Method for refining ultra-low carbon ferritic stainless steel under vacuum

A vacuum refining and ultra-low carbon technology, applied in the field of stainless steel smelting, can solve the problems of undiscussed deoxidation and desulfurization in the reduction process, short treatment time, and no involvement, and achieve good deoxidation effect, suitable vacuum treatment time, and reduce smelting costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The equipment requirements of this embodiment: 120t VOD treatment furnace, the ultimate vacuum degree is less than 100Pa, three argon blowing tuyeres at the bottom, and the total blowing capacity is higher than 60Nm 3 / h, the ladle refractory material is magnesia carbon brick (ie MgO-C brick). The initial molten steel temperature is 1610°C, the molten steel weight is 110t, and the smelted steel type is 409L. The main components before treatment are as follows:

[0046] C: 0.3%, Si: 0.03%, Cr: 11.7%, S: 0.005%, N: 0.015%, Mn: 0.22%, P: 0.015%, and the rest are Fe and trace impurity elements.

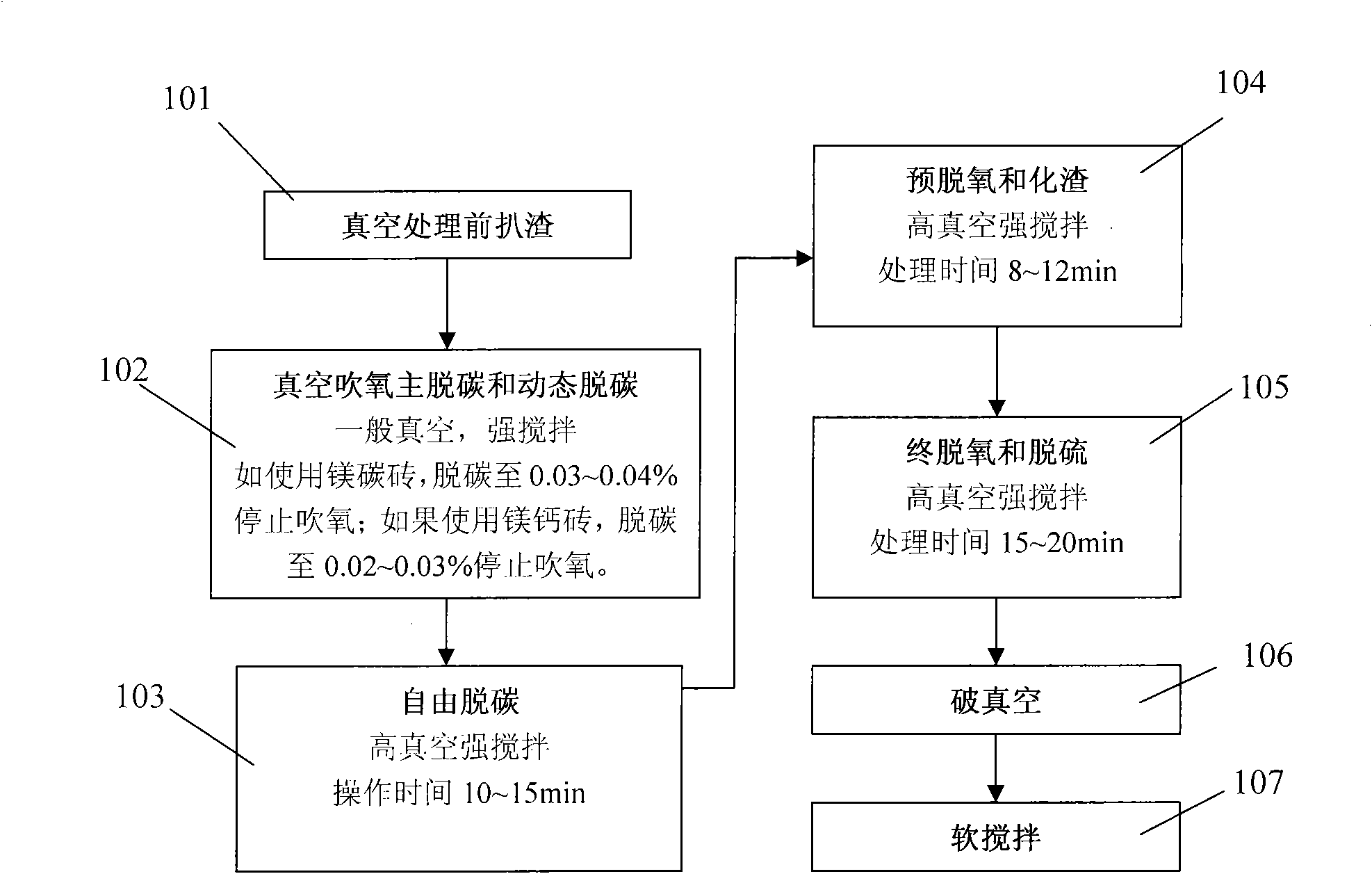

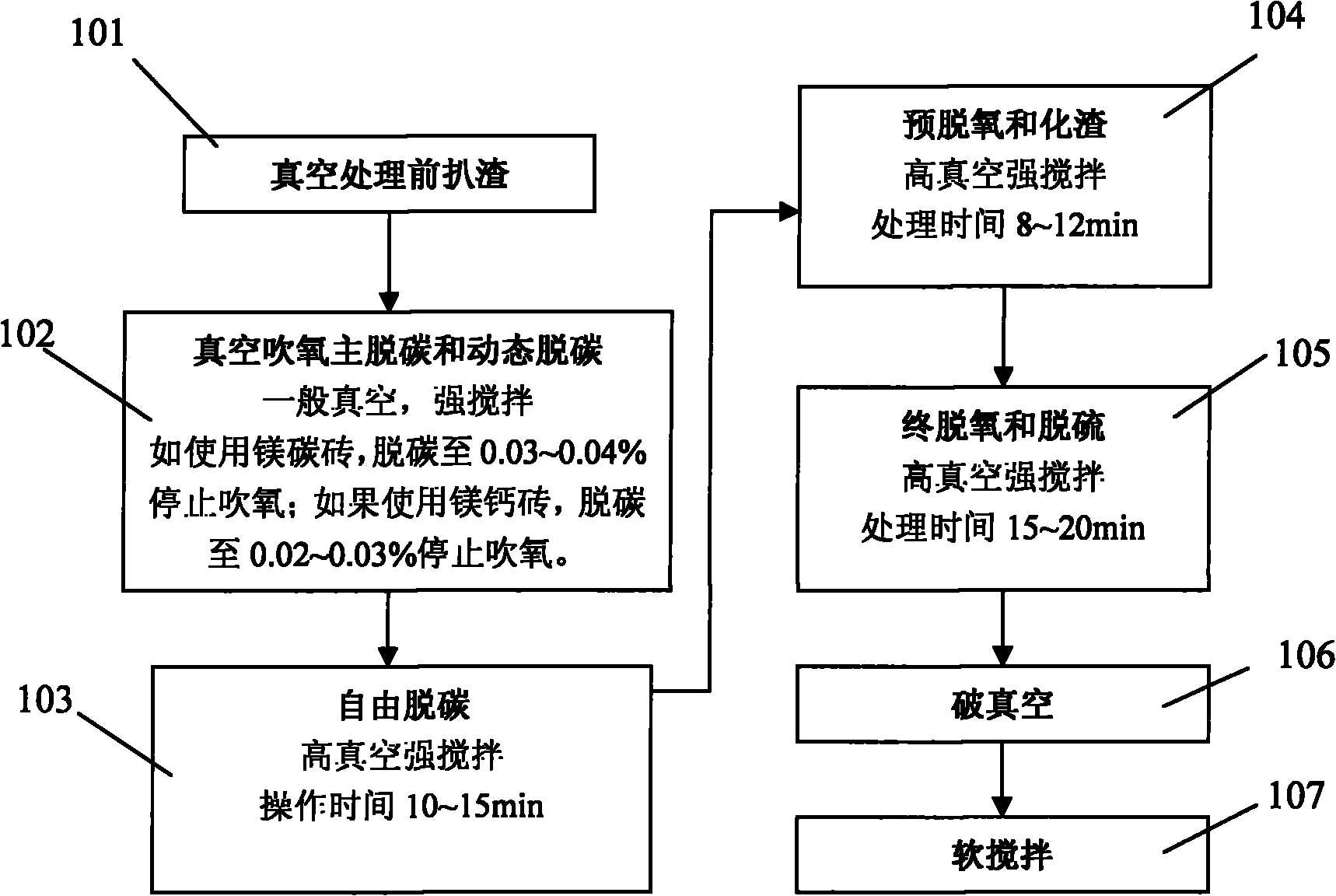

[0047] see figure 1 , combined with the VOD routine operation and this method, the implementation steps are as follows:

[0048] 1. The molten steel in the ladle is subjected to slag removal treatment (101) before entering the VOD station, and the amount of residual slag on the molten steel is less than 500kg;

[0049] 2. The ladle enters the vacuum tank, pre-vacuumizes first, a...

Embodiment 2

[0063] The equipment of this embodiment: 120t VOD treatment furnace, the ultimate vacuum degree is less than 100Pa, three argon blowing tuyeres at the bottom, and the total blowing capacity is higher than 60Nm 3 / h, the ladle refractory material is magnesia-calcium brick (that is, MgO-CaO brick). The initial molten steel temperature is 1621°C, the molten steel weight is 109.8t, and the smelted steel type is 439. The main components before treatment are as follows:

[0064] C: 0.394%, Si: 0.04%, Cr: 17.52%, S: 0.003%, N: 0.010%, Mn: 0.32%, P: 0.012%, and the rest are Fe and trace impurity elements.

[0065] Combining the VOD routine operation and this method, the implementation steps are as follows:

[0066] 1. Before the liquid steel in the ladle enters the VOD station, the slag removal treatment is carried out, and the remaining slag on the molten steel is less than 500kg;

[0067] 2. The ladle enters the vacuum tank, pre-vacuumizes first, and at the same time starts the bo...

Embodiment 3

[0081] The equipment of this embodiment: 120t VOD treatment furnace, the ultimate vacuum degree is less than 100Pa, three argon blowing tuyeres at the bottom, and the total blowing capacity is higher than 60Nm 3 / h, the ladle refractory material is magnesia-calcium brick (that is, MgO-CaO brick). The initial molten steel temperature is 1649°C, the molten steel weight is 118t, and the smelted steel type is 443. The main components before treatment are as follows:

[0082] C: 0.390%, Si: 0.05%, Cr: 20.79%, S: 0.005%, N: 0.020%, Mn: 0.22%, P: 0.010%, and the rest are Fe and trace impurity elements.

[0083] Combining the VOD routine operation and this method, the implementation steps are as follows:

[0084] 1. Before the liquid steel in the ladle enters the VOD station, the slag removal treatment is carried out, and the remaining slag on the molten steel is less than 500kg;

[0085] 2. The ladle enters the vacuum tank, pre-vacuumizes first, and at the same time starts the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com