Multi-flow channel pressure equalized blend spinning component for preparing mesophase asphalt based carbon fibers

A technology of mesophase pitch and mixed spinning, applied in the field of materials, can solve the problems of frequent broken wires, different wire diameters, unstable performance, etc., and achieve the effects of saving costs, improving service life and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

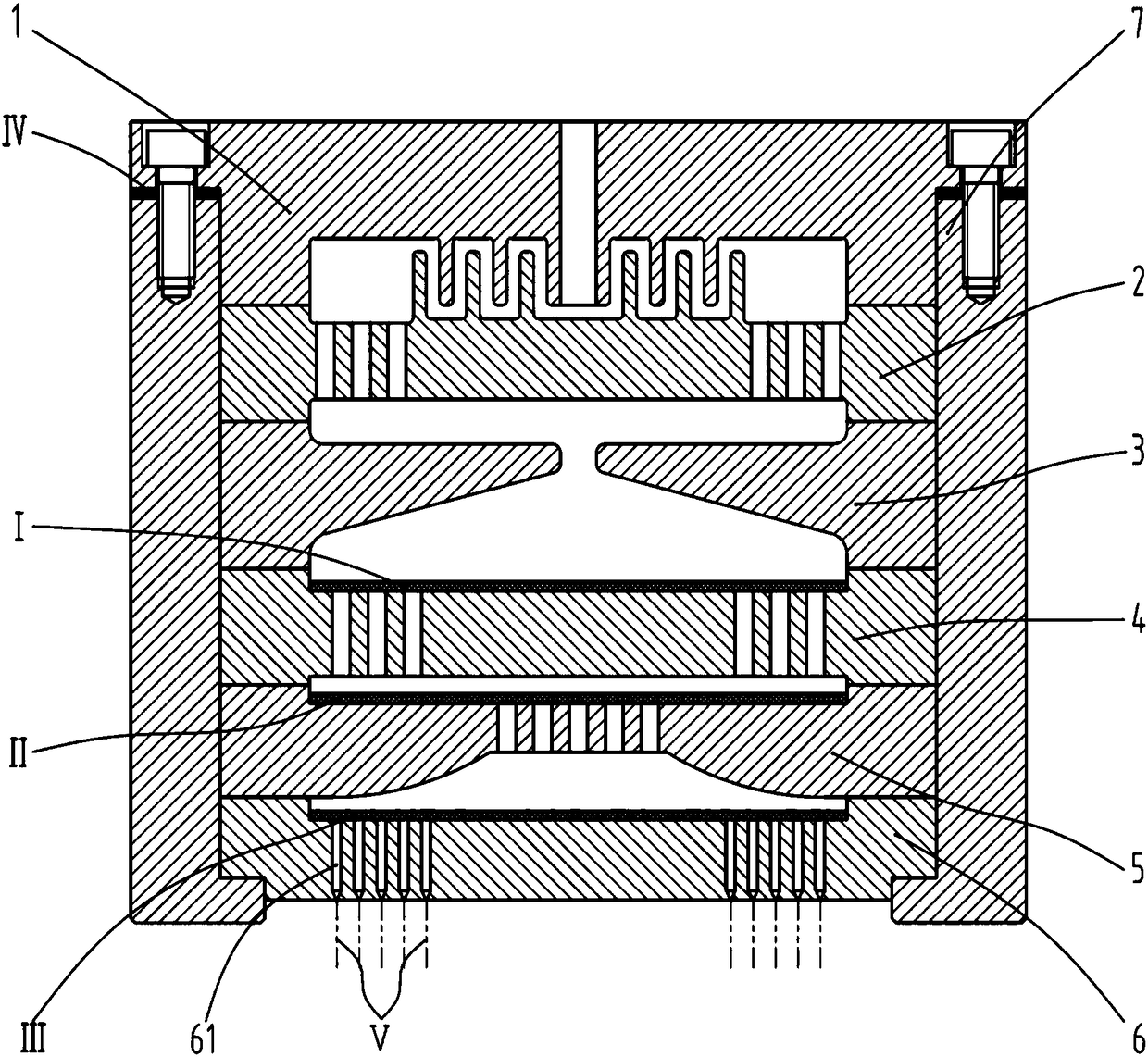

[0021] Such as figure 1 As shown, the multi-channel equal-pressure mixed spinning assembly (hereinafter referred to as the spinning assembly) for preparing mesophase pitch-based carbon fibers provided by the present invention has the functions of flowing, mixing, filtering, and equalizing the molten polymer. It specifically includes raw material inlet plate 1, circular mixing porous plate 2, collection and dispersion plate 3, mixing porous plate 4, mixing distribution plate 5, spinneret plate 6, component jacket 7, first filter screen I, second filter screen II , The third filter screen III, gasket IV, carbon fiber V.

[0022] Wherein, the above-mentioned raw material inlet plate 1 is located at the uppermost end of the entire spinning assembly, and the circular mixing perforated plate 2 is located below it.

[0023] Below the annular mixing perforated plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com