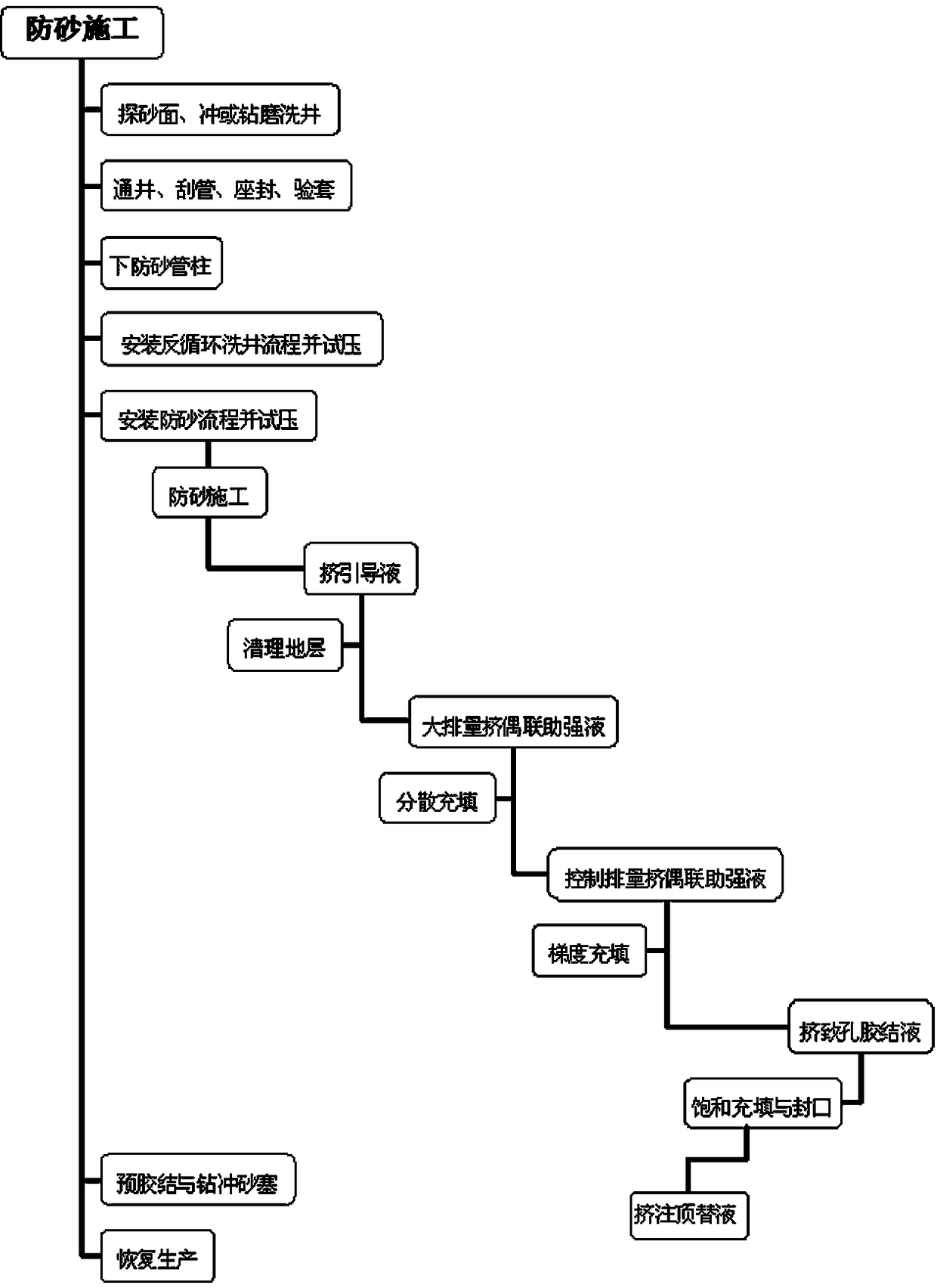

Method for manufacturing artificial borehole wall by saturated filling of bondable gravel around wellbore

A technology of cementing sand and gravel and artificial well wall, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc., and can solve problems such as blockage and difficulty in extubation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

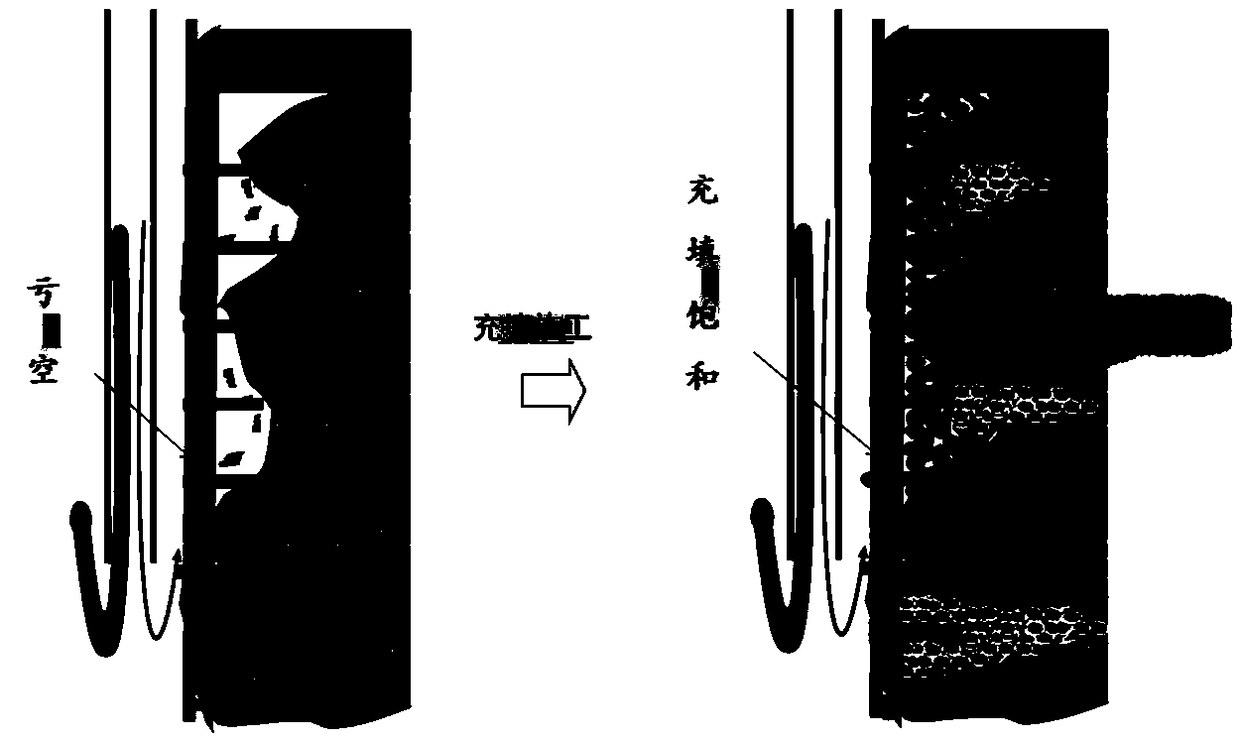

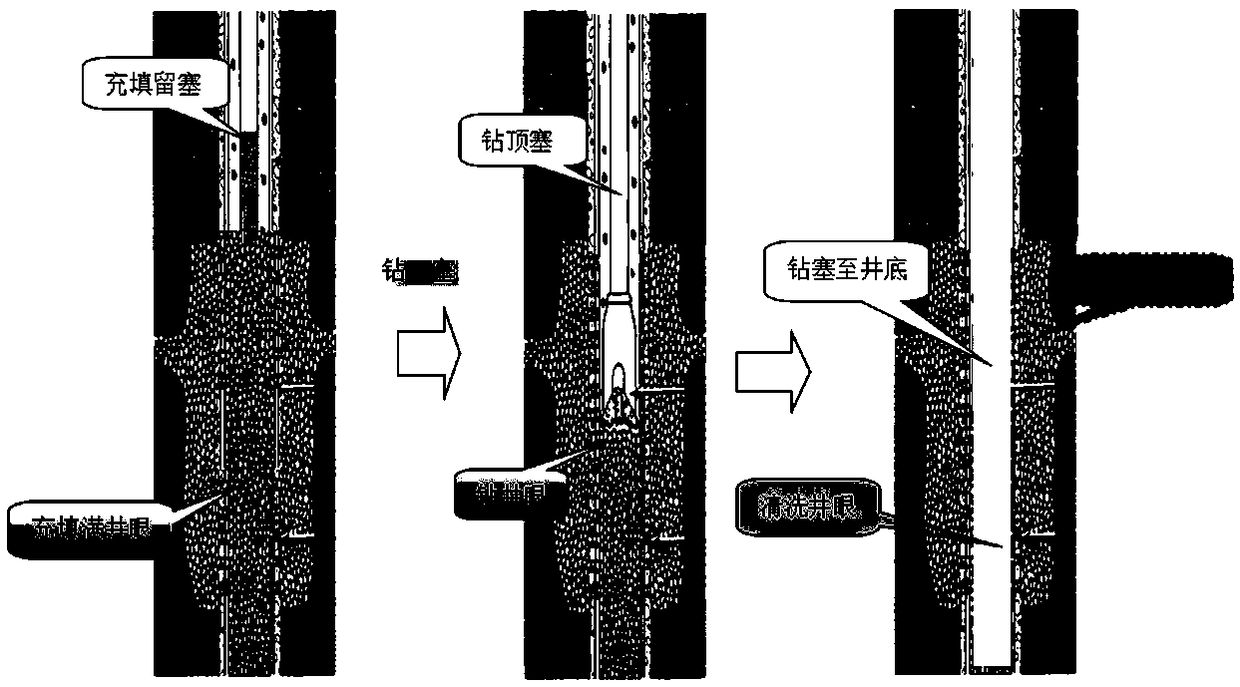

Method used

Image

Examples

Embodiment 1

[0095] Construction well example 1: Well BZ34-1-A18H (CNOOC Bozhong Oilfield - sandstone screen horizontal well)

[0096] see Figure 4 , when the well started construction, the displacement was gradually increased to 2.6m 3 / min, the pump pressure rises to 13.3MPa, and the pollutants are cleaned with a large amount of cementable sand guide fluid, that is, the front fluid. The cementable sand guide fluid is composed of: chelating agent 2.0%, surfactant 3.0%, hydrochloric acid 5.0% , Anti-swelling agent 5.0%. Wherein the chelating agent is selected as ethylenediaminetetraacetic acid or diethylenetriaminepentamethylenephosphonic acid;

[0097] Surfactant includes: 1.5% alkyl polyoxyethylene ether with cloud point ≦30℃, 1.5% alkyl polyoxyethylene ether with cloud point ≥100℃; anti-swelling agent is NH4CL.

[0098] Then use the coupling strengthening fluid, that is, the sand-carrying fluid, to carry the cementable gravel into the void zone of the formation, and control the sand...

Embodiment 2

[0103] Construction well example 2: Well YM2-22 (PetroChina Tarim Yingmaili Oilfield - limestone open hole vertical well)

[0104] see Figure 5 , when the well started construction, the displacement was gradually increased to 2.7m 3 / min, the pump pressure is increased to 25MPa, and the pollutants are cleaned with a large displacement of the cementable sand guide fluid, that is, the front fluid, including 1.5% chelating agent, 3.0% surfactant, 7.0% hydrochloric acid, and 2.50% anti-swelling agent. Among them, the chelating agent is selected as ethylenediaminetetraacetic acid or diethylenetriaminepentamethylenephosphonic acid; the surfactant includes: 1.5% alkyl polyoxyethylene ether with a cloud point ≦30°C, and 1.5% with a cloud point ≥100°C The alkyl polyoxyethylene ether; the anti-swelling agent is NH4CL.

[0105] Then use the coupling strengthening fluid, that is, the sand-carrying fluid, to carry the cementable gravel into the void zone of the formation, and control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloud point | aaaaa | aaaaa |

| Cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com