Vehicle sealing strip glue material and vehicle sealing strip

A technology for automotive sealing strips and rubber materials, applied in the field of automotive sealing strip rubber materials, can solve the problems of affecting the sealing performance, shock absorption performance and service life of the sealing strip, affecting the safety of automobile use, and the safety and instability of automobile use. Excellent sealing performance and compression deformation resistance, enhanced mechanical properties, improved performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

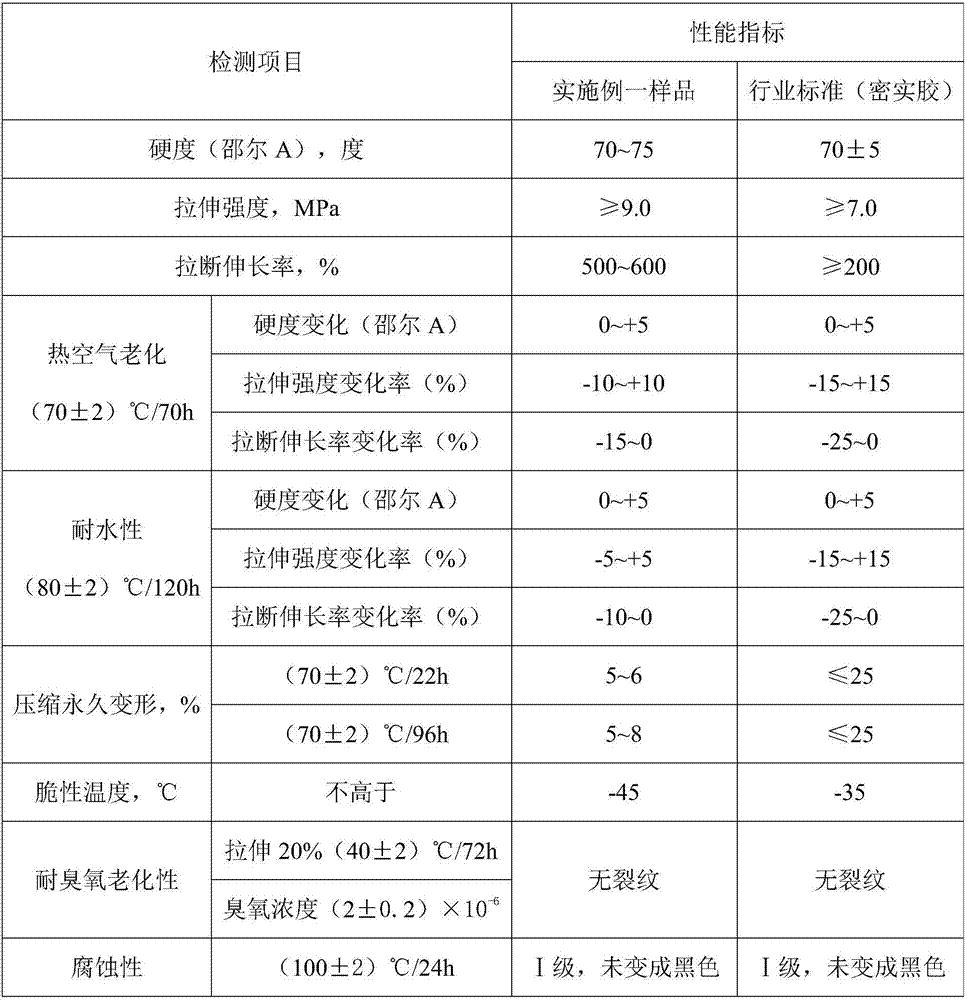

Examples

Embodiment 1

[0023] This embodiment relates to an automobile weather strip and its preparation.

Embodiment 11

[0025] A rubber compound for automobile sealing strips, comprising the following raw material components: 56 parts of EPDM rubber, 23 parts of neoprene rubber, 35 parts of thermoplastic polyurethane elastomer, 21 parts of white carbon black, γ-aminopropyl triethoxy 12 parts of silanized glass fiber surface-modified with base silane, 6 parts of calcium carbonate, 3 parts of accelerator Z, 3 parts of accelerator D, 4 parts of accelerator M, 1 part of lubricant EBS, and 1 part of dispersant FC-303 , 3 parts of cross-linking agent DCP, 1 part of anti-aging agent D, 1 part of anti-aging agent RD;

[0026] Its preparation is carried out according to the following steps:

[0027] a. Obtain silanized glass fibers surface-modified by γ-aminopropyltriethoxysilane:

[0028] Glass fiber (common glass fiber is used, its tensile strength is 6.3-6.9g / d in standard state, 5.4-5.8g / d in wet state, density 2.54g / cm 3 ) chopped strands were fired at 550-600°C for 30 minutes, and then immersed ...

Embodiment 12

[0034] A rubber compound for automobile sealing strips, comprising the following raw material components: 52 parts of EPDM rubber, 26 parts of neoprene rubber, 38 parts of thermoplastic polyurethane elastomer, 18 parts of white carbon black, γ-aminopropyl triethoxy 16 parts of silanized glass fiber surface-modified with base silane, 8 parts of calcium carbonate, 4 parts of accelerator Z, 2 parts of accelerator D, 3 parts of accelerator M, 3 parts of lubricant CNF, 1 part of crosslinking agent TAIC, 2 parts of cross-linking agent H631, 3 parts of anti-aging agent NBC;

[0035] Its preparation is carried out according to the following steps:

[0036] a. Obtain silanized glass fibers surface-modified by γ-aminopropyltriethoxysilane:

[0037] Glass fiber (common glass fiber is used, its tensile strength is 6.3-6.9g / d in standard state, 5.4-5.8g / d in wet state, density 2.54g / cm 3 ) chopped strands were fired at 550-600°C for 35 minutes, and then immersed in an aqueous solution wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com