High-hardness polycrystalline diamond and process for producing the same

A polycrystalline diamond, high hardness technology, used in metal processing equipment, manufacturing tools, turning equipment, etc., can solve problems such as easy cracking and diamond inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10 and comparative example 1-4

[0139] A variety of non-graphite carbon substances are added to graphite powder with excellent crystallinity with a particle size of 0.05-10 μm and a purity of at least 99.95%, or synthetic diamond powder with a particle size of 0.05-3 μm, such as ultrafinely pulverized into powder Graphite, glassy carbon powder, fullerene powder, carbon nanotube powder, and then the resultant is filled into a Mo package and sealed to prepare a raw material composition.

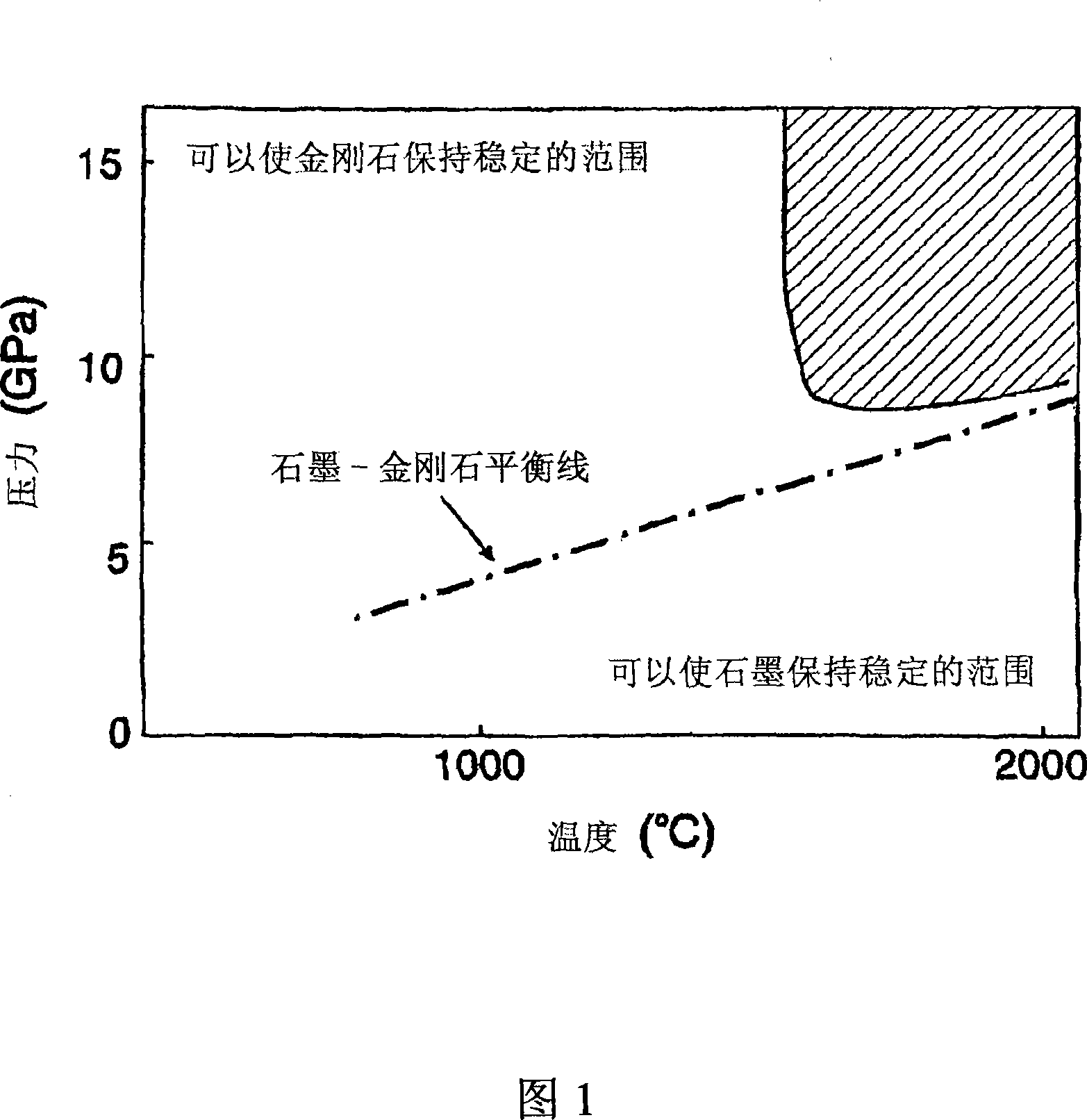

[0140] The raw material composition is treated for 30 minutes under different pressures and different temperatures by using a belt-type ultra-high pressure generating device to prepare high-hardness polycrystalline diamond.

[0141] The generated phase of the prepared polycrystalline diamond was identified by X-ray diffraction technique, and the size of the constituent particles was detected according to the observation results of TEM. In addition, the surface of the obtained high-hardness polycrystalline diamond is ground in...

Embodiment 11-19

[0149] The raw materials used are composed of the following substances: graphite powder with excellent crystallinity having a particle size of 0.05-10 μm and a purity of at least 99.95%; the above-mentioned ultrafinely pulverized graphite powder; glassy carbon powder; fullerene powder and carbon nanotube powder. These powders were mixed and filled into Mo packages and sealed, and then the packages were treated at different pressures and temperatures for 30 minutes using a belt-type ultra-high pressure generator to prepare samples.

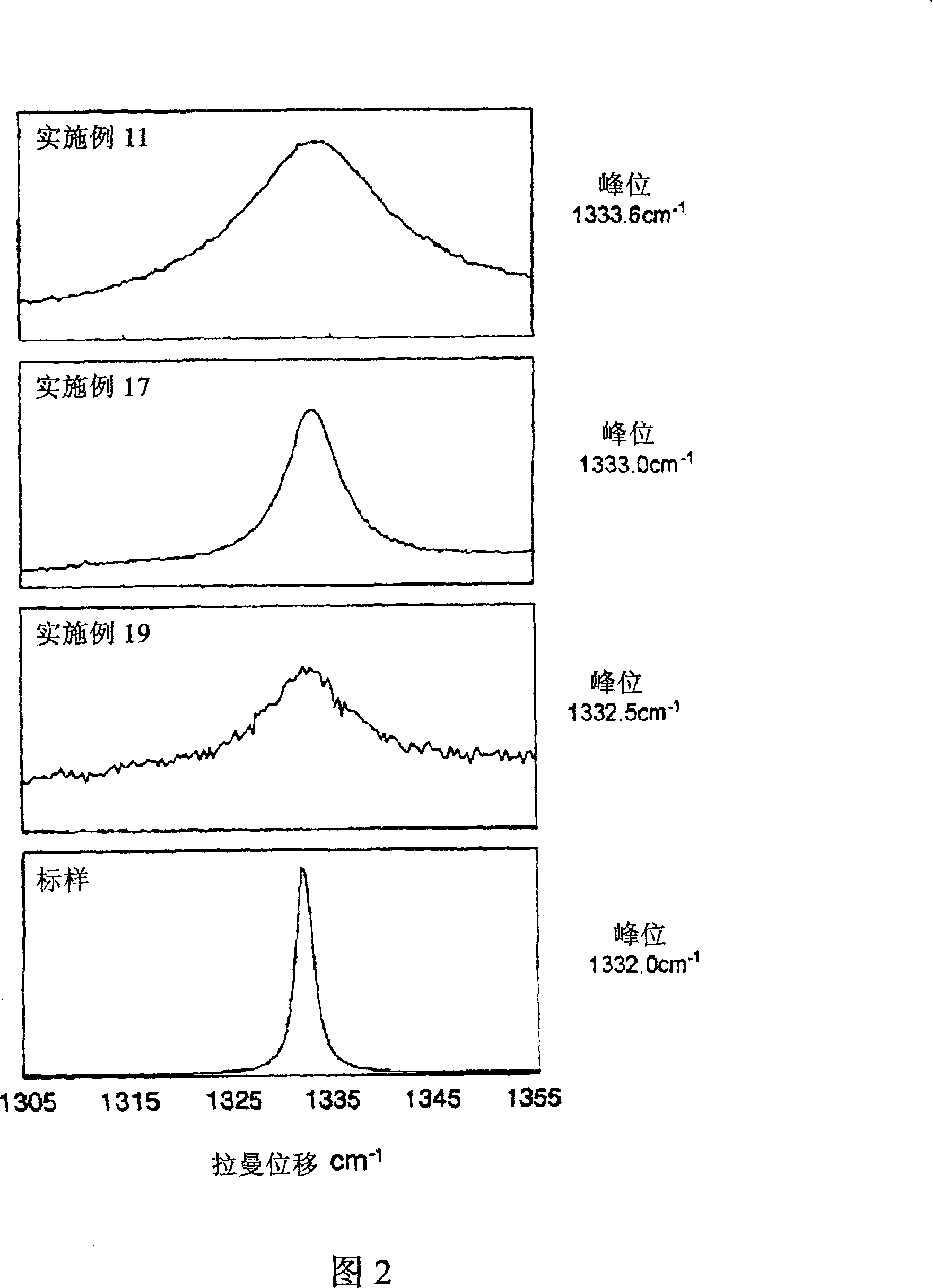

[0150] The generated phase of each sample was identified by X-ray diffraction technique, and the size of the constituent particles of each sample was detected according to the observation result of TEM. In addition, the surface of each sample is ground into a mirror surface, and then the hardness of the mirror surface is measured with a micro-Knoop hardness tester, and the Raman spectrum is measured on the ground surface to obtain the position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com