Ferrite slurry used for wet process stacked inductor printing and manufacturing method thereof

A technology of a laminated inductor and a manufacturing method, which is applied in the manufacturing of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of non-exposed or unevenly exposed conductive dot paste, poor conduction of conductive circuit layers, etc., to reduce precious metals. Consumption, solving the effect of low yield and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

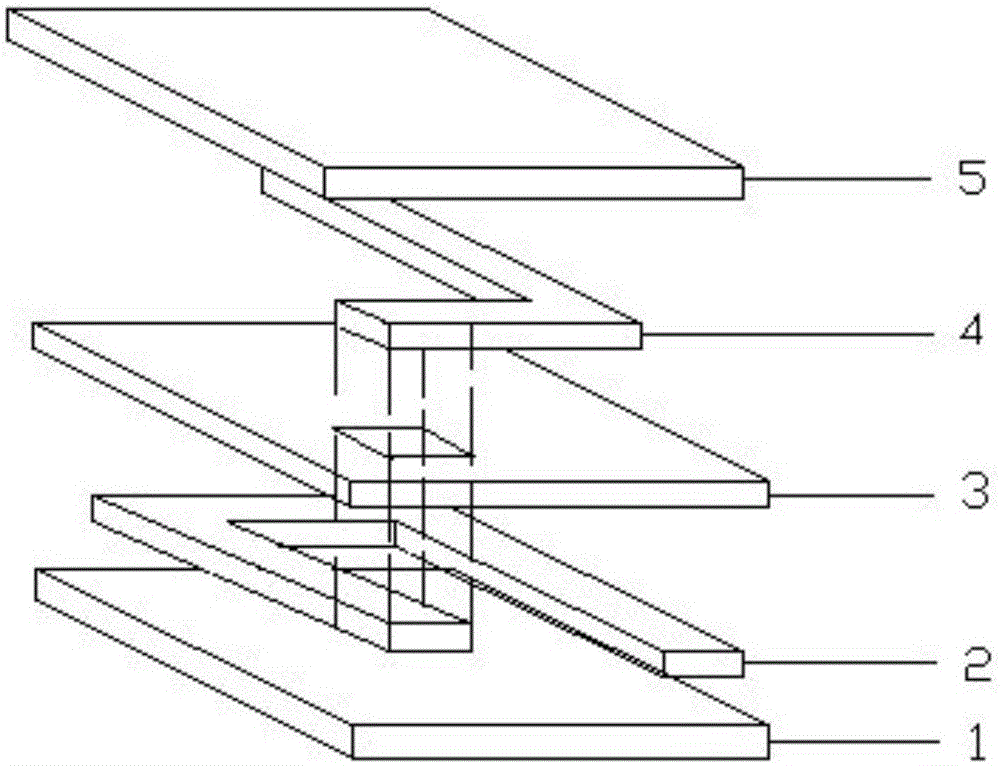

Image

Examples

Embodiment approach 1

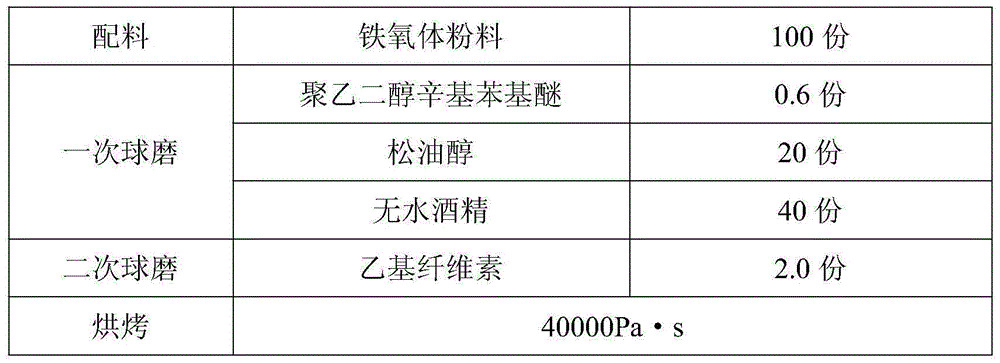

[0049] Embodiment 1, the viscosity of the substances added in each step and baking is as follows:

[0050]

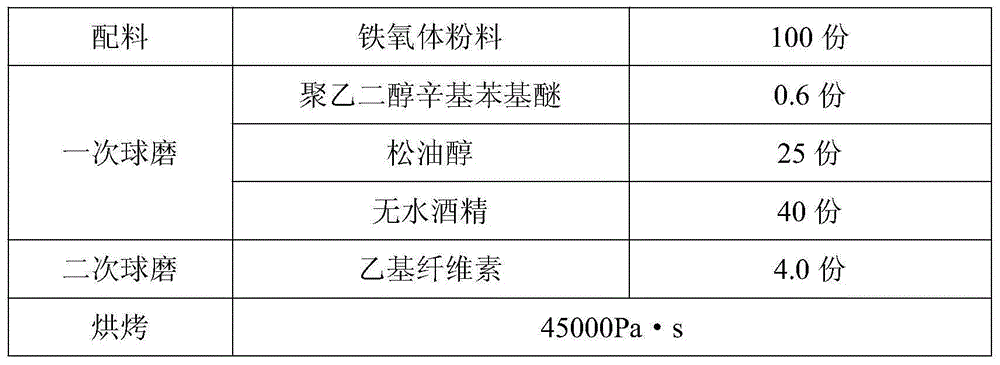

[0051] Embodiment two, the viscosity of the substance added in each step and its baking is as follows:

[0052]

[0053] Embodiment 3, the viscosity of the substance added in each step and its baking is as follows:

[0054]

[0055]

[0056] Embodiment 4, the viscosity of the substance added in each step and its baking is as follows:

[0057]

[0058] The technical scheme provided by the invention has the following beneficial effects:

[0059] 1. Because the existing ferrite slurry cannot be cast out of the through hole during molding and casting, it is impossible to conduct the upper and lower layers of conductive lines by covering the inner wall of the through hole with the conductive line slurry. When the ferrite paste 3 is printed, the through hole can be directly printed during printing, and then the second conductive line paste 4 is printed to cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com