秦皇岛分校

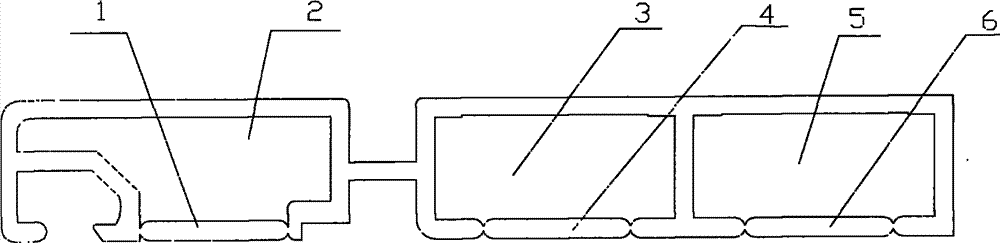

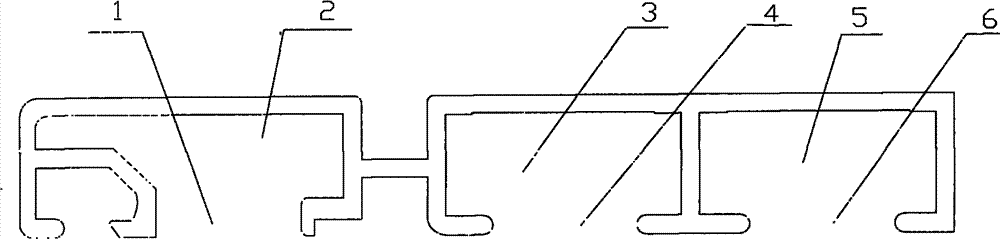

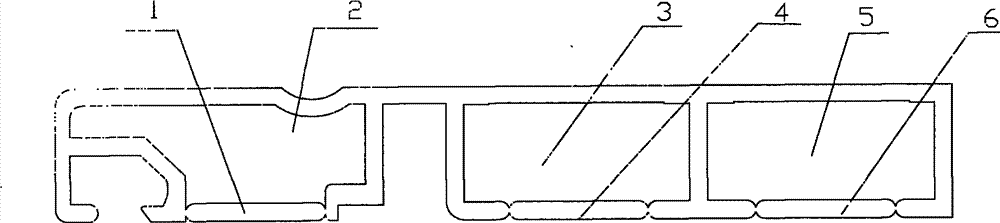

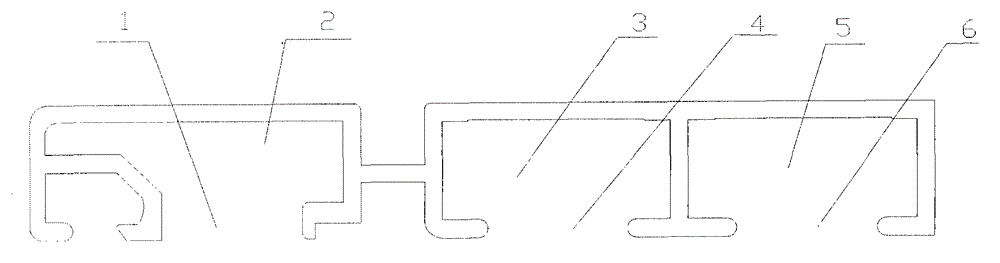

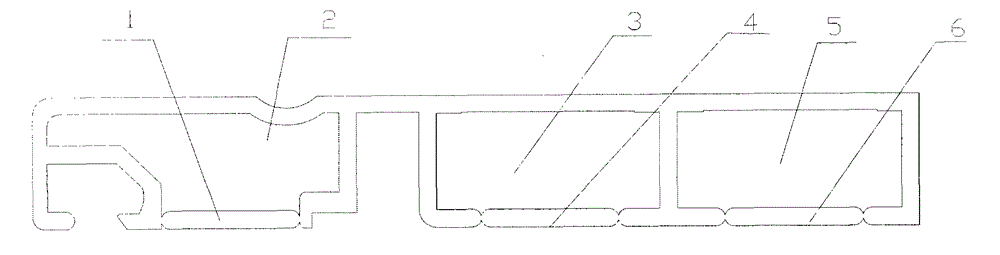

Aluminum alloy section for aluminum-wood composite abnormal-shaped doors and windows

ActiveCN102966290AWith tensile bending strengthNo more scrappingWing framesMetallurgyAbnormal shaped

The invention discloses an aluminum alloy section for aluminum-wood composite abnormal-shaped doors and windows. The aluminum alloy section comprises a plurality of non-closed cavities and connection strips, wherein the number of the connection strips is equal to that of the non-closed cavities and the connection strips are matched with the non-closed cavities; and each connection strip is in an integral structure with and weakly connected with the wall of an opening of each non-closed cavity. The non-closed cavities are closed by the connection strips, the connection strips serve as support pieces when the aluminum alloy section is curved, so that the non-closed cavities have the drawing curve strength which is the same as that of a closed-cavity, and even if the aluminum alloy section is curved into an abnormal-shaped door and window section with the radius less than 1.2 m, the non-closed cavities do not deform, the section is not shrunk or cracked, and a coating is not damaged, etc. The connection strips are torn off after the aluminum alloy section is curved, so that the step of firstly cushioning the support pieces during curving is saved, the section is not discarded as useless, and time and labor are saved. The aluminum alloy section is formed in one-step machining, no test processing is needed, and the reported loss rate is less than 5%.

Owner:HEBEI ORIENT SUNDAR WINDOW

A cutting process for thin-walled parts

ActiveCN113042803BEasy to fixAvoid scrappingShearing machinesMetal working apparatusEngineeringMachining process

The invention relates to the technical field of thin-walled parts processing, in particular to a cutting process for thin-walled parts, which uses a cutting device. The invention uses a fixed cylinder to drive a fixed rod to move downward, so that the first rotating rod and the second rotating rod When the rod rotates, one end of the second rotating rod is slidingly connected with the pressing plate, so that the translational movement of the pressing plate is offset against the inner wall of the workpiece. Press the outer side of the workpiece, so that the inside and outside of the workpiece can be fixed through the synchronous pressing of the arc plate and the pressing plate, so that the workpiece can be fixed more firmly, avoiding the movement of the workpiece during processing and causing material scrapping, and improving work efficiency.

Owner:苏州莱易精密机电有限公司

Casting method of solid stainless steel cooler

The invention discloses a casting method of a solid stainless steel cooler. The technical scheme lies in that a first embodiment and a second embodiment are adopted due to that a die is used for casting to obtain a left half stainless steel solid housing or hollow housing and a right half stainless steel solid housing or hollow housing; according to the first embodiment, the following steps are included: firstly, the left half solid housing and the right half solid housing are obtained by casting by adopting a conventional casting method; secondarily, the left half stainless steel solid housing and the right half stainless steel solid housing are spliced and welded together due to that the pipeline of each of the two halves of stainless steel solid housings is formed by multiple sections of independent cavities; finally, the well welded semi-finished product is ground and polished, so as to obtain the solid stainless steel cooler; according to the second embodiment, the following steps are included: firstly, the left half hollow housing and the right half hollow housing are obtained by casting; secondarily, a preliminarily prepared downward spiral stainless steel pipe is welded together with an upper connector and a lower connector of the preliminarily casted left half stainless steel housing; then, the left half stainless steel housing and the right half stainless steel housing are welded together; metal with the melting point being lower than that of stainless steel is poured into the well welded semi-finished product through an upper reserved port; the upper reserved port is blocked by welding a corresponding filling patch after cooling; and finally, the well welded semi-finished product is ground and polished, so as to obtain the solid stainless steel cooler.

Owner:山东泓阳复合板有限公司

Closing wheel disassembling and assembling tool

PendingCN112123274ACause scrapGuarantee disassembly accuracyMetal-working hand toolsScrew threadIndustrial engineering

The invention discloses a closing wheel disassembling and assembling tool. The closing wheel disassembling and assembling tool is characterized in that a wheel body separation tool body is composed ofa pulling plate abutting rod, pulling plate screws, a pulling plate and a first pressing plate, cylindrical holes are formed in the two ends of the pulling plate, the pulling plate screws penetrate through the cylindrical holes of the pulling plate to be installed on an eccentric sleeve, a threaded hole is formed in the middle of the pulling plate, a limiting groove is formed in the first pressing plate, the pulling plate abutting rod is matched with the threaded hole in the middle of the pulling plate, the lower end of the pulling plate abutting rod is arranged in the limiting groove in an abutting mode, the two ends of the first pressing plate press the upper end face of a closing wheel body, a structure disassembling tool body is composed of three pressing plates and a pressing plate handle, threaded holes are formed in the middles of the three pressing plates, the pressing plate handle is provided with an external thread, the end of the pressing plate handle can be in threaded fitwith the middles of the three pressing plates, the two ends of the three pressing plates can abut against the edge of the inner ring of a 6826 bearing, press the lower end face of the eccentric sleeve and abut against the edge of the inner ring of a 6830 bearing correspondingly. According to the closing wheel disassembling and assembling tool, a closing wheel can be disassembled and assembled easily and rapidly.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

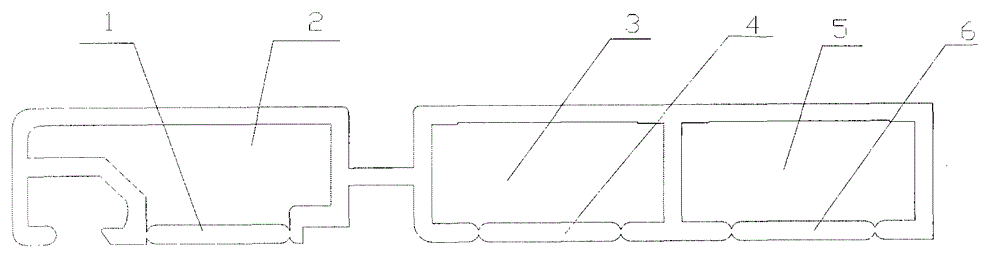

An u-iron frame type straightening drum

The invention relates to a channel steel frame type aligning barrel, which comprises a front hollow-core axis, a rear hollow-core axis, an upper fixing channel steel, a lower fixing channel steel, anupper aligning block middle locating plate, a lower aligning block middle locating plate, an upper aligning block pressure screw adjusting screw cap, a lower aligning block pressure screw adjusting screw cap, an upper aligning block movable pressure screw plate and a lower aligning block movable pressure screw plate, wherein, the upper fixing channel steel and the lower fixing channel steel are distributed symmetrically, and a middle cavity is encircled by the bottom wing of the upper fixing channel steel, the bottom wing of the lower fixing channel steel, the upper aligning block movable pressure screw plate and the lower aligning block movable pressure screw plate. The invention has the advantages that the lower aligning block movable pressure screw plate is a movable screw plate, the adjusting screw and the screw cap of the aligning block can be changed arbitrarily, the whole aligning barrel can not be scraped for the slippage of the screw, the structure is very simple, the maintenance is convenient, the service life is long, the special purposed mechanical processing is unnecessary, and the cost of manufacture is low.

Owner:龙乐武

An aluminum alloy profile for aluminum-wood composite special-shaped doors and windows

ActiveCN102966290BWith tensile bending strengthNo more scrappingWing framesAluminum compositesAbnormal shaped

The invention discloses an aluminum alloy section for aluminum-wood composite abnormal-shaped doors and windows. The aluminum alloy section comprises a plurality of non-closed cavities and connection strips, wherein the number of the connection strips is equal to that of the non-closed cavities and the connection strips are matched with the non-closed cavities; and each connection strip is in an integral structure with and weakly connected with the wall of an opening of each non-closed cavity. The non-closed cavities are closed by the connection strips, the connection strips serve as support pieces when the aluminum alloy section is curved, so that the non-closed cavities have the drawing curve strength which is the same as that of a closed-cavity, and even if the aluminum alloy section is curved into an abnormal-shaped door and window section with the radius less than 1.2 m, the non-closed cavities do not deform, the section is not shrunk or cracked, and a coating is not damaged, etc. The connection strips are torn off after the aluminum alloy section is curved, so that the step of firstly cushioning the support pieces during curving is saved, the section is not discarded as useless, and time and labor are saved. The aluminum alloy section is formed in one-step machining, no test processing is needed, and the reported loss rate is less than 5%.

Owner:HEBEI ORIENT SUNDAR WINDOW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com