An aluminum alloy profile for aluminum-wood composite special-shaped doors and windows

An aluminum alloy profile and aluminum-wood composite technology, which is applied in the field of aluminum alloy profiles for aluminum-wood composite special-shaped doors and windows, can solve the problems of profile wrinkling, coating damage, profile fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

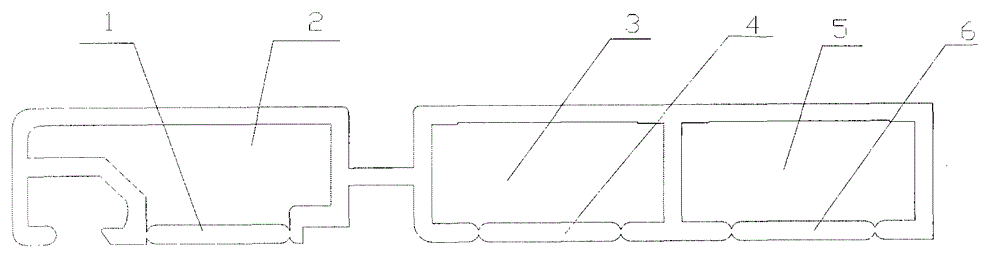

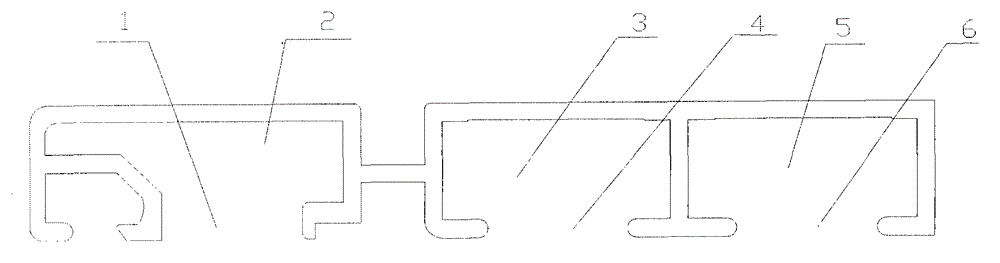

[0011] like figure 1 Shown in Embodiment 1, this embodiment includes three non-closed cavities 2, 3 and 5 and three connecting strips 1, 4 and 6 respectively matched with the three non-closed cavities 2, 3 and 5. The connecting strips 1 , 4 and 6 are weakly connected to the walls at the openings of the non-closed cavities 2 , 3 and 5 . When bending an arc, add two support strips matching the gap in the gap between the two non-closed cavities 2 and 3. figure 2 It is a schematic diagram of the cross-sectional structure after the weak connecting strips 1, 4 and 6 are torn off after the arc bending in this embodiment is completed.

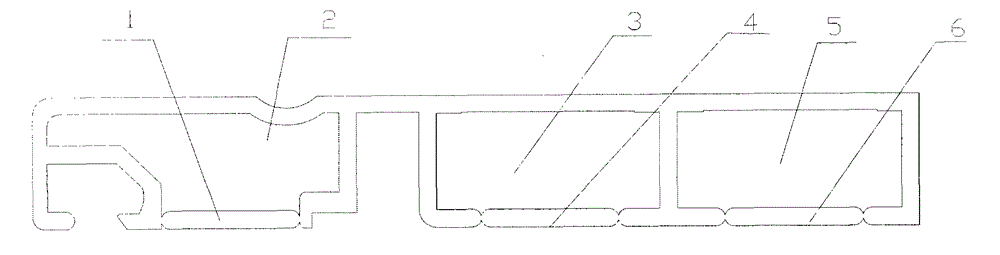

[0012] like image 3 In the shown embodiment 2, other structures of this embodiment are the same as those of embodiment 1, except that a support bar is added in the gap between the two non-closed cavities 2 and 3 . Figure 4 It is a schematic diagram of the cross-sectional structure after the weak connecting strips 1, 4 and 6 are torn off after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com