Preparation method of high-performance carbon nanotube fiber

A carbon nanotube fiber, carbon nanotube technology, applied in the chemical characteristics of fibers, textiles and papermaking, yarn and other directions, can solve the problem that carbon tubes cannot be well oriented, the wet spinning process is complicated, and the mechanical stability of fibers Insufficient and other problems, to achieve the effect of superior mechanical properties, simple and convenient method, and avoid high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

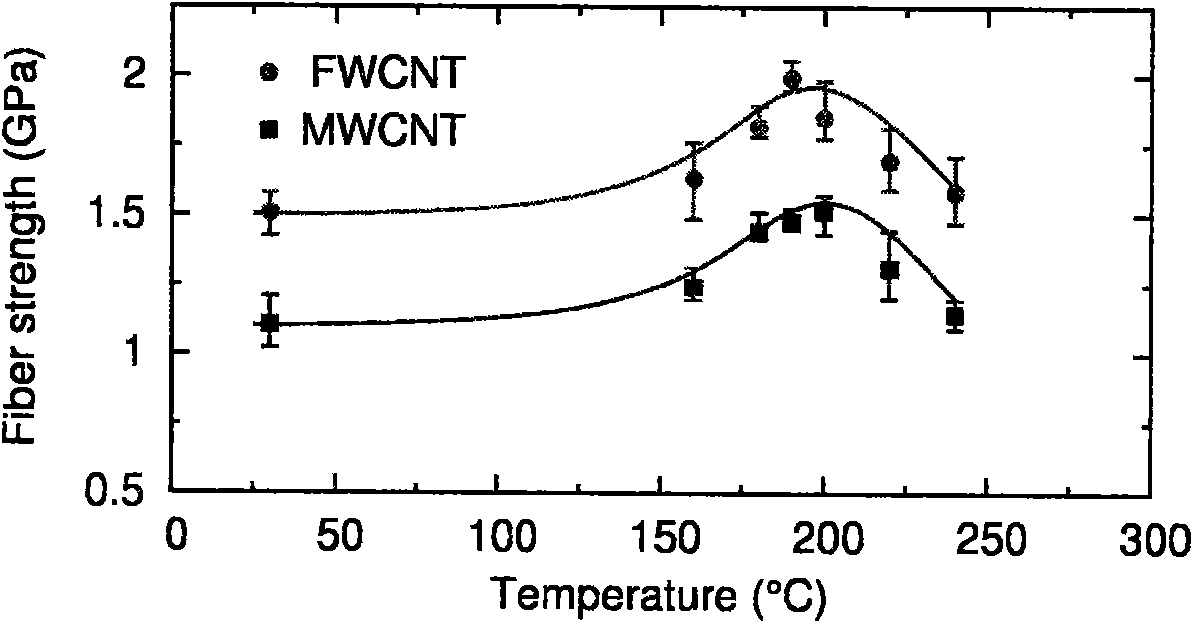

[0037] The purpose of this embodiment is in order to produce high-performance carbon nanotube / polyimide composite fiber, and its technical idea utilizes polymer molecule to improve the interfacial shear modulus of carbon nanotube, thereby improves the mechanics of carbon nanotube fiber performance.

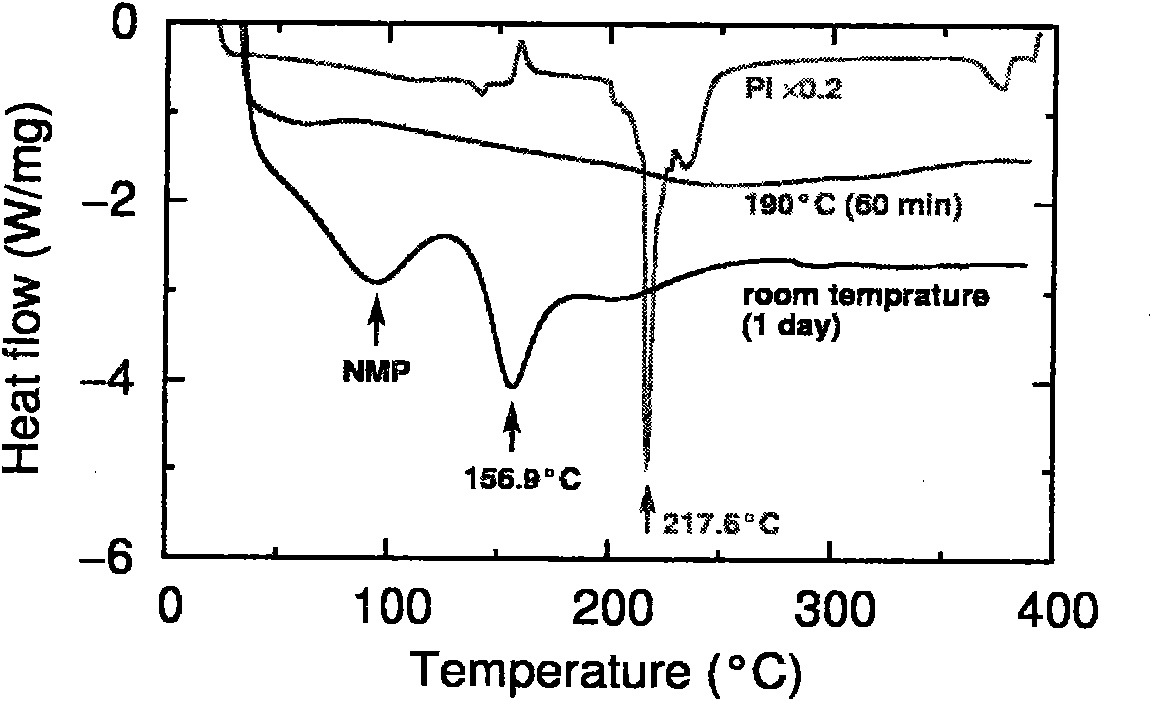

[0038] The carbon nanotube array that can be spun as the operation object in the present embodiment, the carbon source that this carbon nanotube array grows can be ethylene or acetylene, and the polymer source adopts finished product polyamic acid / N-methylpyrrolidone solution ( available directly from the manufacturer).

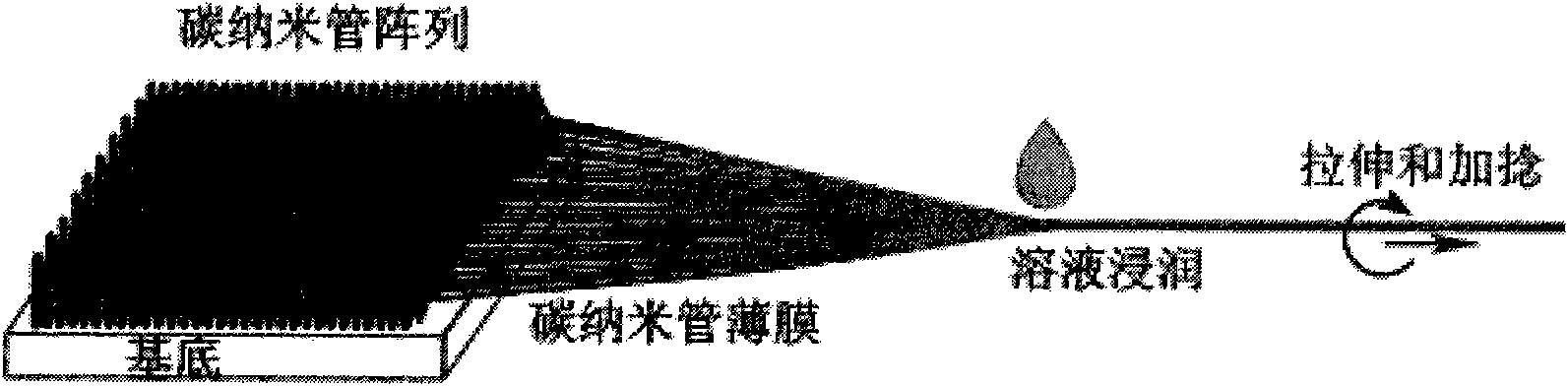

[0039] Such as Figure 1~5 As shown, the preparation process of carbon nanotube / polyimide composite fiber in the present embodiment comprises the following steps:

[0040] 1. Get the spinnable carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com