Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2265results about "Magnetic field measurement using galvano-magnetic devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

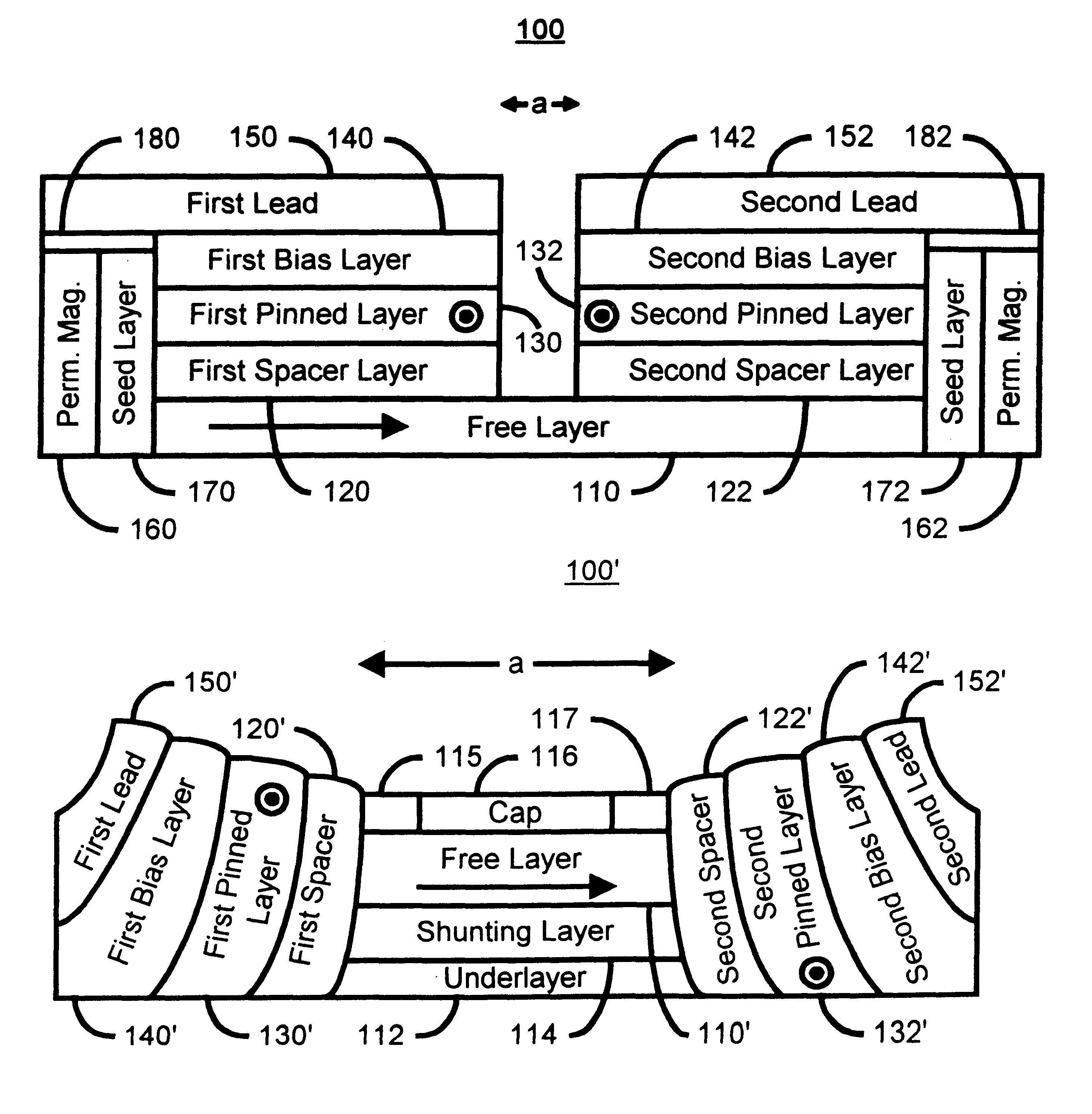

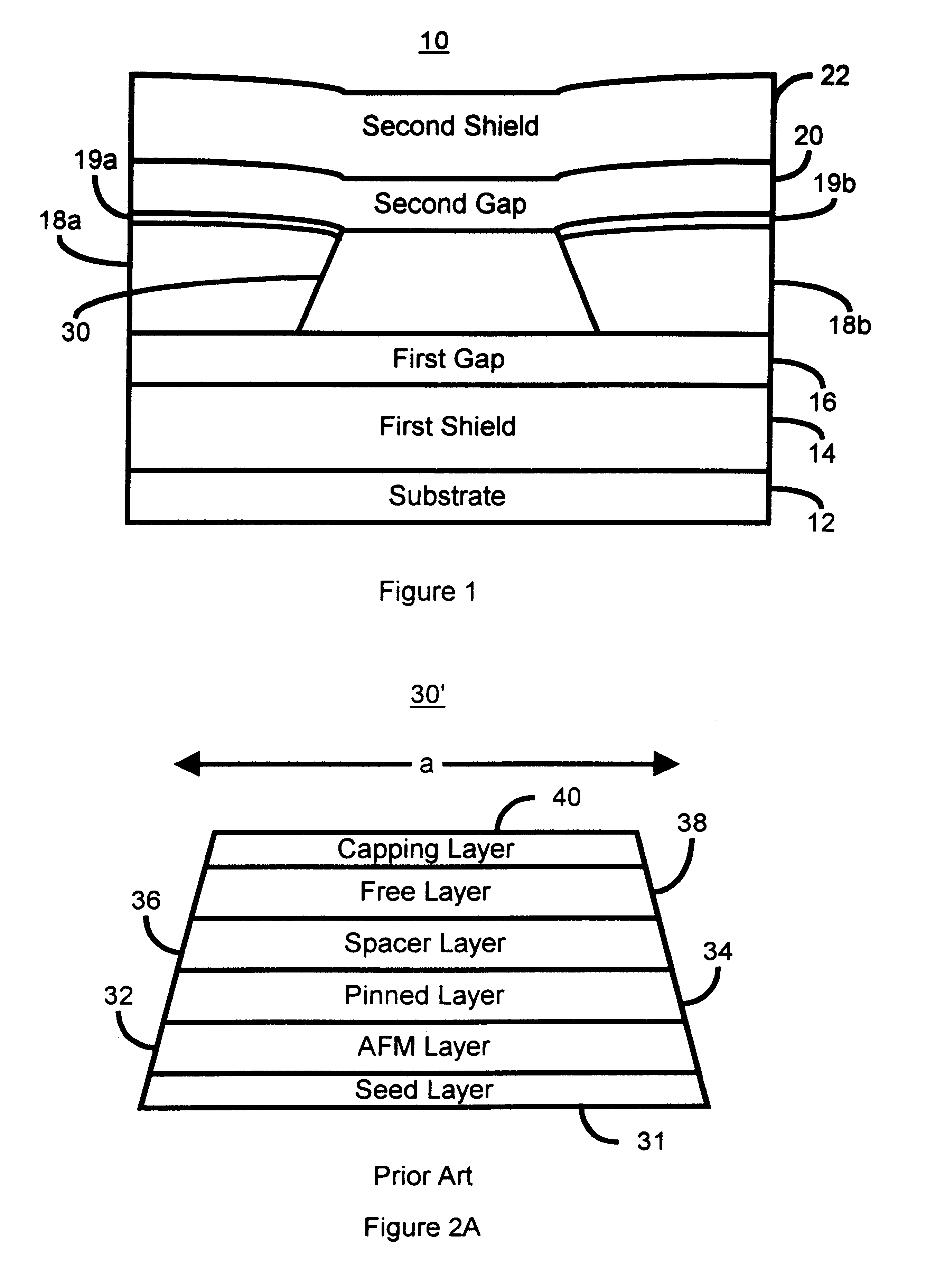

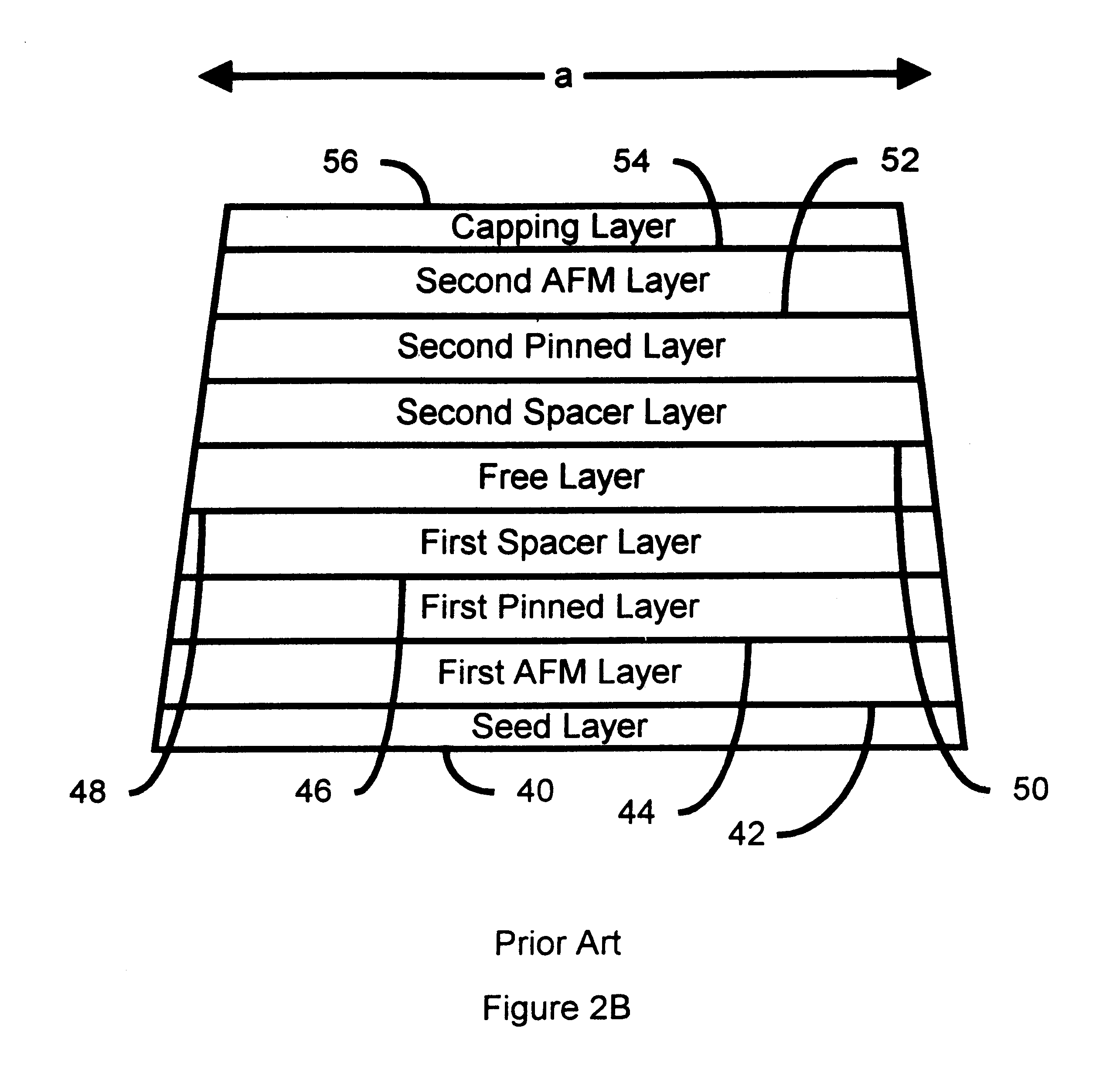

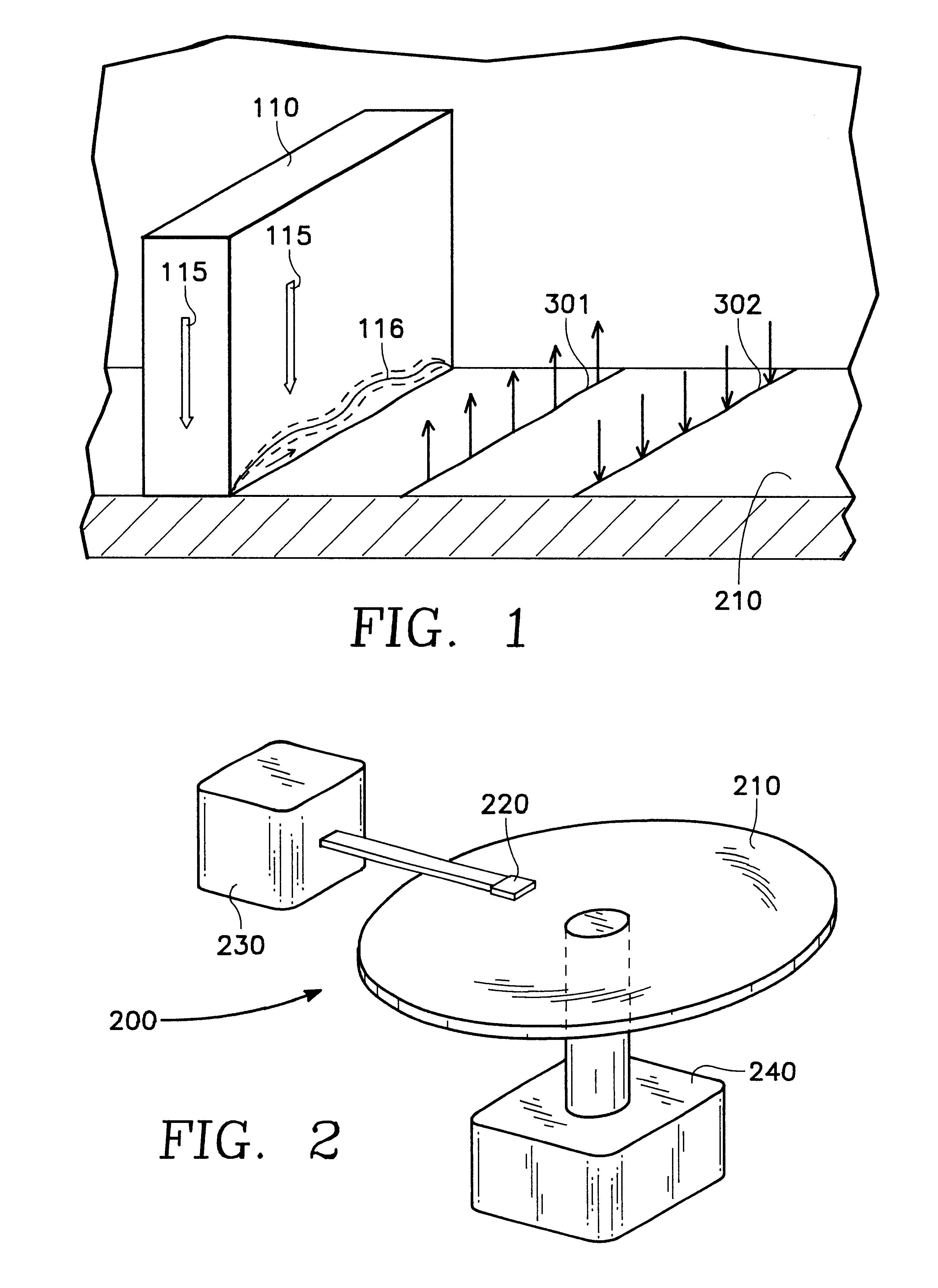

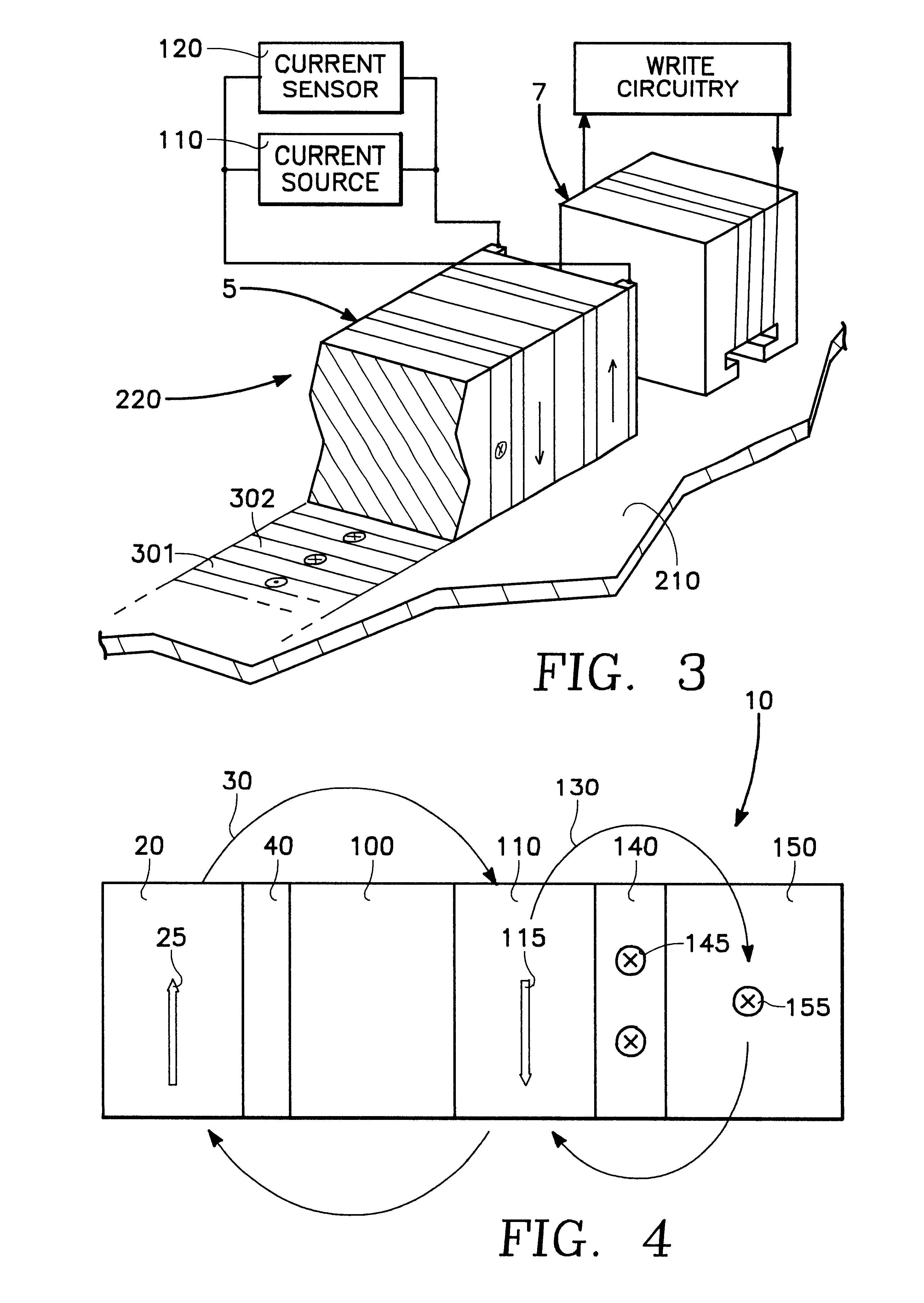

Method and system for providing a dual spin filter

Owner:WESTERN DIGITAL TECH INC

Spin valve device with improved thermal stability

The present invention provides spin valve with a magnetic compensation field which couples to the pinned layer and counteracts sensing current induced magnetic field. The spin valve sensor of the present invention may be formed having a structure comprising: a free layer, a first spacer layer, a pinned layer, a pinning layer, a second spacer layer, and a compensation layer. The compensation layer may be formed of ferromagnetic material with its magnetization set so that the compensation field oriented in a reinforcing relationship with the magnetization of the pinned layer. Current through the compensation layer and the spacer layer may add to the compensation field. The spacer layer may be formed of a nonmagnetic material of sufficient thickness to prevent interaction between the pinning layer and the compensation layer while providing a sufficiently small distance to allow sufficient magnetic coupling to the pinned layer. The present invention may be used to improve thermal stability and reduce Barkhausen noise while not impacting output symmetry.

Owner:WESTERN DIGITAL TECH INC

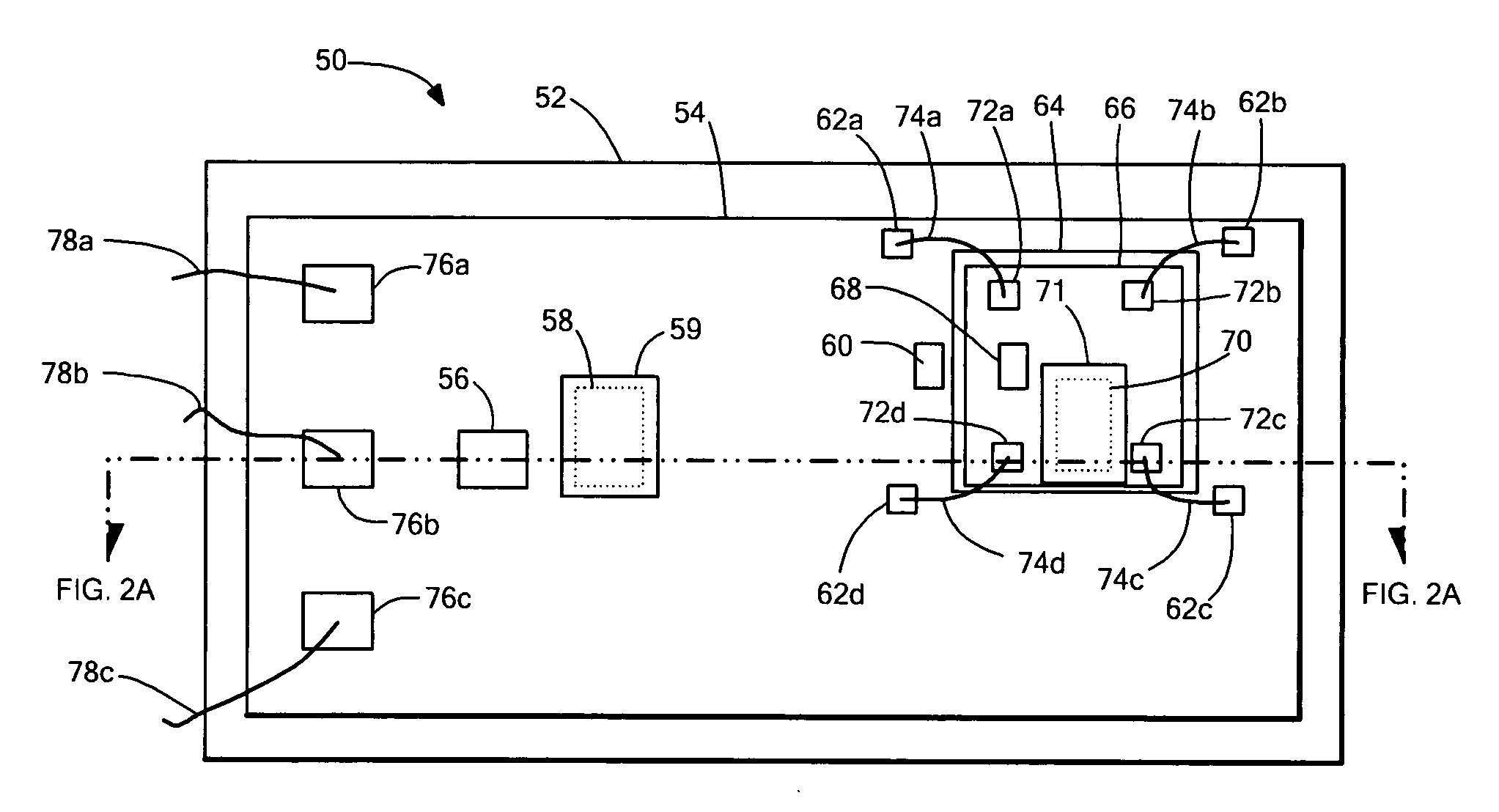

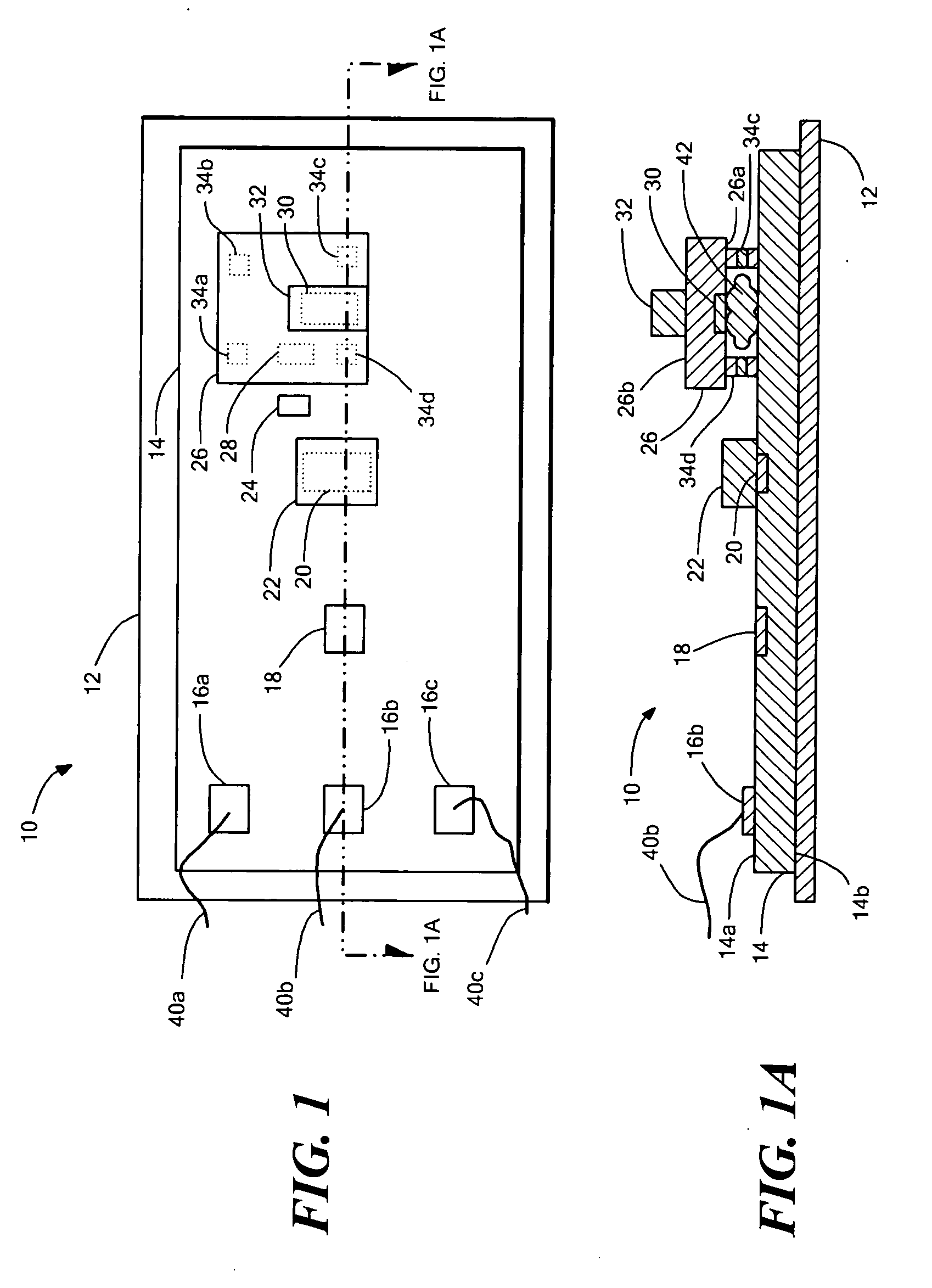

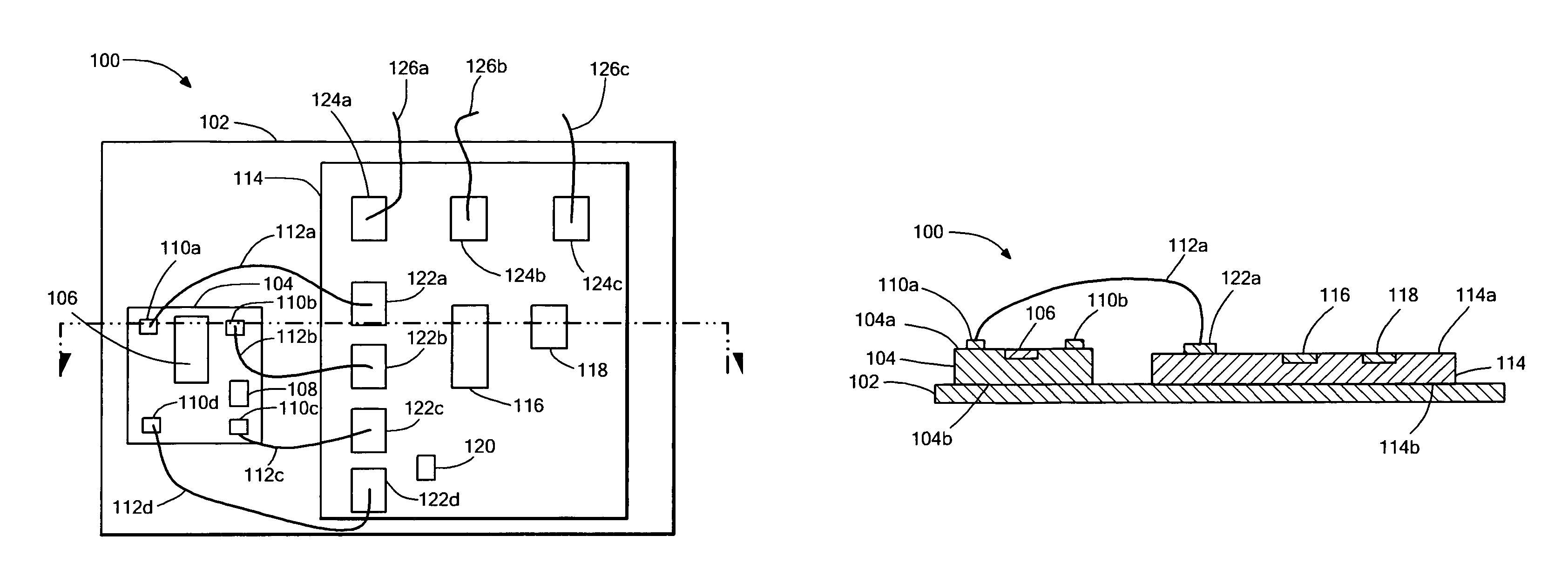

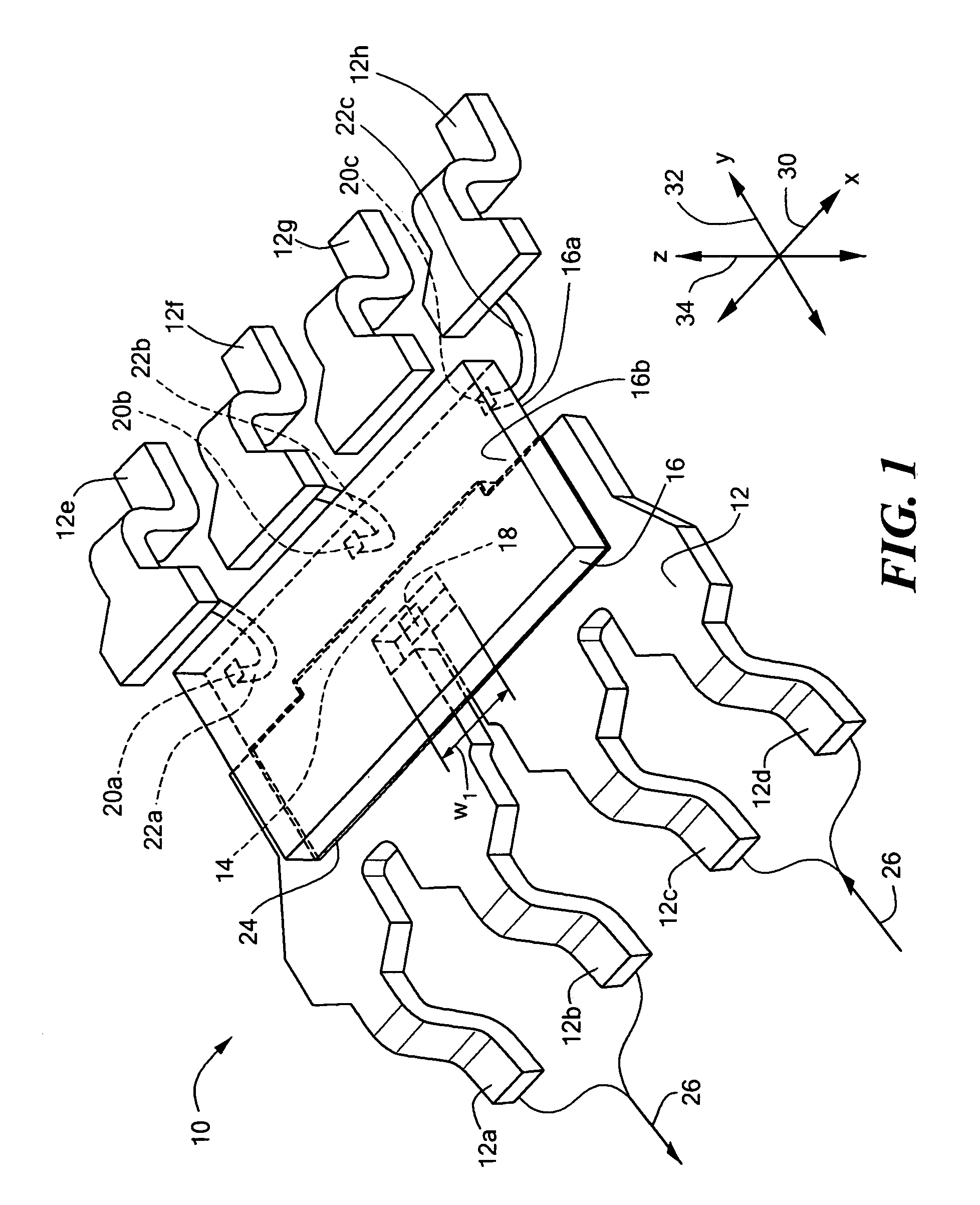

Arrangements for an intergrated sensor

ActiveUS20070170533A1NanomagnetismSemiconductor/solid-state device detailsCondensed matter physicsIntegrated circuit

An integrated circuit can have a first substrate supporting a magnetic field sensing element and a second substrate supporting another magnetic field sensing element. The first and second substrates can be arranged in a variety of configurations. Another integrated circuit can have a first magnetic field sensing element and second different magnetic field sensing element disposed on surfaces thereof.

Owner:ALLEGRO MICROSYSTEMS INC

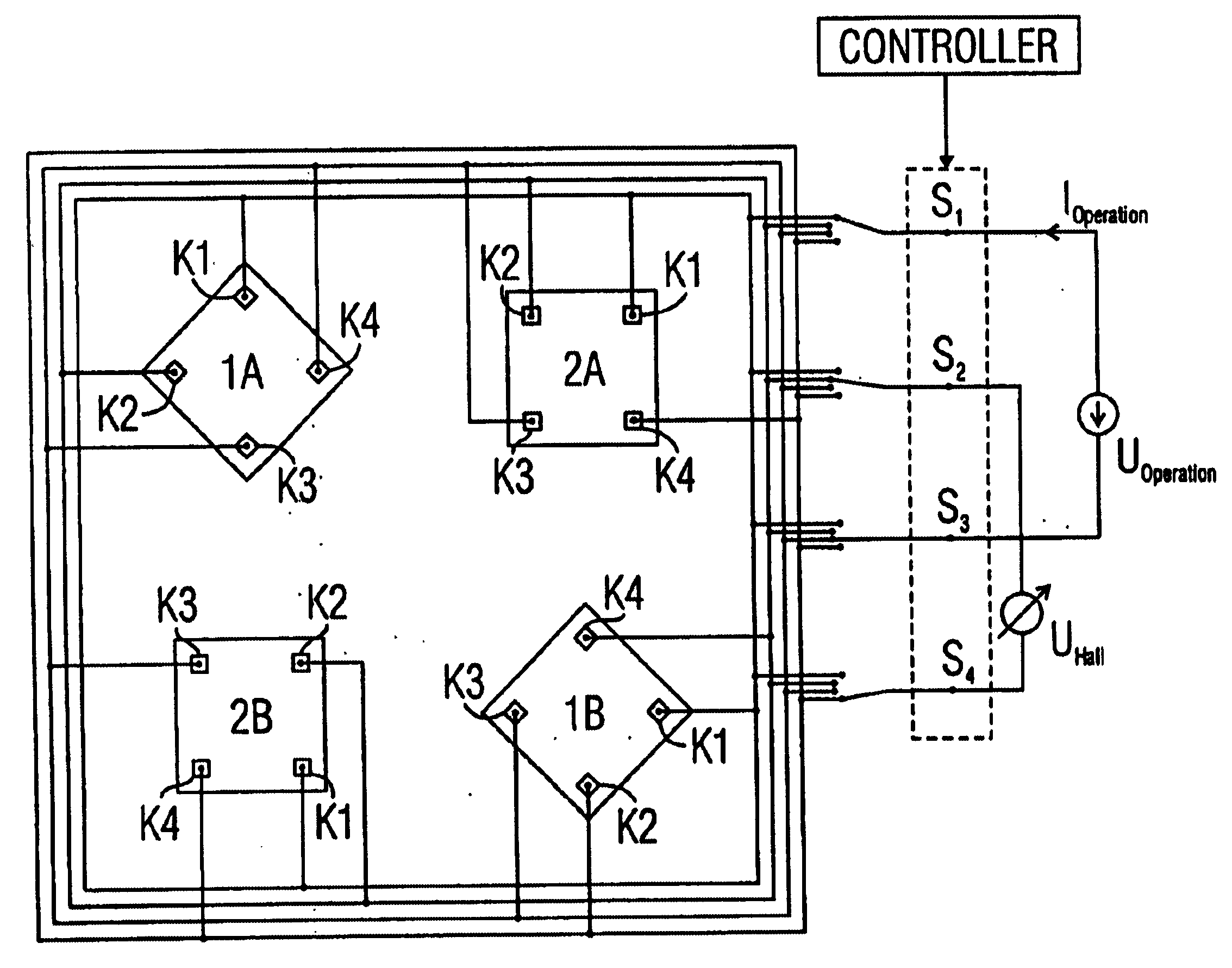

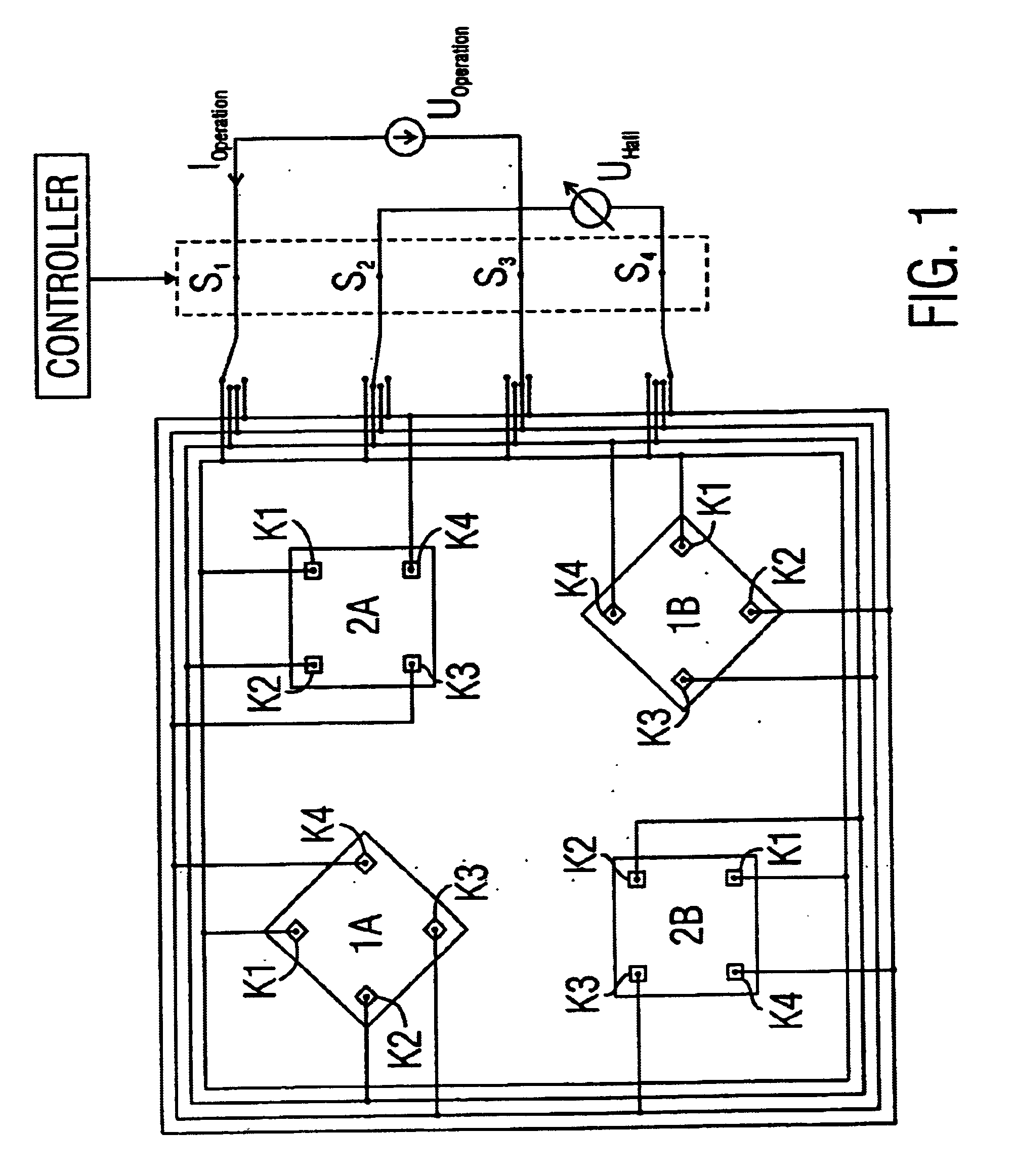

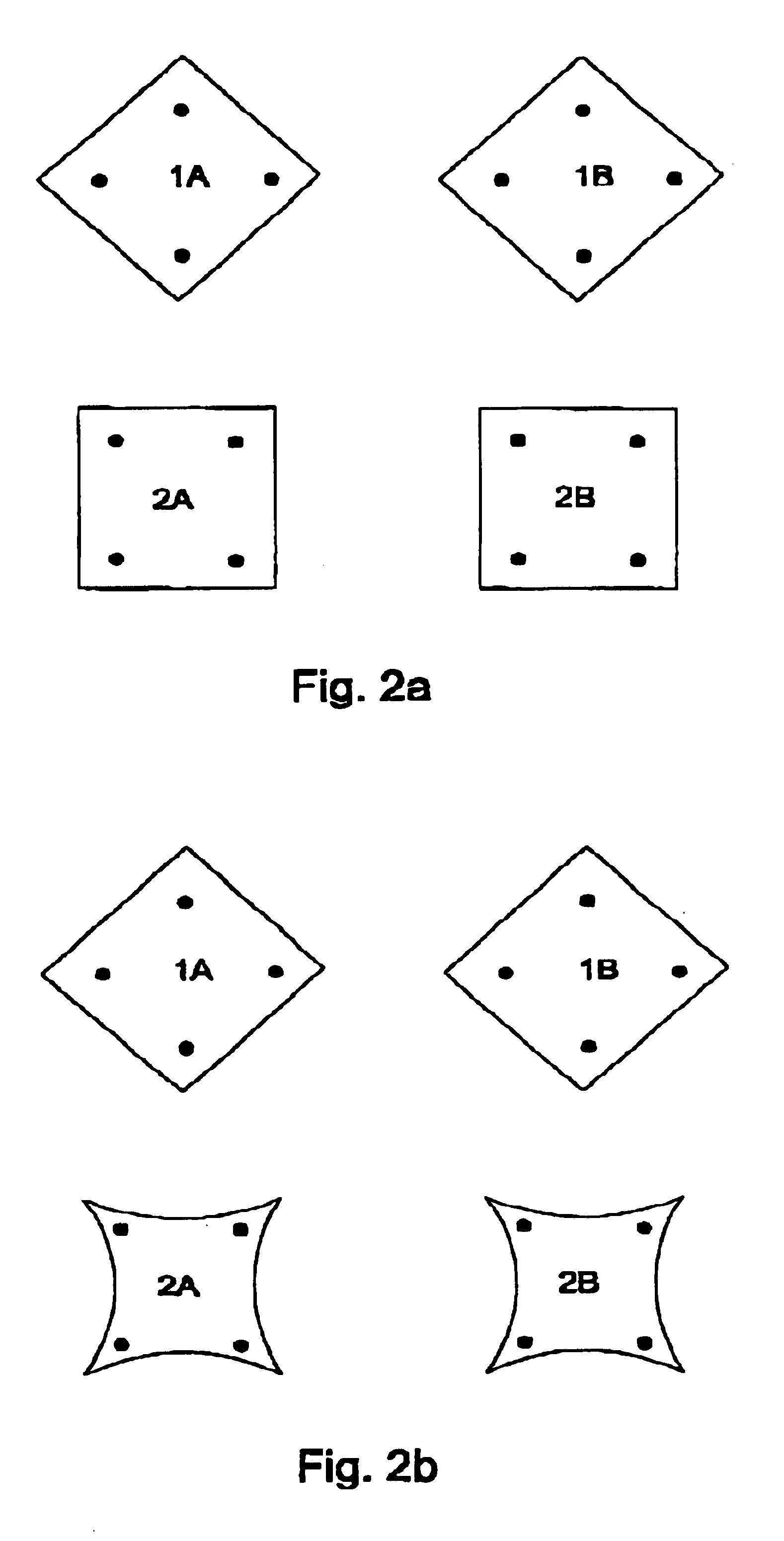

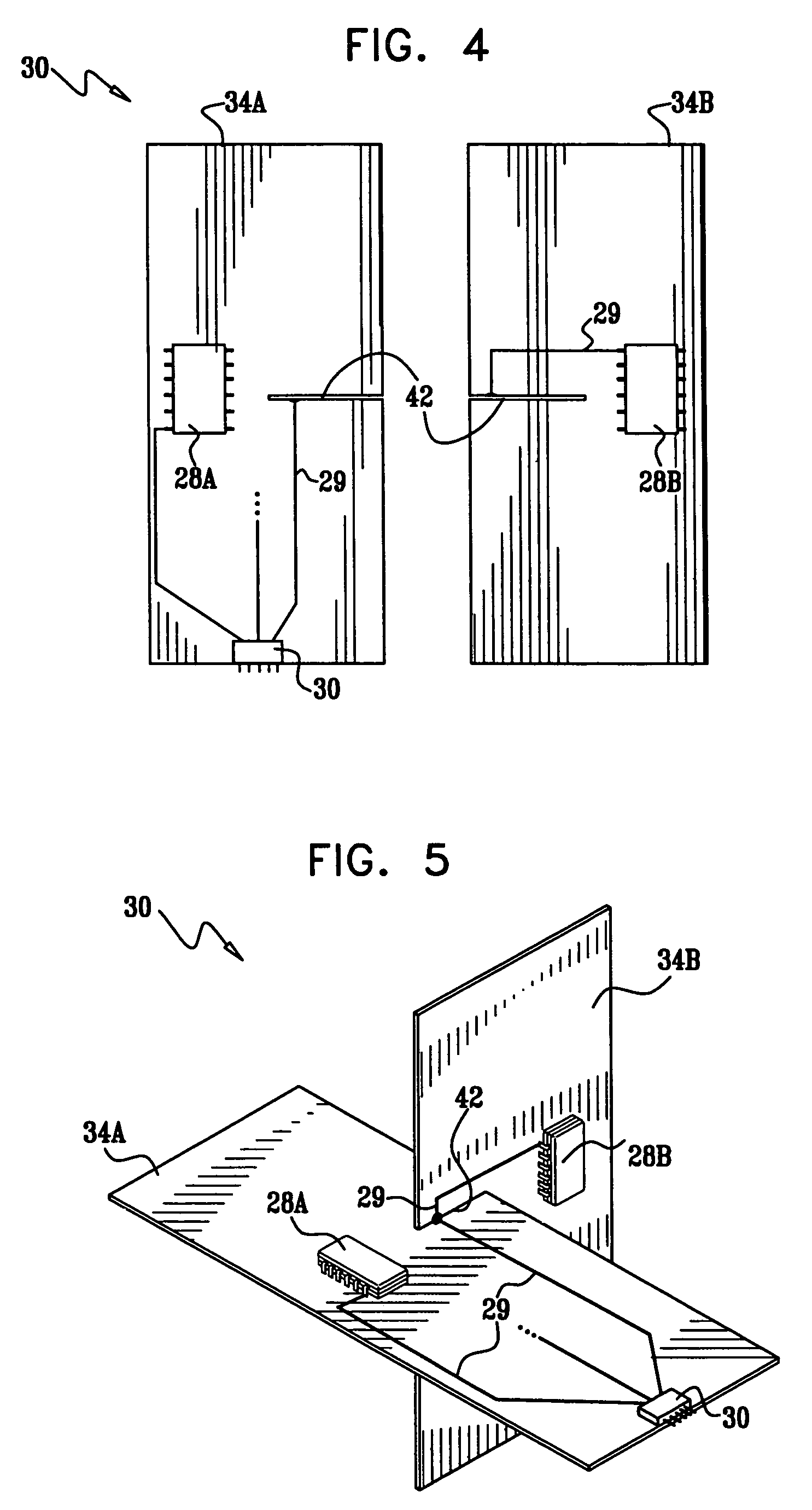

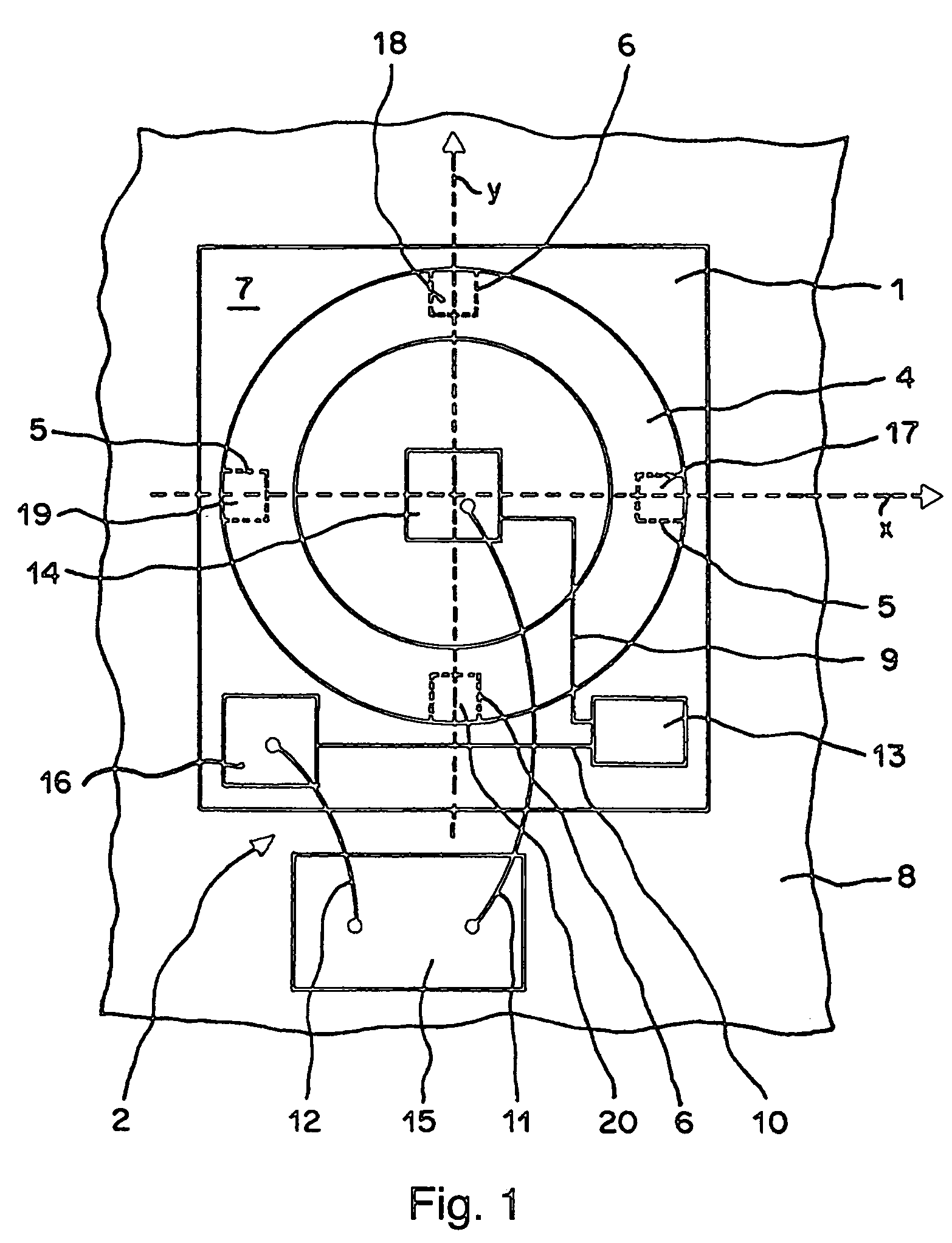

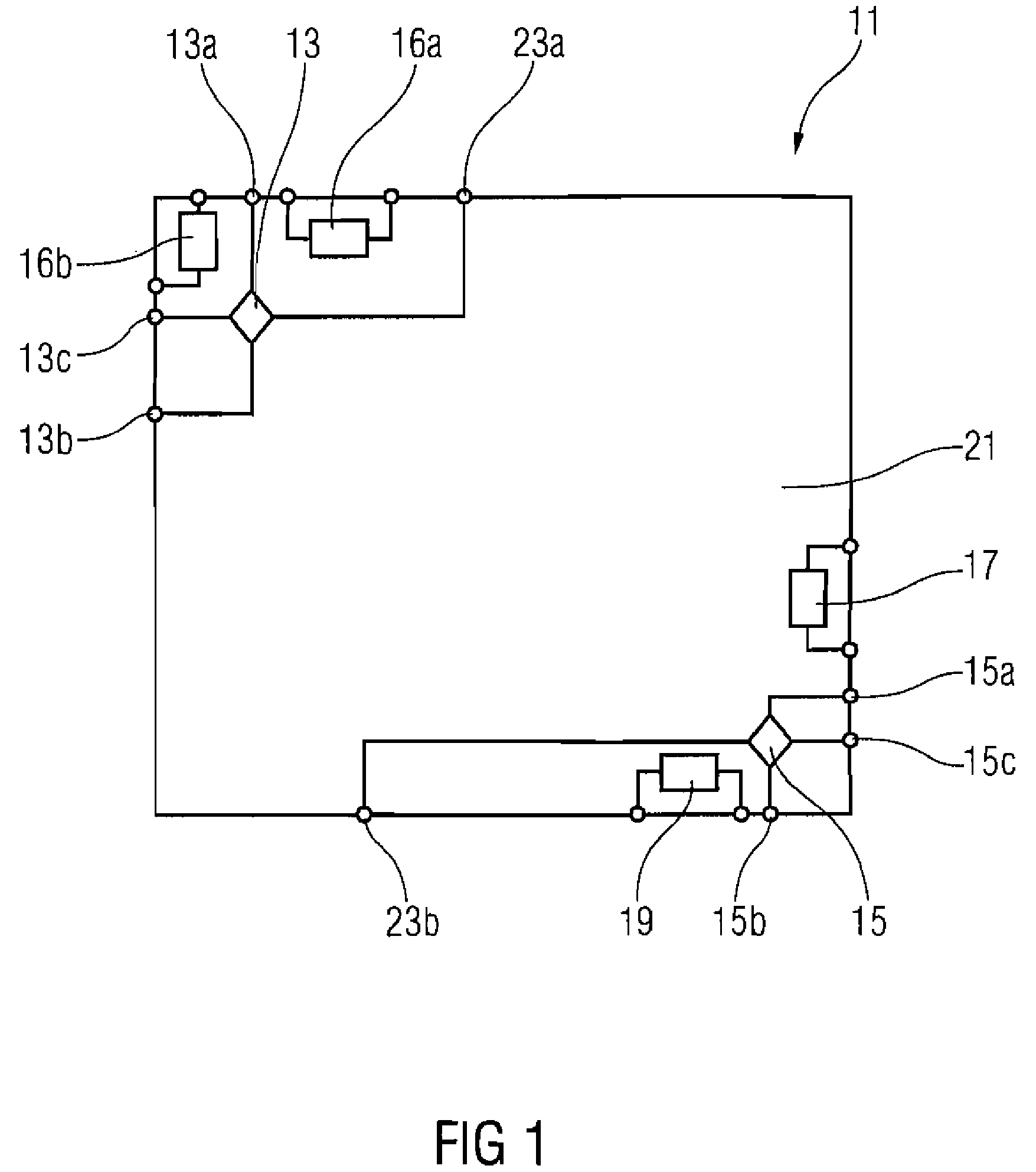

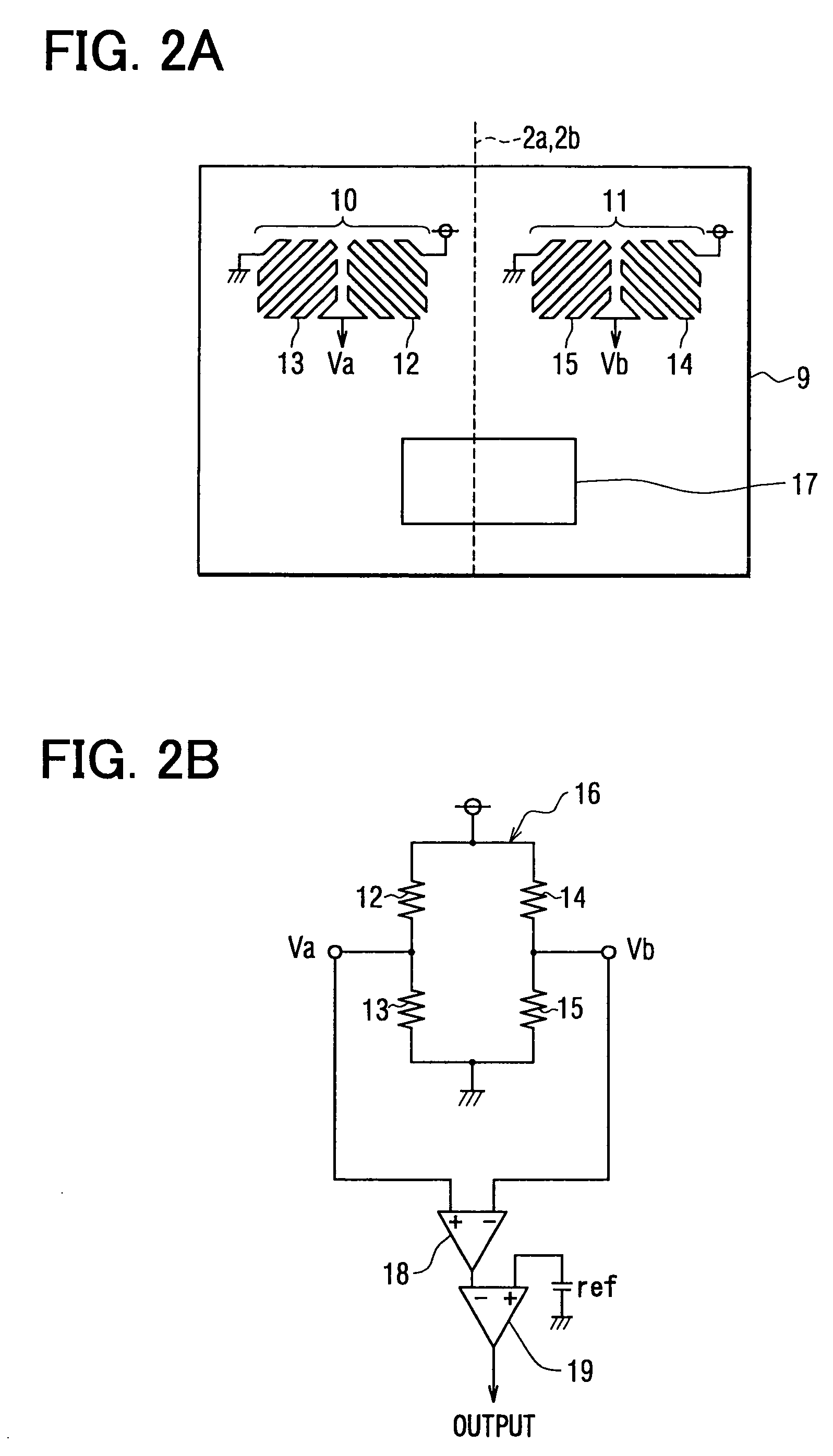

Hall sensor array for measuring a magnetic field with offset compensation

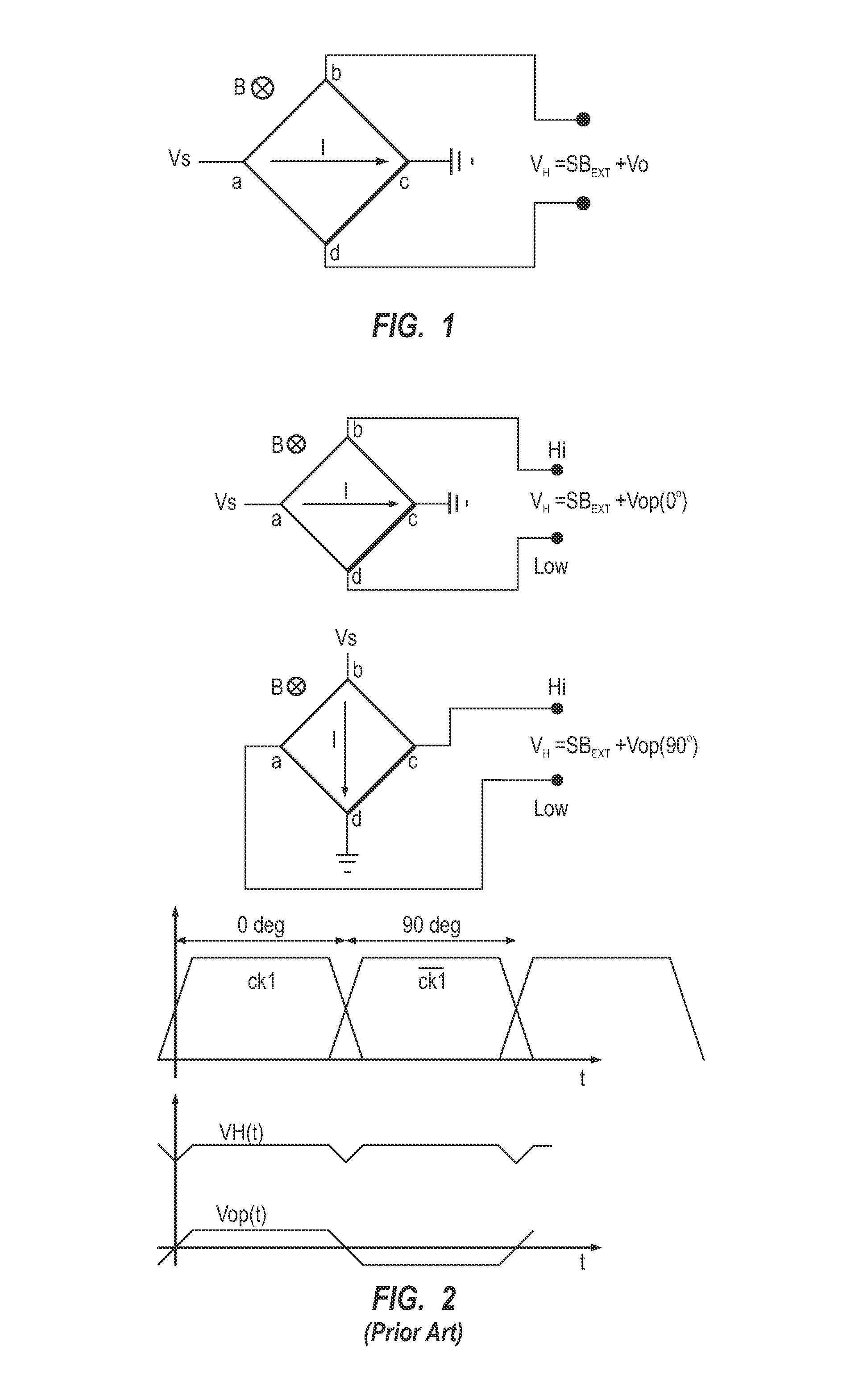

InactiveUS6768301B1Less complicated to manufactureReduce signalingSolid-state devicesMagnetic field measurement using galvano-magnetic devicesSensor arrayVoltage source

A Hall sensor array for offset-compensated magnetic field measurement comprises a first and at least one additional pair of Hall sensor elements. Each Hall sensor element has four terminals, of which two act as power supply terminals for supplying an operating current and two act as measurement terminals for measuring a Hall voltage. Respective first supply terminals of each Hall sensor element are connected together and to a first terminal of a common voltage source and respective second supply terminals of each Hall sensor element are connected together and to a second terminal of the common voltage source so that the common voltage source supplies an operating current for the Hall sensor elements. The Hall sensor elements are operated in the spinning current mode so that the offset voltages of the Hall sensor elements approximately cancel one another out in a revolution so that the Hall signal contributions which actually depend on the magnetic field remain.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

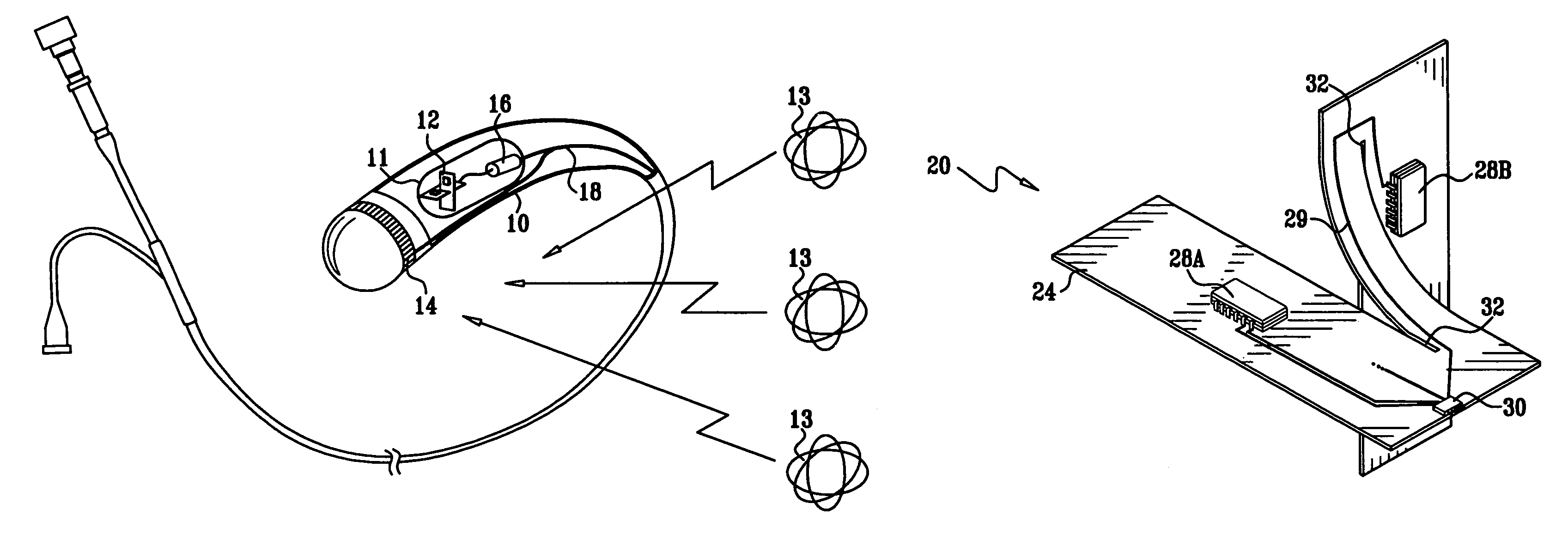

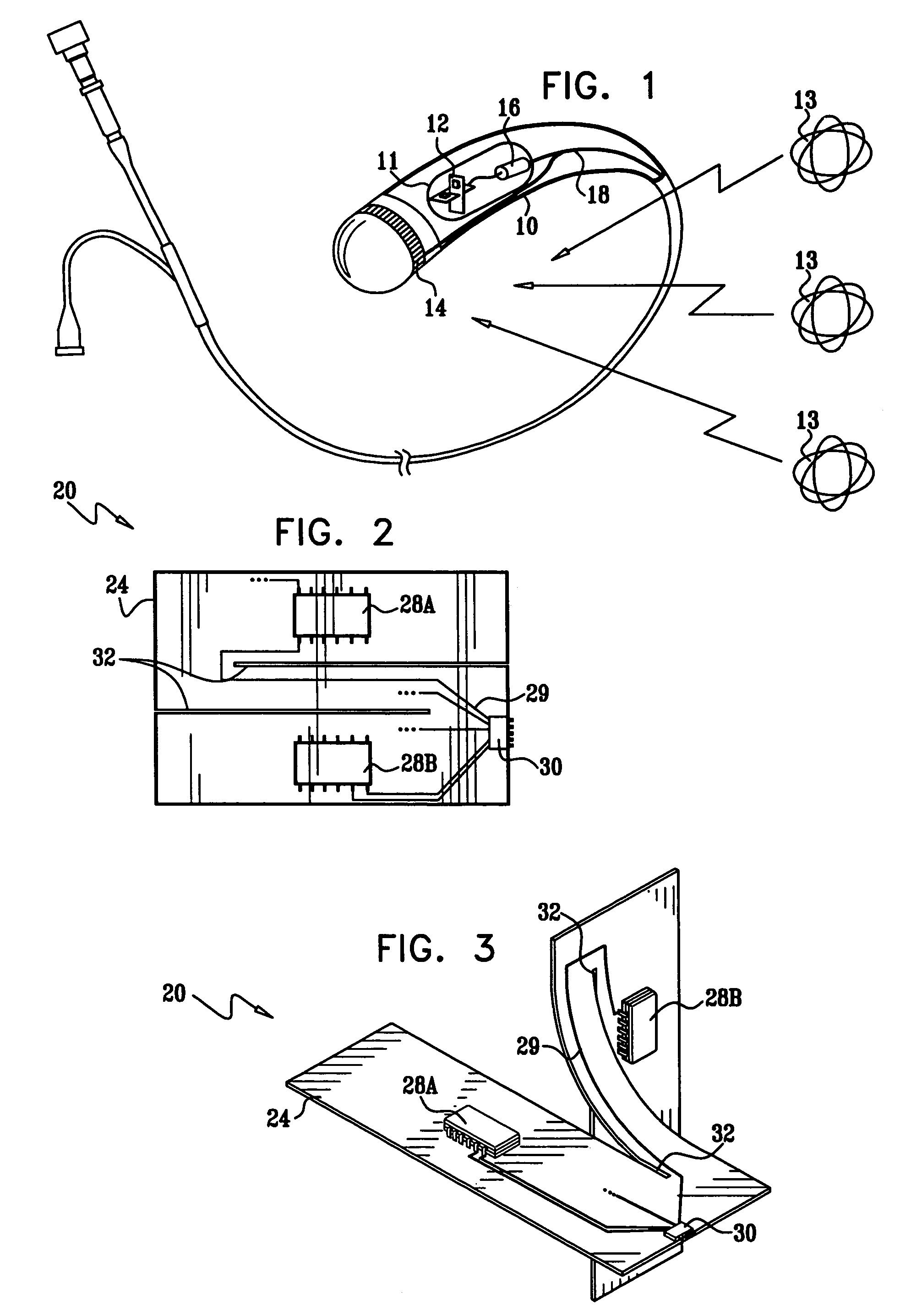

Magnetic sensor assembly

ActiveUS7301332B2Low costSmall profileSurgeryMagnetic-field-controlled resistorsSpatial OrientationsMagneto

Owner:BIOSENSE WEBSTER INC

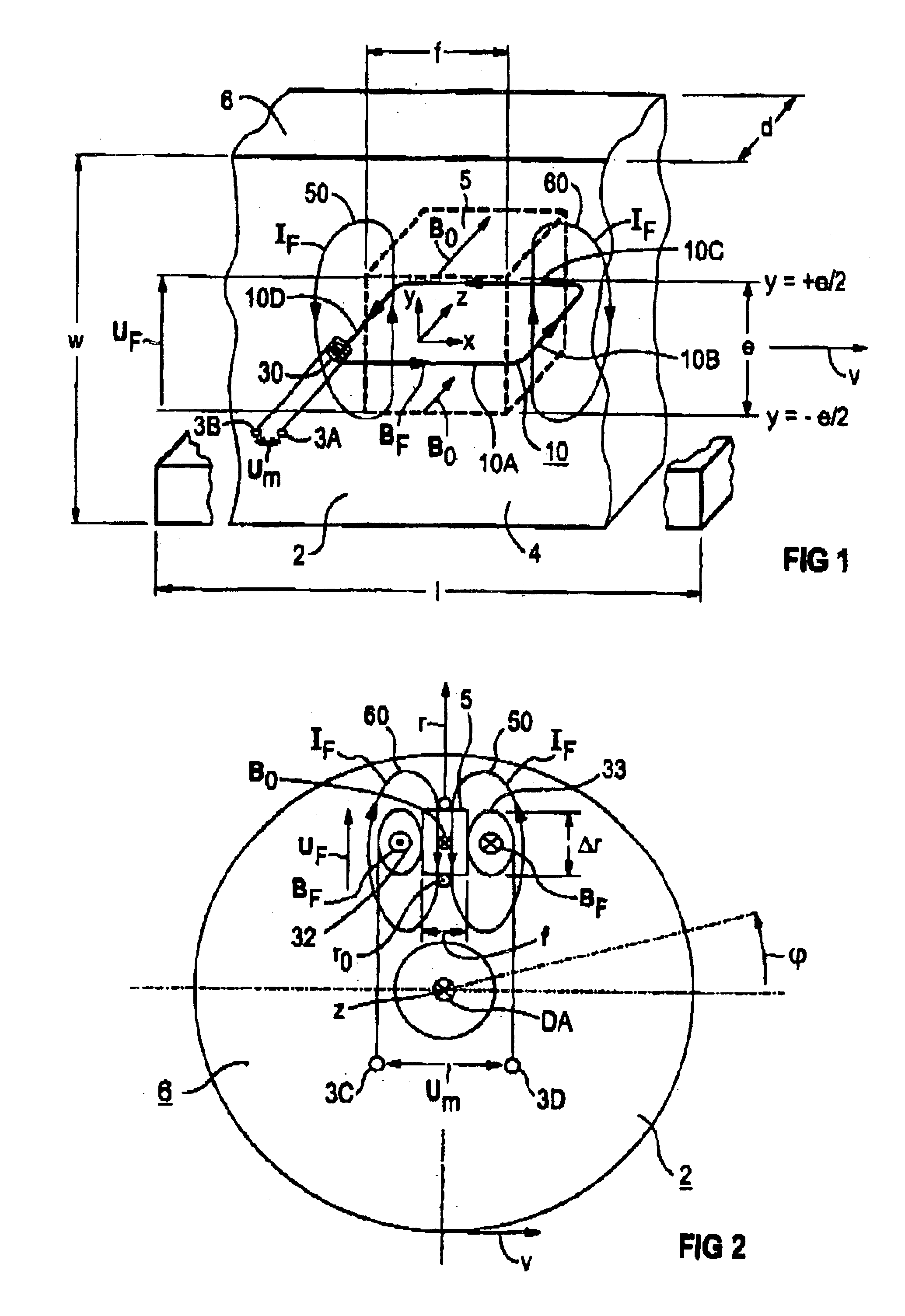

Magnetic field sensor

InactiveUS7038448B2Without loss in sensitivitySmall sizeAcceleration measurement using interia forcesMagnetic field measurement using flux-gate principleElectrical conductorSemiconductor chip

A magnetic field sensor for measuring at least two components of a magnetic field comprises a ferromagnetic core mounted on a semiconductor chip, an exciter coil to which a current can be applied and two read-out sensors. The ferromagnetic core is ring-shaped. The exciter coil is preferably formed from conductor tracks of the semiconductor chip and from bonding wires.

Owner:MELEXIS TECH NV

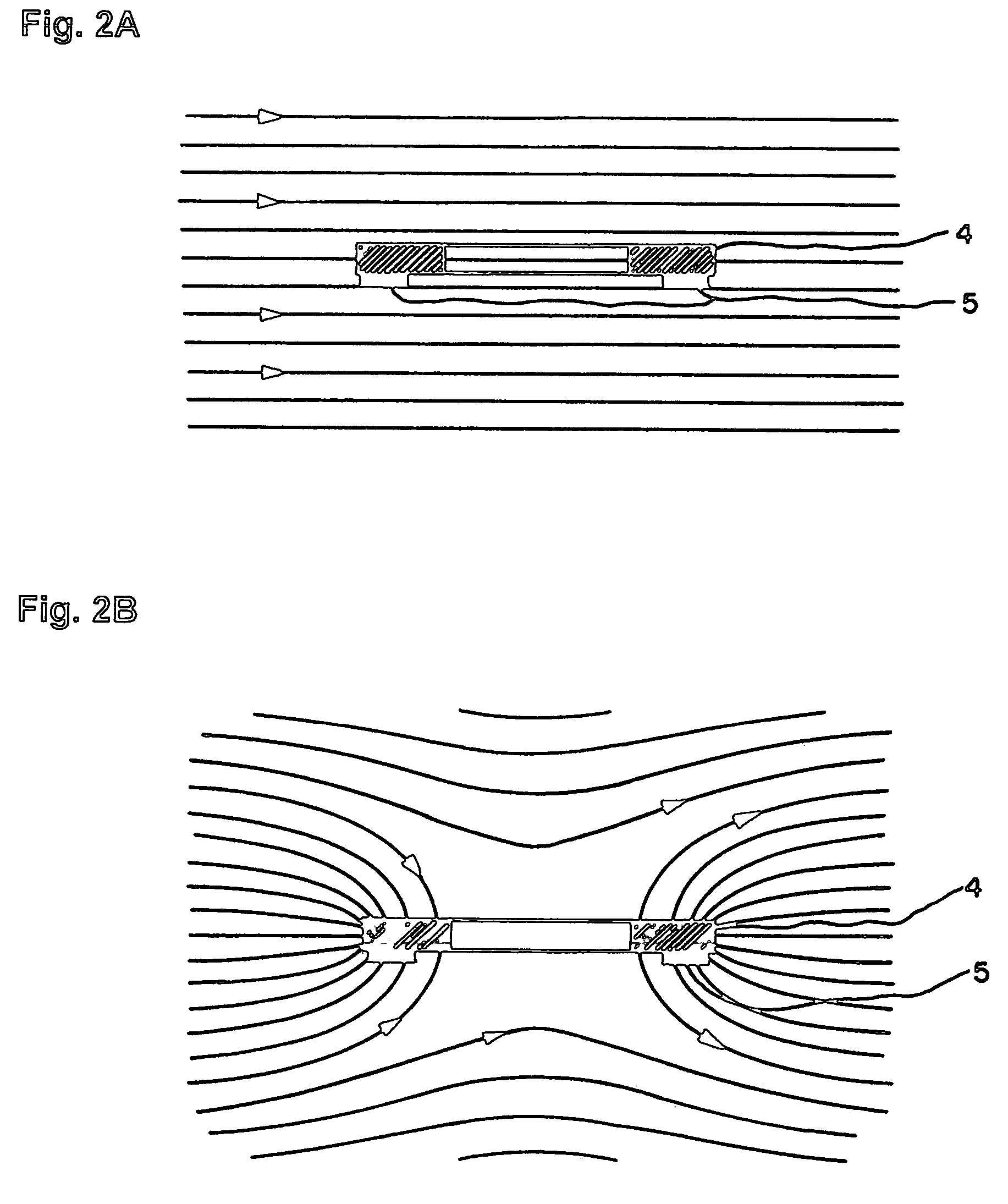

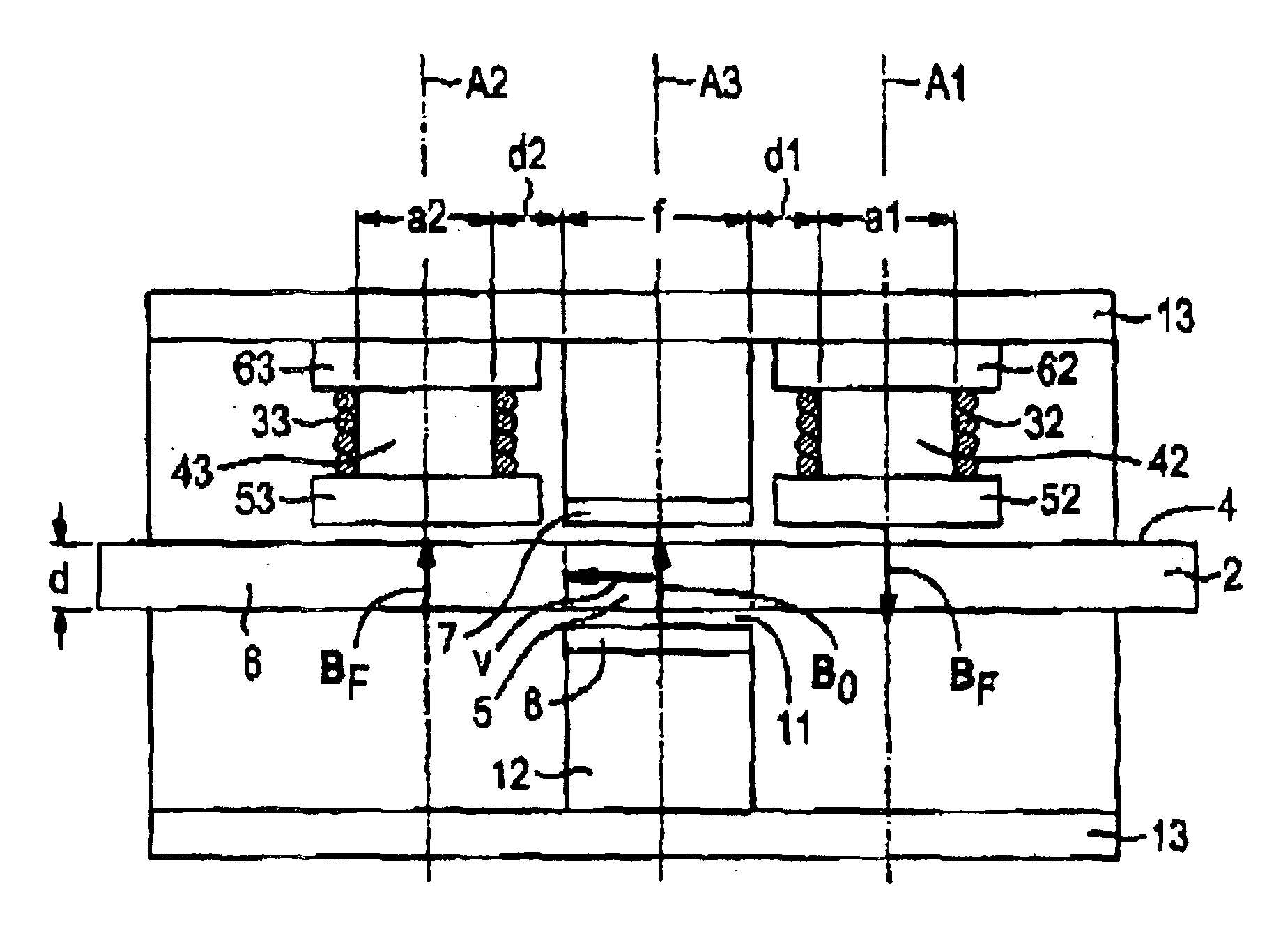

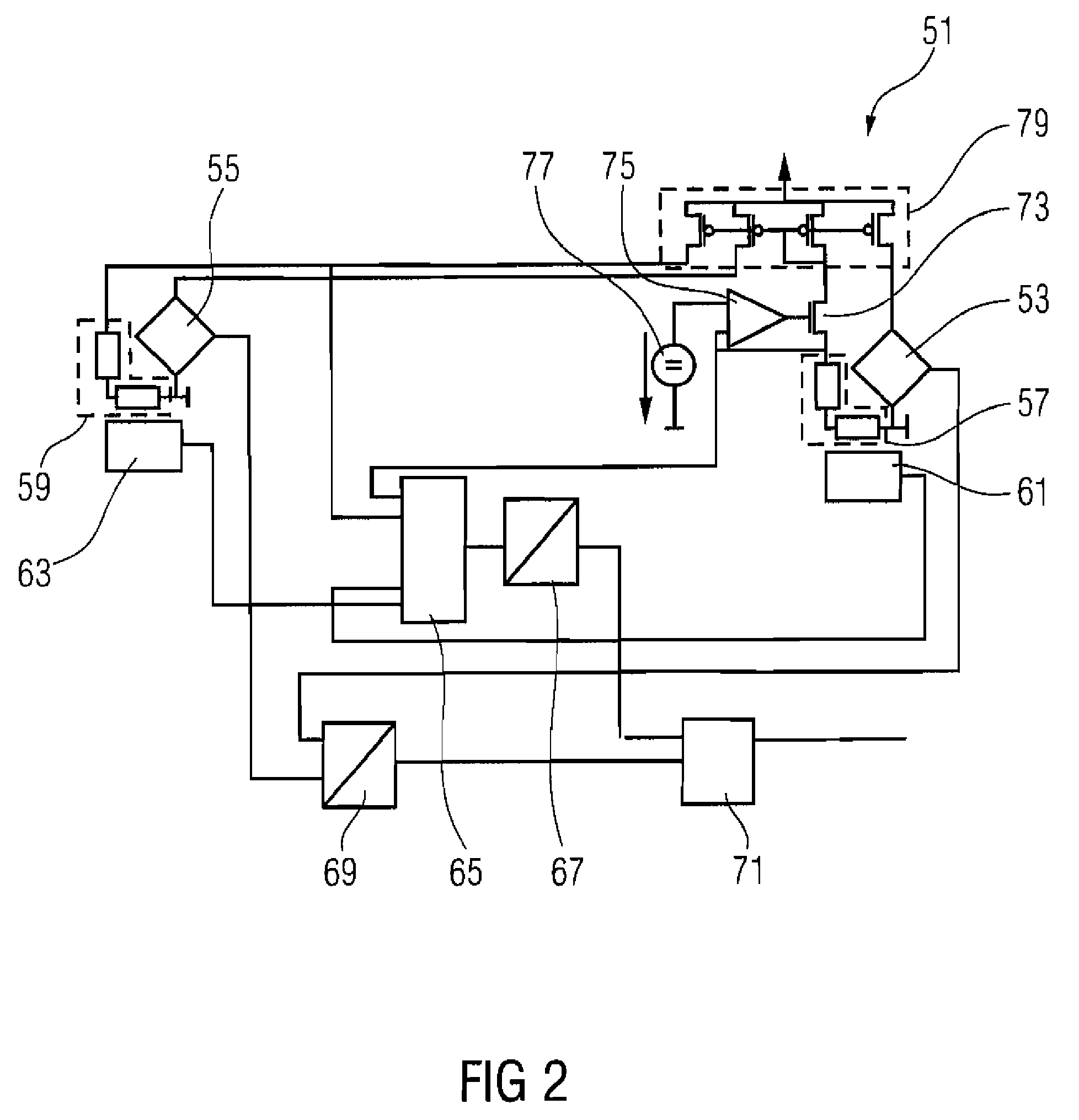

Device for measuring the motion of a conducting body through magnetic induction

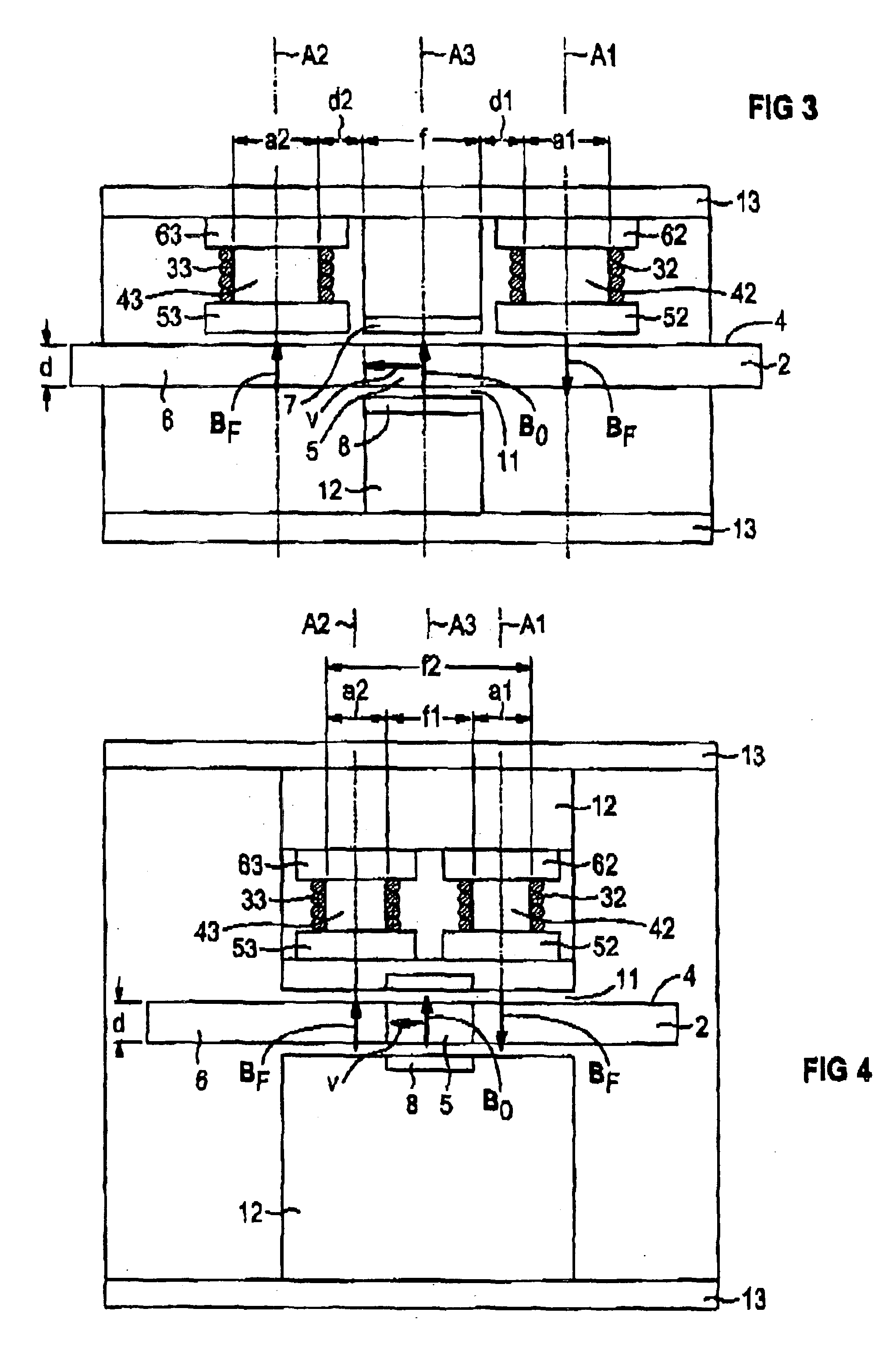

InactiveUS6850053B2Improve cooling effectReduce thermal noiseAcceleration measurement using interia forcesMagnetic-field-controlled resistorsMeasurement deviceClassical mechanics

A device for measuring a motion of a moving electrically conducting body is disclosed. A magnetic field generated by, for example, electromagnets or permanent magnets, penetrates at least a partial area of the moving body. Two or more measuring devices are arranged outside the magnetic field to measure a measurement magnetic field that is induced by electrical currents in the moving body. The measuring devices are arranged essentially symmetrically with respect to the magnetic field generating means or the moving body. The measurement magnetic field represents at least one motion variable of the moving body. The measuring device is thereby no longer subjected to the temperature-dependent variations of the exciting field.

Owner:SIEMENS AG

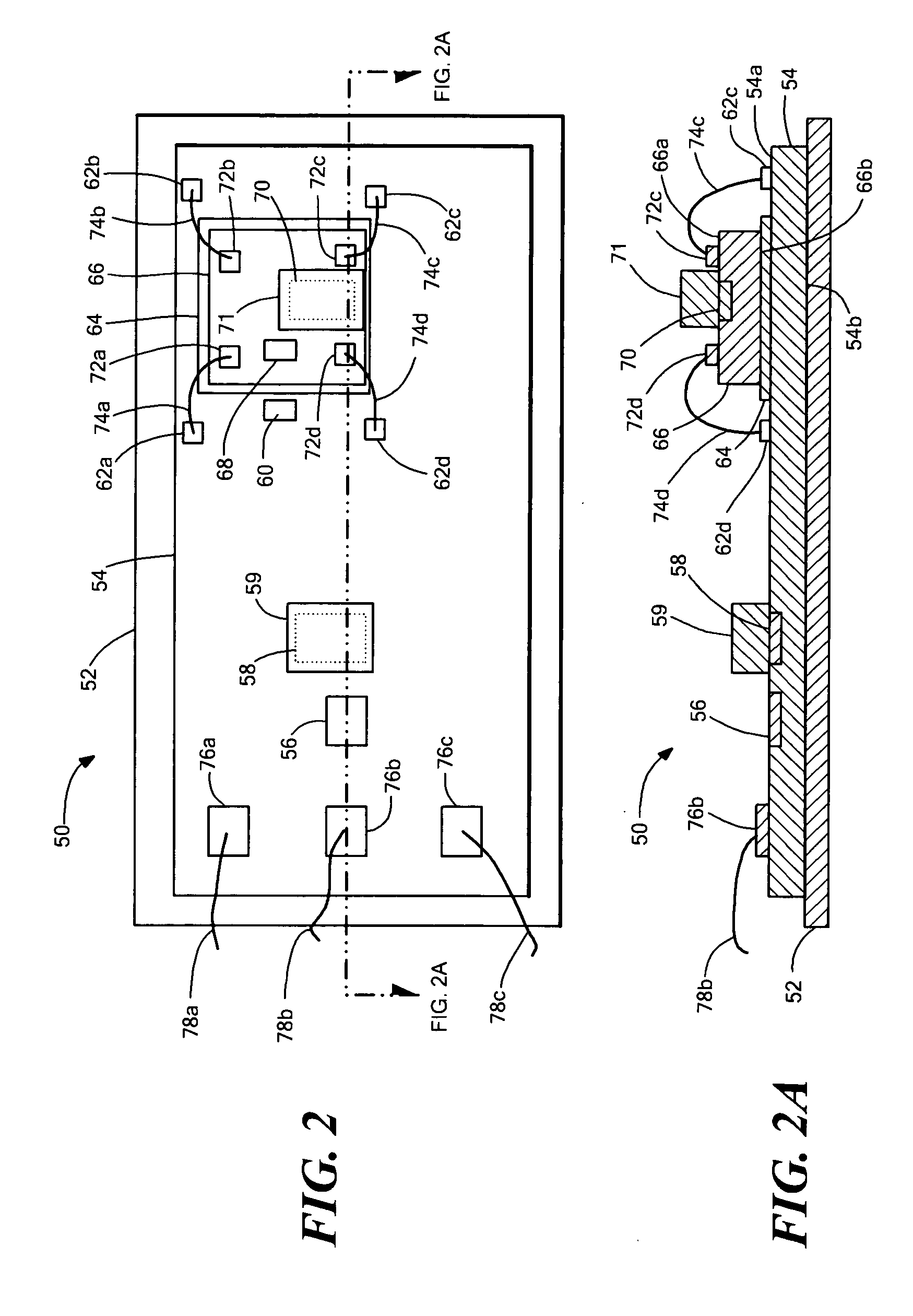

Arrangements for an integrated sensor

ActiveUS7768083B2NanomagnetismSemiconductor/solid-state device detailsCondensed matter physicsIntegrated circuit

An integrated circuit can have a first substrate supporting a magnetic field sensing element and a second substrate supporting another magnetic field sensing element. The first and second substrates can be arranged in a variety of configurations. Another integrated circuit can have a first magnetic field sensing element and second different magnetic field sensing element disposed on surfaces thereof.

Owner:ALLEGRO MICROSYSTEMS INC

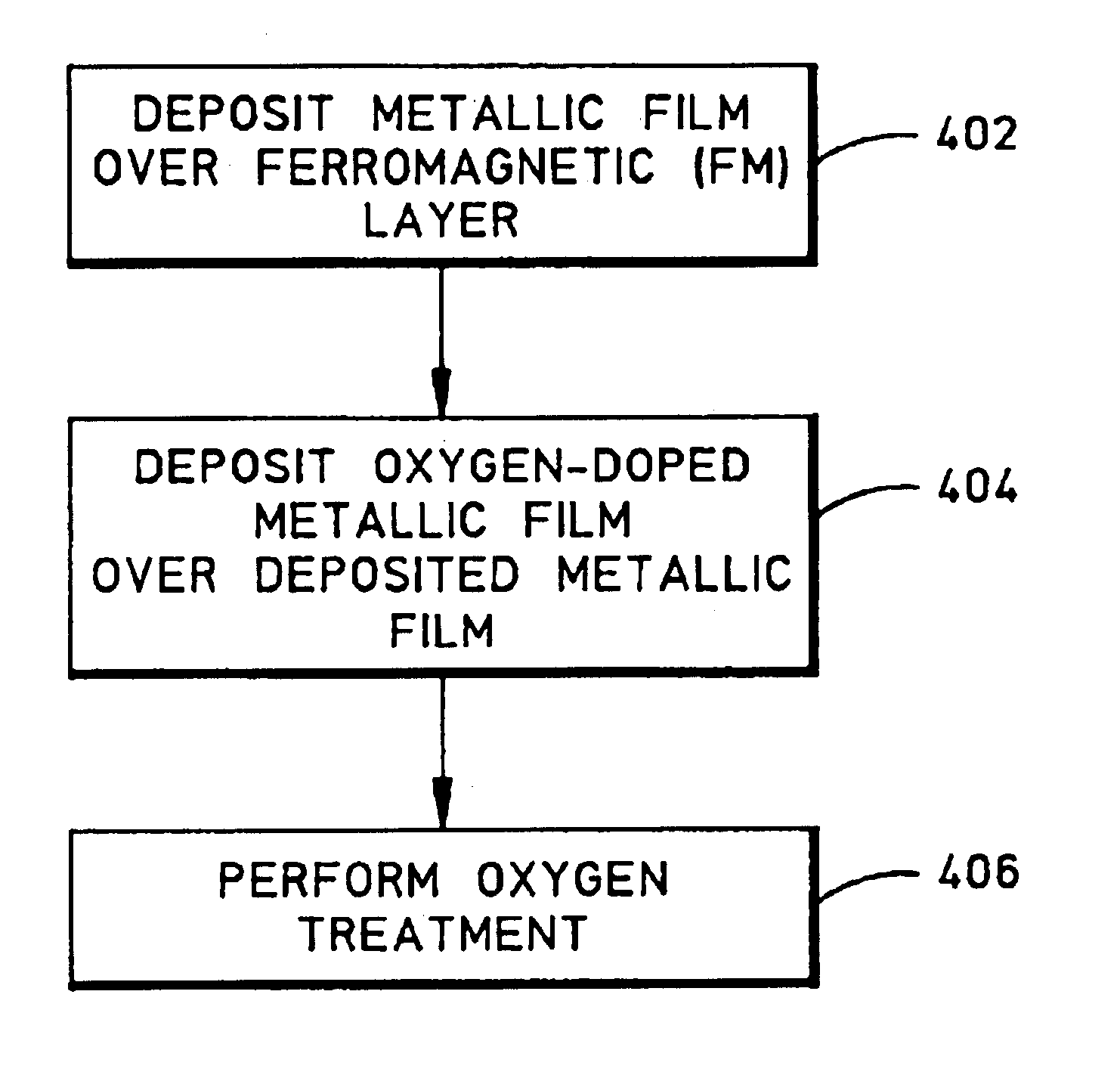

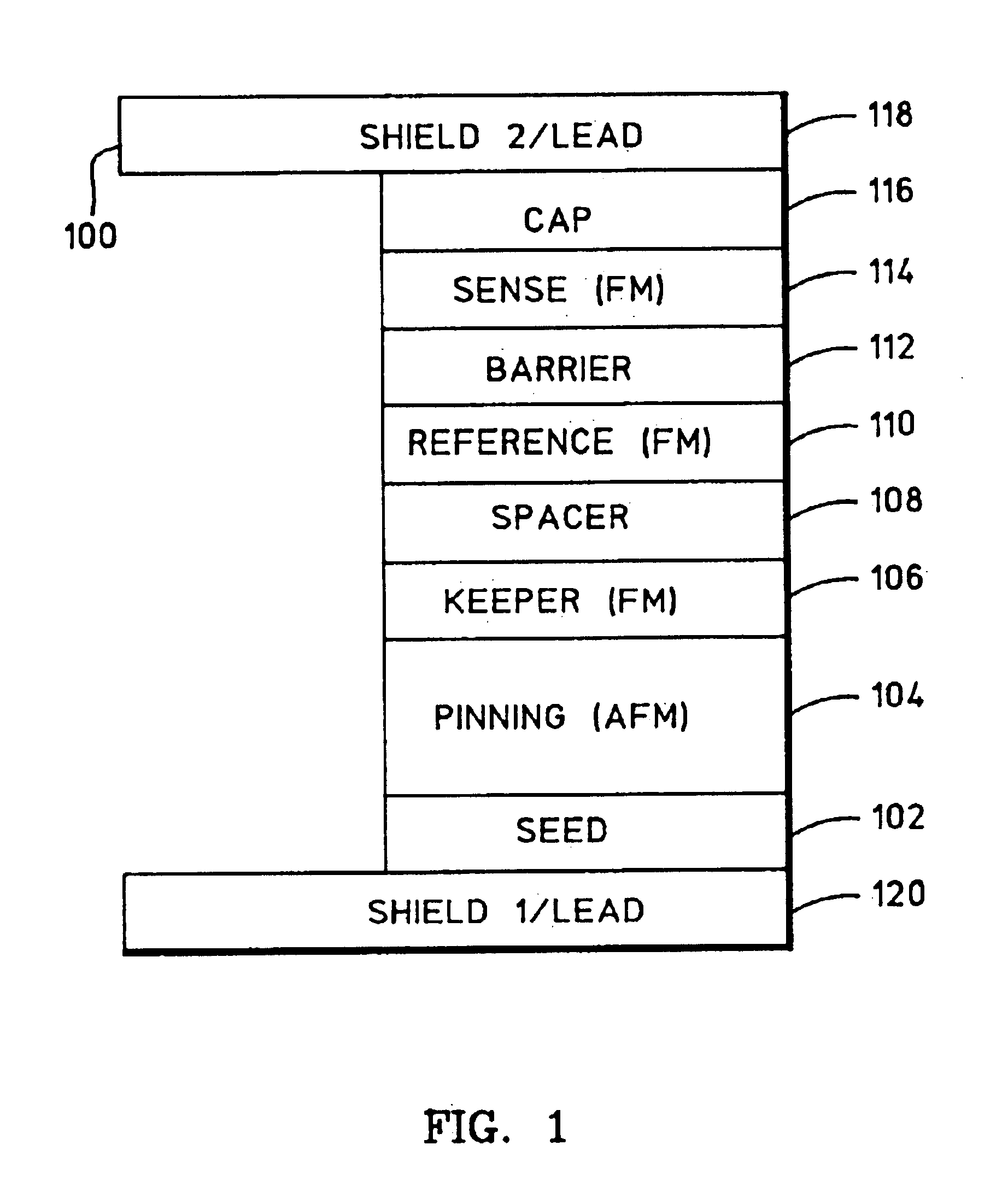

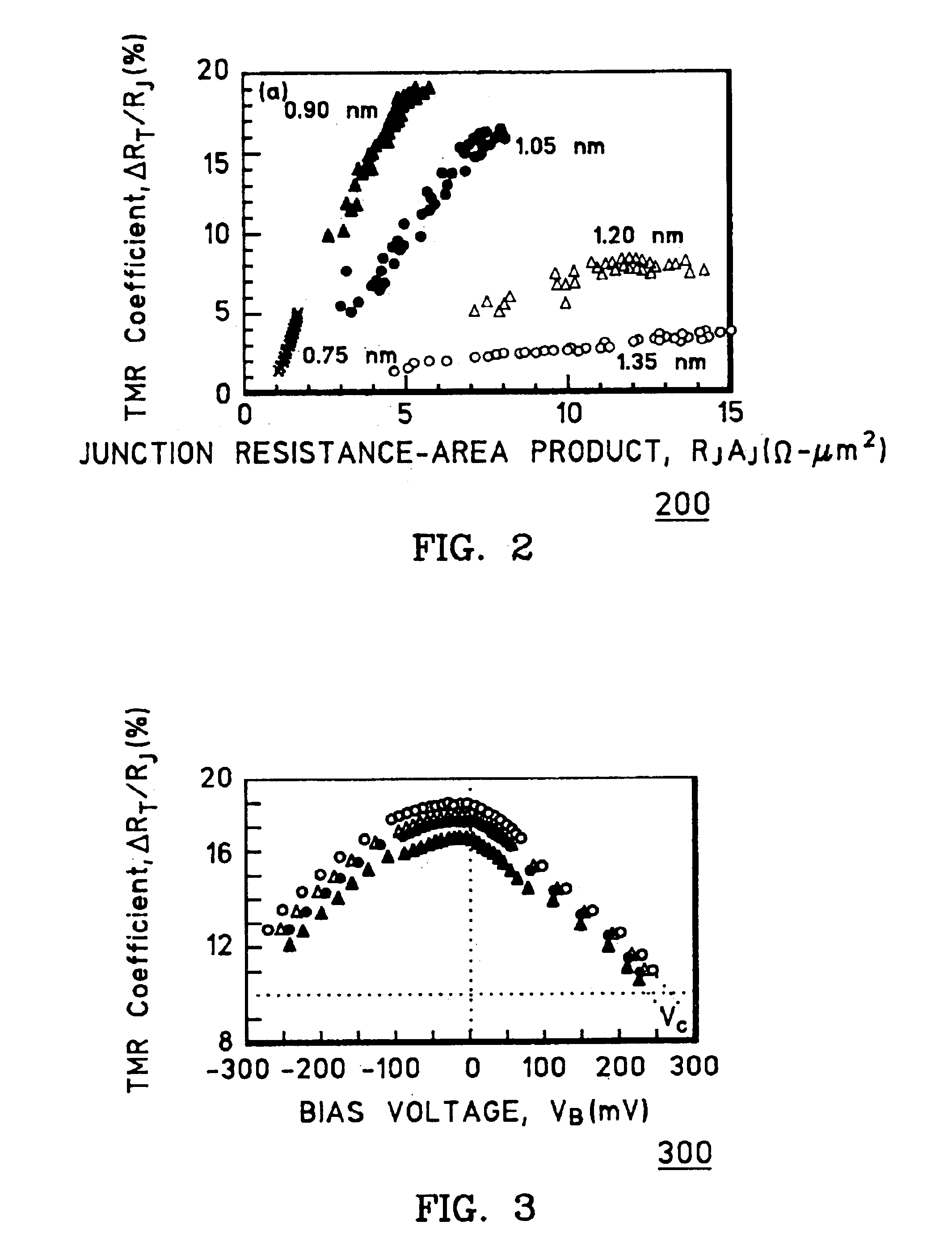

Method of forming a barrier layer of a tunneling magnetoresistive sensor

InactiveUS6841395B2Prevent electrostatic dischargeMagnetic and TMR propertyNanostructure applicationNanomagnetismIon beamXenon

Owner:GLOBALFOUNDRIES INC

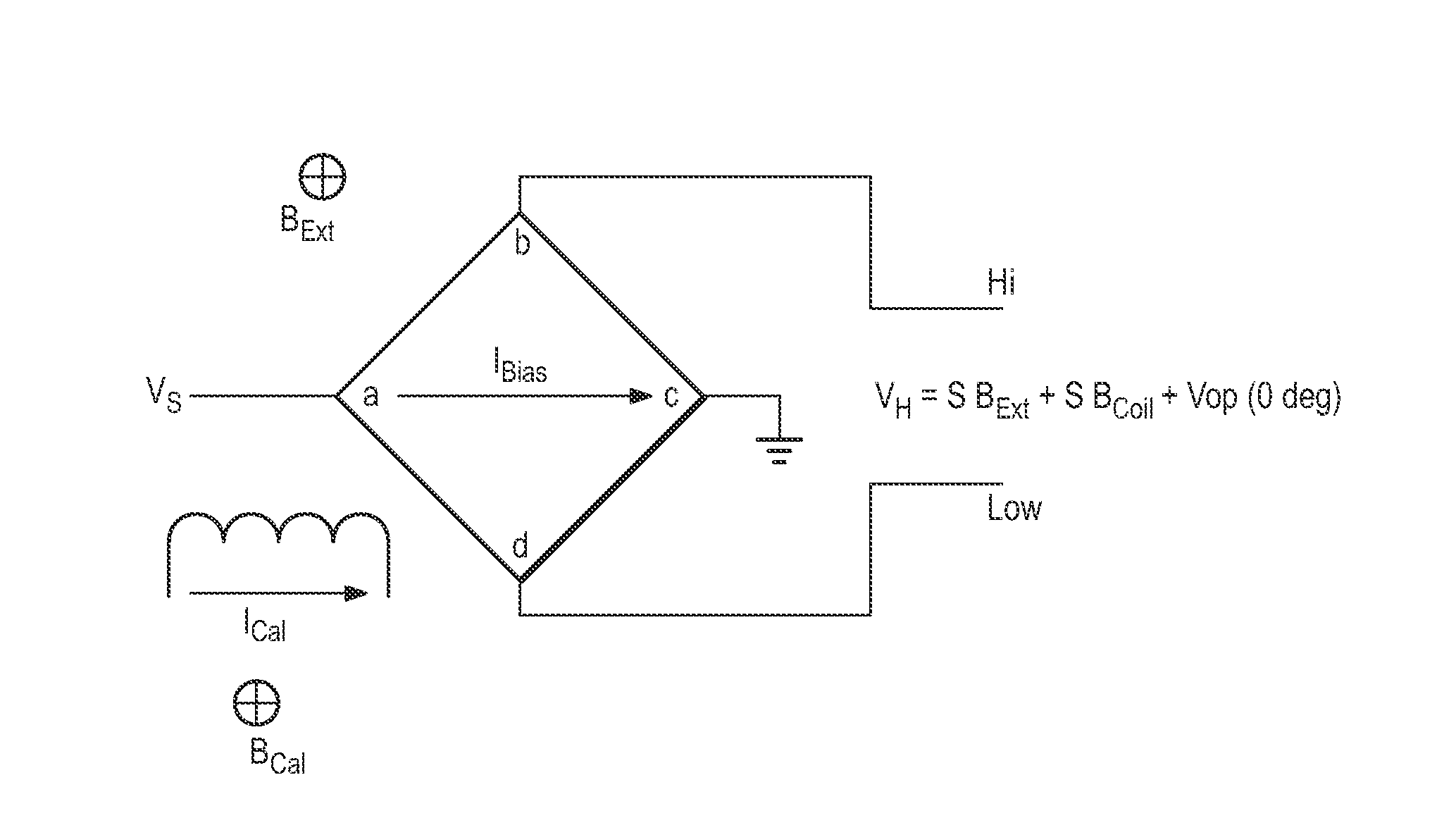

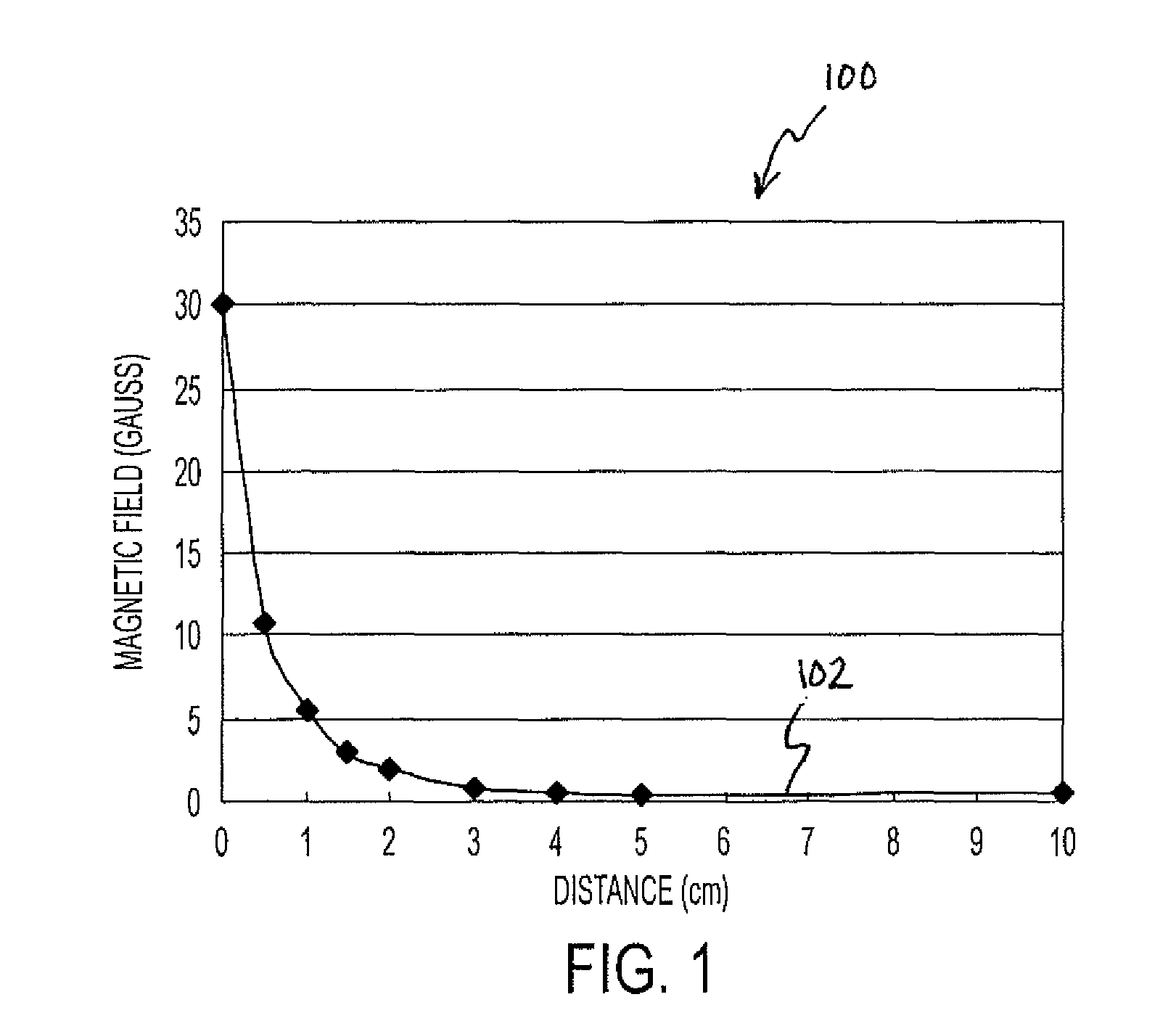

Auto-calibration of magnetic sensor

ActiveUS20080238410A1Magnetic field offset compensationMagnetic field measurement using galvano-magnetic devicesAtomic physicsAuto calibration

The present invention provides a method to compensate for the sensitivity drift of a magnetic field sensor for sensing a magnetic field. The magnetic field sensor comprises at least four electrodes. The method comprises a first step where a first set of two electrodes is used to bias the sensor and a second set of two electrodes is used to sense an output signal of the magnetic field sensor, and a second step where the second set of two electrodes is used to bias the sensor and the first set of two electrodes is used to sense an output signal of the magnetic field sensor. The method is characterized in that at least one of the first or the second step is subdivided in at least a first sub-step and a second sub-step. A reference magnetic field has first magnetic field parameters, e.g. a first amplitude and / or direction, in the first sub-step and second magnetic field parameters, a second amplitude and / or direction, in the second sub-step. An output signal is sensed in the first and in the second step, and within the first or the second step an output signal is sensed in the first and the second sub-step.

Owner:AMI SEMICON BELGIUM

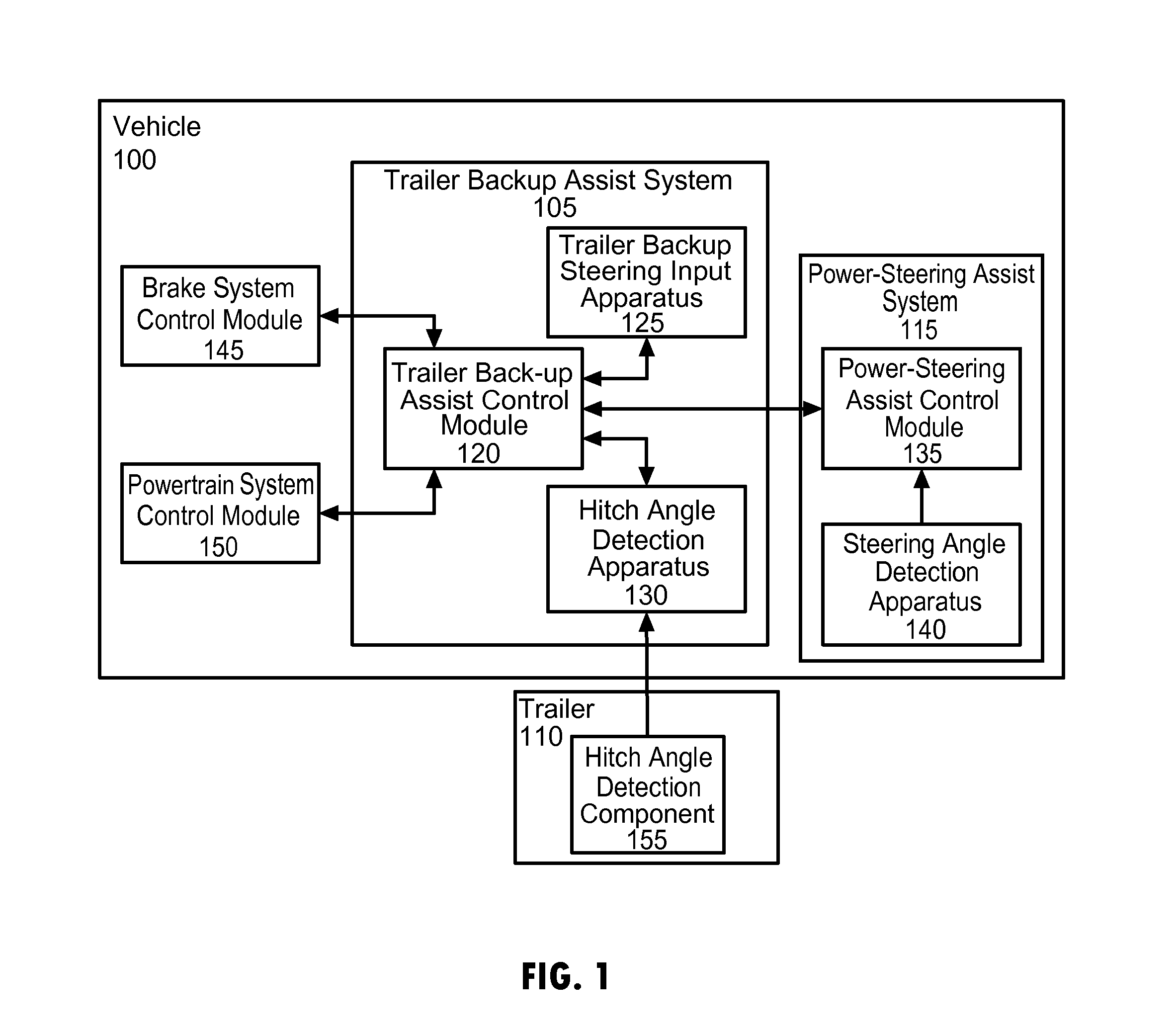

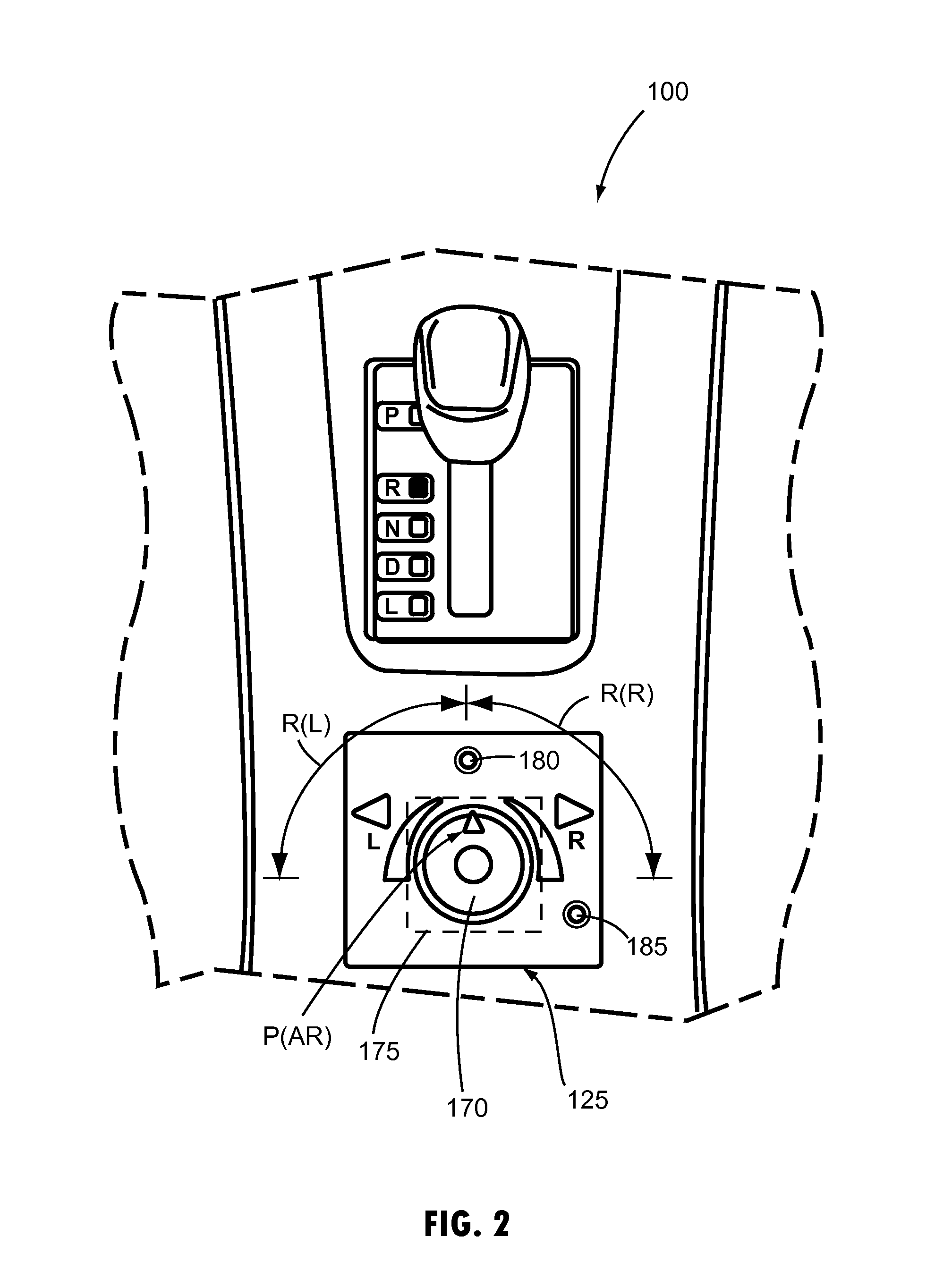

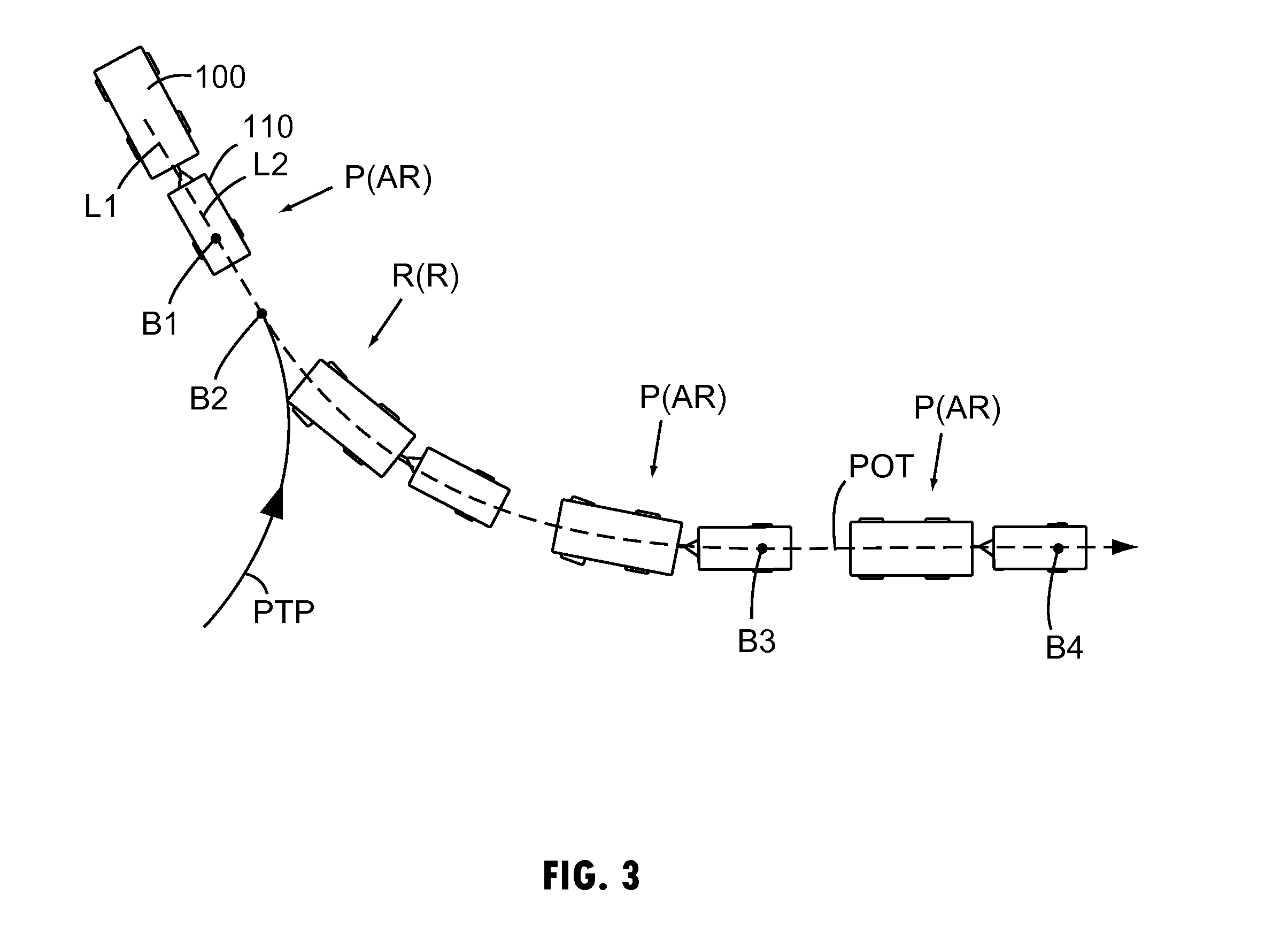

Hitch angle sensor assembly

ActiveUS20140210456A1Solid-state devicesMagnetic field measurement using galvano-magnetic devicesEngineeringVertical axis

In one embodiment, a hitch angle sensor assembly includes a spacer fixed between a hitch ball and a mounting surface on a vehicle. An element is rotatably coupled with the spacer about a vertical axis defined by the hitch ball, and connecting member secures the element to a trailer. A hall sensor is coupled with the spacer and senses a magnetic portion of the element to determine a hitch angle between the vehicle and trailer. This and other embodiments of the hitch angle sensor assembly may be used independently or in combination with other hitch angle sensors or systems to estimate the hitch angle between the vehicle and trailer, which may be advantageously used for operation of the vehicle with a trailer backup assist system.

Owner:FORD GLOBAL TECH LLC

Magnetic position sensor having a variable width magnet mounted into a rotating disk and a hall effect sensor

InactiveUS6124709AEddy current effect is minimized and eliminatedMagnetic-field-controlled resistorsSolid-state devicesPosition sensorPhysics

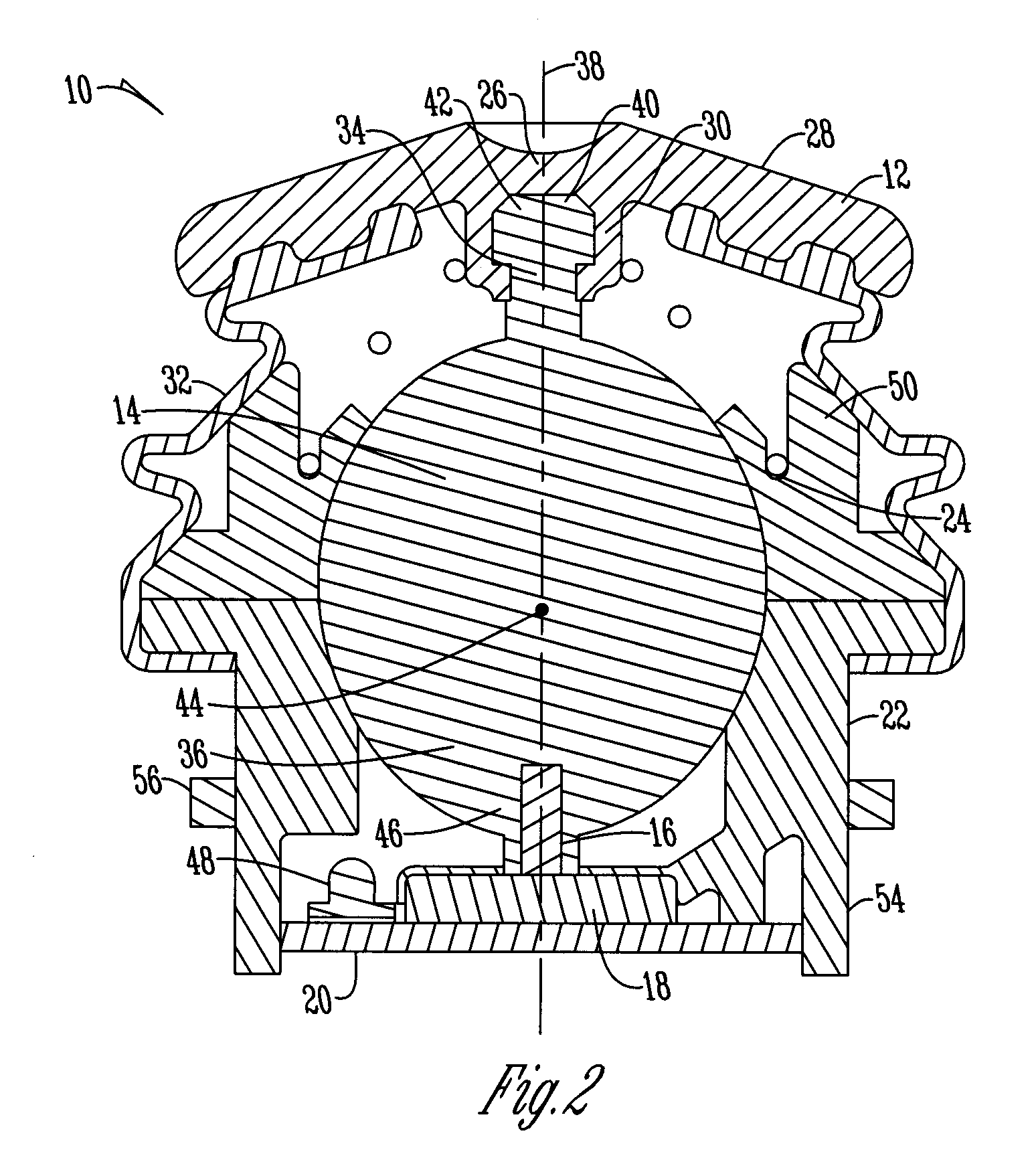

A linear analog rotary 360 degree magnetic position sensor assembly for sensing the position of rotating objects. A magnet having a varying width is mounted to a magnet disc. A flux return disc is mounted on a shaft opposed to the magnet disc. The magnet generates a magnetic field in an air gap between the discs. A magnetic field sensor such as a hall effect sensor is positioned in the gap and operates to provide an output signal representative of the magnetic field density as the shaft and disc rotate. The output signal changes magnitude in relation to the relative position of the magnet with respect to the magnetic field sensor.

Owner:CTS CORP ELKHART

Magnetic field sensor apparatus

ActiveUS7474093B2Force measurement by measuring magnetic property varationAmplifier modifications to reduce noise influenceStress sensorAcoustics

A magnetic field sensor apparatus includes a first magnetic field sensor and a second magnetic field sensor, arranged on a substrate in a spaced manner from each other, a first temperature sensor with an output for a first temperature sensor signal, a second temperature sensor with an output for a second temperature sensor signal, a first stress sensor with an output for a first stress sensor signal, and a second stress sensor with an output for a second stress sensor signal, wherein the first temperature sensor and the first stress sensor are arranged more closely to the first magnetic field sensor or at a location identical with the first magnetic field sensor, and the second temperature sensor and the second stress sensor are arranged more closely to the second magnetic field sensor than to the first magnetic field sensor or at a location identical with the second magnetic field sensor.

Owner:INFINEON TECH AG

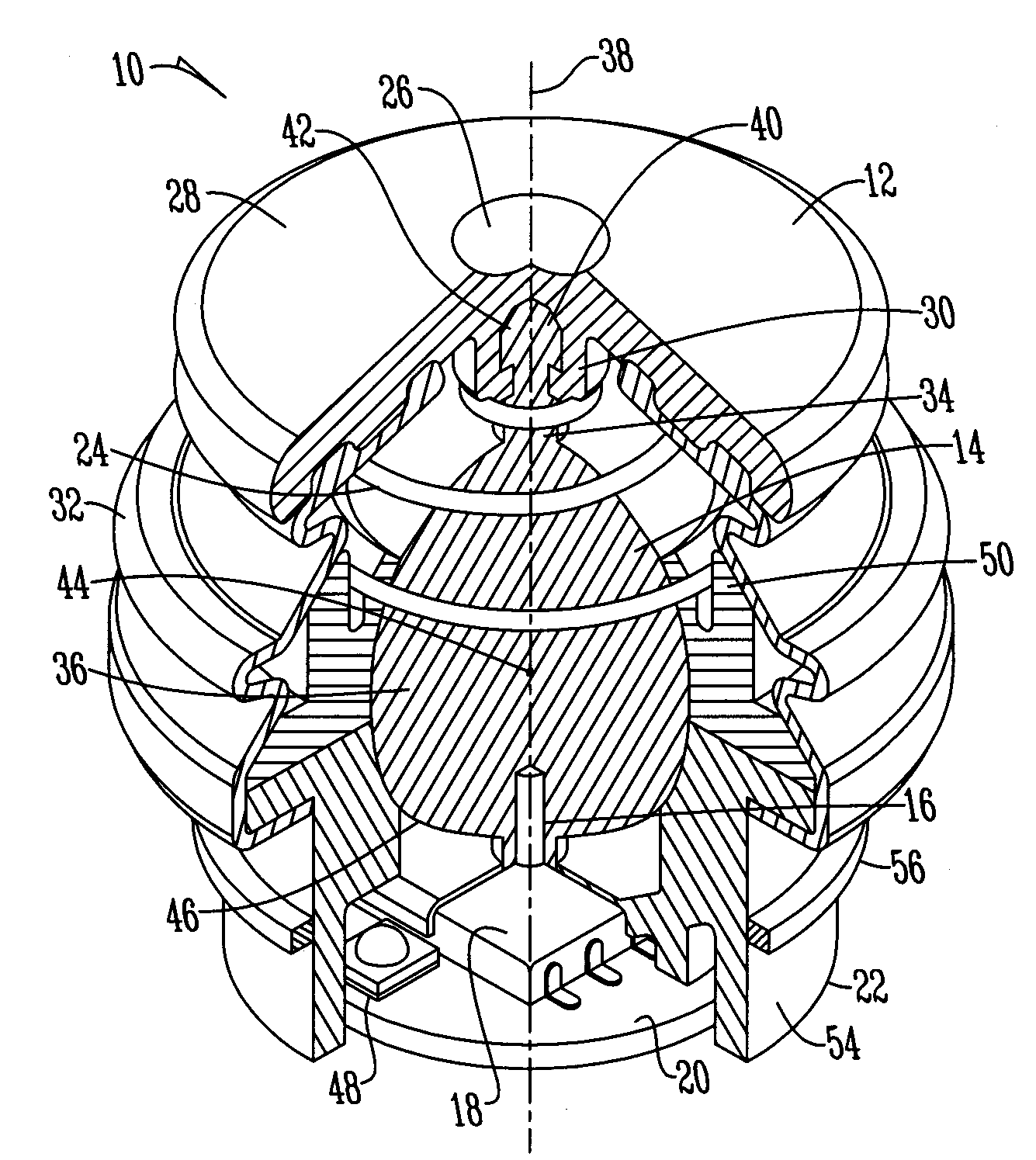

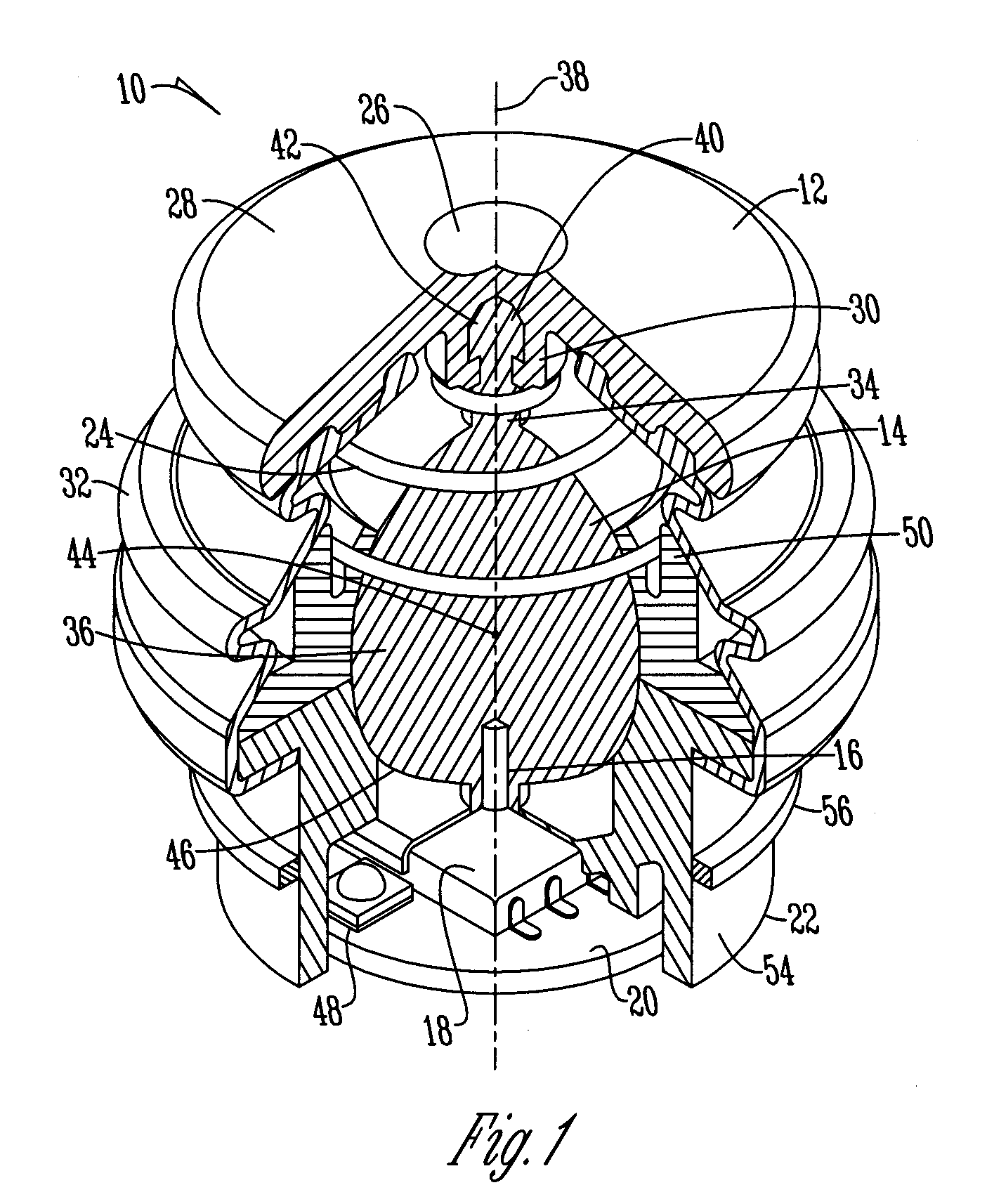

Joystick and method of manufacturing the same

ActiveUS20090212766A1Manual control with multiple controlled membersControlling membersJoystickEngineering

A joystick having a movable member that includes a shaft portion and a spherical portion wherein the shaft portion has a diameter less than the spherical portion. An actuating member is secured to the shaft portion of the movable member to provide actuation of the movable member. A magnet is disposed within the spherical portion of the movable member and positioned adjacent a three axis sensor such that the magnet moves in a hemispherical pattern along the three axis sensor to operate a device.

Owner:DANFOSS POWER SOLUTIONS INC

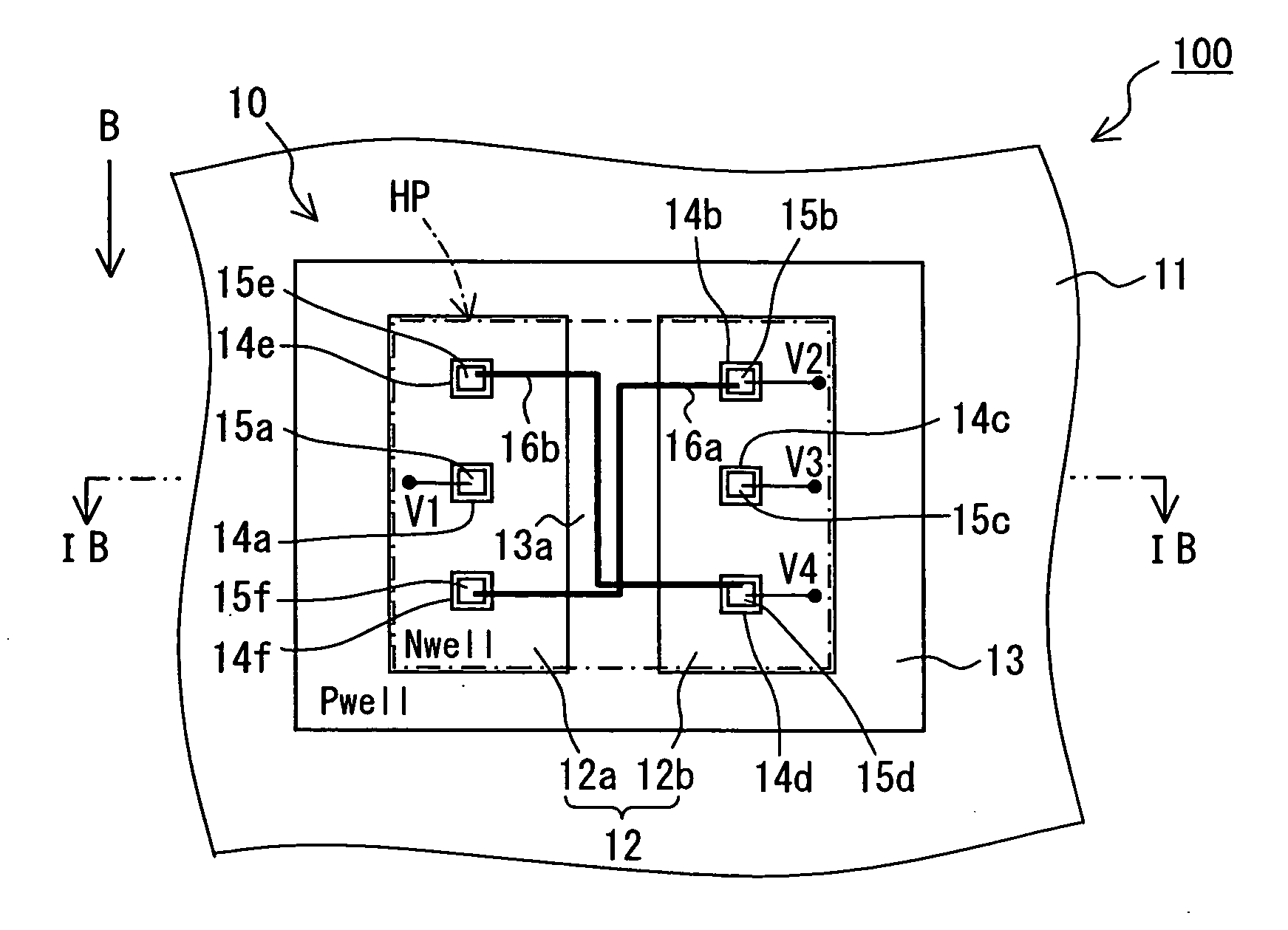

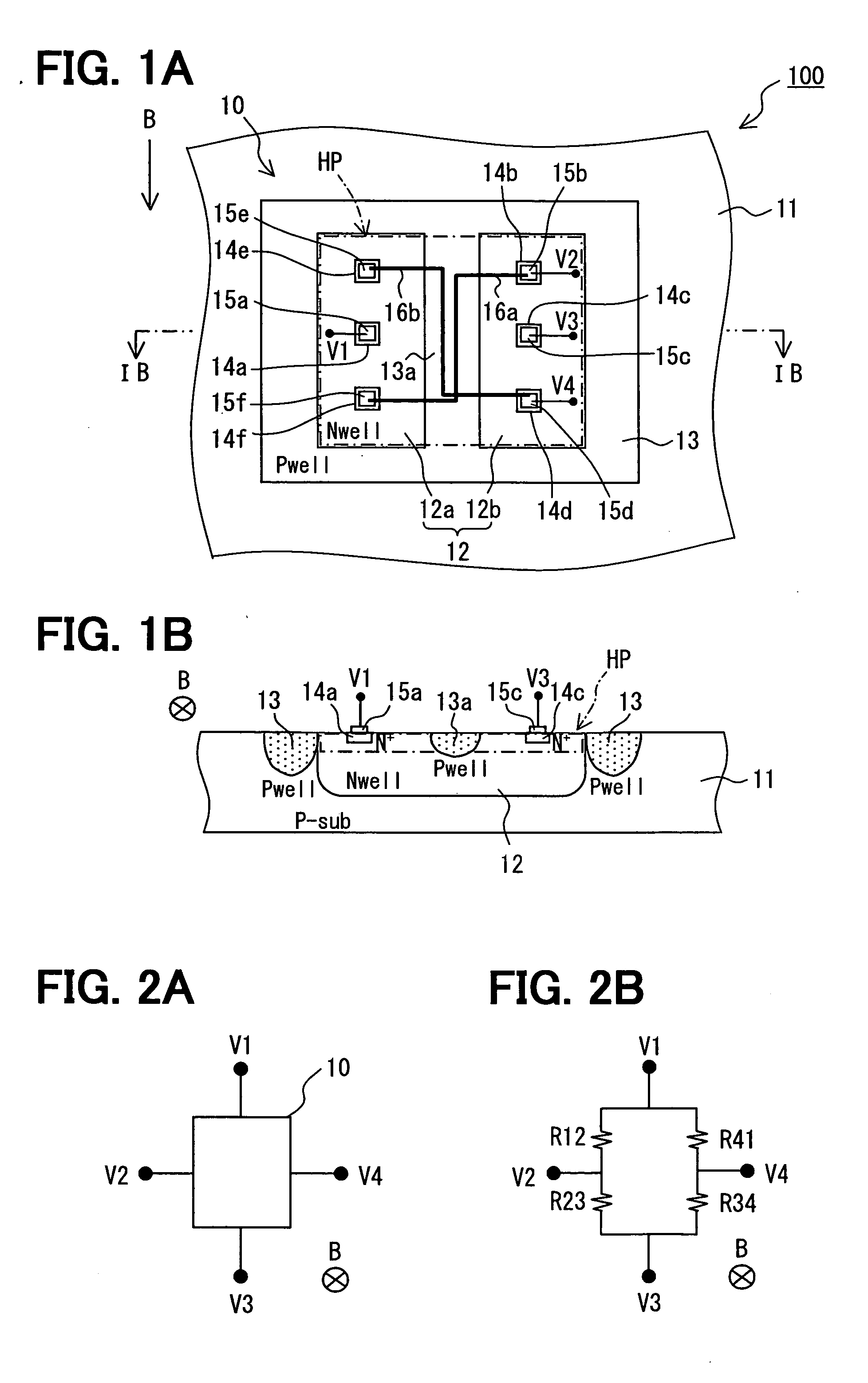

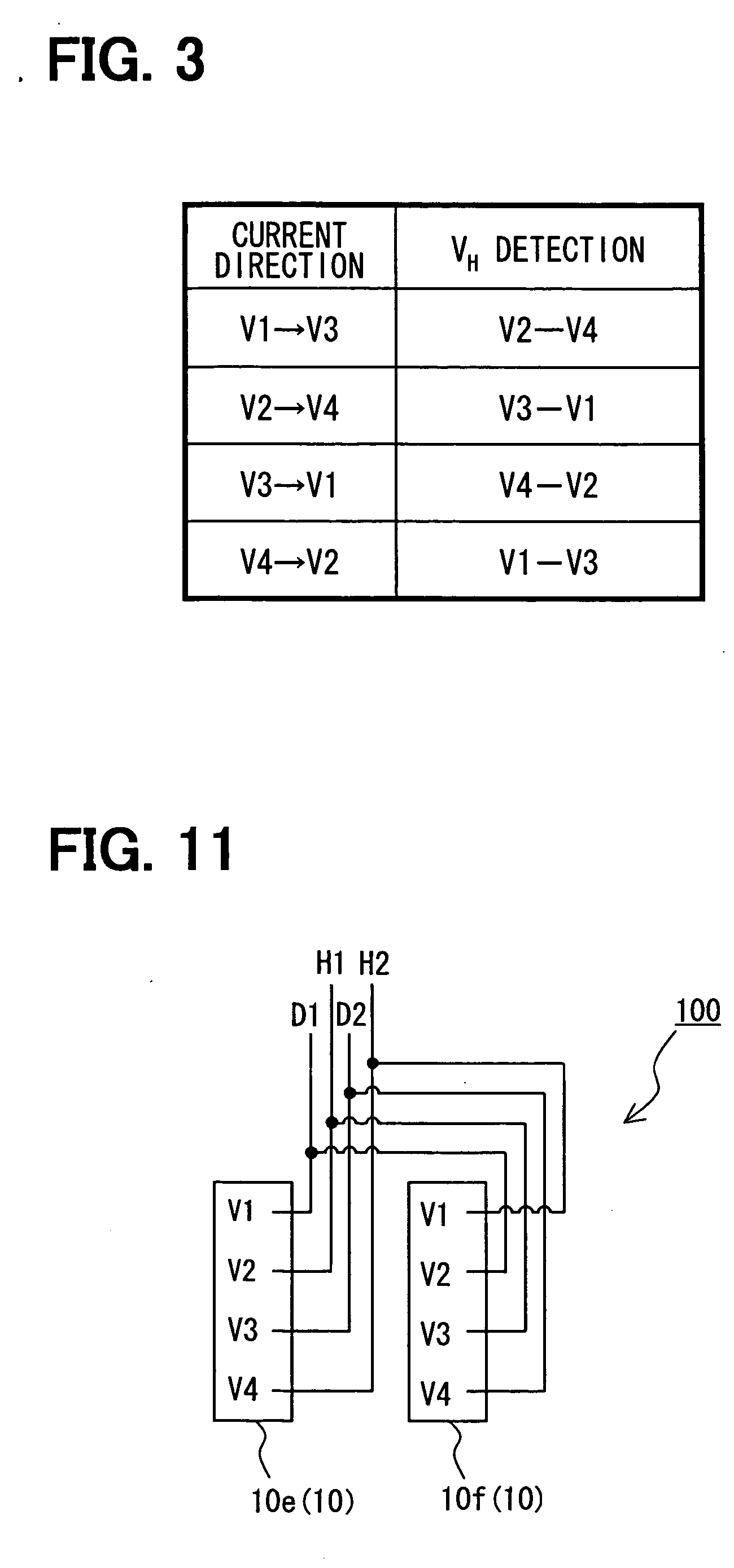

Magnetic sensor and method for detecting magnetic field

InactiveUS20070290682A1Lower Offset VoltageGalvano-magnetic devicesSolid-state devicesDriving currentElectricity

A magnetic sensor includes: a substrate; a semiconductor region; a magnetic field detection portion; a pair of first electrodes; and two pairs of second electrodes. One pair of second electrodes includes first and second terminals, and the other pair includes third and fourth terminals. The first and third terminals are disposed on one side, and the second and fourth terminals are disposed on the other side. The first and fourth terminals are electrically coupled, and the second and third terminals are electrically coupled. The magnetic field detection portion and the first and second electrodes provide a vertical Hall element. One of the first and second electrodes supplies a driving current, and the other one detects the Hall voltage.

Owner:DENSO CORP

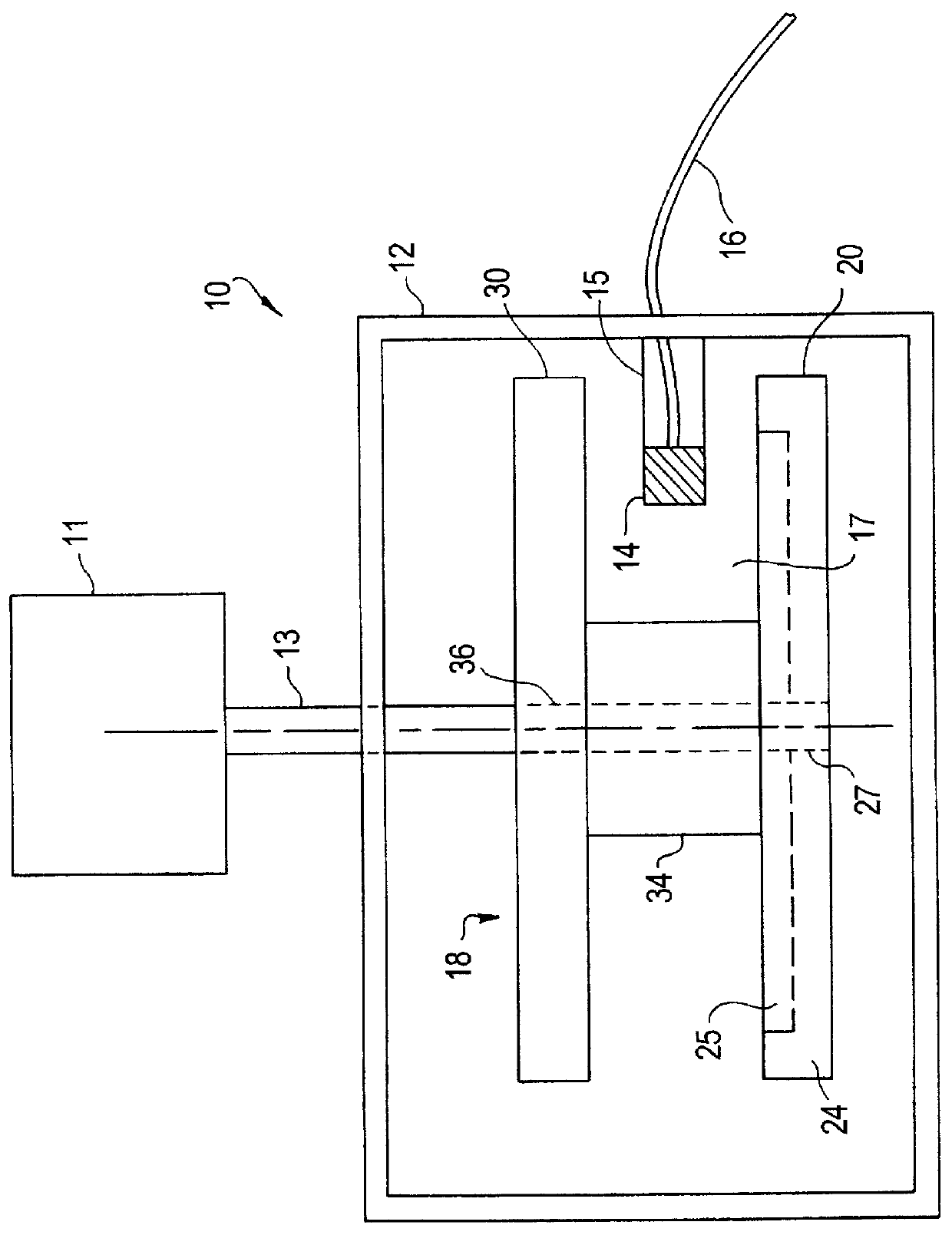

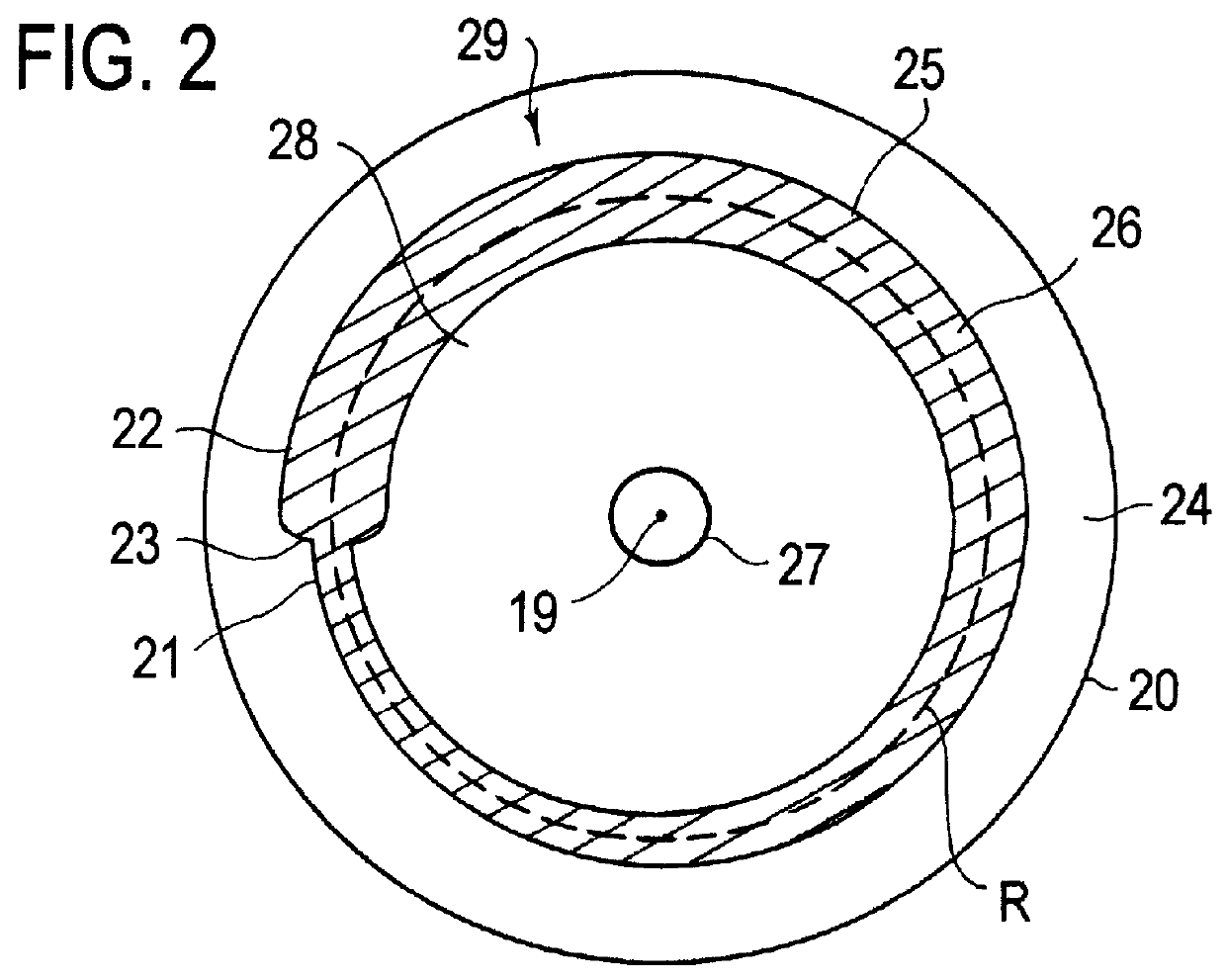

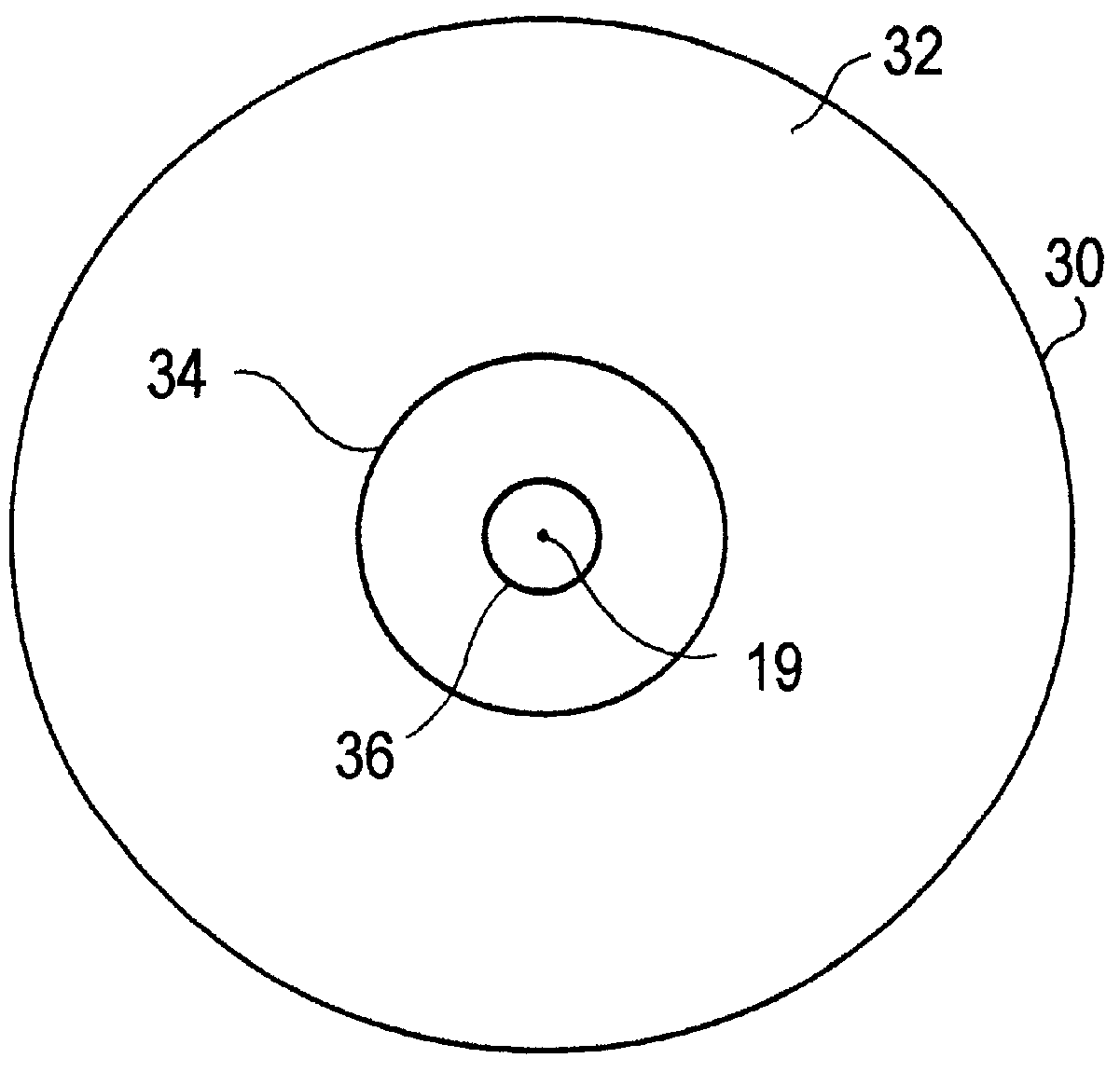

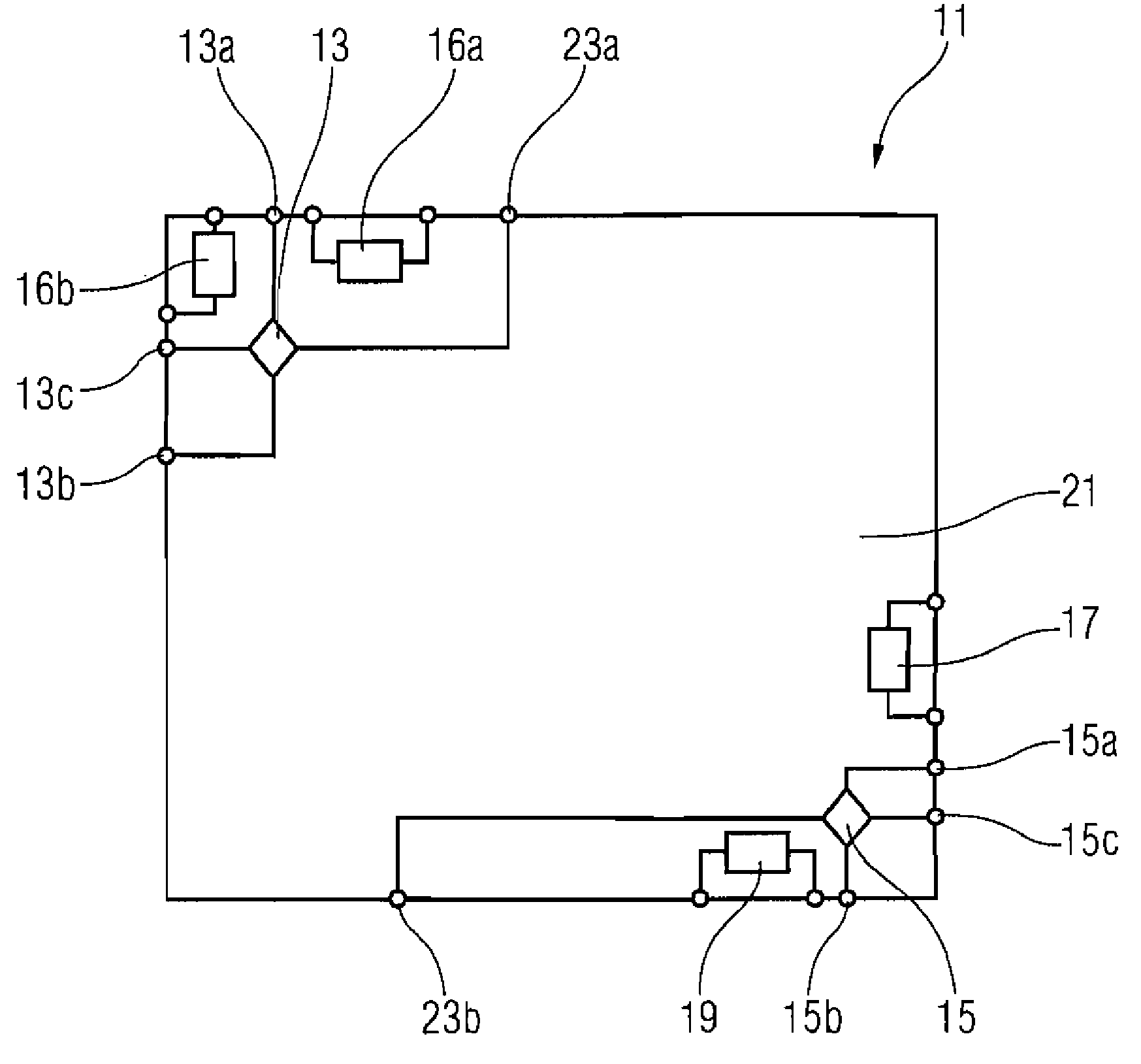

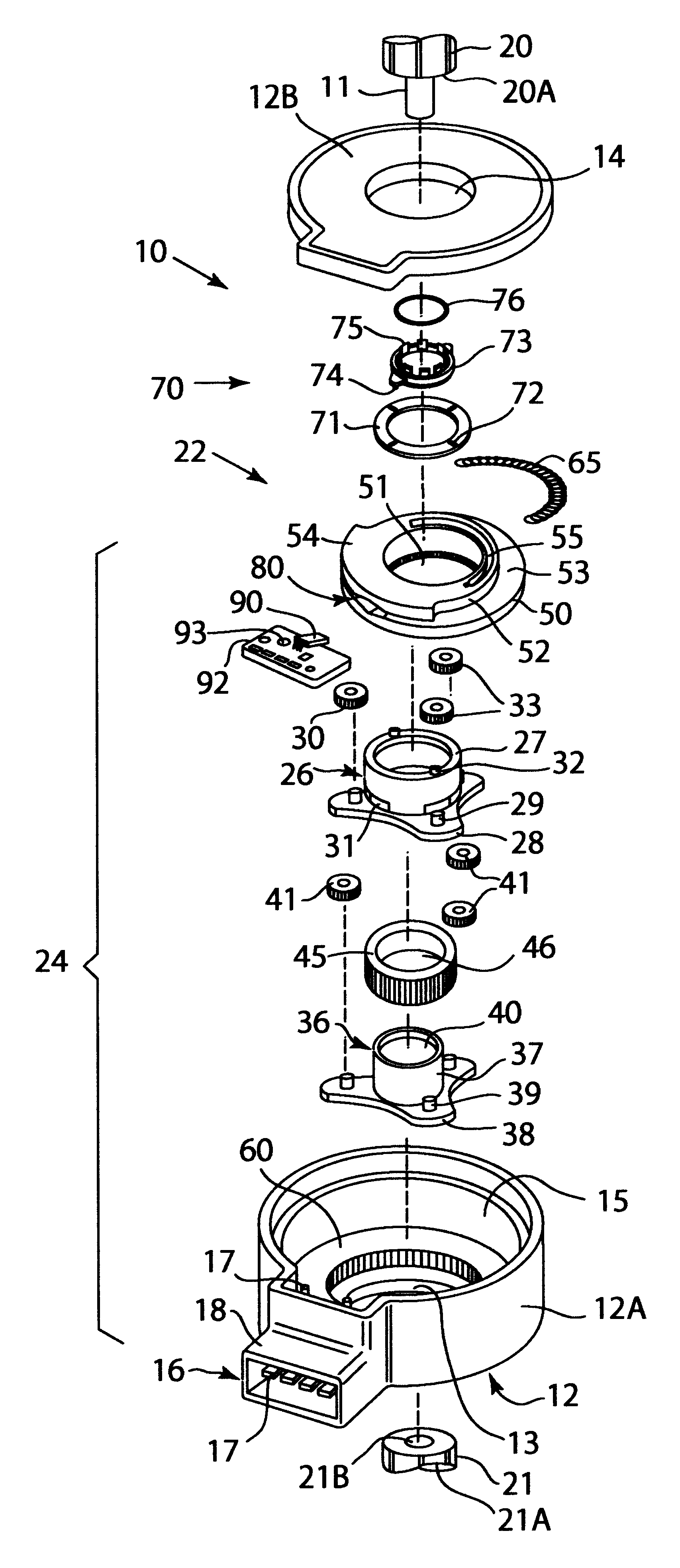

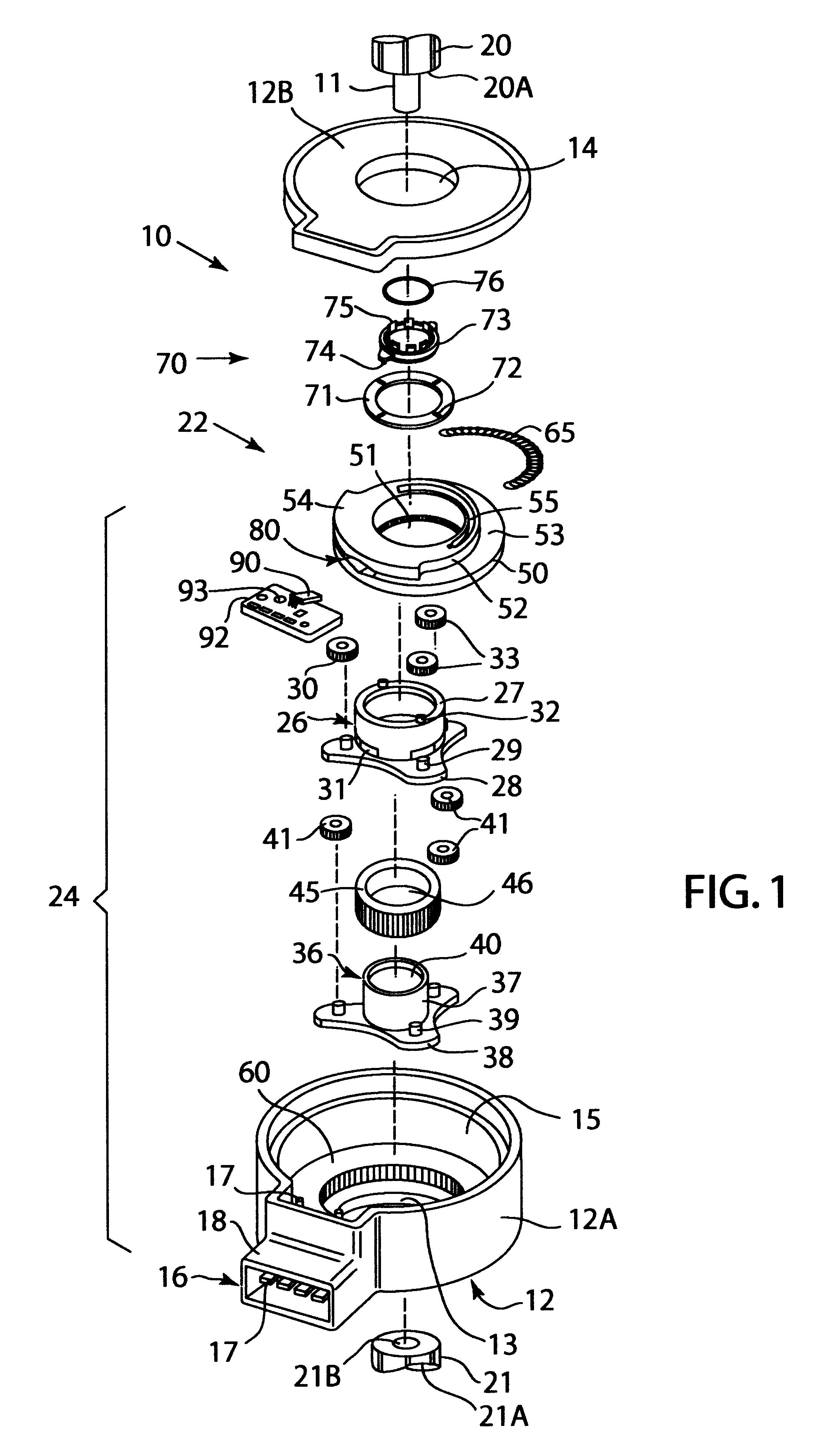

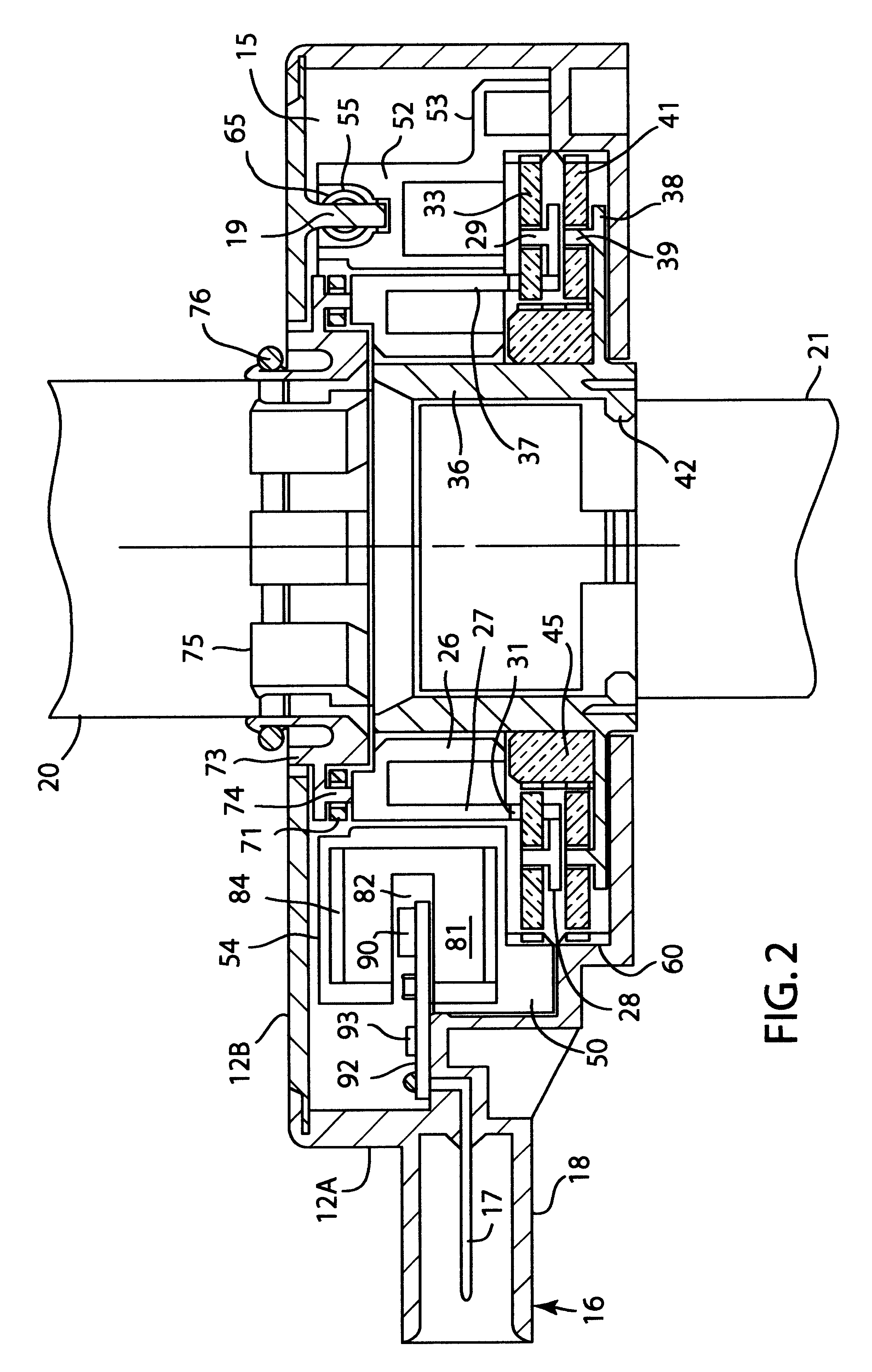

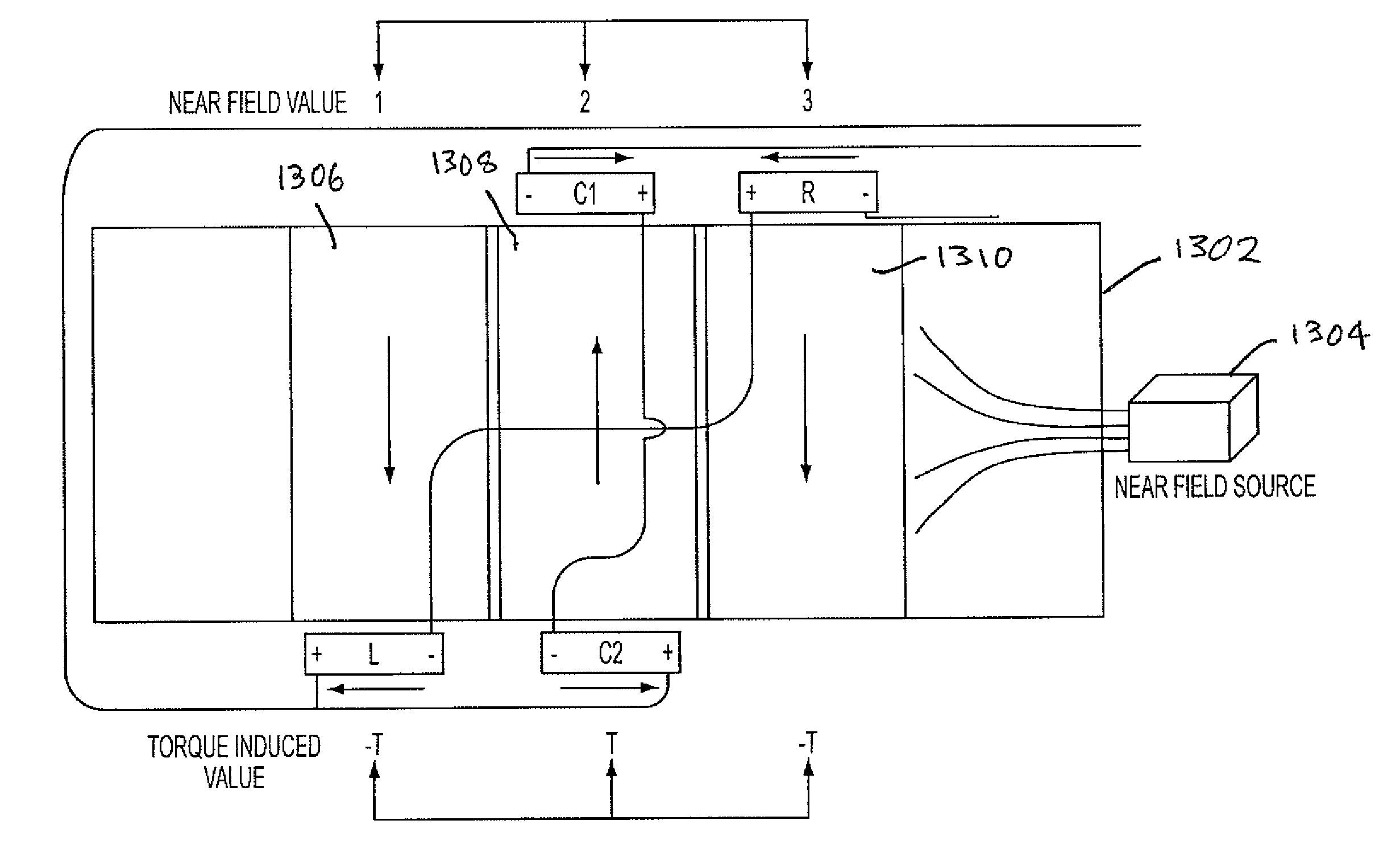

Non-contacting sensor for measuring relative displacement between two rotating shafts

A sensor for measuring the relative displacement between two rotating shafts. The sensor can sense a torque applied to the steering wheel of a vehicle. The sensor has a housing that has apertures at each end. The rotating shafts pass into the housing. A sensor assembly is located in the housing and connected to the shafts. The sensor assembly generates an electrical signal that is proportional to the relative rotational displacement between the shafts. An electrical connector is located in the housing and electrically connects with the sensor assembly. The sensor assembly has a planetary gear assembly that is connected to the shafts. A variable magnetic field generator is connected to the planetary gear assembly and moves proportional to the relative rotational displacement of the shafts. A magnetic field sensor is located adjacent the variable magnetic field generator and generates the electrical signal as the variable magnetic field generator moves.

Owner:CTS CORP ELKHART

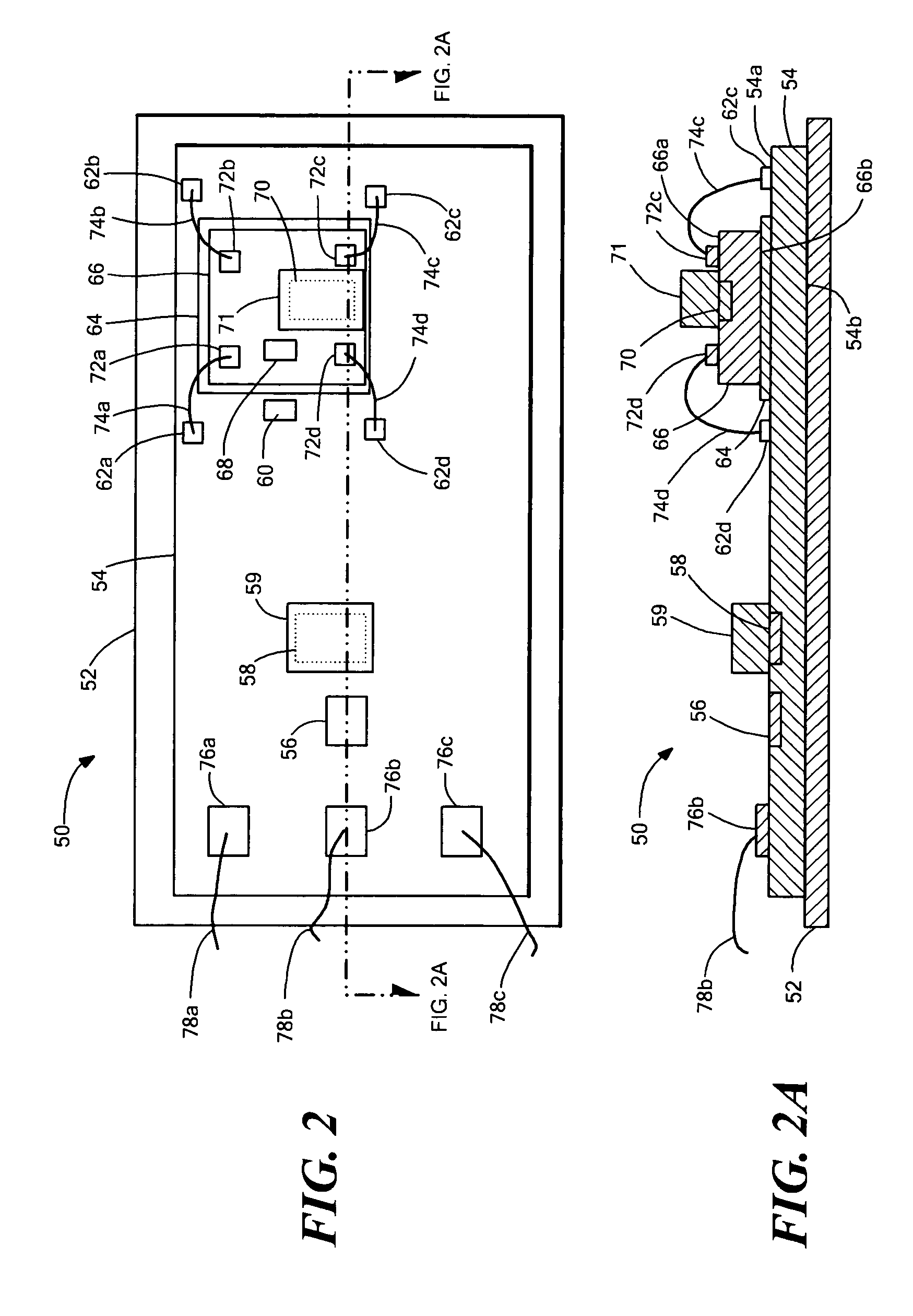

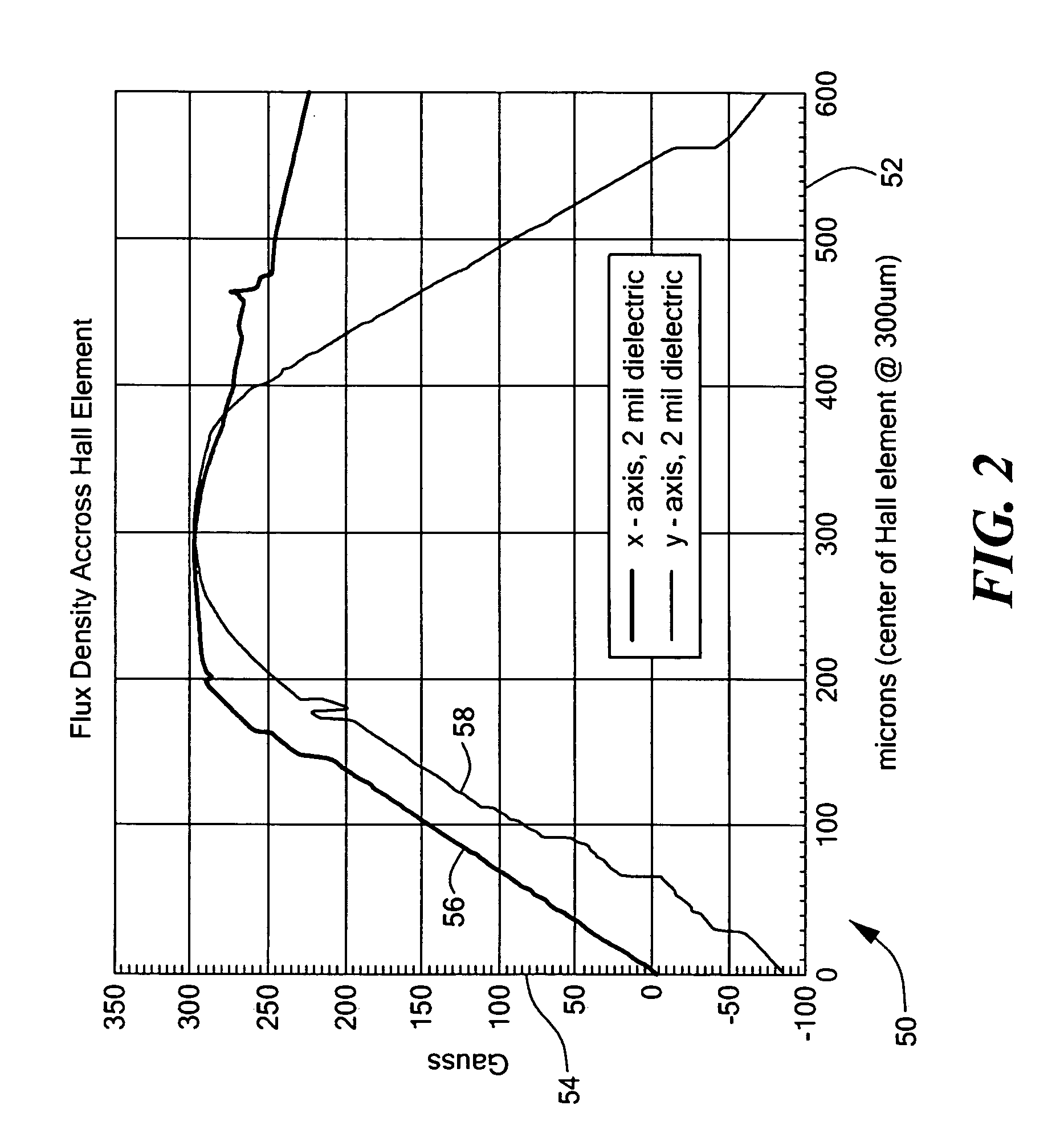

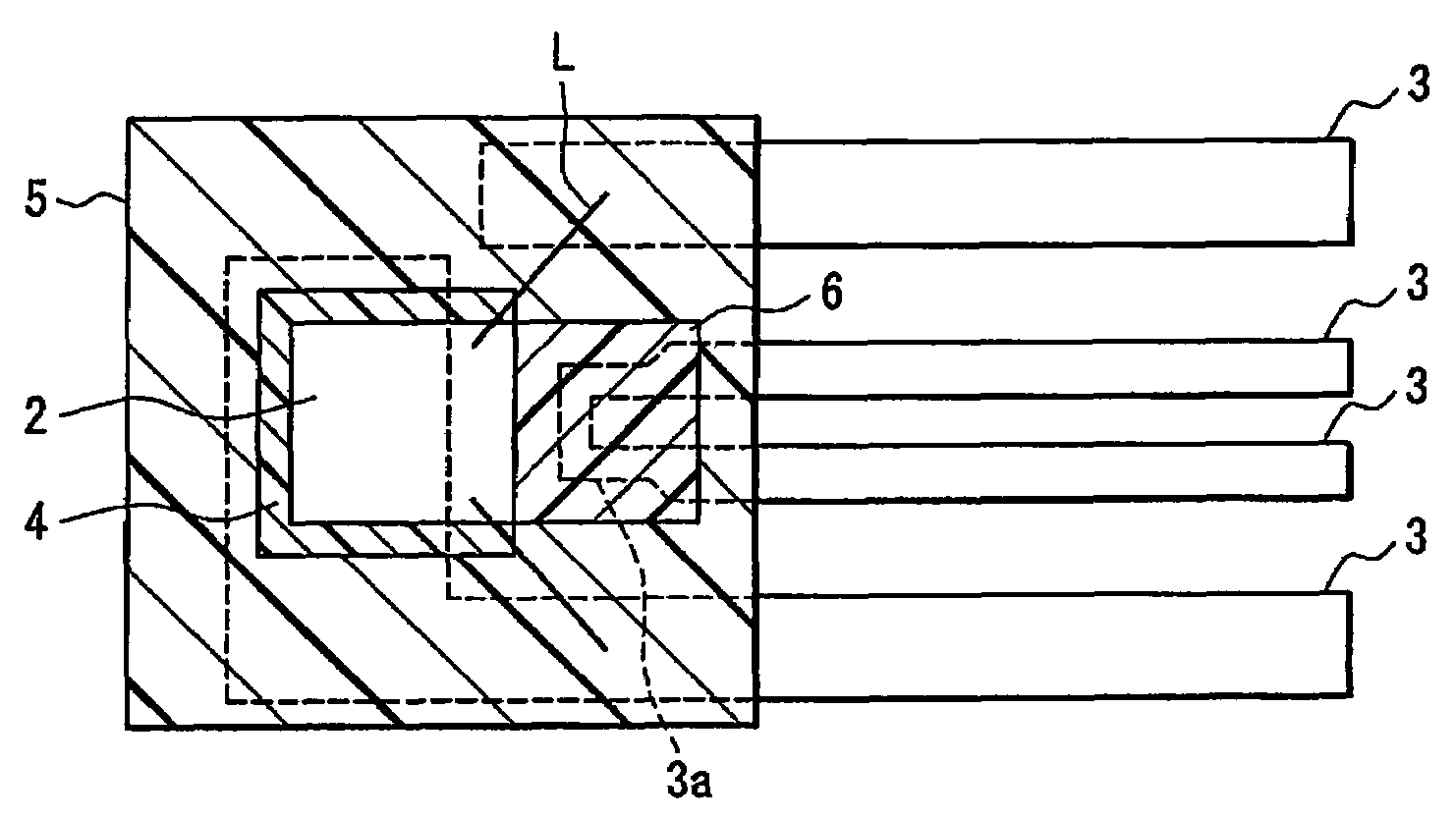

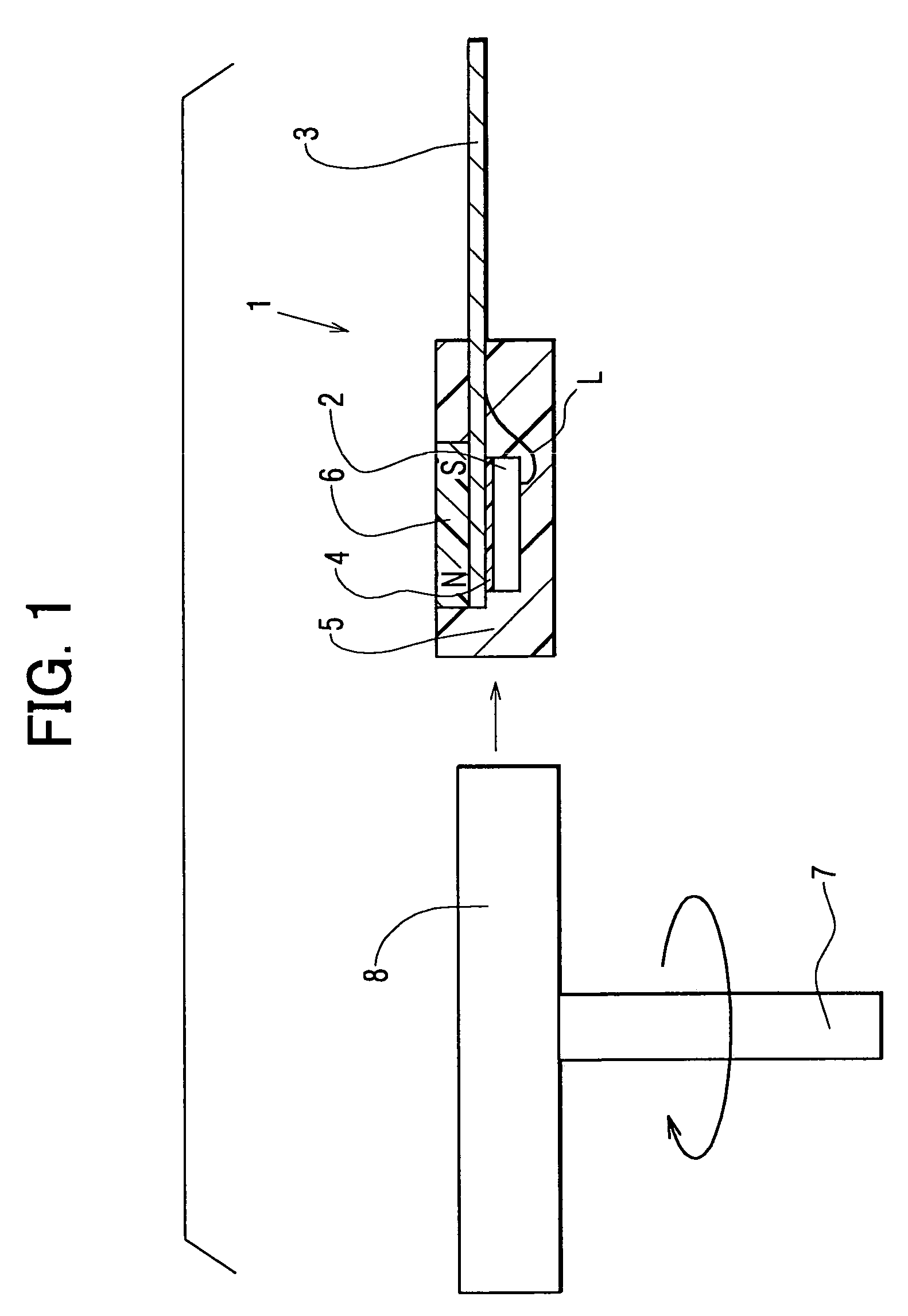

Current sensor

InactiveUS7166807B2Measurement using dc-ac conversionSemiconductor/solid-state device detailsElectrical conductorCurrent sensor

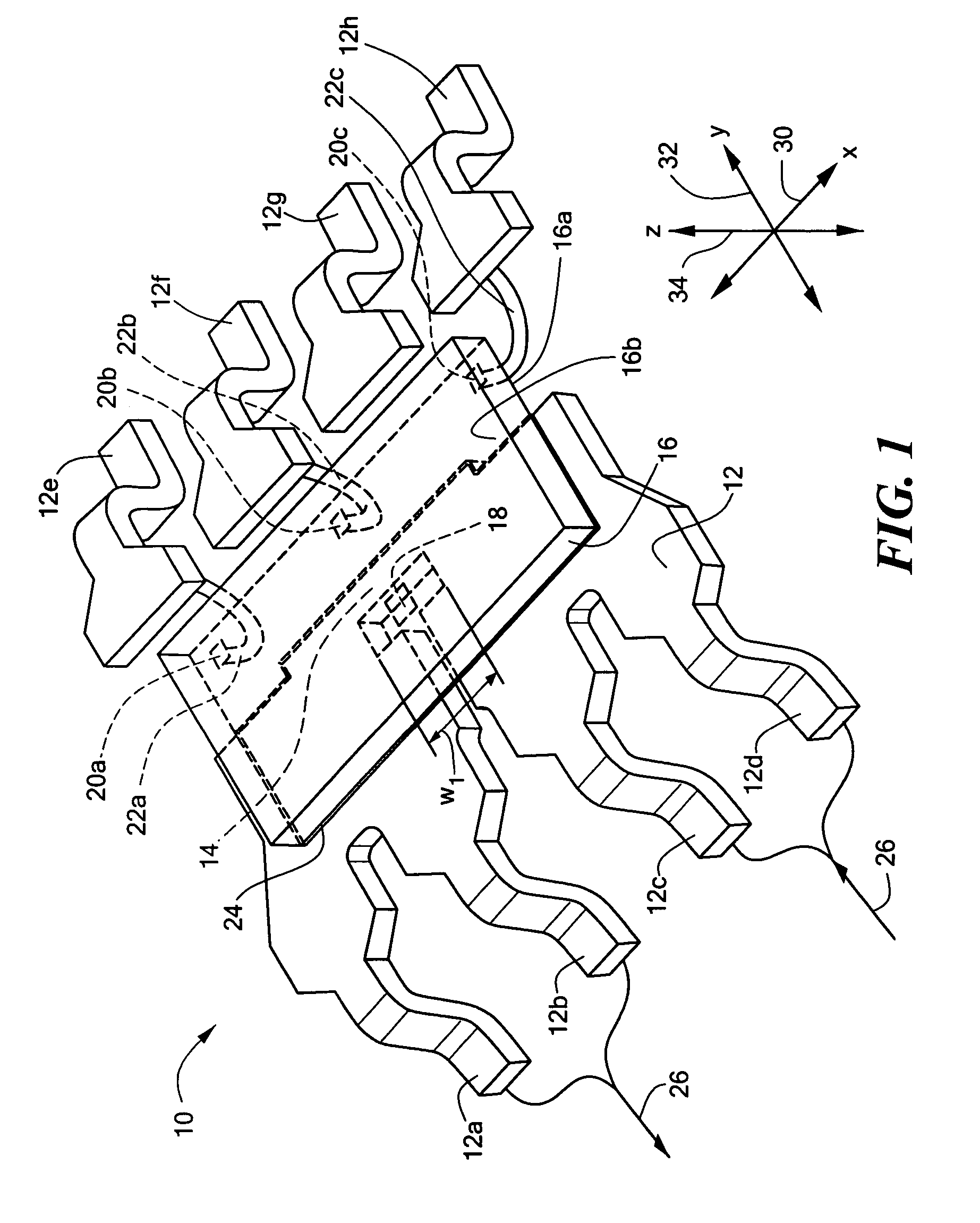

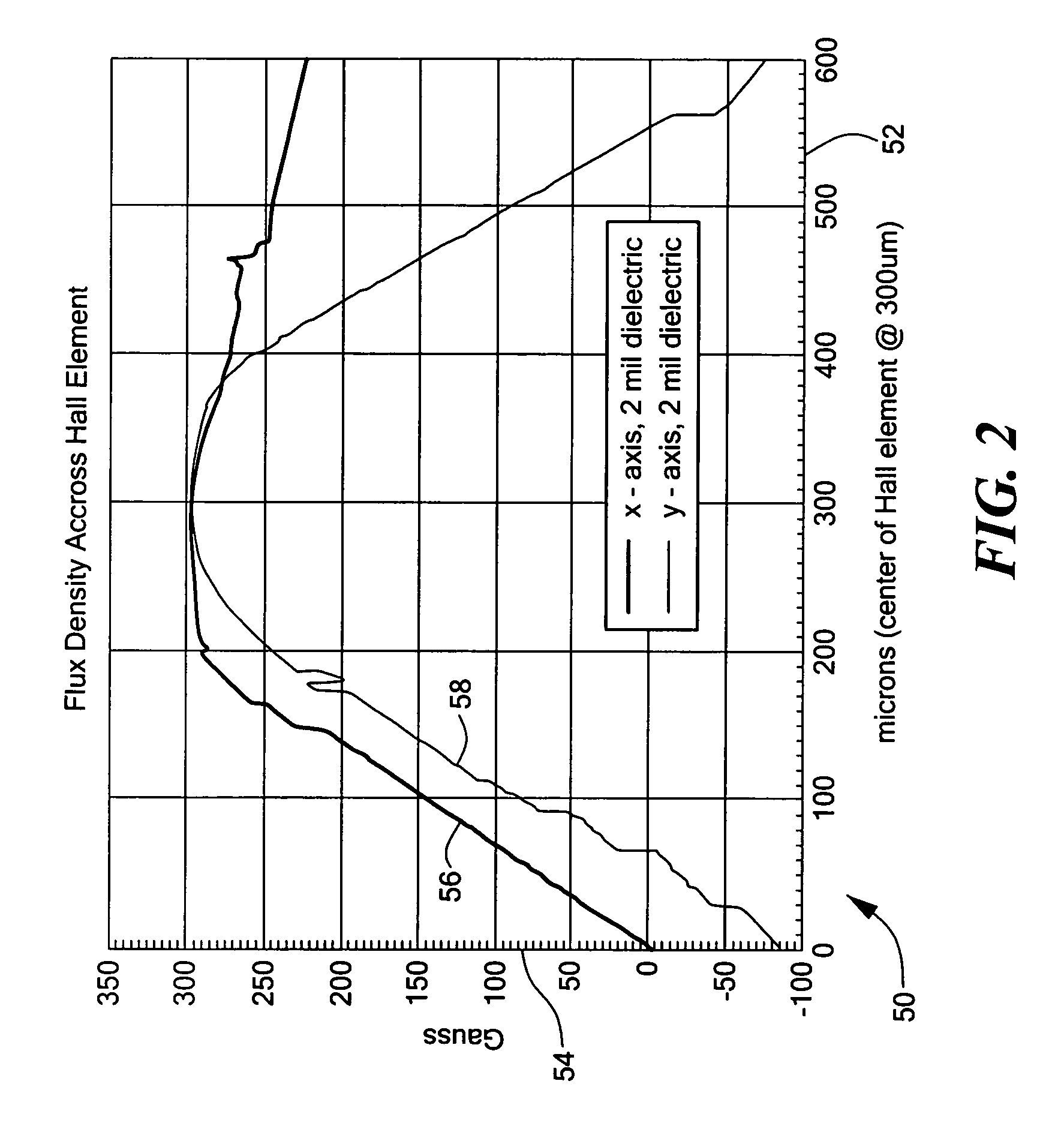

An integrated circuit current sensor includes a lead frame having at least two leads coupled to provide a current conductor portion, and substrate having a first surface in which is disposed one or more magnetic field transducers, with the first surface being proximate the current conductor portion and a second surface distal from the current conductor portion. In one particular embodiment, the substrate is disposed having the first surface of the substrate above the current conductor portion and the second surface of the substrate above the first surface. In this particular embodiment, the substrate is oriented upside-down in the integrated circuit relative to a conventional orientation. A current conductor portion can be deposited proximate to a surface of the substrate and proximate to the one or more magnetic field sensors. With this arrangement, a current sensor is provided for which the one or more magnetic field transducers are very close to the current conductor portion, resulting in a current sensor having improved sensitivity. An insulating layer can be disposed between the current conductor portion and the substrate.

Owner:ALLEGRO MICROSYSTEMS INC

High performance magnetic tunnel barriers with amorphous materials

ActiveUS20060003185A1Improve barrier propertiesImprove performanceNanomagnetismNanoinformaticsTunnel junctionMagnetic layer

A magnetic tunneling element is constructed from a MgO or Mg—ZnO tunnel barrier and an amorphous magnetic layer in proximity with the tunnel barrier. The amorphous magnetic layer includes Co and at least one additional element selected to make the layer amorphous. Magnetic tunnel junctions formed from the amorphous magnetic layer, the tunnel barrier, and an additional ferromagnetic layer have tunneling magnetoresistance values of up to 200% or more.

Owner:IBM CORP

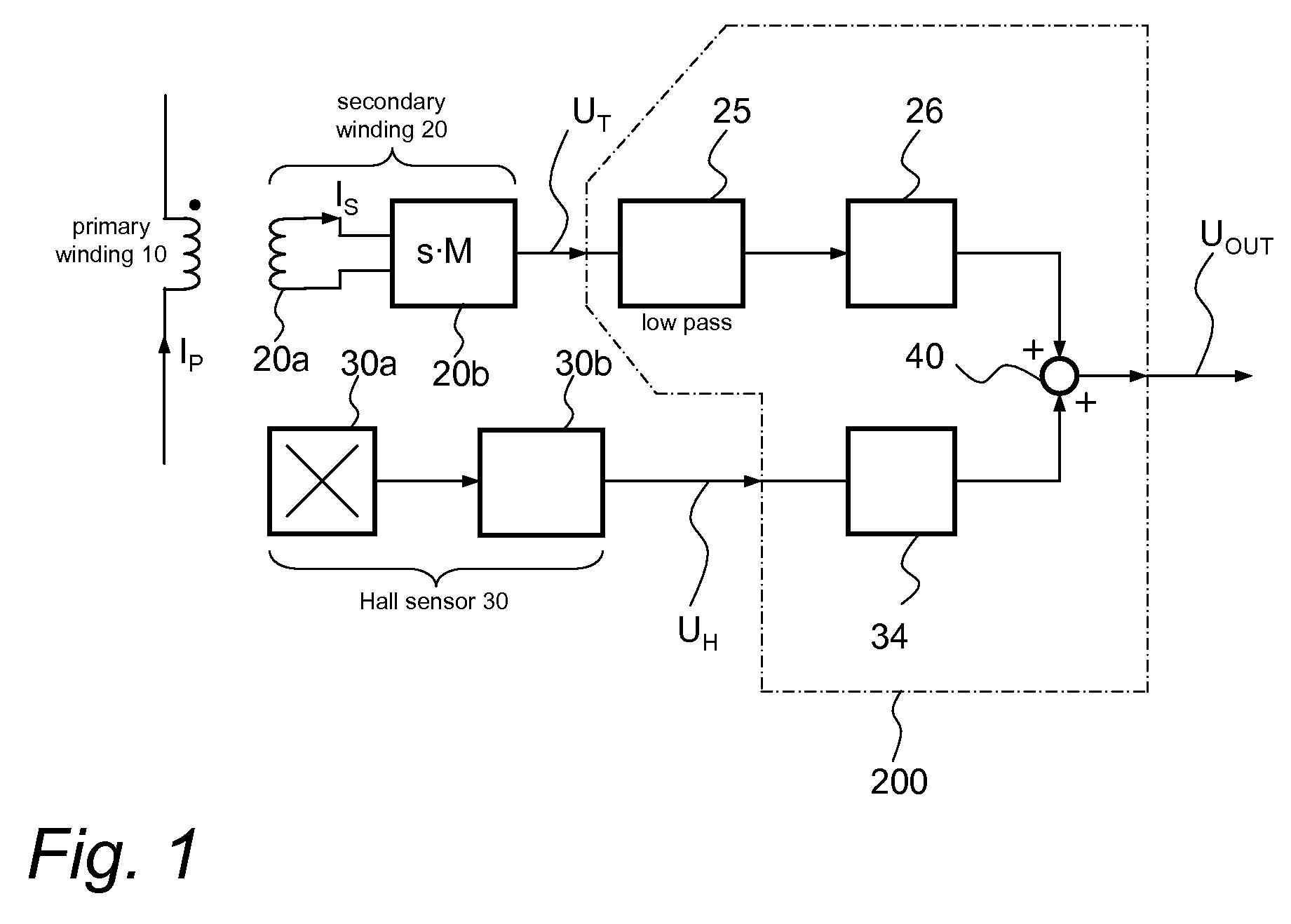

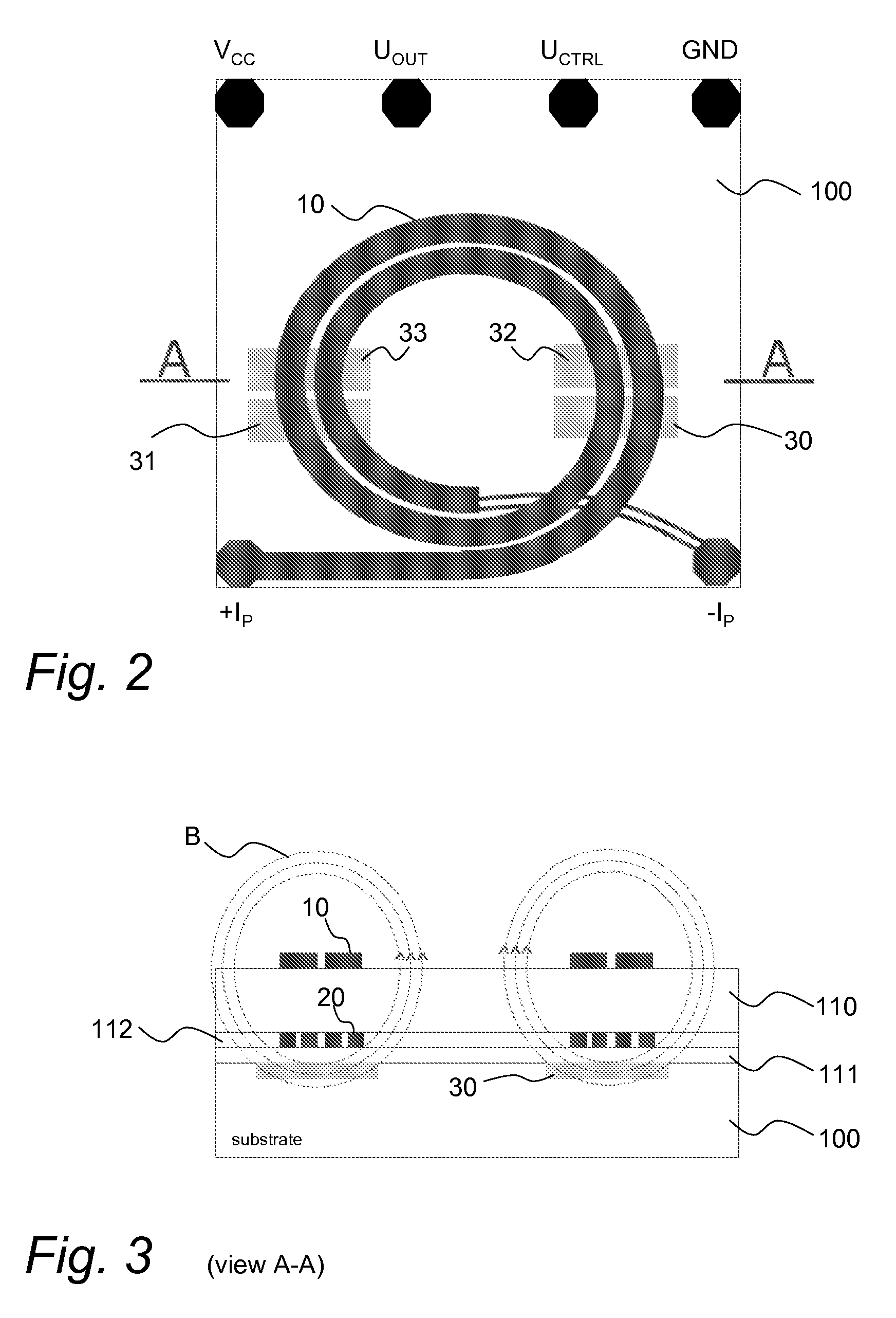

Integrated Hybrid Current Sensor

InactiveUS20090001964A1Magnetic field measurement using galvano-magnetic devicesElectrical measurementsEngineeringCurrent sensor

A sensor arrangement for measuring current is disclosed. The sensor arrangement includes a substrate, at least one Hall element integrated in or arranged on the substrate, a first coil that is spaced apart from a surface of the substrate in a vertical direction, a second coil that is spaced apart in a vertical direction from the first coil, and an isolation layer that is arranged between the first coil and the second coil.

Owner:INFINEON TECH AUSTRIA AG

GMR sensor with flux concentrators

ActiveUS20050280411A1Improve dynamic rangeMinimize impactMagnetic-field-controlled resistorsSolid-state devicesMagnetic sourceProximity sensor

A proximity sensor that is capable of producing a relatively larger output signal than past proximity sensors, and in some cases, an output signal that is relatively independent of the speed at which a target passes the sensor. In one illustrative embodiment, the proximity sensor includes a first magnetoresistive resistor and a second magnetoresistive resistor connected in a bridge configuration. The first magnetoresistive resistor is spaced from the second magnetoresistive resistor along the path of a moving ferrous target. A bias magnet source is positioned behind the proximity sensor, and the ferrous target passes in front of the proximity sensor. The ferrous target alters the direction of the bias magnetic field in the vicinity of the first and second magnetoresistive resistors as the ferrous target passes by the proximity sensor. Flux concentrators are positioned proximate to each of the first and second magnetoresistive resistors. The flux concentrators may help redirect or shunt the magnetic field component produced by the bias magnet source that is perpendicular to the direction of motion of the target through the first and second magnetoresistive resistors in a direction that is parallel to the direction of motion of the target.

Owner:HONEYWELL INT INC

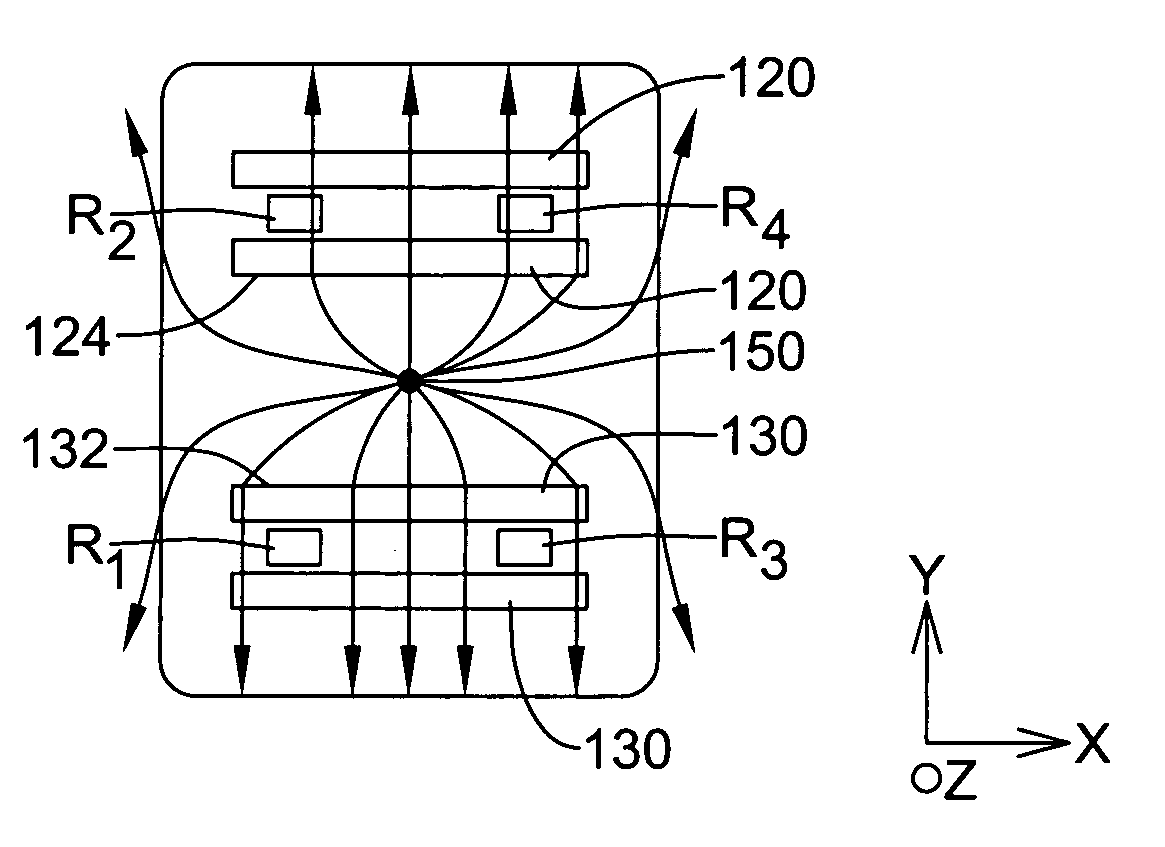

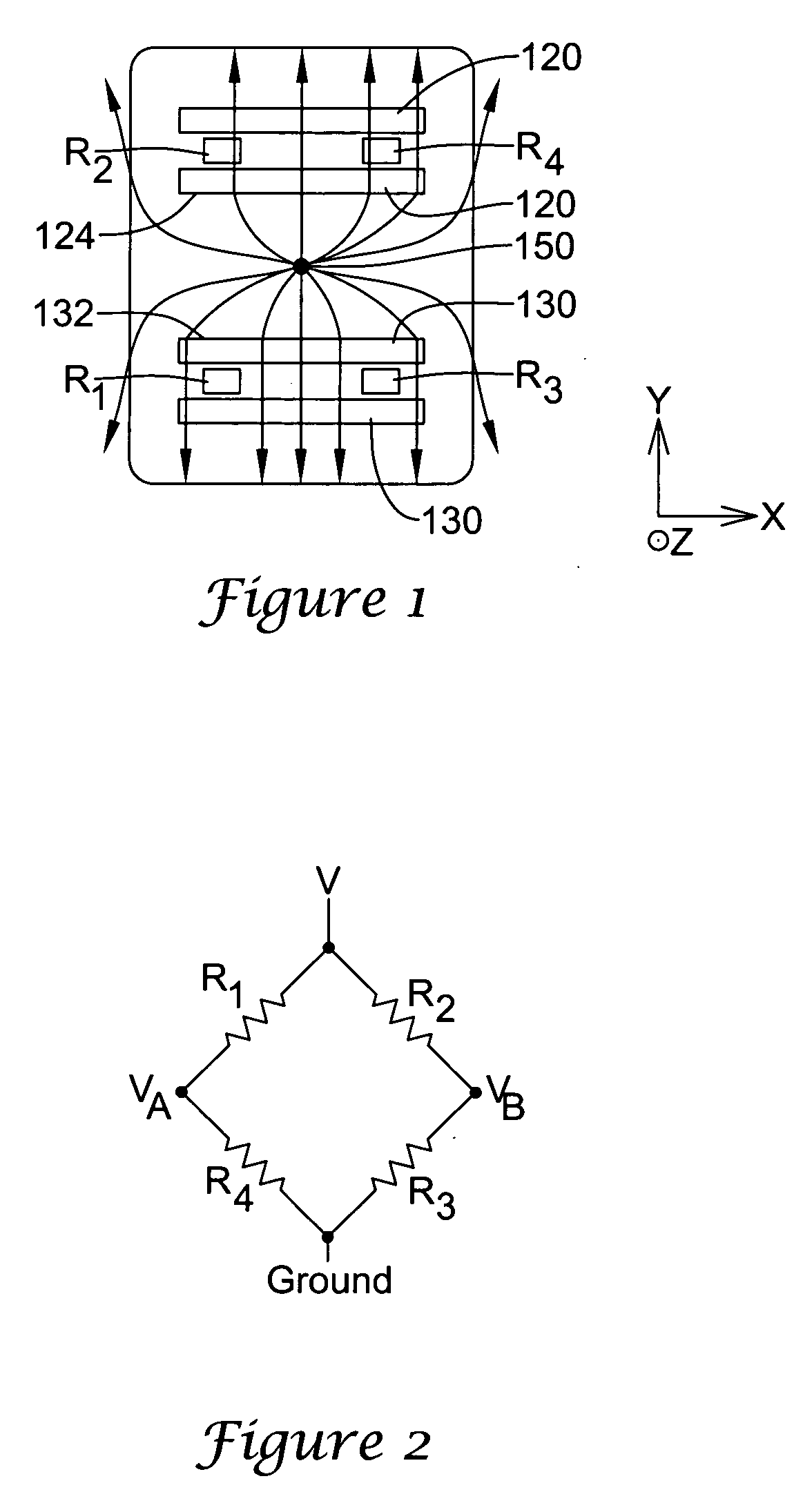

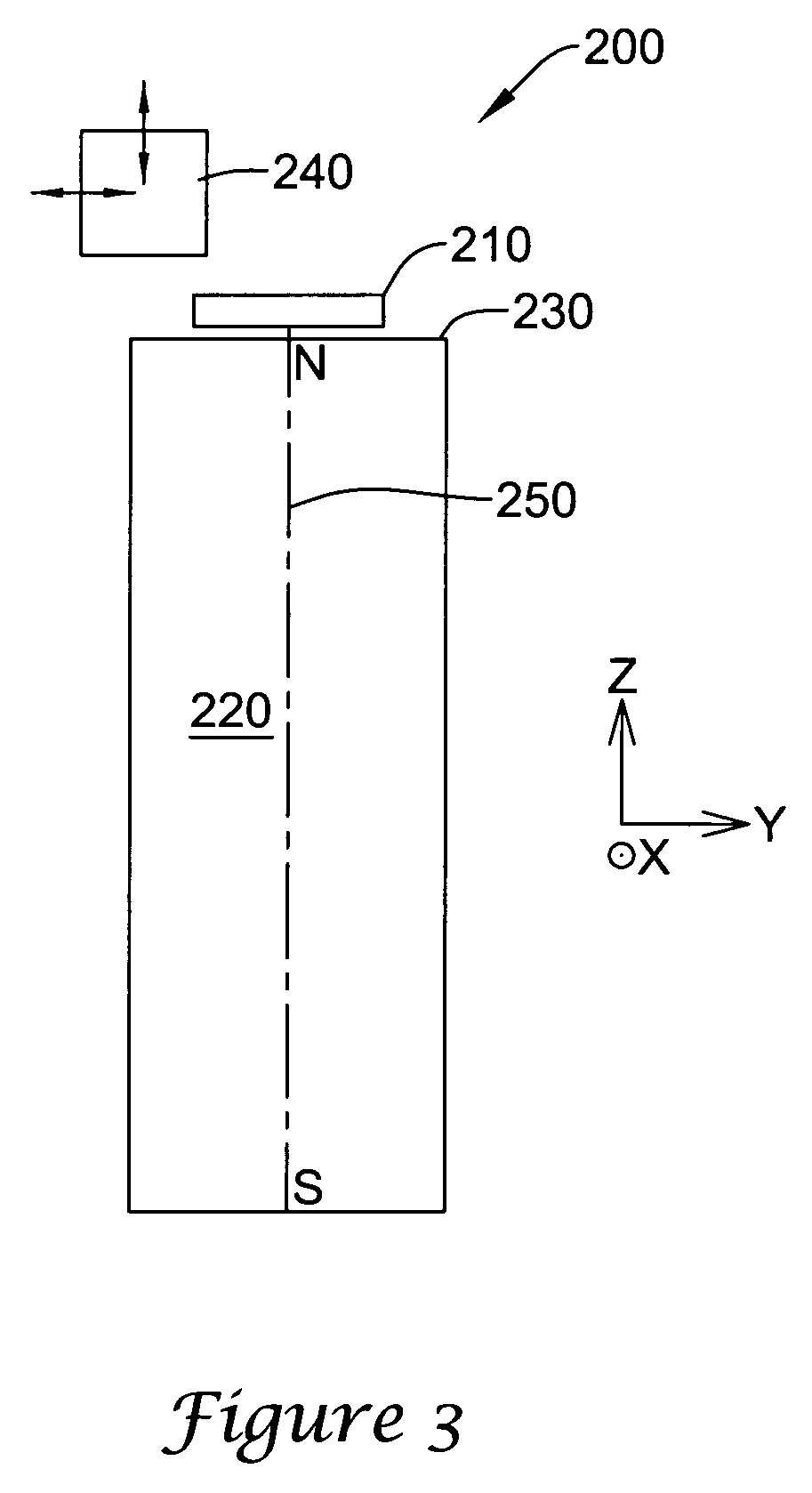

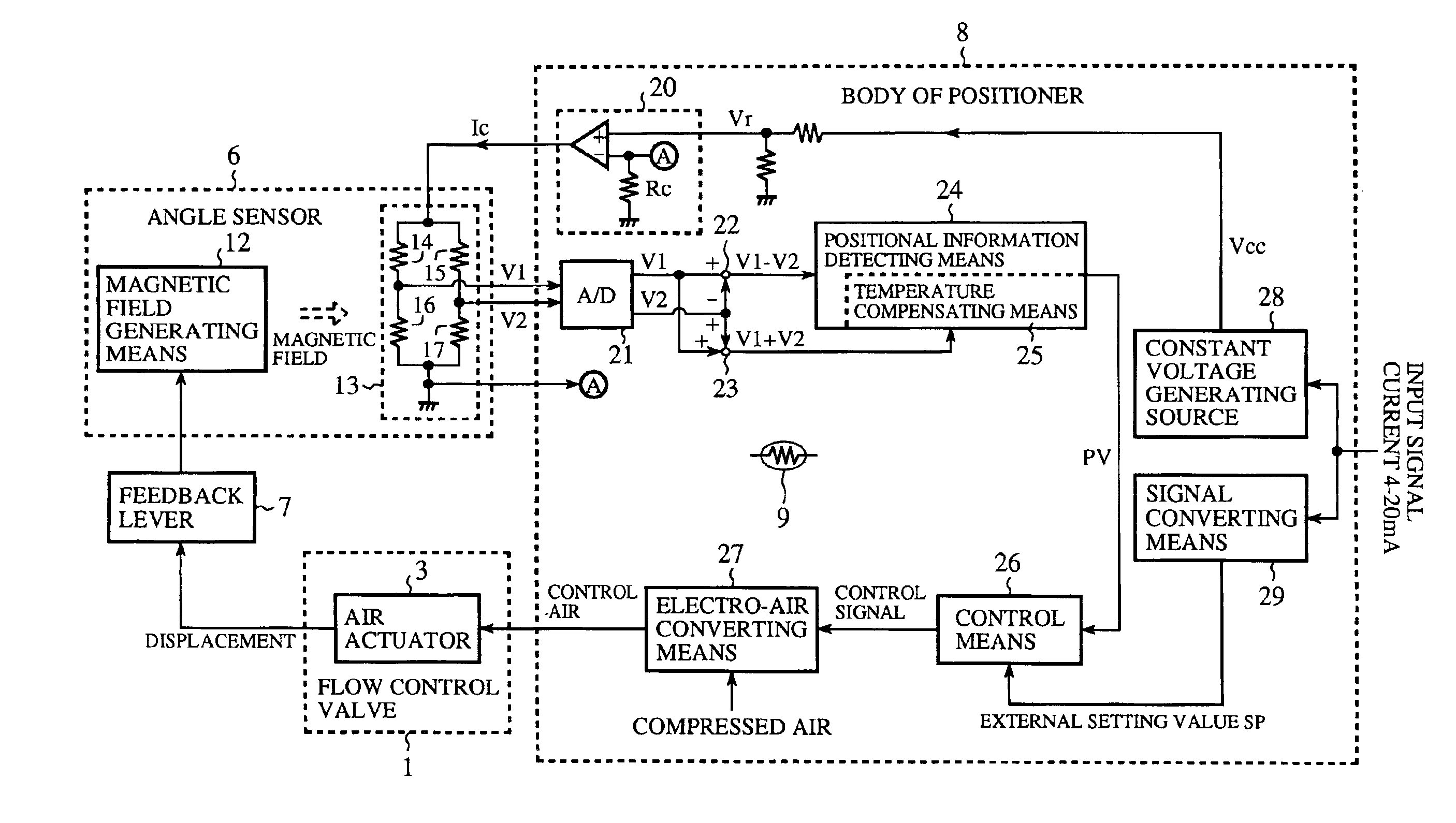

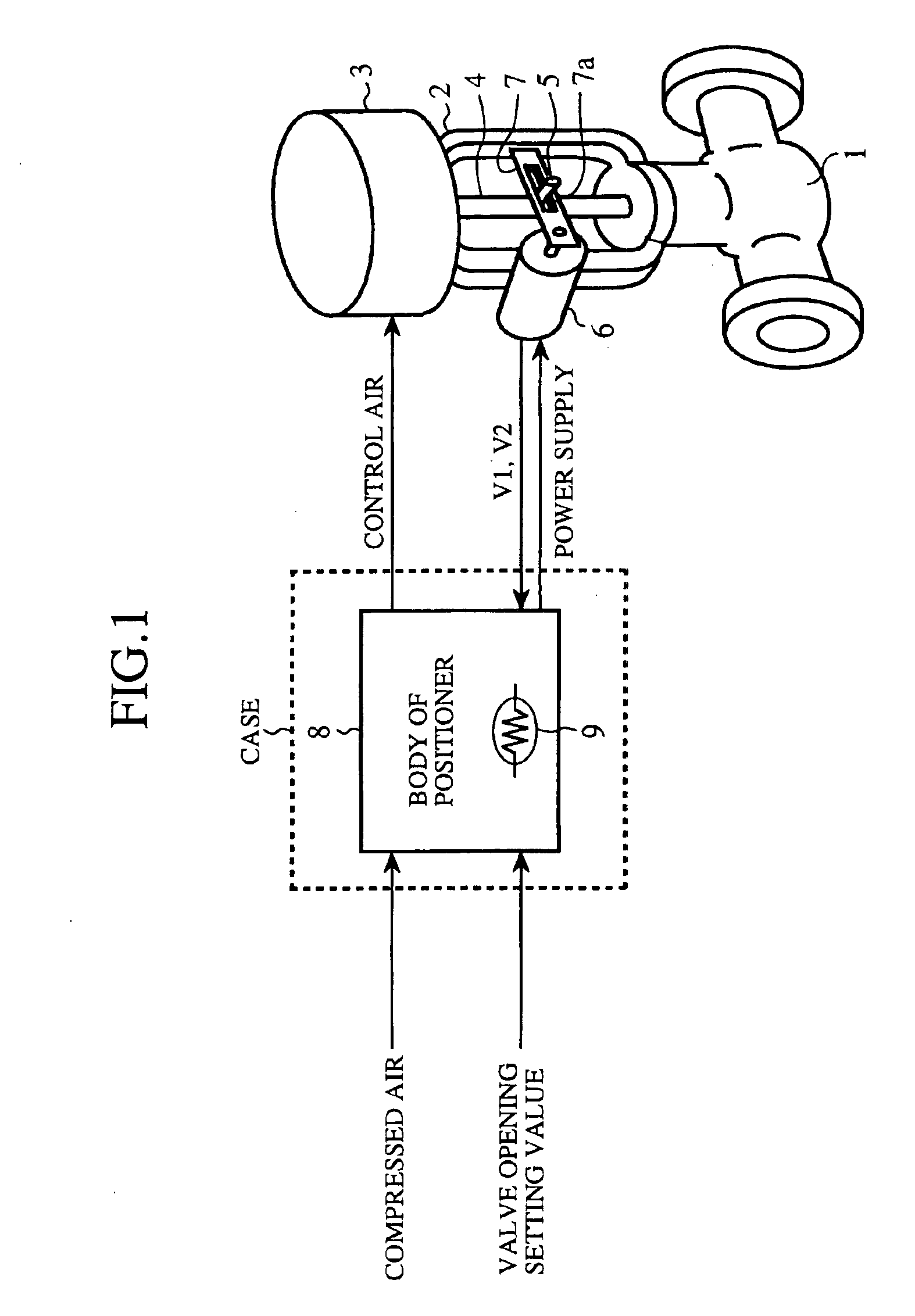

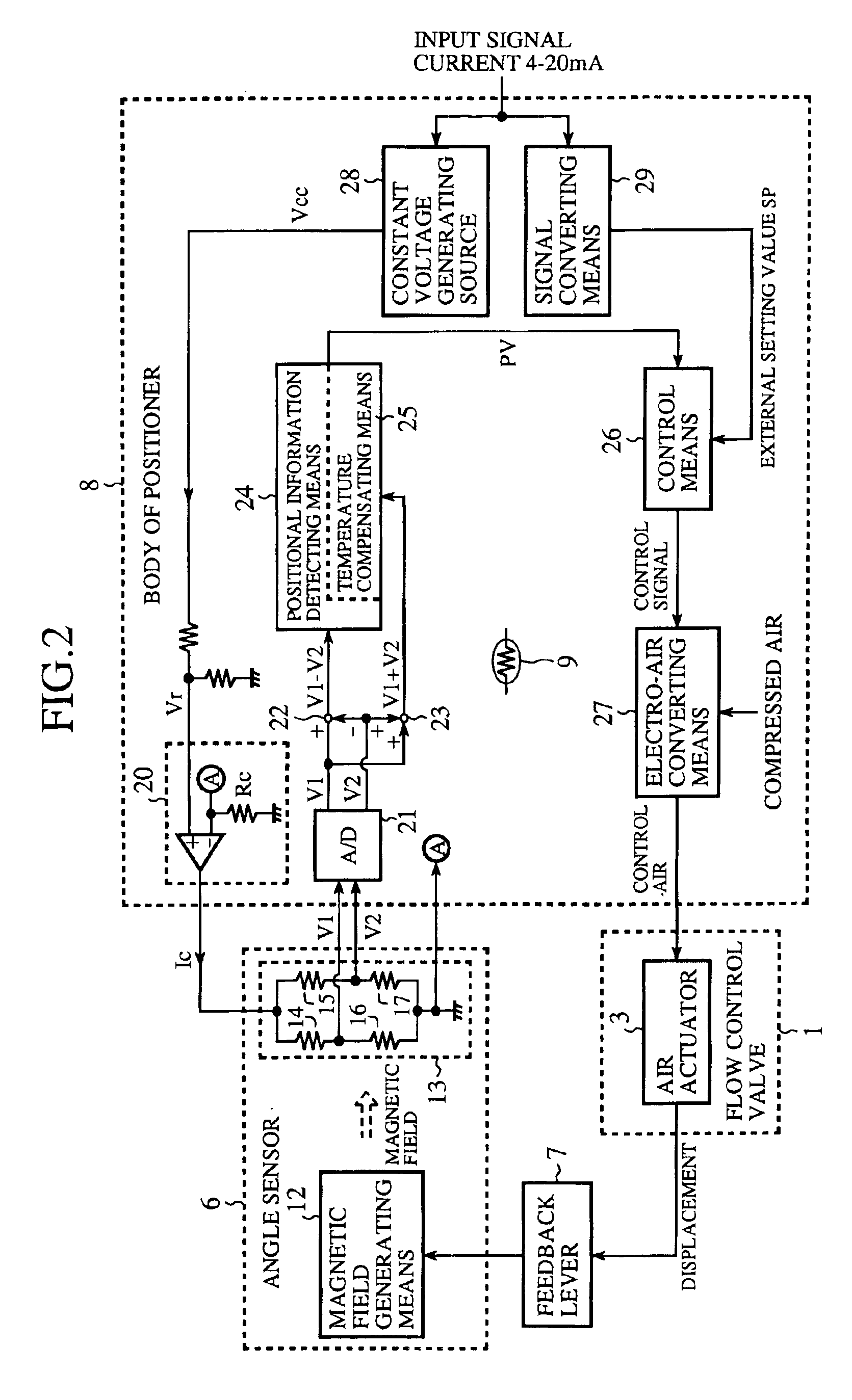

Temperature information detecting device for angle sensor and position detecting device

InactiveUS6896407B2Improve accuracyThermometer detailsOperating means/releasing devices for valvesLocation detectionAutomatic control

A temperature information detecting device for an angle sensor is provided for detecting only temperature-dependent components based on middle-point potentials when a constant current is supplied to a bridge circuit for an angle sensor, for acquiring a temperature of the angle sensor from the temperature-dependent components, for employing compensating information corresponding to the acquired temperature without separately providing any additional temperature sensor, and for making temperature compensation of the output of the temperature sensor in automatically controlling the valve opening of a flow control valve.

Owner:YAMATAKE HONEYWELL CO LTD

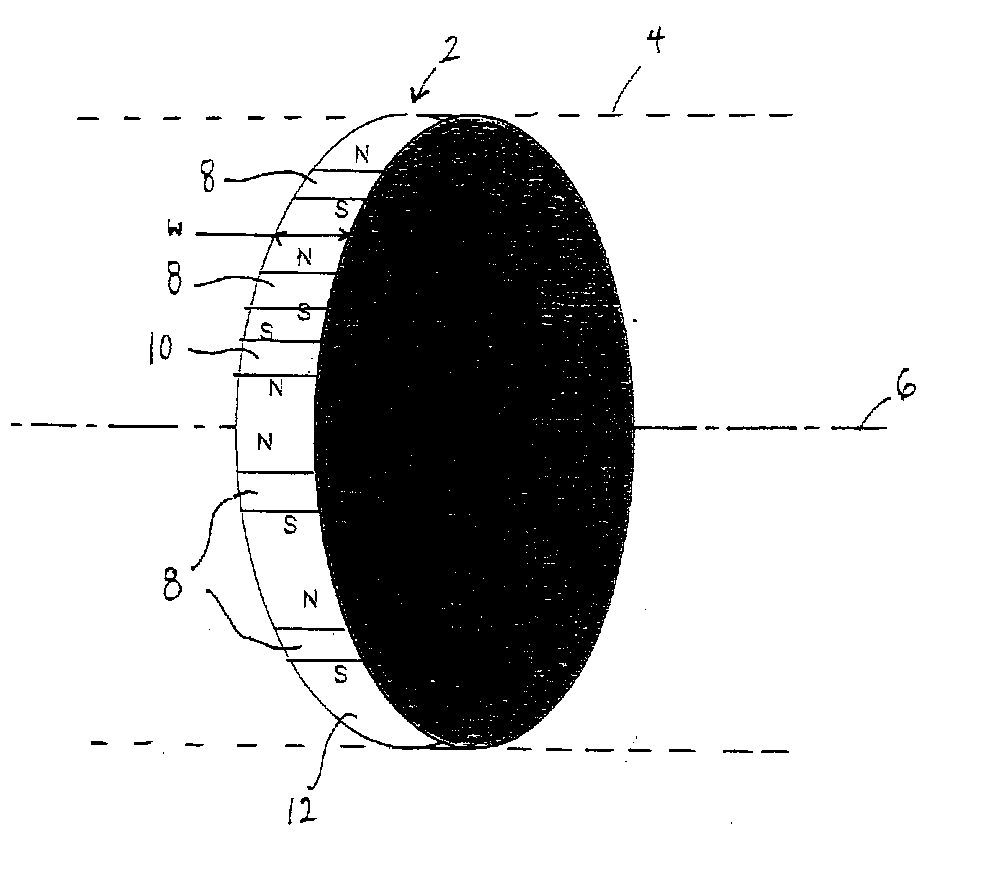

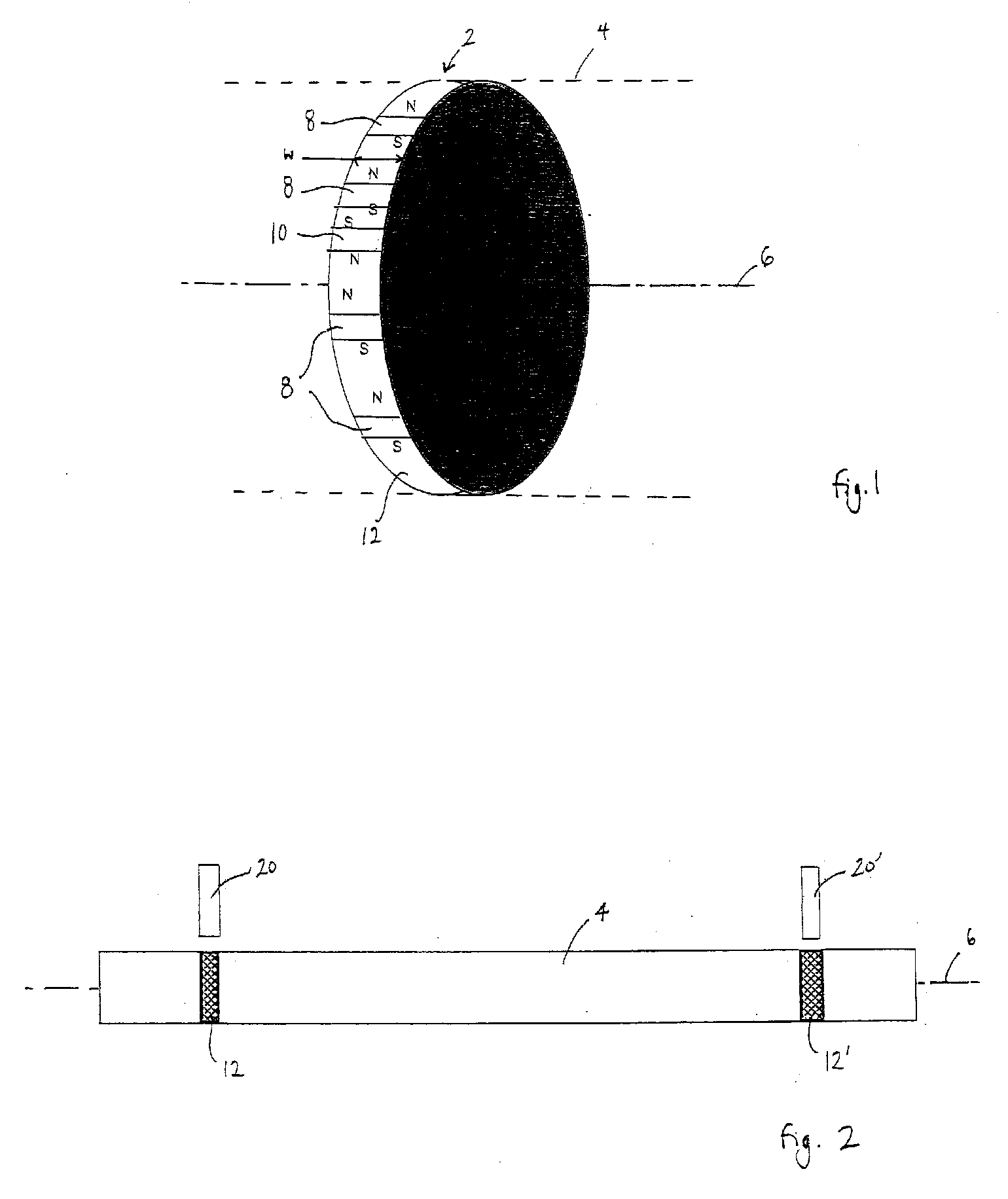

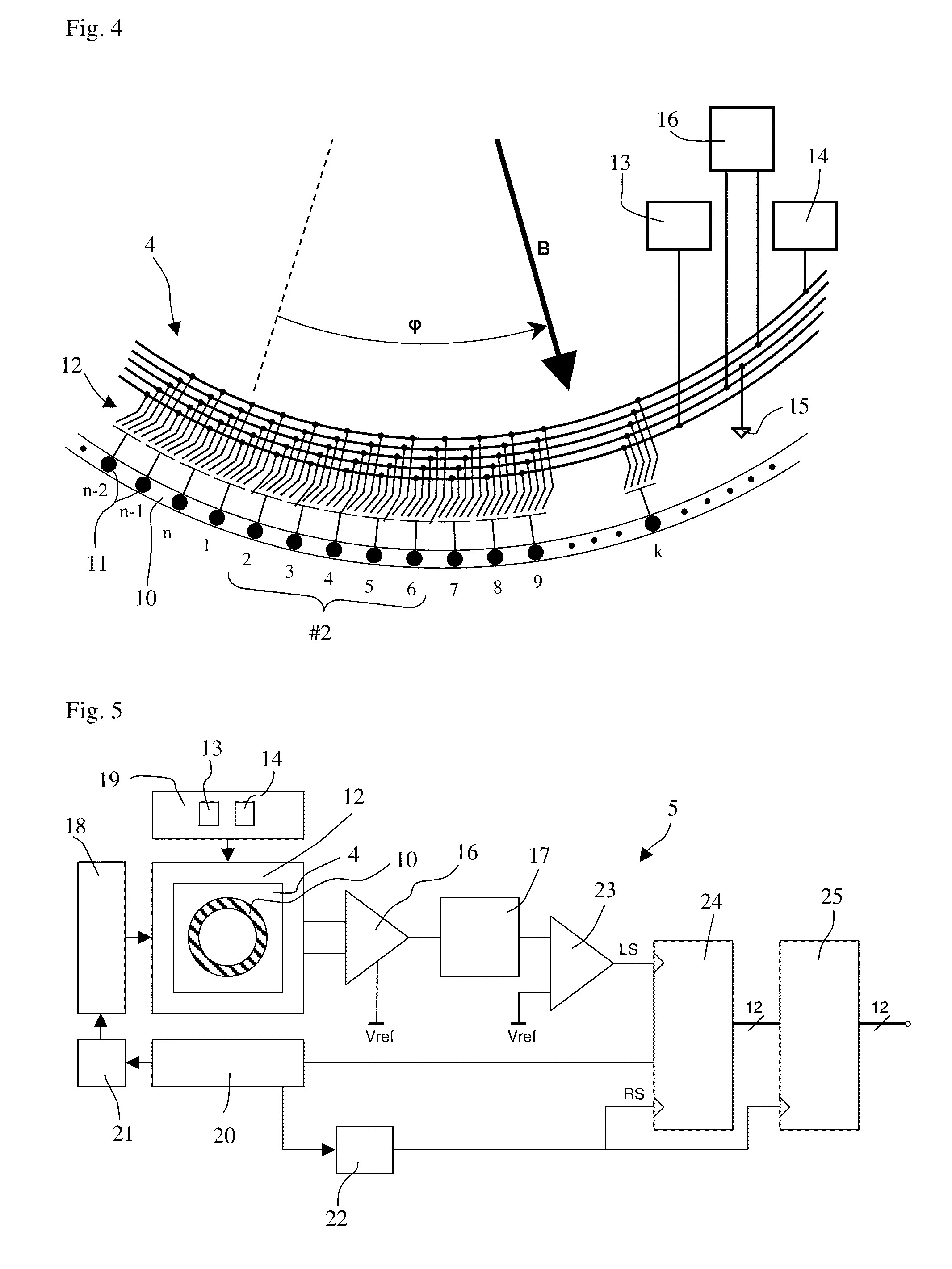

Rotation Sensing

A compact arrangement which enables rotation of a component (4) of an apparatus to be sensed is provided. A component adapted for use in such an arrangement comprises a body having an axis of rotation (6) and a plurality of discrete magnetised regions (8) thereon, each formed in a layer of material (12) on the surface of the body, the magnetised regions being circumferentially distributed at substantially the same axial position to enable rotation of the component relative to a sensor (20, 20′) to be monitored. Methods for manufacturing a suitable component are also described. The arrangement disclosed enables the rotational position of component, such as a shaft for example, to be sensed using a Hall effect sensor, and a component may be modified in accordance with the invention without substantially increasing its volume.

Owner:EQUIPMAKE

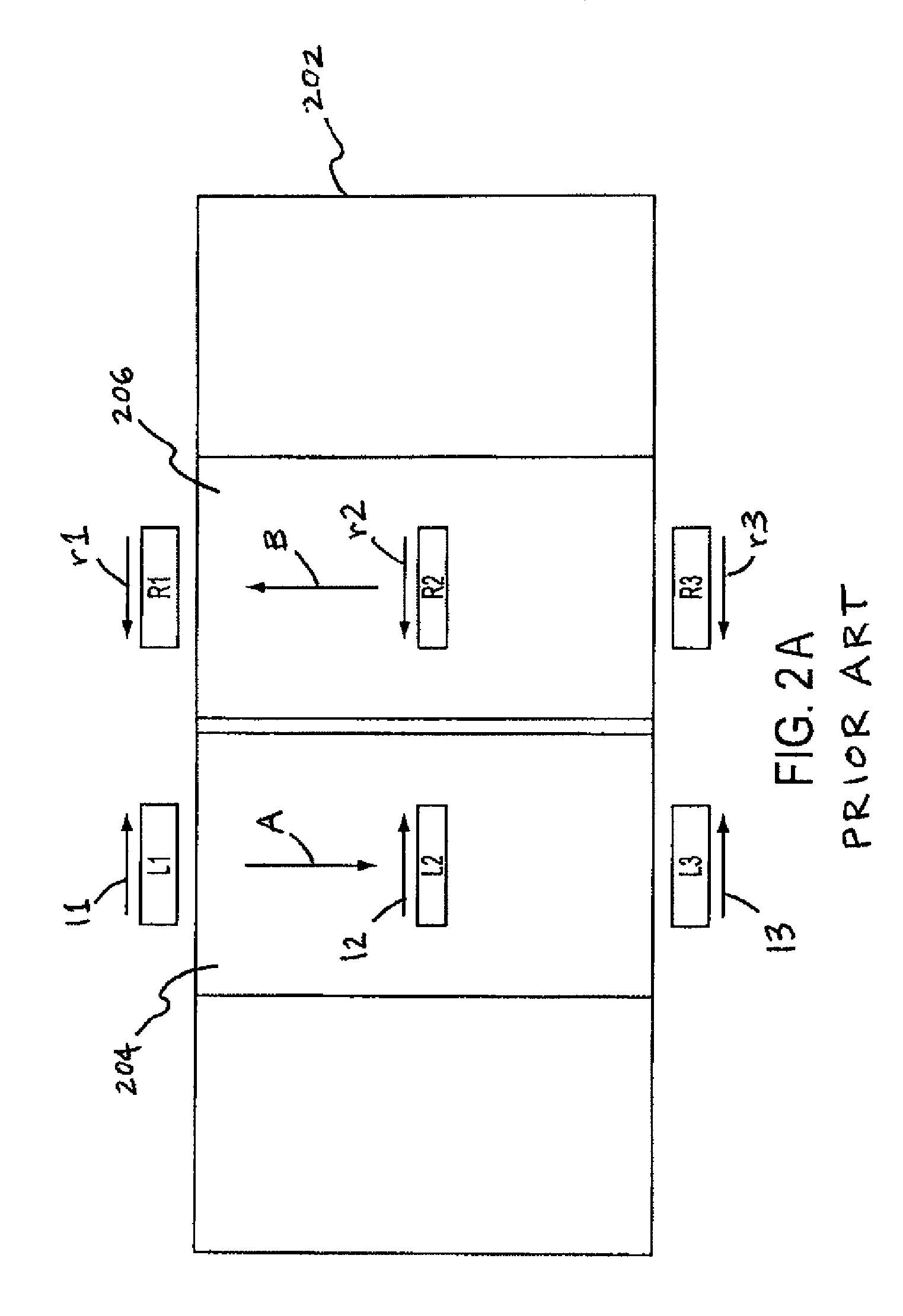

Apparatus and method for providing an output signal indicative of a speed of rotation and a direction of rotation as a ferromagnetic object

ActiveUS8624588B2Magnetic field measurement using galvano-magnetic devicesUsing electrical meansRotation velocityClassical mechanics

Owner:ALLEGRO MICROSYSTEMS INC

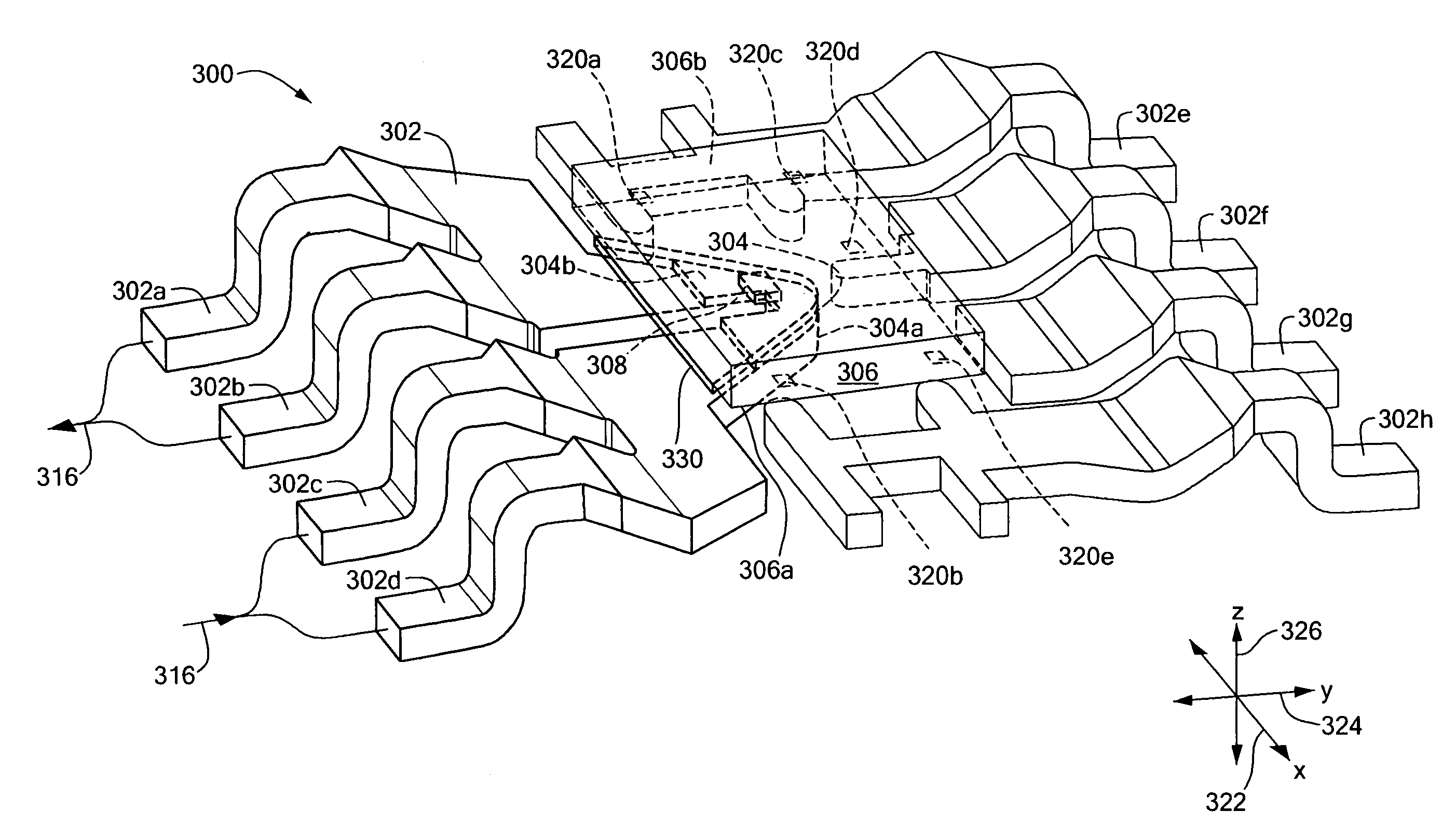

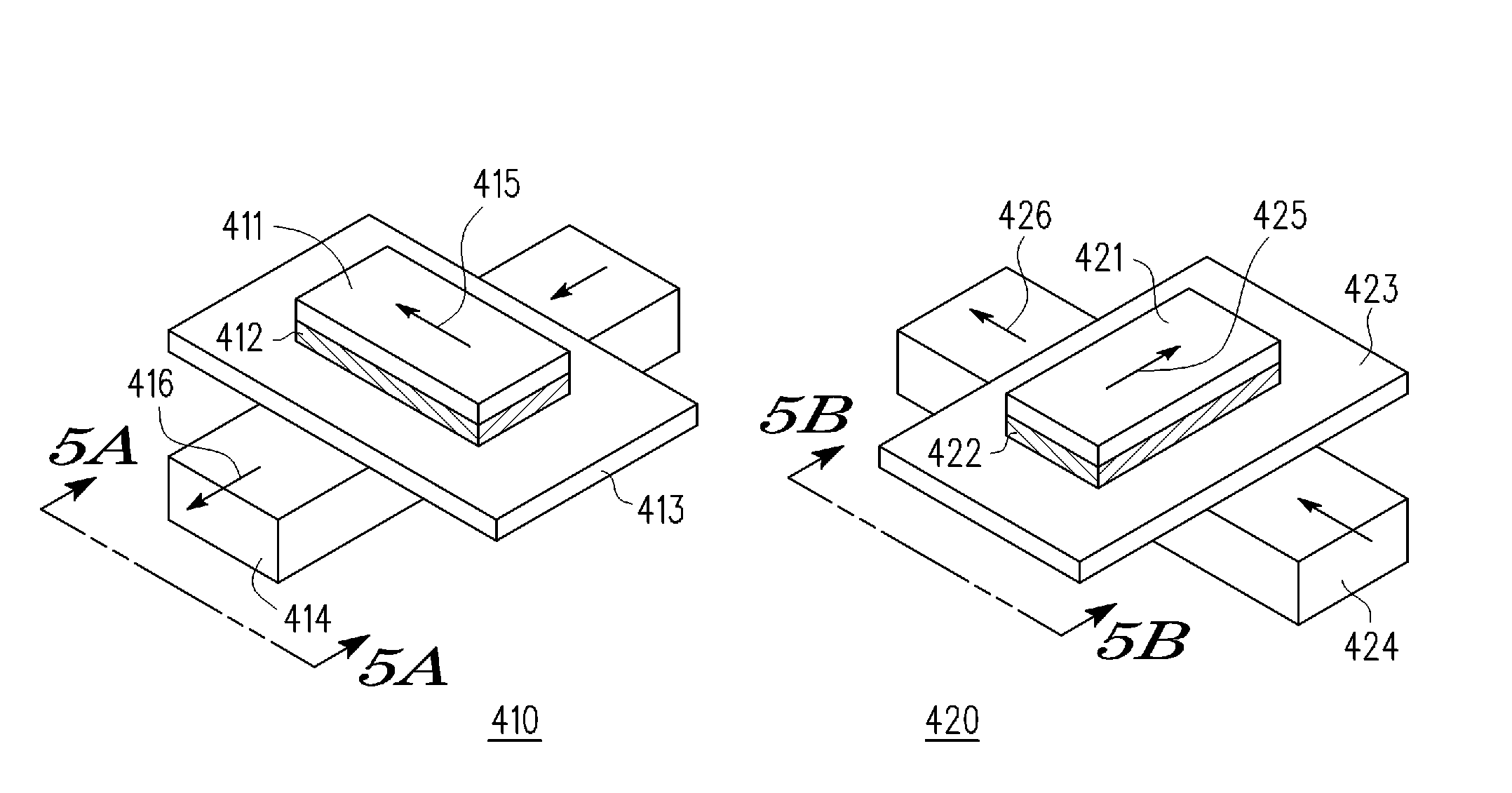

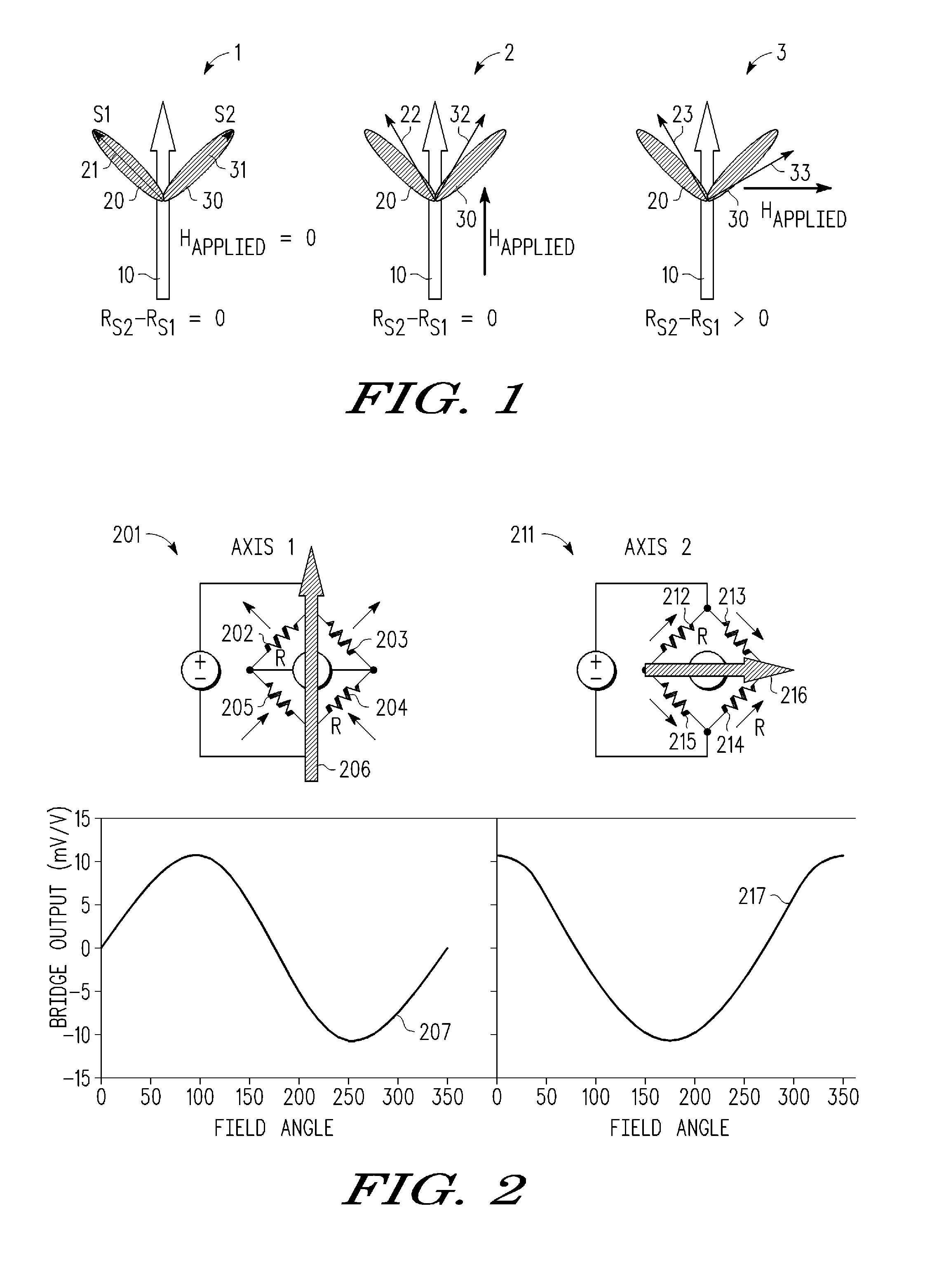

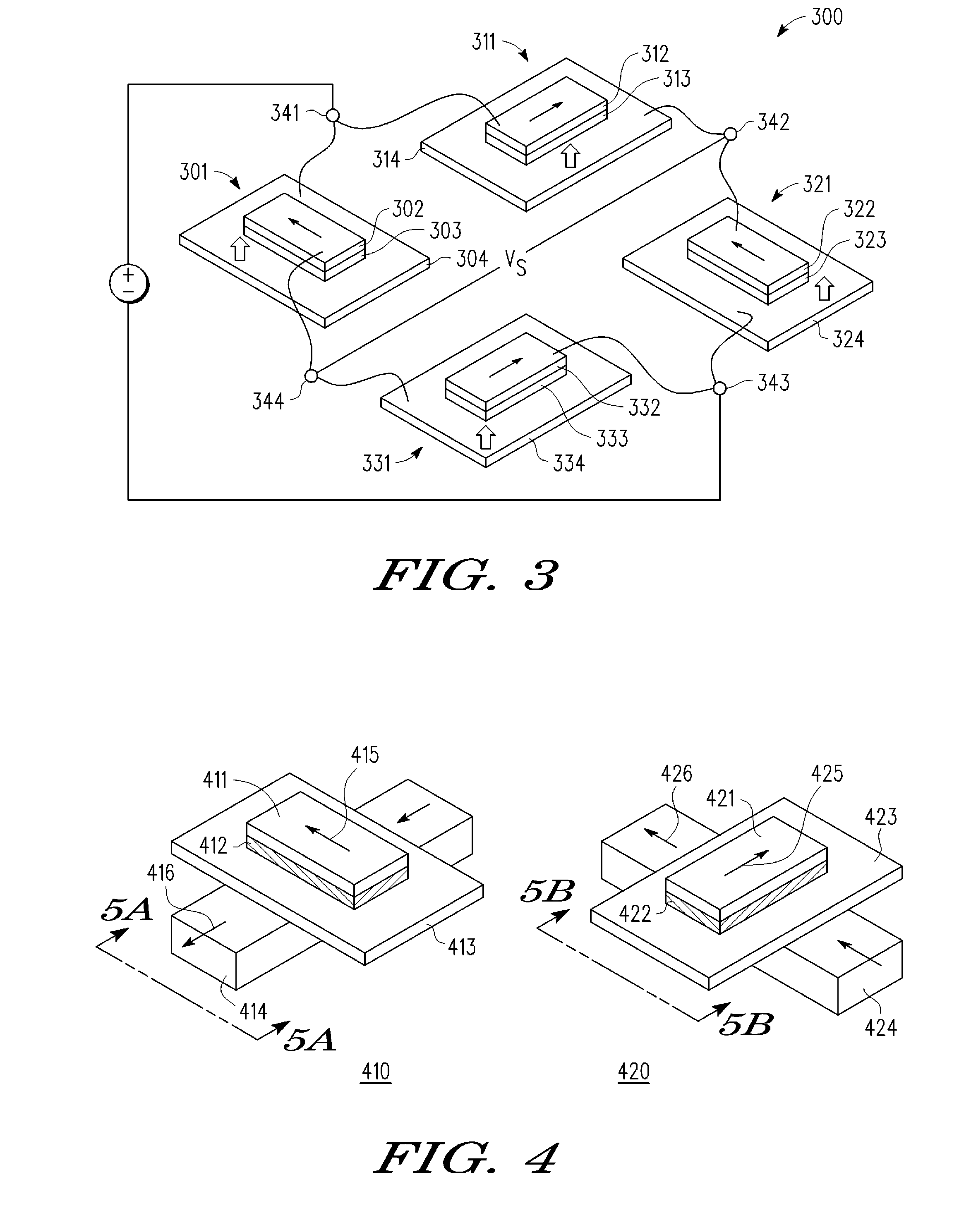

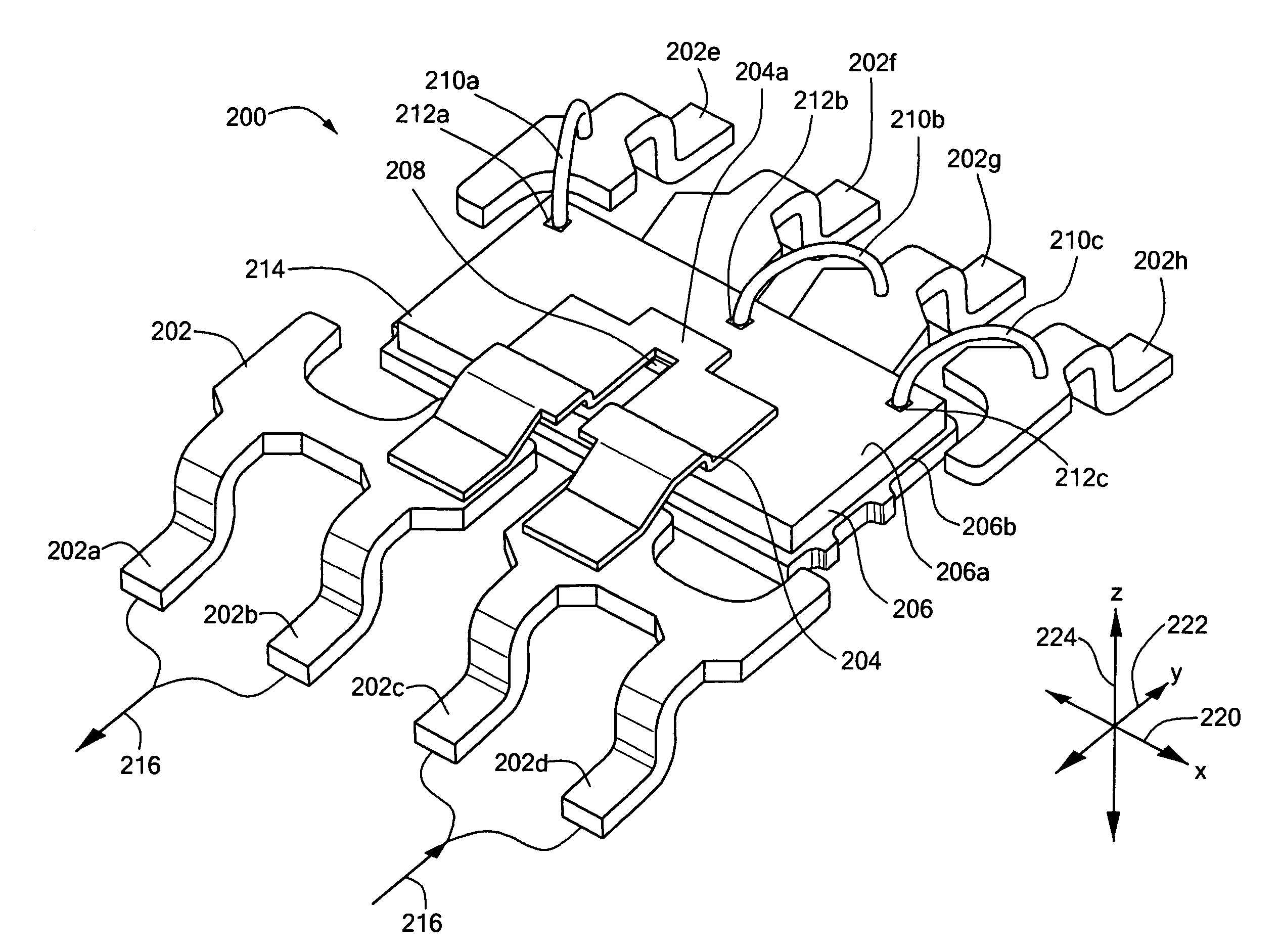

Magnetic Sensor Design for Suppression of Barkhausen Noise

A semiconductor process and apparatus provide a high-performance magnetic field sensor from two differential sensor configurations (201, 211) which require only two distinct pinning axes (206, 216), where each differential sensor (e.g., 201) is formed from a Wheatstone bridge structure with four unshielded MTJ sensors (202-205), each of which includes a magnetic field pulse generator (e.g., 414) for selectively applying a field pulse to stabilize or restore the easy axis magnetization of the sense layers (e.g., 411) to eliminate micromagnetic domain switches during measurements of small magnetic fields.

Owner:EVERSPIN TECHNOLOGIES

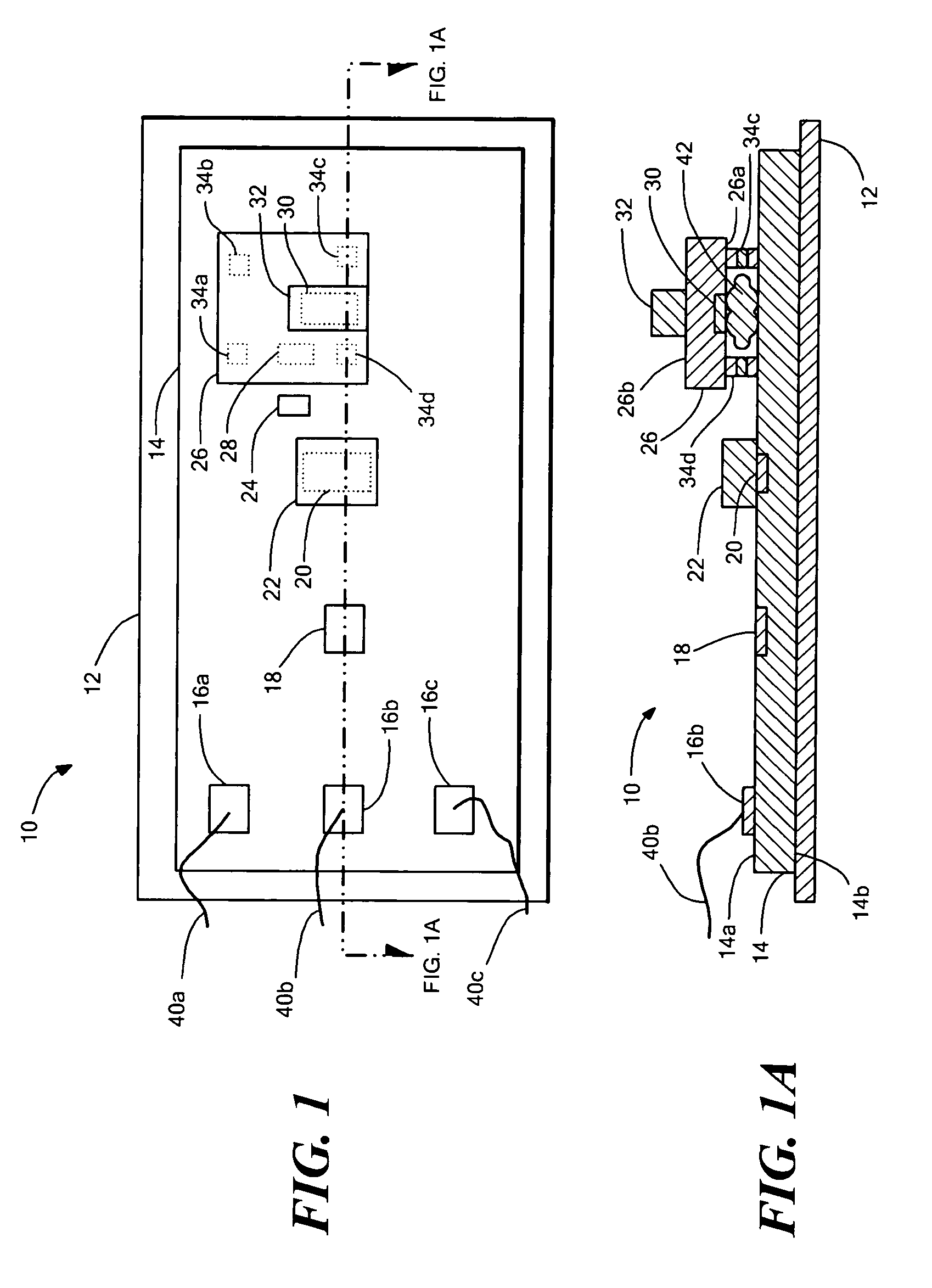

Current sensor

InactiveUS6995315B2High sensitivityMeasurement using dc-ac conversionSemiconductor/solid-state device detailsElectrical conductorCurrent sensor

An integrated circuit current sensor includes a lead frame having at least two leads coupled to provide a current conductor portion, and substrate having a first surface in which is disposed one or more magnetic field transducers, with the first surface being proximate the current conductor portion and a second surface distal from the current conductor portion. In one particular embodiment, the substrate is disposed having the first surface of the substrate above the current conductor portion and the second surface of the substrate above the first surface. In this particular embodiment, the substrate is oriented upside-down in the integrated circuit relative to a conventional orientation. A current conductor portion can be deposited on a surface of the substrate proximate to the one or more magnetic field sensors. With this arrangement, a current sensor is provided for which the one or more magnetic field transducers are very close to the current conductor portion, resulting in a current sensor having improved sensitivity.

Owner:ALLEGRO MICROSYSTEMS INC

Magnetoelastic torque sensor with ambient field rejection

ActiveUS8087304B2Cancellation effectEliminate the effects ofSolid-state devicesWork measurementCondensed matter physicsTorque sensor

Owner:METHODE ELETRONICS INC

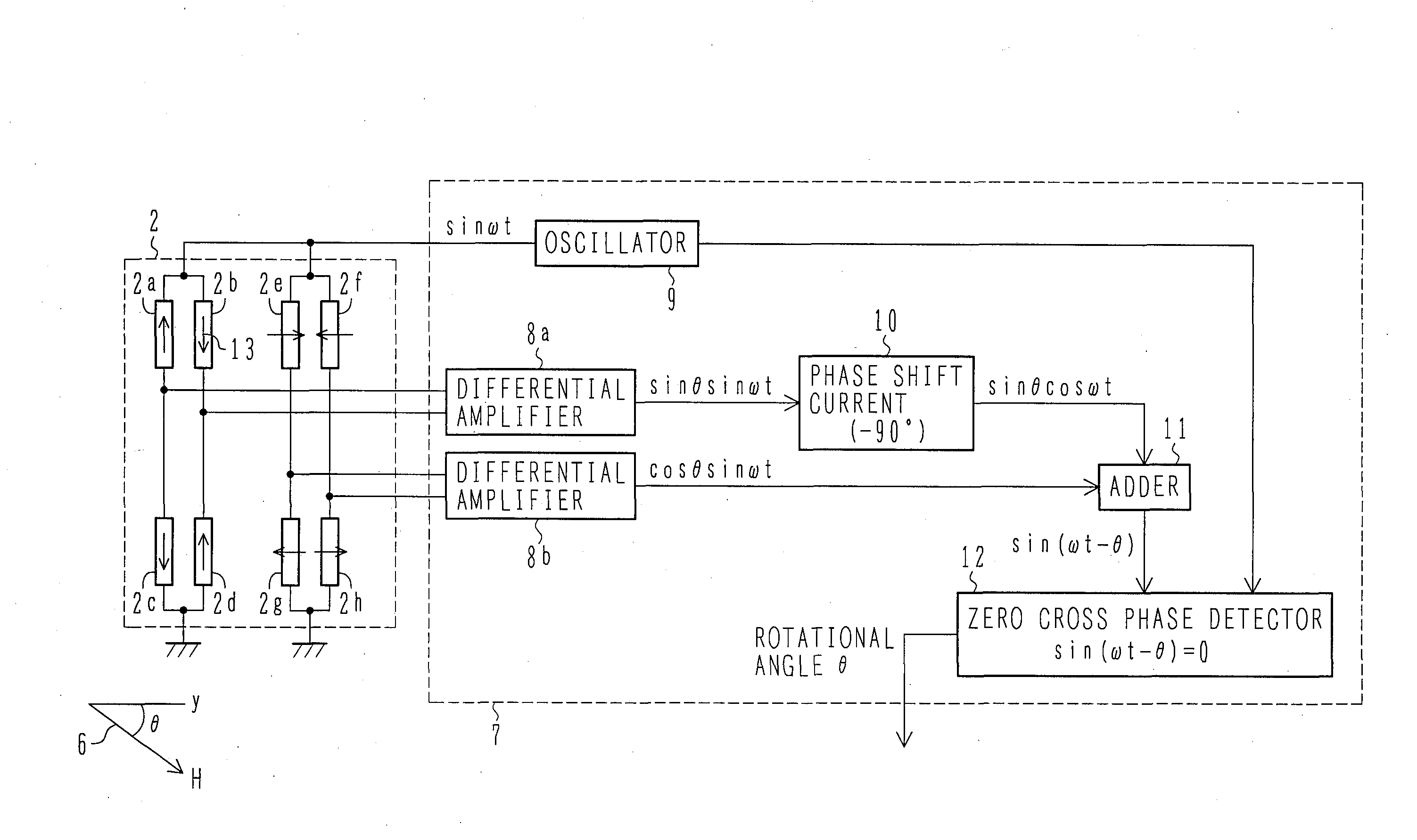

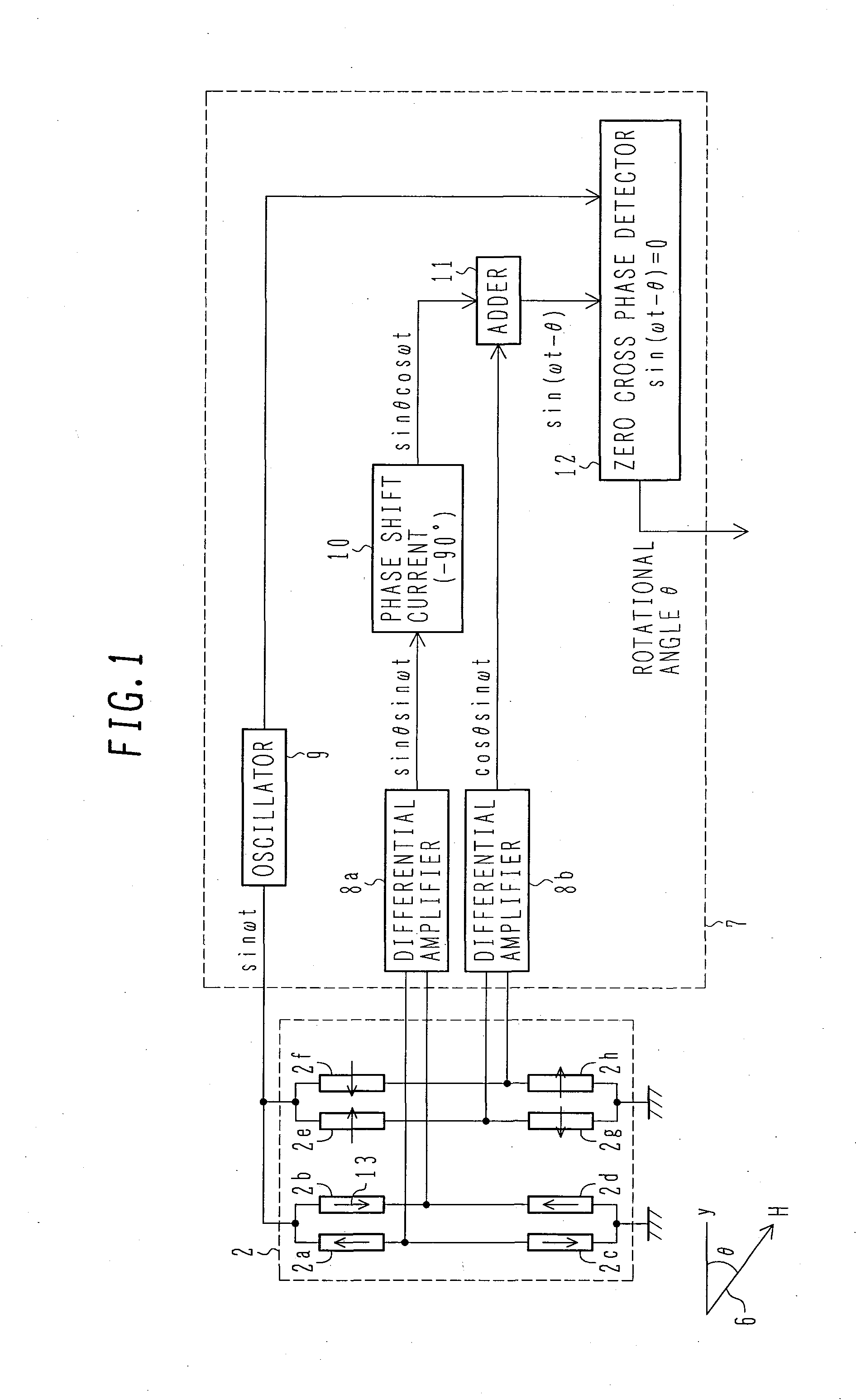

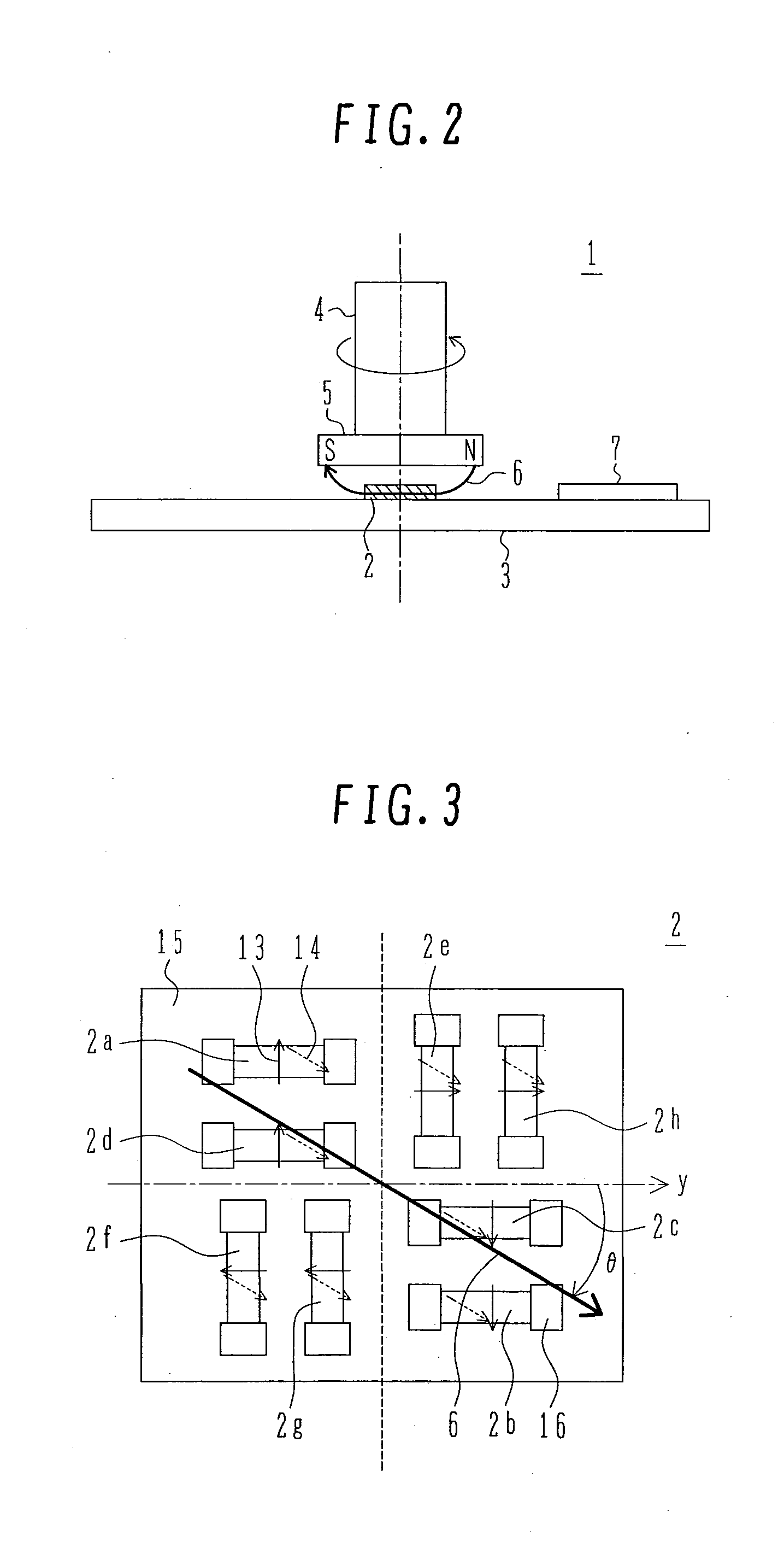

Displacement Sensor Using GMR Elements, Angle Sensor Using GMR Elements, And Semiconductor Device Used For Them

InactiveUS20080116886A1Avoid it happening againWithout impairing industrial productivityMagnetic-field-controlled resistorsSolid-state devicesMagnetizationEngineering

A highly accurate displacement sensor using GMR elements for detecting a displacement of a physical quantity such as angle is to be provided wherein a waveform distortion of output voltage is diminished.There are installed at least two Wheatstone bridge circuits having a predetermined angular offset and each comprising a plurality of GMR elements, the GMR elements each having a fixed magnetic layer set to a predetermined magnetization direction. An AC power supply is use as a power supply of the Wheatstone bridge circuits and a displacement of a physical quantity such as a rotational angle is detected on the basis of AC-modulated outputs from the Wheatstone bridge circuits.An anisotropic self-bias effect of a free magnetic layer in each GMR element can be diminished and hence it is possible to remedy a waveform distortion of an output signal based on the anisotropic self-bias effect of the free magnetic layer.

Owner:HITACHI LTD

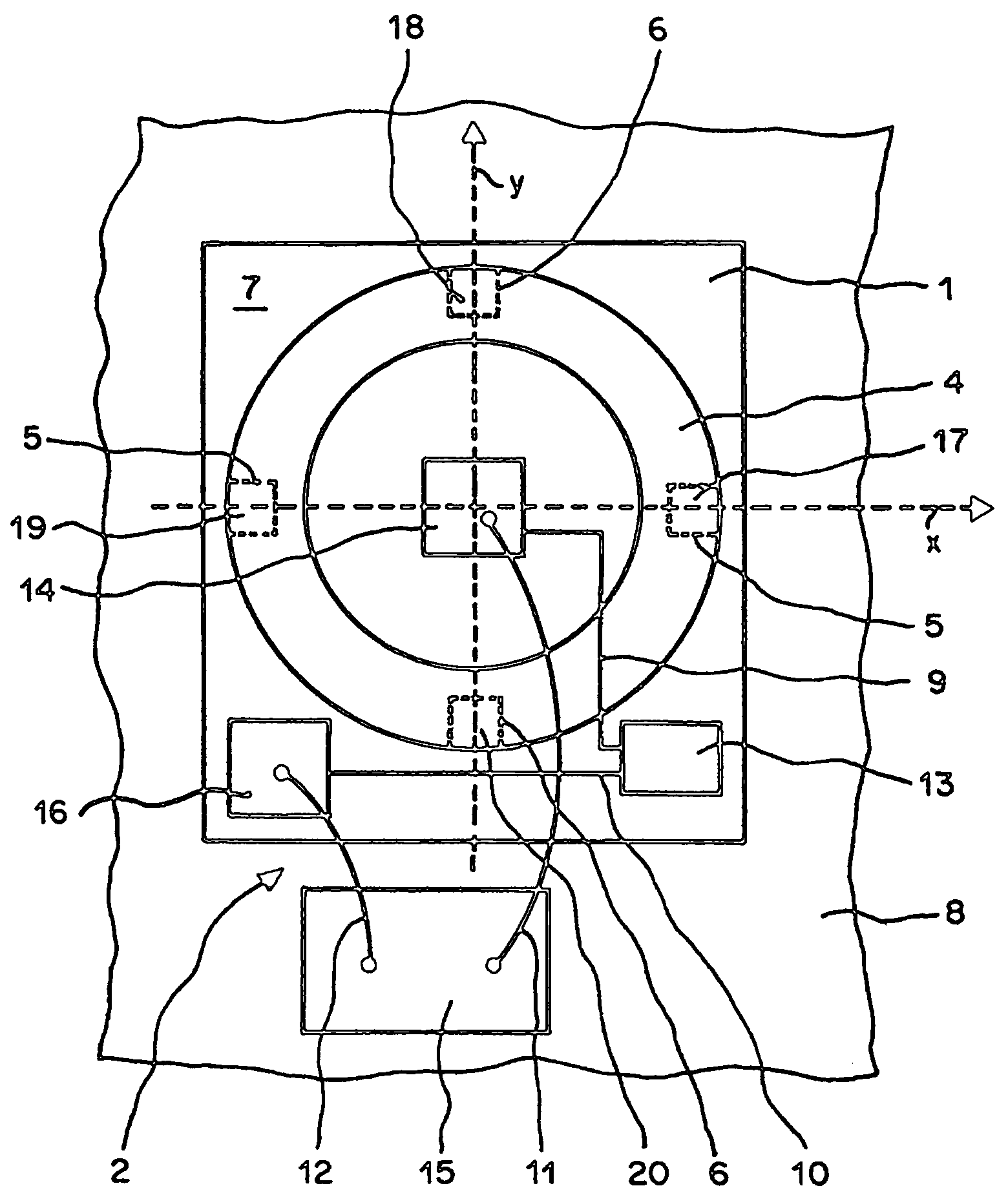

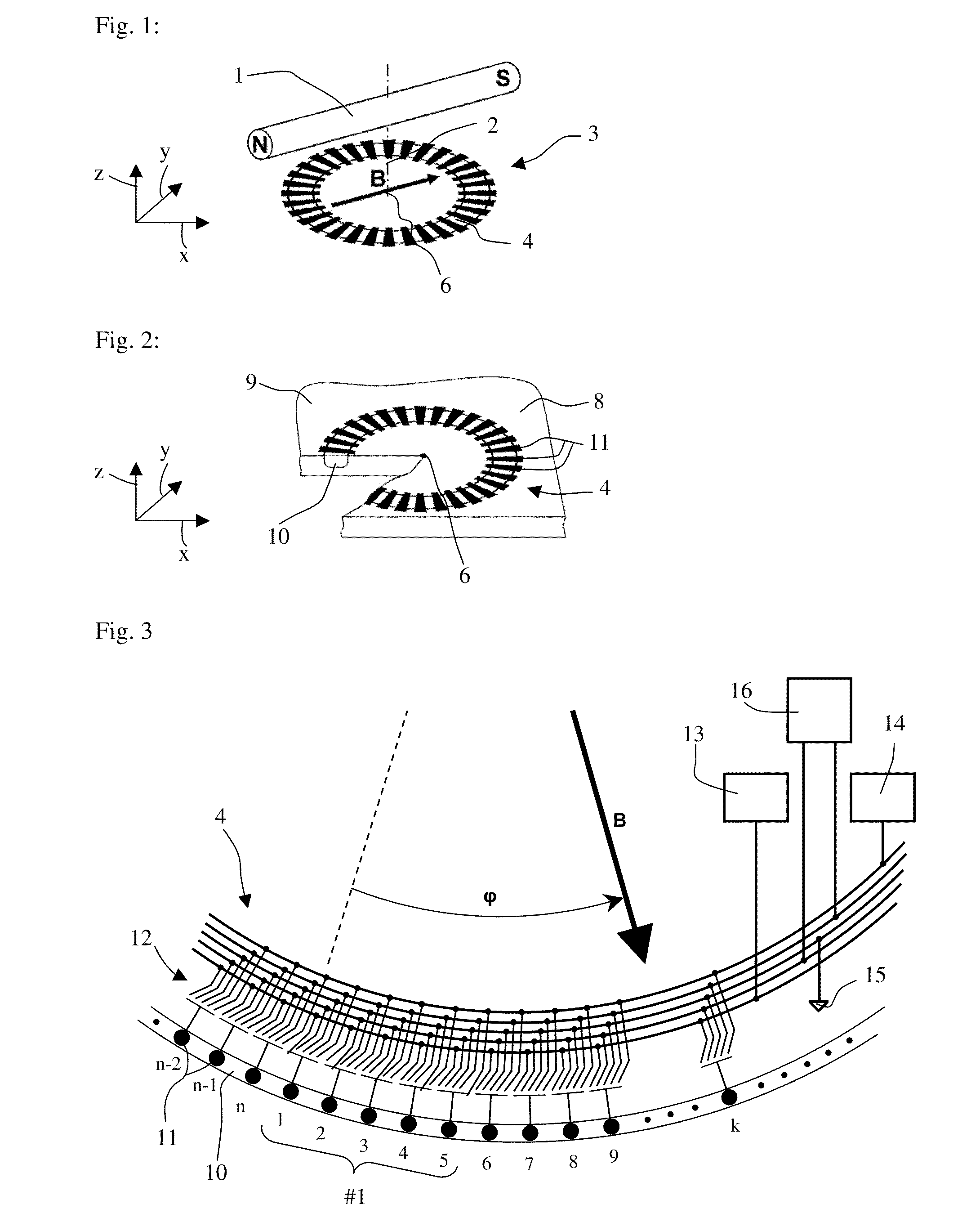

Magnetic Field Sensor For Measuring A Direction Of A Magnetic Field In A Plane

ActiveUS20100164491A1Solid-state devicesMagnetic field measurement using galvano-magnetic devicesControl signalElectronic switch

A magnetic field sensor for measuring a direction of a magnetic field in a plane comprises a sensing structure comprising a ring-shaped well, a plurality of contacts of equal size placed at equal distance from each other along the ring-shaped well, and an electronic circuit comprising a plurality of electronic switches associated with the contacts of the sensing structure, a logic block for controlling the electronic switches, at least one current source, a means for measuring a difference between a first voltage and a second voltage, a timing circuit providing a control signal for controlling the logic block and providing a reference signal, wherein the logic block is adapted to close and open the electronic switches under the control of the control signal according to a predetermined scheme such that a predetermined number of contacts of the plurality of contacts form a vertical Hall element that is supplied with current from the at least one current source and that has two contacts connected to the means for measuring, and such that the vertical Hall element is moved in steps along the ring-shaped well, and a means for measuring a phase shift between the reference signal and an output signal of the voltage measuring means.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Magnetic sensor

ActiveUS7250760B2Small sizeImprove detection accuracySemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The magnetic sensor is fabricated such that a magnetic sensor chip, having a one-chip structure in which MRE bridges and a comparator are included, is mounted onto a lead frame using an adhesive material, and then the magnetic sensor chip mounted on the lead frame is encapsulated by molding in a molded material. The magnetic sensor includes a magnetic-field generating portion formed by magnetizing at least one of the chip mounting member, the adhesive material, and the encapsulating material.

Owner:DENSO CORP

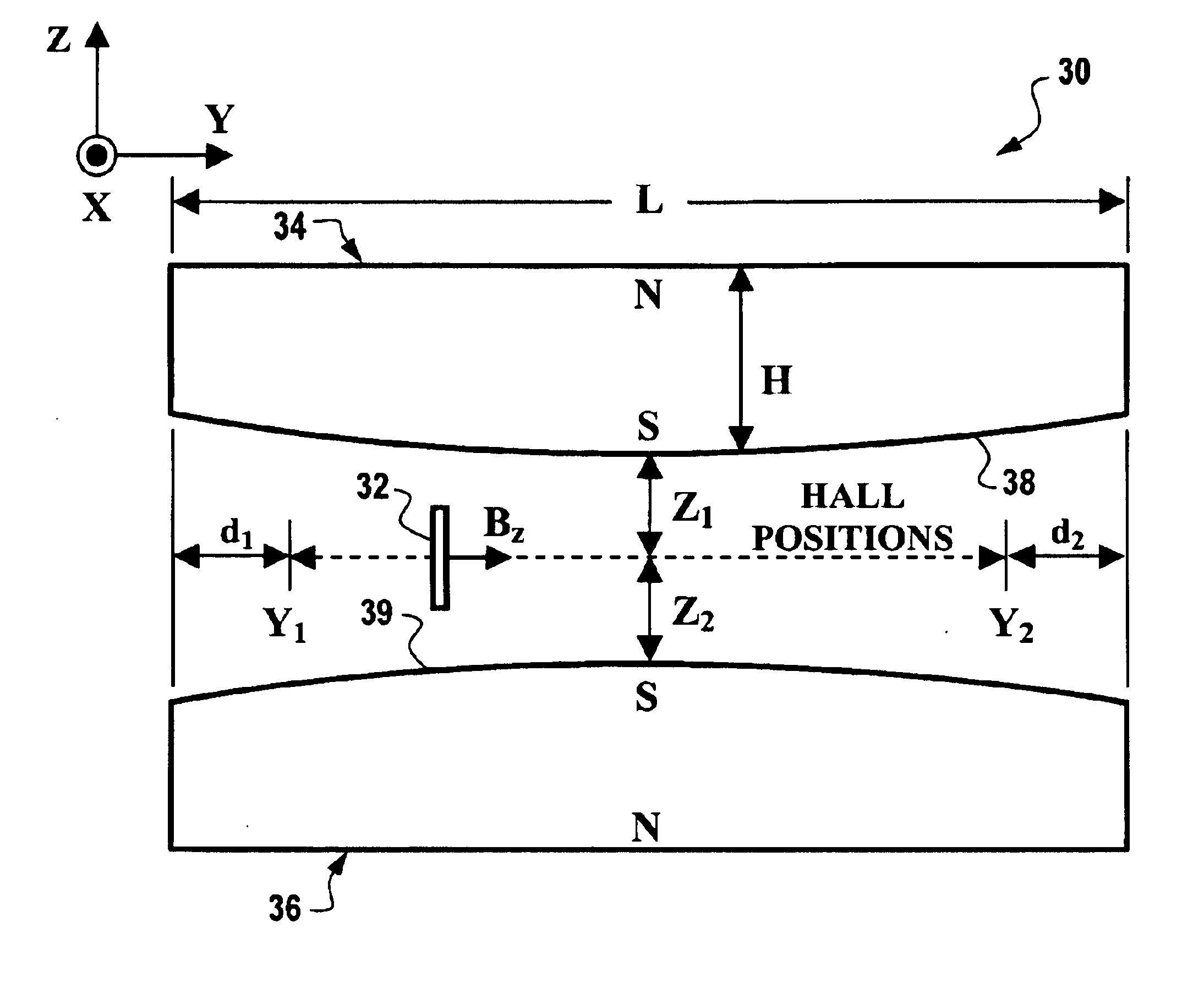

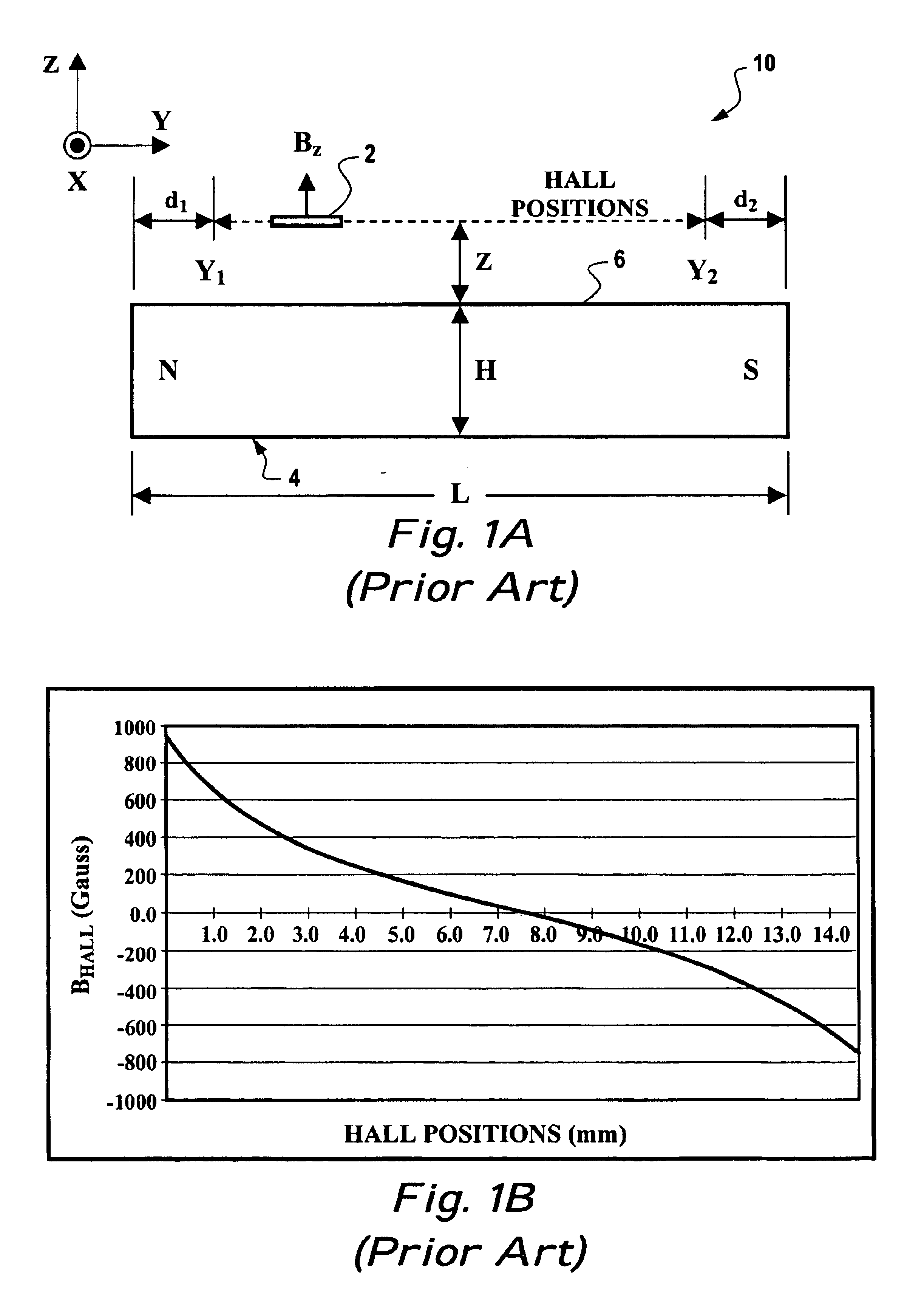

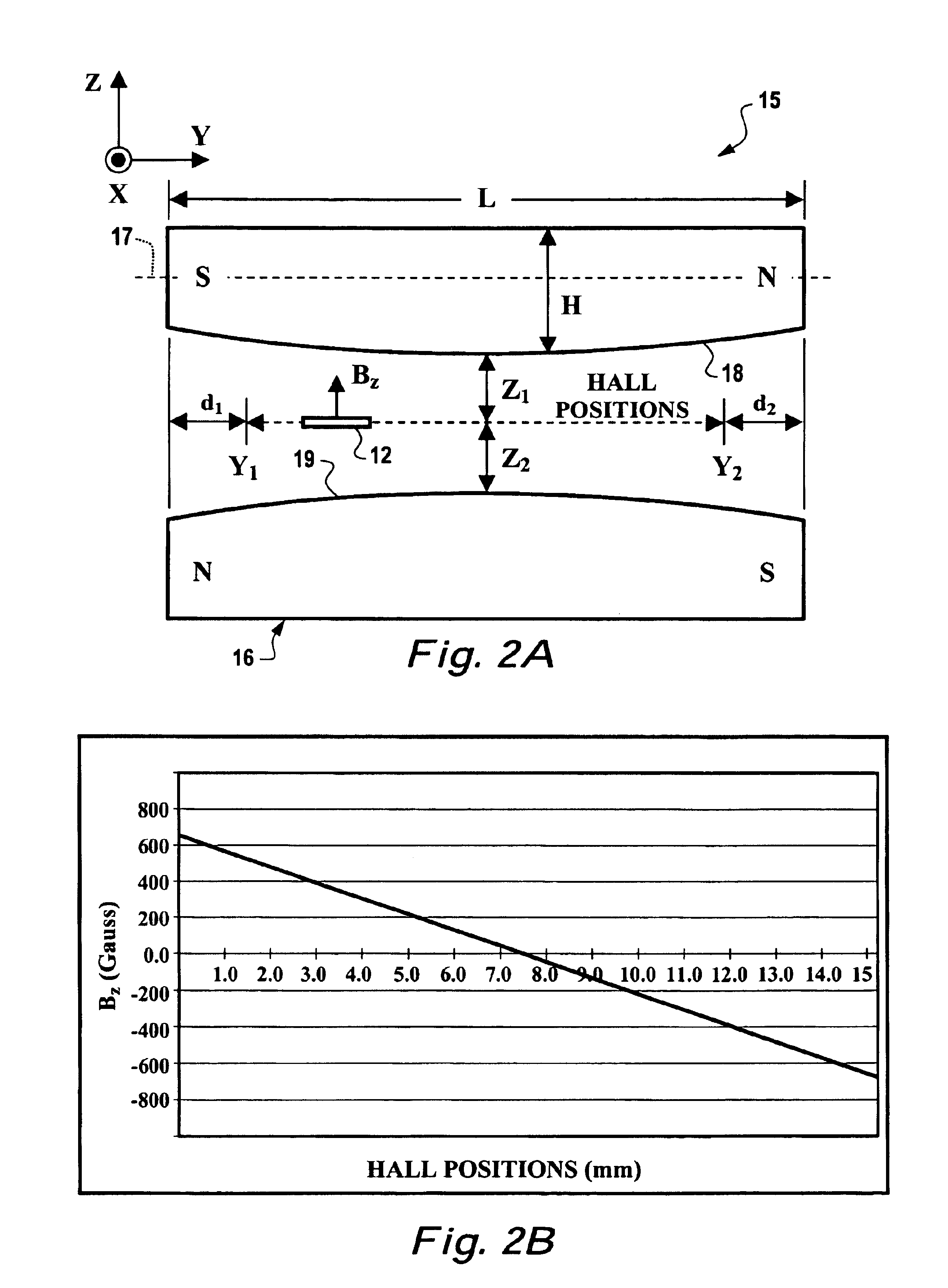

Balanced magnetic linear displacement sensor

ActiveUS7088095B1Easy to understandSolid-state devicesMagnetic field measurement using galvano-magnetic devicesHall elementTransducer

A magnetic linear displacement sensor. In accordance with one embodiment, the displacement sensor includes a Hall transducer element having a sensor plate surface and at least one magnet having a lengthwise dimension along which said Hall element detects a magnetic field component orthogonal to the sensor plate surface during displacement sensing. The magnet includes first and second pole faces disposed on opposite lengthwise sides thereof and a polarization axis aligned orthogonally with respect to the lengthwise dimension. The first pole face opposes the Hall, element and is characterized as having a non-planar surface contoured to generate a substantially linear orthogonal magnetic field component sensed by said Hall element during linear displacement sensing.

Owner:SENSATA TECHNOLOGIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com