Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

462results about "Cathode sputtering application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

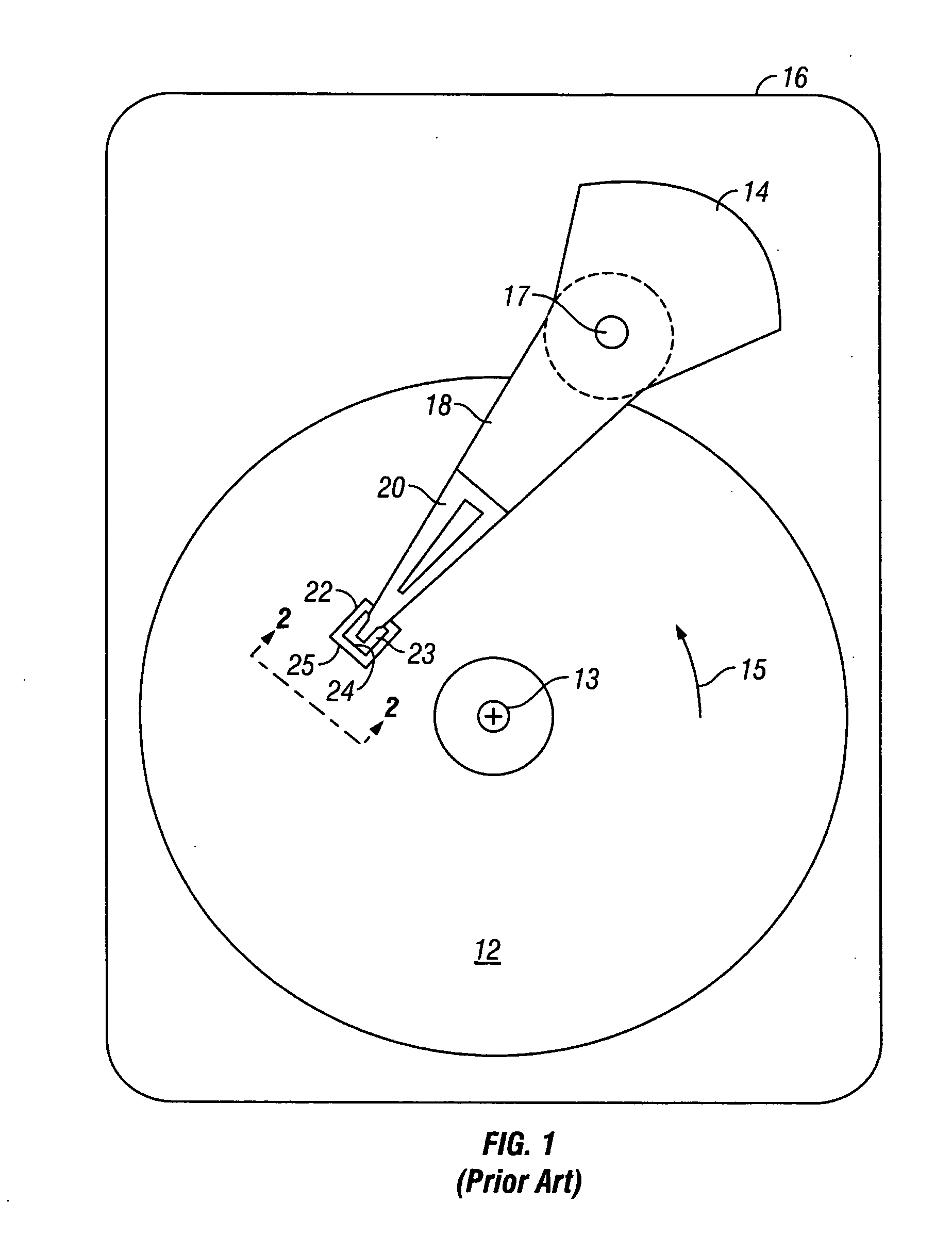

Method of forming a barrier layer of a tunneling magnetoresistive sensor

InactiveUS6841395B2Prevent electrostatic dischargeMagnetic and TMR propertyNanostructure applicationNanomagnetismIon beamXenon

Owner:GLOBALFOUNDRIES INC

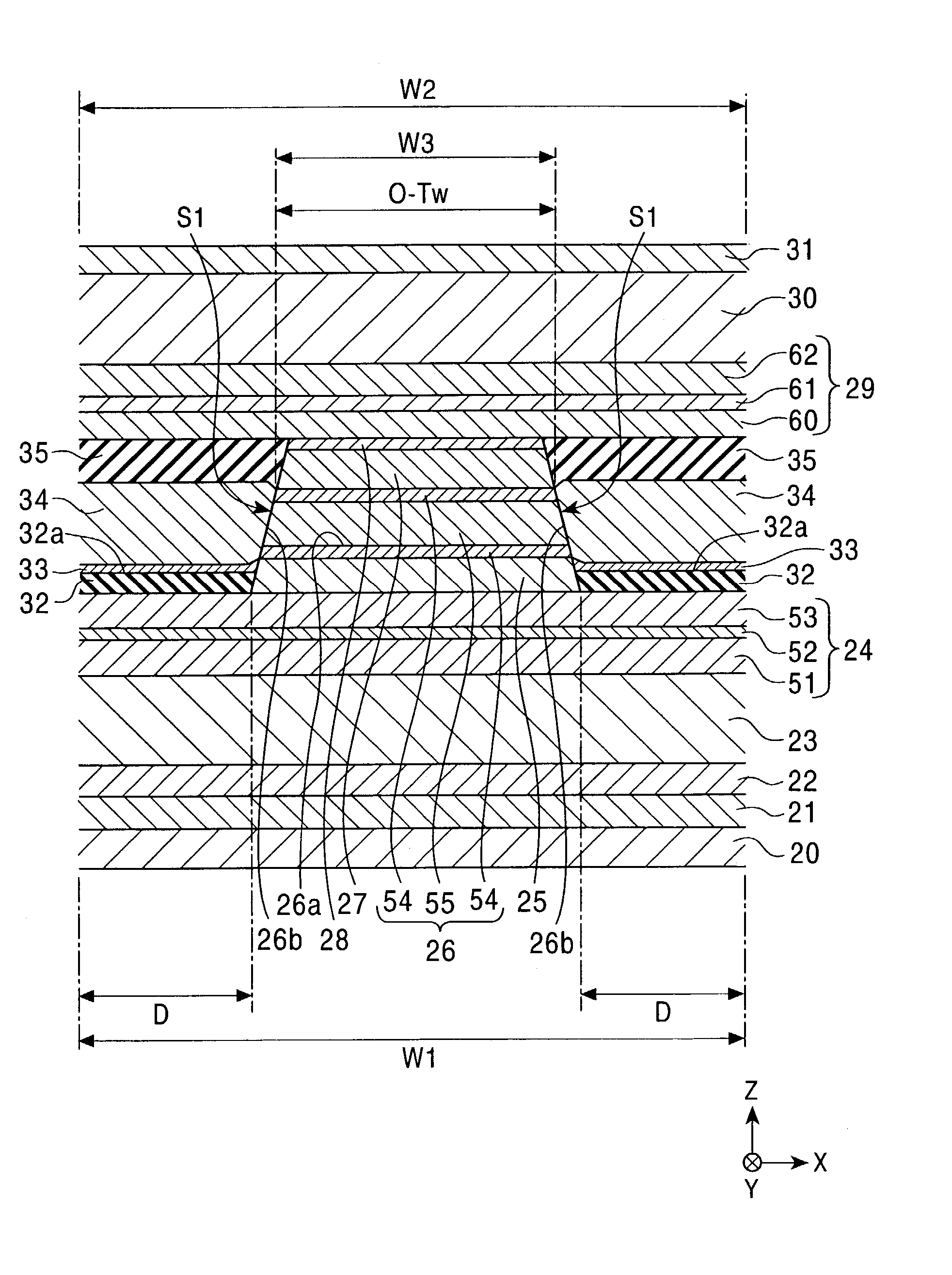

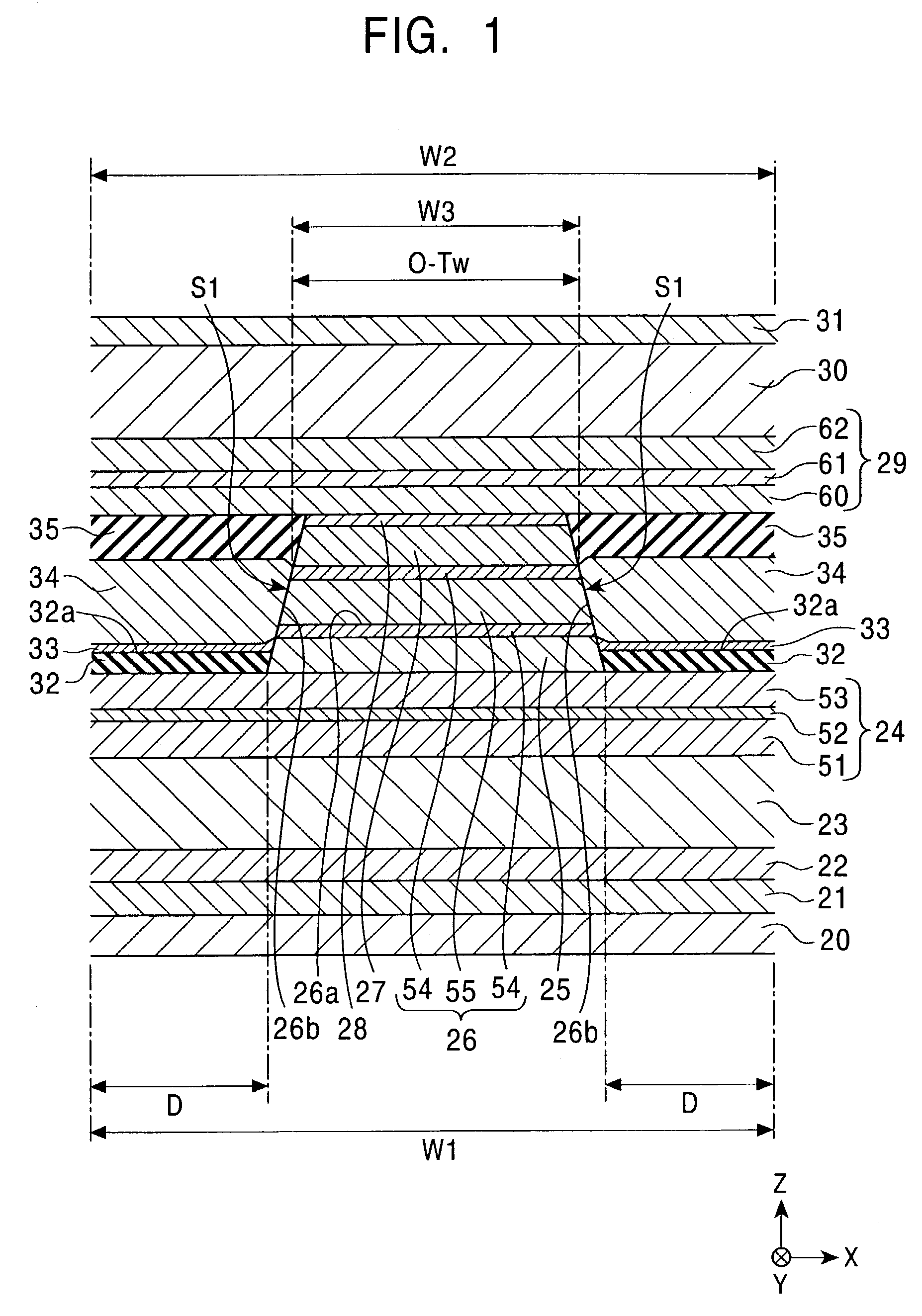

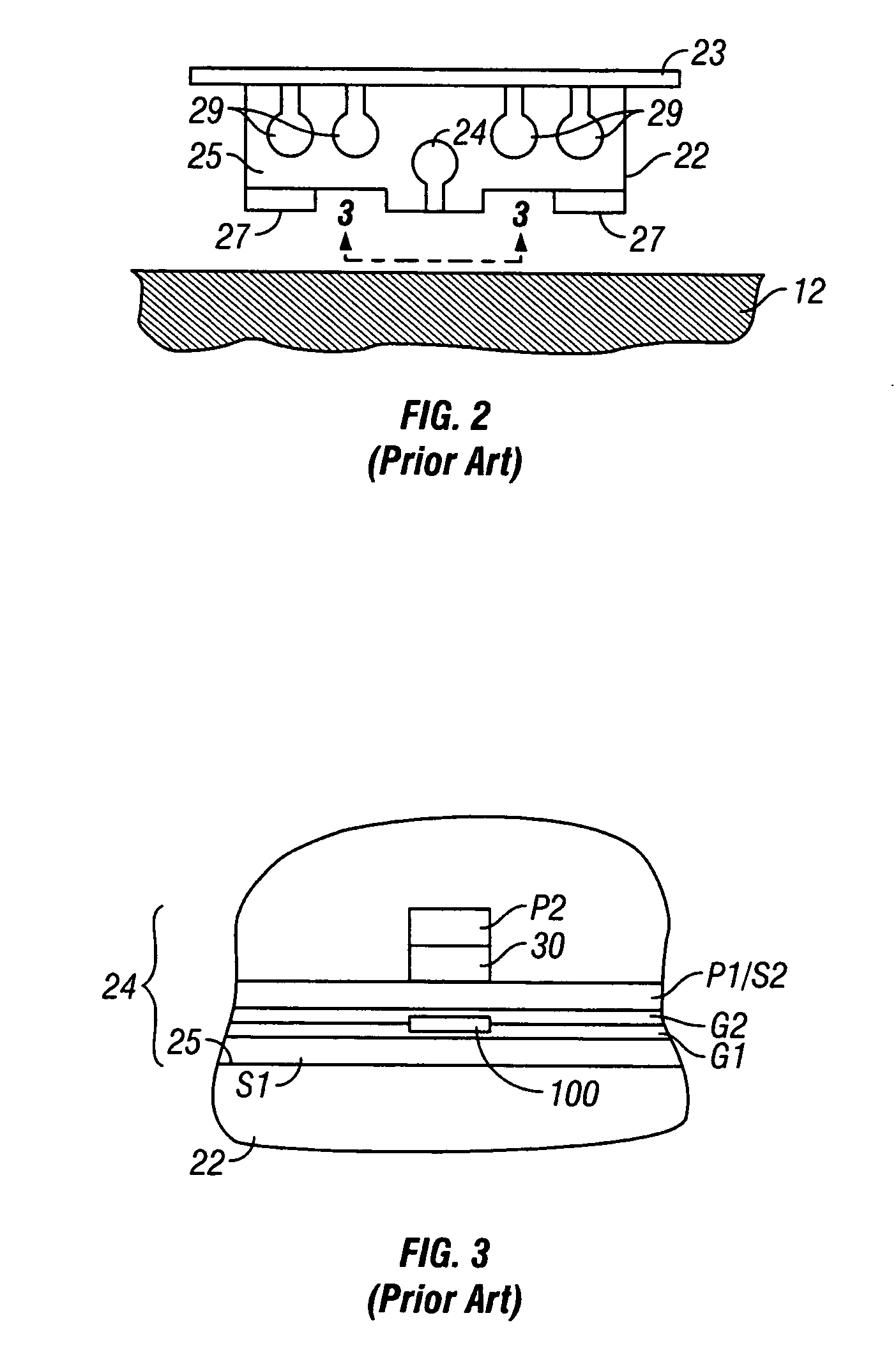

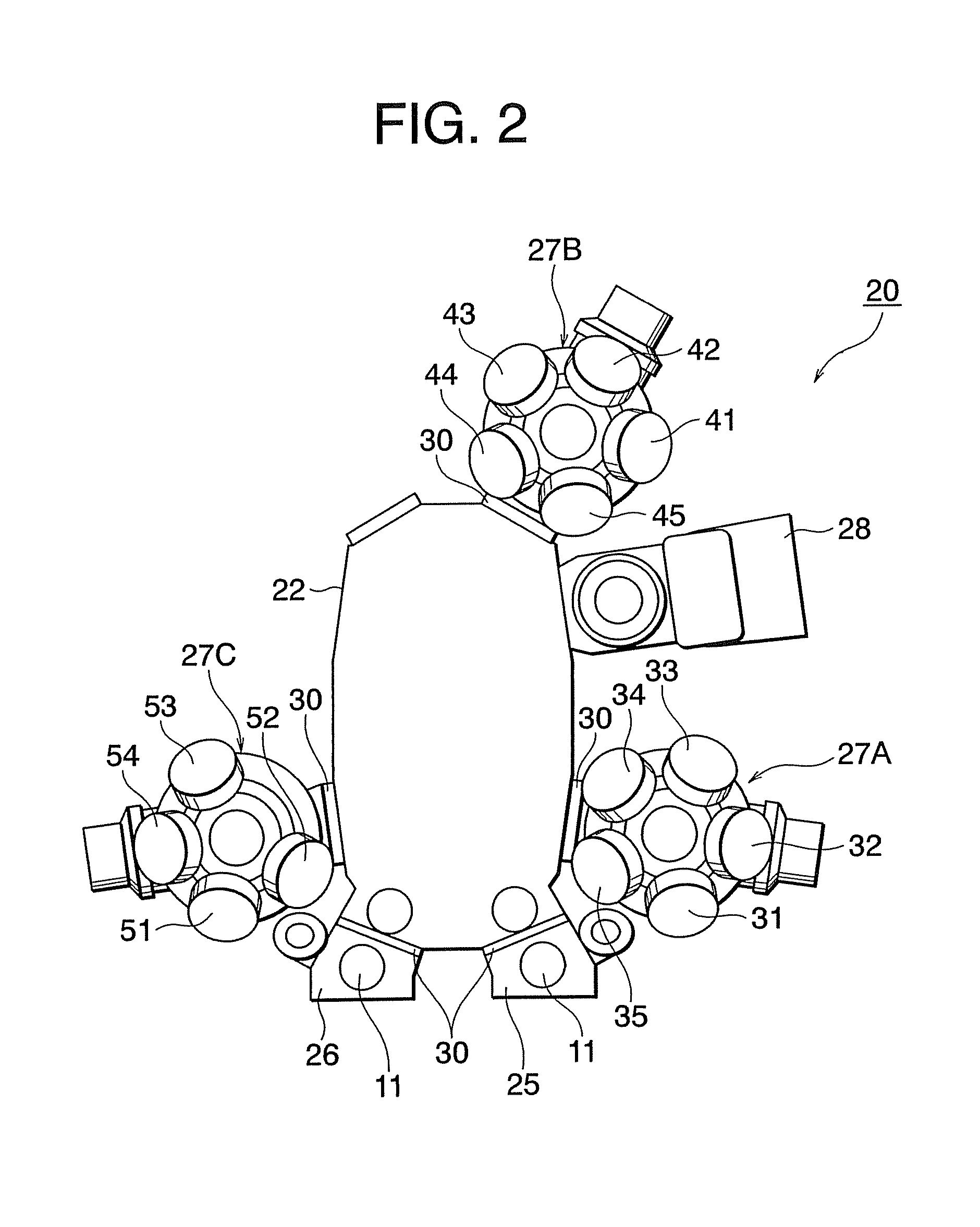

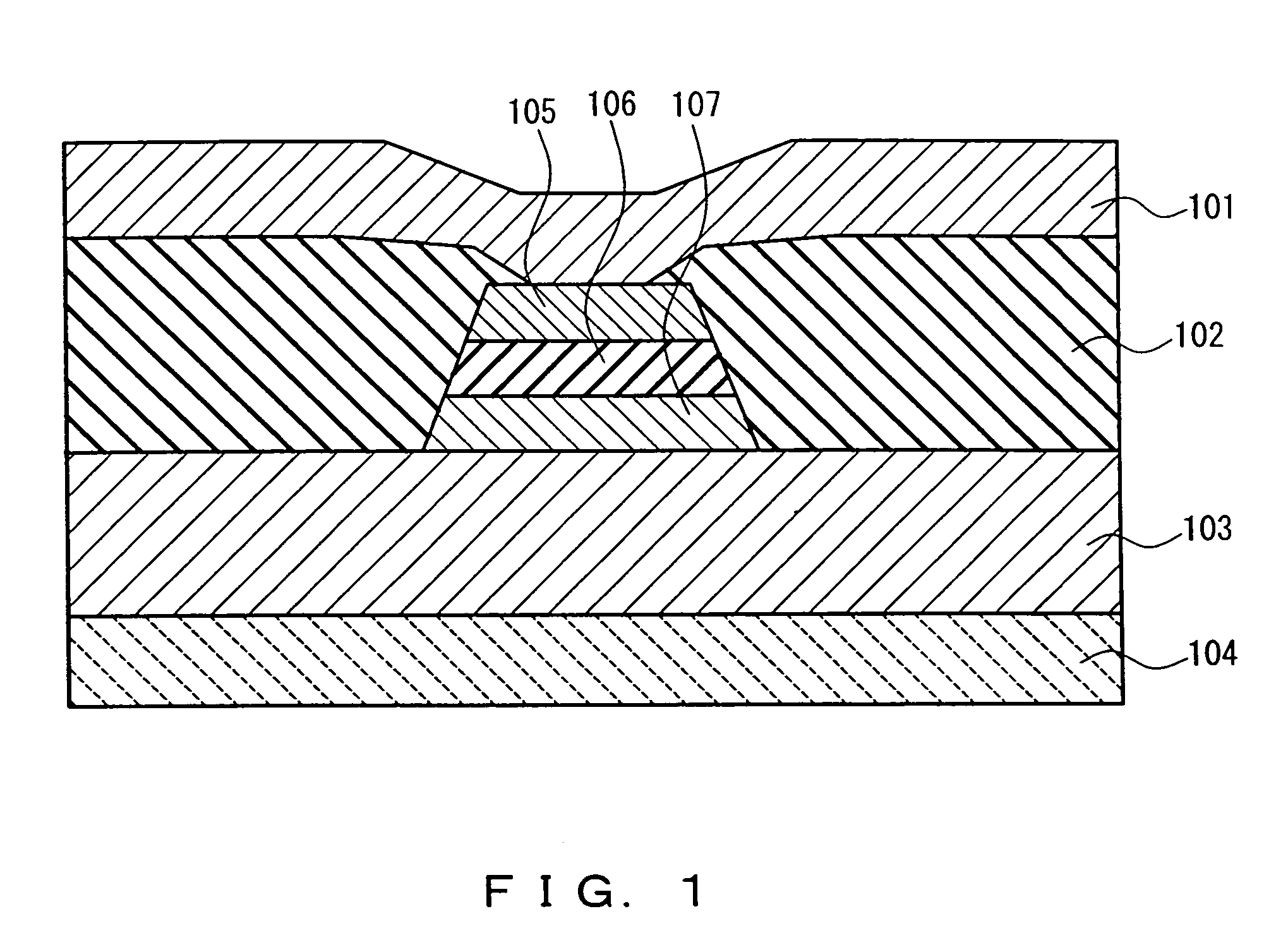

GMR magnetic sensing element having an antiferromagnetic layer extending beyond the track width and method for making the same

InactiveUS7050276B2Easy to disassembleHigh outputNanomagnetismMagnetic measurementsMagnetic layerAntiferromagnetism

A magnetic sensing element with improved magnetic detection output and a method for making the same are provided. In the magnetic sensing element, the length of an upper pinned magnetic layer an upper antiferromagnetic layer in a track width direction is larger than the length of a free magnetic layer in the track width direction. In making the magnetic sensing element, there is no need to remove side portions of the upper pinned magnetic layer and the upper antiferromagnetic layer. The materials of the upper pinned magnetic layer and the upper antiferromagnetic layer are thus prevented from redepositing on two side faces of the free magnetic layer during milling.

Owner:TDK CORPARATION

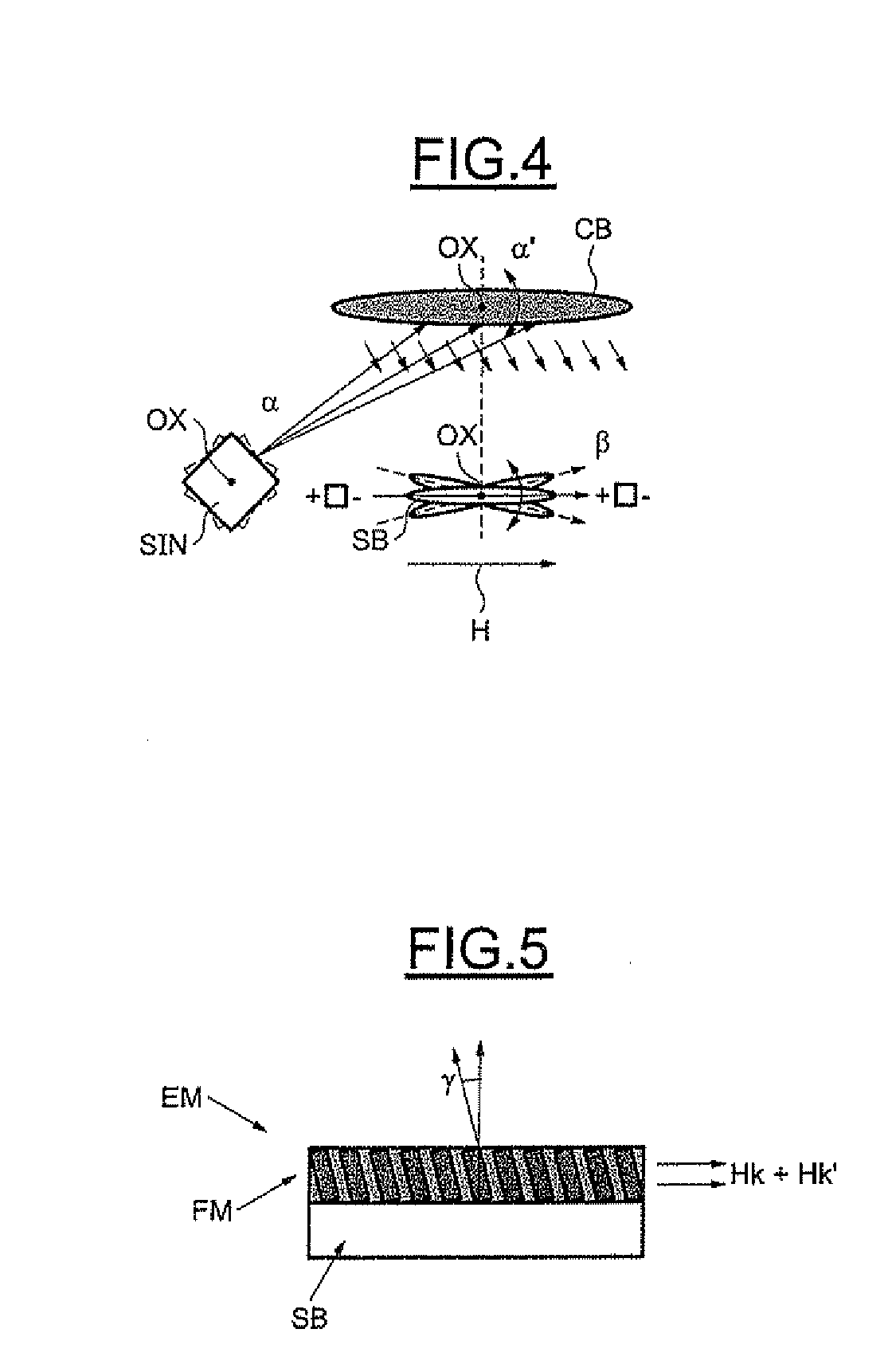

Radio Frequency Device with Magnetic Element, Method for Making Such a Magnetic Element

InactiveUS20080297292A1Easy to controlAdjustable angleNanomagnetismVacuum evaporation coatingRadio frequencyPhysics

Owner:STMICROELECTRONICS SRL +1

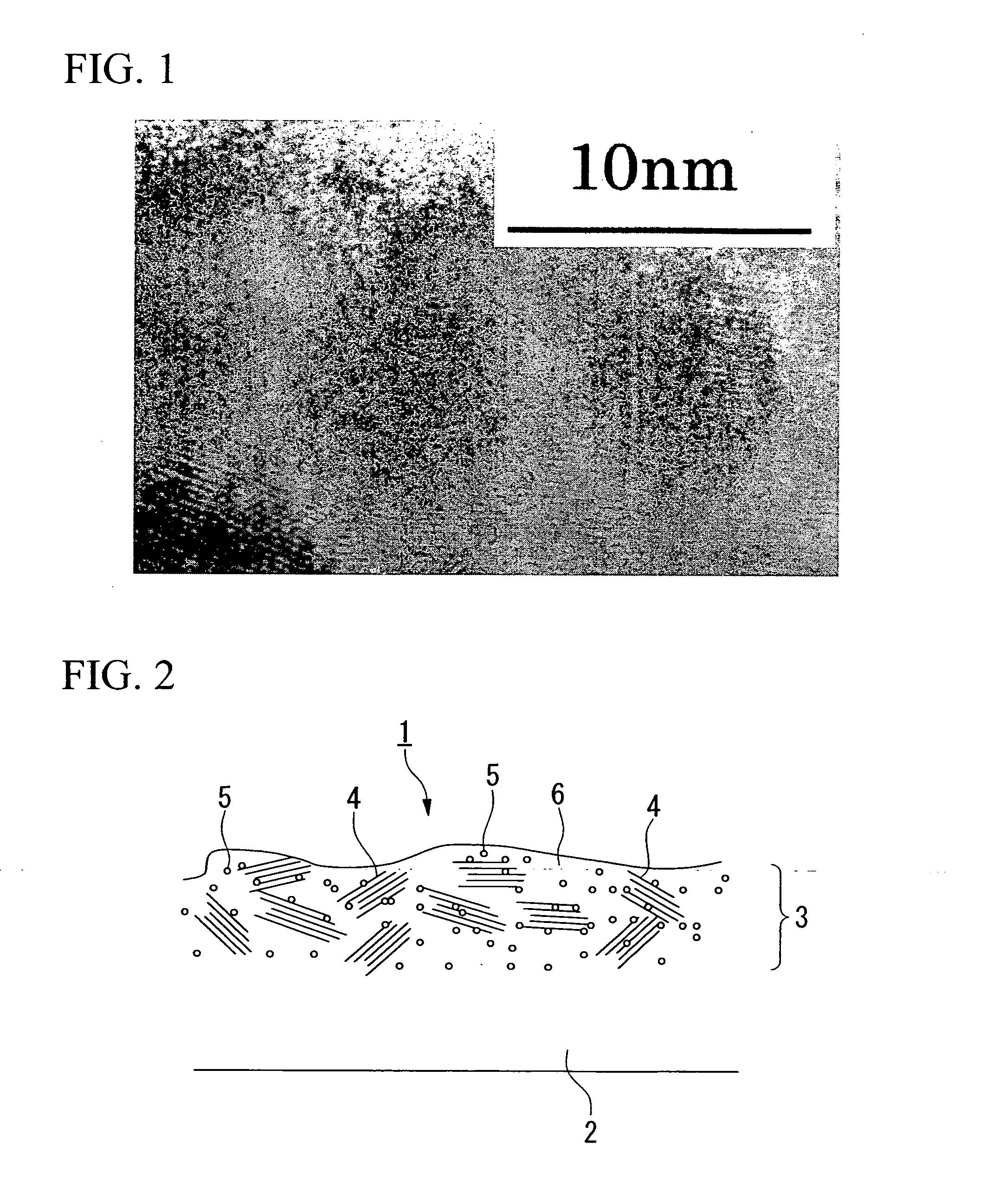

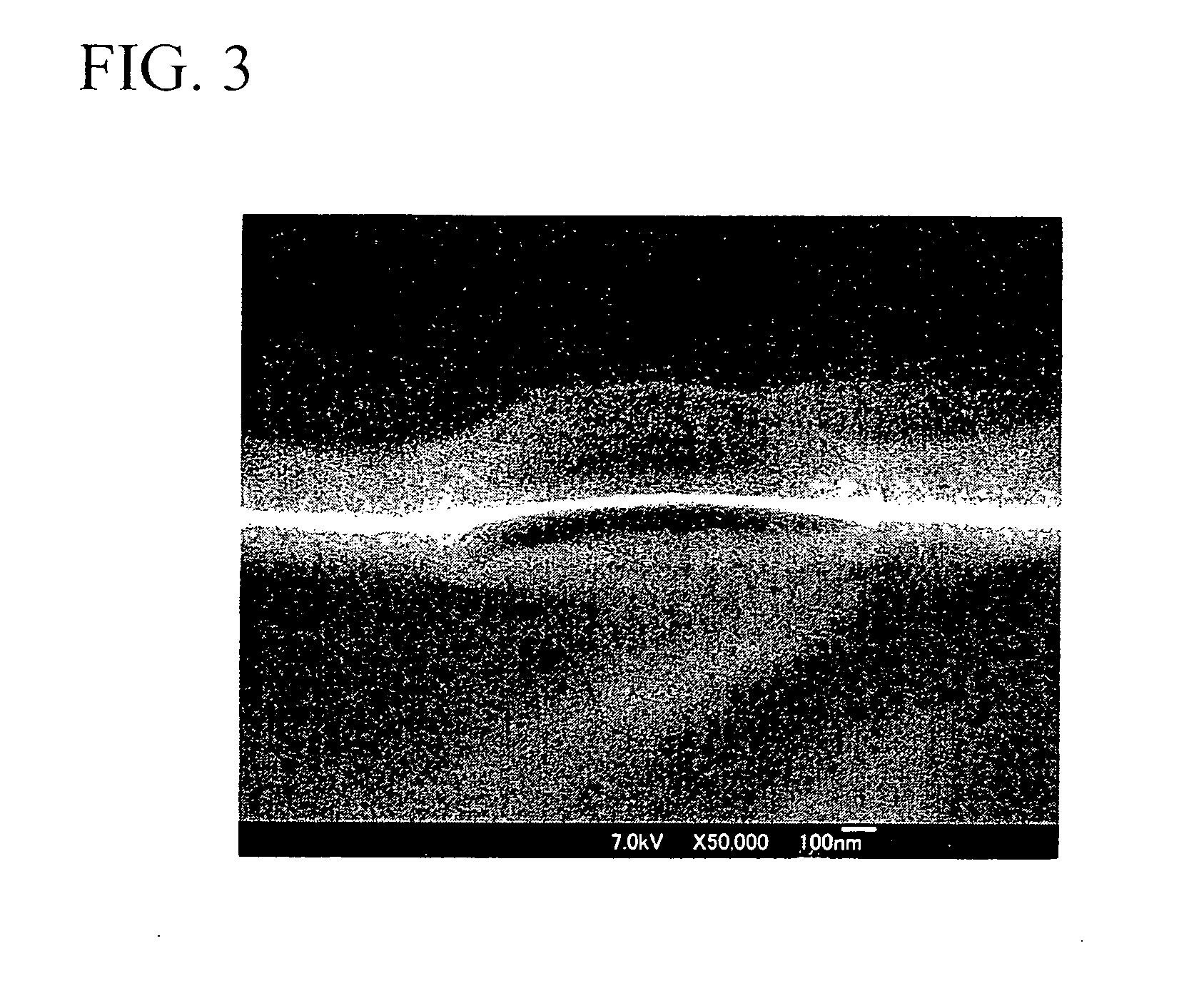

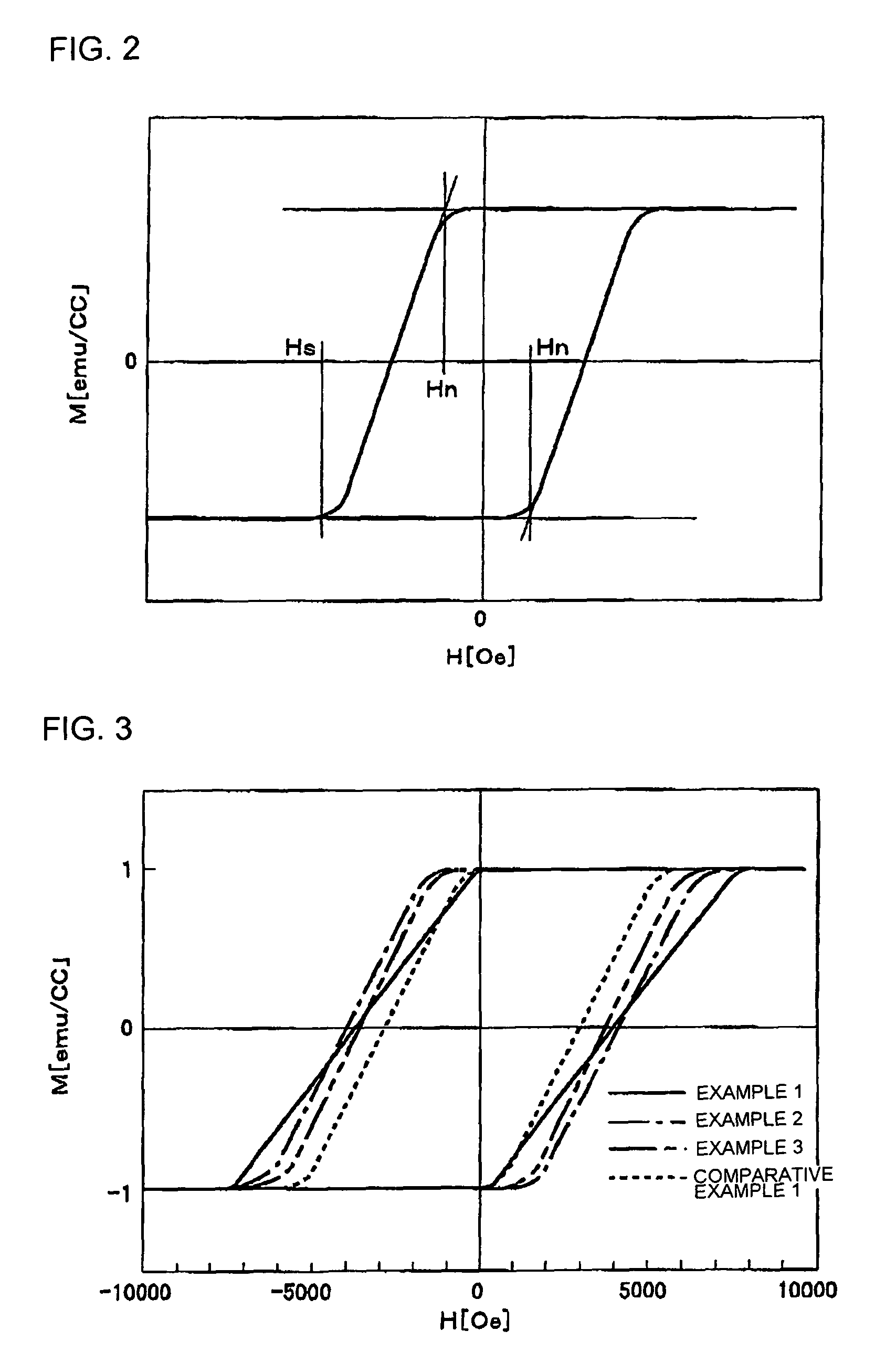

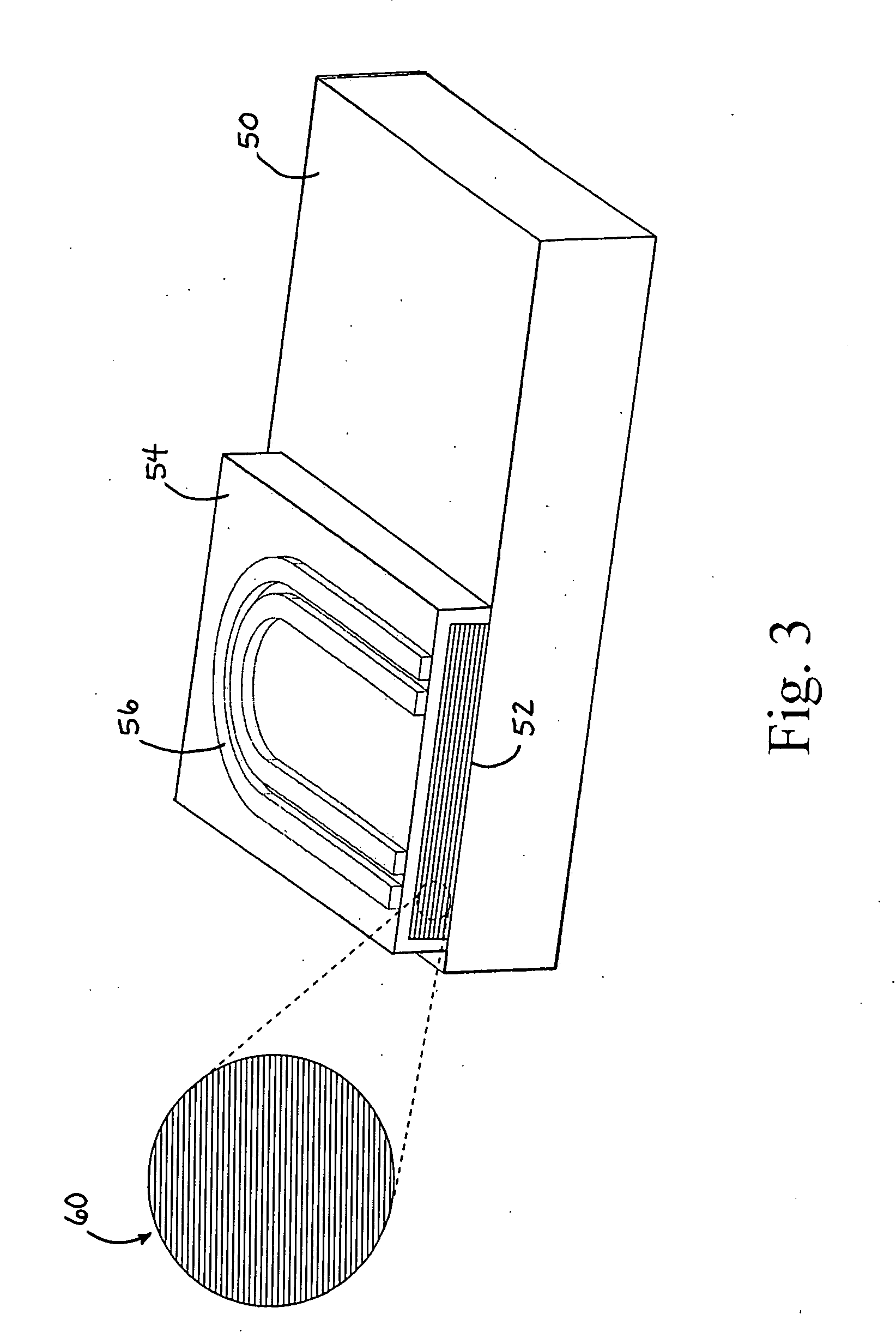

Electromagnetic noise suppressor, article with electromagnetic noise suppressing function, and their manufacturing methods

InactiveUS20060083948A1Eliminate the effects ofMeet cutting requirementsMagnetic/electric field screeningCross-talk/noise/interference reductionGas phaseSuppressor

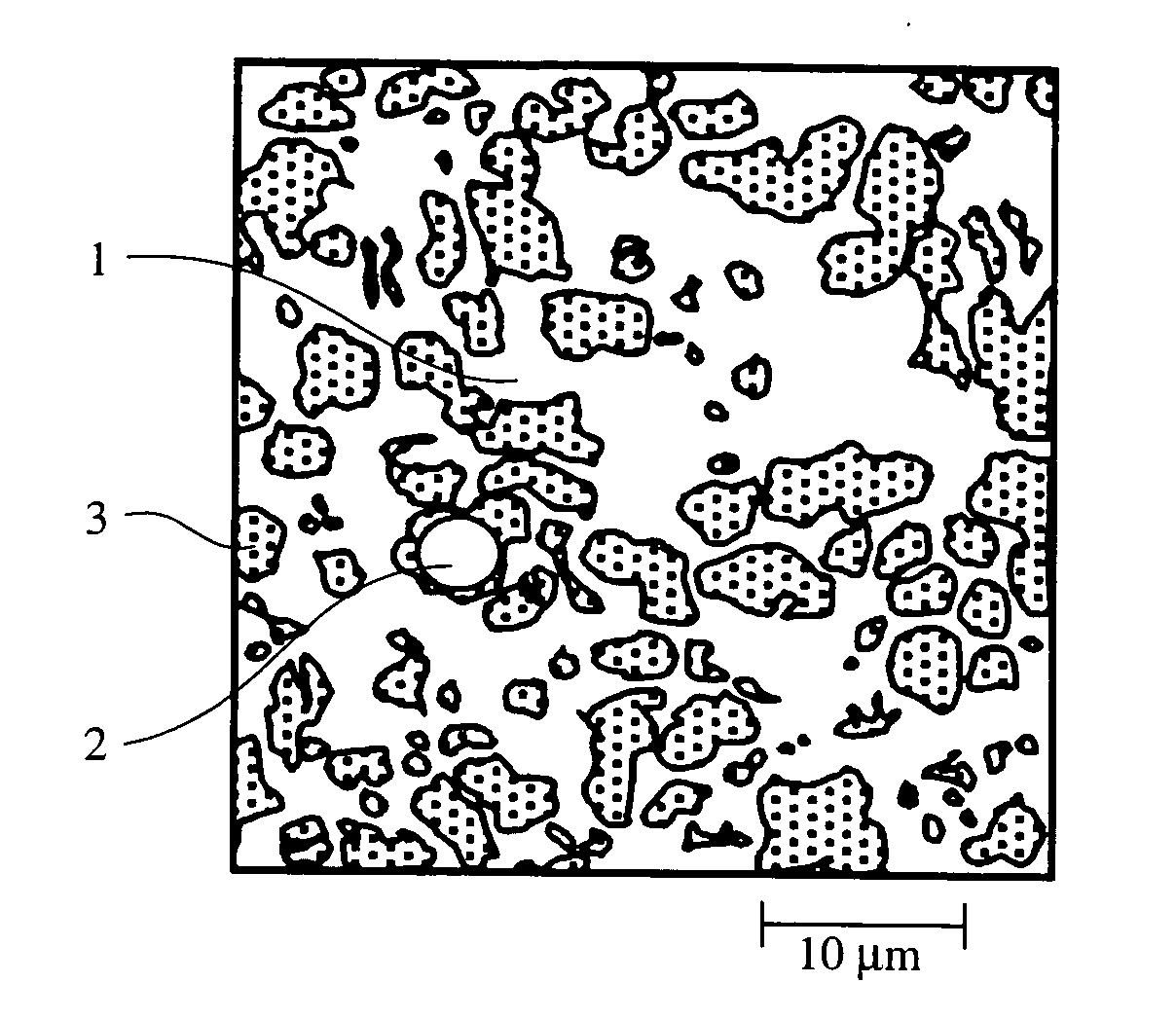

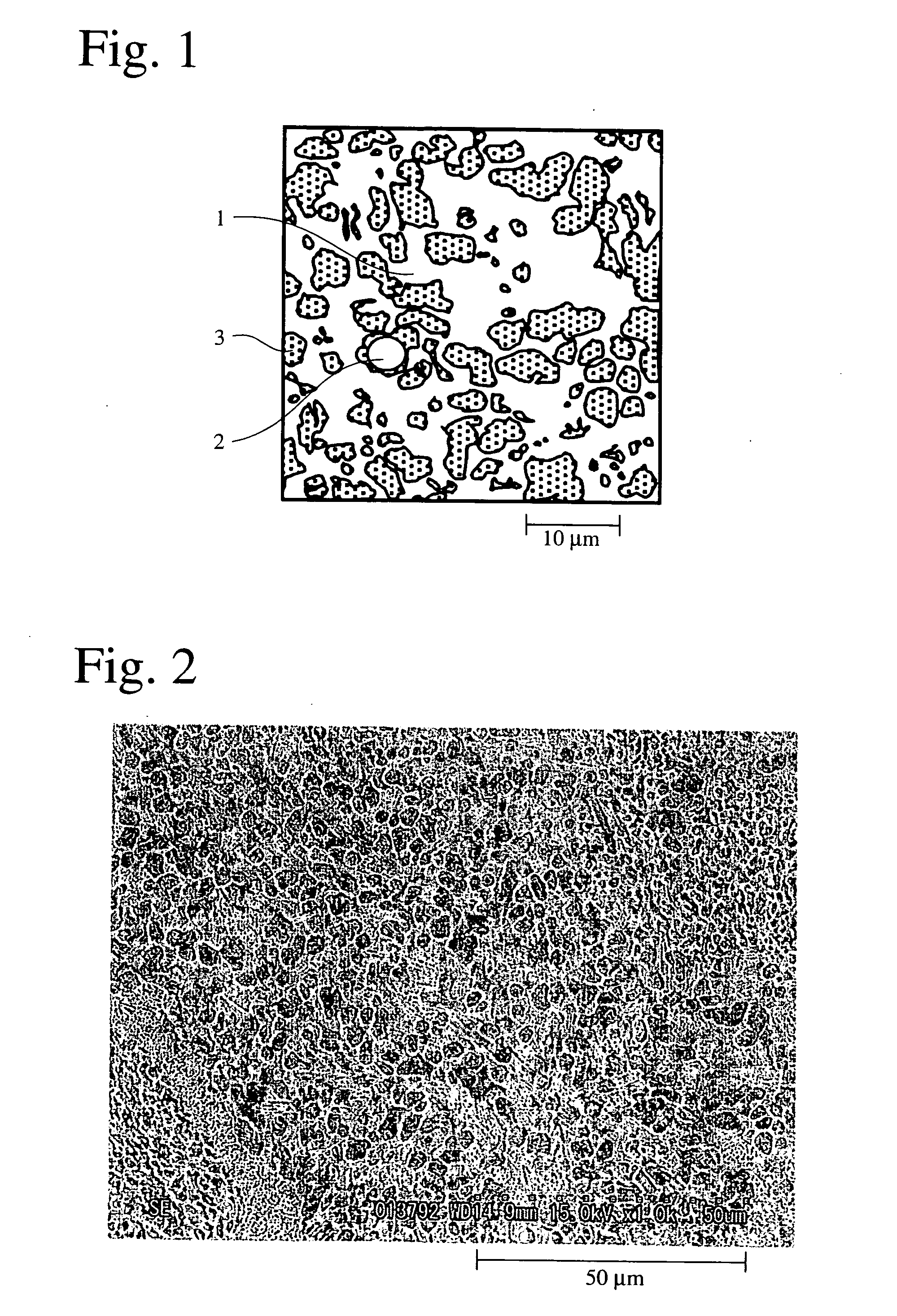

An electromagnetic noise suppressor of the present invention includes a base material 2 containing a binding agent and a composite layer 3 formed by integrating the binding agent that is a part of the base material 2 and the magnetic material. This electromagnetic noise suppressor has high electromagnetic noise suppressing effect in the sub-microwave band, and enables it to reduce the space requirement and weight. The electromagnetic noise suppressor can be manufactured by forming the composite layer 3 on the surface of the base material 2 by physical vapor deposition of the magnetic material onto the surface of the base material 2. The article with an electromagnetic noise suppressing function of the present invention is an electronic component, a printed wiring board, a semiconductor integrated circuit or other article of which at least a part of the surface is covered by the electromagnetic noise suppressor of the present invention.

Owner:SHIN-ETSU POLYMER CO LTD

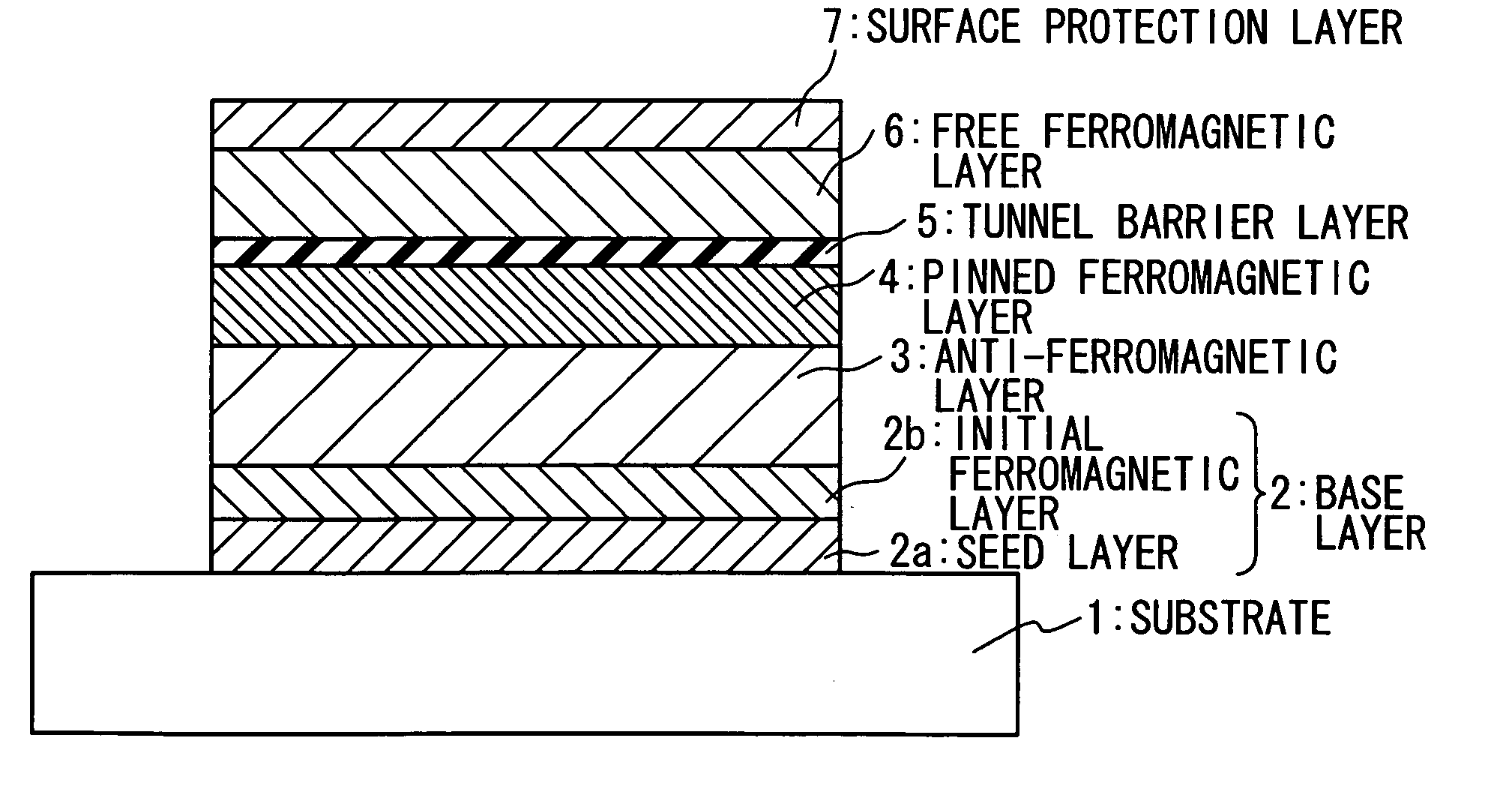

Magnetic tunnel magneto-resistance device and magnetic memory using the same

ActiveUS7379280B2Thermal stability (thermal treatment resistance)Improve thermal stabilityNanomagnetismMagnetic measurementsMagnetic memoryMagnetic reluctance

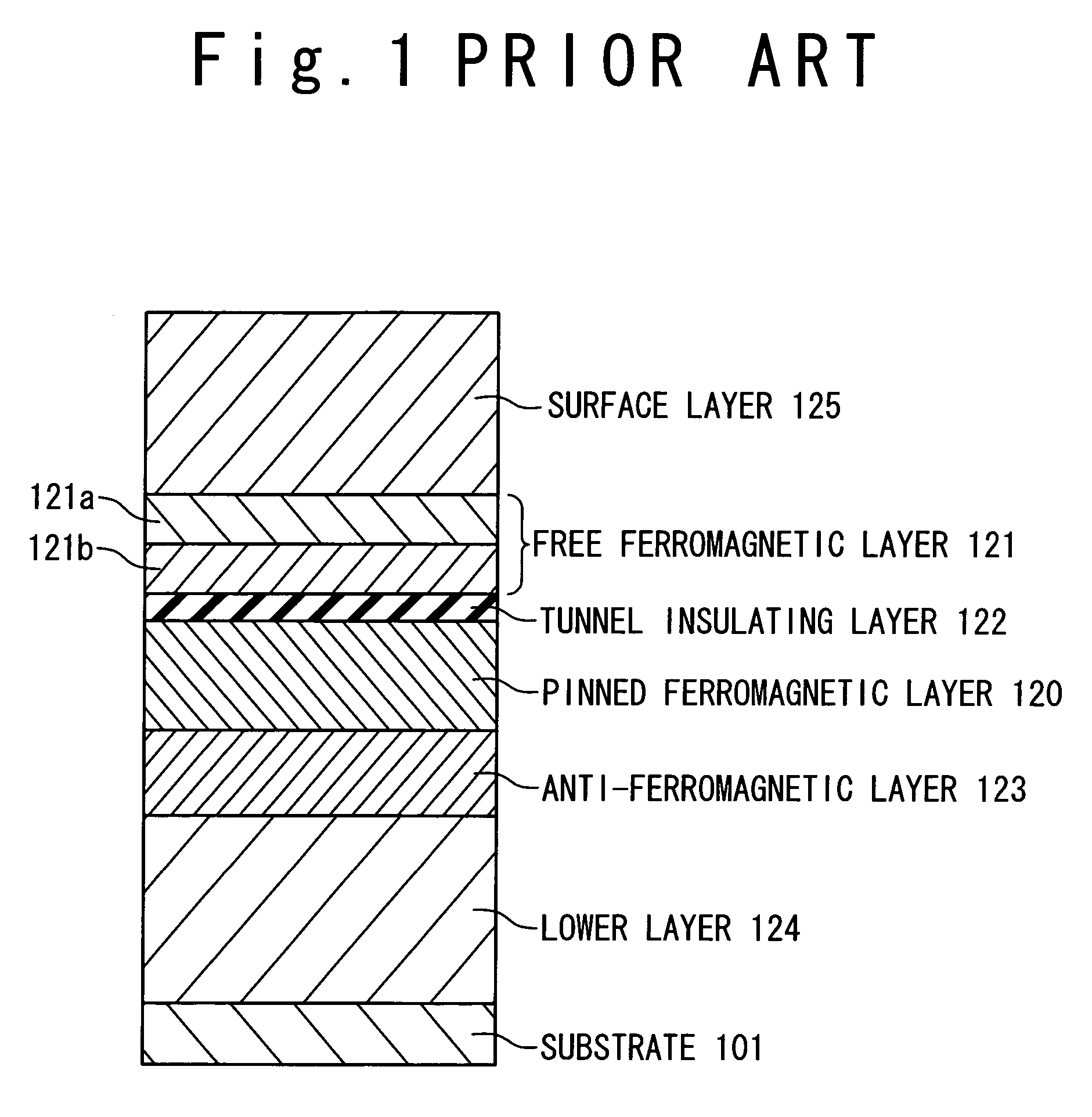

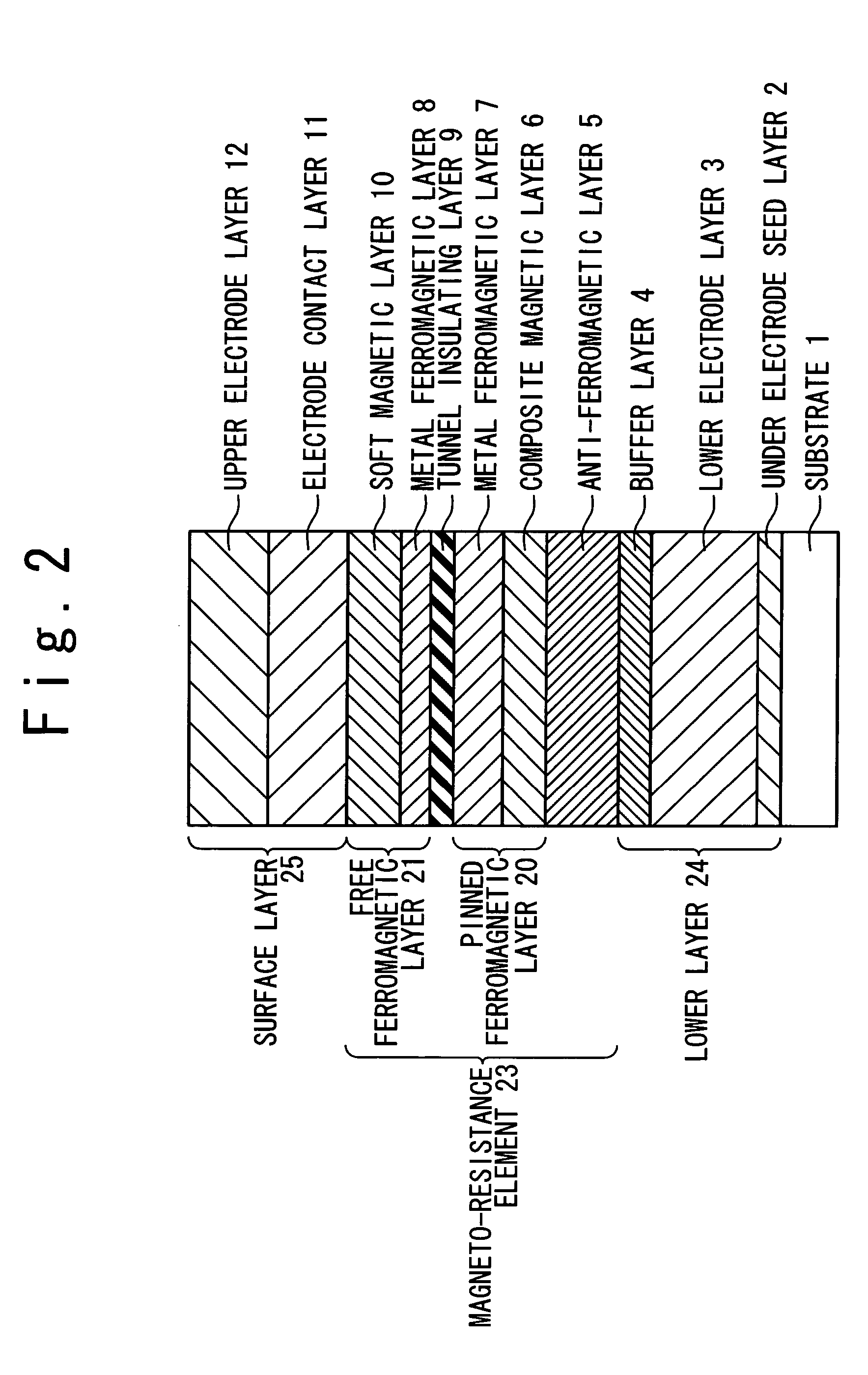

A magneto-resistance device is composed of an anti-ferromagnetic layer (5), a pinned ferromagnetic layer (20), a tunnel insulating layer (9) and a free ferromagnetic layer (21). The pinned ferromagnetic layer (20) is connected to the anti-ferromagnetic layer (5) and has a fixed spontaneous magnetization. The tunnel insulating layer (9) is connected to the pinned ferromagnetic layer (20) and is non-magnetic. The free ferromagnetic layer (21) is connected to the tunnel insulating layer (9) and has a reversible free spontaneous magnetization. The pinned ferromagnetic layer (20) has a first composite magnetic layer (6) to prevent at lest one component of the anti-ferromagnetic layer (5) from diffusing into tunnel insulating layer (9).

Owner:NEC CORP

Magnetoresistance effect device and method of production of the same

InactiveUS20060056115A1Increase valueMaintain good propertiesNanomagnetismMagnetic-field-controlled resistorsMethods of productionMolecular physics

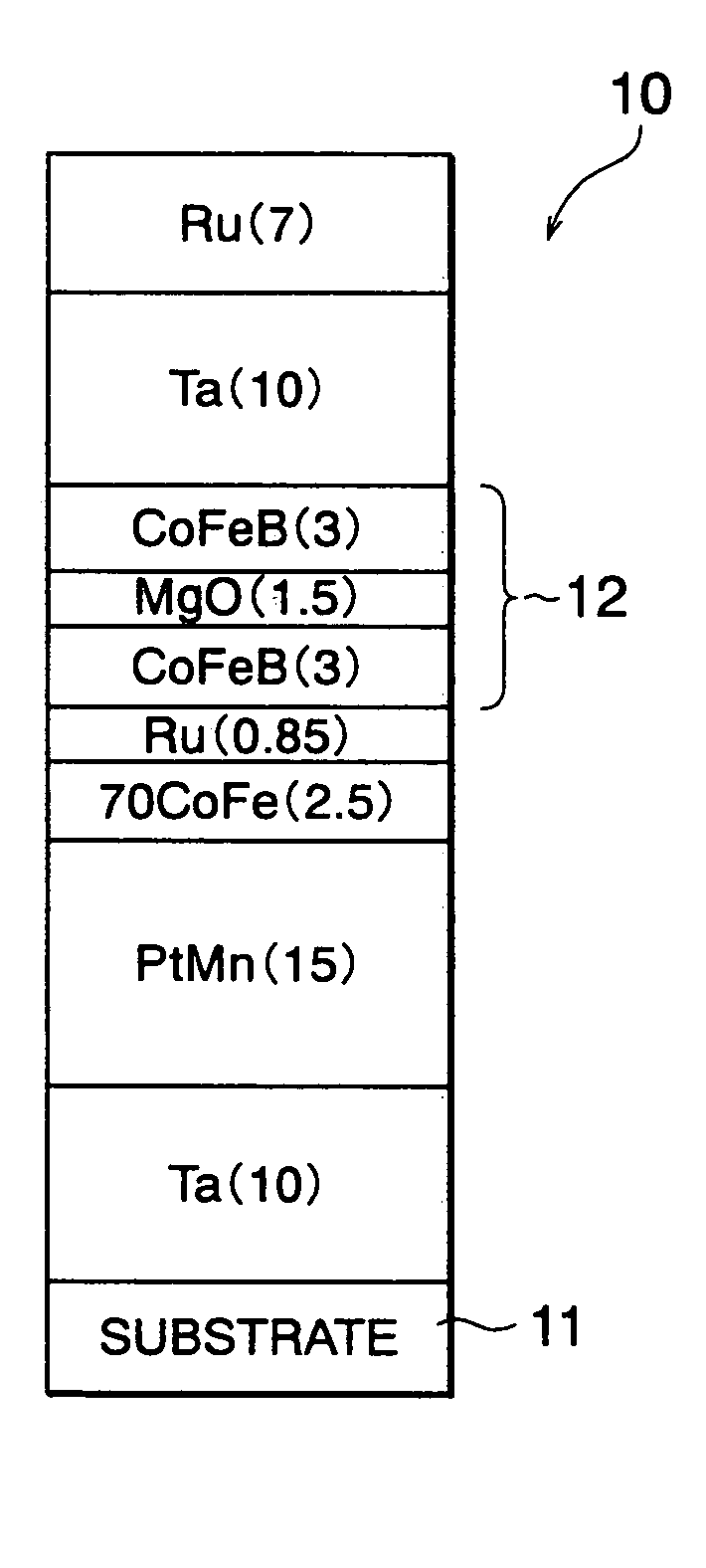

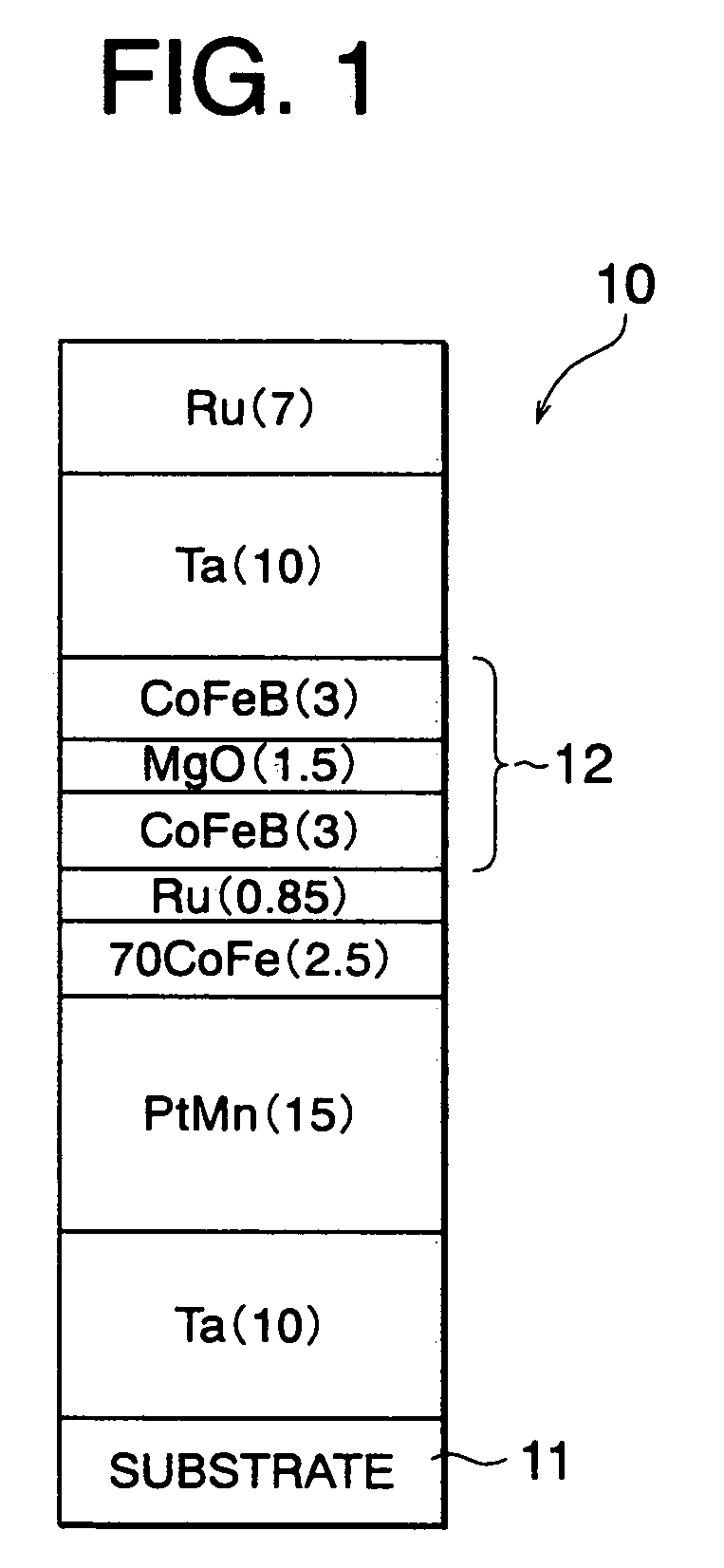

A magnetoresistance effect device including a multilayer structure having a pair of ferromagnetic layers and a barrier layer positioned between them, wherein at least one ferromagnetic layer has at least the part contacting the barrier layer made amorphous and the barrier layer is an MgO layer having a highly oriented texture structure.

Owner:CANON ANELVA CORP +1

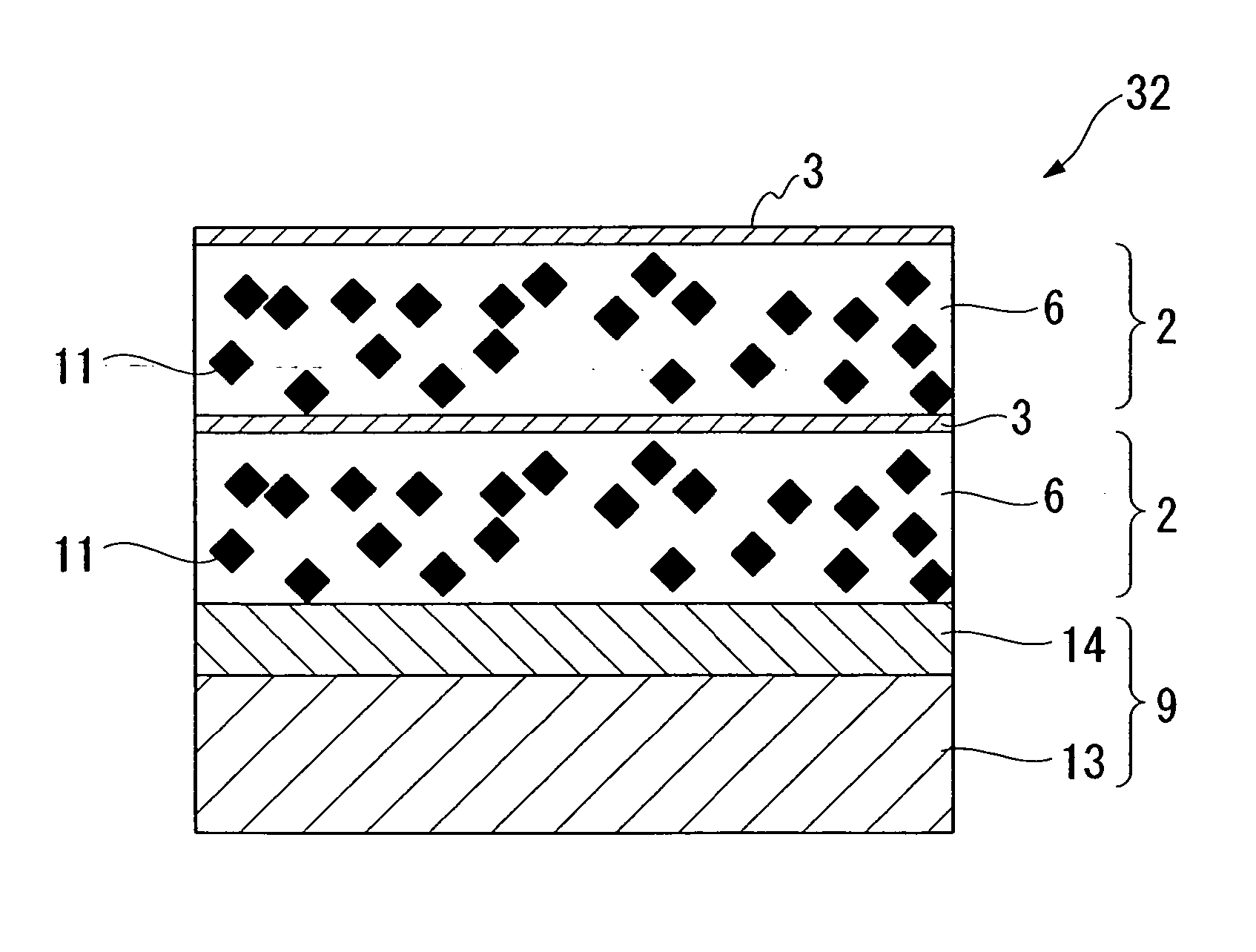

Magnetic multilayer device, method for producing such a device, magnetic field sensor, magnetic memory and logic gate using such a device

ActiveUS20080151615A1High perpendicular anisotropyHigh resistivityNanostructure applicationNanomagnetismMagnetic anisotropyMagnetic memory

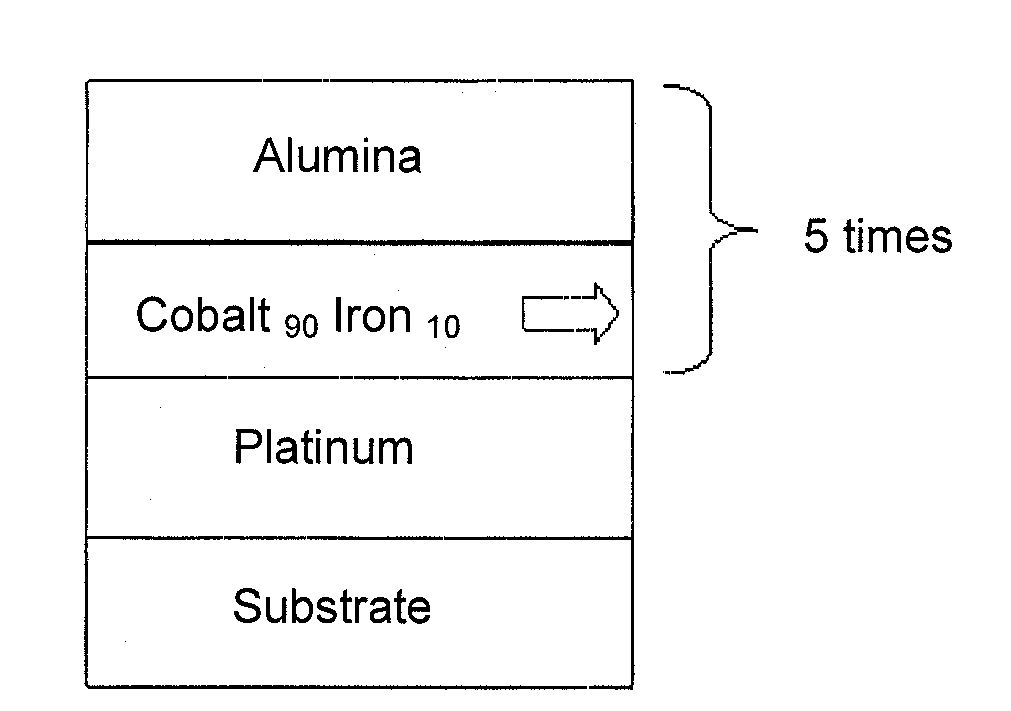

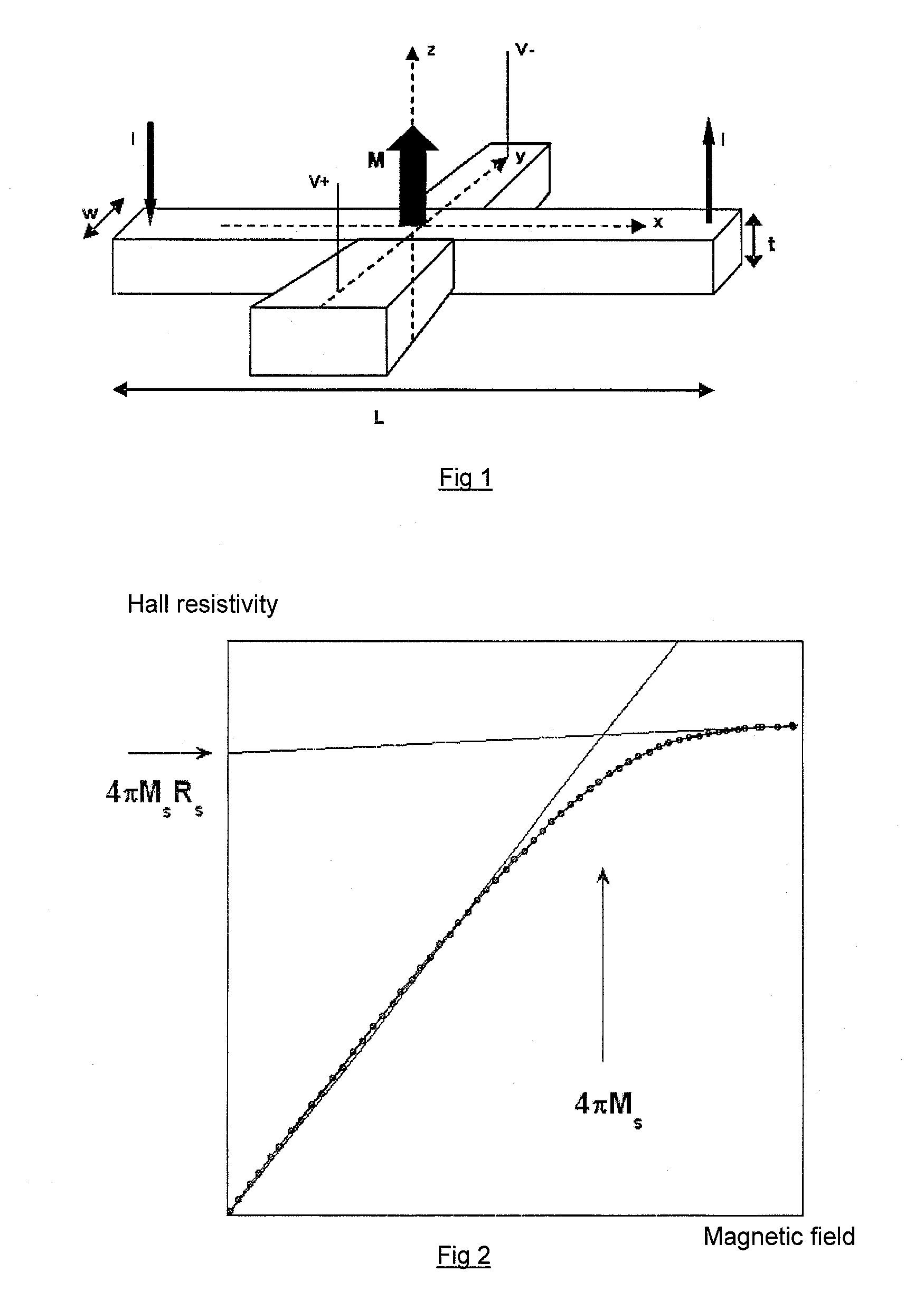

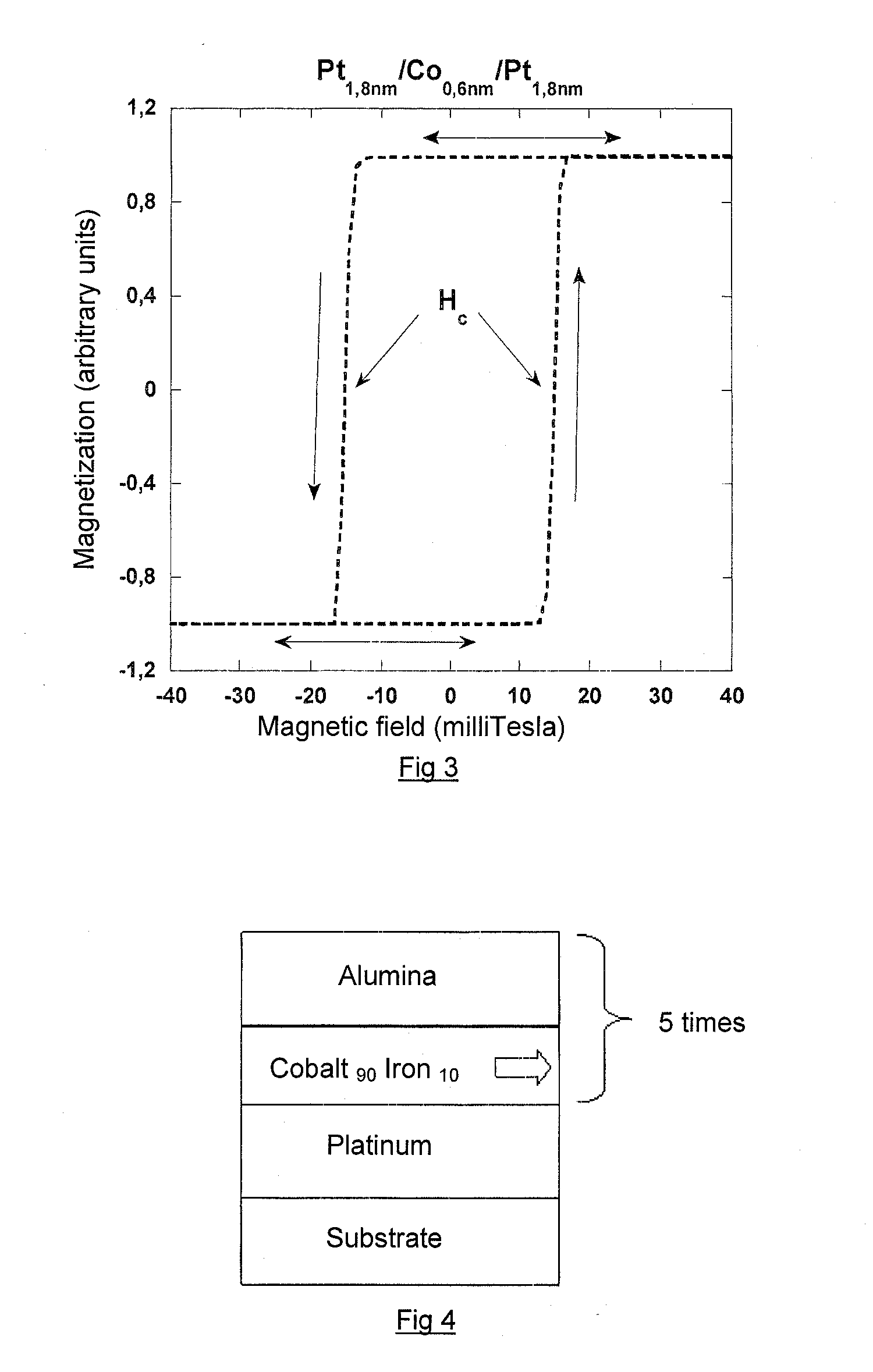

This magnetic multilayer device comprises, on a substrate, an alternating sequence of magnetic metallic layers M and oxide, hydride or nitride layers O. The number of layers M equals at least two. The layers M are continuous. There is interfacial magnetic anisotropy perpendicular to the plane of the layers at the level of the M / O interfaces.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

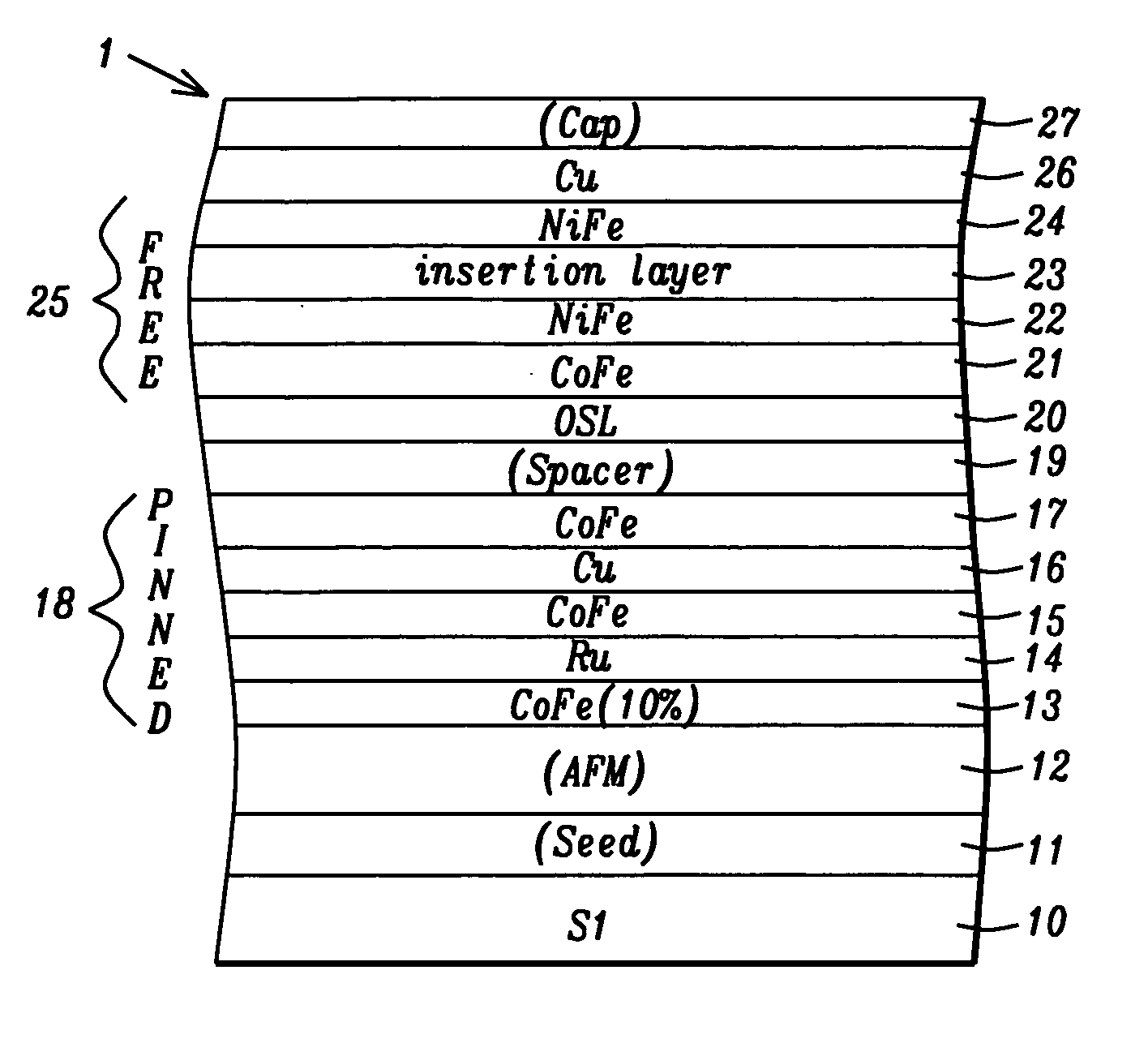

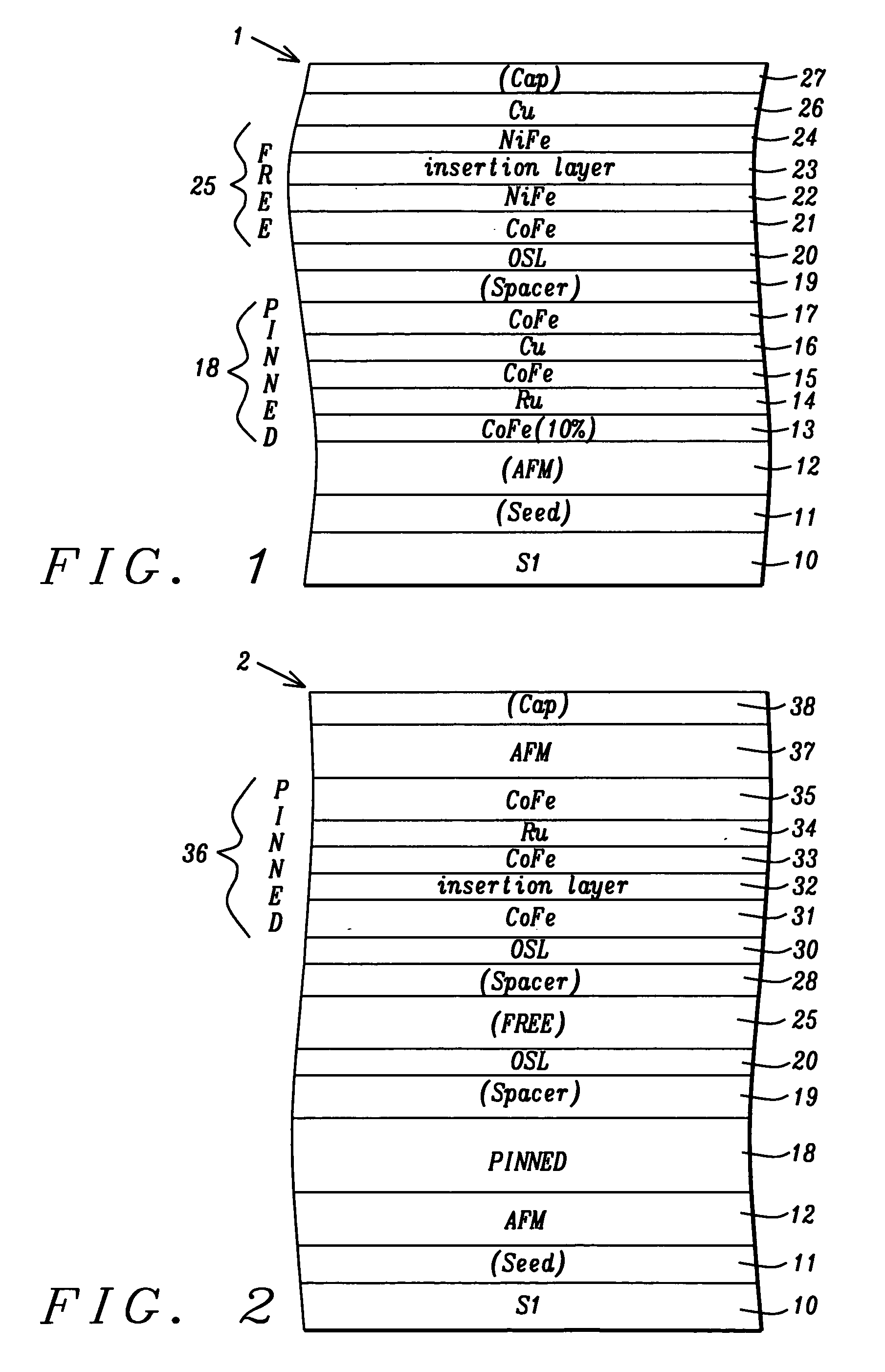

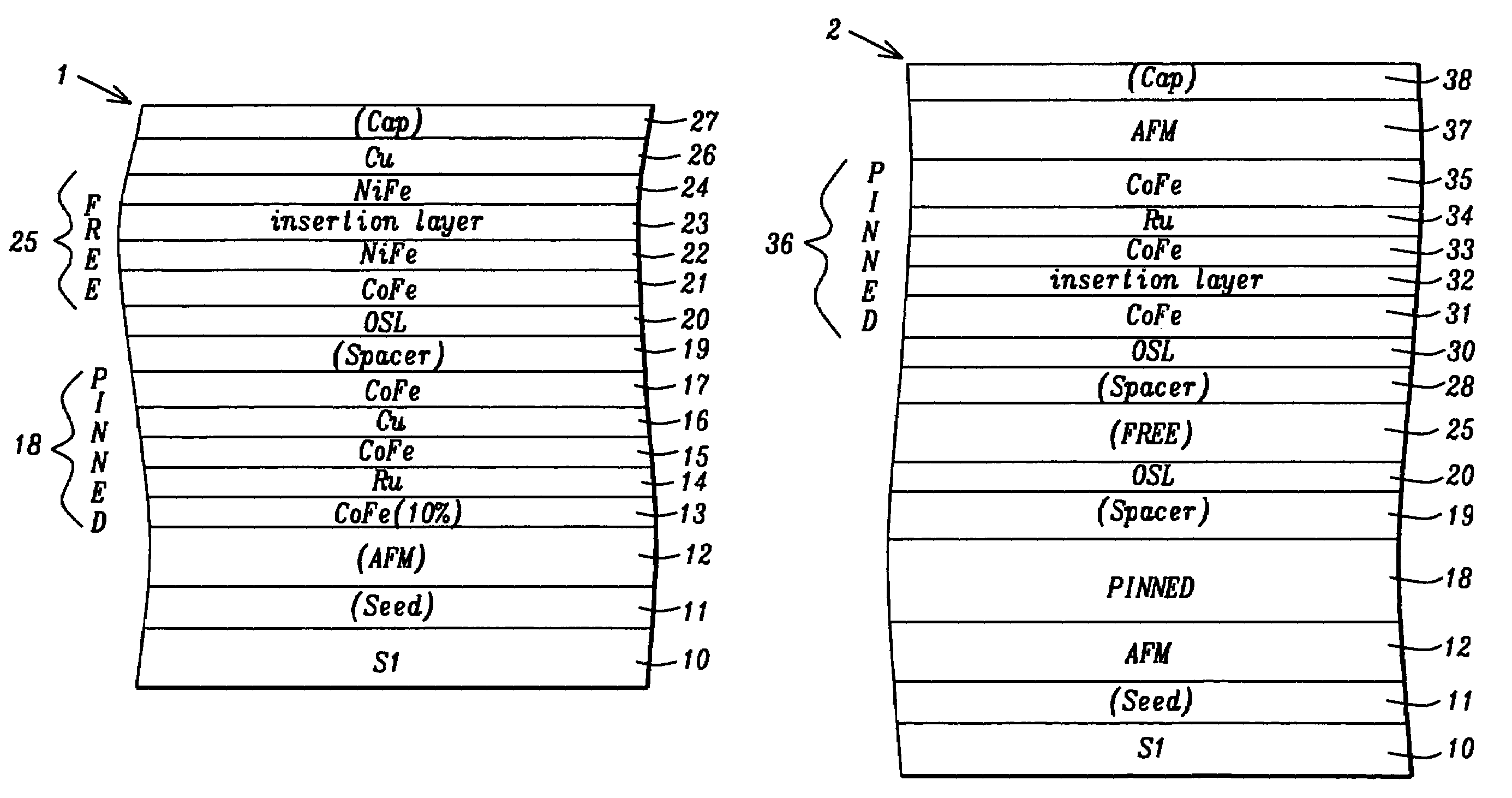

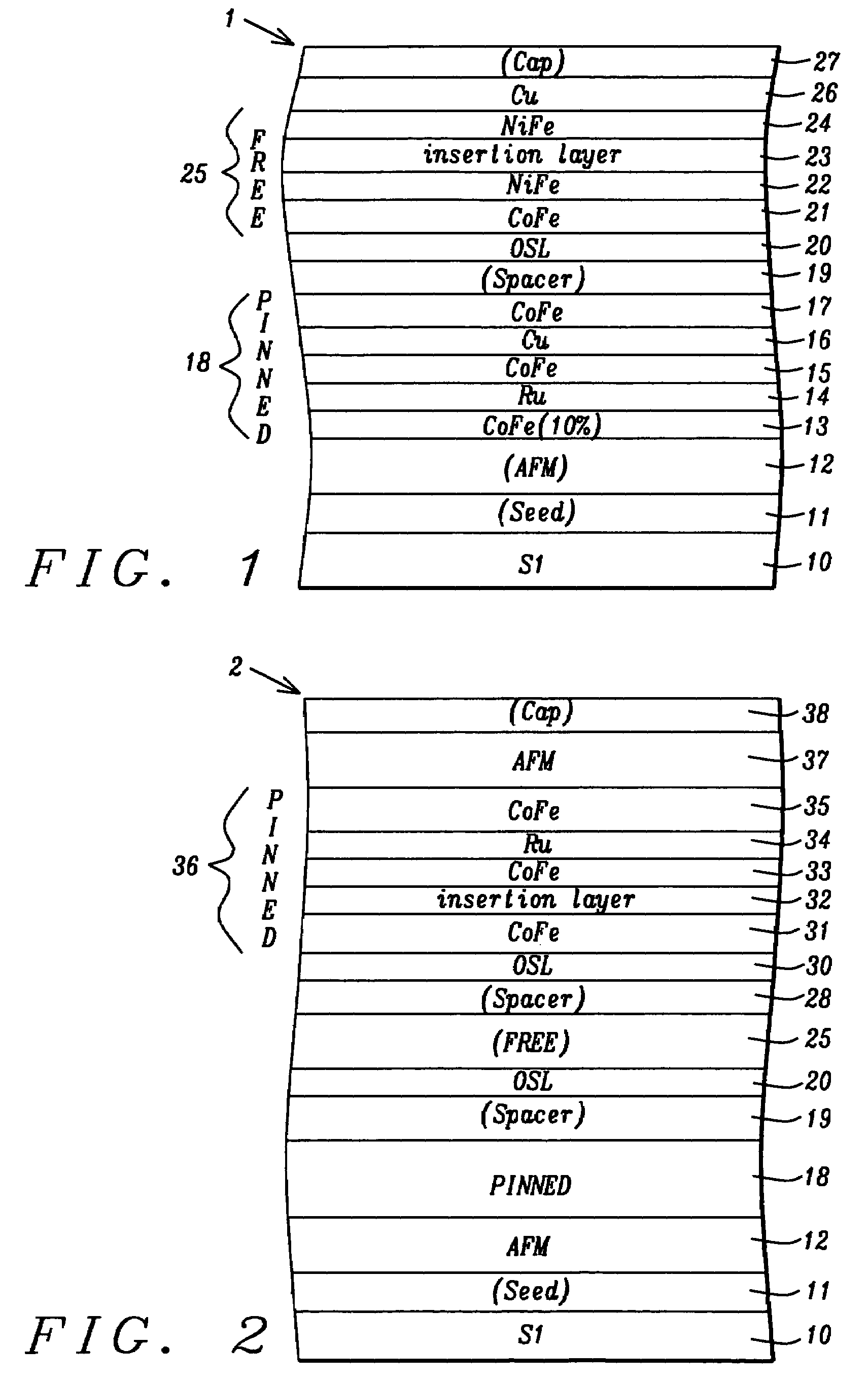

Novel process and structure to fabricate CPP spin valve heads for ultra-hing recording density

InactiveUS20050201022A1Enhanced Specular ReflectionIncrease bulk scatteringNanostructure applicationNanomagnetismDopantSpins

A CPP-GMR spin value sensor structure with an improved MR ratio and increased resistance is disclosed. All layers except certain pinned layers, copper spacers, and a Ta capping layer are oxygen doped by adding a partial O2 pressure to the Ar sputtering gas during deposition. Oxygen doped CoFe free and pinned layers are made slightly thicker to offset a small decrease in magnetic moment caused by the oxygen dopant. Incorporating oxygen in the MnPt AFM layer enhances the exchange bias strength. An insertion layer such as a nano-oxide layer is included in one or more of the free, pinned, and spacer layers to increase interfacial scattering. The thickness of all layers except the copper spacer may be increased to enhance bulk scattering. A CPP-GMR single or dual spin valve of the present invention has up to a threefold increase in resistance and a 2 to 3% increase in MR ratio.

Owner:HEADWAY TECH INC

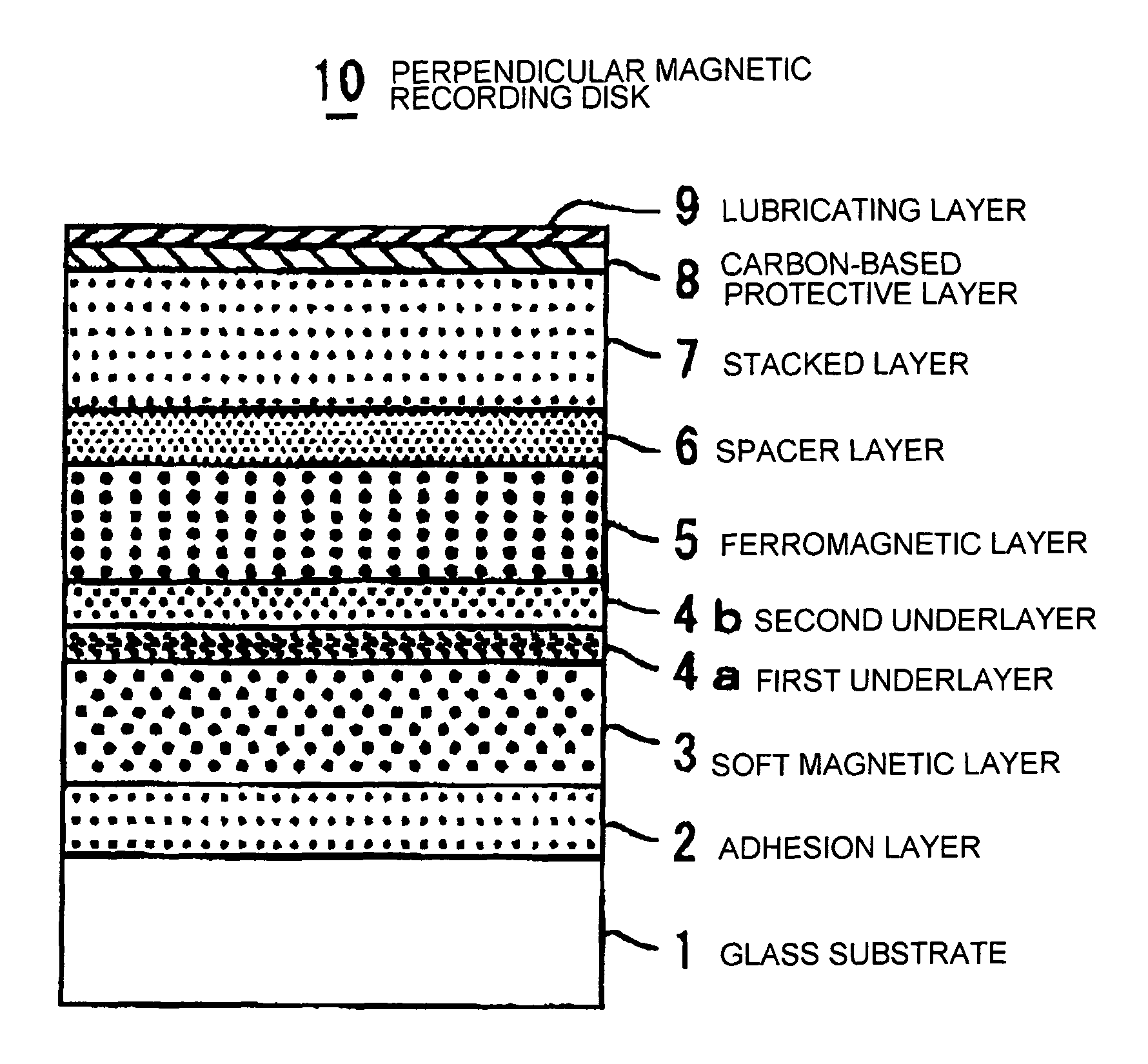

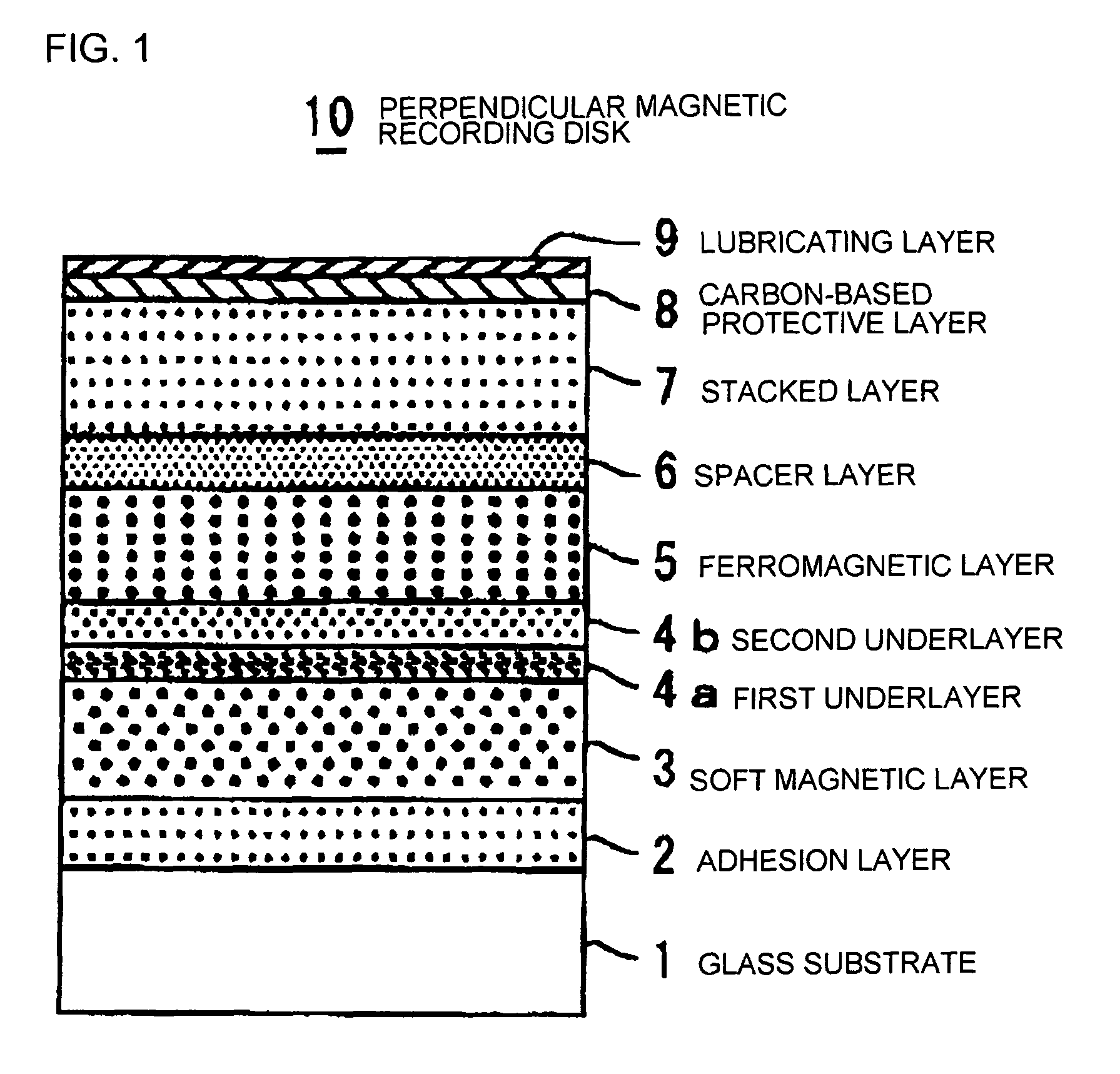

Perpendicular magnetic recording disk and manufacturing method thereof

ActiveUS8603650B2Improve noiseImprove recording densityNanomagnetismVacuum evaporation coatingAlloyRecording layer

A magnetic disk 10 for use in perpendicular magnetic recording has at least a magnetic recording layer on a substrate 1. The magnetic recording layer is composed of a ferromagnetic layer 5 of a granular structure containing silicon (Si) or an oxide of silicon (Si) between crystal grains containing cobalt (Co), a stacked layer 7 having a first layer containing cobalt (Co) or a Co alloy and a second layer containing palladium (Pd) or platinum (Pt), and a spacer layer 6 interposed between the ferromagnetic layer 5 and the stacked layer 7. After forming the ferromagnetic layer 5 on the substrate 1 by sputtering in an argon gas atmosphere, the stacked layer 7 is formed by sputtering in the argon gas atmosphere at a gas pressure lower than that used when forming the ferromagnetic layer 5.

Owner:WESTERN DIGITAL TECH INC

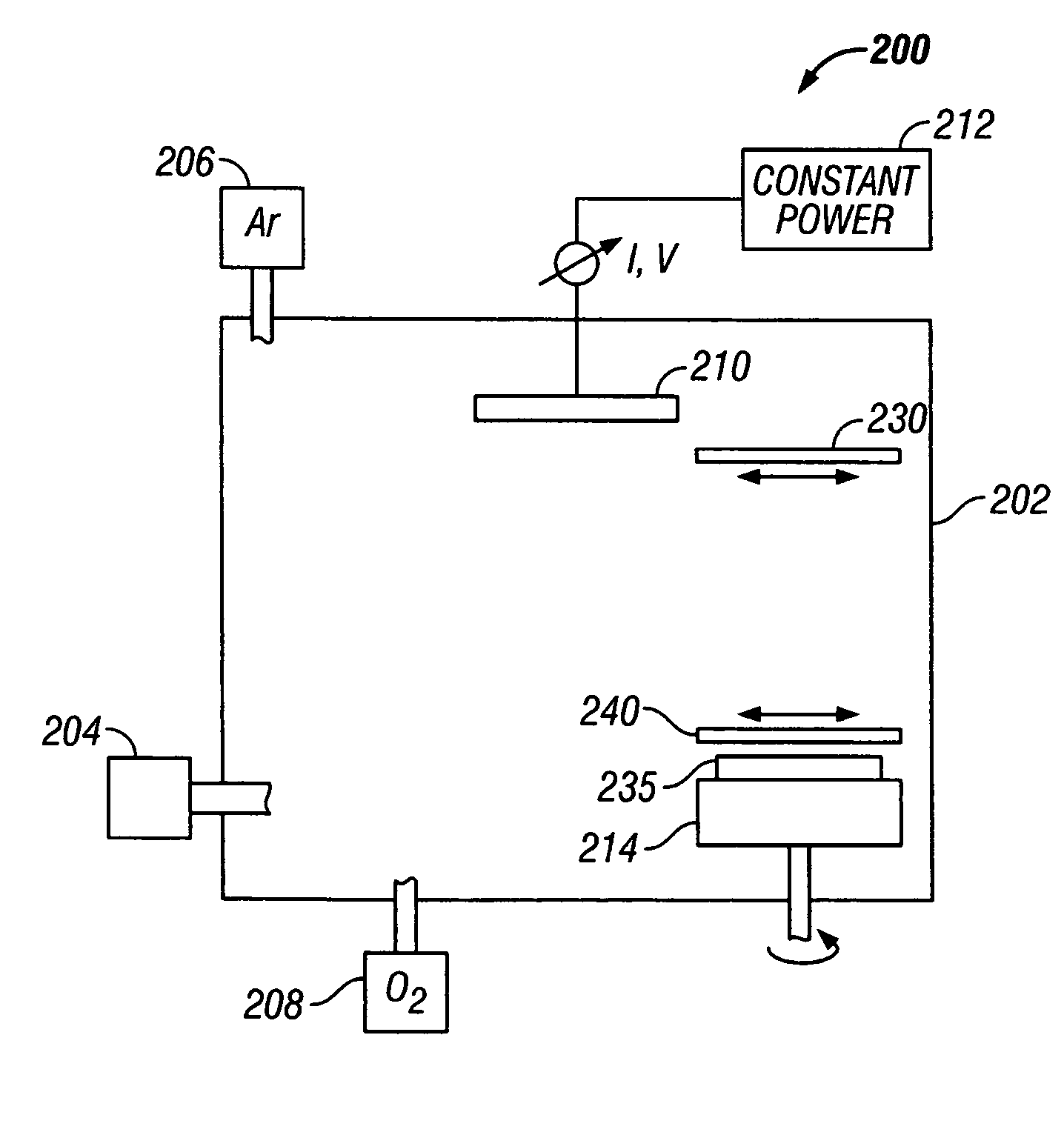

Method for reactive sputter deposition of a magnesium oxide (MgO) tunnel barrier in a magnetic tunnel junction

As part of the fabrication of a magnetic tunnel junction (MTJ), a magnesium oxide (MgO) tunnel barrier is reactively sputter deposited from a Mg target in the presence of reactive oxygen gas (O2) in the “high-voltage” state to assure that deposition occurs with the Mg target in its metallic mode, i.e., no or minimal oxidation. Because the metallic mode of the Mg target has a finite lifetime, a set of O2 flow rates and associated sputter deposition times are established, with each flow rate and deposition time assuring that deposition occurs with the Mg target in the metallic mode and resulting in a known tunnel barrier thickness. The commencement of undesirable Mg target oxidation is associated with a decrease in target voltage, so the sputtering can also be terminated by monitoring the target voltage and terminating application of power to the target when the voltage reaches a predetermined value.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

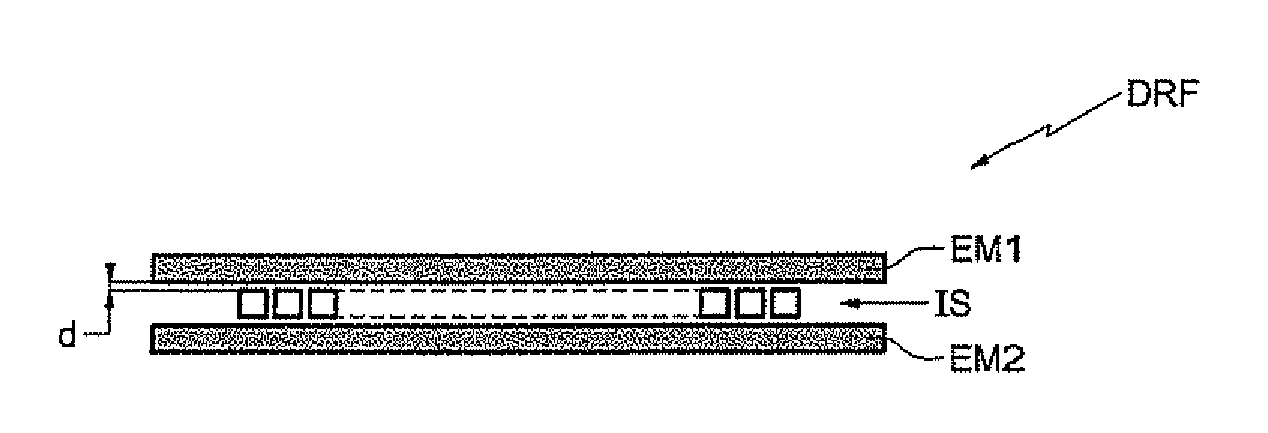

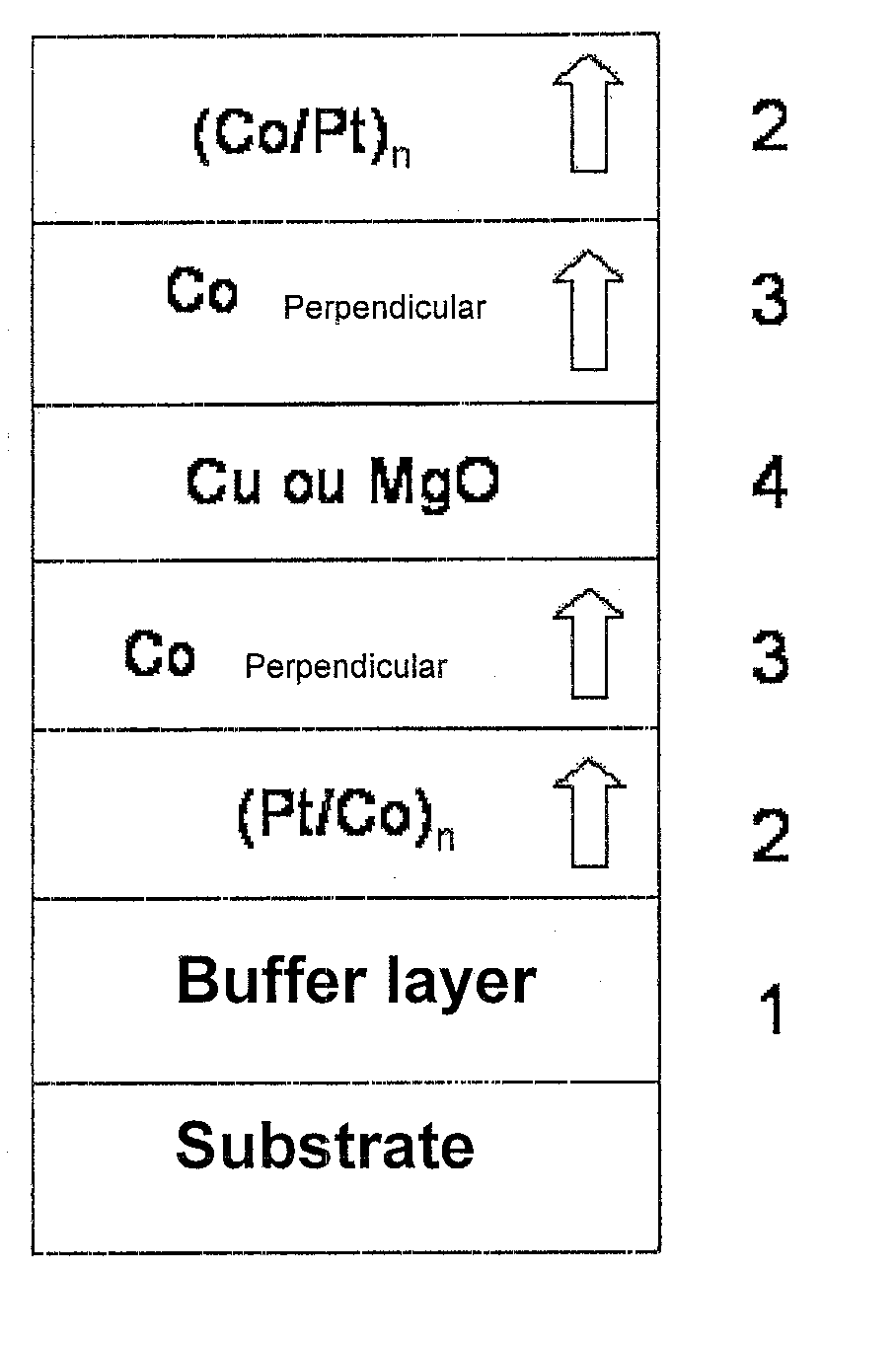

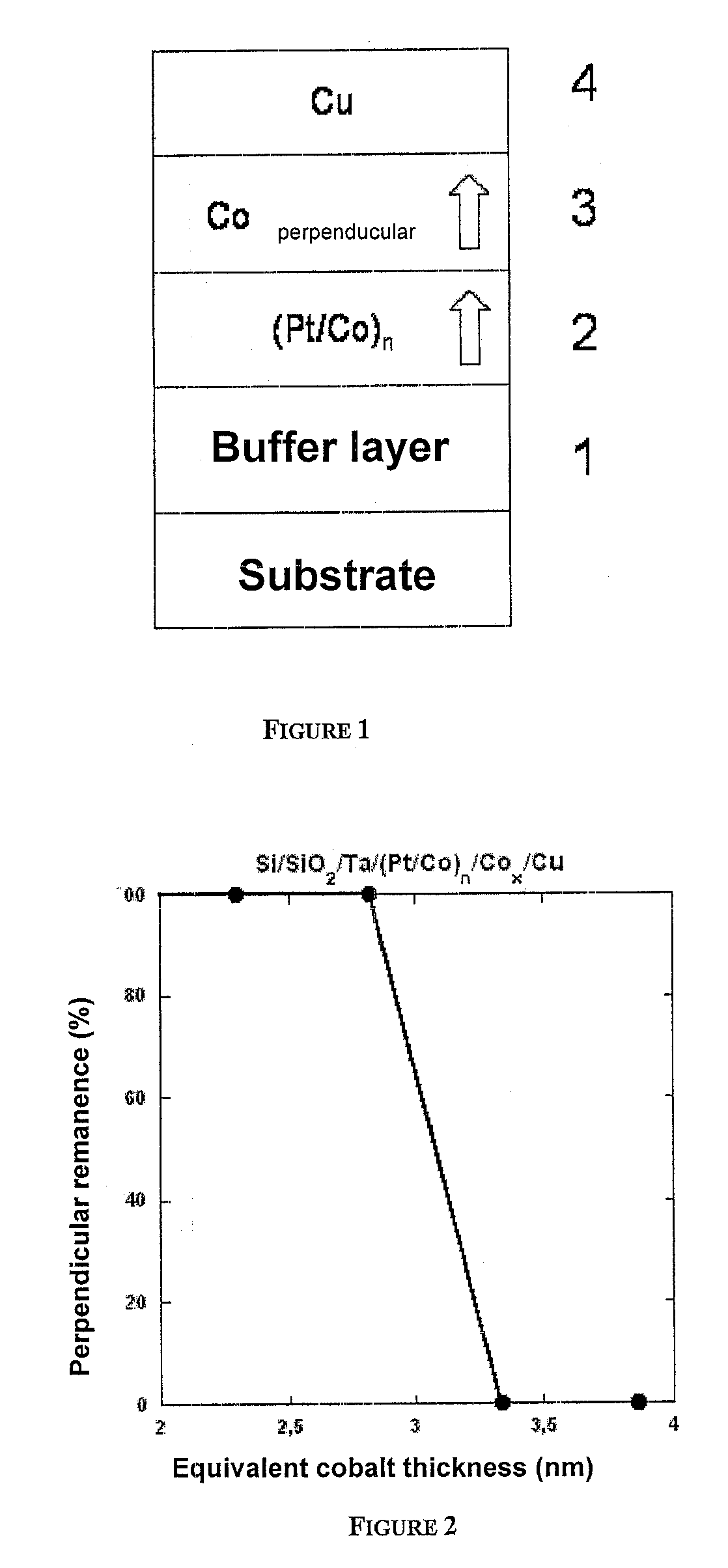

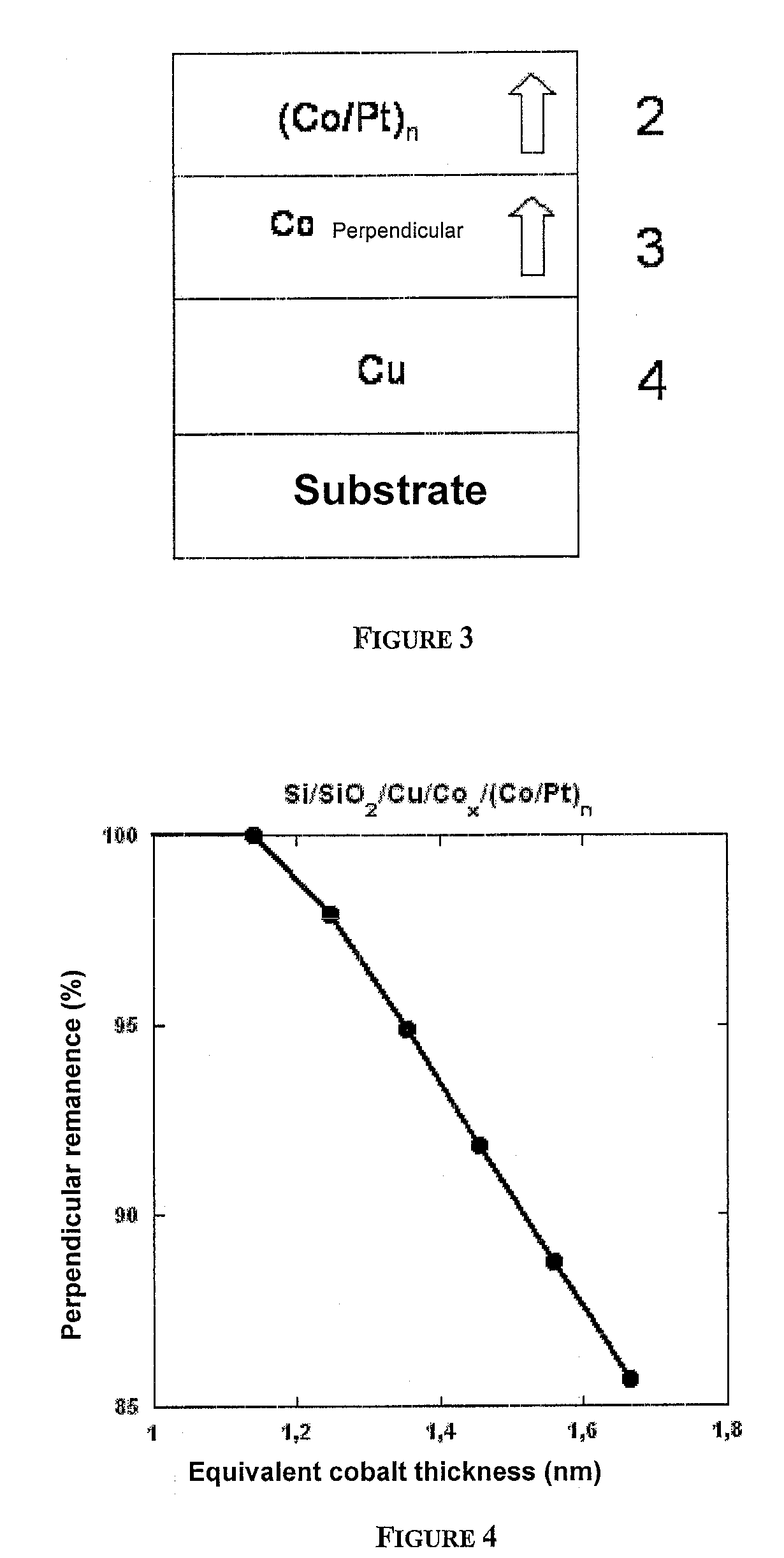

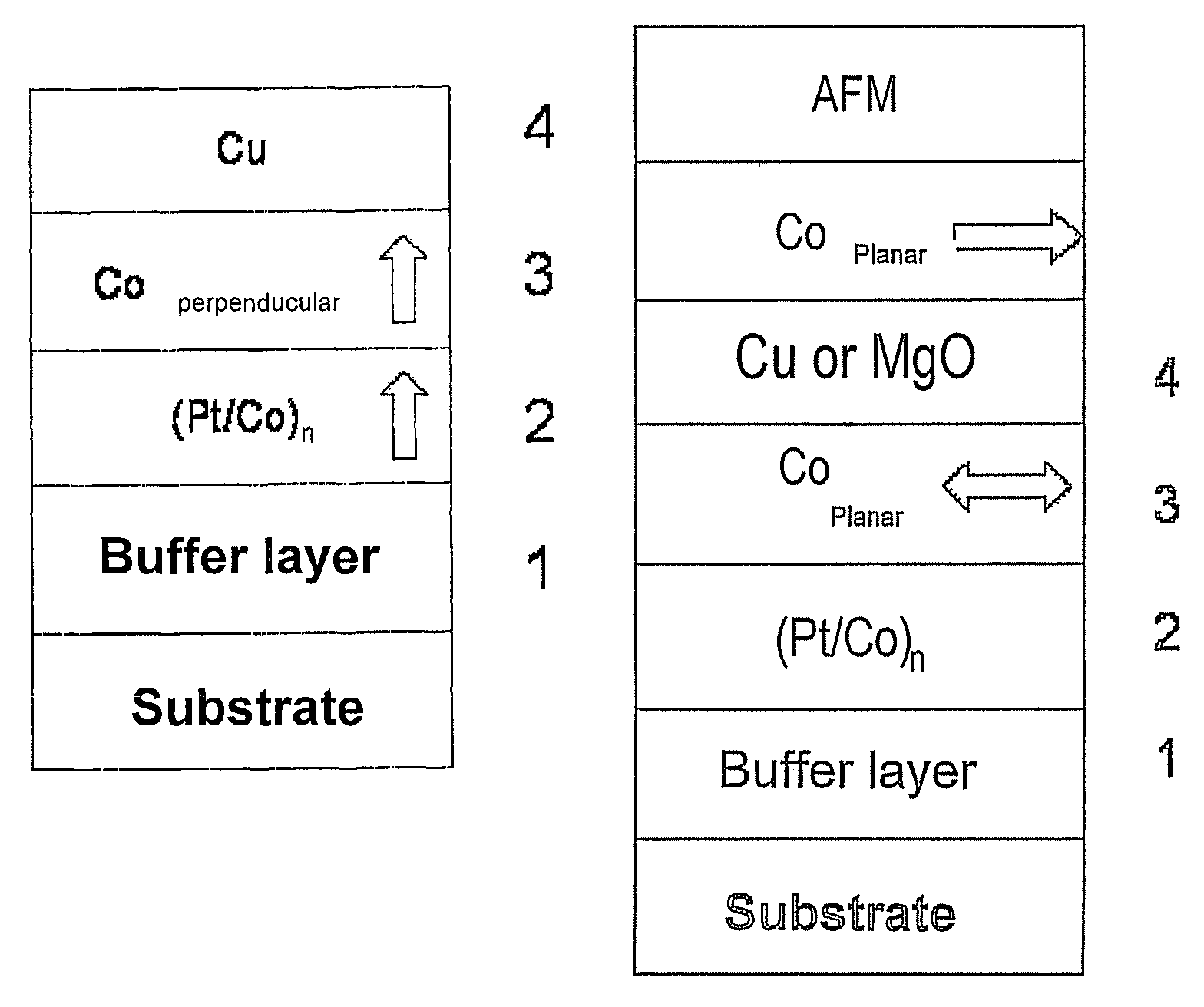

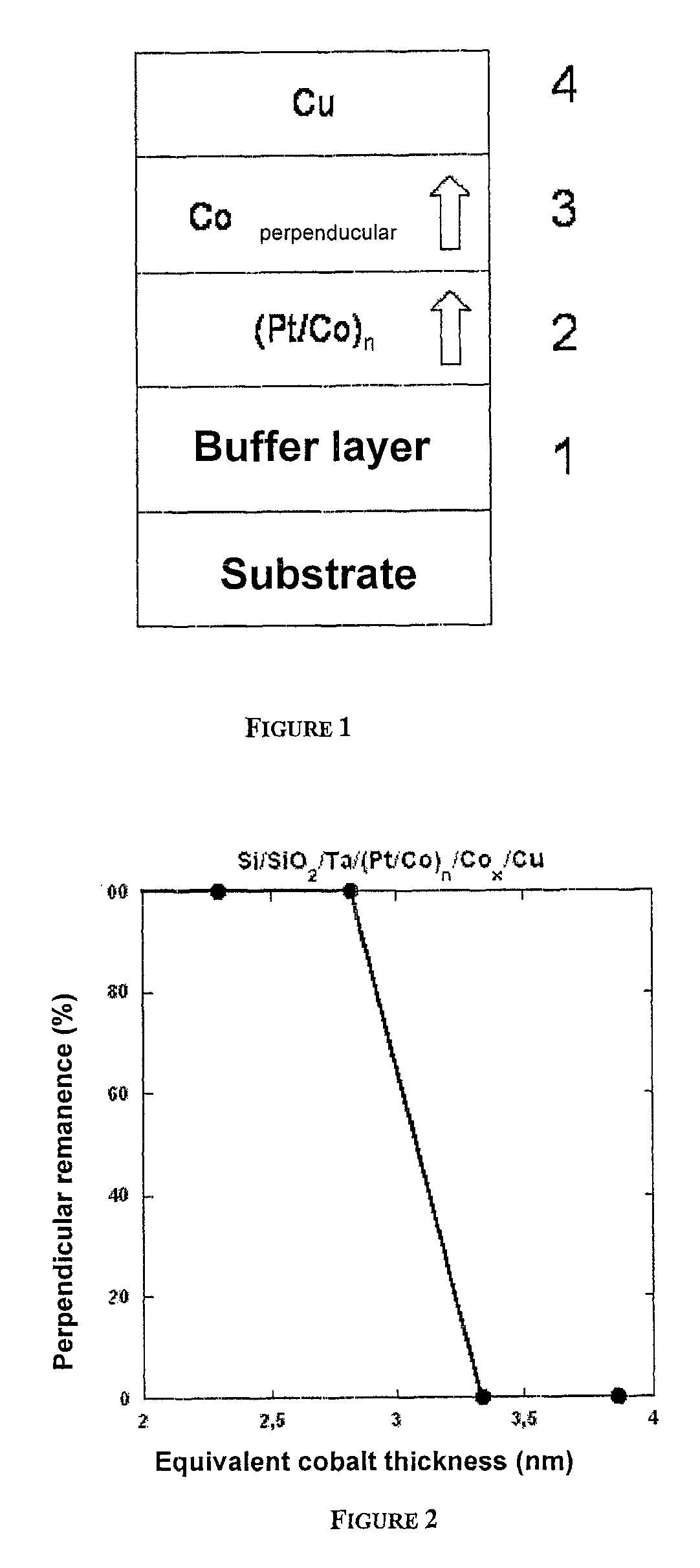

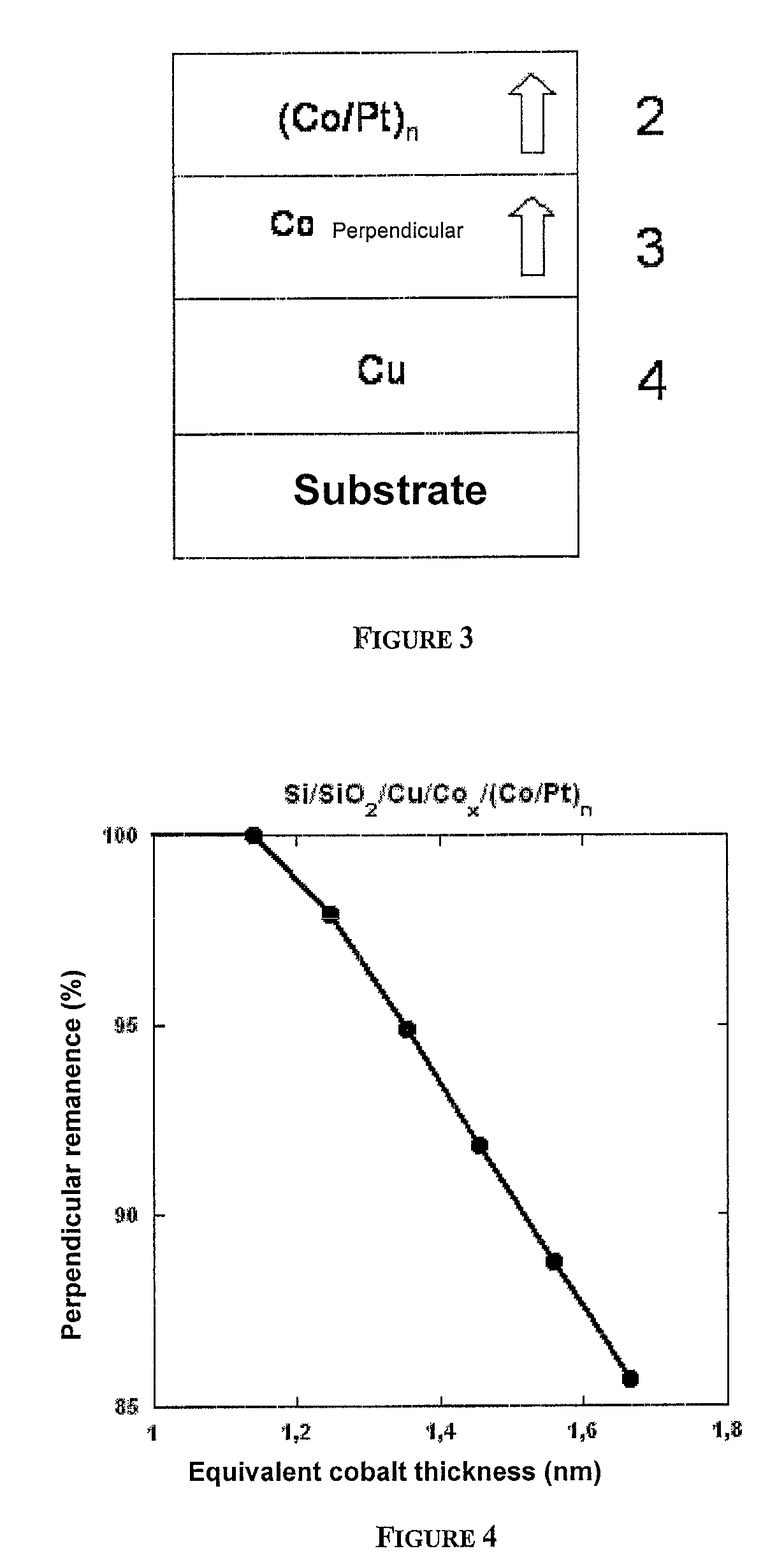

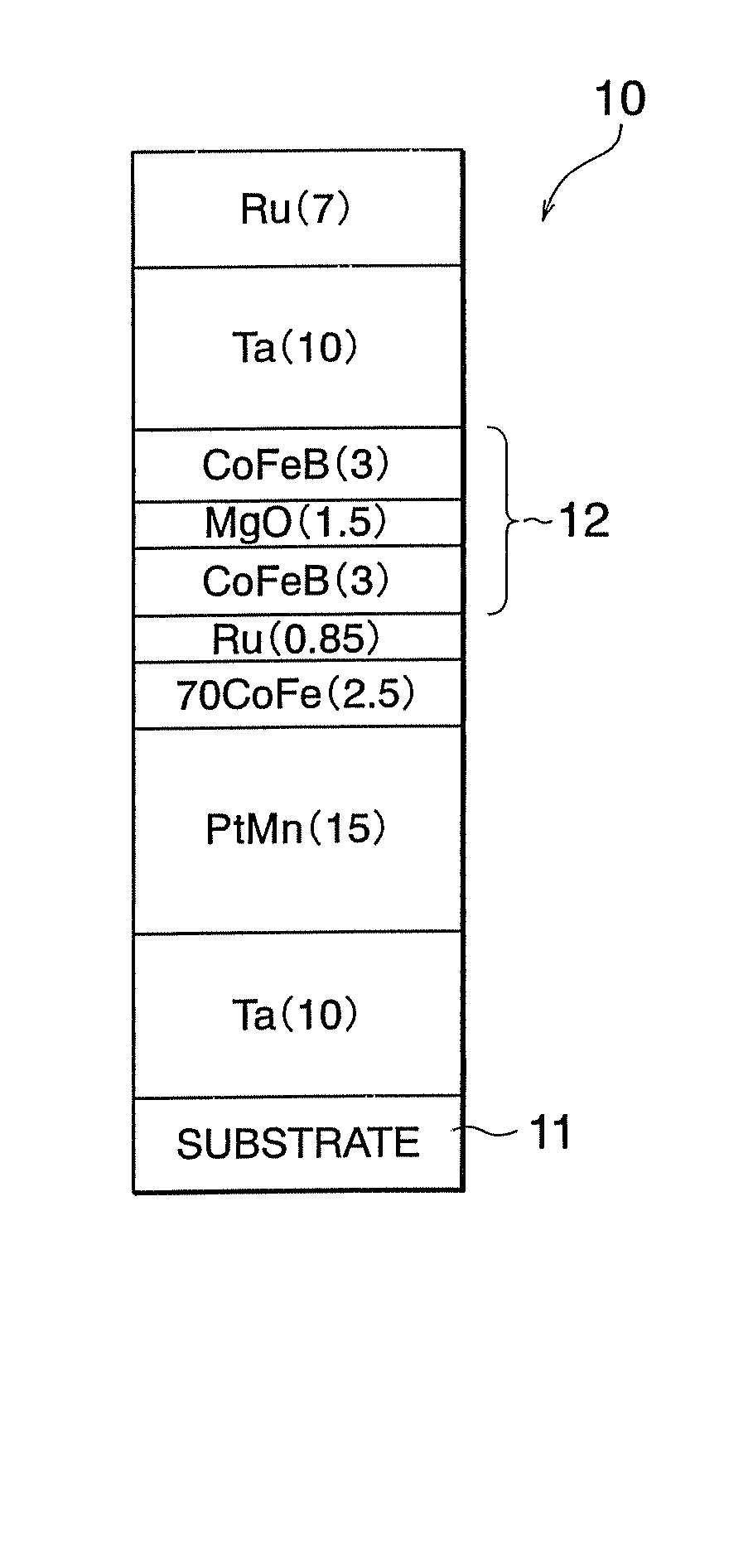

Thin-film magnetic device with strong spin polarisation perpendicular to the plane of the layers, magnetic tunnel junction and spin valve using such a device

ActiveUS20080031035A1Improve scalabilityImprove adhesionNanomagnetismMagnetic measurementsIn planeHigh rate

A thin-film magnetic device comprises, on a substrate, a composite assembly deposited by cathode sputtering and consists of a first layer made of a ferromagnetic material with a high rate of spin polarisation, the magnetisation of which is in plane in the absence of any electric or magnetic interaction, a second layer made of a magnetic material with high perpendicular anisotropy, the magnetisation of which is outside the plane of said layer in the absence of any electric or magnetic interaction, and coupling of which with said first layer induces a decrease in the effective demagnetising field of the entire device, a third layer that is in contact with the first layer via its interface opposite to that which is common to the second layer and made of a material that is not magnetic and not polarising for electrons passing through the device.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

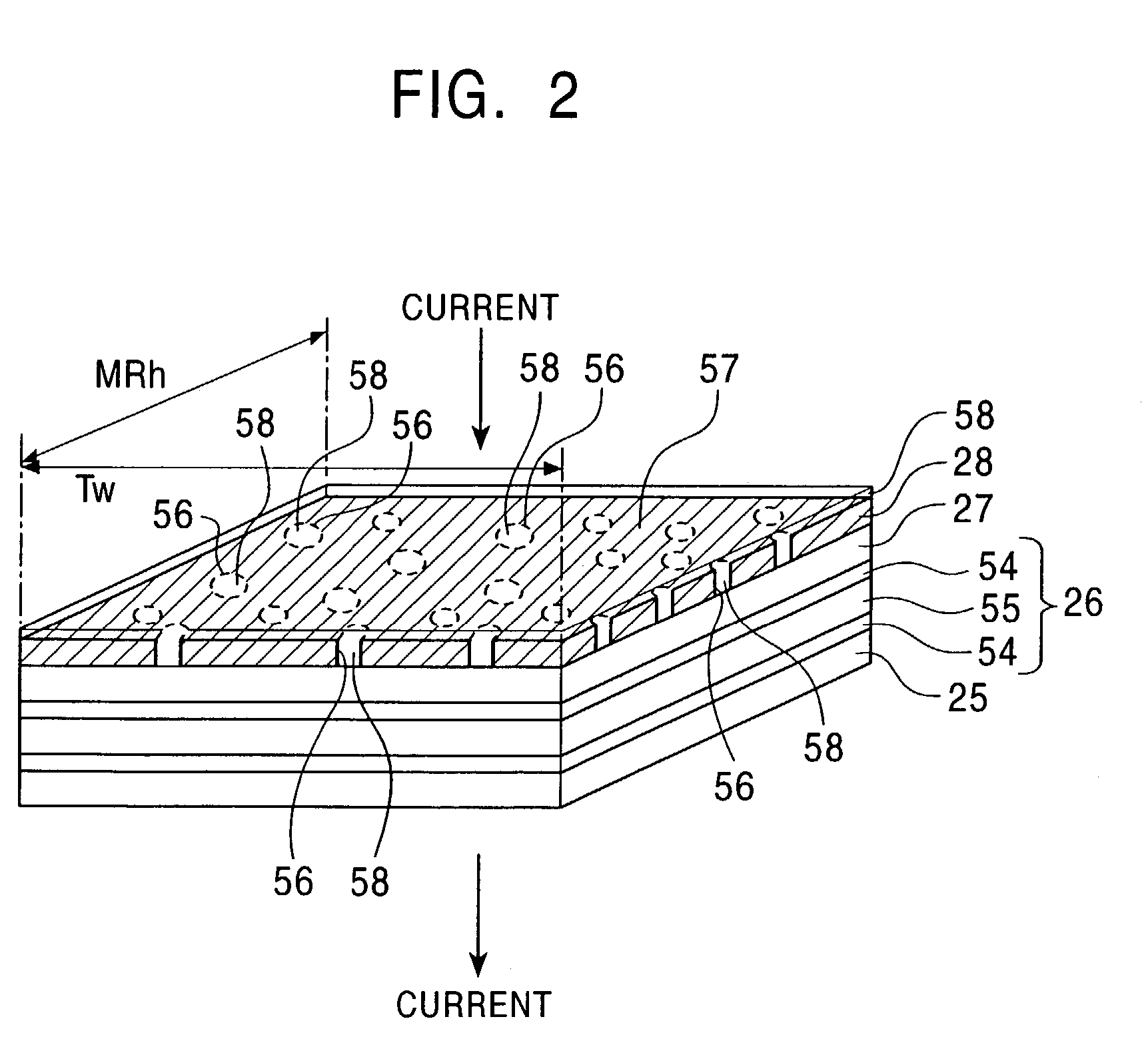

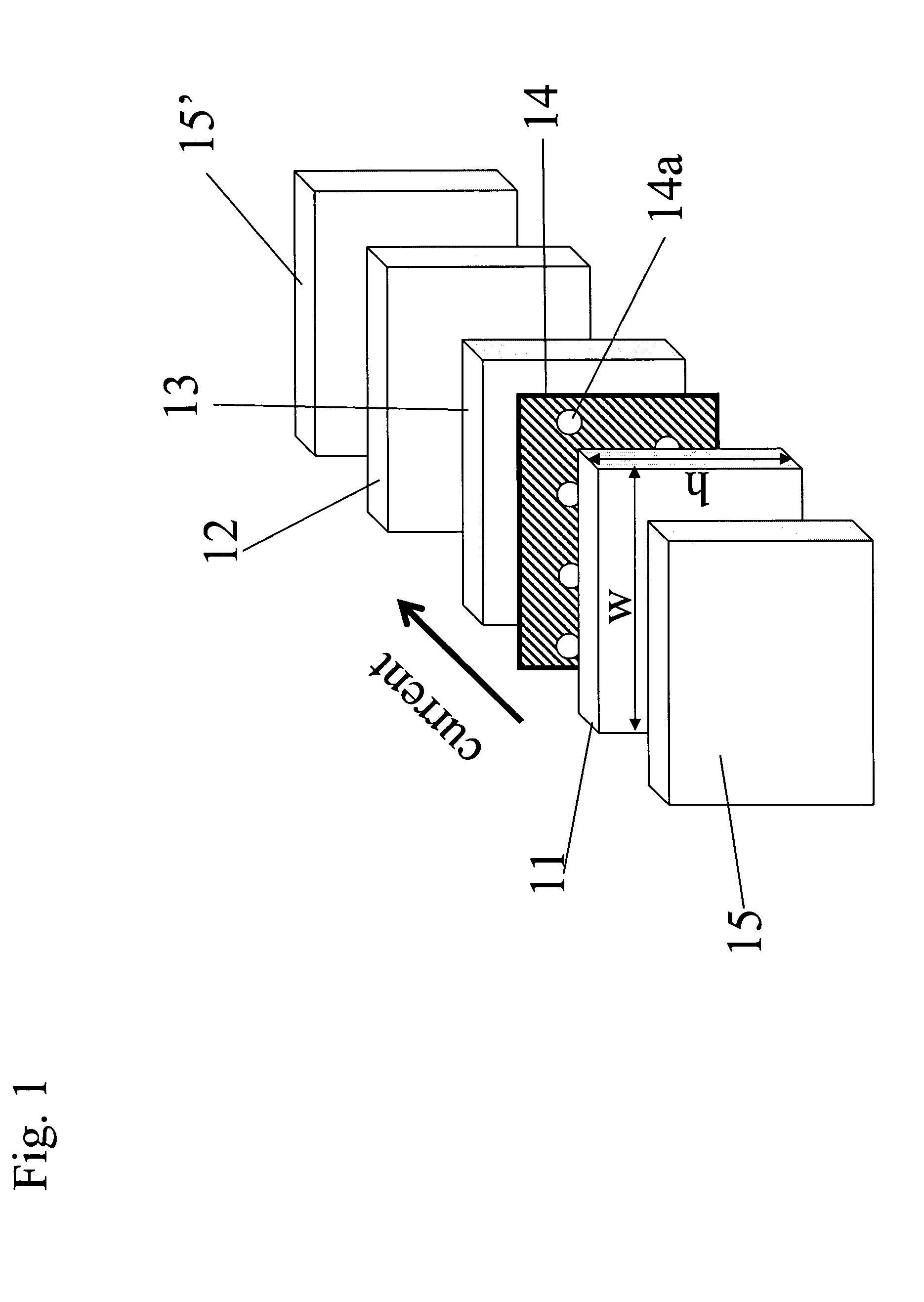

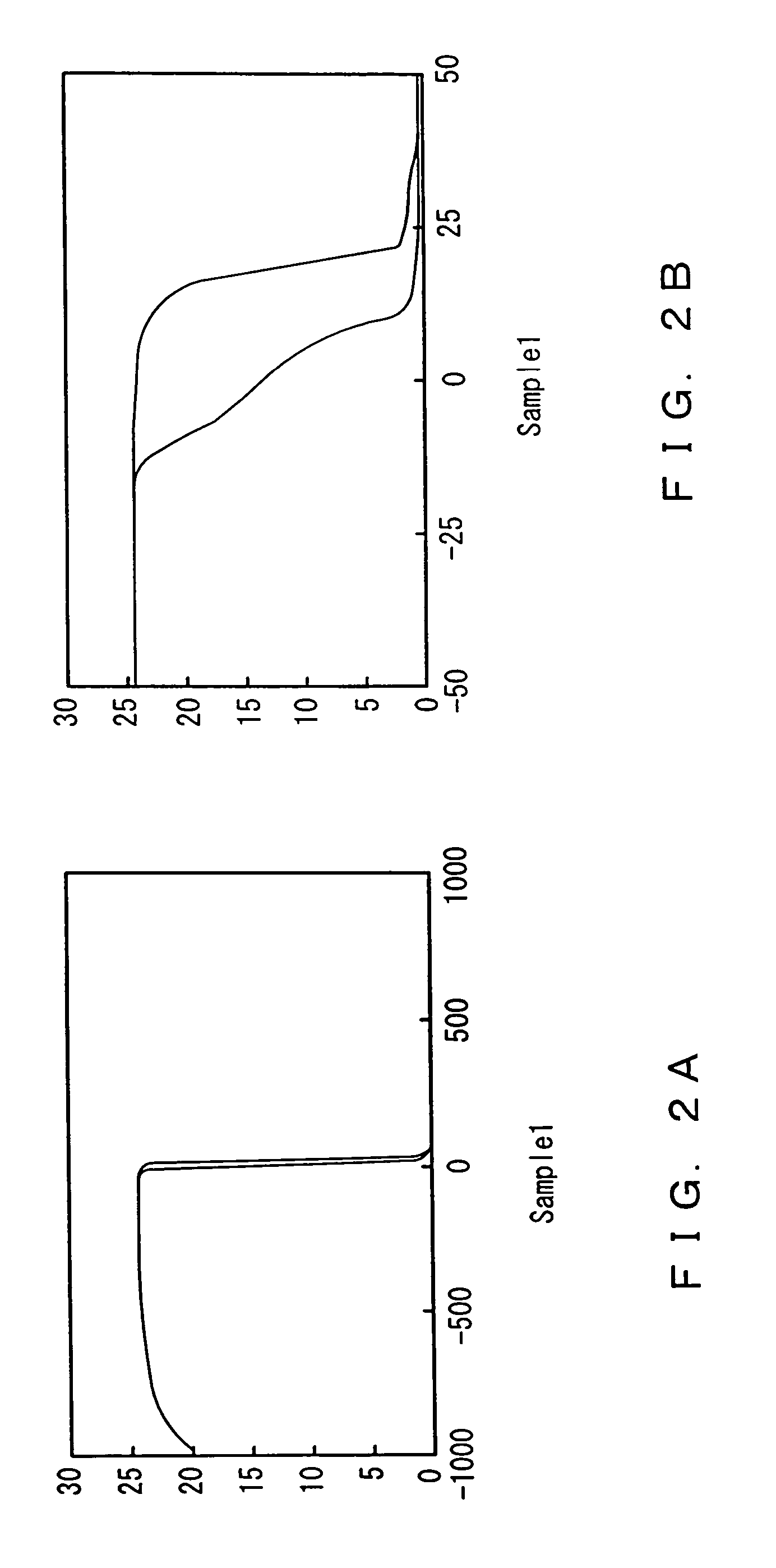

CPP spin-valve element

InactiveUS20050002126A1Increase resistanceLower average currentMagnetic-field-controlled resistorsSolid-state devicesCurrent limitingCoupling

A CPP spin-valve element formed on a substrate including a free layer structure including at least one ferromagnetic layer and a pinned layer structure including at least one ferromagnetic layer. The free layer is magnetically softer than the pinned layer. A thin non-magnetic spacer layer structure configured to separate the free layer and the pinned layer is provided in order to prevent a magnetic coupling between the free and pinned layer structures, and to allow an electric current to go there through. At least two current-confining (CC) layer structures including at least two parts having significantly different current conductivities are incorporated therein.

Owner:UNIVERSITY OF ALABAMA +1

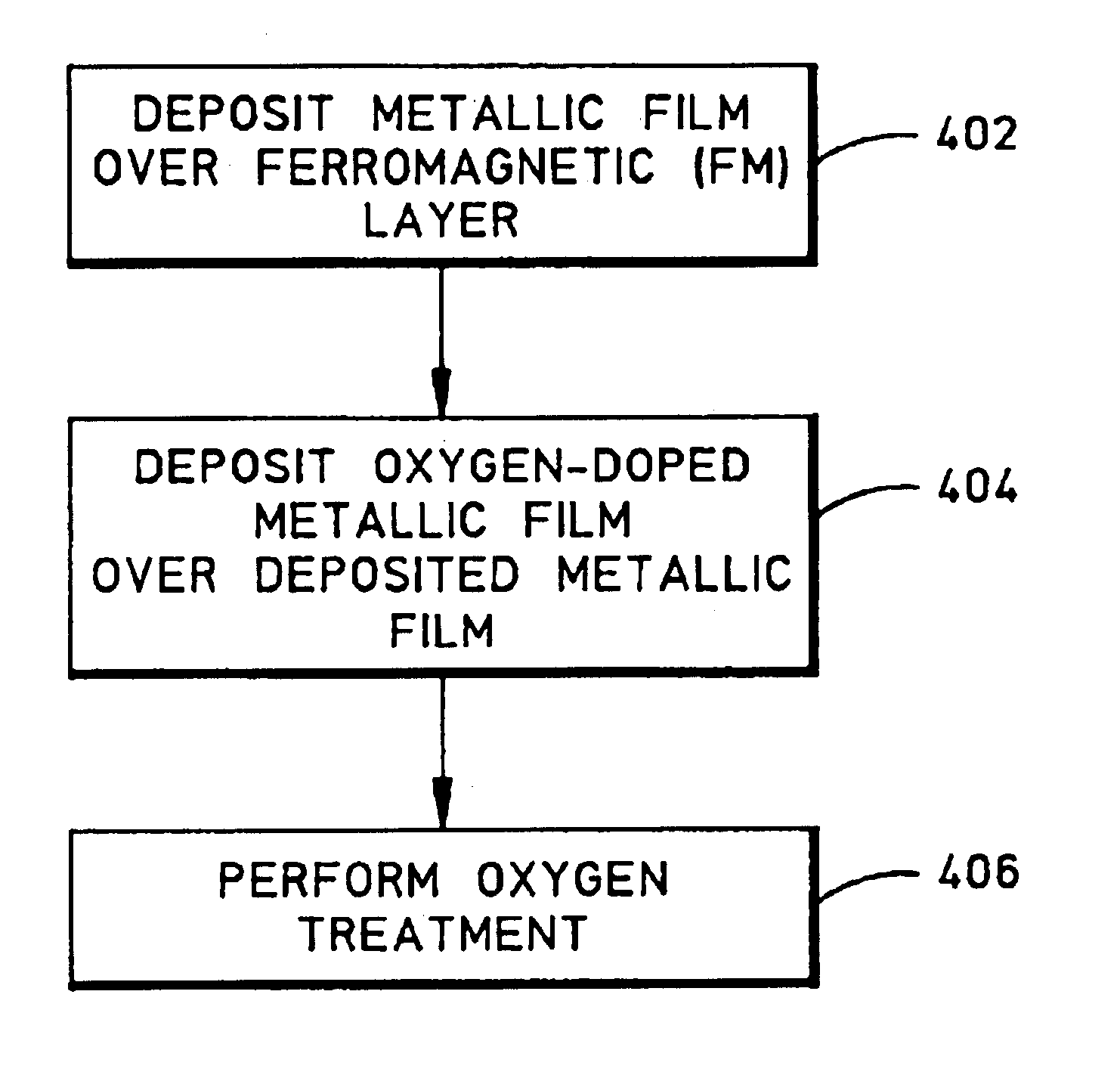

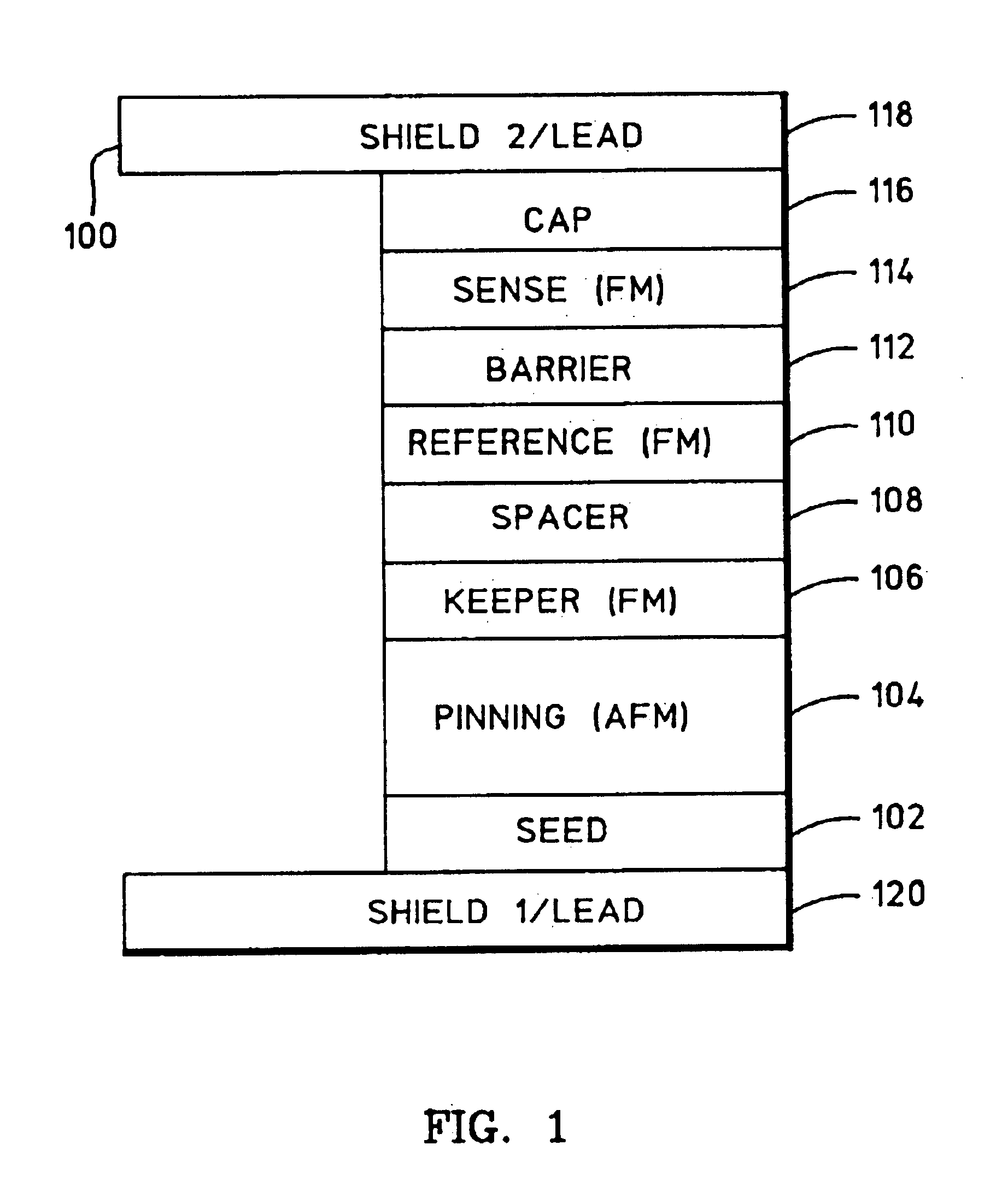

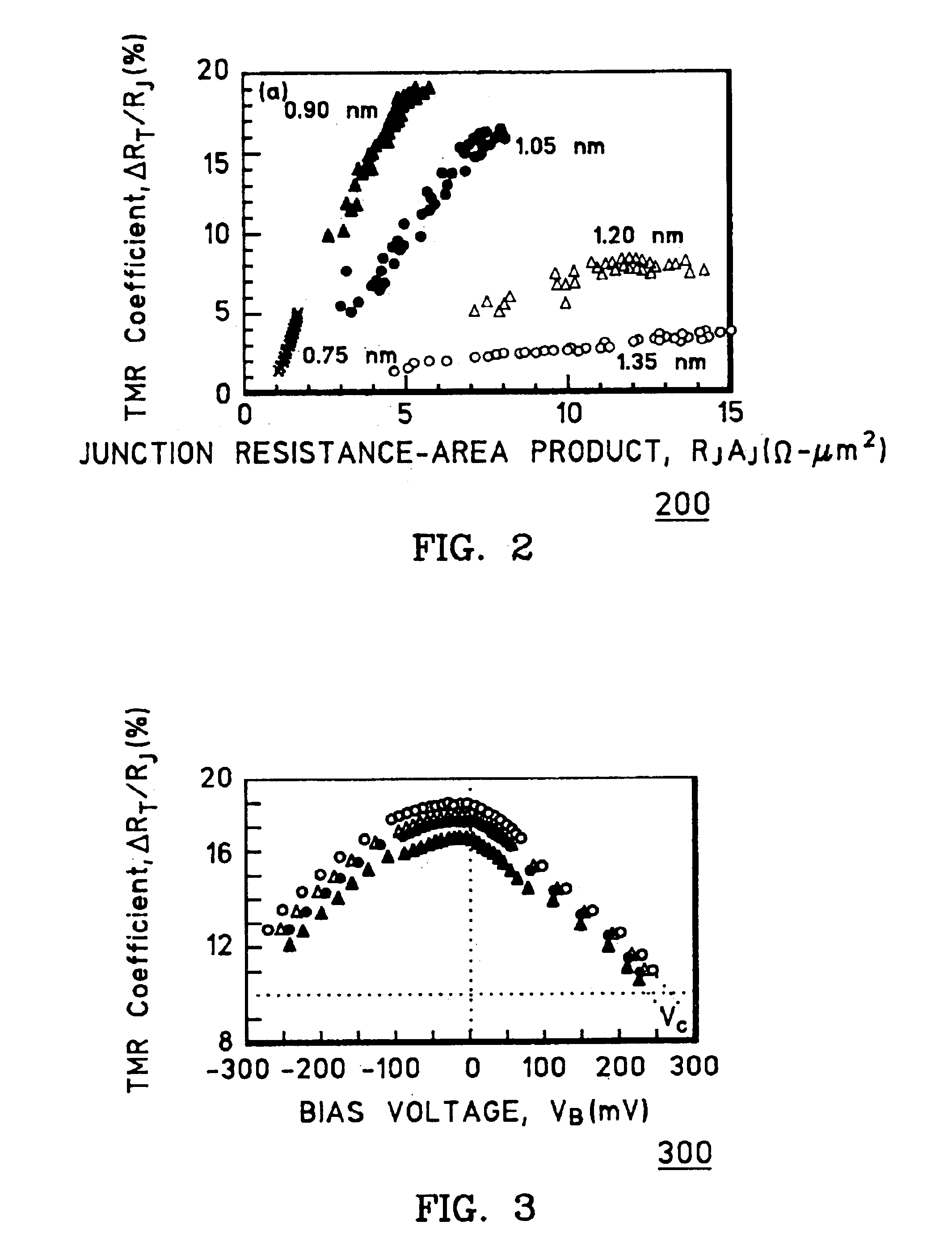

Method of forming a barrier layer of a tunneling magnetoresistive sensor

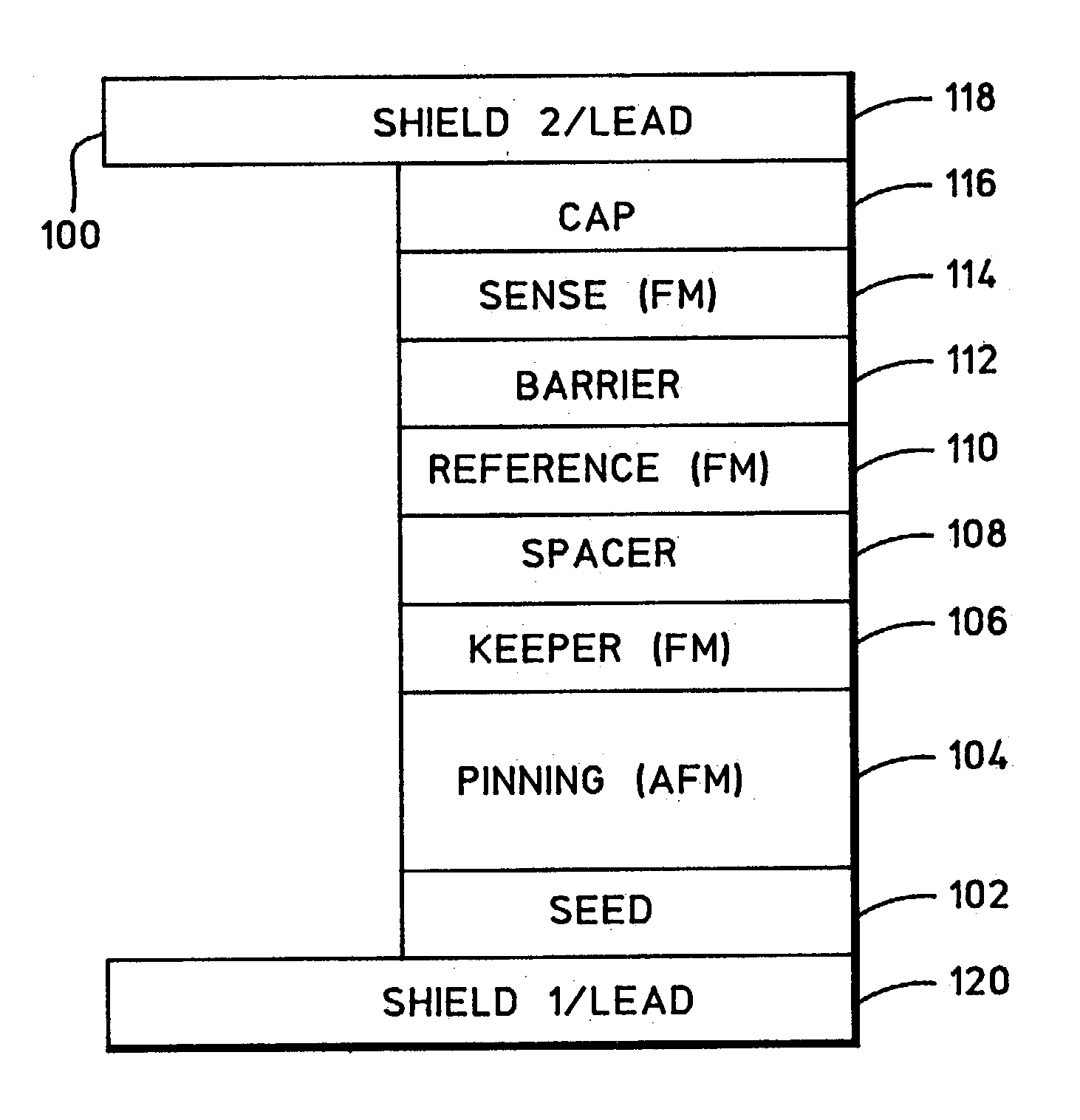

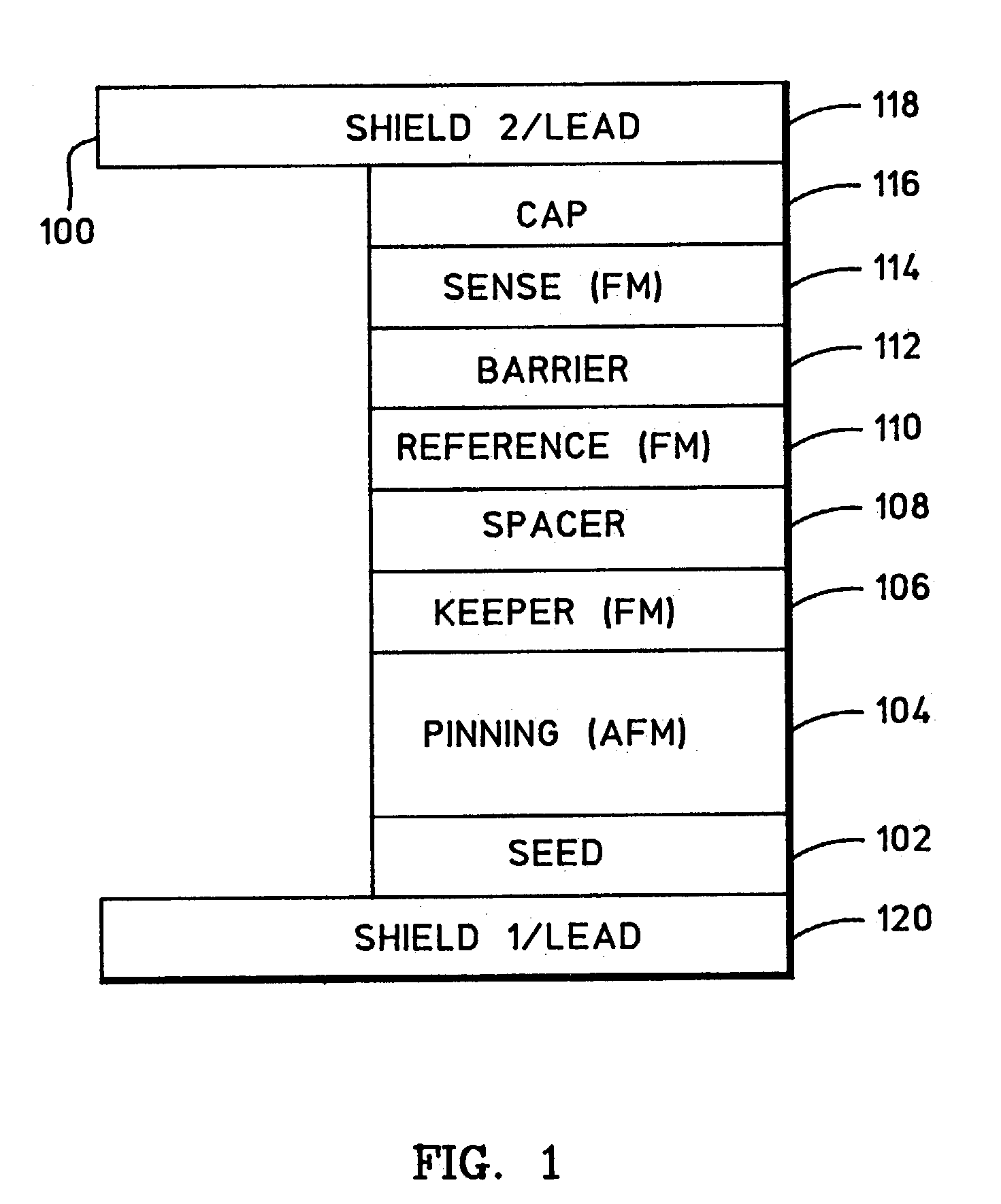

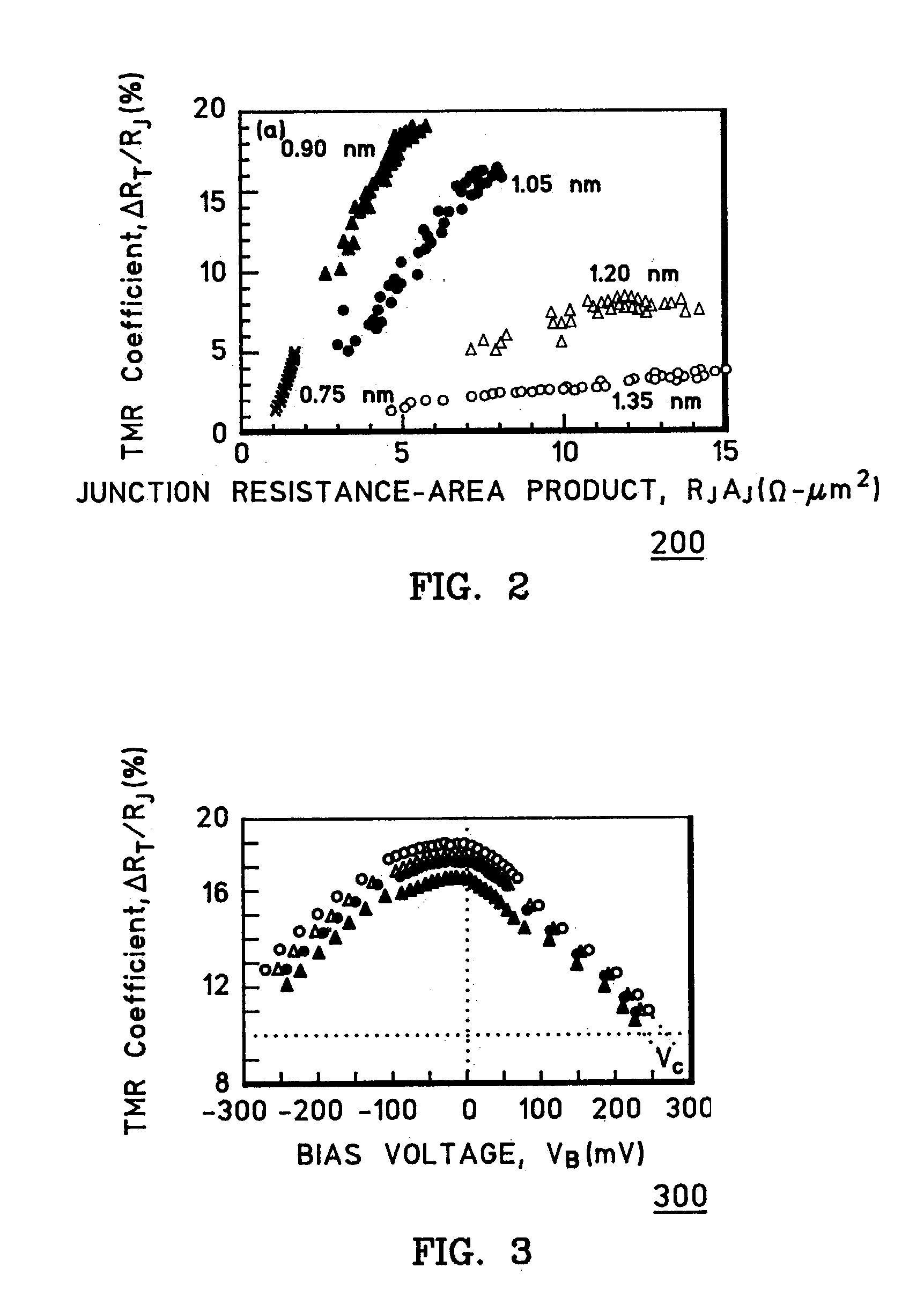

A fabrication process for a tunneling magnetoresistance (TMR) sensor is disclosed. In particular, a unique method of forming a barrier layer of the TMR sensor is utilized so that the TMR sensor exhibits good magnetic and TMR properties. In one particular example, the barrier layer is formed by depositing a metallic film in an argon gas in a DC magnetron sputtering module, depositing an oxygen-doped metallic film in mixed xenon and oxygen gases in an ion-beam sputtering module, and oxidizing these films in an oxygen gas in an oxygen treatment module. This three-step barrier layer formation process minimizes oxygen penetration into ferromagnetic (FM) sense and pinned layers of the TMR sensor and optimally controls oxygen doping into the barrier layer. As a result, the FM sense and pinned layers exhibit controlled magnetic properties, the barrier layer provides a low junction resistance-area product, and the TMR sensor exhibits a high TMR coefficient.

Owner:GLOBALFOUNDRIES INC

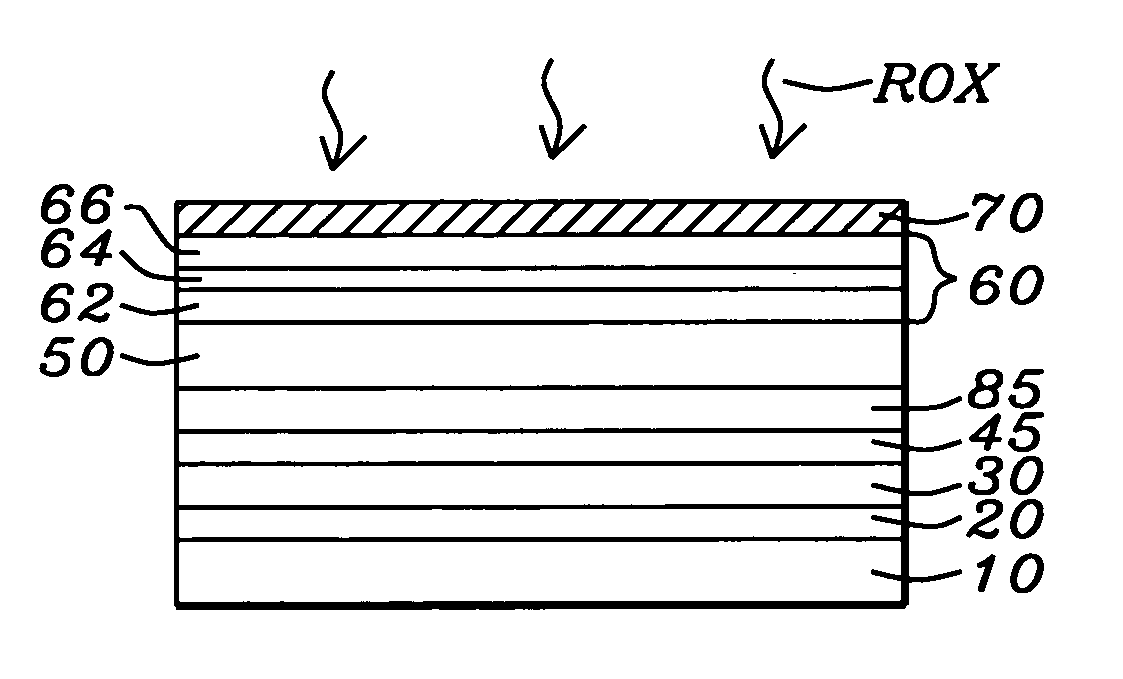

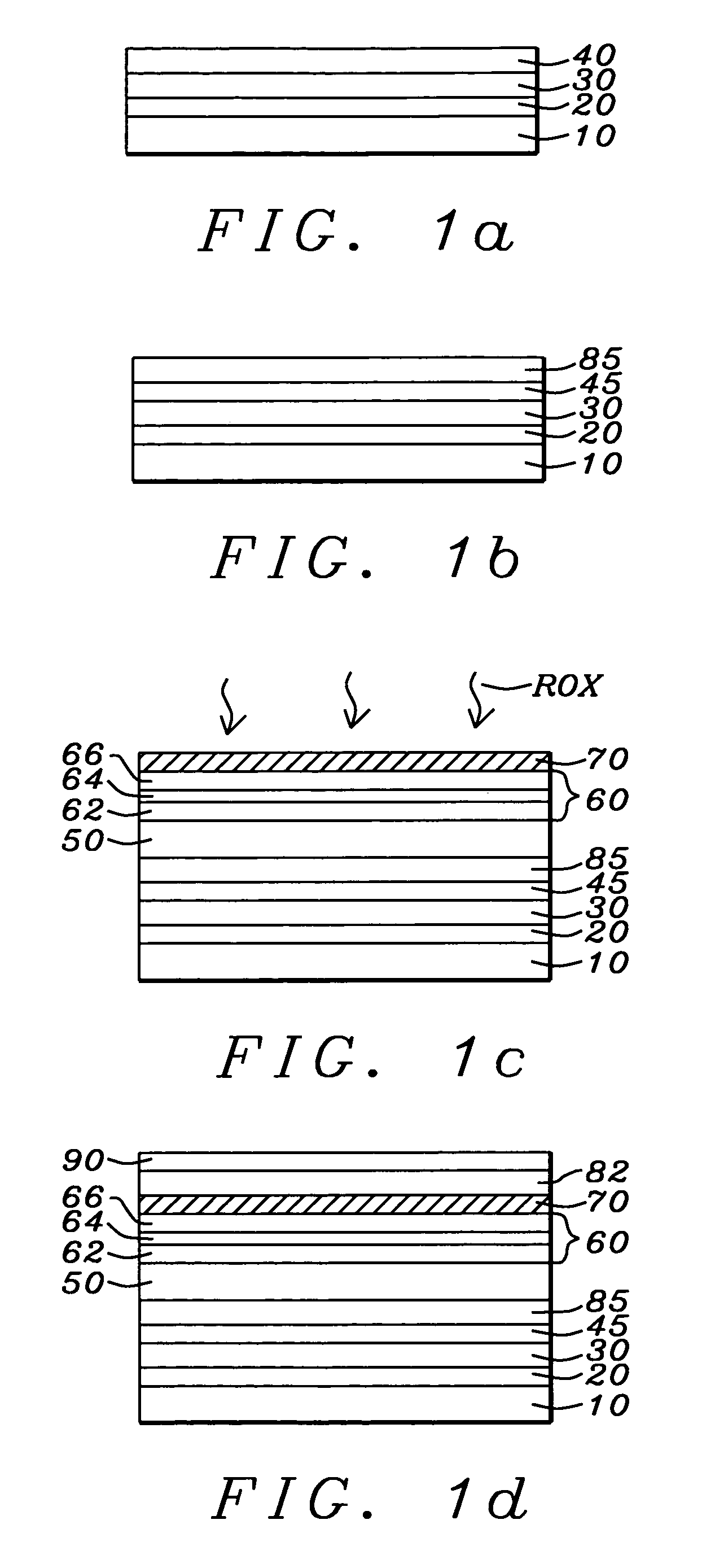

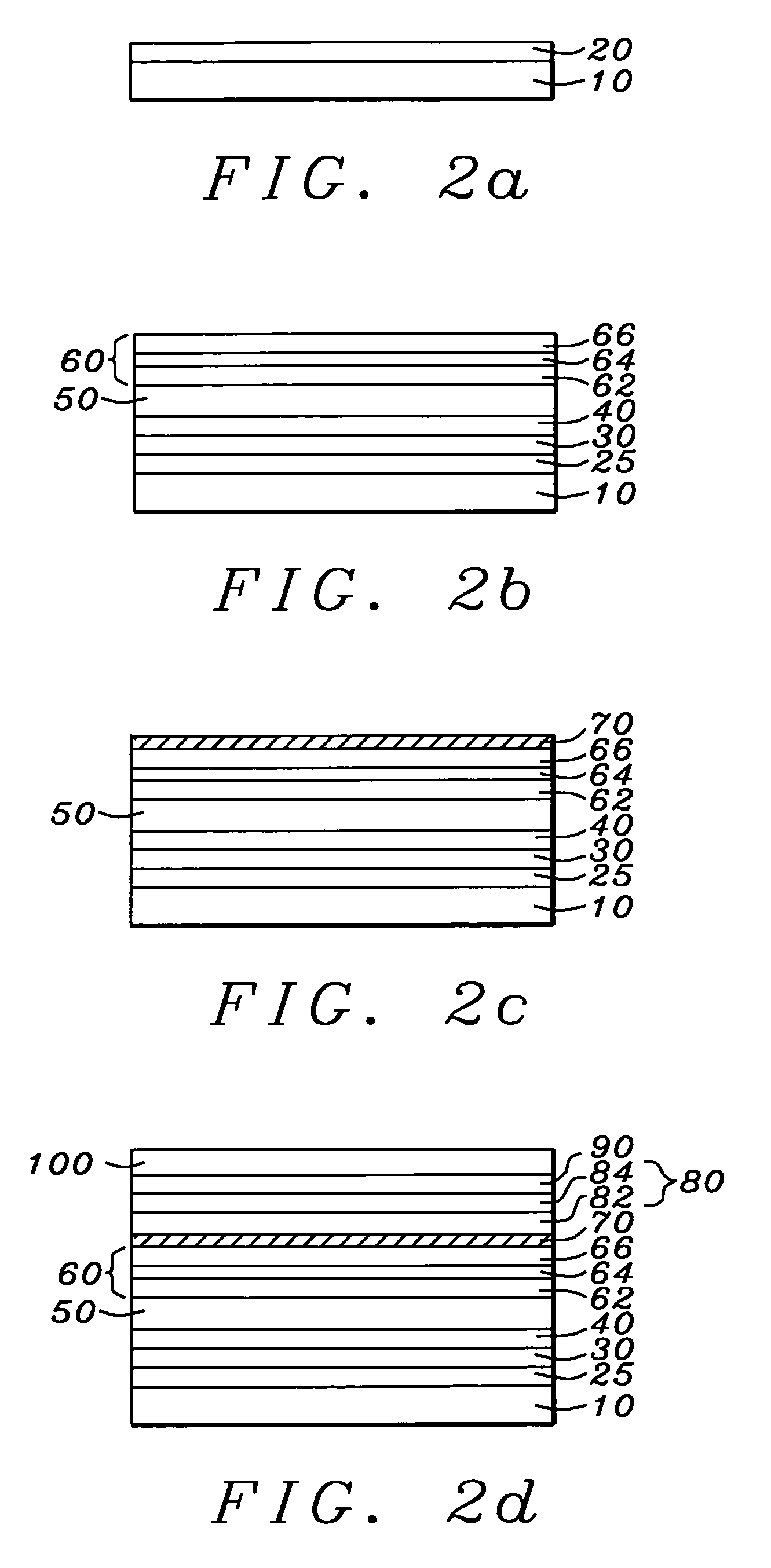

Method of forming a magnetic tunneling junction (MTJ) MRAM device and a tunneling magnetoresistive (TMR) read head

ActiveUS6960480B1Easy to controlSignificant exchangeNanostructure applicationNanomagnetismRandom access memoryThin layer

An MTJ (magnetic tunneling junction) device particularly suitable for use as an MRAM (magnetic random access memory) or a tunneling magnetoresistive (TMR) read sensor, is formed on a seed layer which allows the tunneling barrier layer to be ultra-thin, smooth, and to have a high breakdown voltage. The seed layer is a layer of NiCr which is formed on a sputter-etched layer of Ta. The tunneling barrier layer for the MRAM is formed from a thin layer of Al which is radically oxidized (ROX), in-situ, to form the layer with characteristics described above. The tunneling barrier layer for the read sensor formed from a thin layer of Al or a HfAl bilayer which is naturally oxidized (NOX), in situ, to form the barrier layer. The resulting device has generally improved performance characteristics in terms of GMR ratio and junction resistance.

Owner:APPLIED SPINTRONICS +1

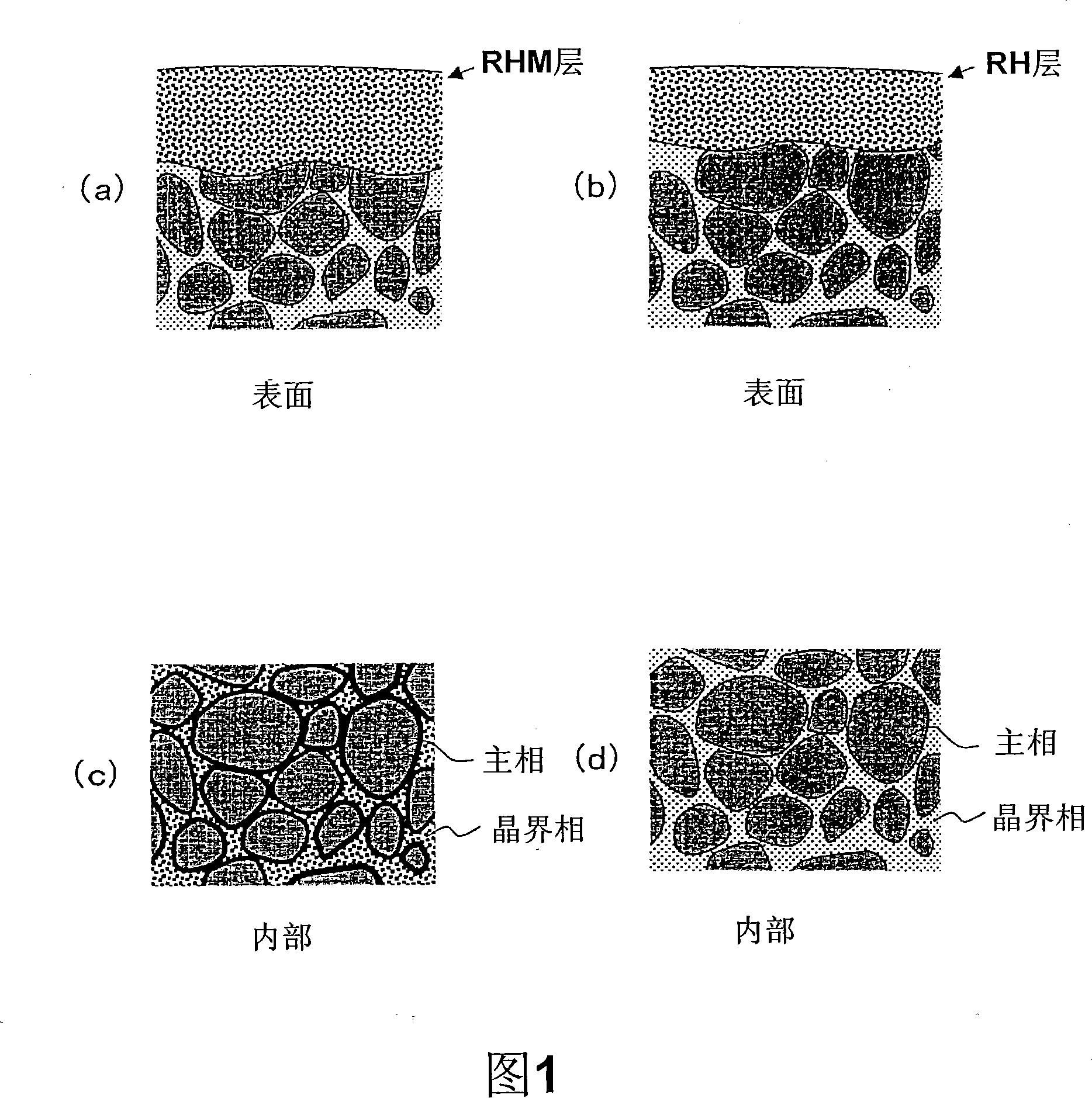

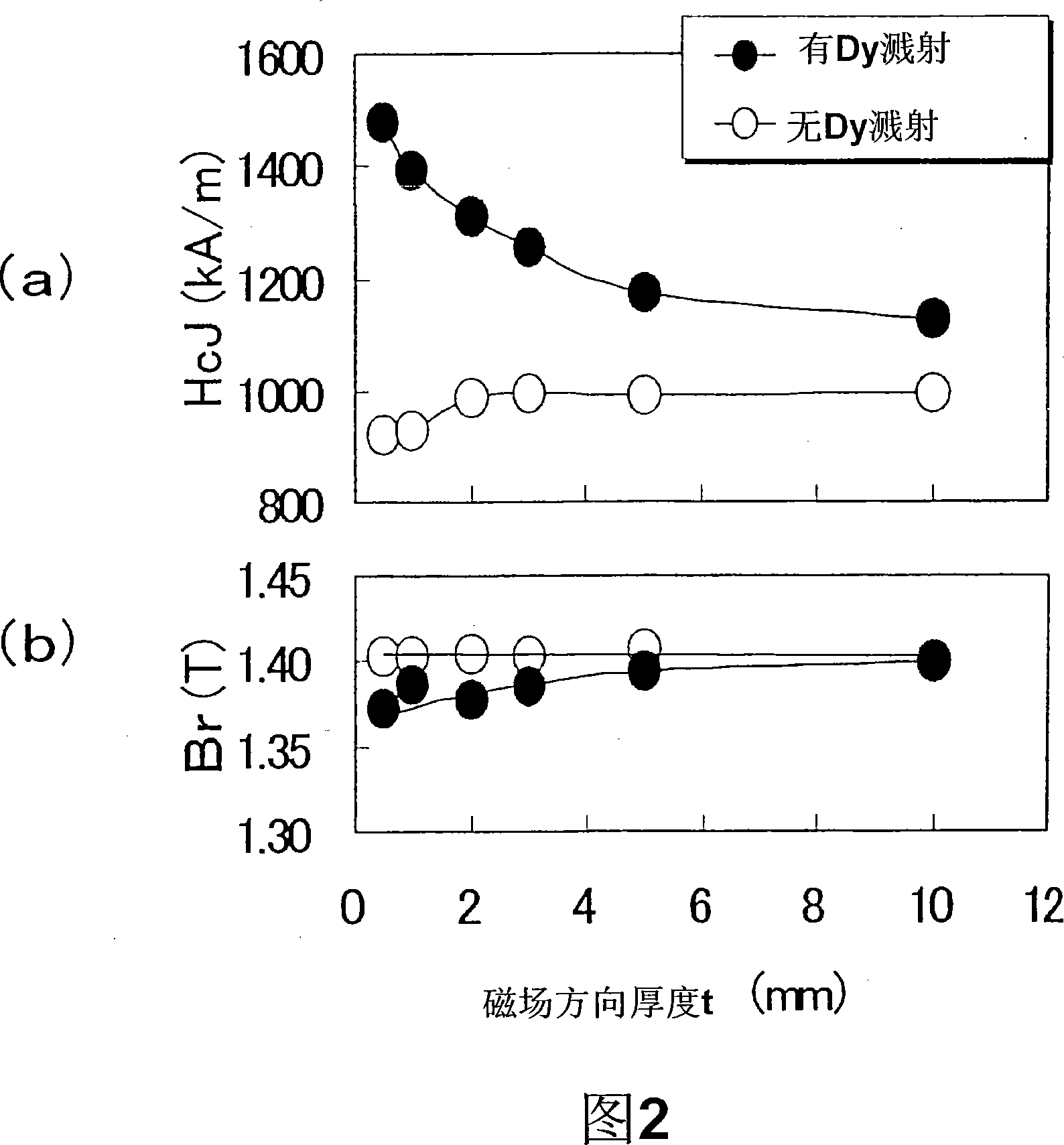

Rare earth sintered magnet and process for producing the same

ActiveCN101006534APhenomena that promote grain boundary diffusionEfficient replacementLiquid applicationPermanent magnetsRare-earth elementSintered magnets

Owner:HITACHI METALS LTD

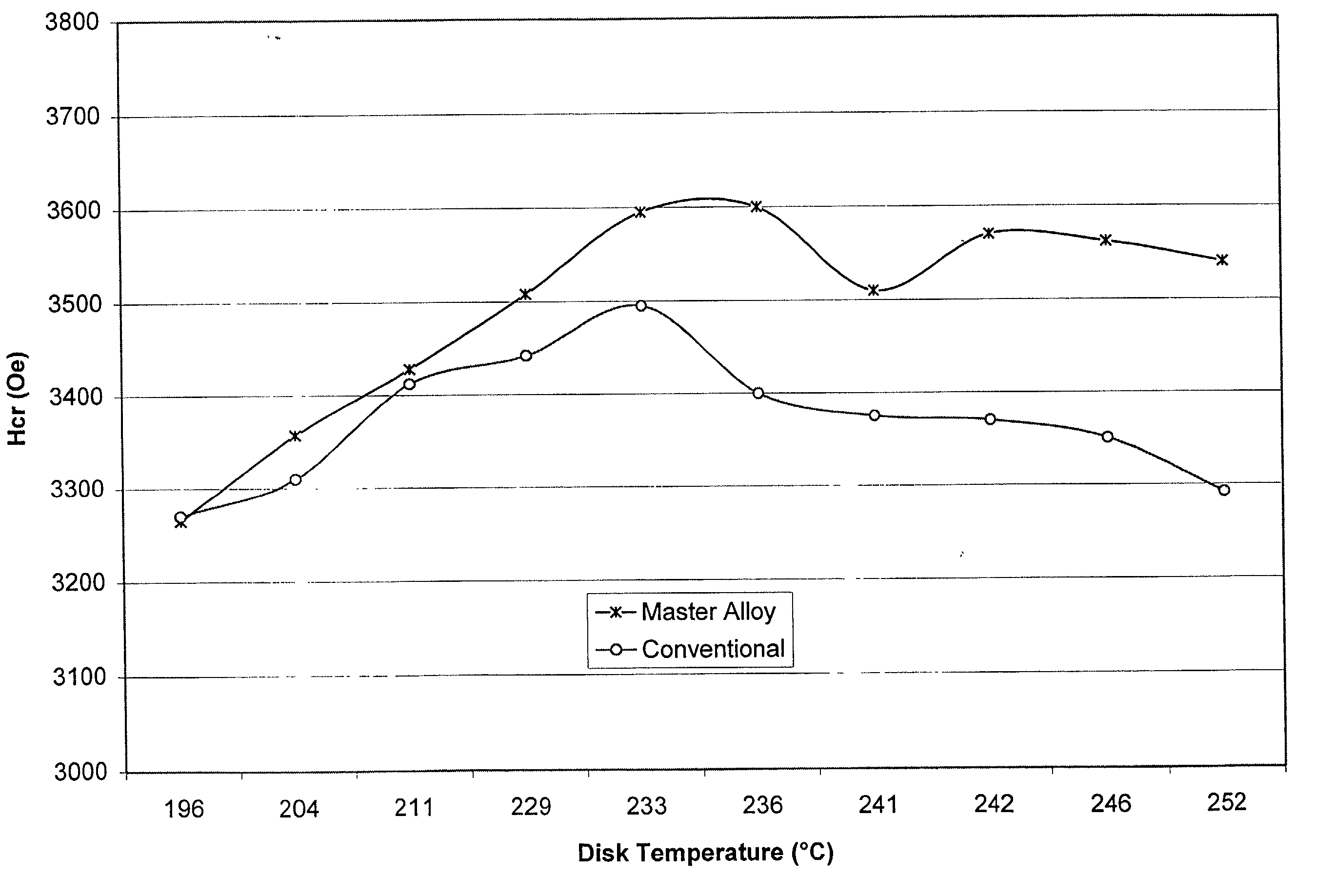

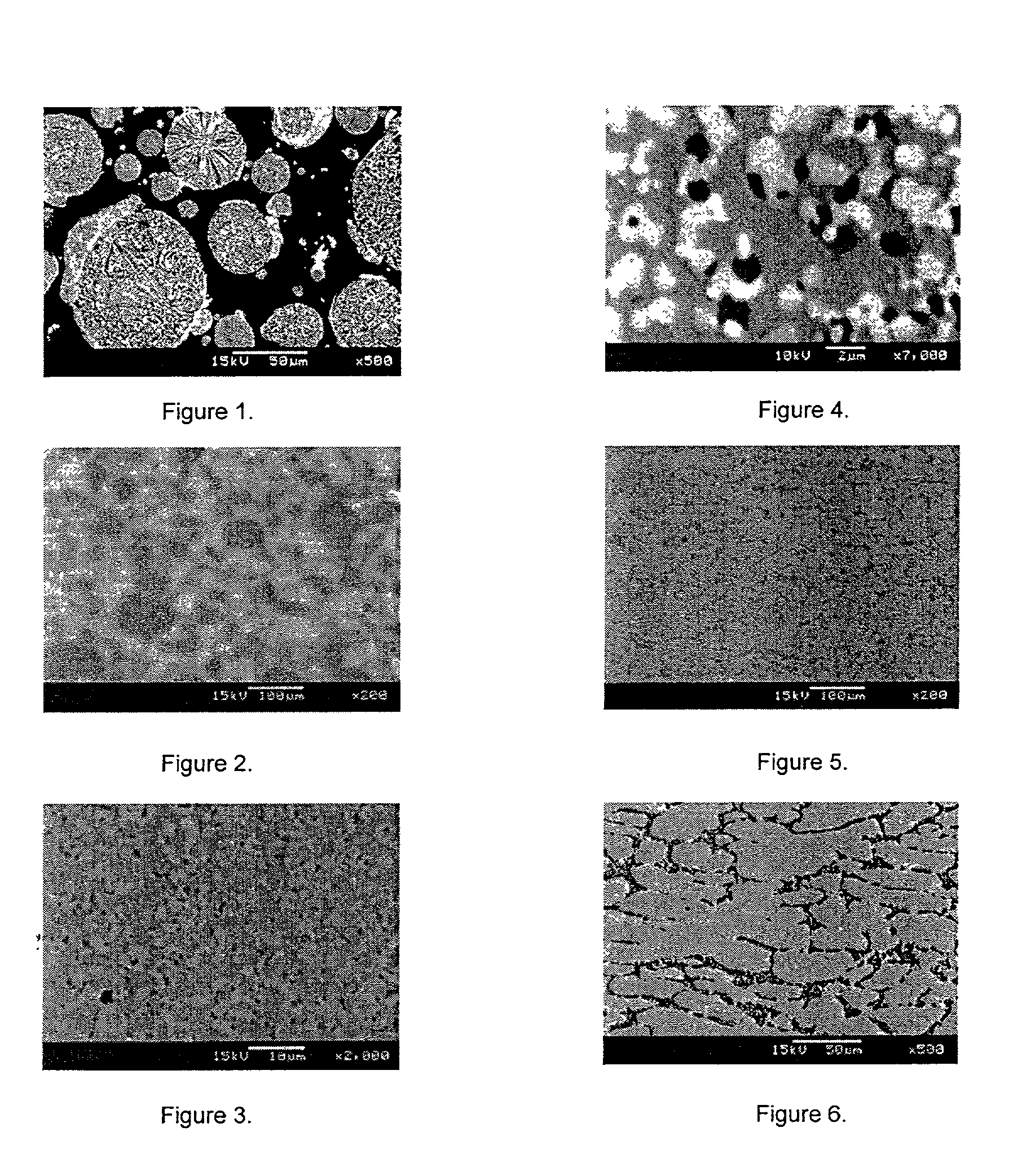

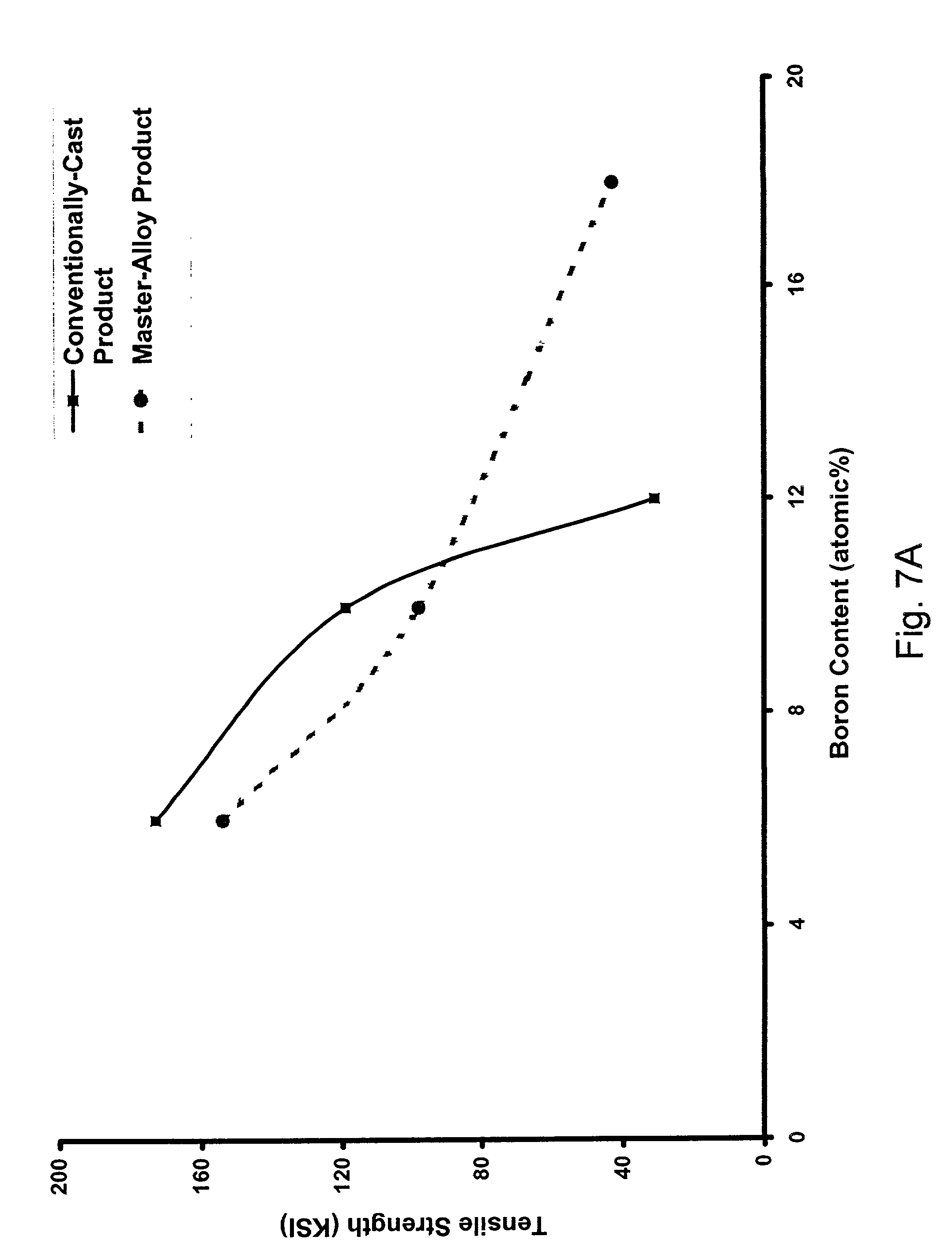

Mechanically alloyed precious metal magnetic sputtering targets fabricated using rapidly solidified alloy powders and elemental Pt metal

InactiveUS20020170821A1Improve featuresImprove manufacturabilityCellsVacuum evaporation coatingPlatinumAlloy

A cobalt-chromium-boron-platinum sputtering target alloy having multiple phases. The alloy can include Cr, B, Ta, Nb, C, Mo, Ti, V, W, Zr, Zn, Cu, Hf, O, Si or N. The alloy is prepared by mixing Pt powder with a cobalt-chromium-boron master alloy, ball milling the powders and HIP'ing to densify the powder into the alloy.

Owner:HERAEUS INC

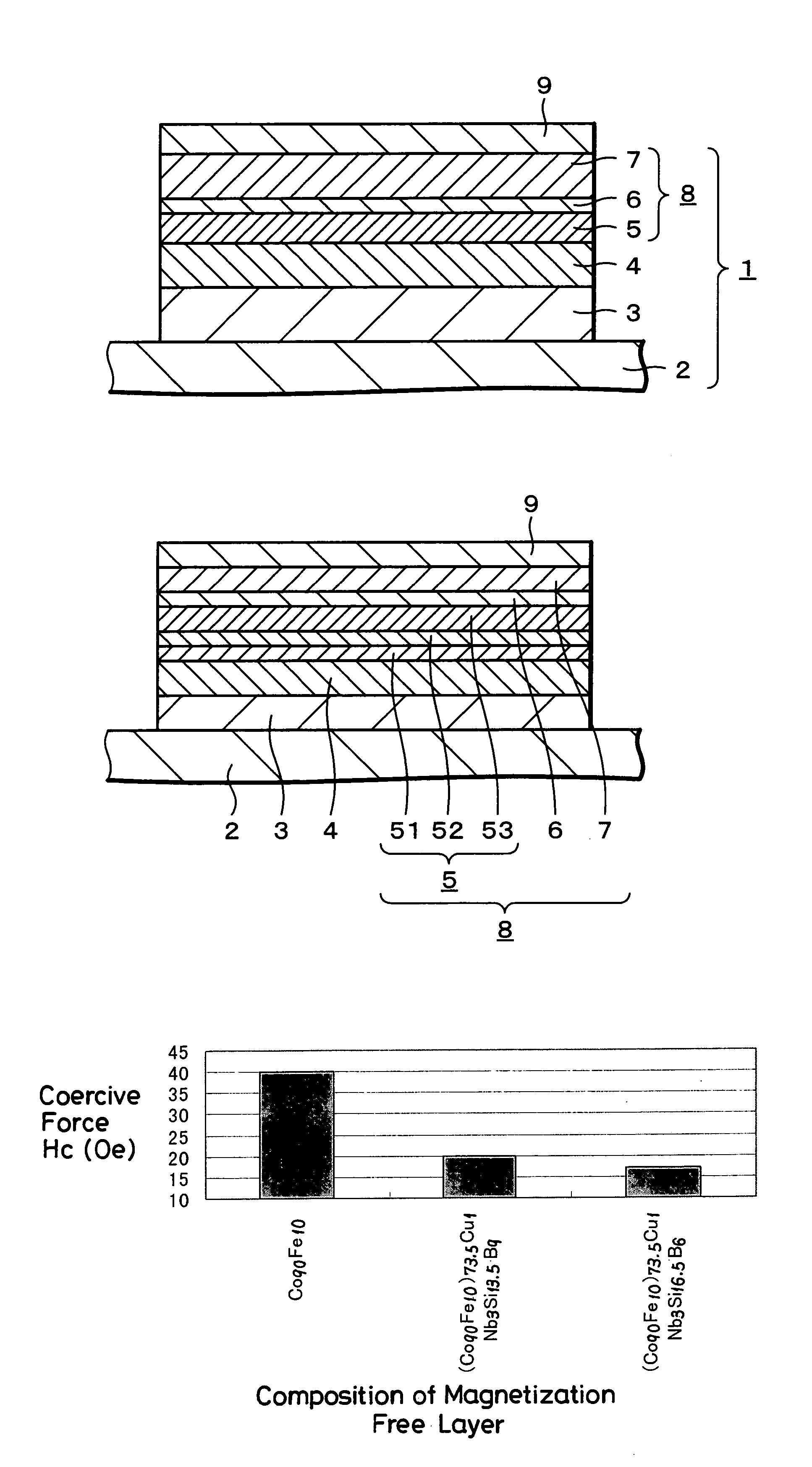

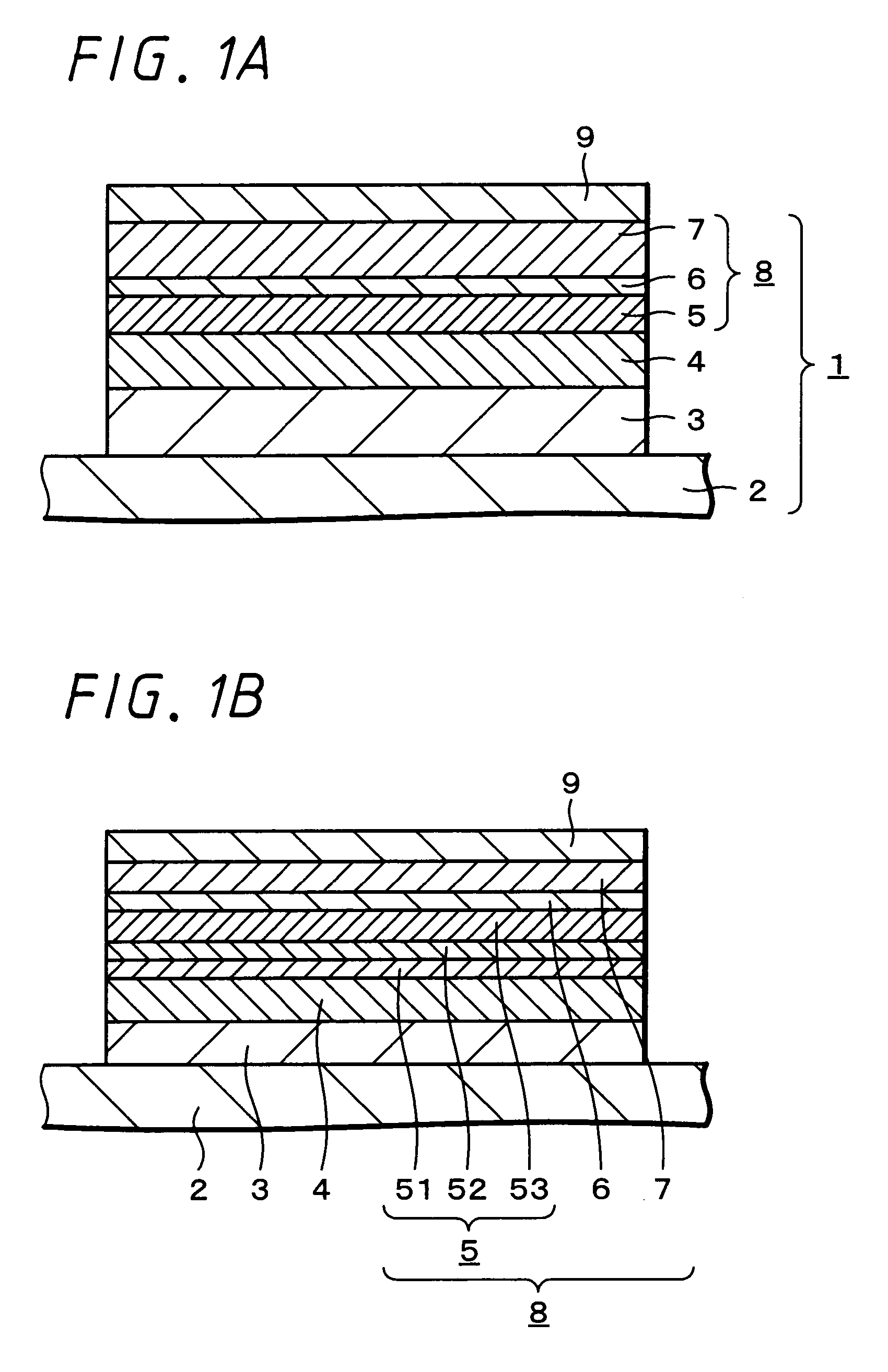

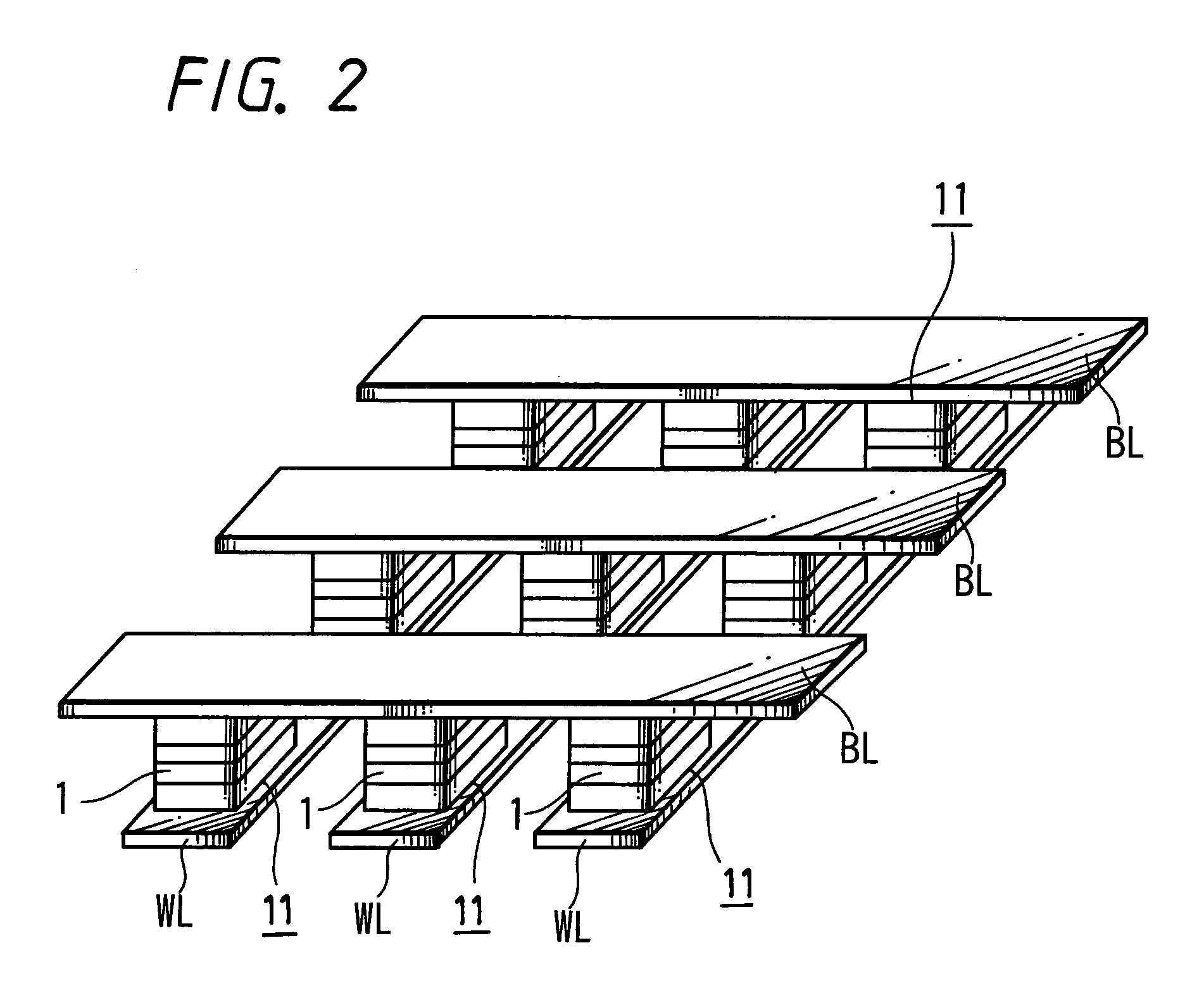

Magnetoresistive effect element, magnetic memory element magnetic memory device and manufacturing methods thereof

InactiveUS7262064B2Low coercivityBarkhausen noise increaseNanostructure applicationNanomagnetismMagnetic memoryTunnel junction

In a magnetoresistive effect element using a ferromagnetic tunnel junction having a tunnel barrier layer sandwiched between at least a pair of ferromagnetic layers, a magnetization free layer comprising one of the ferromagnetic layers is composed of a single layer of a material having an amorphous or microcrystal structure or a material layer the main portion of which has an amorphous or microcrystal structure. The magnetoresistive effect element can produce excellent magnetic-resistance characteristics, and a magnetic memory element and a magnetic memory device using the magnetoresistive effect element as a memory element thereof can improve both of write and read characteristics at the same time.

Owner:SONY CORP

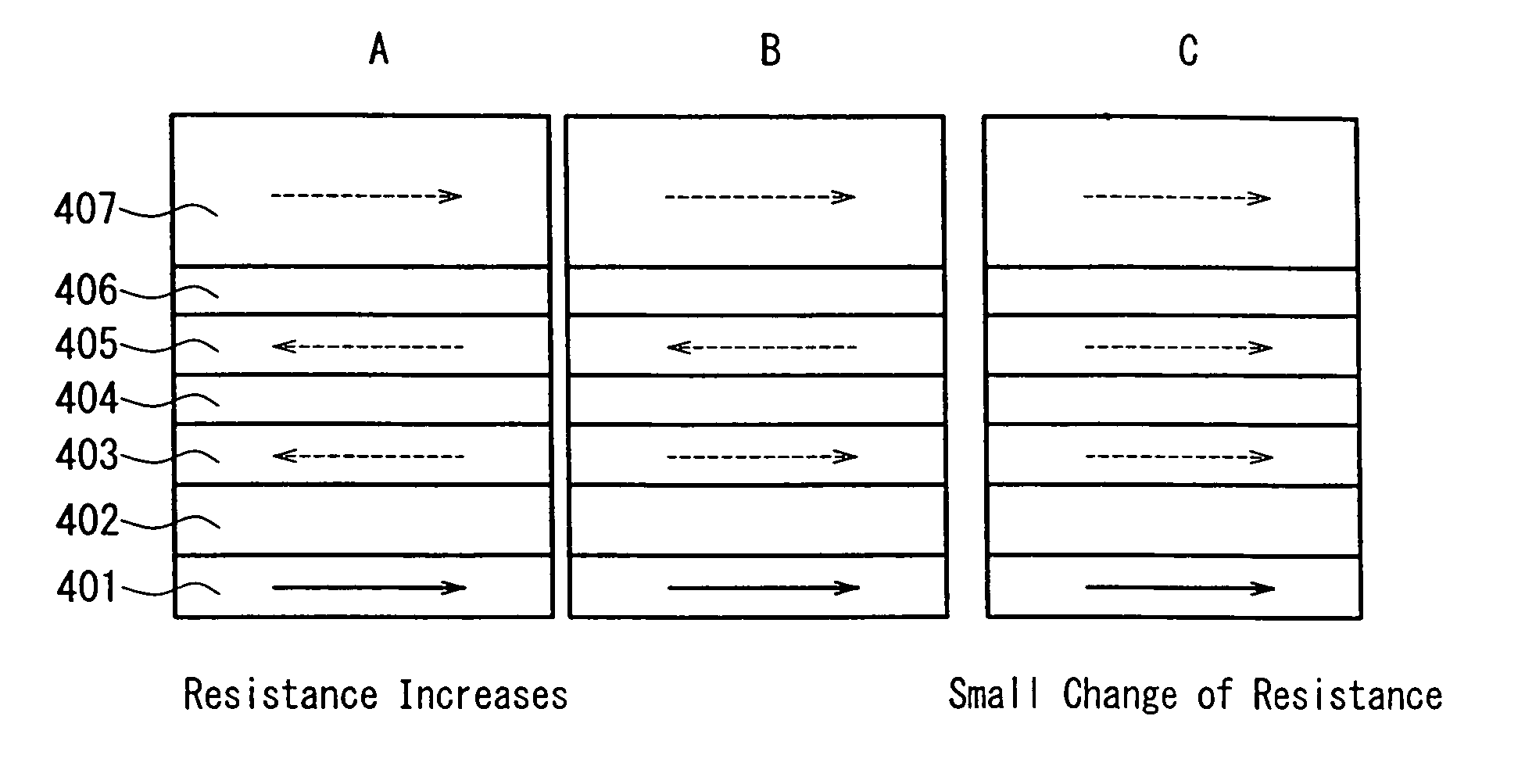

Process and structure to fabricate CPP spin valve heads for ultra-high recording density

InactiveUS7256971B2Raise the ratioIncrease resistanceNanostructure applicationNanomagnetismDopantElectrical resistance and conductance

A CPP-GMR spin value sensor structure with an improved MR ratio and increased resistance is disclosed. All layers except certain pinned layers, copper spacers, and a Ta capping layer are oxygen doped by adding a partial O2 pressure to the Ar sputtering gas during deposition. Oxygen doped CoFe free and pinned layers are made slightly thicker to offset a small decrease in magnetic moment caused by the oxygen dopant. Incorporating oxygen in the MnPt AFM layer enhances the exchange bias strength. An insertion layer such as a nano-oxide layer is included in one or more of the free, pinned, and spacer layers to increase interfacial scattering. The thickness of all layers except the copper spacer may be increased to enhance bulk scattering. A CPP-GMR single or dual spin valve of the present invention has up to a threefold increase in resistance and a 2 to 3% increase in MR ratio.

Owner:HEADWAY TECH INC

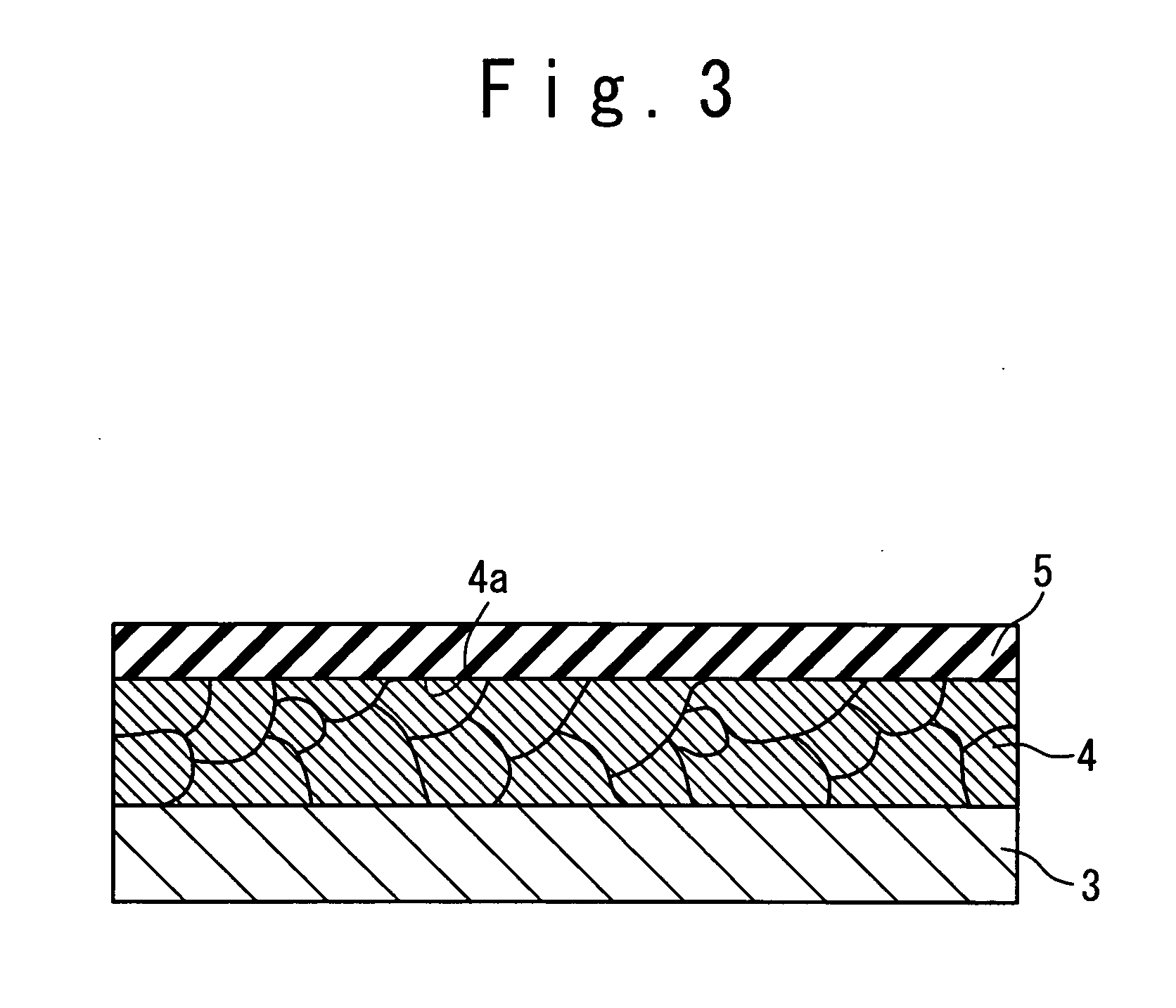

Magnetoresistive device and method for manufacturing same

ActiveUS20050219769A1Improve heat resistanceInhibitionNanomagnetismNanoinformaticsHeat resistanceMagnetic reluctance

The heat resistance of a magnetic resistance device utilizing the TMR effect is improved. Also, the Neel effect of the magnetic resistance device utilizing the TMR effect is restrained. The magnetic resistance device includes a first ferromagnetic layer formed of ferromagnetic material, a non-magnetic insulative tunnel barrier layer coupled to the first ferromagnetic layer, a second ferromagnetic layer formed of ferromagnetic material and coupled to the tunnel barrier layer, and an anti-ferromagnetic layer formed of anti-ferromagnetic material. The second ferromagnetic layer is provided between the tunnel barrier layer and the anti-ferromagnetic layer. A perpendicular line from an optional position of the surface of the second ferromagnetic layer passes through at least two of the crystal grains of the second ferromagnetic layer.

Owner:NEC CORP

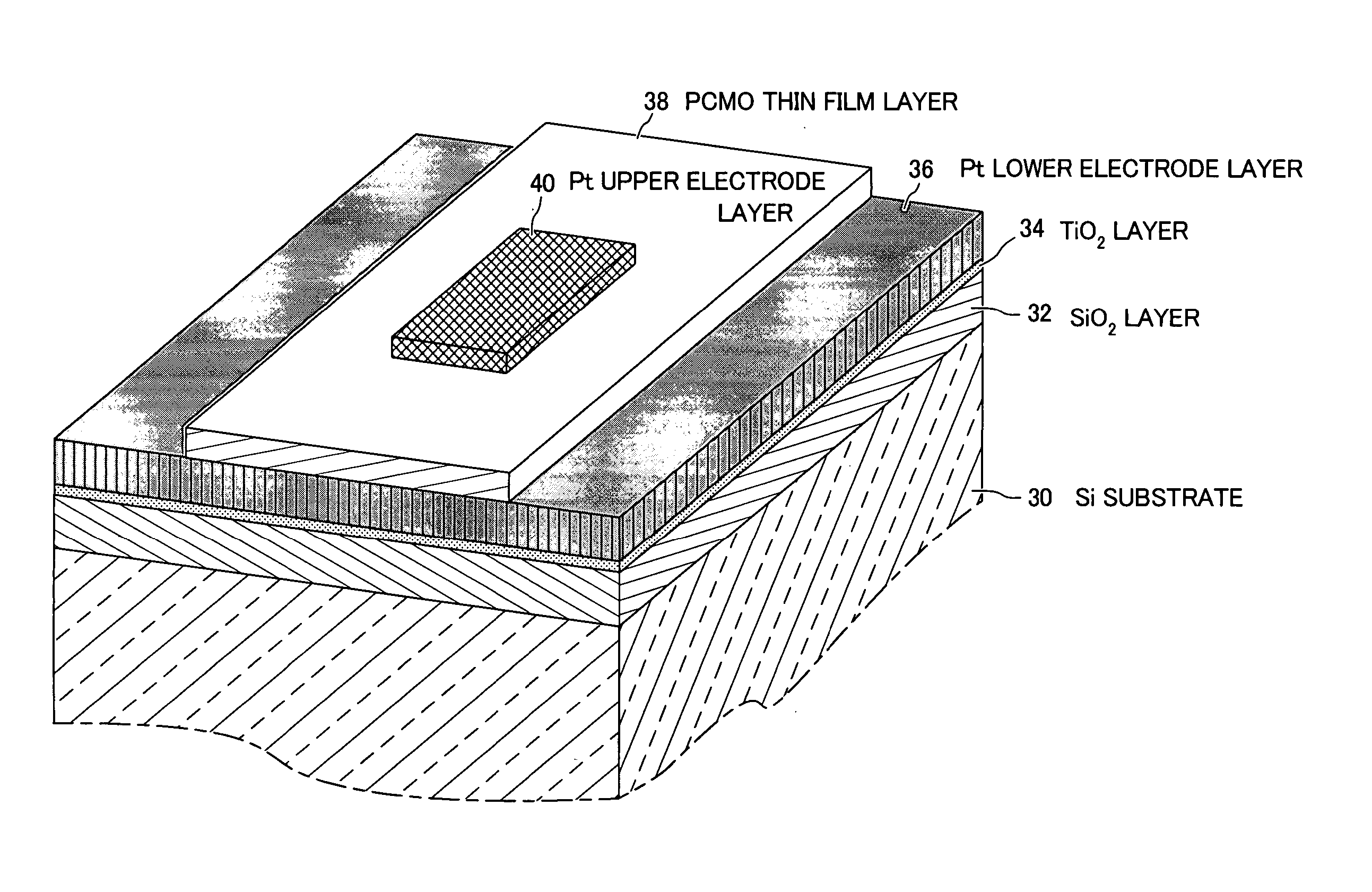

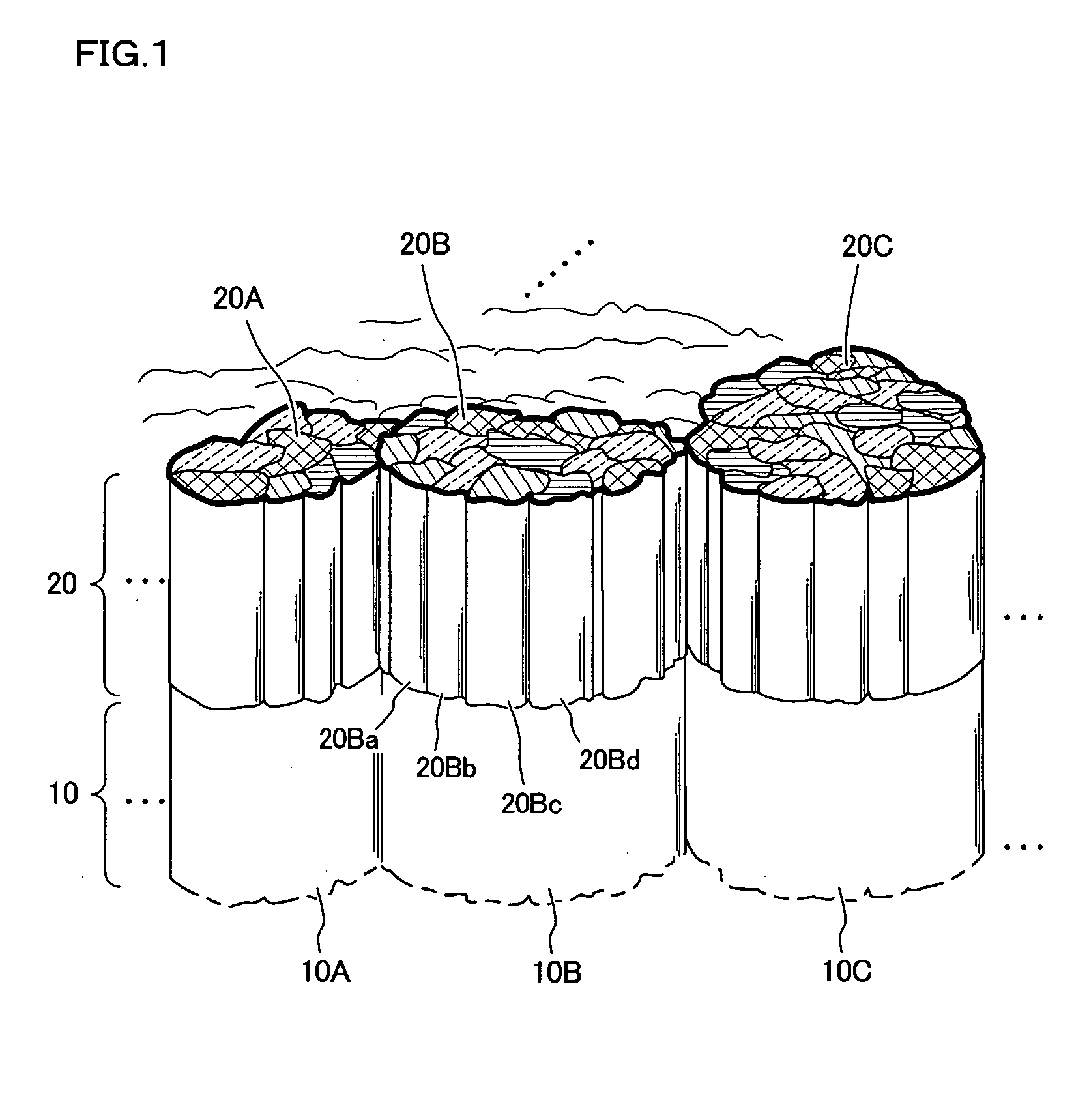

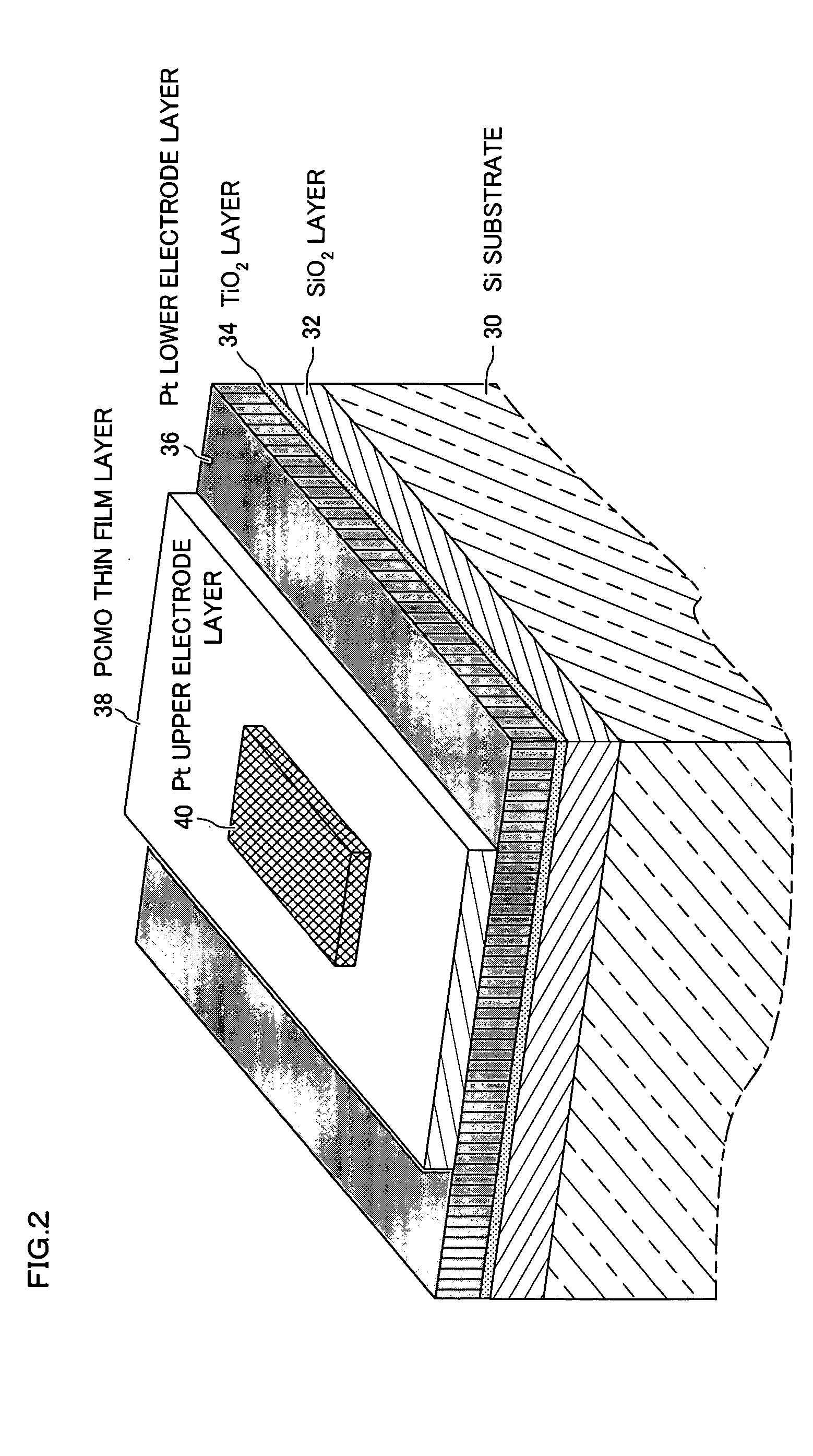

EPIR device and semiconductor devices utilizing the same

InactiveUS20050040482A1Improve batch productivityHigh in practical utilityTransistorNanoinformaticsSemiconductorSubstrate surface

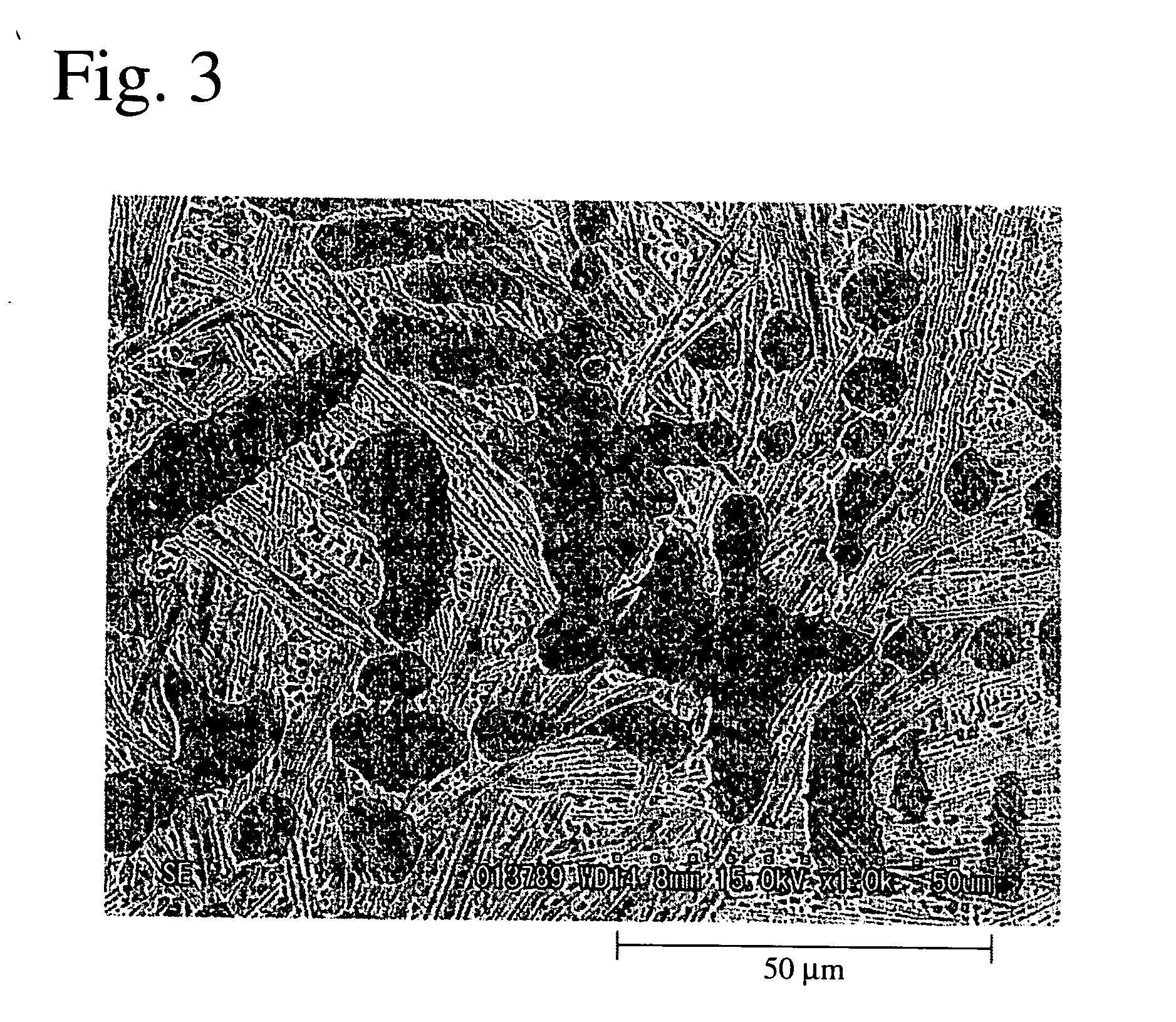

There is provided an EPIR device which is excellent in mass productivity and high in practical utility. The EPIR device includes a lower electrode layer, a CMR thin film layer and an upper electrode layer which are laminated in this order on any of various substrates. A Pt polycrystal thin film 10 forming the lower electrode layer includes columnar Pt crystal grains 10A, 10B, 10C, . . . and over 90% of these crystal grains is oriented to a (1 1 1) face. Columnar PCMO crystal grain groups 20A, 20B, 20C, . . . are respectively locally grown epitaxially on the respective outermost surfaces of the Pt crystal grains 10A, 10B, 10C, Then, the crystal faces of the crystal grains included in the PCMO crystal grain groups 20A, 20B, 20C, . . . and vertical in the substrate surface normal direction are any one of (1 0 0)p, (1 1 0)p and (1 1 1)p planes.

Owner:XENOGENIC DEV LLC

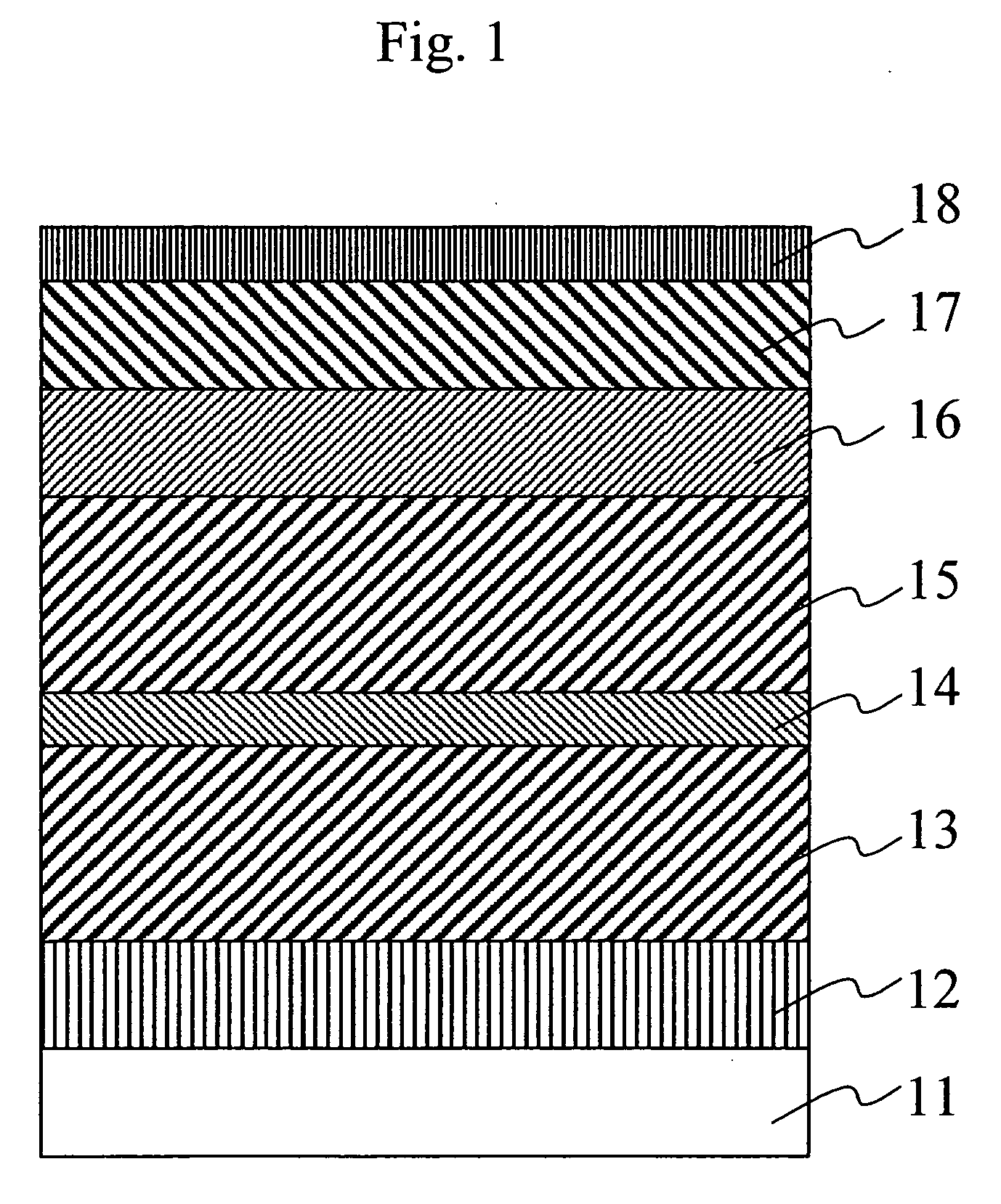

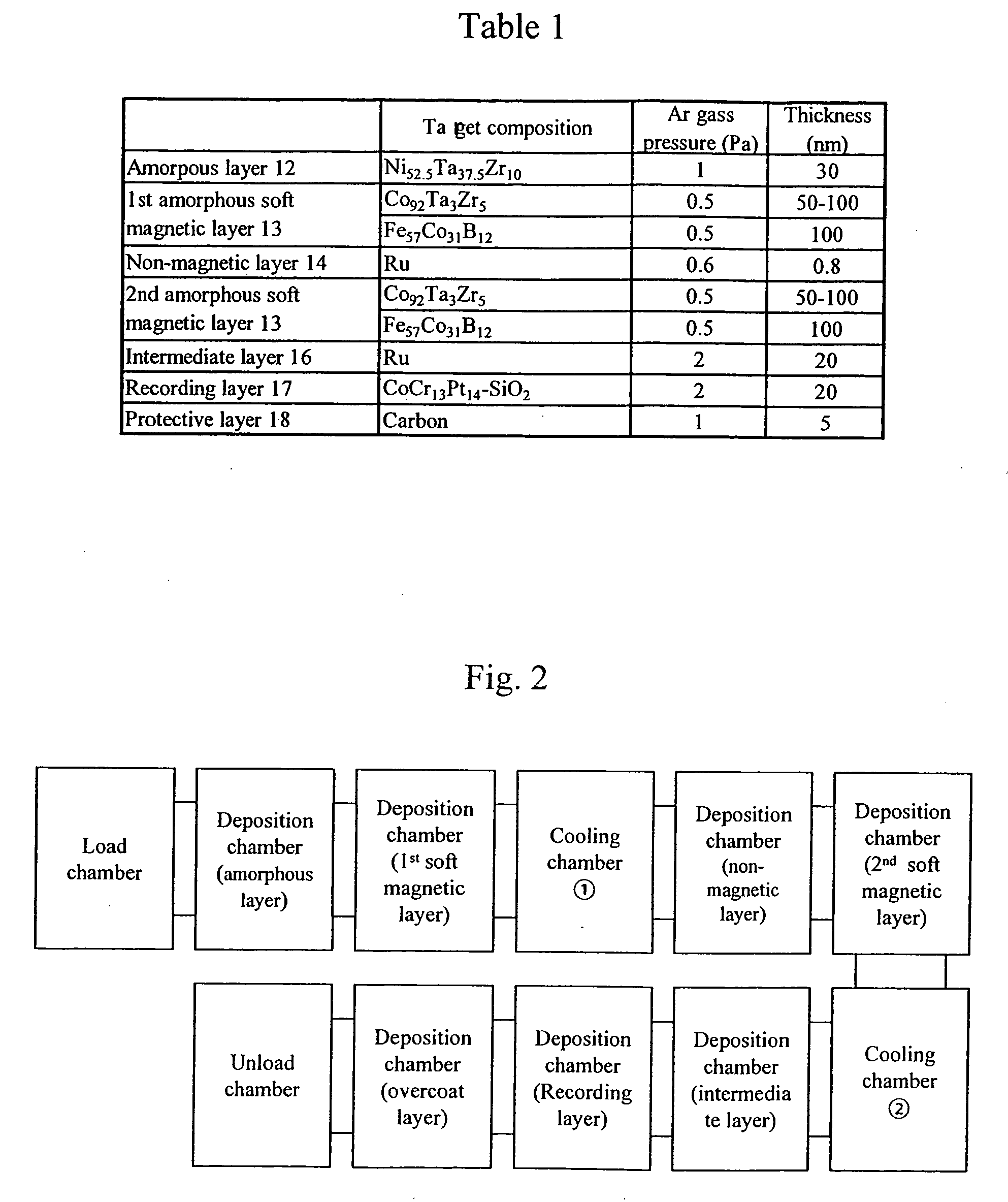

Perpendicular magnetic recording medium, manufacturing process of the same, and magnetic recording/reproducing apparatus using the same

ActiveUS20050244679A1Suppressing amplitude modulationSuppressing spike noiseMagnetic field orientationBase layers for recording layersSignal qualityAntiferromagnetic coupling

Embodiments of the invention provide a perpendicular magnetic recording medium improved for fly ability, high in read signal quality, and capable of suppressing magnetic decay of recorded magnetization to be caused by stray fields. In one embodiment, a perpendicular recording layer is formed over a substrate with a soft magnetic underlayer therebetween, then an amorphous or nano-crystalline layer is formed between the substrate and the soft magnetic underlayer. The soft magnetic underlayer includes first and second amorphous soft magnetic layers, as well as a nomnagnetic layer formed between those first and second amorphous soft magnetic layers. The first and second amorphous soft magnetic layers are given uniaxial anisotropy in the radial direction of the substrate respectively and coupled with each other antiferromagnetically.

Owner:WESTERN DIGITAL TECH INC

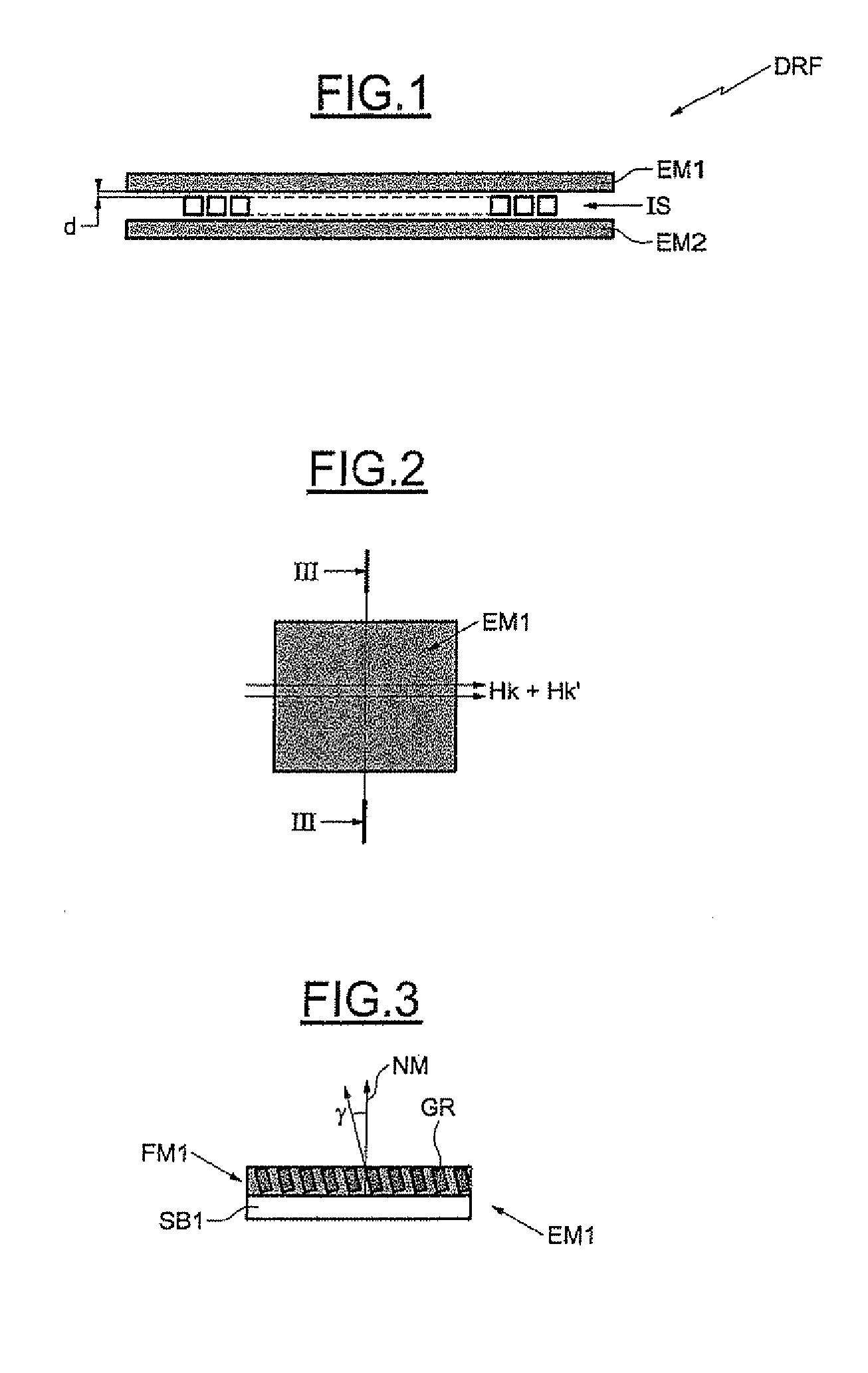

Thin-film magnetic device with strong spin polarization perpendicular to the plane of the layers, magnetic tunnel junction and spin valve using such a device

ActiveUS7813202B2Optimize spin polarizationImprove polarizationNanomagnetismMagnetic measurementsIn planeHigh rate

A thin-film magnetic device comprises, on a substrate, a composite assembly deposited by cathode sputtering and consists of a first layer made of a ferromagnetic material with a high rate of spin polarization, the magnetization of which is in plane in the absence of any electric or magnetic interaction, a second layer made of a magnetic material with high perpendicular anisotropy, the magnetization of which is outside the plane of said layer in the absence of any electric or magnetic interaction, and coupling of which with said first layer induces a decrease in the effective demagnetizing field of the entire device, a third layer that is in contact with the first layer via its interface opposite to that which is common to the second layer and made of a material that is not magnetic and not polarizing for electrons passing through the device.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

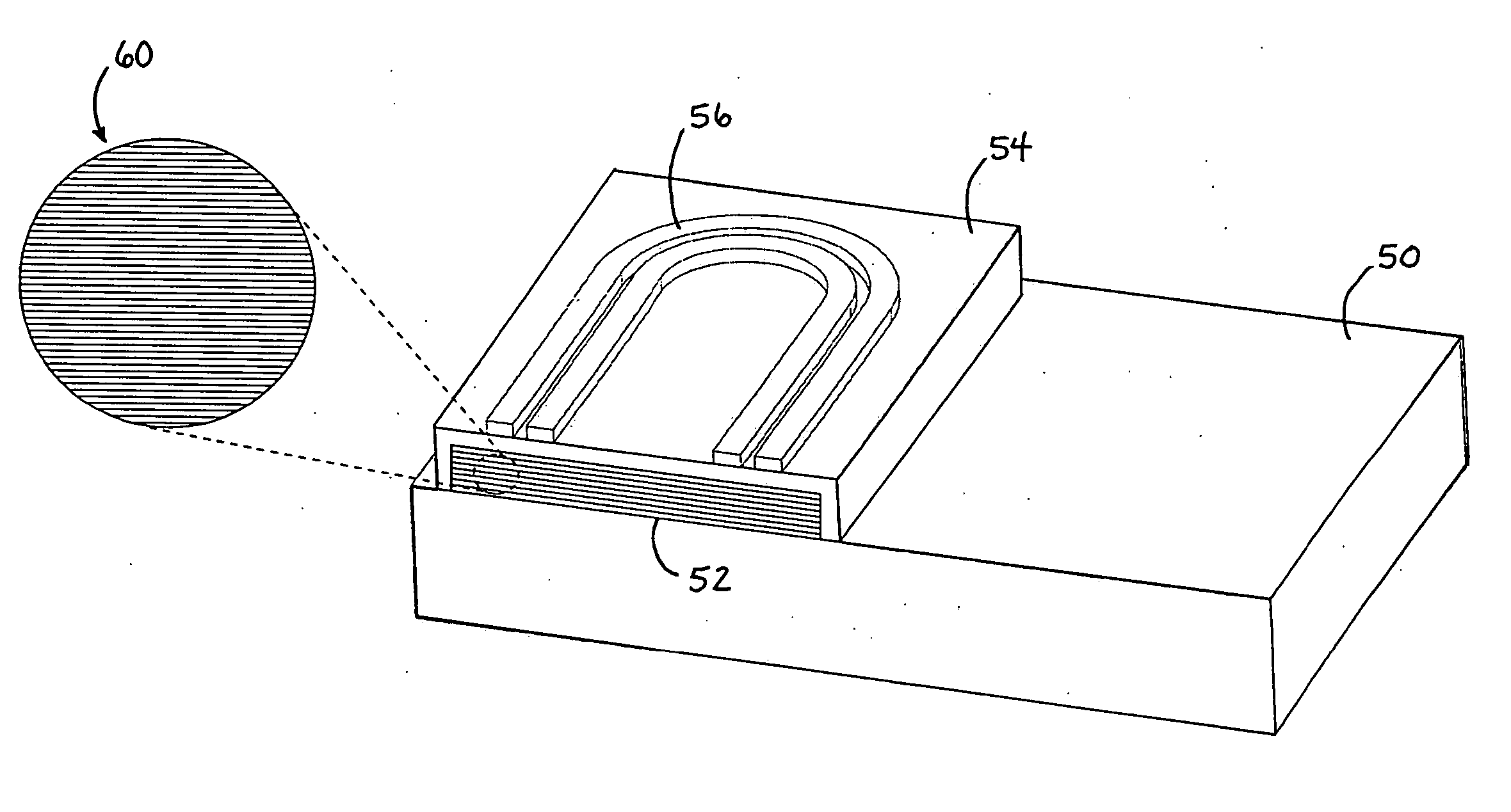

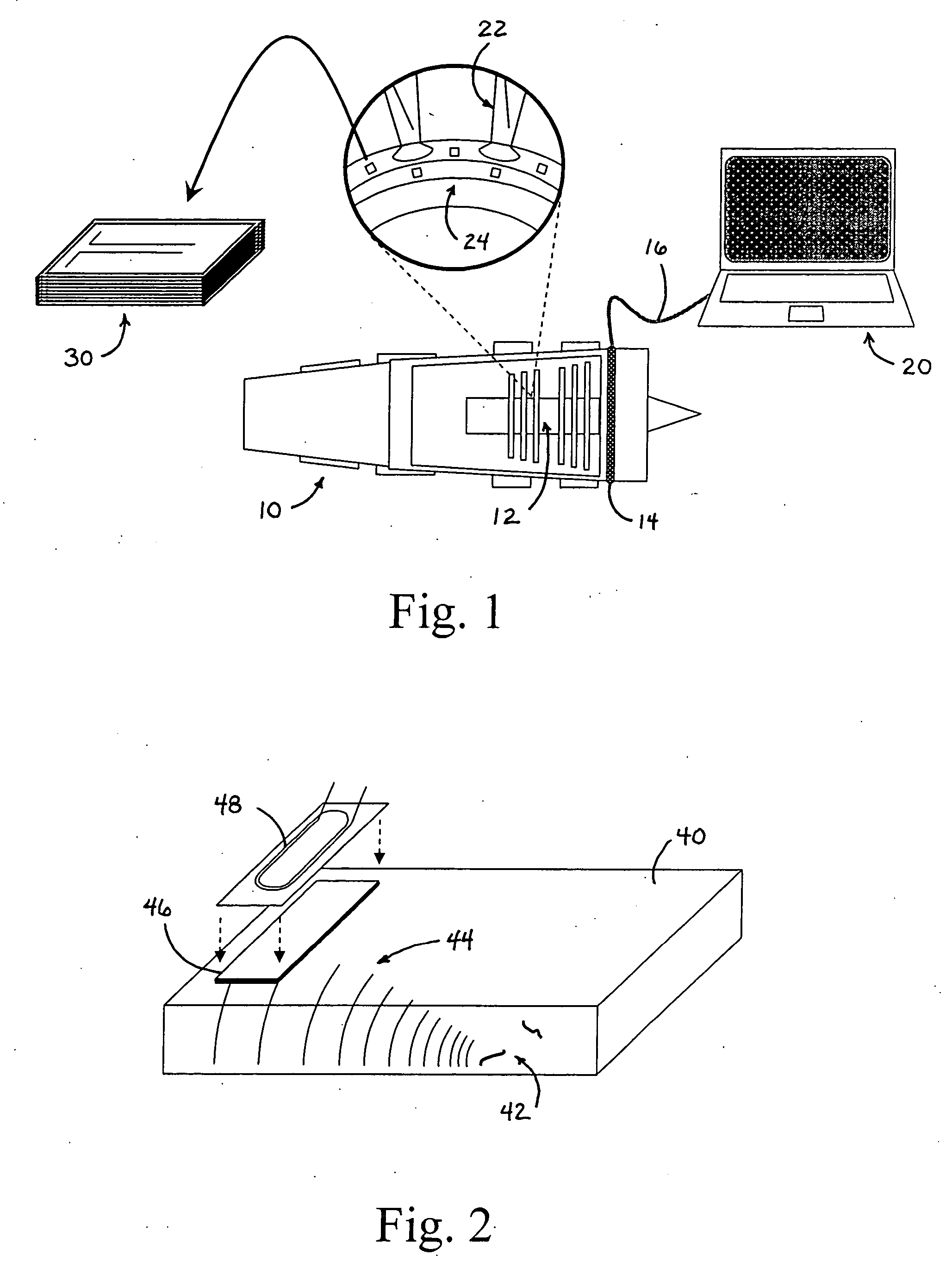

Systems & methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors

ActiveUS20070108973A1Effective structural health managementEffective prognosisNanomagnetismVacuum evaporation coatingThin film sensorElectricity

Systems and methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors. The sensor is a monolithically integrated, multi-layered (nano-composite), thin-film sensor structure that incorporates a thin-film, multi-layer magnetostrictive element, a thin-film electrically insulating or dielectric layer, and a thin-film activating layer such as a planar coil. The method for manufacturing the multi-layered, thin-film sensor structure as described above, utilizes a variety of factors that allow for optimization of sensor characteristics for application to specific structures and in specific environments. The system and method integrating the multi-layered, thin-film sensor structure as described above, further utilizes wireless connectivity to the sensor to allow the sensor to be mounted on moving components within the monitored assembly.

Owner:SOUTHWEST RES INST

Magnetoresistance effect device

InactiveUS20080055793A1High MR ratioImprove mass productionNanomagnetismMagnetic-field-controlled resistorsMolecular physicsMagnetic layer

A magnetoresistance effect device including a multilayer structure having a pair of ferromagnetic layers and a barrier layer positioned between them, wherein at least one ferromagnetic layer has at least the part contacting the barrier layer made amorphous and the barrier layer is an MgO layer having a highly oriented texture structure.

Owner:ANELVA CORP +1

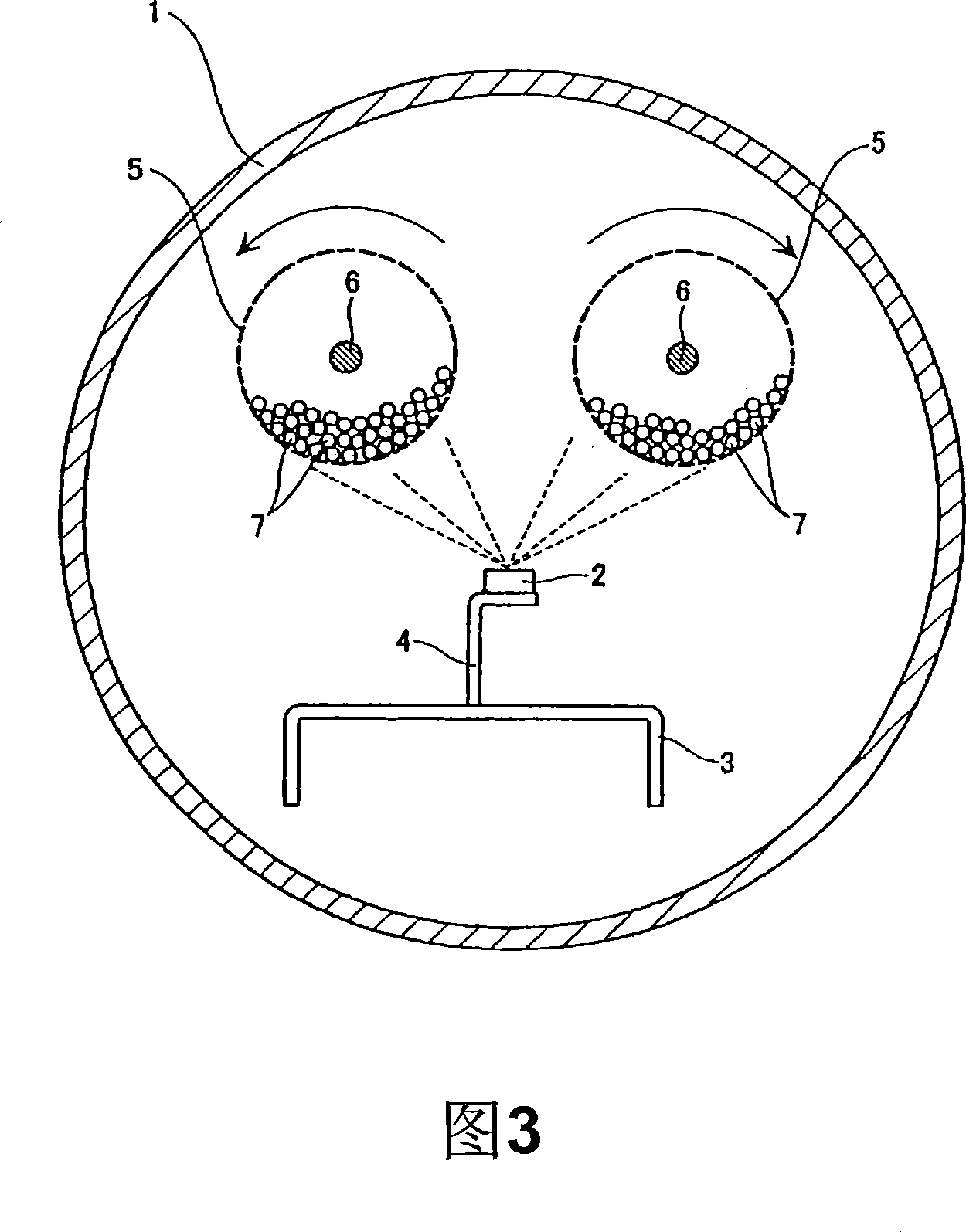

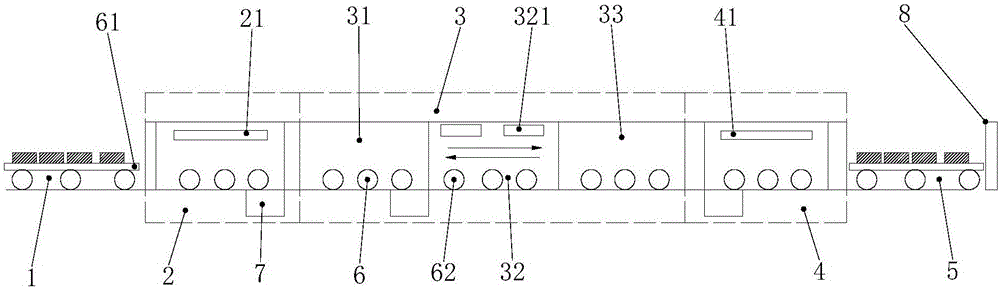

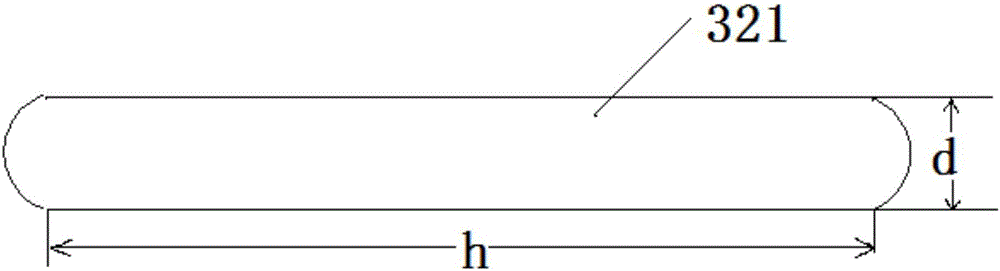

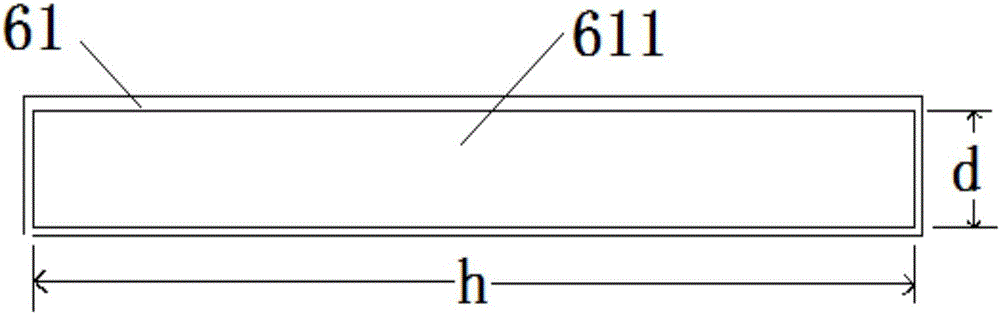

Coating method, coating system and method for preparing rare-earth magnet

ActiveCN106282948AImprove consistencyEffective thickness controlVacuum evaporation coatingSputtering coatingSputteringCoating system

The invention discloses a coating method, a coating system and a method for preparing rare-earth magnets. In the method and the system disclosed by the invention, magnets are arranged on a conveying device in a plurality of rows in a horizontal direction; the magnets which are arranged in the plurality of rows sequentially pass through a sputtering area of sputter coating equipment to complete coating; a vertical distance between the sputter coating equipment and the upper surface of the magnets is 10mm to 200mm. The method and the system disclosed by the invention adopt continuous pass type magnetron sputtering equipment to sputter heavy rare earth such as Dy and Tb onto the surfaces of the magnets, the thickness of the sputtering layer is effectively controlled, the uniformity of the sputtering layer is guaranteed, thereby the uniformity of the magnetic property of magnetic sheets obtained by performing grain boundary diffusion to the sputtered magnets is guaranteed, and the rapid and continuous production of magnets by adopting the grain boundary diffusion technique can be realized.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Magneto-resistive element

InactiveUS7163755B2Suppresses the demagnetizing fieldNanostructure applicationNanomagnetismMagnetic reluctanceOptoelectronics

The present invention provides a vertical current-type magneto-resistive element. The element includes an intermediate layer and a pair of magnetic layers sandwiching the intermediate layer, and at least one of a free magnetic layer and a pinned magnetic layer is a multilayer film including at least one non-magnetic layer and magnetic layers sandwiching the non-magnetic layer. The element area defined by the area of the intermediate layer through which current flows perpendicular to the film is not larger than 1000 μm2.

Owner:PANASONIC CORP

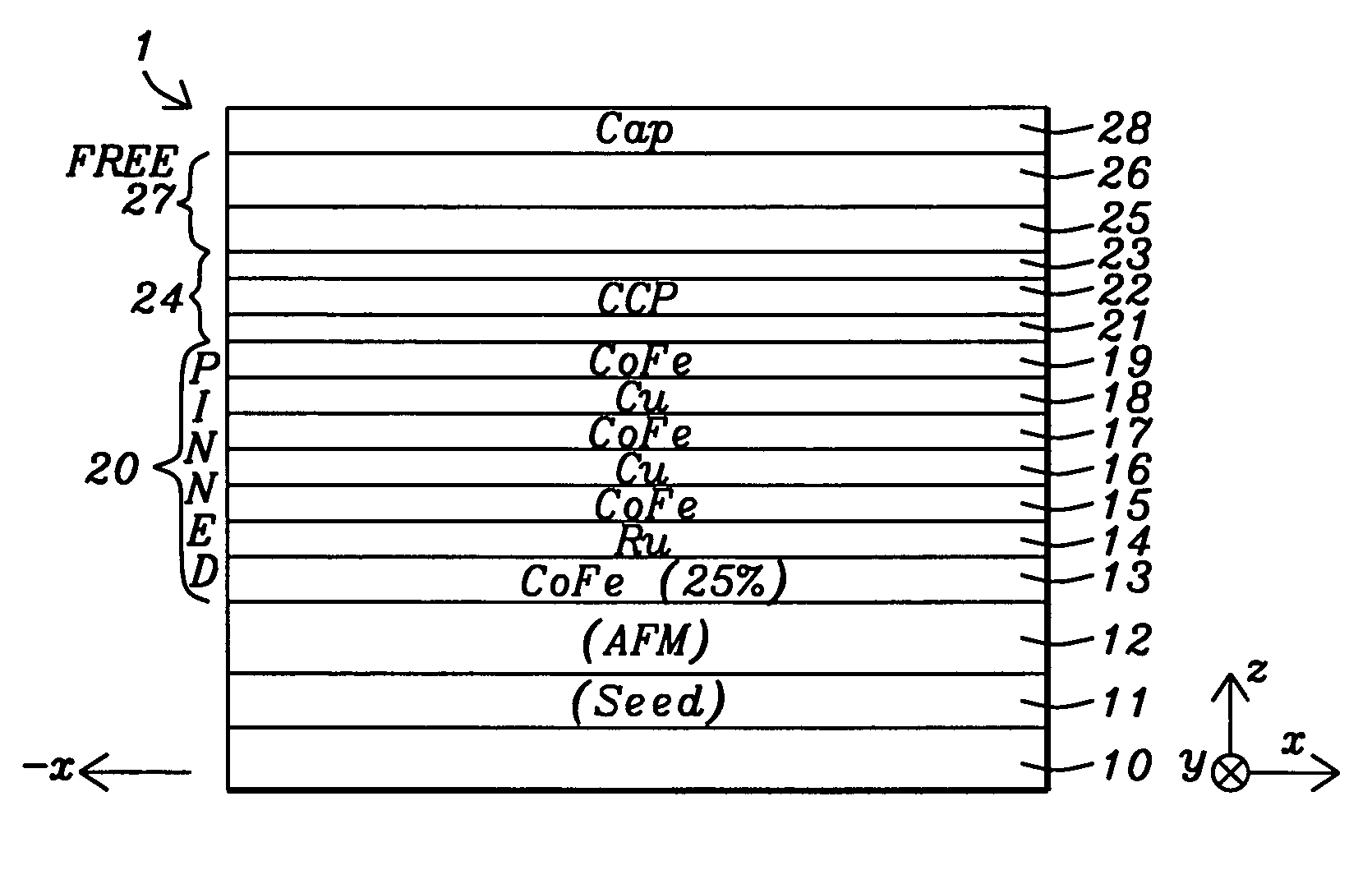

CPP structure with enhanced GMR ratio

InactiveUS20070014054A1Raise the ratioLow coercivityElectrical transducersMagnetic-field-controlled resistorsCopperSpin valve

A CPP-GMR spin valve having a CoFe / NiFe composite free layer is disclosed in which Fe content of the CoFe layer ranges from 20 to 70 atomic % and Ni content in the NiFe layer varies from 85 to 100 atomic % to maintain low Hc and λS values. A higher than normal Fe content in the CoFe layer improves the MR ratio by ≧16% compared with conventional CoFe / NiFe free layers in which the Fe content in CoFe is typically <20 atomic % and the Ni content in NiFe is <85 atomic %. The CPP-GMR performance may also be optimized by incorporating a confining current path layer in the copper spacer between the pinned layer and free layer. For a pinned layer with an AP2 / Ru / AP1 configuration, the spin valve performance is further improved by an AP1 layer comprised of a lamination of CoFe and Cu layers as in [CoFe / Cu]2 / CoFe.

Owner:HEADWAY TECH INC

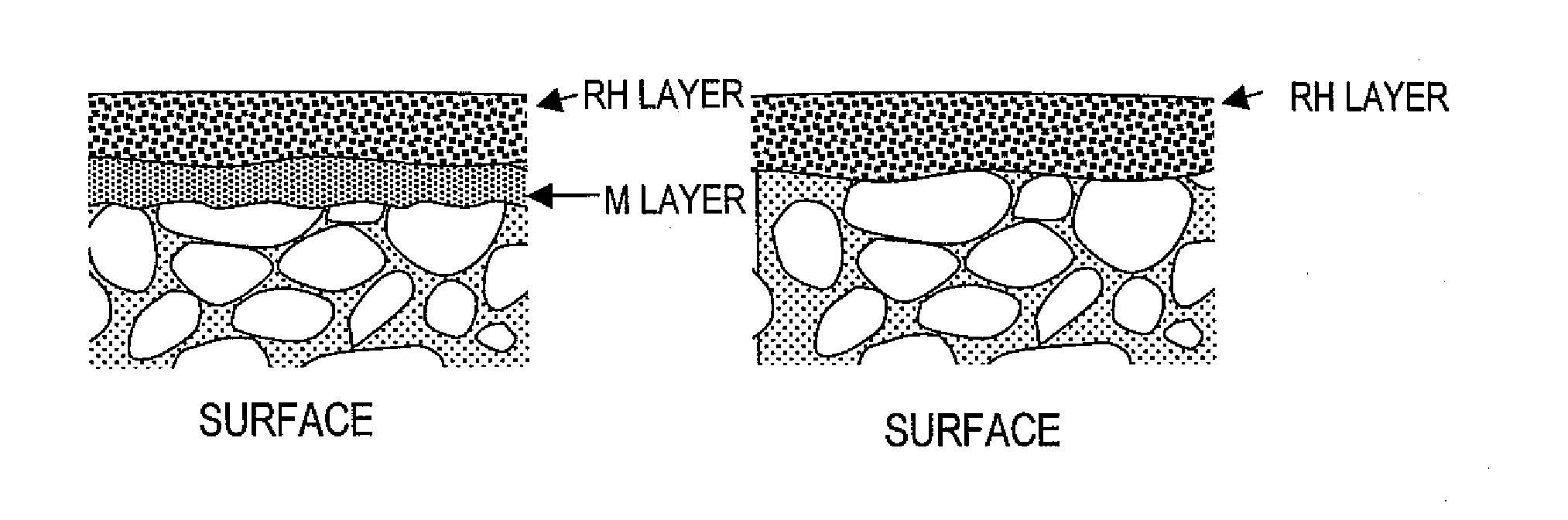

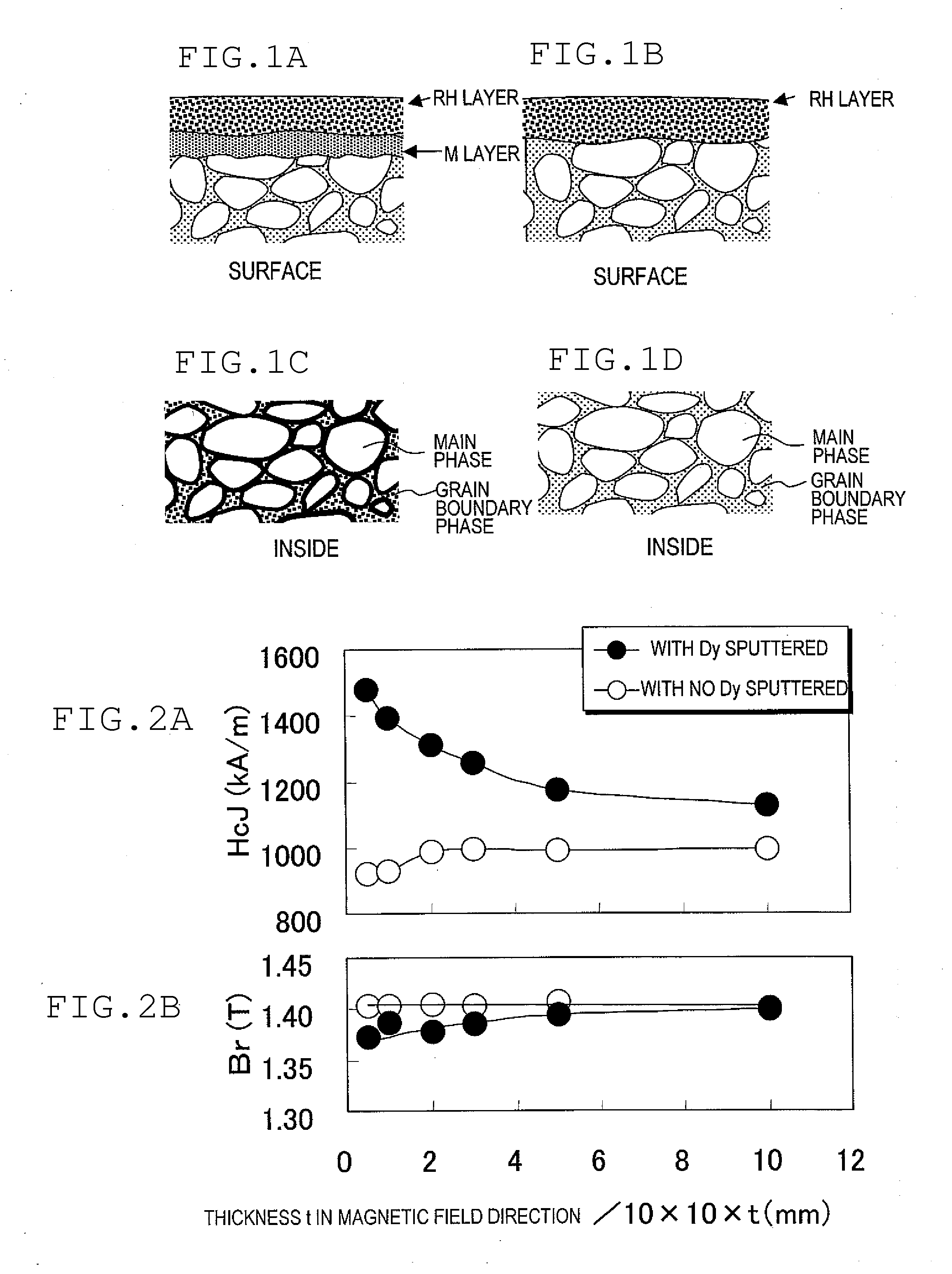

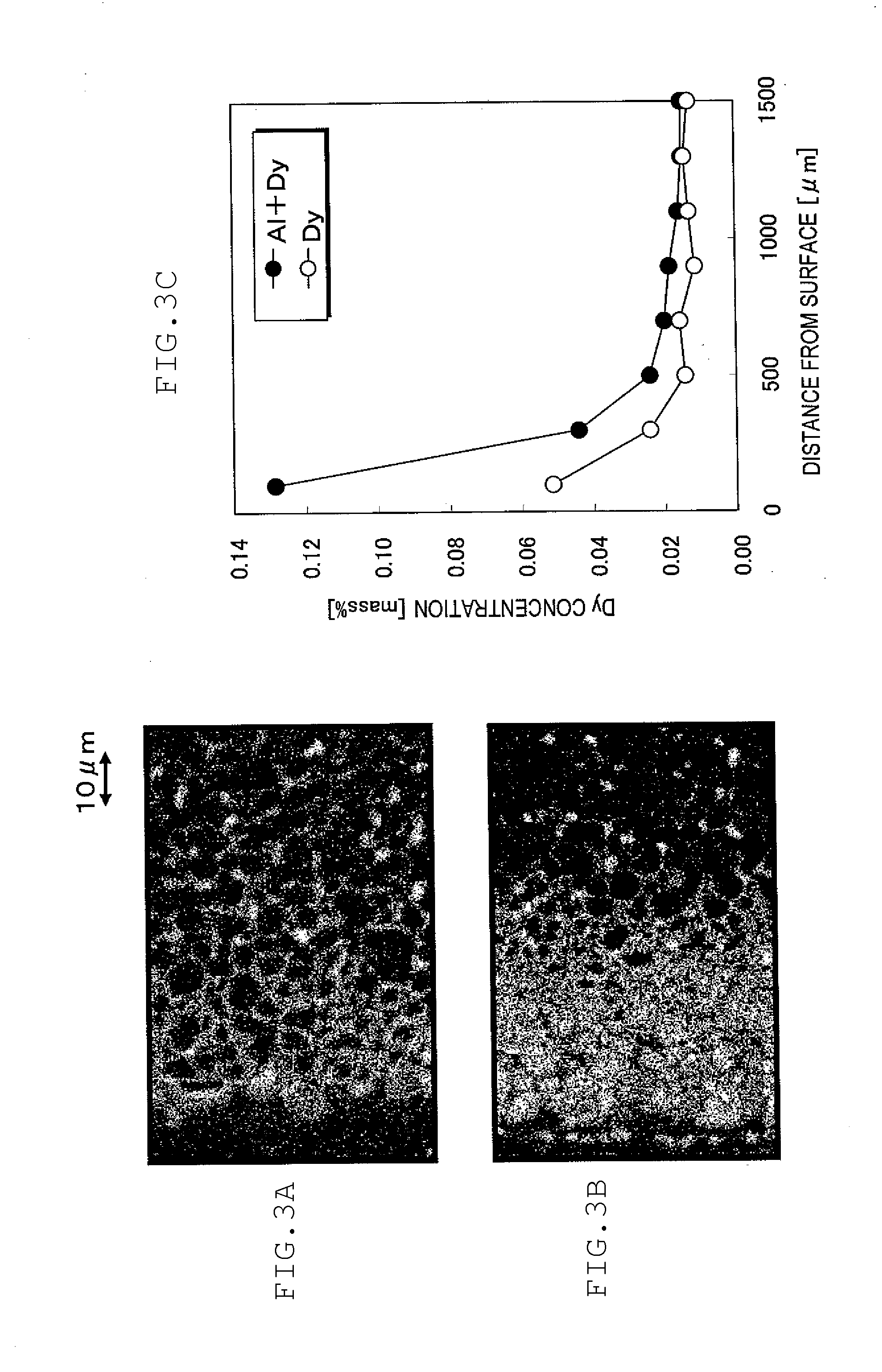

R-Fe-B RARE-EARTH SINTERED MAGNET AND PROCESS FOR PRODUCING THE SAME

ActiveUS20100231338A1Easy to useImprove remanenceVacuum evaporation coatingSputtering coatingRare-earth elementSintered magnets

First, an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R is provided. Next, an M layer, including a metallic element M that is at least one element selected from the group consisting of Al, Ga, In, Sn, Pb, Bi, Zn and Ag, is deposited on the surface of the sintered magnet body and then an RH layer, including a heavy rare-earth element RH that is at least one element selected from the group consisting of Dy, Ho and Tb, is deposited on the M layer. Thereafter, the sintered magnet body is heated, thereby diffusing the metallic element M and the heavy rare-earth element RH from the surface of the magnet body deeper inside the magnet.

Owner:HITACHI METALS LTD

Co alloy target and its production method, soft magnetic film for perpendicular magnetic recording and perpendicular magnetic recording medium

InactiveUS20050223848A1Reduce unevennessReduce particlesBase layers for recording layersTransportation and packagingAlloyImpurity

Owner:HITACHI METALS LTD

Target of high-purity nickel or nickel alloy and its producing method

ActiveUS20040256035A1Improve permeabilityFlux changeVacuum evaporation coatingSputtering coatingSputteringNickel alloy

Provided is high purity nickel or nickel alloy target for magnetron sputtering having superior sputtering film uniformity and in which the magnetic permeability of the target is 100 or more, and this high purity nickel or a nickel alloy target for magnetron sputtering capable of achieving a favorable film uniformity (evenness of film thickness) and superior in plasma ignition (firing) even during the manufacturing process employing a 300 mm wafer. The present invention also provides the manufacturing method of such high purity nickel or nickel alloy target.

Owner:NIKKO MATERIAL

Popular searches

Semiconductor/solid-state device manufacturing Record information storage Cathode sputtering application Substrate/intermediate layers Spin-exchange-coupled multilayers Galvano-magnetic device manufacture/treatment Heads using thin films Magnetic field measurement using galvano-magnetic devices Manufacture of flux-sensitive heads Protective measures for recording heads

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com