Intelligent film capacitor full-automatic winding machine based on Internet of Things

A film capacitor, fully automatic technology, applied in the direction of winding capacitor machines, etc., can solve the problem of not having remote monitoring and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

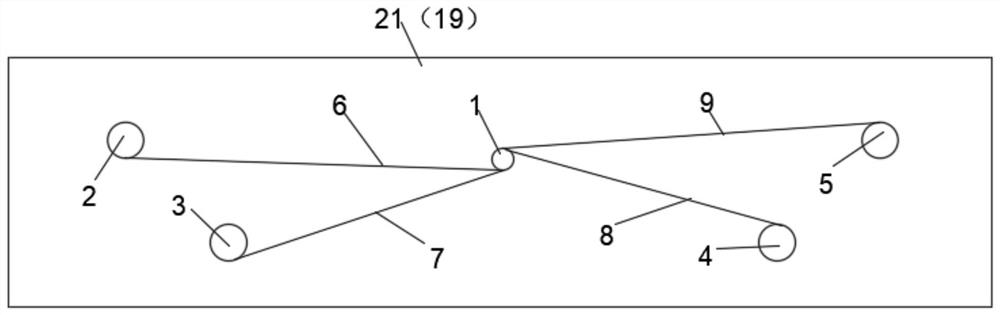

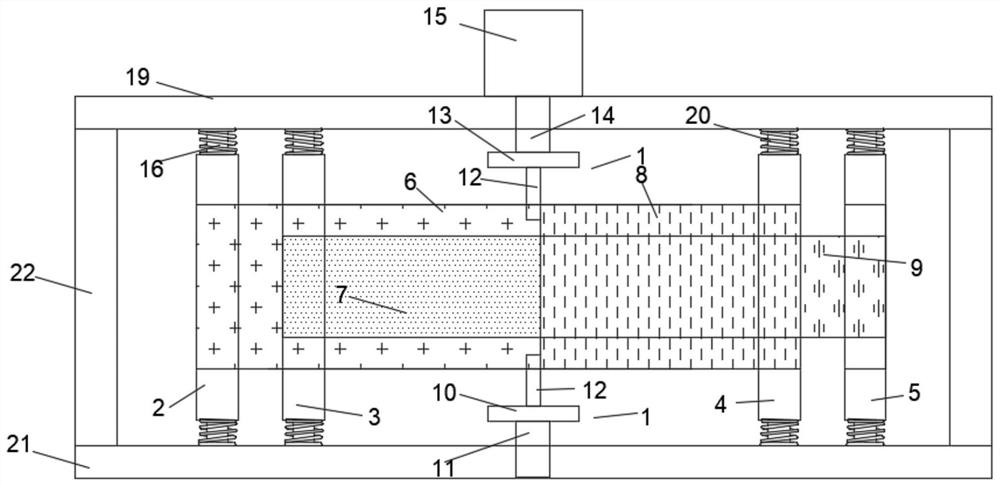

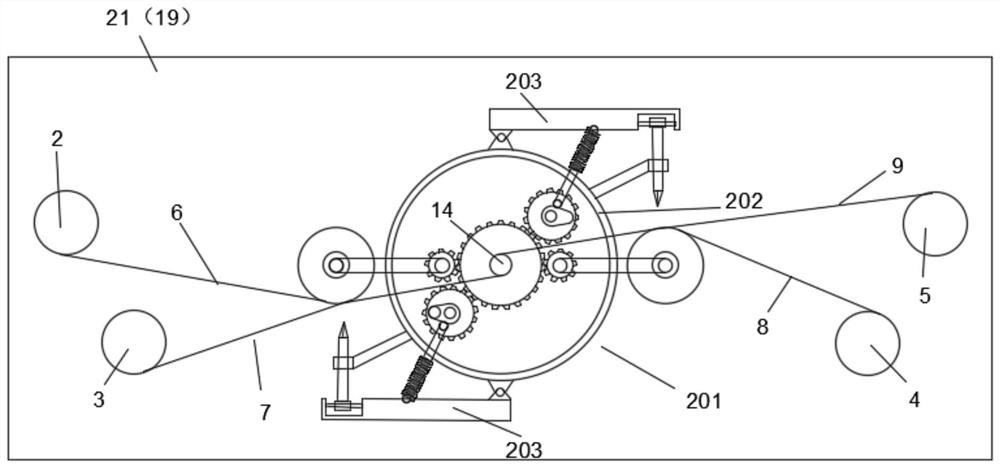

[0043] see Figure 1-2 , an embodiment provided by the present invention: an intelligent film capacitor automatic winding machine based on the Internet of Things, including a winding mechanism 1, a first film roll 2, a first aluminum foil roll 3, a bottom plate 21, a side plate 22, Top plate 19, monitoring equipment, the side plate 22 is fixed on the bottom plate 21, the top plate 19 is fixed with the bottom plate 21 through the side plate 22, the winding mechanism 1, the first film roll 2, the second An aluminum foil roll 3 is arranged between the bottom plate 21 and the top plate 19, the monitoring equipment is fixed on the top plate 19, and the monitoring equipment is used to obtain the operation information of the automatic winding machine. The device is connected to the remote monitoring terminal through the Internet of Things.

[0044] Preferably, a first film 6 is connected between the winding mechanism 1 and the first film roll 2 , and a first aluminum foil 7 is conne...

Embodiment 2

[0052] On the basis of embodiment 1,

[0053] Preferably, the monitoring device includes a data acquisition module, a data processing module, a gateway and a cloud service center;

[0054] The data acquisition module is arranged on the top plate 19, and is used to collect the current operation information of the winding machine, including the remaining amount of raw materials of film and aluminum foil, the current winding quantity and the remaining winding quantity of the film capacitor, and the working hours of the equipment , operating power and other information;

[0055] The data processing module is arranged on the top plate 19, and is used to process and analyze the current operation information of the winding machine collected by the data acquisition module (may include comparing the data with the corresponding normal range after processing, When it exceeds the corresponding normal range, it is judged that the operation information is abnormal), and the comprehensive i...

Embodiment 3

[0061] refer to Figure 1-2 , on the basis of any one of the above-mentioned embodiments 1-2, it also includes a second film roll 4 and a second aluminum foil roll 5, and the second film roll 4 and the second aluminum foil roll 5 are all arranged on the bottom plate 21 , top plate 19, the first film roll 2 and the first aluminum foil roll 3 are located on the left side of the winding mechanism 1, and the second film roll 4 and the second aluminum foil roll 5 are located on the left side of the winding mechanism 1 On the right side, and the first film roll 2, the first aluminum foil roll 3, the second film roll 4, and the second aluminum foil roll 5 are arranged counterclockwise around the winding mechanism 1; the winding mechanism 1 and the A second film 8 is connected between the second film rolls 4 , and a second aluminum foil 9 is connected between the winding mechanism 1 and the second aluminum foil roll 5 .

[0062] Preferably, a second rotating shaft 16 is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com