Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Improve fiber performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

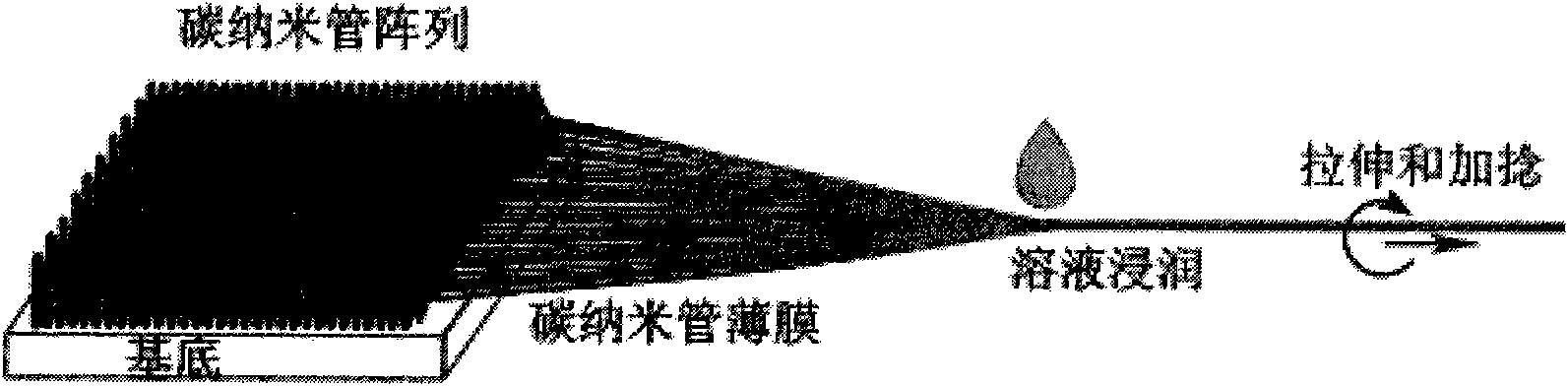

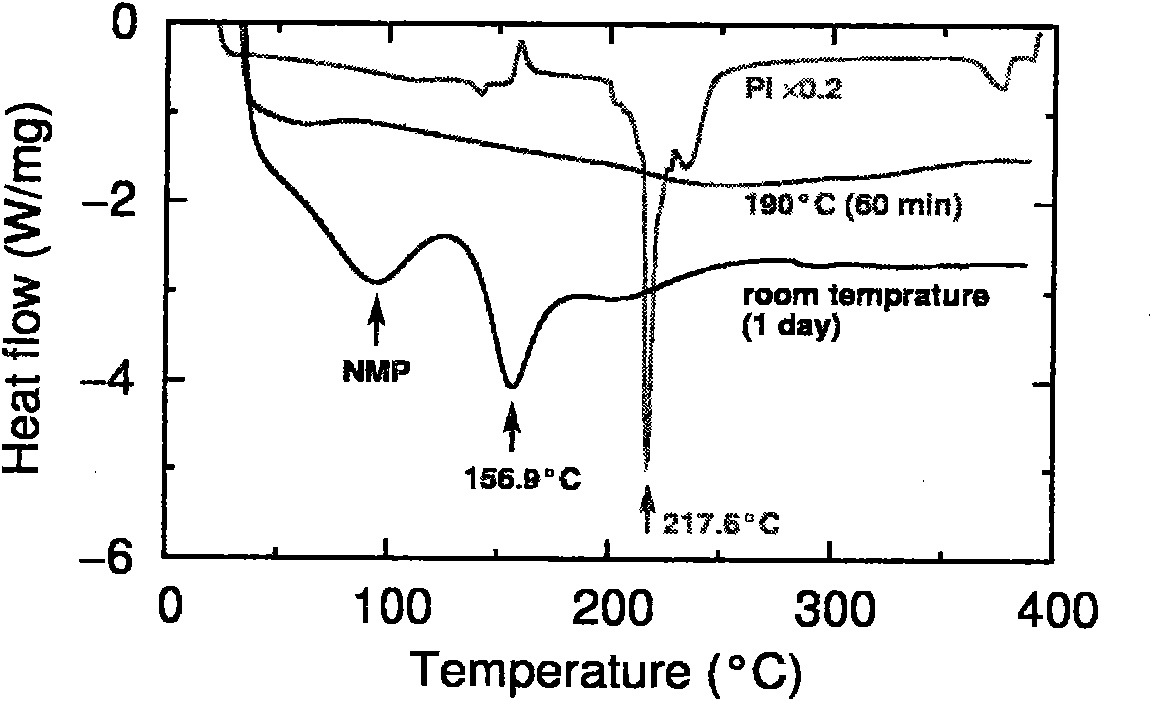

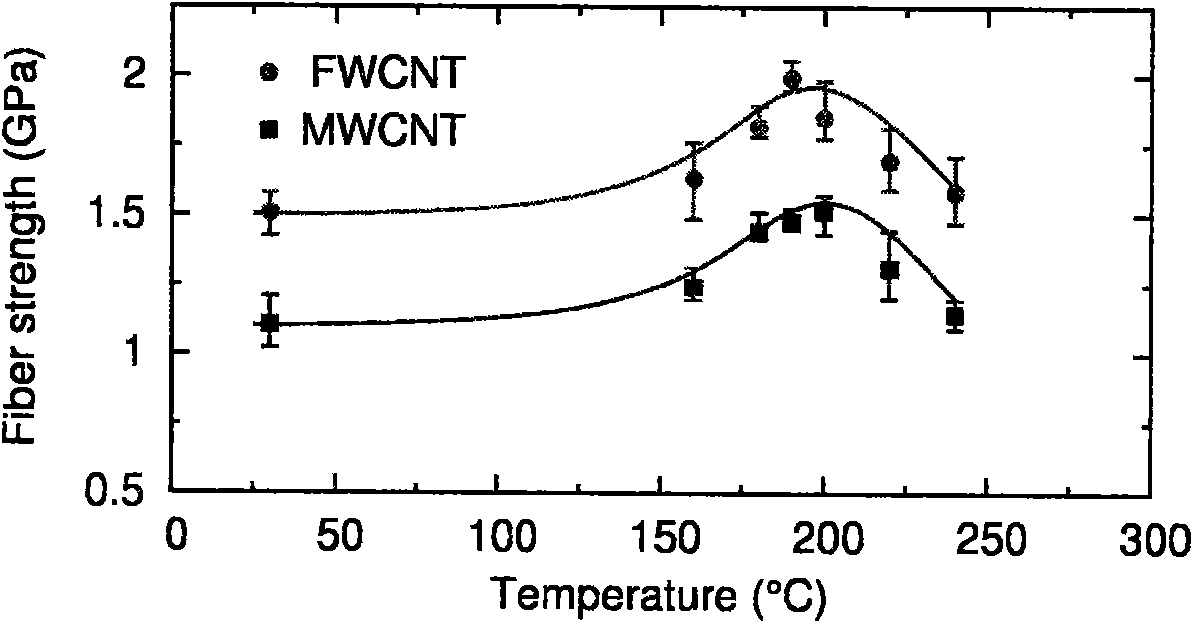

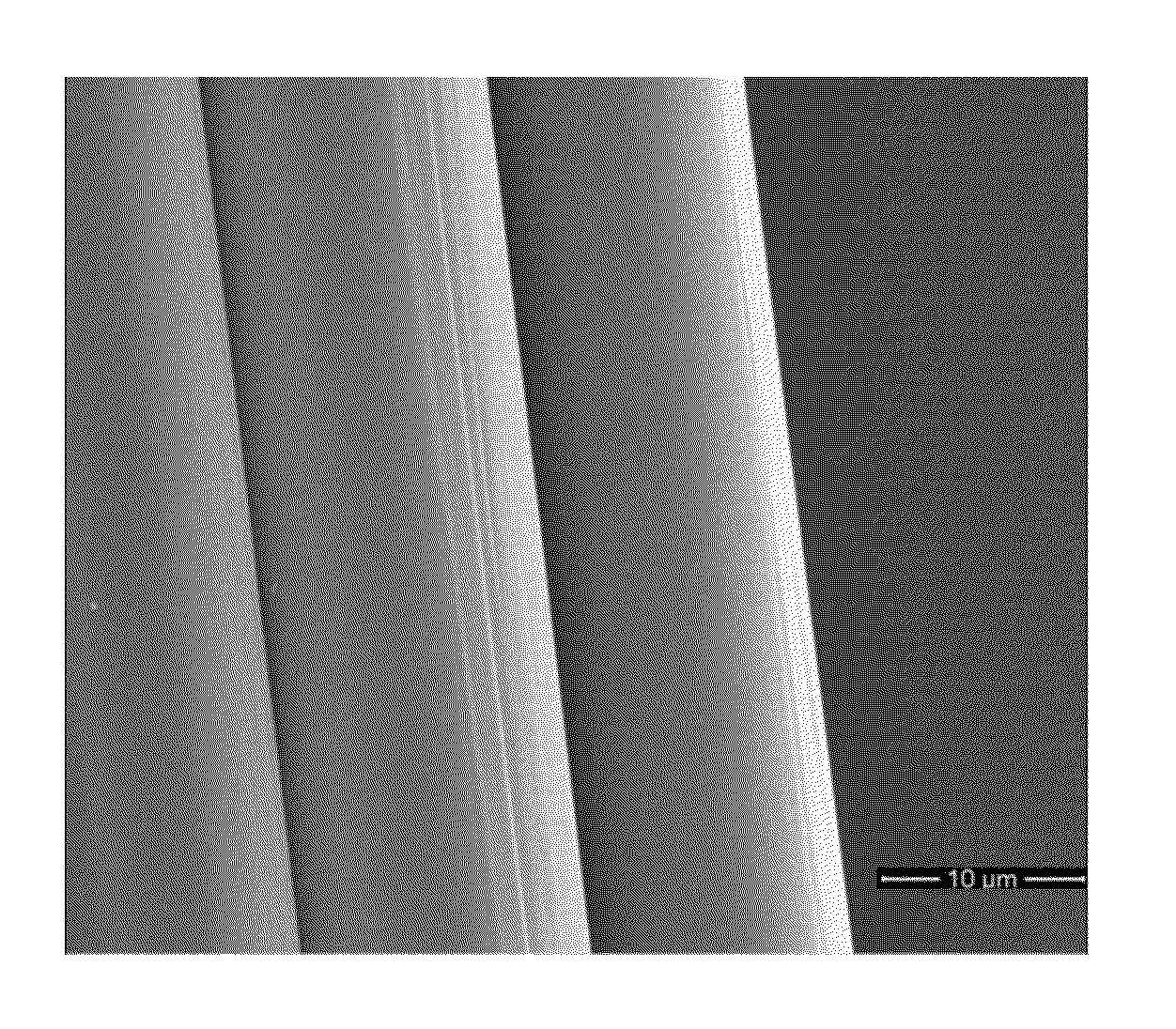

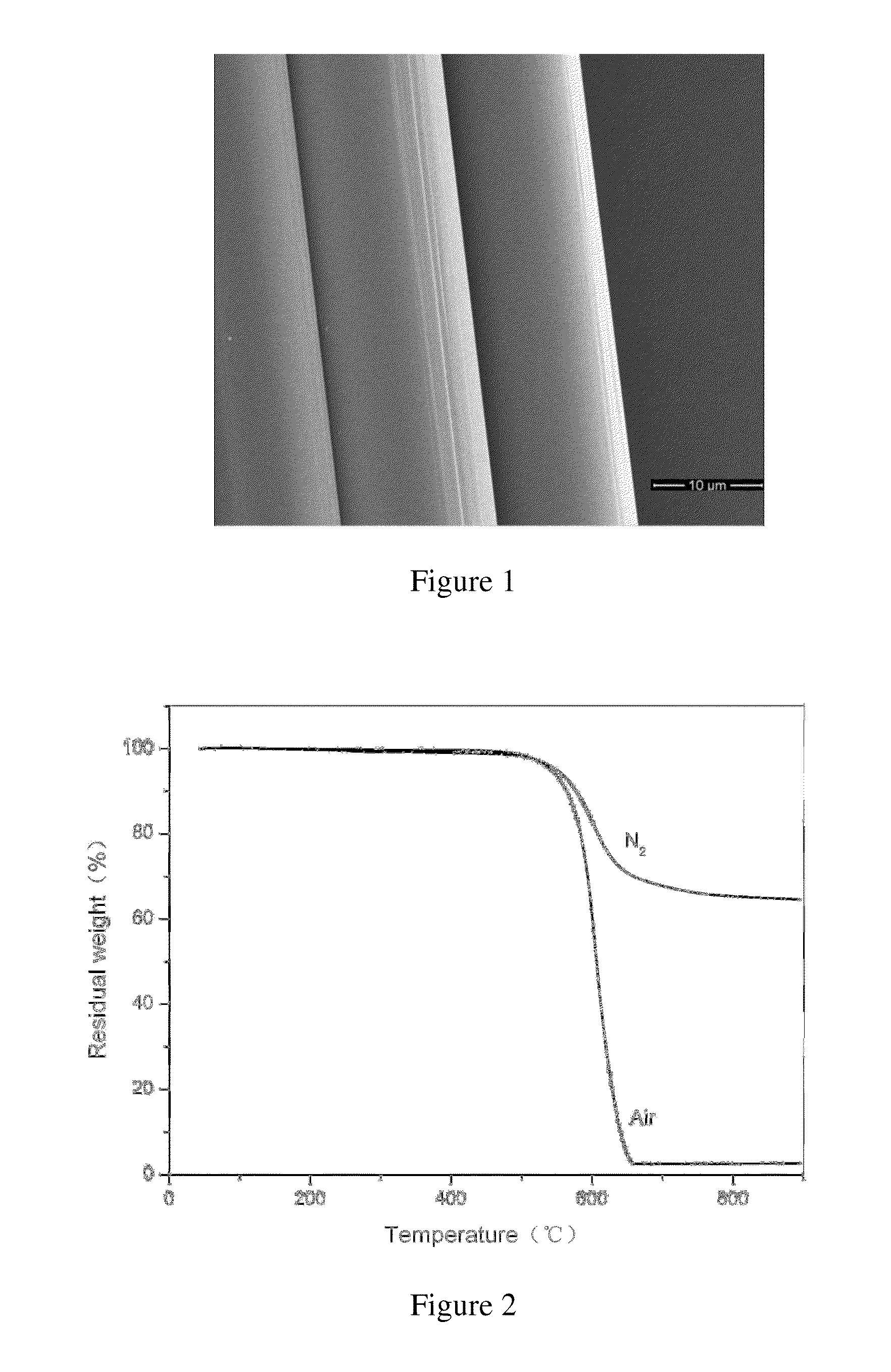

Preparation method of high-performance carbon nanotube fiber

ActiveCN101967699AExcellent mechanical propertiesReduce dosageYarnArtificial filament chemical after-treatmentYarnMechanical properties of carbon nanotubes

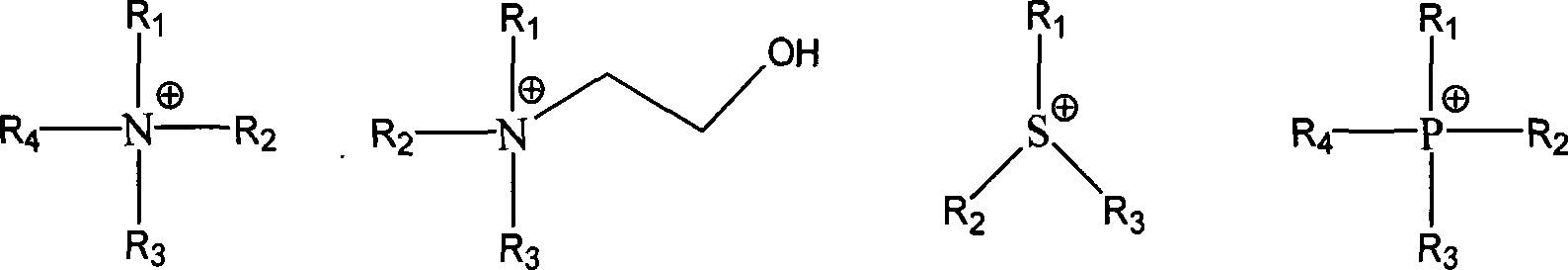

The invention relates to a preparation method of a high-performance carbon nanotube fiber, which comprises the following specific steps of: drawing a carbon nanotube film from a spinning carbon nanotube array; then, immersing the carbon nanotube film in a thermosetting polyamic acid / N-methyl pyrrolidone solution, and twisting to form a carbon nanotube / polyamic acid composite fiber; subsequently, curing the carbon nanotube / polyamic acid composite fiber so that polyamic acid in the composite fiber forms polyimide with a net type crosslinking structure; and finally preparing the carbon nanotube / polyimide composite fiber. The invention has the advantages of simple and easy process, low cost and easy realization of large-scale production; moreover, the prepared carbon nanotube composite fiber has excellent mechanical performance, the strength can reach 2.06 GPa, the tenacity is superior to that of carbon fiber, and the conducting property is maintained unchanged as compared with that of pure carbon nanotube fiber; meanwhile, the carbon nanotube composite fiber also has the operability of common yarn, so that the requirements on subsequent treatment processes of stretching, stranding, weaving and the like can be satisfied.

Owner:SUZHOU CREATIVE CARBON NANOTECH

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Method for preparing protein modified cellulose fibre

InactiveCN101113535AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsYarnCellulose fiber

The invention relates to a preparation method of a protein modified cellulose fiber, comprising the steps that: (1) a protein and a cellulose are dissolved in ion solution to prepare homogeneous mixing spinning solution; (2) the spinning solution is deaerated, filtered, measured, and extruded out through spinning jet to form spinning rills, and the spinning rills pass through a wet air layer and enter into a solidification bath to be solidified and molded; (3) the yarn is extended, cleaned by water, dried and heat molded, and formed into fiber to prepare the protein modified cellulose fiber. The method has the advantages of environmental protective, low cost, fast spinning speed and high production efficiency, and the prepared fiber has the advantages of comfort and health care, etc.

Owner:DONGHUA UNIV

Preparation method of phenolic resin matrix nano activated carbon fiber material

InactiveCN102677193AIncrease flexibilityGood fiber diameterCarbon fibresHeating/cooling textile fabricsFiberCarbon fibers

The invention provides a preparation method of a phenolic resin matrix nano activated carbon fiber material. The preparation method is characterized in that the method specifically comprises the steps of: dissolving benzoxazine monomers and curing catalysts in solvent, adding blending polymers for electrostatic spinning, putting the obtained benzoxazine composite nano fiber membrane in a drying oven for curing, placing the cured benzoxazine composite nano fiber membrane in potassium hydroxide solution for soaking, taking out the benzoxazine composite nano fiber membrane and drying the benzoxazine composite nano fiber membrane in a drying oven to obtain the pretreated benzoxazine composite nano fiber membrane; and placing the pretreated benzoxazine composite nano fiber membrane in a vacuum tube furnace, heating for carbonization under the protection of nitrogen, cooling to room temperature after the carbonization process is ended, acidizing and drying to obtain the phenolic resin matrix nano activated carbon fiber material. The preparation method has a wide application prospect in fields such as activated adsorption, high-temperature catalysis, energy storage and hydrogen storage.

Owner:DONGHUA UNIV

Method of preparing protein modified polyacrylonitrile fibre

InactiveCN101109115AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsIonic liquidHigh productivity

The invention relates to a preparing method for a protein modified polyacrylonitrile fiber, which comprises the following procedures: (1) some protein and polyacrylonitrile are solved in some ion liquid to prepare some equal-phase mixed crude liquid for spinning; (2) the spinning liquid is de-bubbled, filtered, dosed, then extruded by a spinning jet to form a fine spinning flow, which passes a wet air layer and enters into a condensing bath to condense and form; (3) fiber is spun after pre-tensioning, tensioning, water washing, drying and thermal forming, so protein modified polyacrylonitrile fiber is prepared. The method is environmental friendly, easy to recycle, of low production cost and high productivity; the clothing from the product made by the method is highly comfortable and healthy, and is of high fiber property.

Owner:DONGHUA UNIV

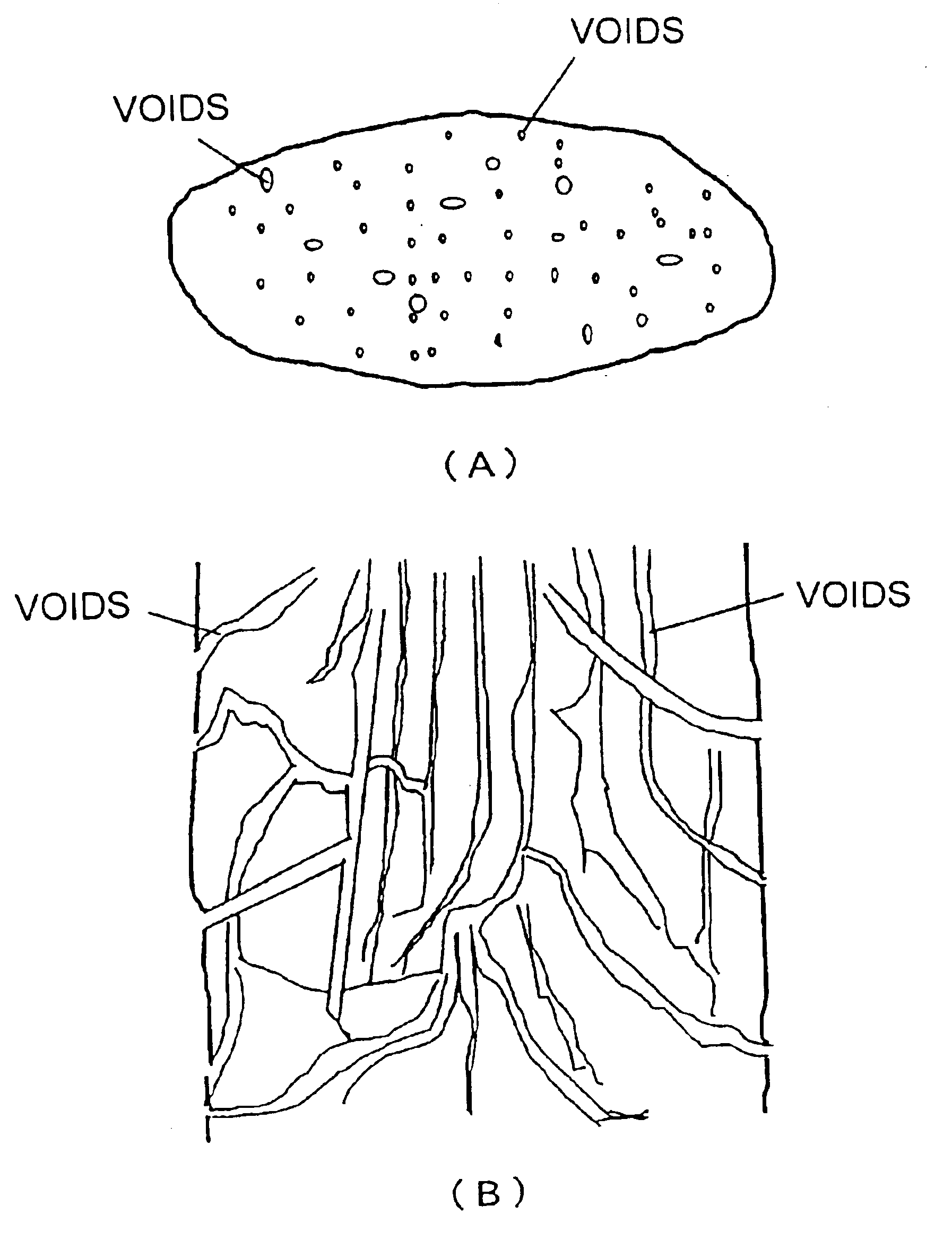

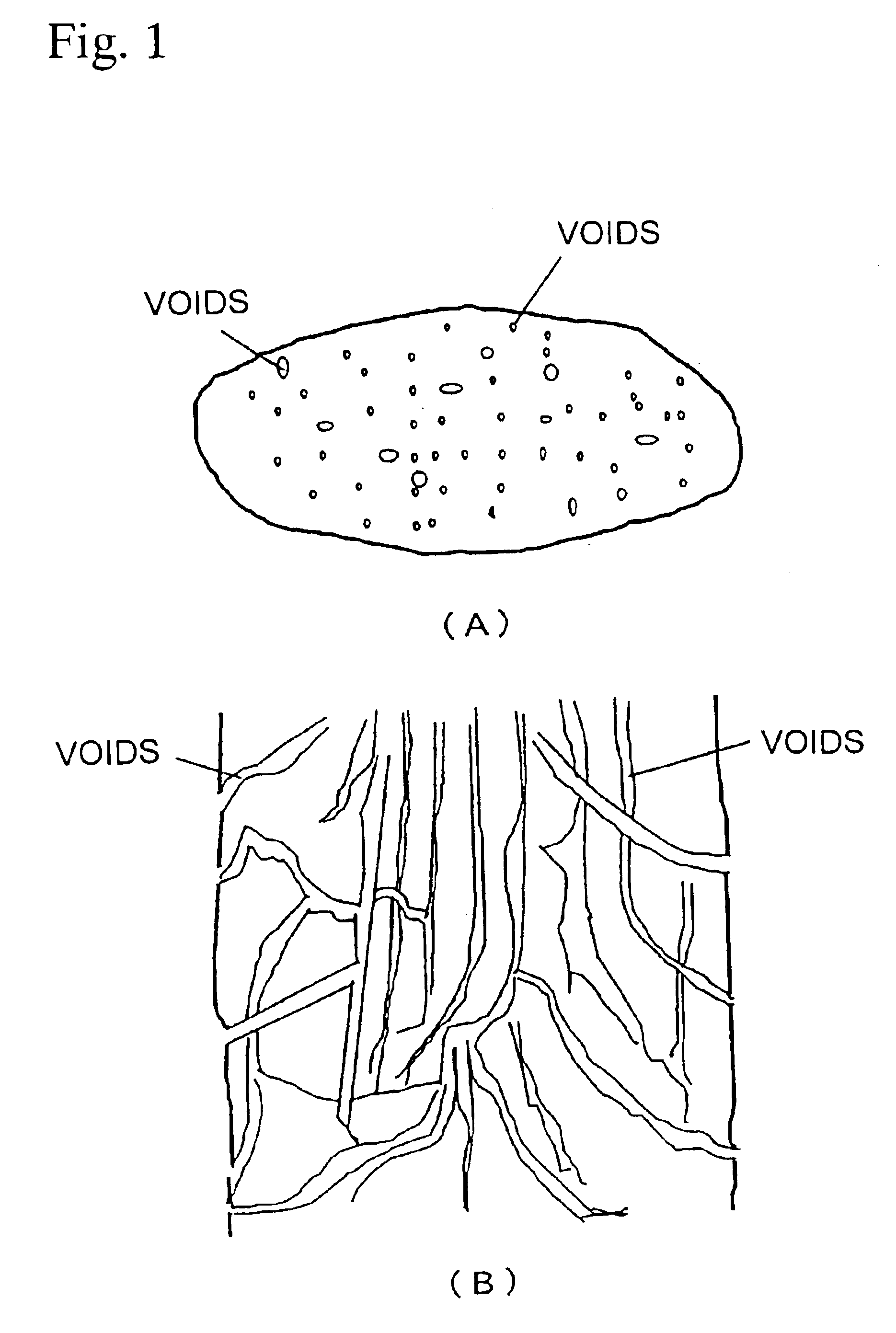

Porous acrylic fiber and fabric comprising the same, and method of producing the same

InactiveUS6821599B1Avoid decompositionImprove featuresLayered productsMonocomponent synthetic polymer artificial filamentSingle fiberThermal water

Porous acrylic fibers produced by a method comprising subjecting a spinning dope containing 0.3 to 20 parts by weight of poly(vinyl acetate) relative to 100 parts of an acrylic copolymer to a wet spinning to give fibers, crimping and cutting the fibers, subjecting the resultant fibers to a treatment by hot water at 90 to 100° C. for 30 to 120 minutes or by saturated steam at 90 to 130° C. for 10 to 90 minutes to thereby form porous fibers; and a pile fabric having pile portions which comprise the porous fibers in an amount of 3 wt % or more, and, in the pile fabric, respective single fibers are visible being separate and emphasized, and thus the pile fabric has an appearance being highly decorative and excellent in design characteristics.

Owner:KANEKA CORP

Preparation method of polyacrylonitrile fibres by using protein as modifier

InactiveCN103397400AImprove protectionGood for healthArtificial thread manufacturing machinesArtificial filament washing/dryingTrickle flowHeat setting

The invention relates to a preparation method of polyacrylonitrile fibres by using protein as a modifier. The preparation method comprises the following steps of (1) dissolving protein and polyacrylonitrile in an ionic liquid, and preparing a homogeneous-phase mixed spinning solution; (2) defoaming, filtering and measuring the spinning solution, and then extruding via a spinning jet to form a spinning trickle flow, and passing the spinning trickle flow through a humid air layer and then entering into a coagulating bath, and performing coagulating forming; and (3) performing pre-drawing, drawing, water-washing, drying and heat-setting, and then performing spinning forming, so as to prepare protein-modified polyacrylonitrile filaments or short fibres.

Owner:SUZHOU LONGJIE SPECIAL FIBER

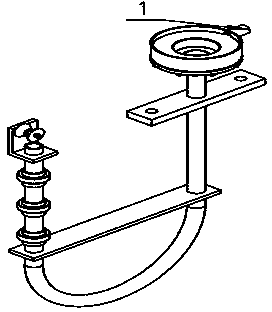

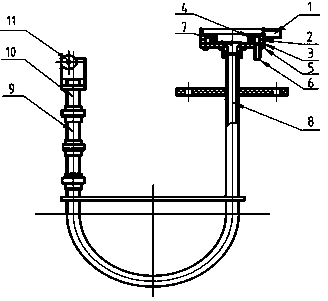

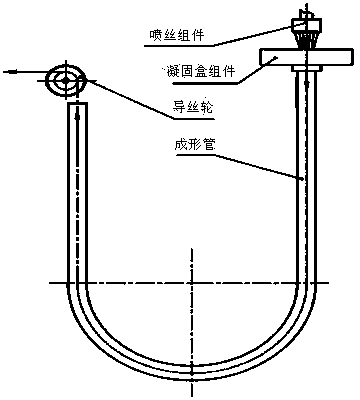

Dry spraying-wet spinning method for manufacturing aramid III fiber

ActiveCN103572390AIncrease spinning speedIncrease productivityWet spinning methodsDry spinning methodsYarnEngineering

The invention discloses a dry spraying-wet spinning method for manufacturing an aramid III fiber. The method comprises the following processing steps that A, a spinning stock solution is subjected to fine filtering and defoaming, and then extruded by a spinneret plate to form trickle; the trickle passes through an air layer and then enters a coagulating bath; B, the spinneret plate extruded trickle is coagulated in a coagulating forming device by the coagulating bath; a nascent fiber is obtained; the coagulating forming device comprises a coagulating disc and a U-shaped coagulating pipe; C, a solvent and an impurity of the coagulated and formed aramid III nascent fiber are removed by a washing technology; D, the washed fiber is oiled and dried; an aramid III fiber grey yarn is obtained; and E, the aramid III fiber grey yarn is subjected to heat treatment by heat shaping equipment; and the finished fiber is obtained. According to the method, a spinning speed and the production efficiency of the aramid III fiber are increased and improved greatly, so that the production cost of the fiber is lowered effectively; the manufactured aramid III fiber has excellent fiber performance and appearance quality and high cost performance; and the strength of the aramid III fiber is higher than that of a commercially available aramid 1414 high-strength product K129.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

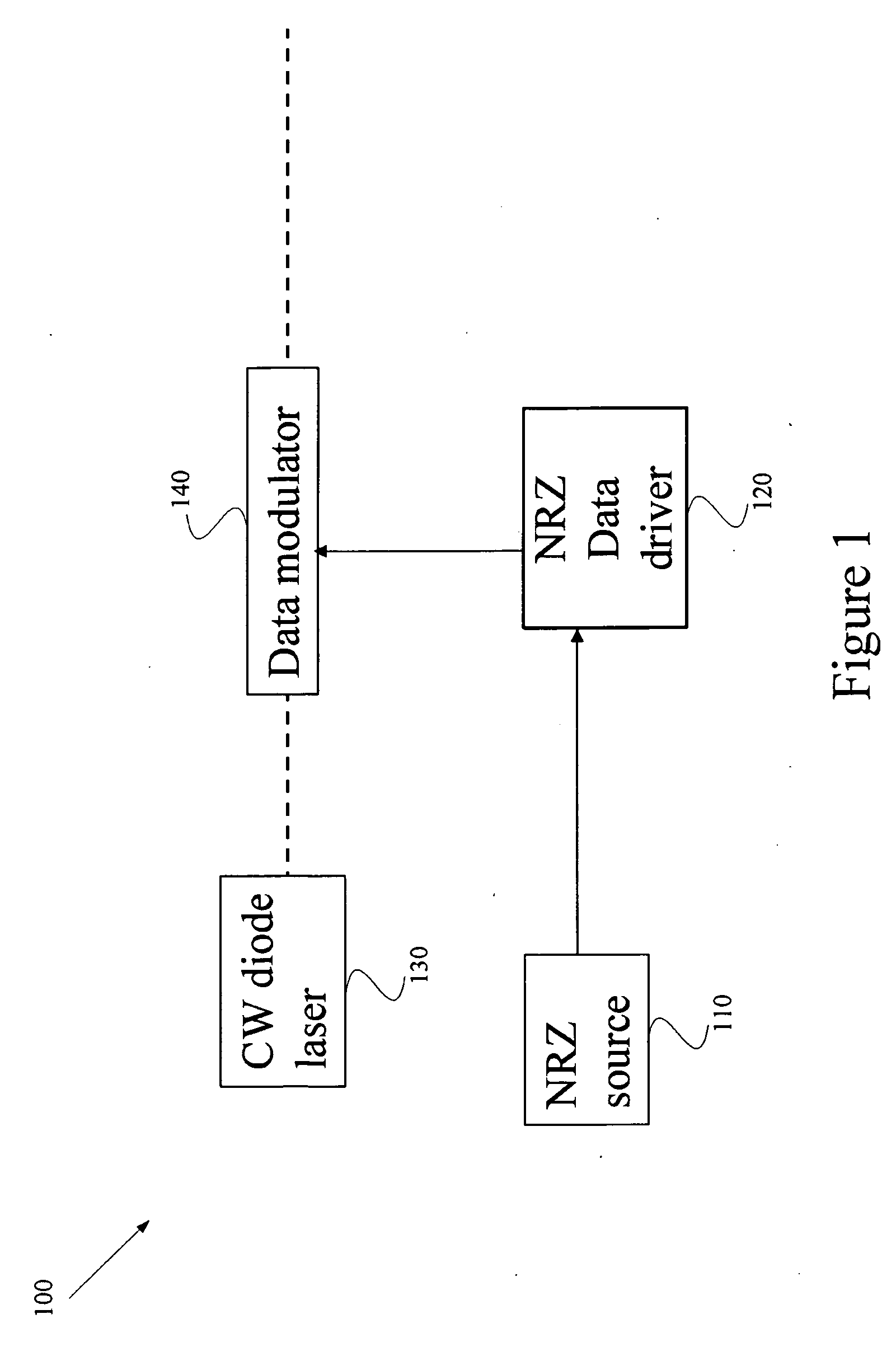

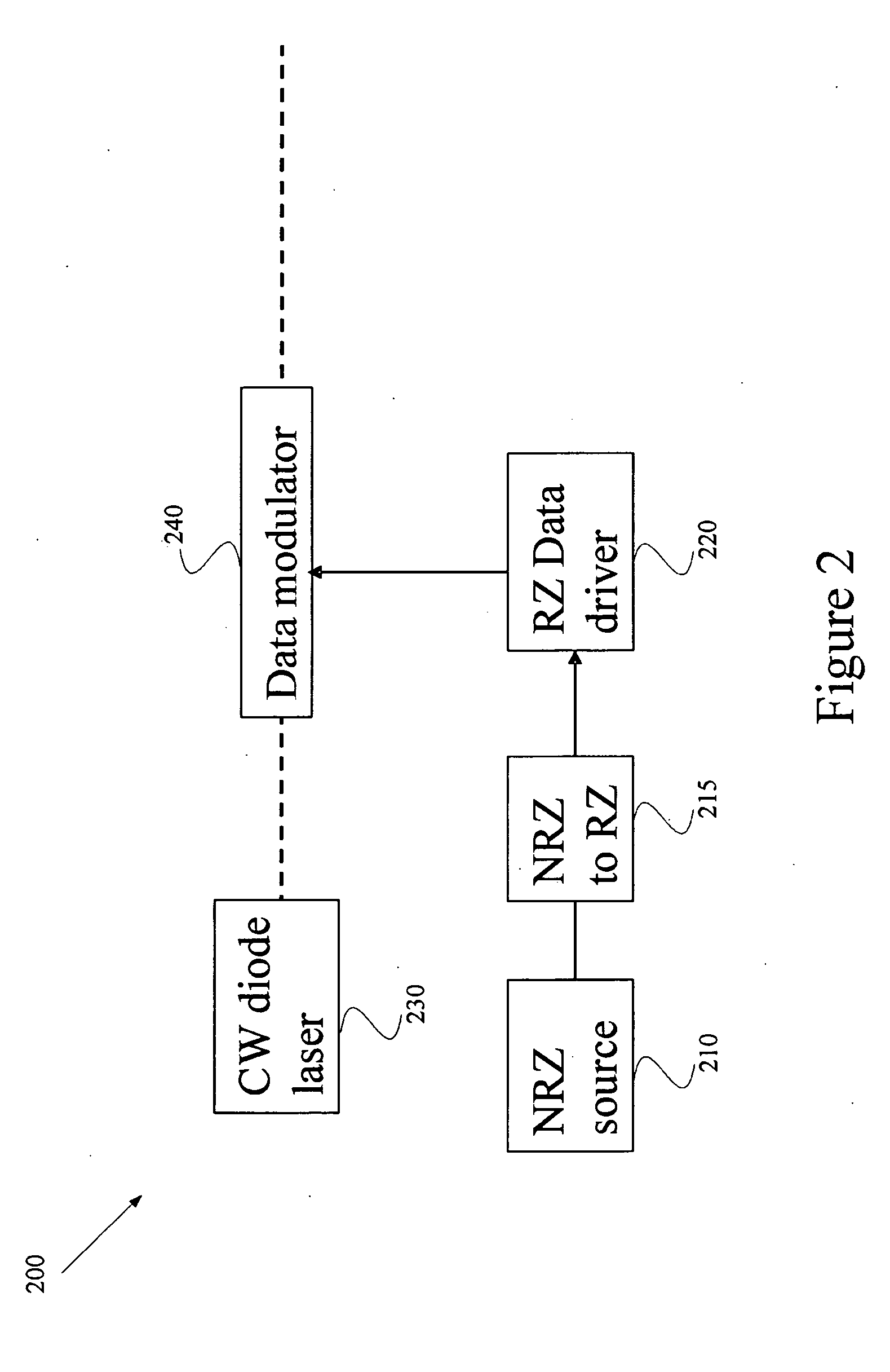

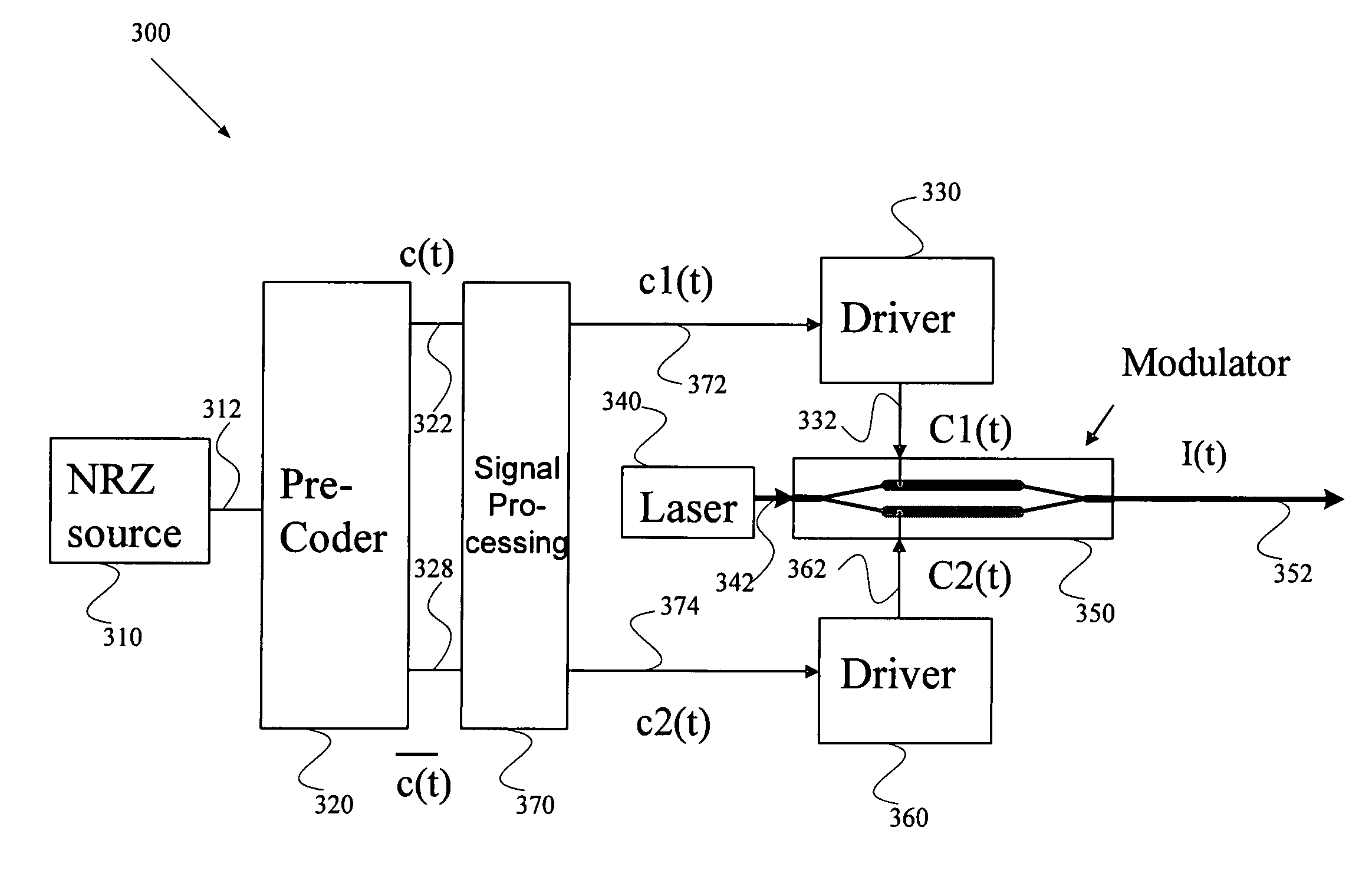

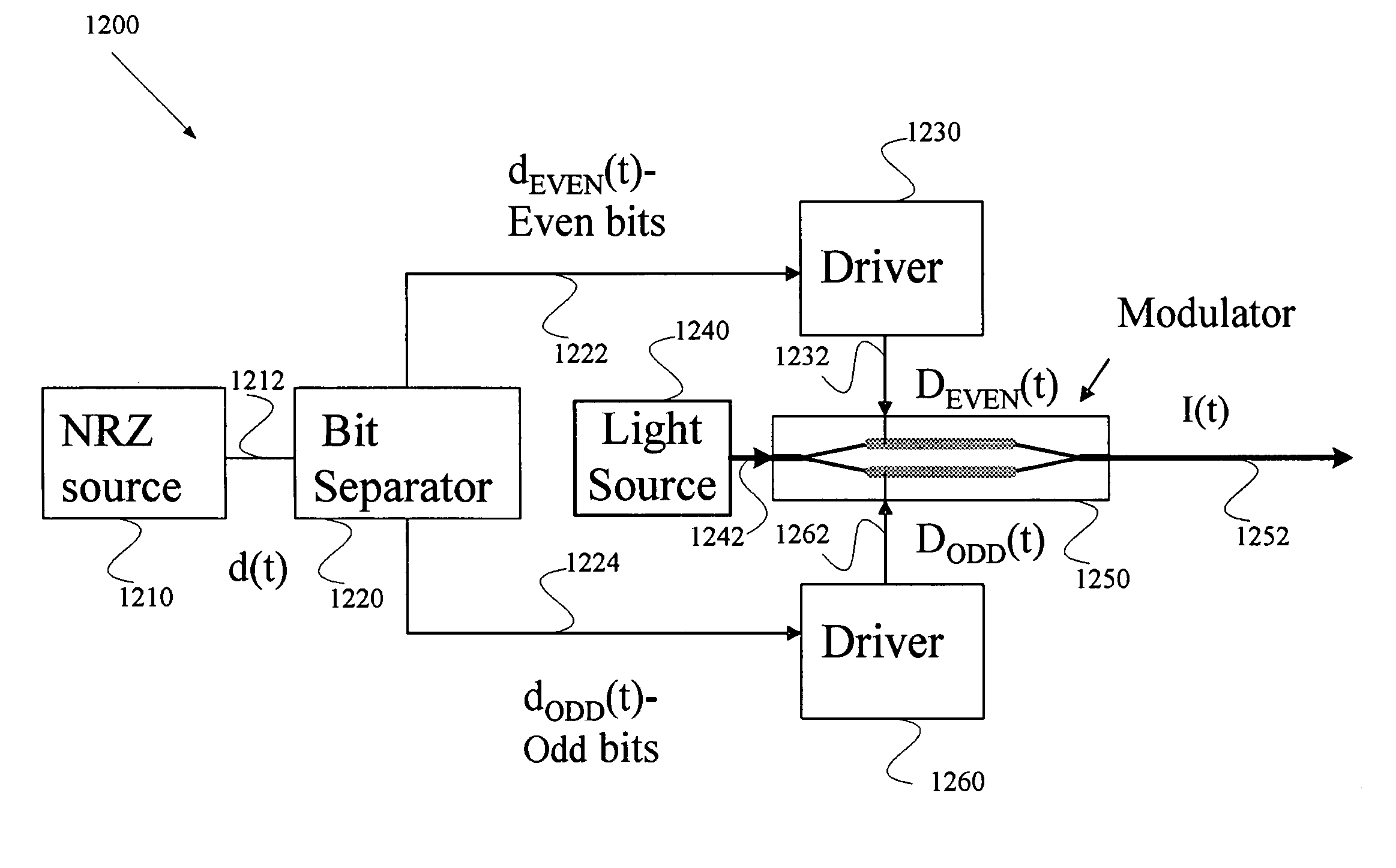

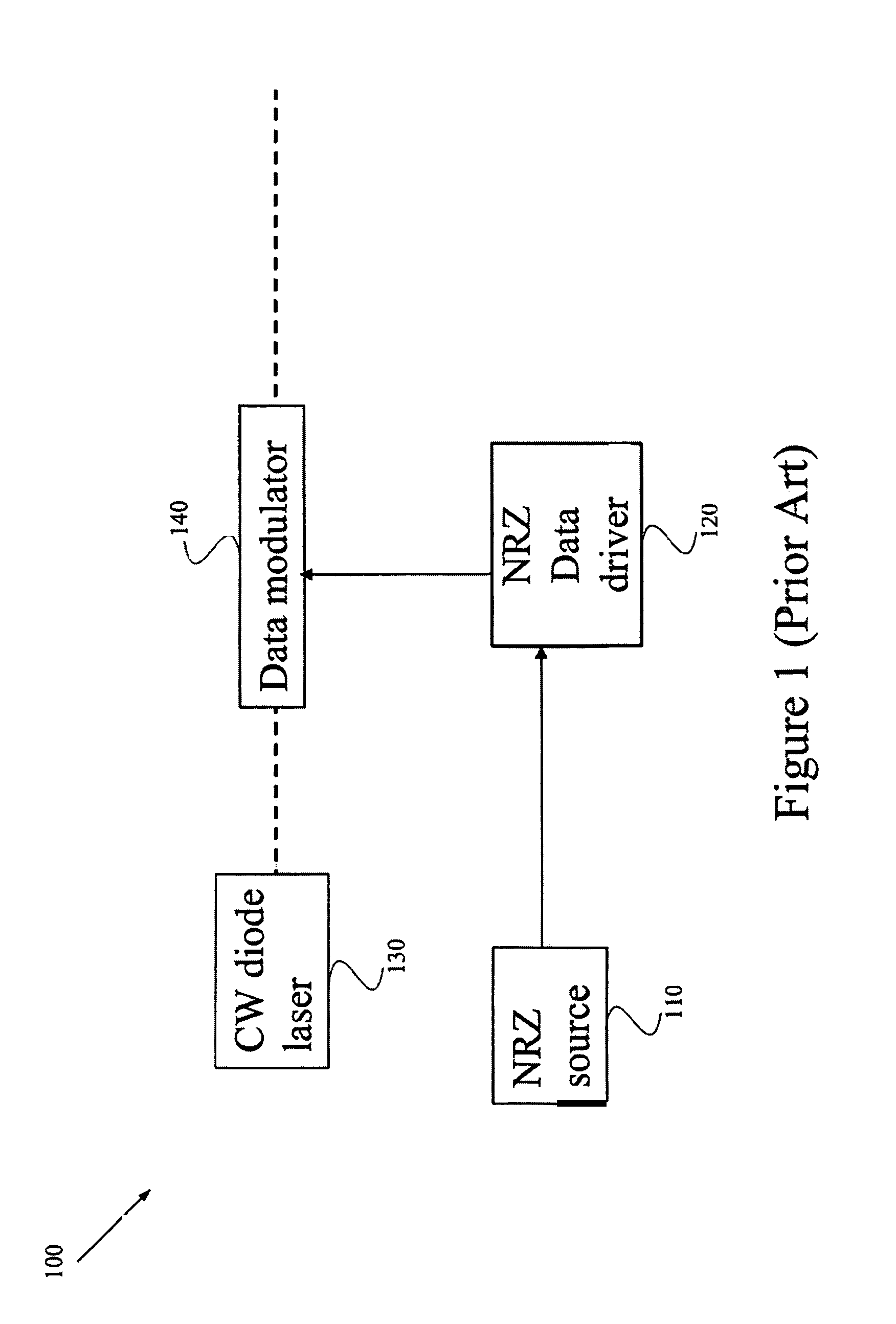

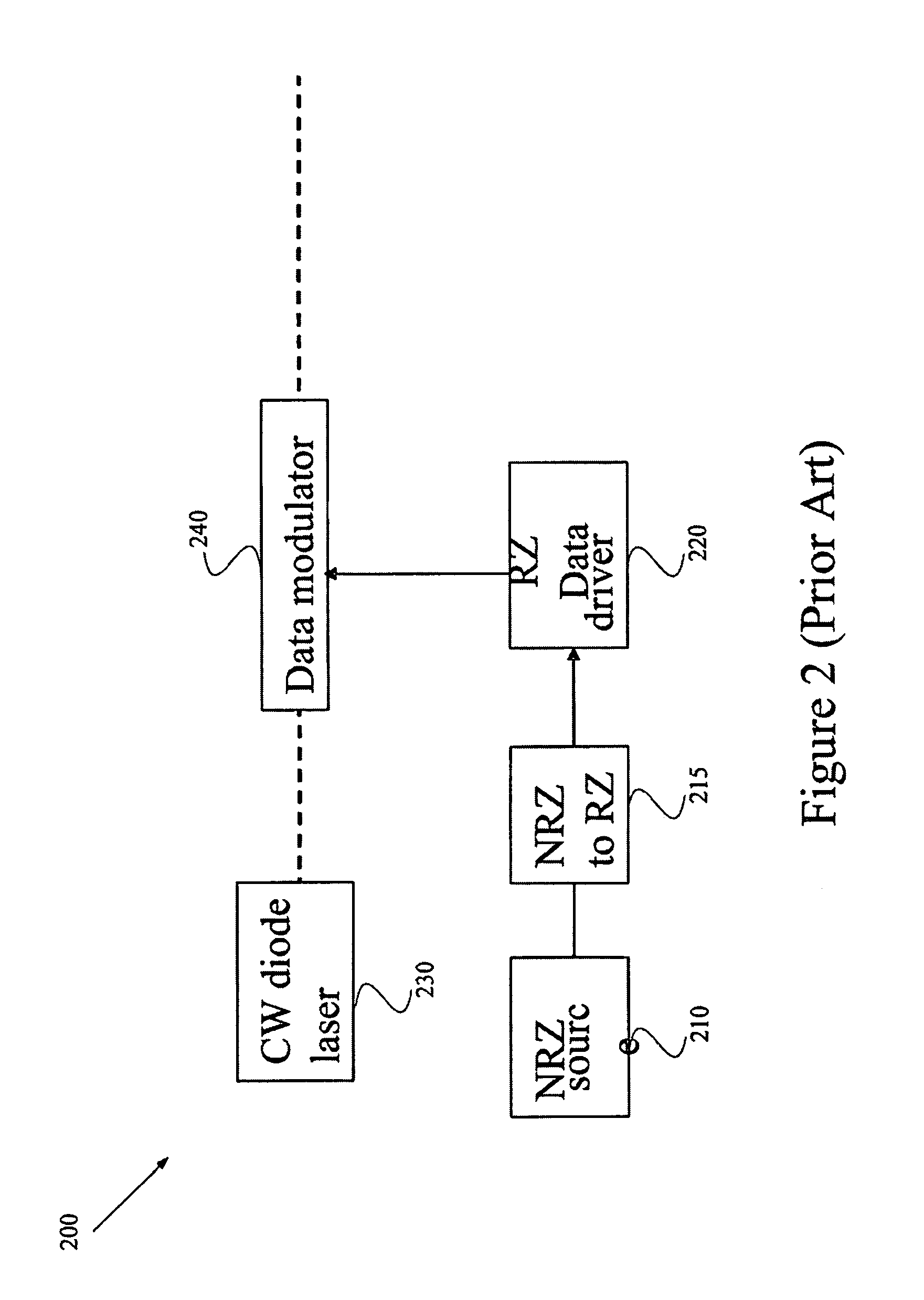

System and method for generating optical return-to-zero signals with alternating bi-phase shift and frequency chirp

ActiveUS20060193228A1Low costReduce complexityTelevision system detailsRecord information storageElectricityReturn-to-zero

A system and method for generating an optical return-to-zero signal with frequency chirp. The system includes a bit separator configured to receive an electrical non-return-to-zero signal and generate a first input signal and a second input signal. Additionally, the system includes a first driver configured to receive the first input signal and generate a first driving signal. The first driving signal is proportional to the first input signal in signal strength. Moreover, the system includes a second driver configured to receive the second input signal and generate a second driving signal. The second driving signal is proportional to the second input signal in signal strength. Also, the system includes a light source configured to generate a light, and an electro-optical modulator.

Owner:FUTUREWEI TECH INC

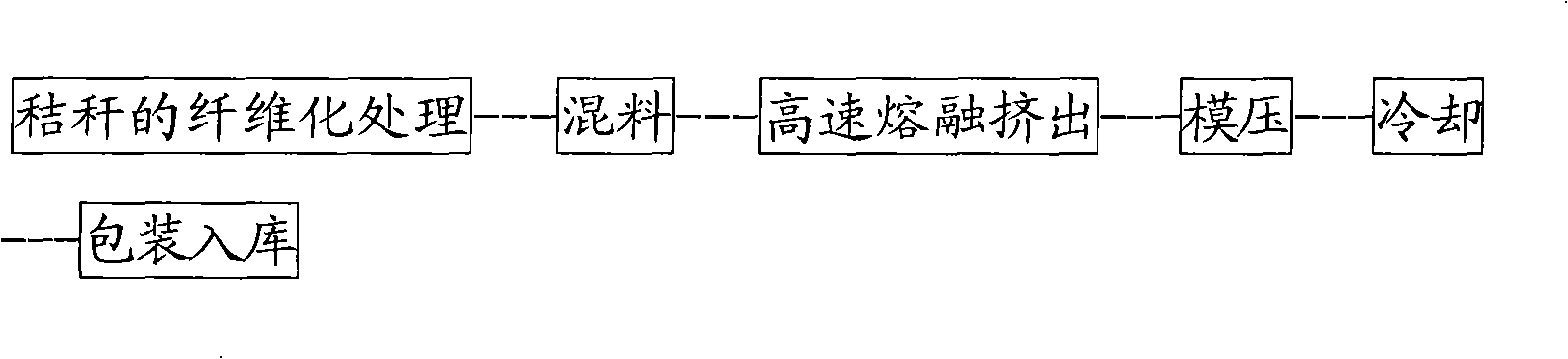

Straw fiber silicon plastic composite building form board and method for making same

InactiveCN101307641AReduce land occupationSolve the problem that the price is too high and difficult to promoteFlat articlesDomestic articlesFiberPlastic waste

The invention discloses a straw fiber silicon-plastic composite building formwork and a method for preparing the same. The proportion of the formulation of per 100 kilogram of straw fiber silicon-plastic composite building formworks is as follows: 28 to 39 kilograms of plastic waste, 35 to 55 kilograms of plant straw short fibers, 15 to 25 kilograms of fly ash and 1 to 2 kilograms of auxiliary agent. The preparation method comprises the following steps of: fiber treatment of straws; mixing; high-speed fusing and extruding; mould pressing; cooling; and product package and storage. The straw fiber silicon-plastic composite building formwork and the method have the advantages of low production cost, high cost performance, good product quality, waste recycling, energy conservation and environmental protection, accordance with the development requirements of recycling economy and so on.

Owner:绍兴一普塑业有限公司

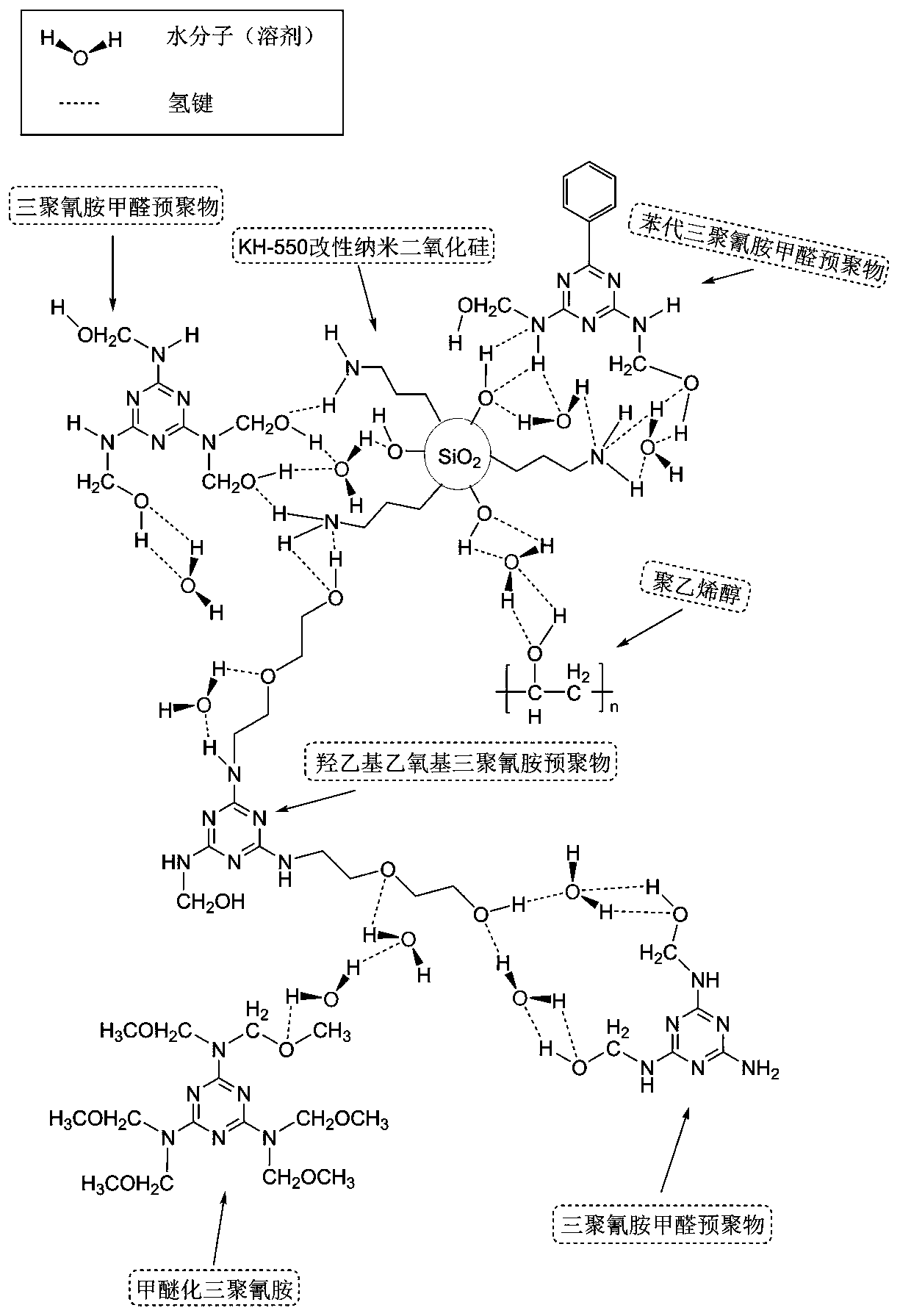

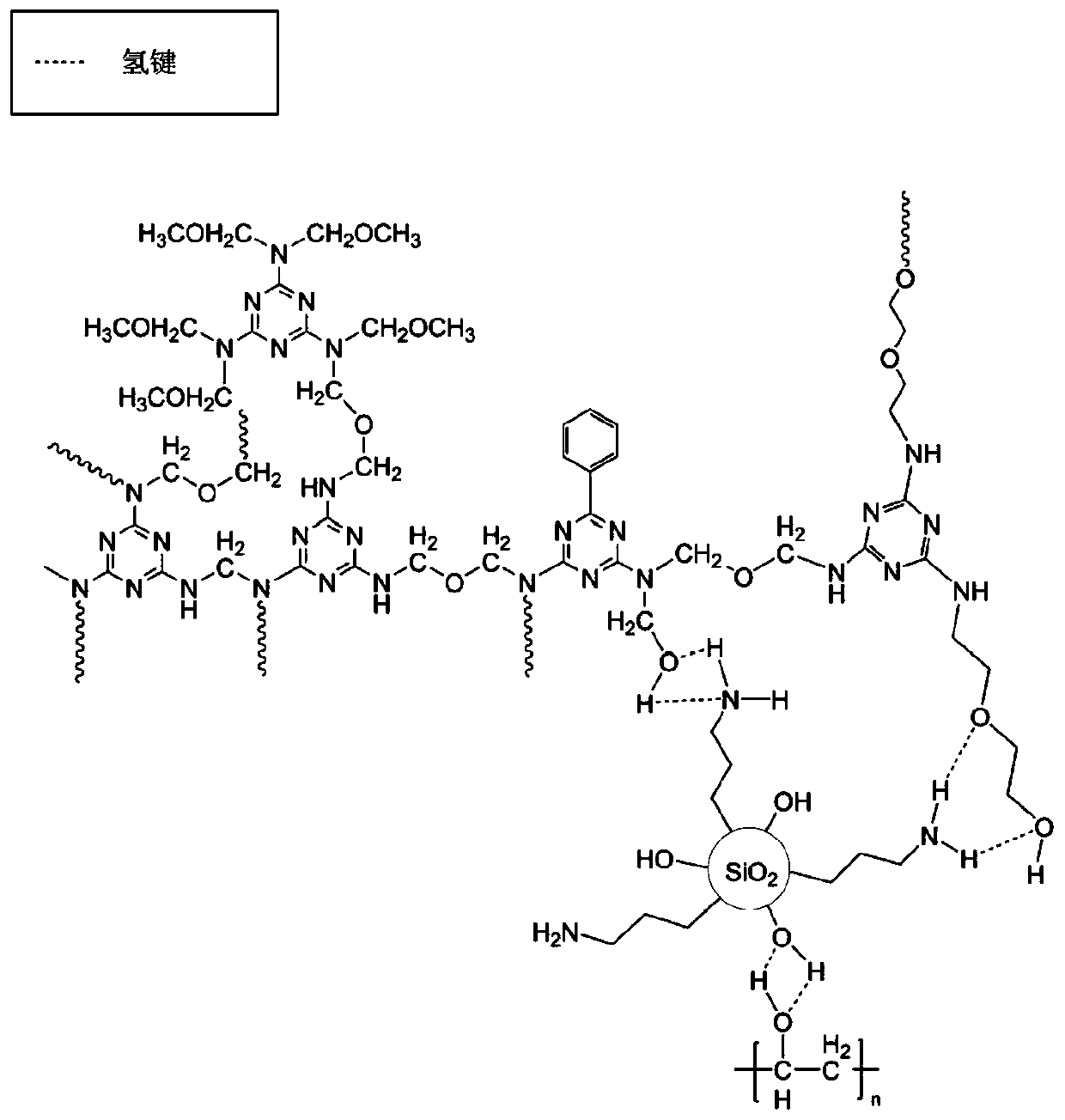

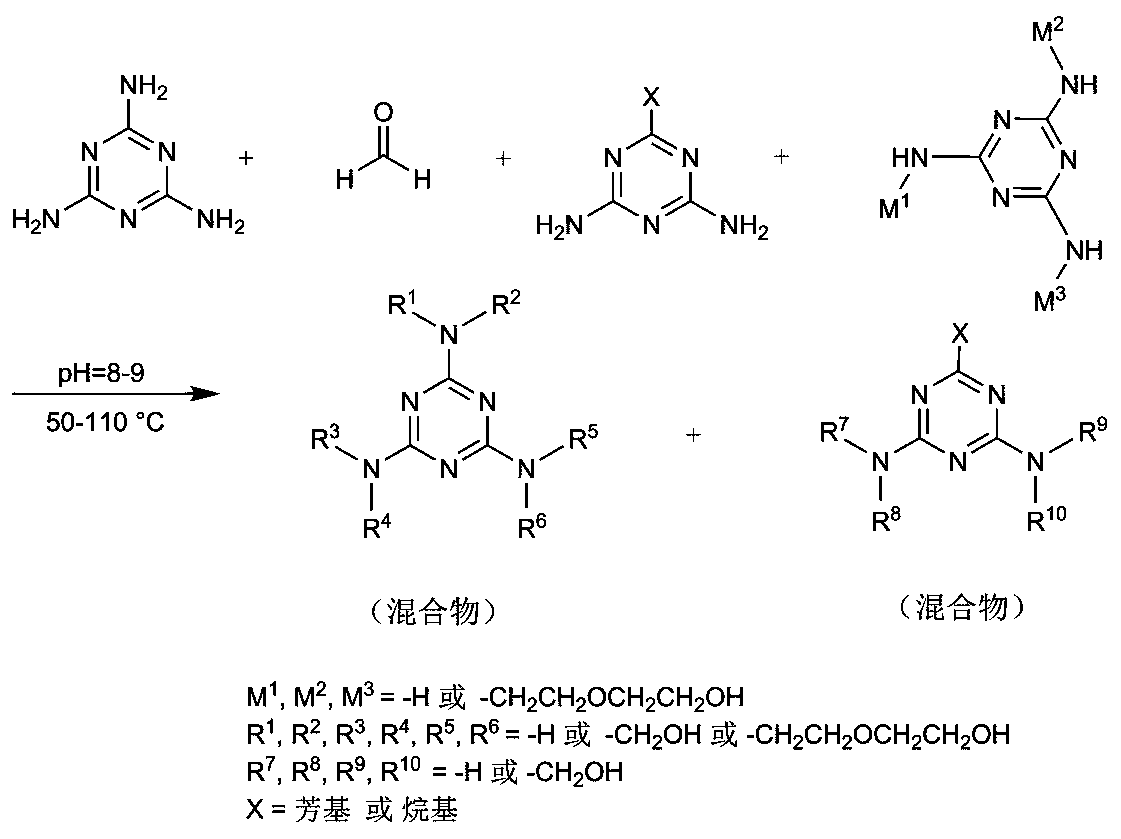

Melamine composite fiber and manufacturing method thereof

ActiveCN109881293AImprove rheologyEliminate Bubble ProblemsFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberHydrogen

The invention discloses a melamine composite fiber and a manufacturing method thereof. The melamine composite fiber is prepared from melamine formaldehyde modified resin, an inorganic nano material subjected to surface modification through a coupling agent and a water-soluble polymer, the composite fiber is less in internal defect and high in strength and toughness, the tensile strength of the composite fiber reaches 2-6 cN / dtex, and the elongation at break reaches 15%-40%; the flame resistance is excellent, the composite fiber is extinguished immediately after leaving a flame, no molten droplet exists, smoldering does not occur, and the limit oxygen index reaches 38%-45%. According to the melamine composite fiber manufacturing method, in the spinning solution manufacturing process, hydrogen bonds are formed among all components of a spinning solution, and the compatibility is good; by means of the inorganic nano material subjected to surface modification through the coupling agent, alarge number of bubbles in the spinning solution are eliminated, the fluidity of the spinning solution is improved, and meanwhile the stability and the fiber forming property of the spinning solutionare improved; by means of the method, the melamine composite fiber can be manufactured economically.

Owner:SICHUAN UNIV

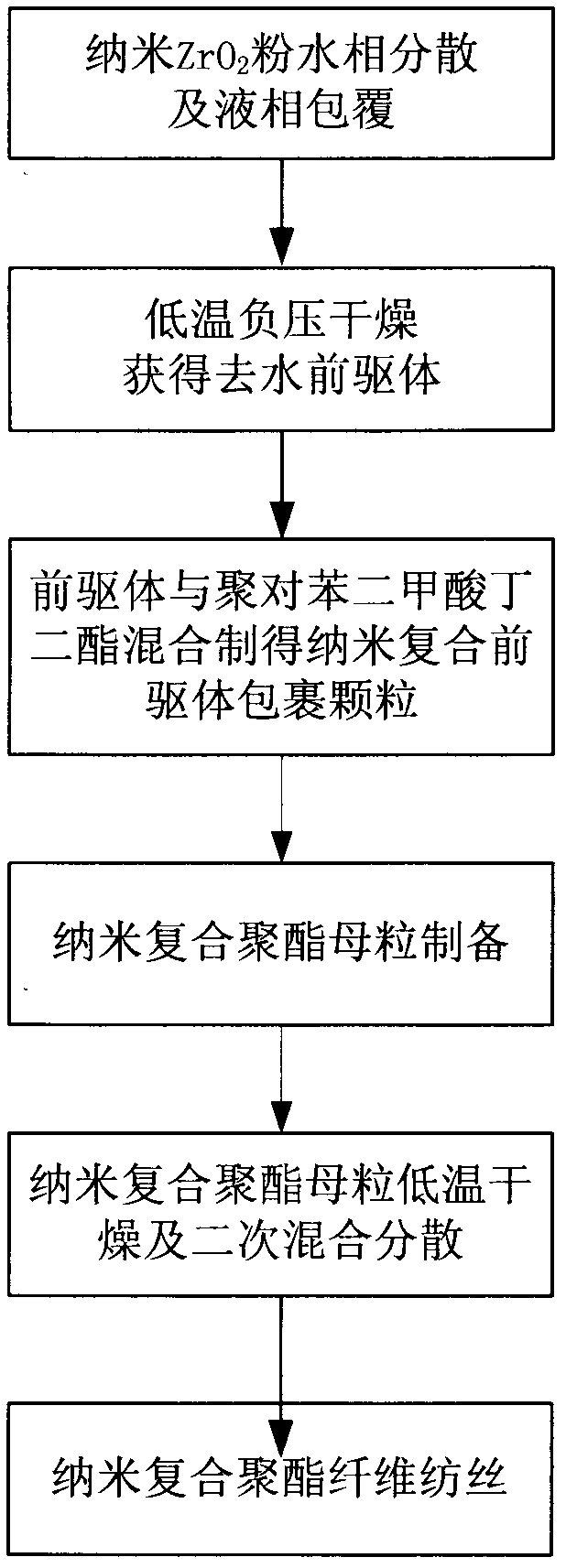

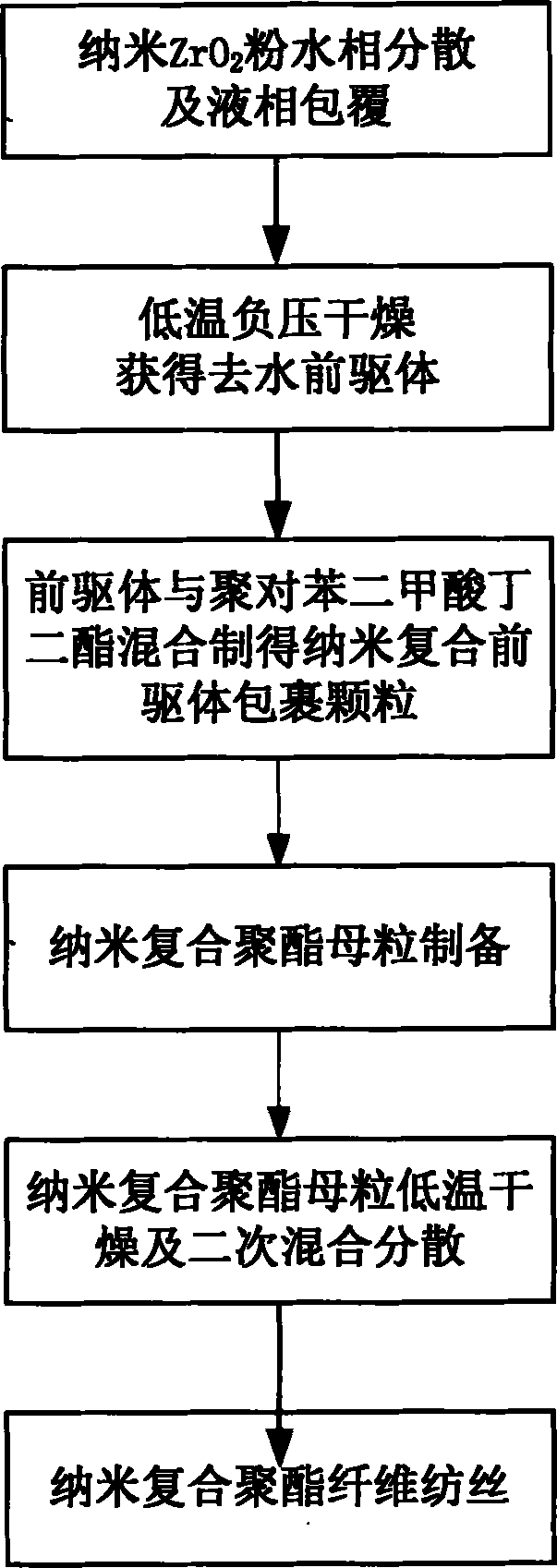

Nano ZrO2 composite polyester functional fiber, manufacturing method thereof and application

InactiveCN102660799AHigh surface energyImprove yieldConjugated synthetic polymer artificial filamentsArtifical filament manufactureState of artFiber

A nano ZrO2 composite polyester functional fiber contains ZrO2, polybutylene terephthalate, polyethylene terephthalate and a small quantity of auxiliaries, and is manufactured by means of a novel nano ZrO2 powder dispersing and wrapping process and by adjusting a spinning process. The nano ZrO2 composite polyester functional fiber realizes nano-dispersion of nano ZrO2 in a polyester carrier, hydrolysis of composite polyester master batch preparation and degradation of nano composite master batch in polybutylene terephthalate during secondary melting dispersion, and overcomes the shortcomings of the prior art, so that nano ZrO2 powder particles are uniformly distributed and organically compounded in polyester fibers, and mass production of the fiber is realized. A product made of the fiber can efficiently emit biological infrared waves in a long-acting manner, is ultraviolet-resistant, has the health care function of improving human microcirculation and has a sunscreen effect, and a novel fabric market is certainly activated owing to the advantages of functionality, comfort and variety and color diversity of the fiber.

Owner:NANJING LONGYI TEXTILE TECH DEV

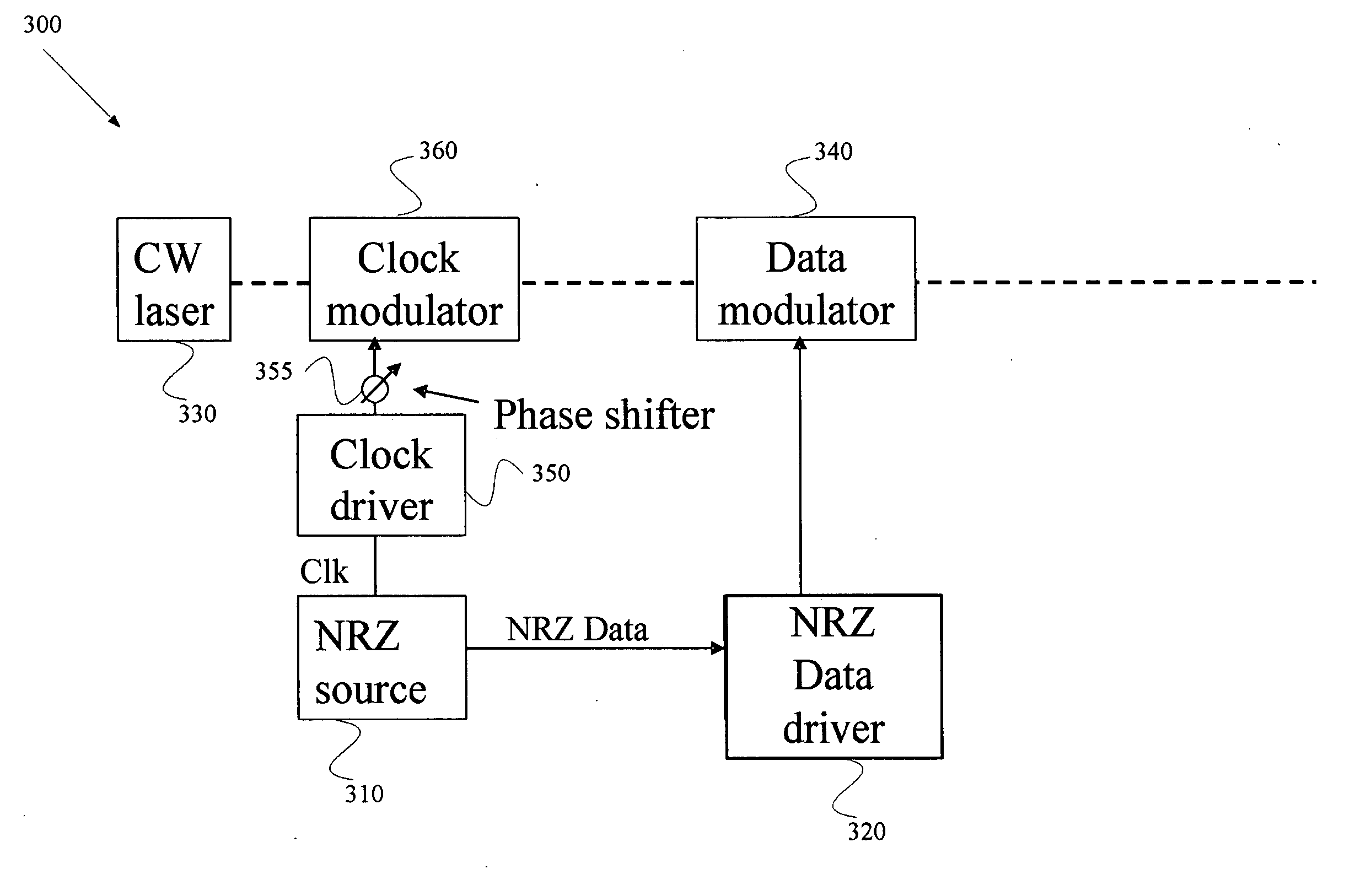

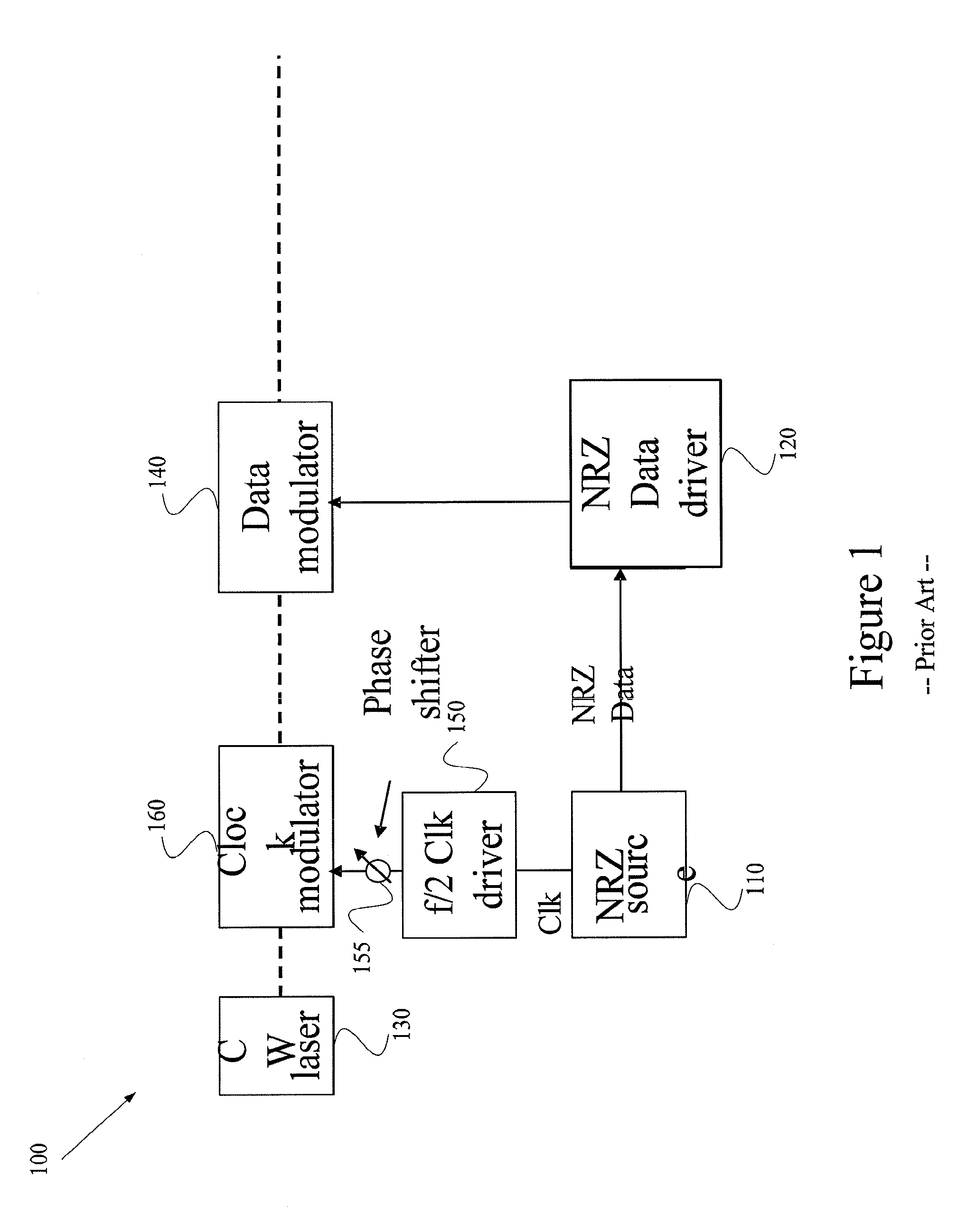

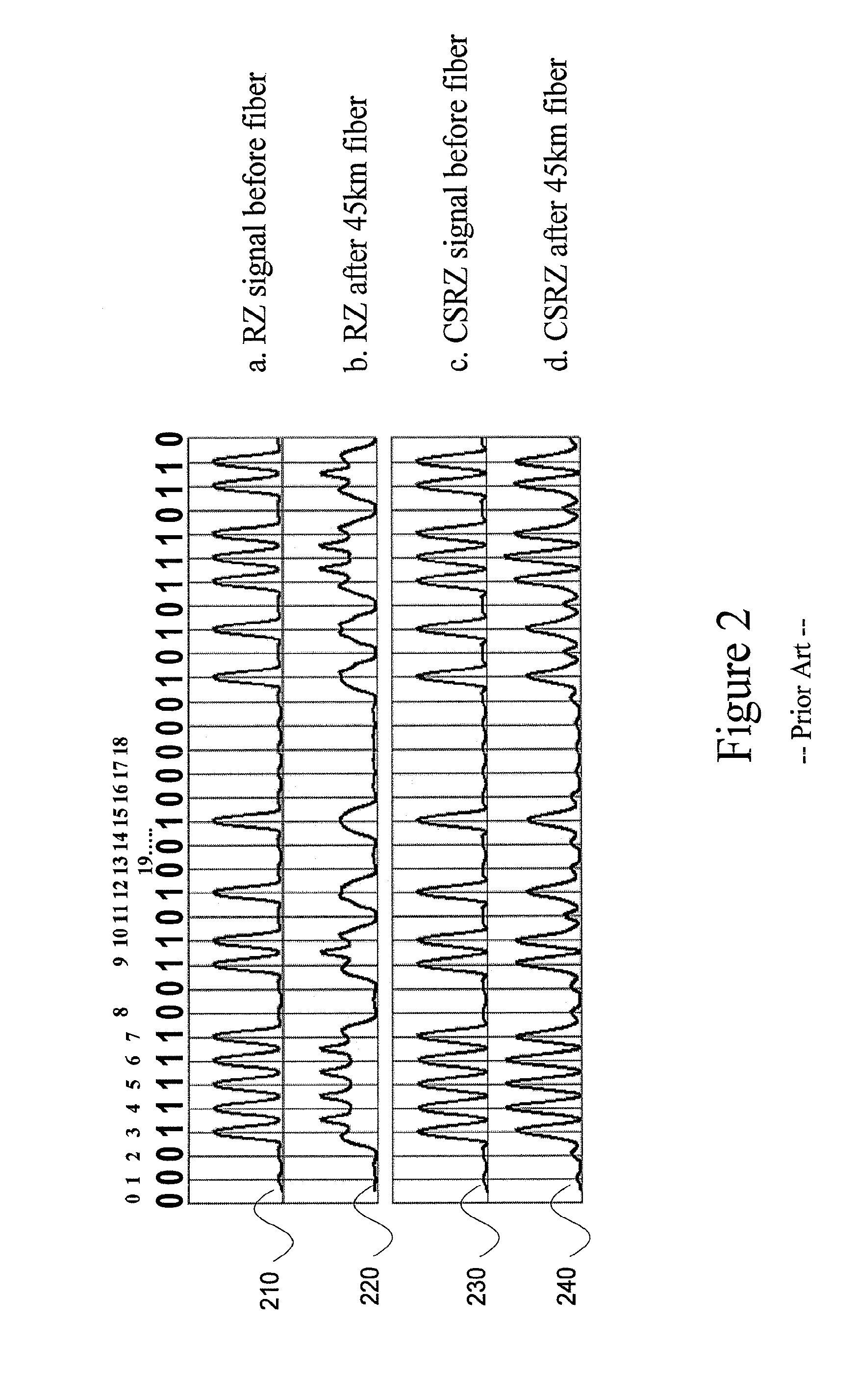

System and method for generating optical return-to-zero signals with differential bi-phase shift and frequency chirp

ActiveUS7792433B2Improve dispersion toleranceEnhanced signalElectromagnetic transmittersBaseband systemsPhase shiftedReturn-to-zero

A system and method for generating an optical return-to-zero signal. The system includes an electro-optical conversion system. The electro-optical conversion system is configured to receive an input electrical non-return-to-zero signal, process information associated with the input electrical non-return-to-zero signal, and generate an output optical return-to-zero signal based on at least information associated with the input electrical non-return-to-zero signal. The output optical return-to-zero signal is an optical differential return-to-zero signal, and the optical differential return-to-zero signal is associated with a frequency chirp.

Owner:FUTUREWEI TECH INC

Porous air filtering film as well as preparation method and application thereof

ActiveCN110732186AImprove storage effectSlow down the rate of charge decayMembrane filtersFiltration separationPorous substrateFiber

The invention provides a porous air filtering film as well as a preparation method and application thereof. The porous air filtering film comprises a porous substrate material and a polymer layer which covers fibers of the porous substrate material and has a pyroelectric function. The porous air filtering film disclosed by the invention can retain fine particles which are much smaller than pores of the porous air filtering film, is high in dust holding capacity, high in filtering efficiency and low in air filtering resistance, and can be regenerated for repeated use. According to the preparation method, the fibers of the porous substrate material are covered with the polymer layer with the pyroelectric function through a spraying method, so that the porous air filtering film is prepared, and the preparation method is simple, mild in preparation condition, low in energy consumption and easy for industrial production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

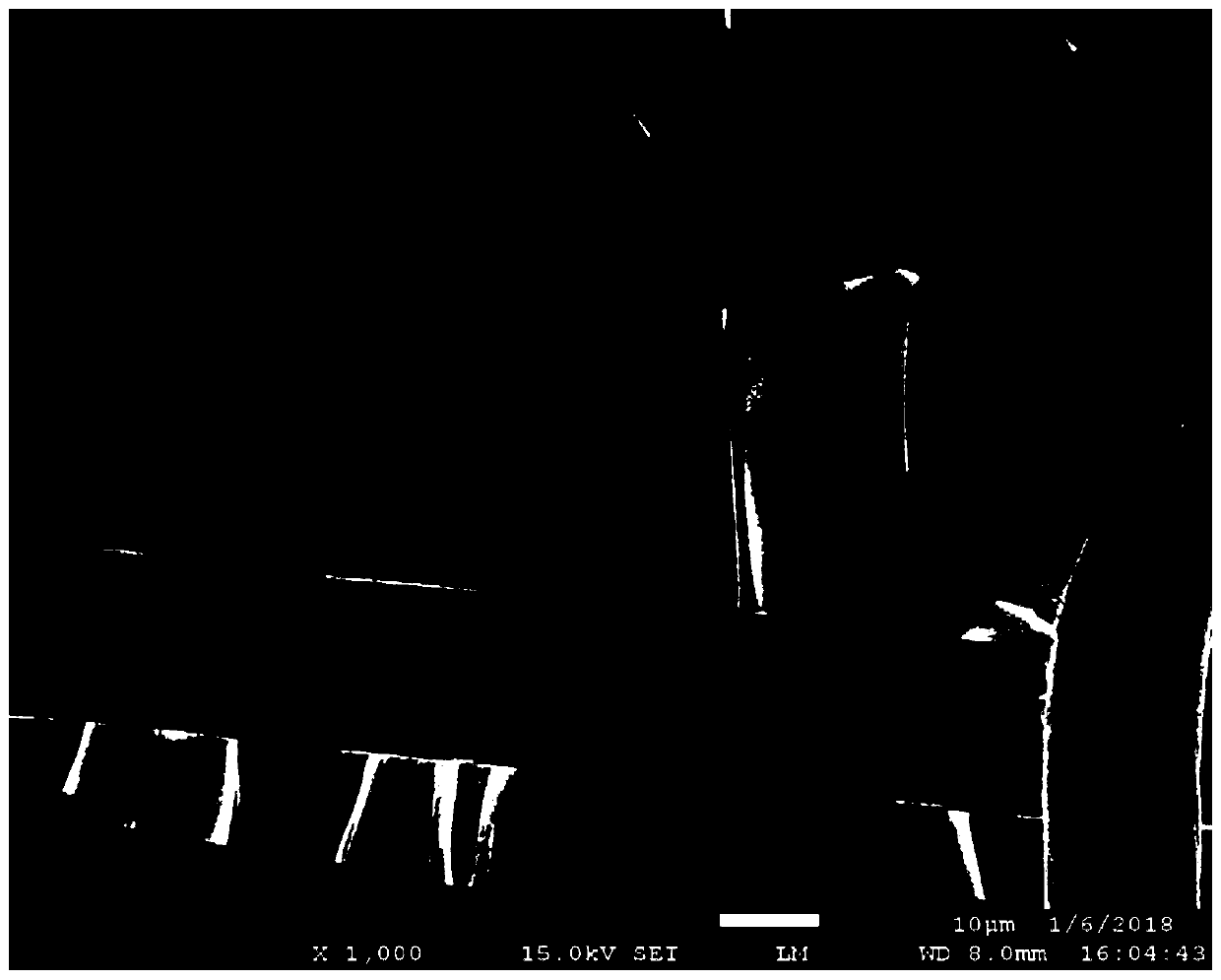

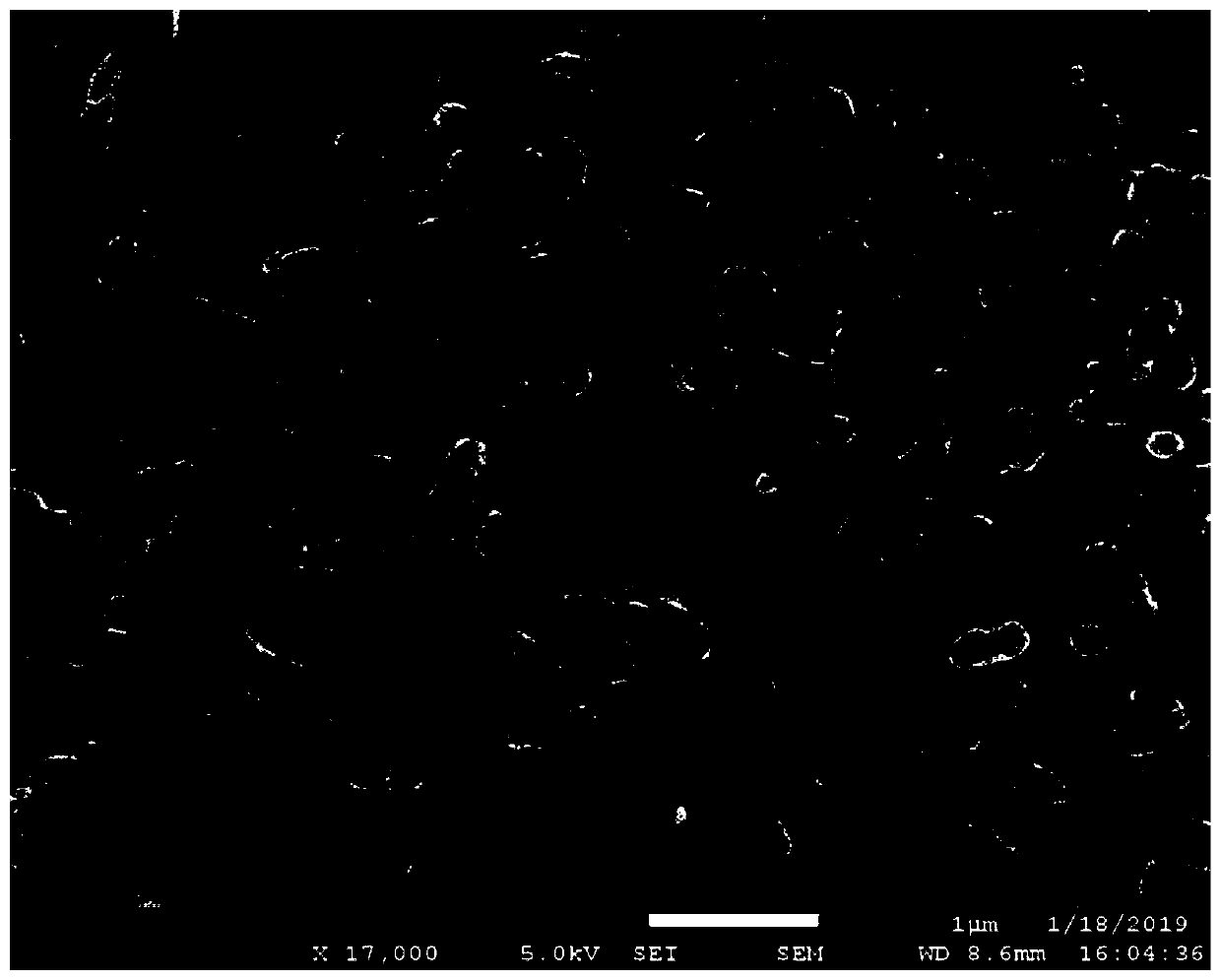

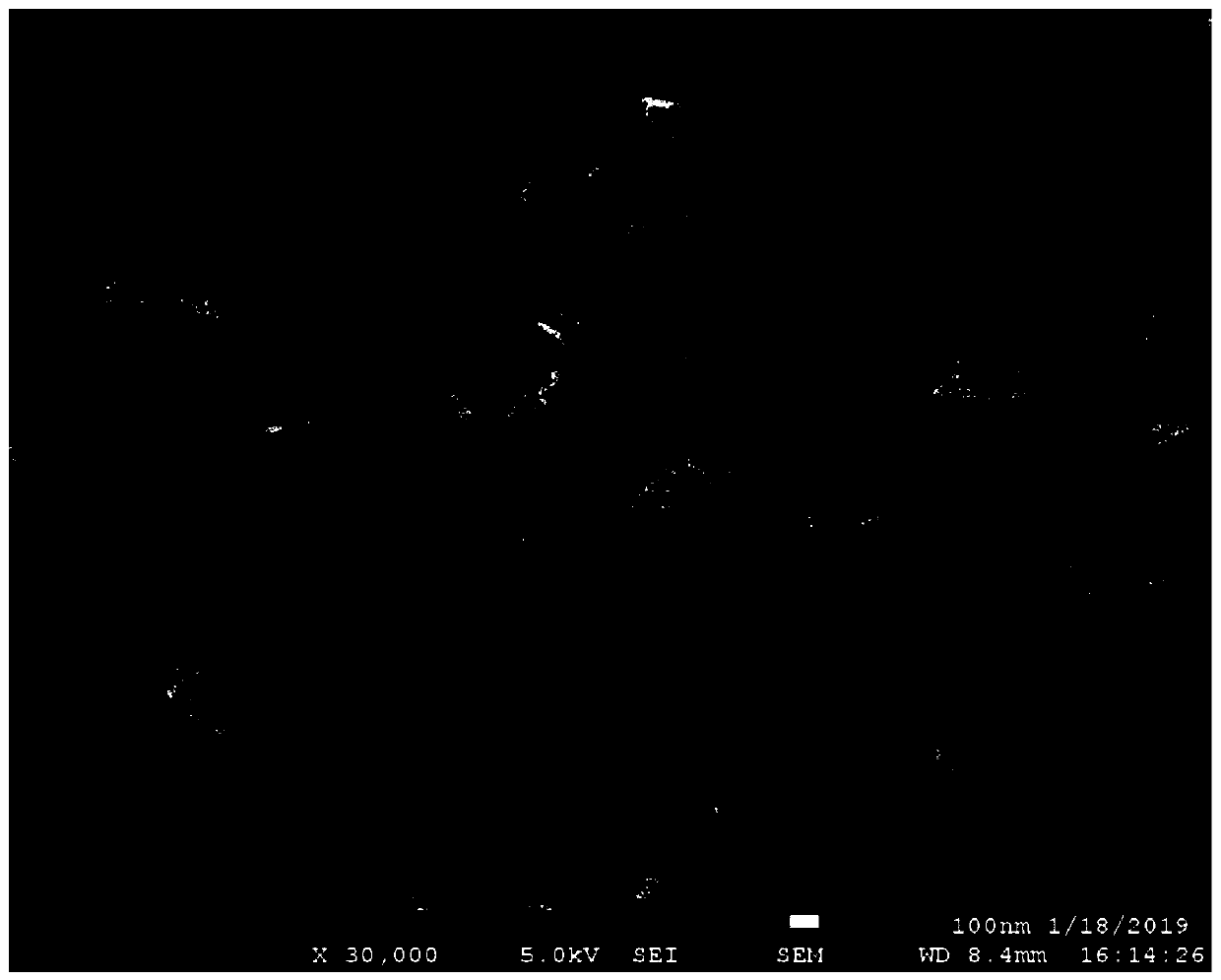

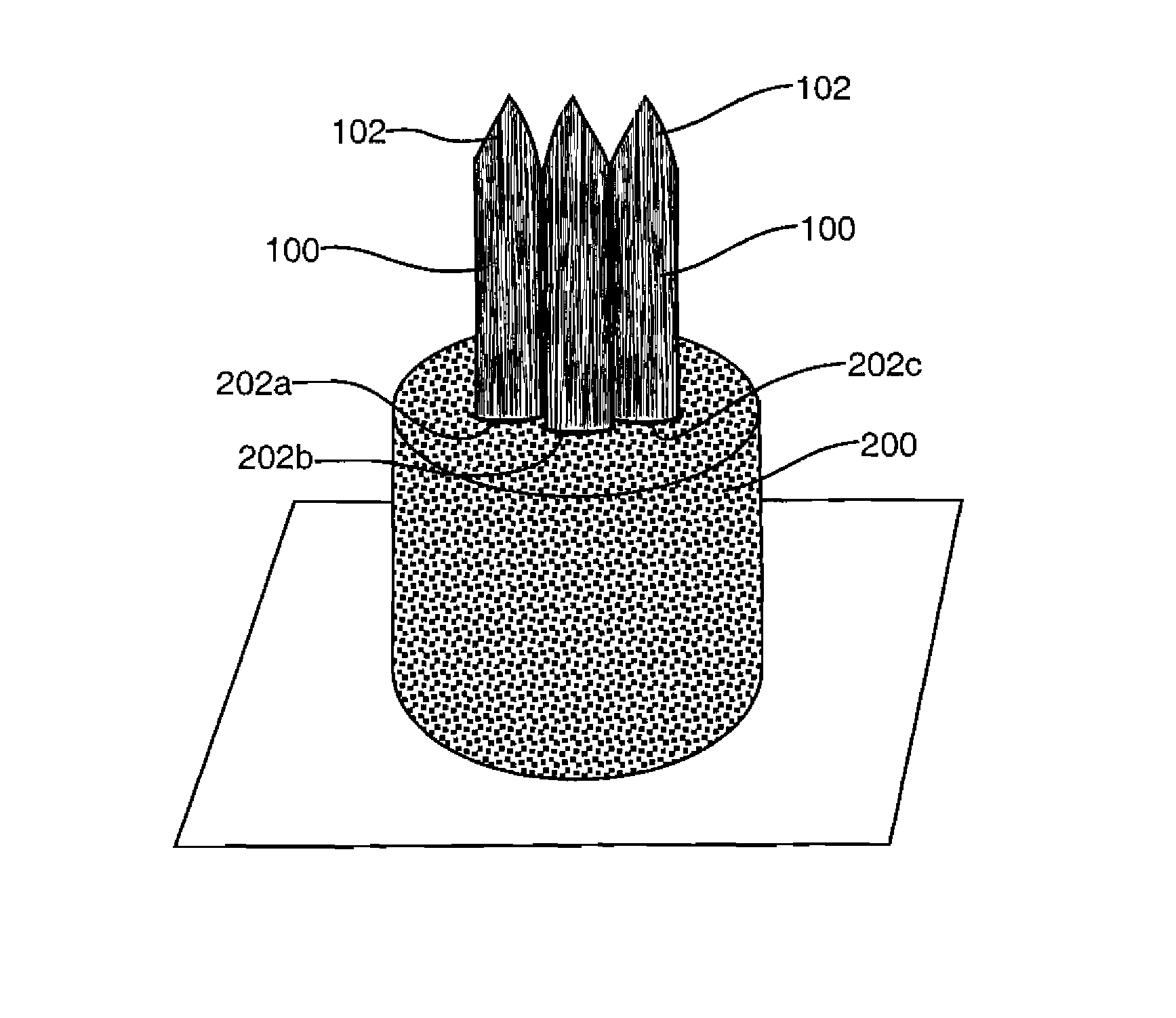

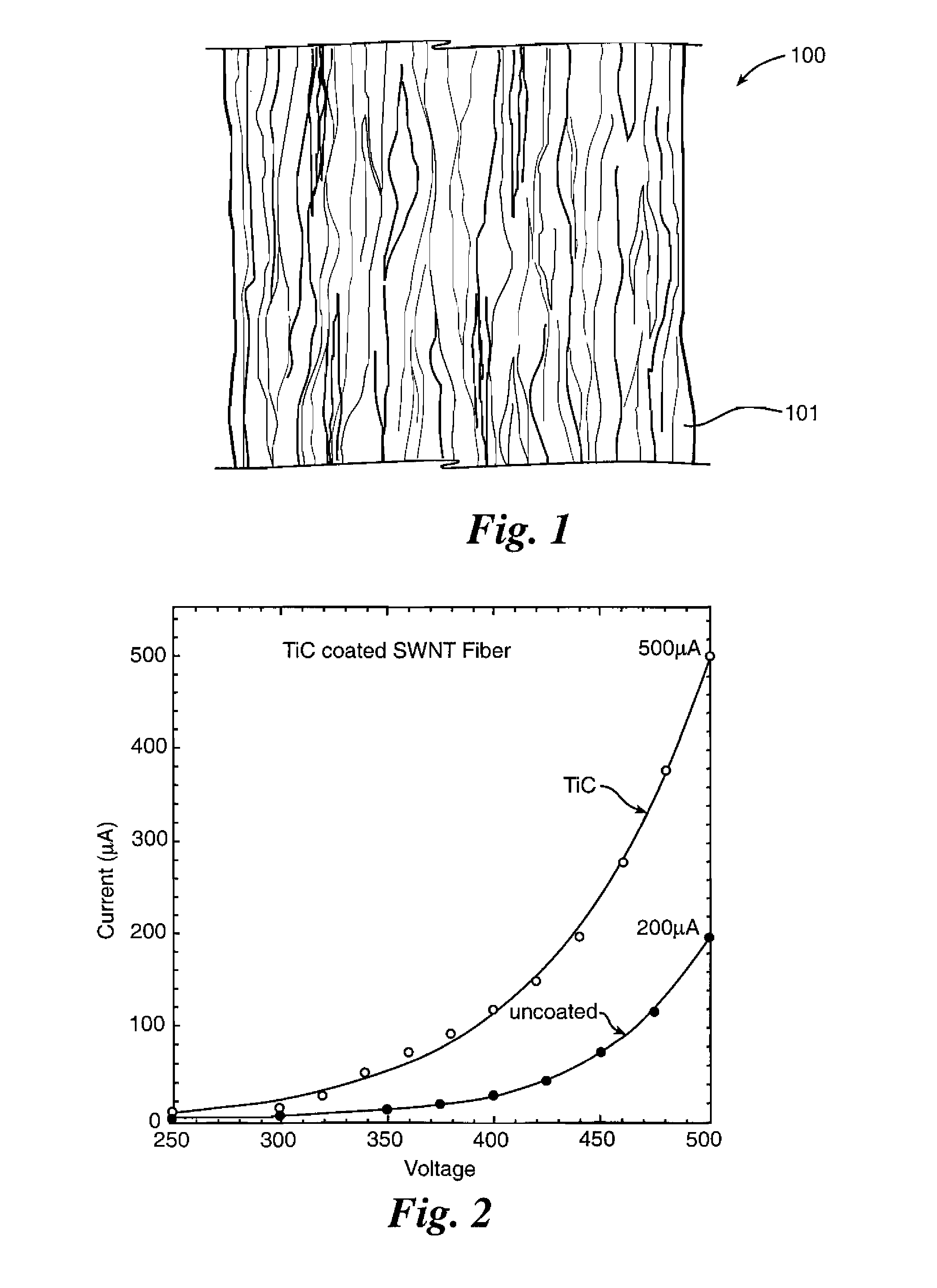

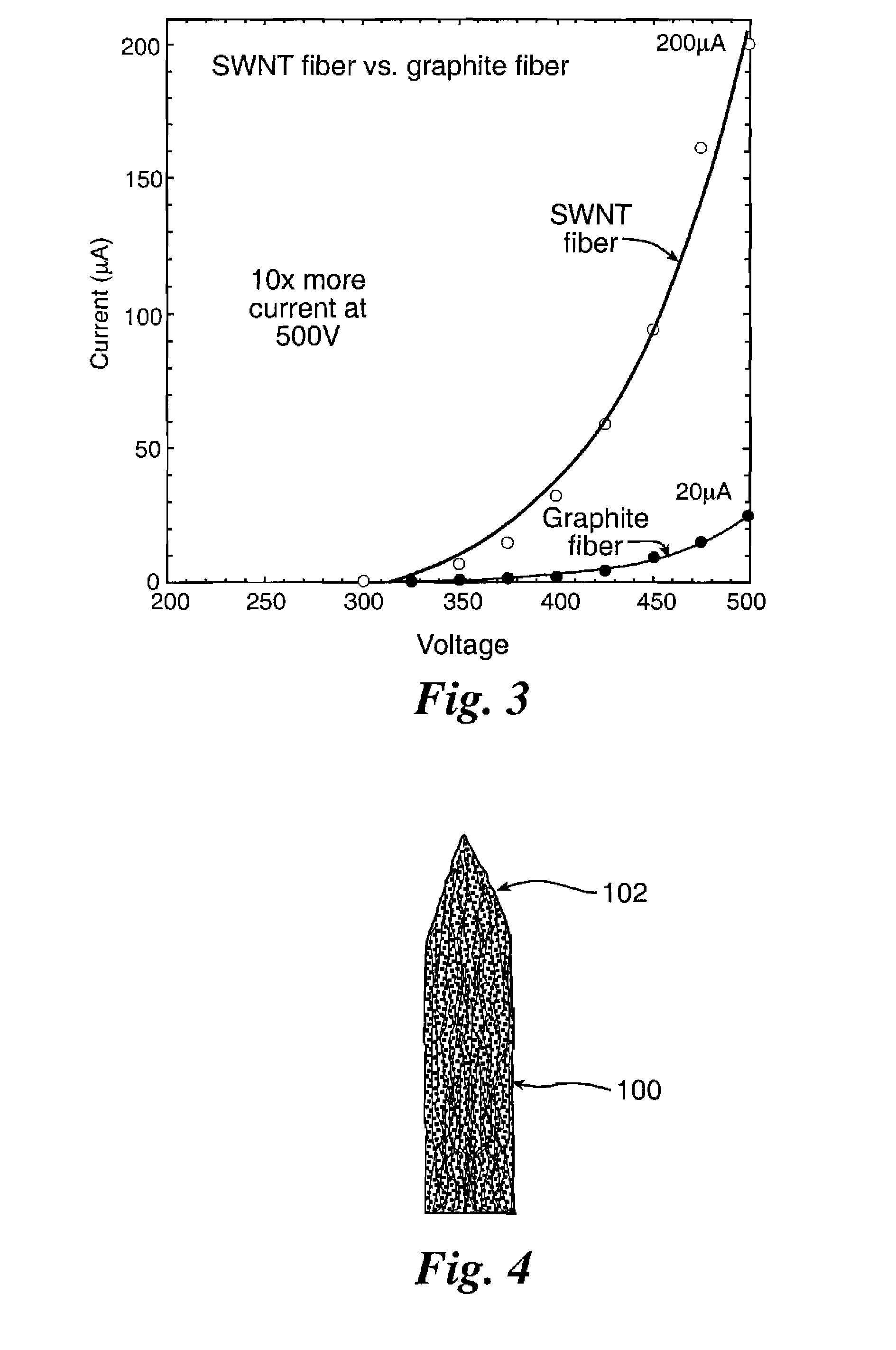

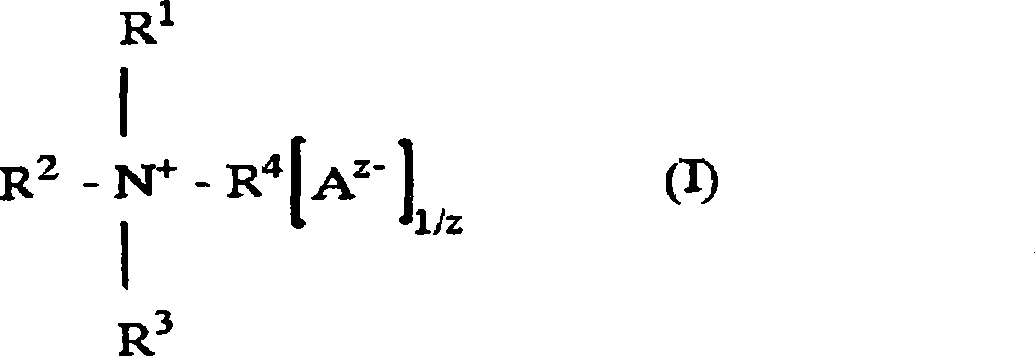

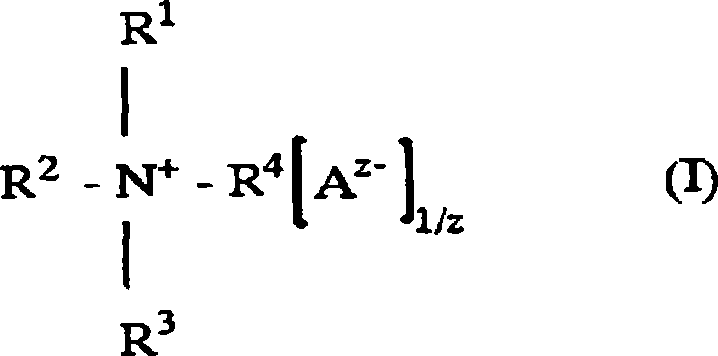

Carbon nanotube fiber cathode

ActiveUS8766522B1Superior and unprecedented performanceImprove fiber performanceGas-filled discharge tubesControl electrodesFiberDouble wall

Improved field emission cathodes comprise a fiber of highly aligned and densely packed single-wall carbon nanotubes, double-wall carbon nanotubes, multi-wall carbon nanotubes, grapheme nanoribbons, carbon nanofibers, and / or carbon planar nanostructures. The fiber cathodes provide superior current carrying capacity without degradation or adverse effects under high field strength testing. The fibers also can be configured as multi-fiber field emission cathodes, and the use of low work function coatings and different tip configurations further improves their performance.

Owner:GOVERNMENT OF THE UNTIED STATES

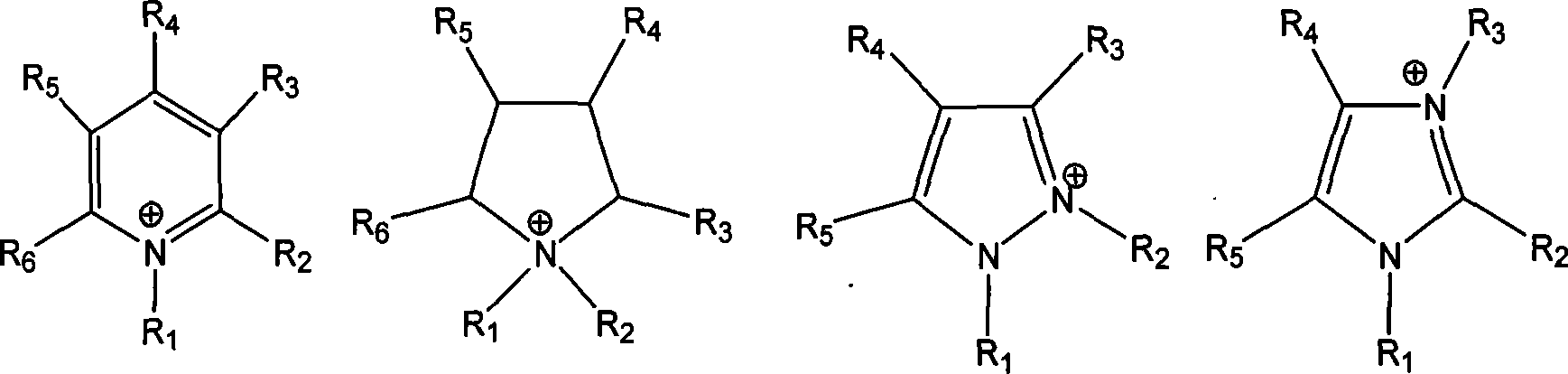

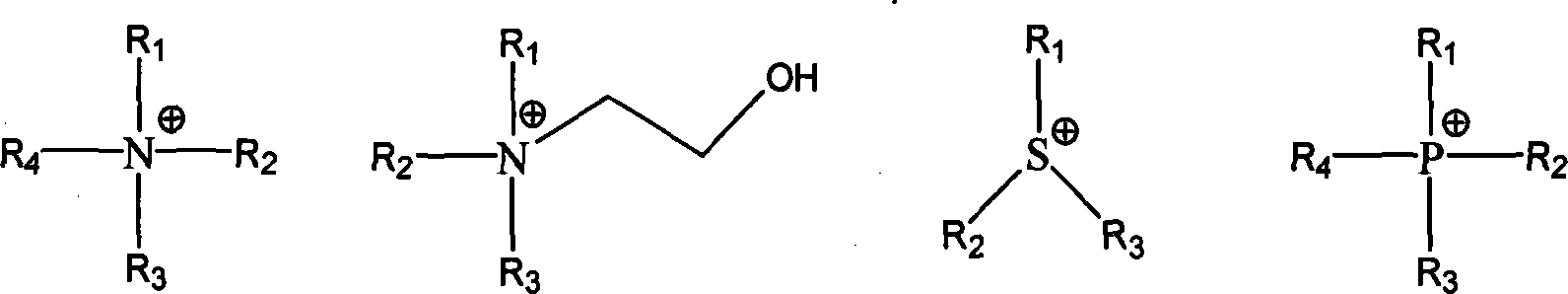

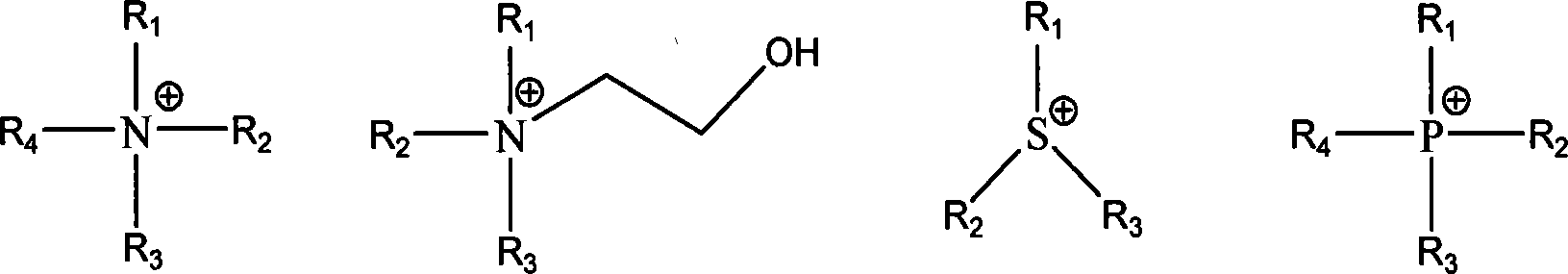

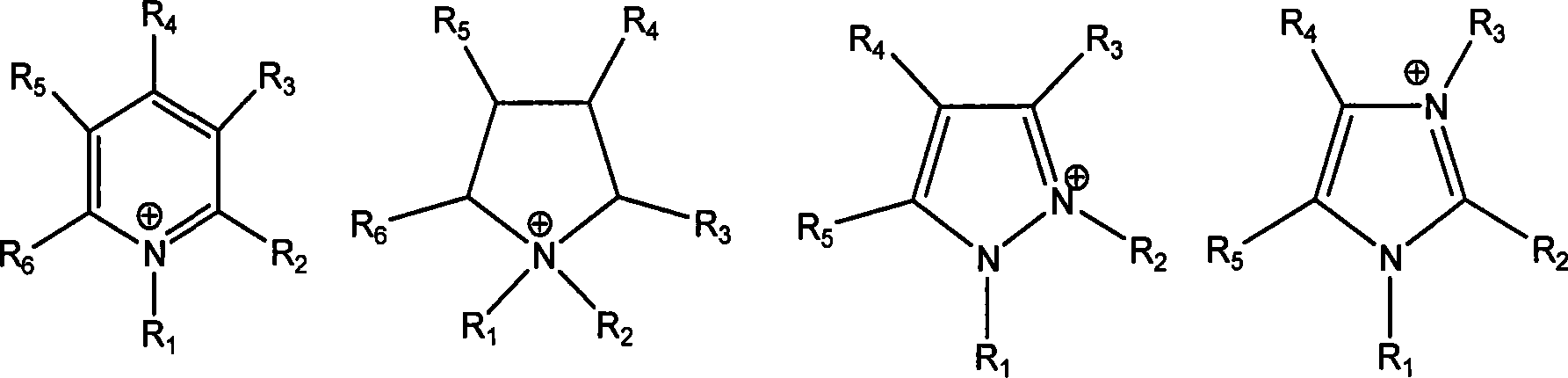

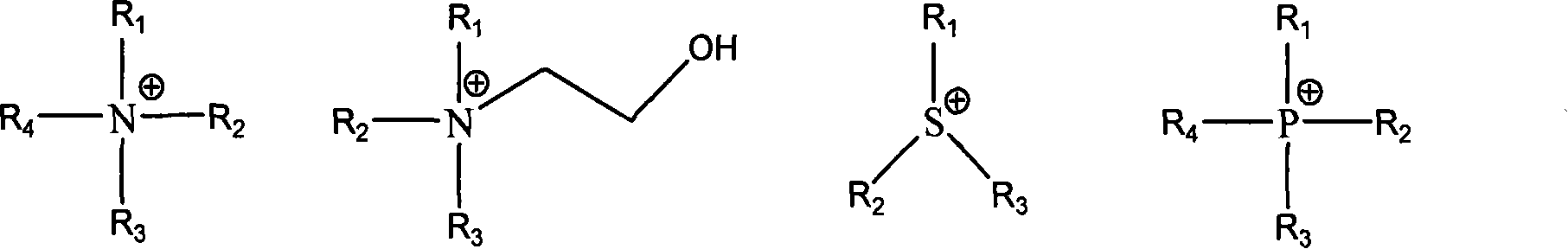

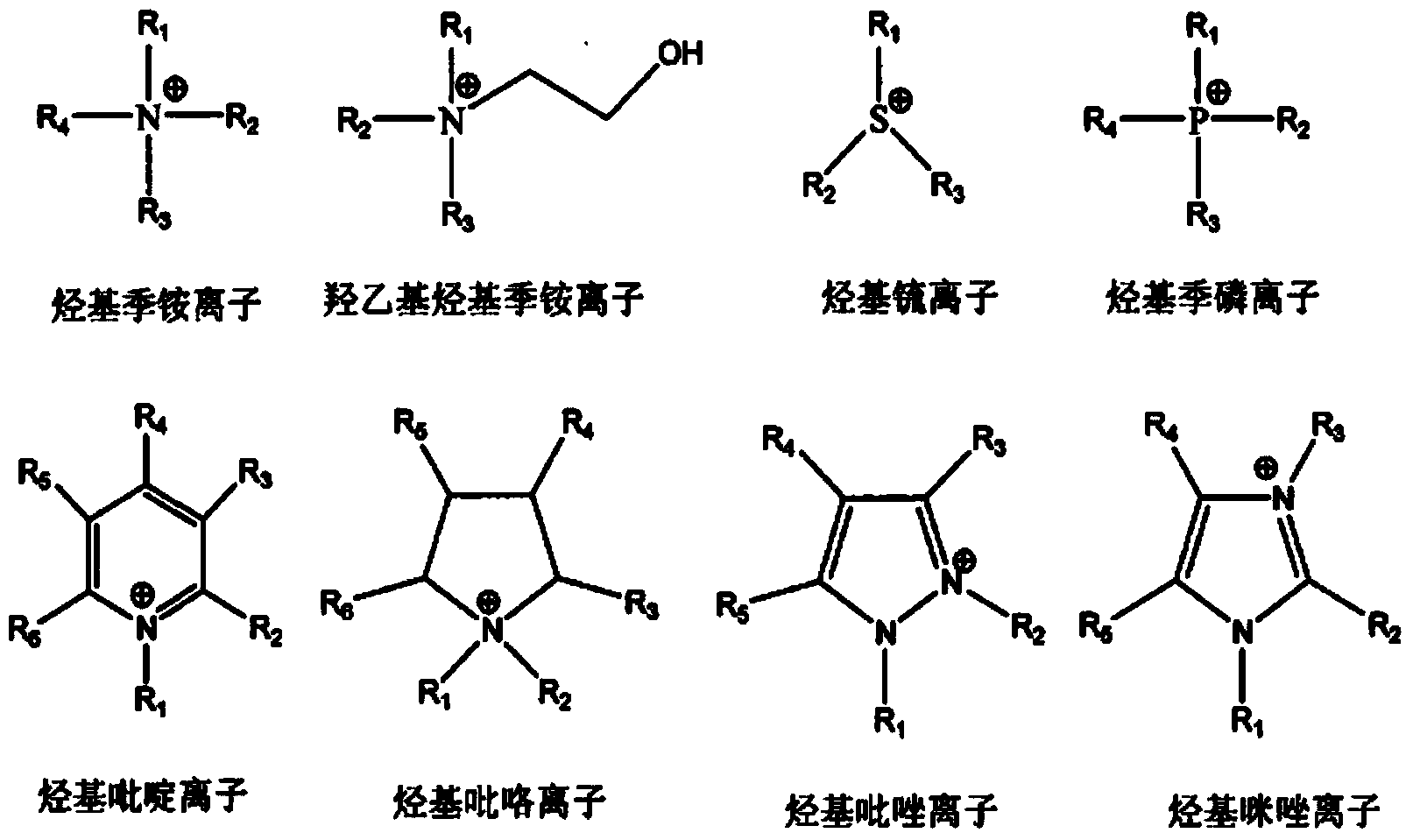

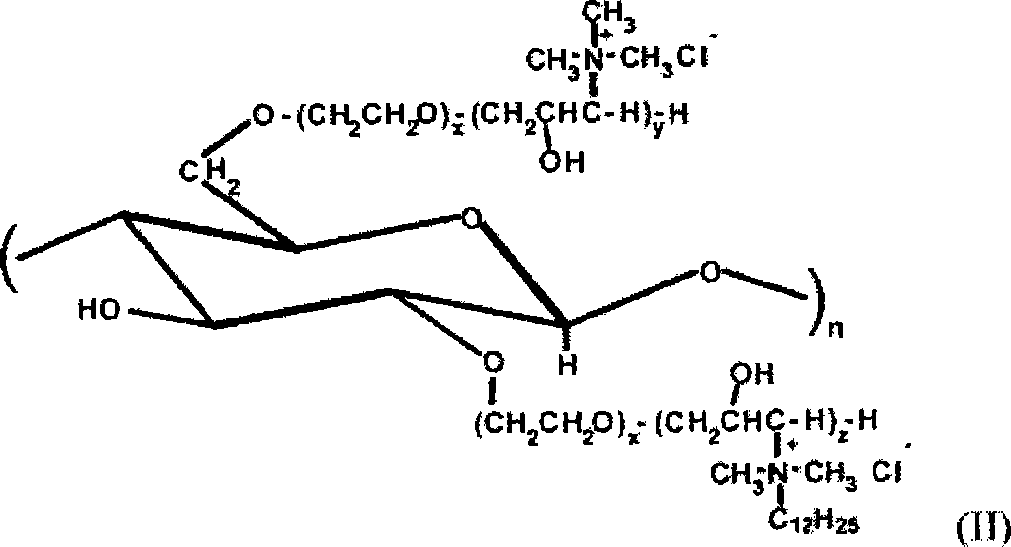

Quaternized cellulose ethers for personal care products

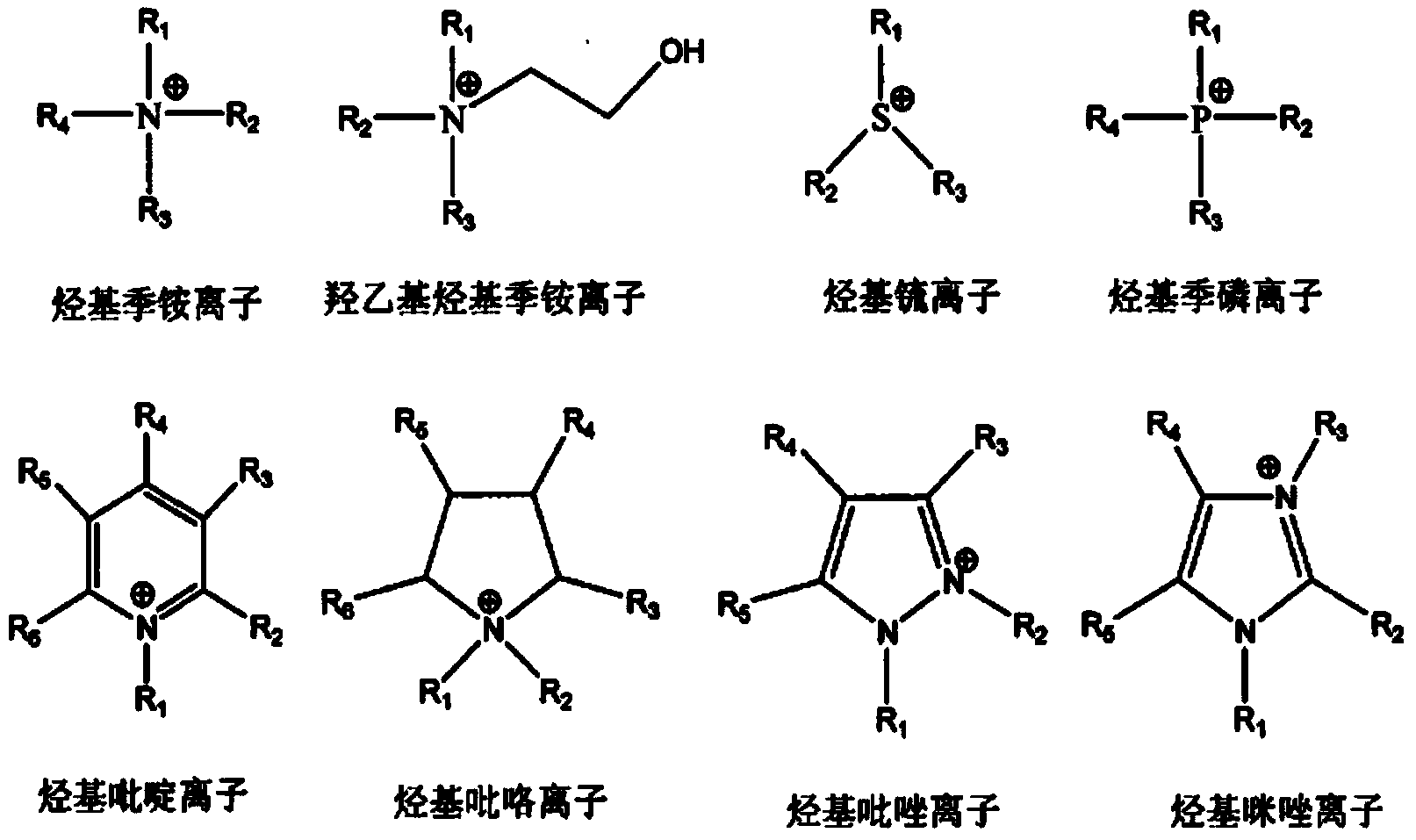

ActiveCN101547681AHigh viscosityThe average degree of substitution is smallCosmetic preparationsHair cosmeticsCelluloseEther

Owner:UNION CARBIDE CORP

System and method for generating optical return-to-zero signals with alternating bi-phase shift and frequency chirp

ActiveUS7606501B2Low costReduce complexityCoupling light guidesElectromagnetic transmittersPhase shiftedReturn-to-zero

A system and method for generating an optical return-to-zero signal with frequency chirp. The system includes a bit separator configured to receive an electrical non-return-to-zero signal and generate a first input signal and a second input signal. Additionally, the system includes a first driver configured to receive the first input signal and generate a first driving signal. The first driving signal is proportional to the first input signal in signal strength. Moreover, the system includes a second driver configured to receive the second input signal and generate a second driving signal. The second driving signal is proportional to the second input signal in signal strength. Also, the system includes a light source configured to generate a light, and an electro-optical modulator.

Owner:FUTUREWEI TECH INC

Feather protein viscose filament yarn and manufacturing method thereof

InactiveCN102851786AImprove fixation effectExcellent fiber performanceConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseLoss rateCellulose

The invention relates to feather protein viscose filament yarn and a manufacturing method thereof. The invention belongs to the material field of textile industry. According to the invention, feather protein liquid and a cellulose sulfonate solution with a weight ratio of 1-40%:60-99% are adopted; the materials are subjected to static blending, spinning, solidifying, and post-processing, such that the feather protein viscose filament yarn is obtained. During the production process, a protein loss of the feather protein viscose filament yarn is lower than 30%. After 50 times of washing upon a finished product, a fiber protein loss rate is no higher than 5%. According to the invention, the feather protein viscose filament yarn is manufactured by using waste feathers. The fiber performance is good, the cost is low, and the raw material sources are wide. The filament yarn and the manufacturing method are beneficial for environment protection.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +2

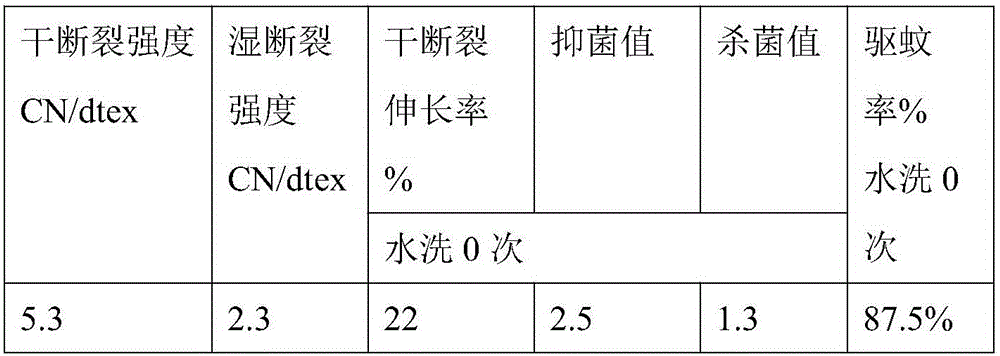

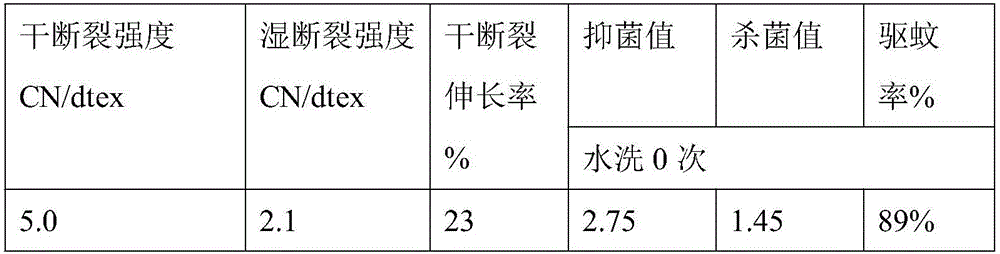

Multifunctional protein fiber and preparation method thereof

ActiveCN106012092AGood disinfection and sterilization functionEliminate odorConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsSkin coolingPolyvinyl alcohol

The invention discloses a multifunctional protein fiber and a preparation technology thereof. The preparation technology comprises adding natural additives with functions of antibiosis, mildew resistance, mosquito and insect prevention and cooling into main fiber raw materials such as soybean protein, polyvinyl alcohol (PVA) and carboxymethyl chitosan to obtain a spinning stock solution with a plurality of functions, preparing a fiber semi-finished product from the spinning stock solution through a wet spinning technology and carrying out finishing so that mechanical properties of the protein fiber are improved and the multifunctional protein fiber with excellent mechanical properties is obtained. The multifunctional protein fiber and the preparation technology solve the problem that the common protein fiber on the market has a single function, is produced by complex processes, has no lasting effects and has a high production cost. The multifunctional protein fiber has effects of softness, skin adaptability, moisture absorption, humidity elimination, antibiosis, mildew resistance, mosquito repellency, insect prevention and skin cooling and has a good market prospect.

Owner:广东安之伴实业有限公司

Preparing method of high-performance polyethylene fiber and carbon nano tube composite fiber

InactiveCN106521676ASolve reunionGood dispersionMonocomponent polyolefin artificial filamentArtifical filament manufactureCarbon nanotubeSynthetic fiber

The invention relates to the technical field of synthetic fiber industry, in particular to a preparing method of high-performance polyethylene fiber and carbon nano tube composite fiber. The preparing method of the high-performance polyethylene fiber and carbon nano tube composite fiber includes the steps that carbon nano tubes are added into concentrated sulfuric acid, the mixed solution is heated under the condition of magnetic stirring, a KMnO4 water solution is added, reflux is carried out for 2-2.5 h at the temperature, and concentrated sulfuric acid is added after cooling to obtain purified carbon nano tubes; the carbon nano tubes are added into ethyl alcohol and ultrasonically treated for 1 h, heating and stirring are carried out under high-speed magnetic stirring, isopropanol liquid is added, filtering and drying are carried out, and the functionalized carbon nano tubes are obtained through Soxhlet extraction; a high-performance polyethylene fiber solution is prepared, the carbon nano tubes and antioxidant are added, and high-performance polyethylene fiber and carbon nano tube gel solution is prepared through ultrasonic treatment and heating; the high-performance polyethylene fiber and carbon nano tube gel solution is added into a double-screw spinning machine to conduct spinning to obtain gel protofilament, and extraction and drying stretch are carried out to obtain the high-performance polyethylene fiber and carbon nano tube composite fiber. The fiber performance is improved.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

Copolyester and preparation method and use thereof

InactiveUS20120202964A1Improve dyeing effectReducing expensive equipment investmentMonocomponent copolyesters artificial filamentDisperse dyeAlcohol

A copolyester and preparation method and use thereof are disclosed. In the diacid components constituting the copolyester, the content of the structure unit of terephthalic acid is 90 mol % or more. In the dihydric alcohol components constituting the copolyester, the content of the structure unit of ethylene glycol is 70-99 mol % and the content of the structure unit of aliphatic dihydric alcohol having 6 or less carbon atoms and having a side chain is 1-30 mol %. The copolyester further comprises a structure unit of polyethylene glycol. The copolyester can be made into fiber by common method, and further made into fabric, and the obtained finished-product has good dyeability to disperse dyes under normal temperature and normal pressure.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

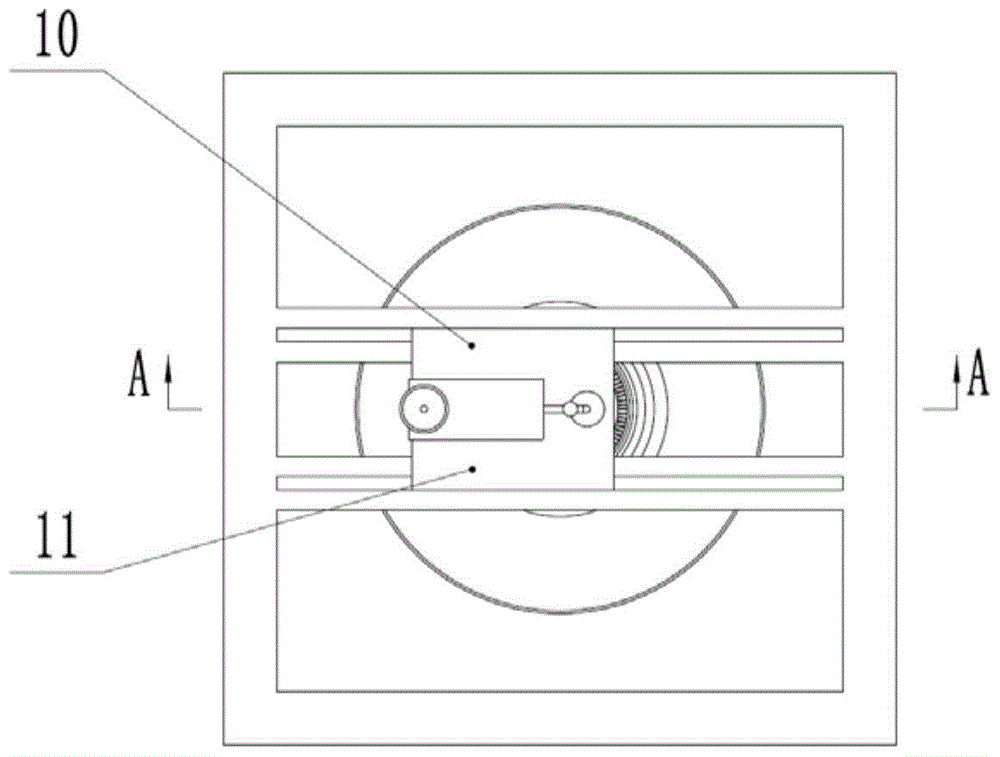

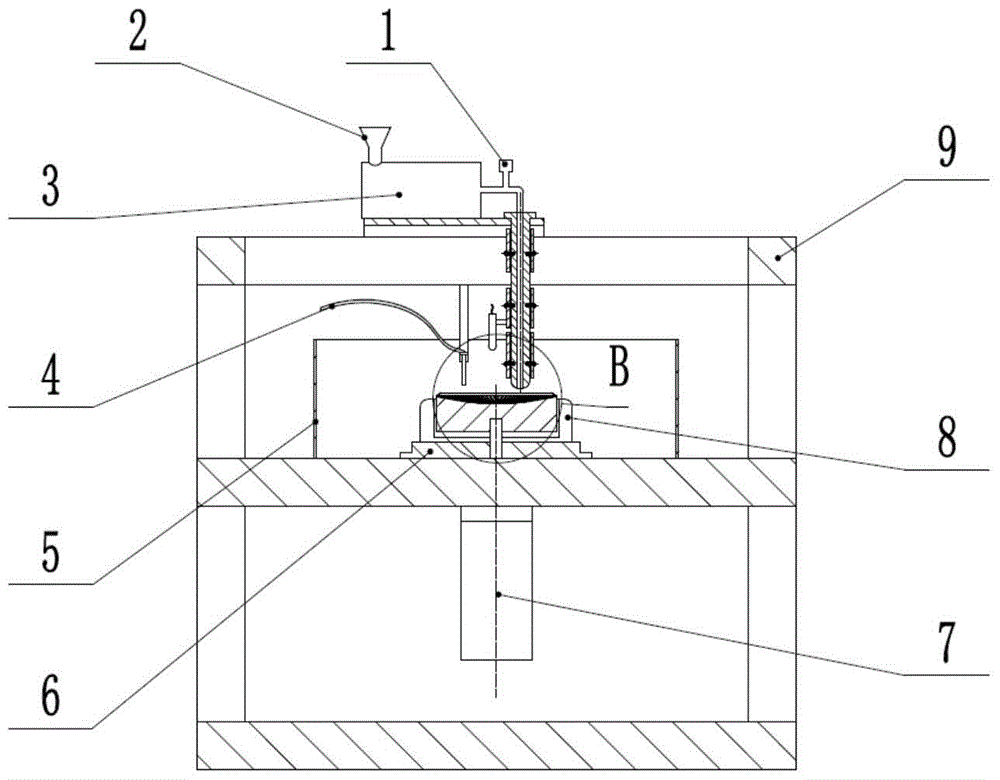

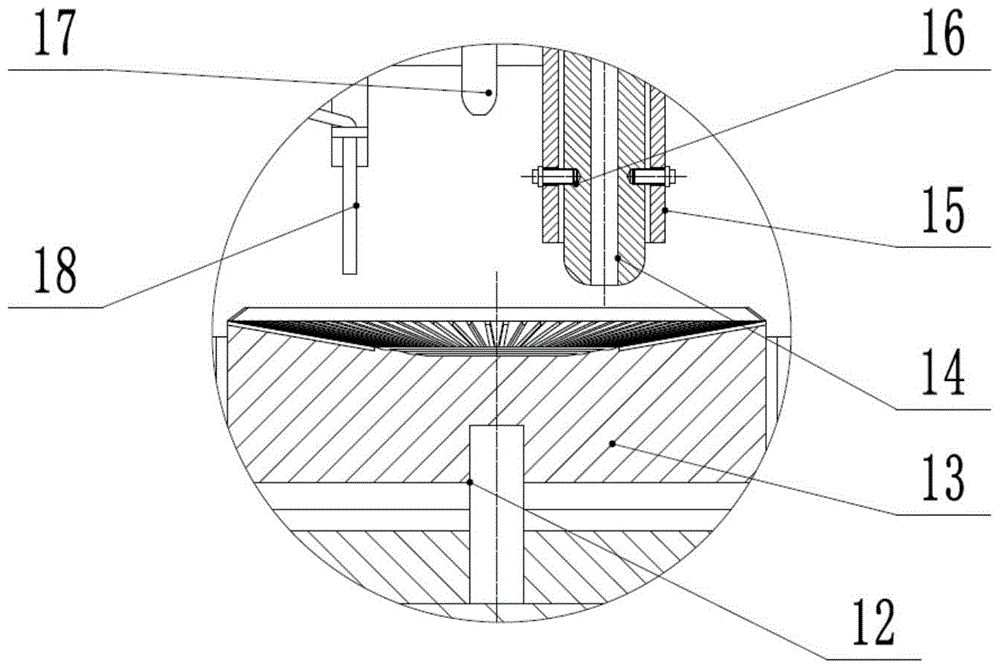

Airflow-assisted melt micro-separation centrifugal spinning device and method

ActiveCN104674360BPromote Thinning and RefinementReduce RPM requirementsArtificial thread manufacturing machinesFilament/thread formingMeasuring instrumentEngineering

The invention discloses a device and a method for differential centrifugal spinning by using air flow to assist a melt, and belongs to the field of spinning forming. The device comprises a melt metering pump, a material hopper, a continuous material supply device, an air pipe, a receiving device, an electromagnetic heating bracket, a motor, an electromagnetic heating device, a spinning tank body, a spray head bracket, a slide rail, a shaft, a centrifugal differential disc, a spray head, a spray head heating coil, a thermocouple, an infrared temperature measuring instrument, an air pipe bracket and the like, wherein the melt enters the centrifugal differential disc through the eccentric spray head to obtain the initial linear speed, is equalized by a plurality of grooves which are formed in the disc center, enters a comb tooth-shaped structure of the conical surface of the disc edge, is thinned, differentiated and fined under the actions of centrifugal force, high-speed air flow and attaching force of the melt on the conical surface, and is thrown out at high speed, so as to finally form superfine fibers. The device and the method have the advantages that in the fiber preparation process, the efficiency is high, and the green and pollution-free effects are realized; the prepared fiber has higher net surface density and degree of orientation, and the property is excellent; the device is simple, the processing is easy, and the device is suitable for preparing the superfine fibers in a batch way.

Owner:BEIJING UNIV OF CHEM TECH

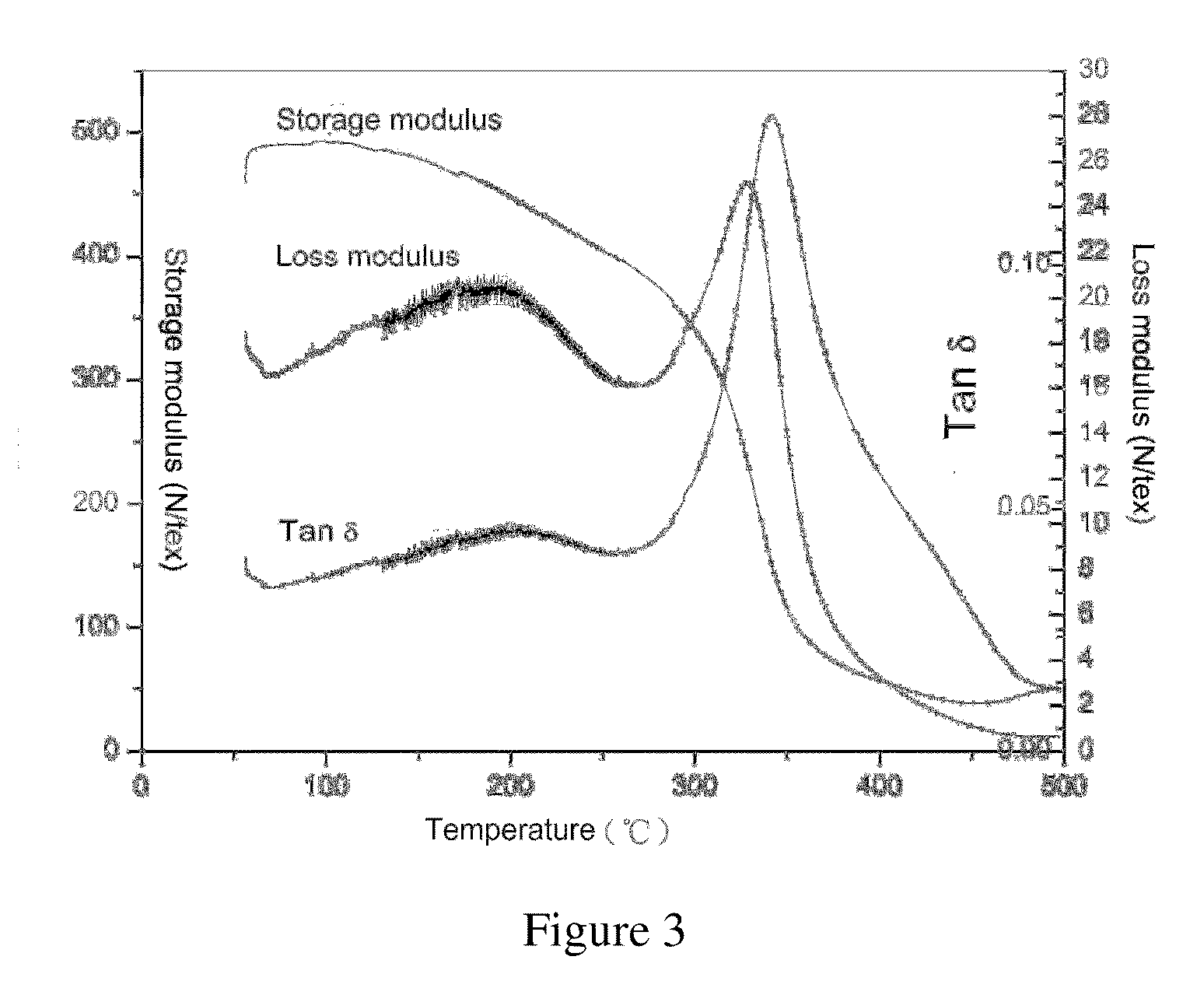

Polyimide fiber with high strength and high modulus and its preparation method

ActiveUS20130137846A1Improve mechanical propertiesPerformance requirementArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberBPDA

A high-strength high-modulus polyimide fiber and its preparation method pertain to the technical field of high-performance organic fiber. This fiber includes the polyimide (PI) fiber made from 3,3′,4,4′-biphenyl tetracarboxylic diandhydride (BPDA), p-phenylenediamine (pPDA) and 2-(4-aminophenyl)-1H-benzimidazol-5-amine (BIA), wherein the molar ratio between PPDA and BIA is 1:10˜3:1. During the synthesis, other diamine and diandhydride monomers may also be added. In the preparation process, the gradient temperature reaction method and one-step continuous preparation method are adopted, the synthesis and processing difficulty caused by the increase of the content of BIA is overcome, the problem of poor uniformity and stability of fiber is solved and PI fiber with high strength and high modulus is obtained. Its strength may reach 4.5 GPa and modulus may reach 201 GPa. Moreover, the sources of the raw materials are extensive, the spinning process is continuous, the cost is low, the efficiency is high and industrial production may be realized.

Owner:BEIJING UNIV OF CHEM TECH

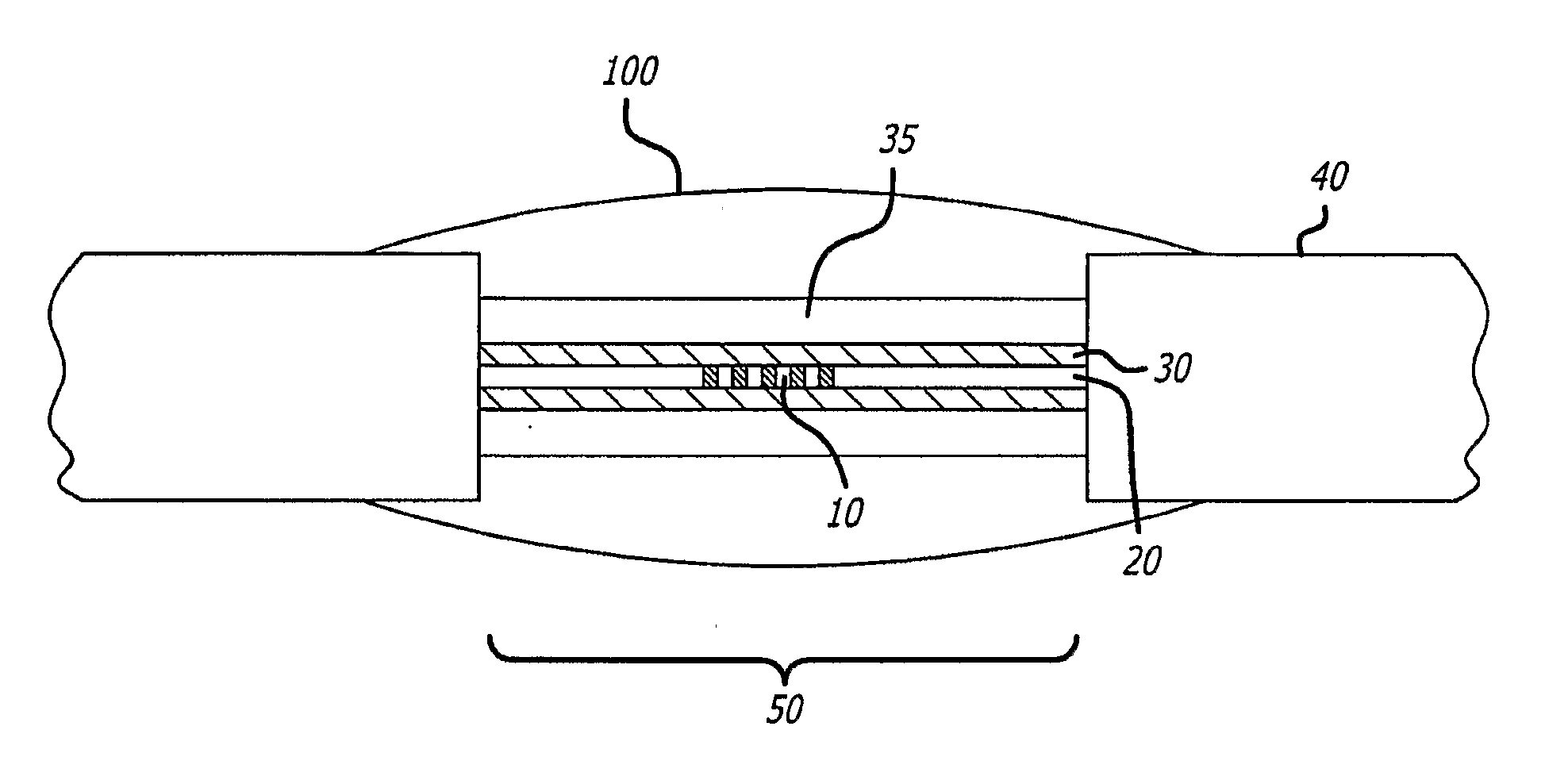

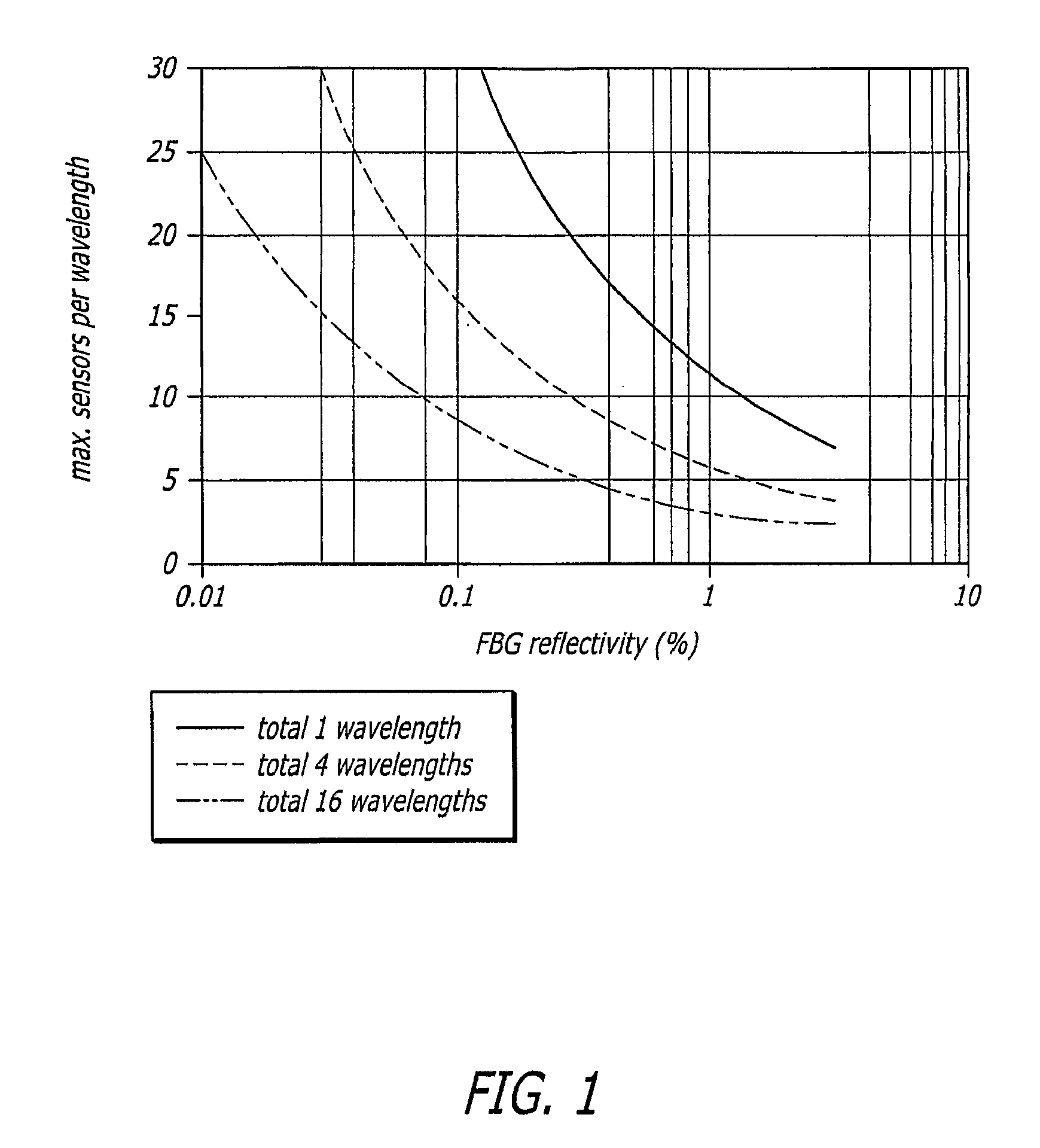

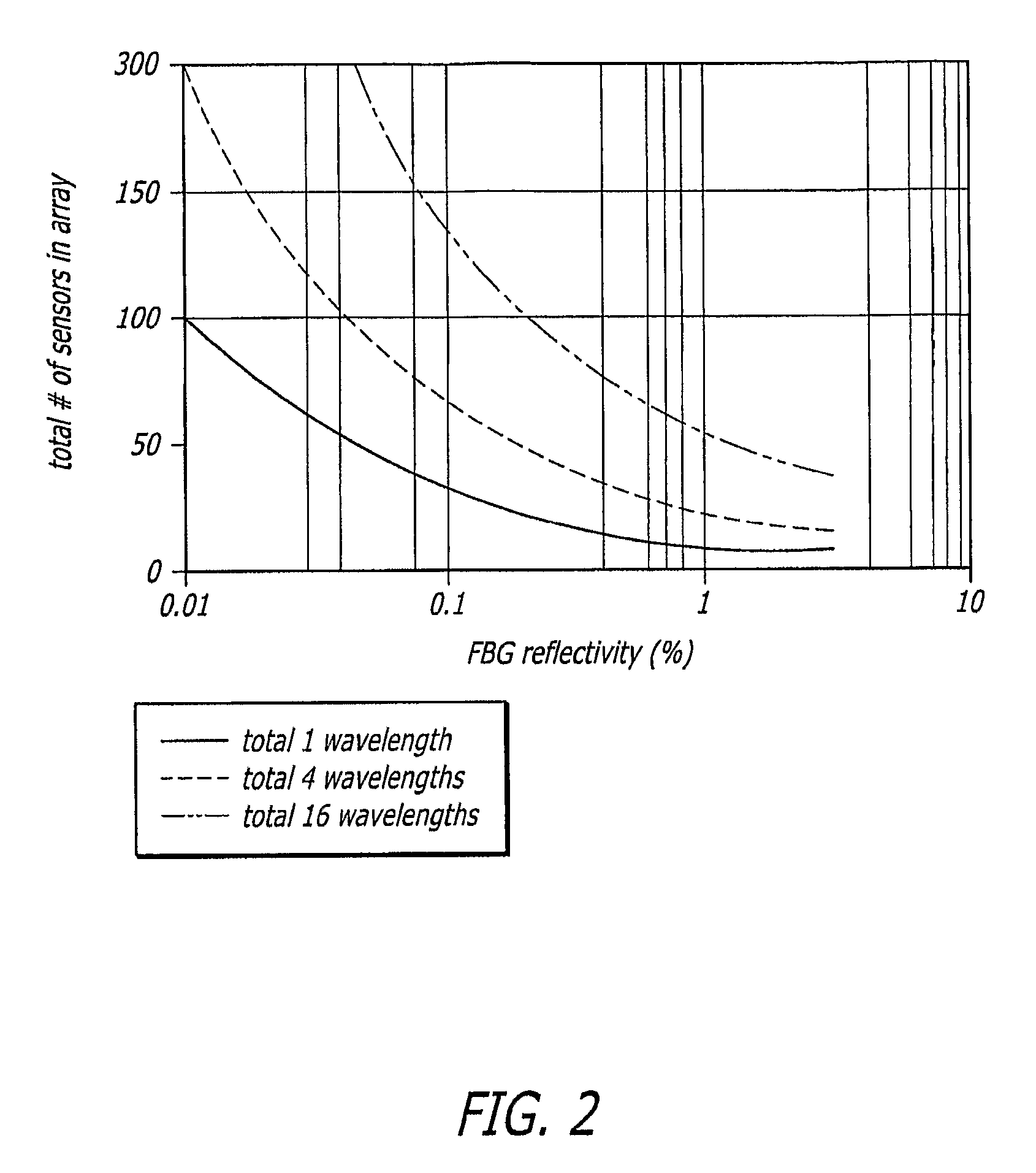

High density fiber optic acoustic array

InactiveUS20090092351A1Low costMinimize the numberCladded optical fibreSubsonic/sonic/ultrasonic wave measurementSensor arrayFiber

A method for optimizing the architecture of a linear sensor array using WDM-TDM technology and stabilizing the reflectivity spectral profile of the fiber Bragg gratings of the sensors against the influence of environmental factors such as pressure and temperature is provided. The method includes stripping a portion of the foamed coating on the exterior of an optical fiber in the region of the fiber Bragg grating to thin the coating in the region of the grating. After the coating is stripped and the optical fiber cleaned, the area of stripped fiber is recoated with an unvoided plastic.

Owner:SABEUS

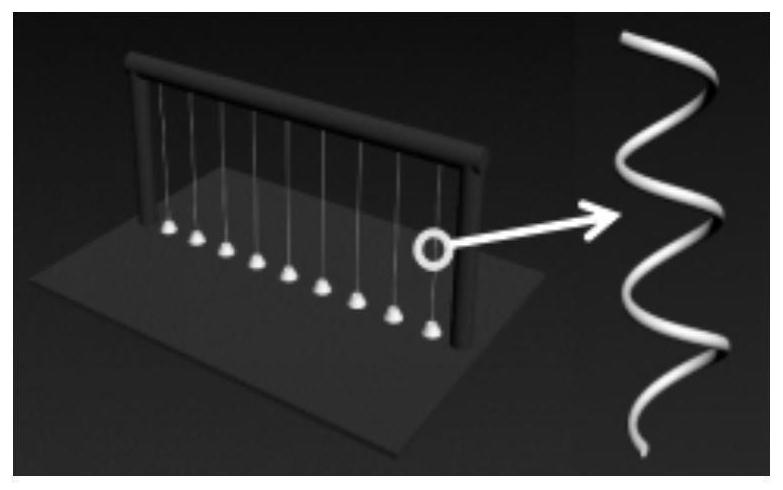

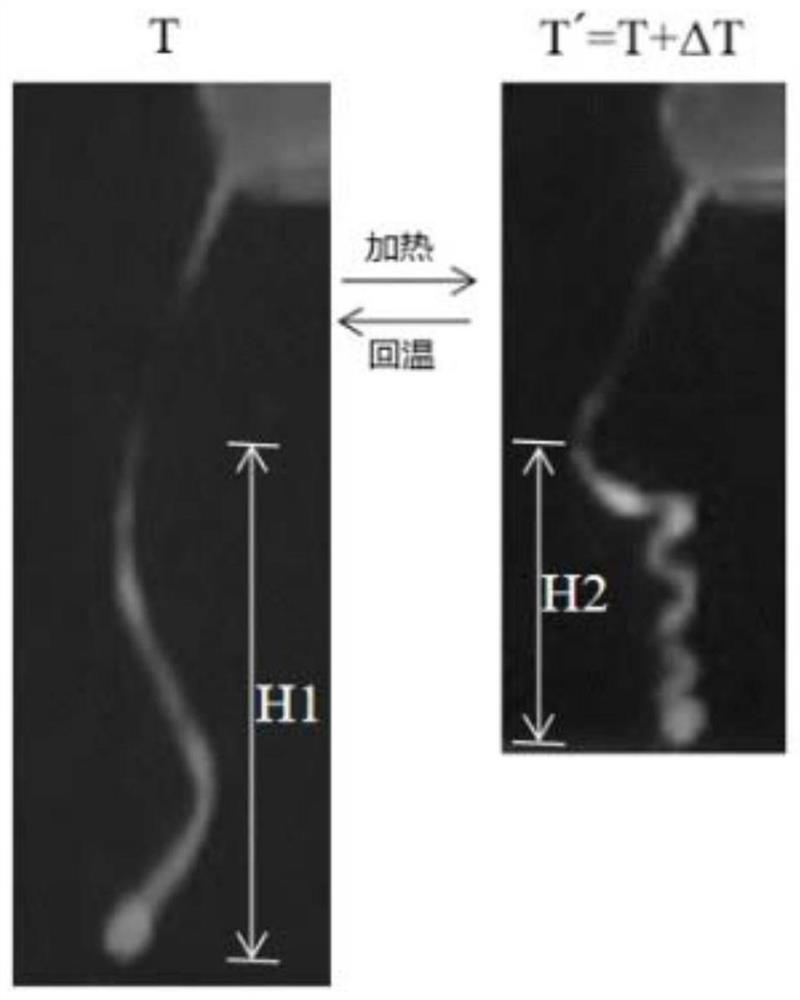

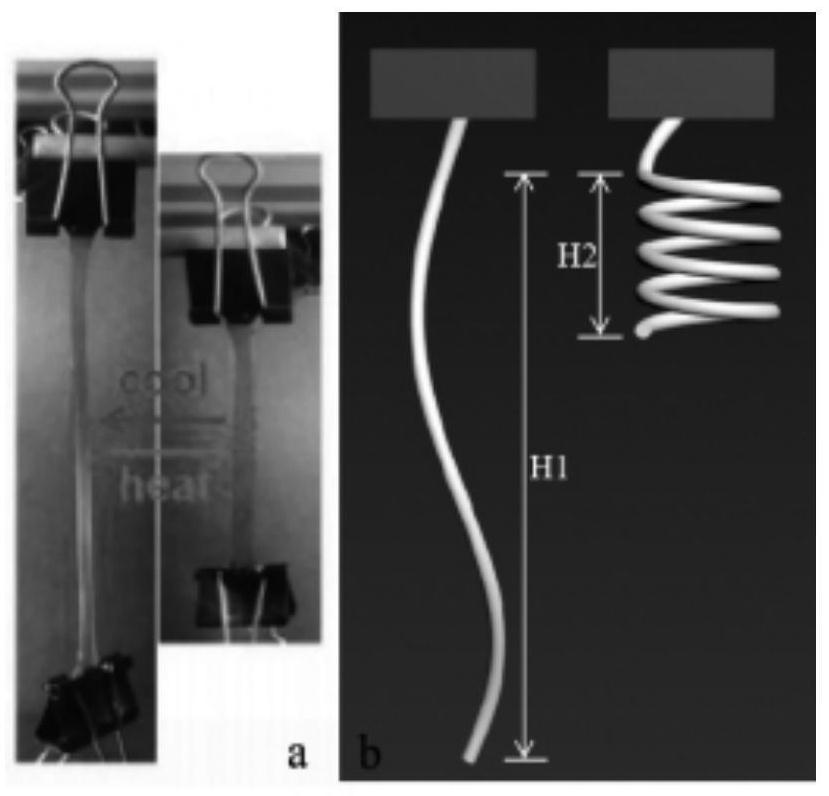

Liquid crystal elastomer fiber capable of being spirally bent and preparation method and application thereof

ActiveCN113802209AIncreased deformation rangeImprove fiber performanceLiquid crystal compositionsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention belongs to the technical field of liquid crystal materials, and discloses a liquid crystal elastomer fiber capable of being spirally bent and a preparation method and application thereof. The preparation method of the liquid crystal elastomer fiber comprises the following steps that (1), a liquid crystal monomer, mercaptan, a Michael addition reaction catalyst and a photoinitiator are dispersed in a volatile organic solvent for reaction, and continuously stirring is carried out until the volatile organic solvent is completely volatilized to prepare a liquid crystal elastomer prepolymer; and (2), the liquid crystal elastomer prepolymer is drawn into filaments, fixing is carried out after twisting, and polymerizing is carried out by ultraviolet irradiation to obtain the liquid crystal elastomer fiber. The liquid crystal elastomer fiber can realize three-dimensional spiral curling, overcomes the defect of single telescopic deformation of an existing liquid crystal elastomer material, and has the advantages of larger deformation range, thermal deformation and reversible recovery.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

Method for preparing zirconium oxide fibers through inorganic hybridization of organic polymer

InactiveCN102190490AExcellent fiber processing performanceImprove fiber performanceElectrospinningIon

The invention discloses a method for preparing zirconium oxide fibers through inorganic hybridization of organic polymer, which comprises the following steps of: adding one of dimethylformamide, ammonia water and oxalic acid into zirconium oxychloride, and stirring to form transparent sol; washing with water and ethanol sequentially until chloride ions are absent through detection of a silver nitrate reagent, drying and grinding, and roasting in a microwave sintering furnace to obtain nano zirconium oxide powder; blending the nano zirconium oxide powder and organic polymer resin, and preparing organic / inorganic hybrid fibers through solvent spinning, melting spinning or electrostatic spinning; and performing thermal stabilization and carbonization on the zirconium oxide fibers to obtain inorganic zirconium oxide fibers. Raw materials are cheap and readily available; the prepared zirconium oxide fibers can be short fibers and continuous fibers, and also can be nano zirconium oxide fibrous membranes; the zirconium oxide fibers can be prepared by several pieces of conventional process equipment, and the manufacturing cost is reduced; and the product stability is improved and continuous filament fibers are easily obtained.

Owner:ZHONGYUAN ENGINEERING COLLEGE

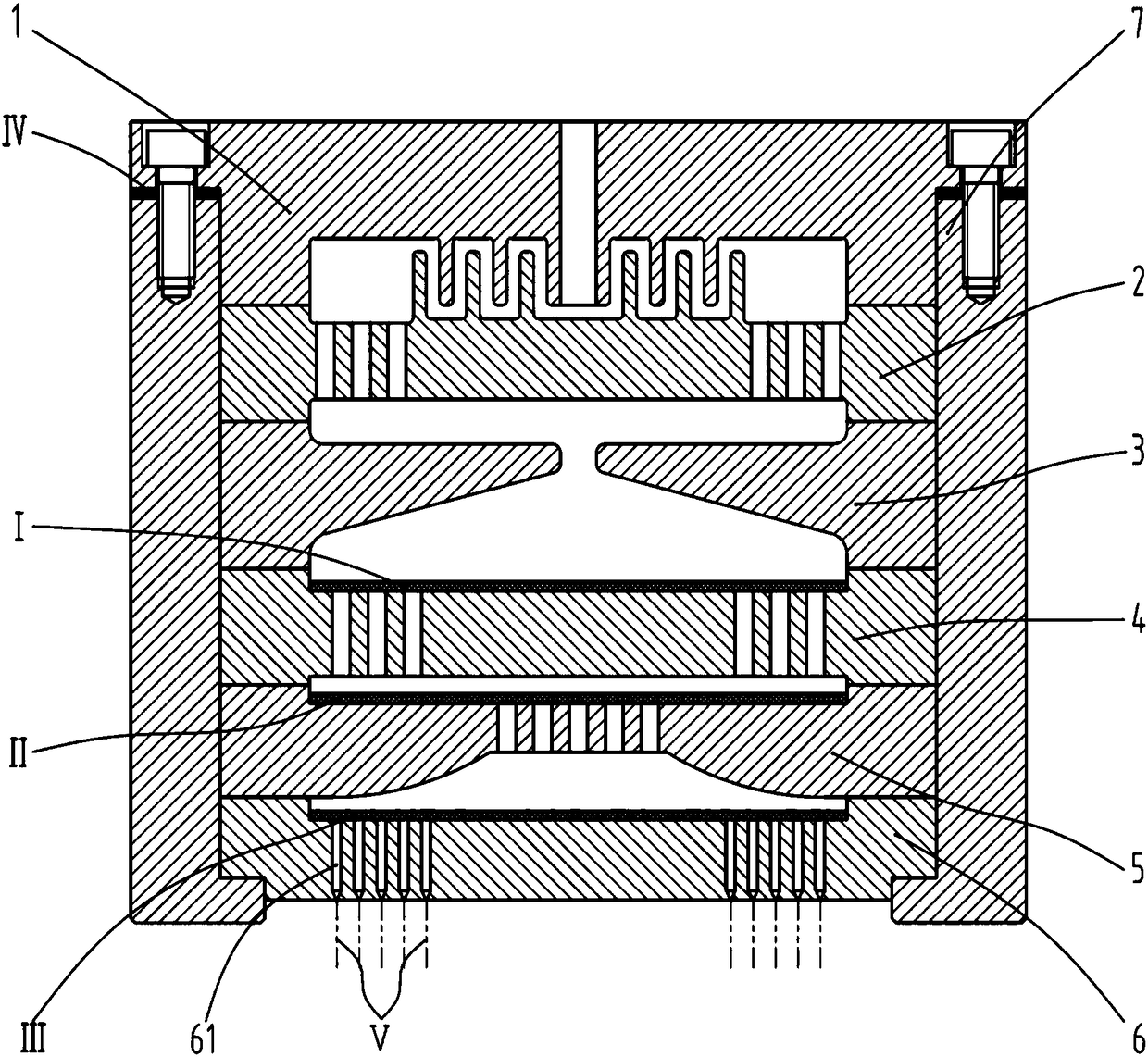

Multi-flow channel pressure equalized blend spinning component for preparing mesophase asphalt based carbon fibers

ActiveCN108060463ARealize multi-occasion useExtended service lifeSpinning solution de-aeratingSpinnerette packsFiberPolymer science

The invention provides a multi-flow channel pressure equalized blend spinning component for preparing mesophase asphalt based carbon fibers. The multi-flow channel pressure equalized blend spinning component comprises a raw material inlet plate; an annular blending porous plate, an aggregation dispersion plate, a blending porous plate, a blending distribution plate, a spinneret and a component jacket are sequentially arranged below the raw material inlet plate. After entering the component, a molten polymer enters a flow channel of a concentric circle maze-shaped S-shaped structure firstly soas to be subjected to primary blending, then is subjected to flowing processes of dispersion, aggregation, flow blending and the like of a series of round hole-shaped blending flow channels to be further uniformly blended and passes through a multi-layer filter screen finally to enable residual bubbles in the molten polymer are broken, large-diameter particles to be fined and the molten polymer tobe more uniformly blended, so that the quality of spun fibers, the consistency of the fiber performance and the stability of the spinning process are improved.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

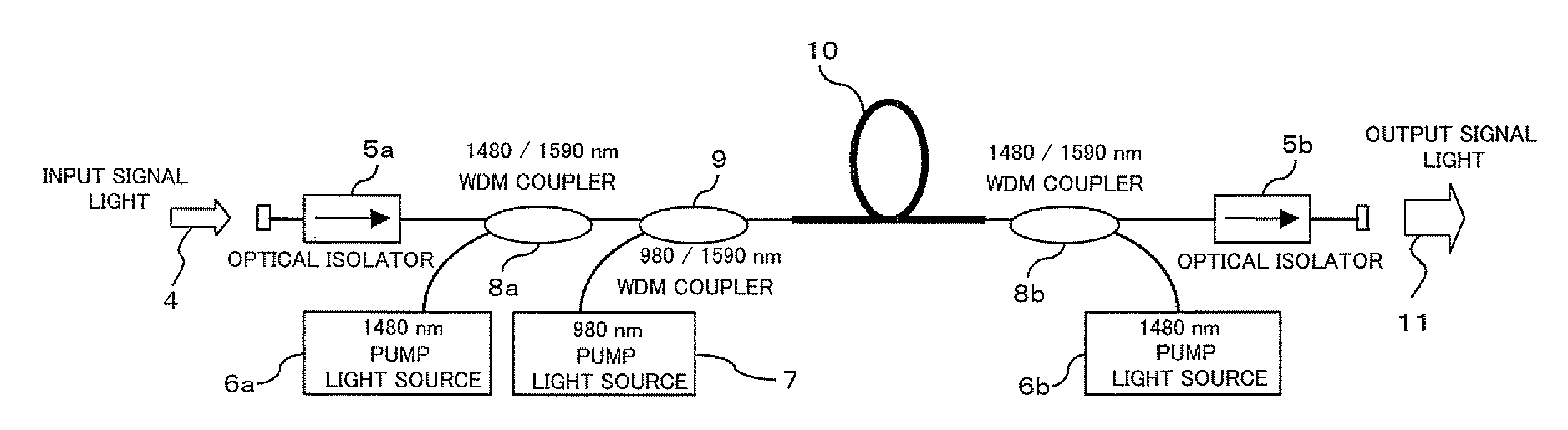

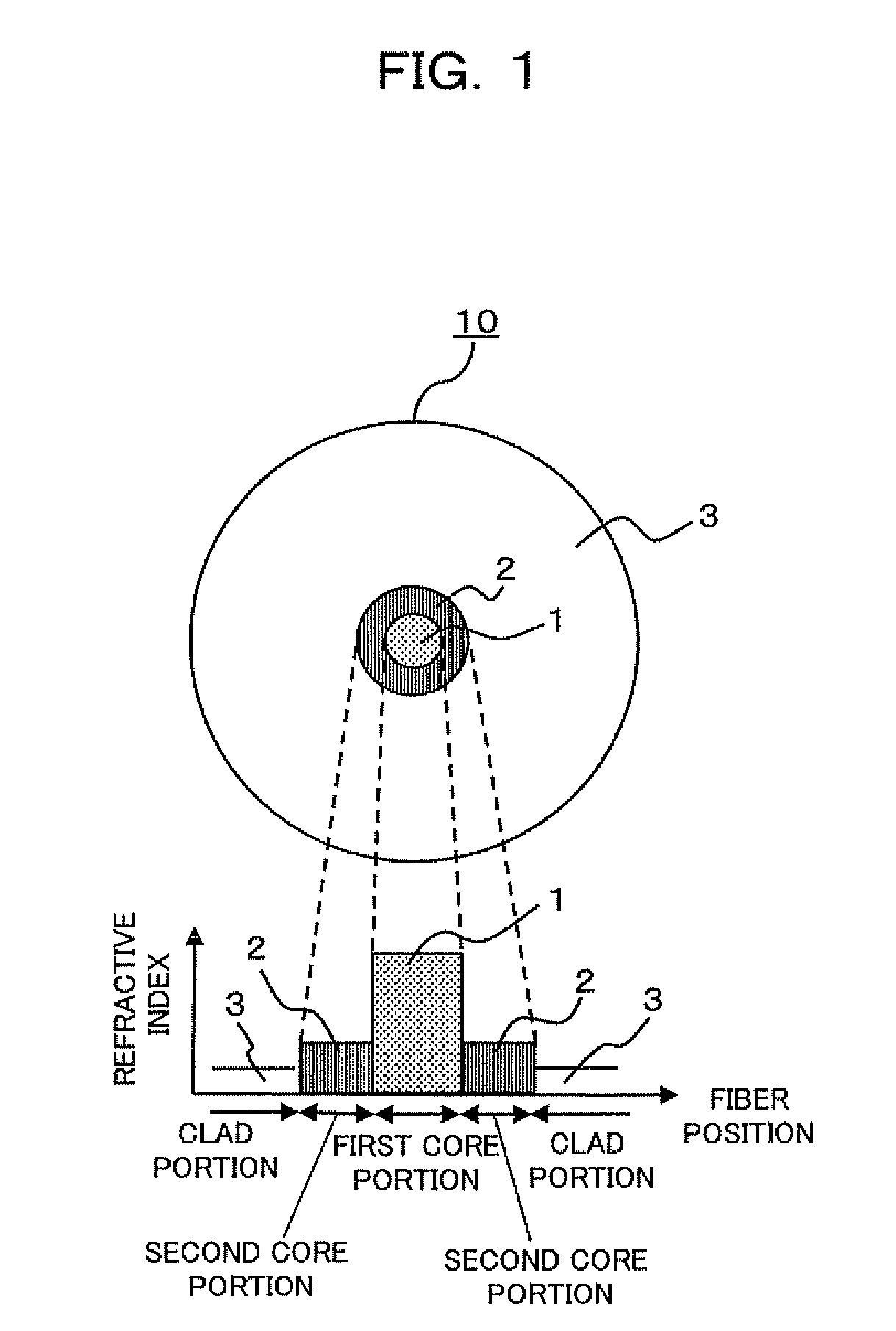

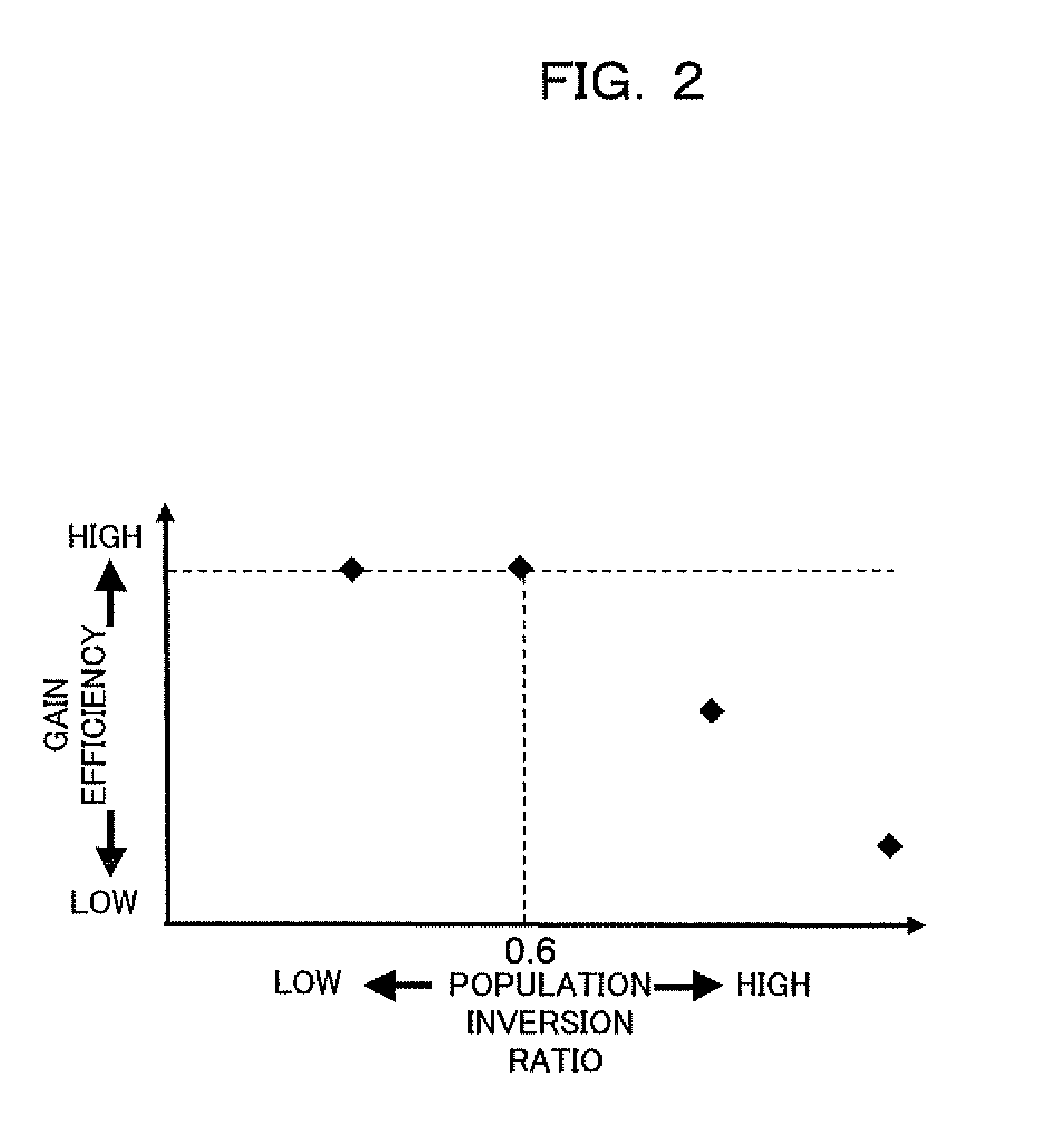

Optical fiber, manufacturing method of the same, and optical amplifier

InactiveUS20080013904A1Maximum efficiencyInhibitionGlass making apparatusLaser detailsFiberRare earth ions

An optical fiber includes: a first core portion doped with rare earth ions; a second core portion having a lower refractive index than that of the first core portion, provided along an outer circumference of the first core portion, and doped with the rare earth ions; and a clad portion having a lower refractive index than that of the second core portion and provided along an outer circumference of the second core portion, and is configured such that a concentration of the rare earth ions added to the second core portion is higher than that to the first core portion. With this configuration, it is possible to suppress an amount of FWM crosstalk in an optical amplification by decreasing the length of a fiber while alleviating efficiency deterioration due to concentration quenching.

Owner:FUJITSU LTD

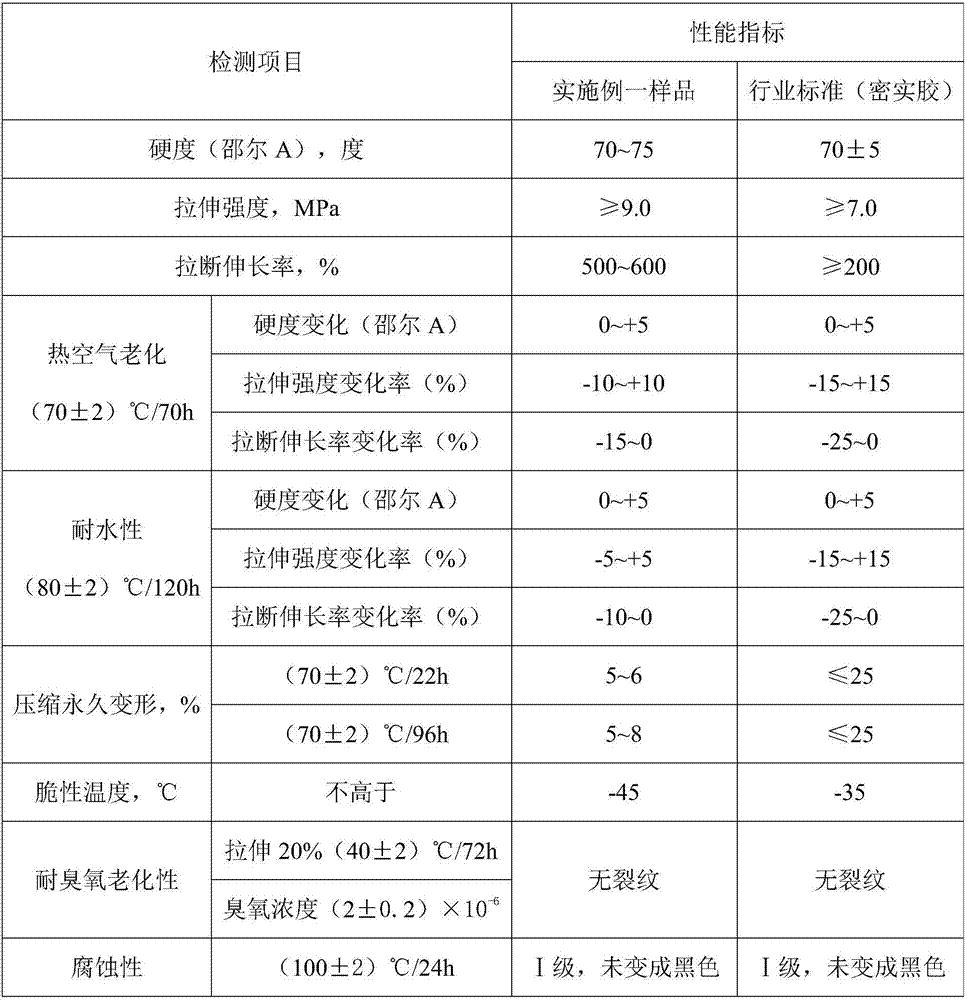

Vehicle sealing strip glue material and vehicle sealing strip

The present invention discloses a vehicle sealing strip glue material, which comprises the following raw materials by weight: 50-60 parts of ethylene propylene diene monomer, 20-30 parts of chloroprene rubber, 30-40 parts of a thermoplastic polyurethane elastomer, 15-25 parts of white carbon black, 10-20 parts of silanized glass fiber being subjected to surface modification with gamma-aminopropyltriethoxysilane, 5-10 parts of calcium carbonate, 3-5 parts of an accelerator Z, 2-4 parts of an accelerator D, 2-4 parts of an accelerator M, 1-3 parts of a lubricating dispersant, 1-3 parts of a cross-linking agent, and 1-3 parts of an anti-aging agent, wherein the raw material components are mixed and treated with the specific steps to ensure the smooth and efficient performing of the reaction so as to obtain the vehicle sealing strip glue material with advantages of excellent sealing performance, excellent tolerance, excellent compression deformation resistance and excellent mechanical property, substantially-improved vehicle sealing strip use performance and substantially-improved service life. According to the present invention, the vehicle sealing strip has more colors and more patterns so as to meet the vehicle decoration design and performance demand development and promote the progress in the vehicle sealing strip field.

Owner:HEBEI KAIXUAN SEALING CO LTD

Method for preparing high-strength slag wool through direct fibrosis of blast furnace slag

ActiveCN107098594AConvenient lengthImproved shot contentGlass furnace apparatusGlass productionFiberHeat stability

The invention discloses a method for preparing high-strength slag wool through direct fibrosis of blast furnace slag. Efficient utilization of sensible heat of the slag is achieved. Molten slag is firstly pretreated in a rotary kiln in a nitrogen atmosphere, pure metal elements or non-metal elements, such as silicon, in the slag react with nitrogen at a high temperature to generate nitrides with very good hardness and heat stability, so that the strength of the slag wool can be improved and rupture is prevented. In addition, a texturizer prepared by compounding nano-zirconia, rare earth tailings, quartz sand and other raw materials has good toughening and crystal structure refining effects, the fiber forming property of the slag can be significantly improved, the properties, such as the length, the strength, the shot content and the moisture content stability, of prepared fiber are effectively improved, and high-value and high-efficiency direct recycling of the molten slag is achieved.

Owner:阜阳市鑫源建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com