Hydrogen atom frequency standard storage bubble opening vacuum sealing device and vacuum sealing method

A vacuum sealing and bubble port technology, which is applied to valve devices, engine sealing, engine components, etc., can solve problems such as micro-leakage and equipment scrap, avoid micro-leakage, improve sealing reliability, and ensure long-term reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

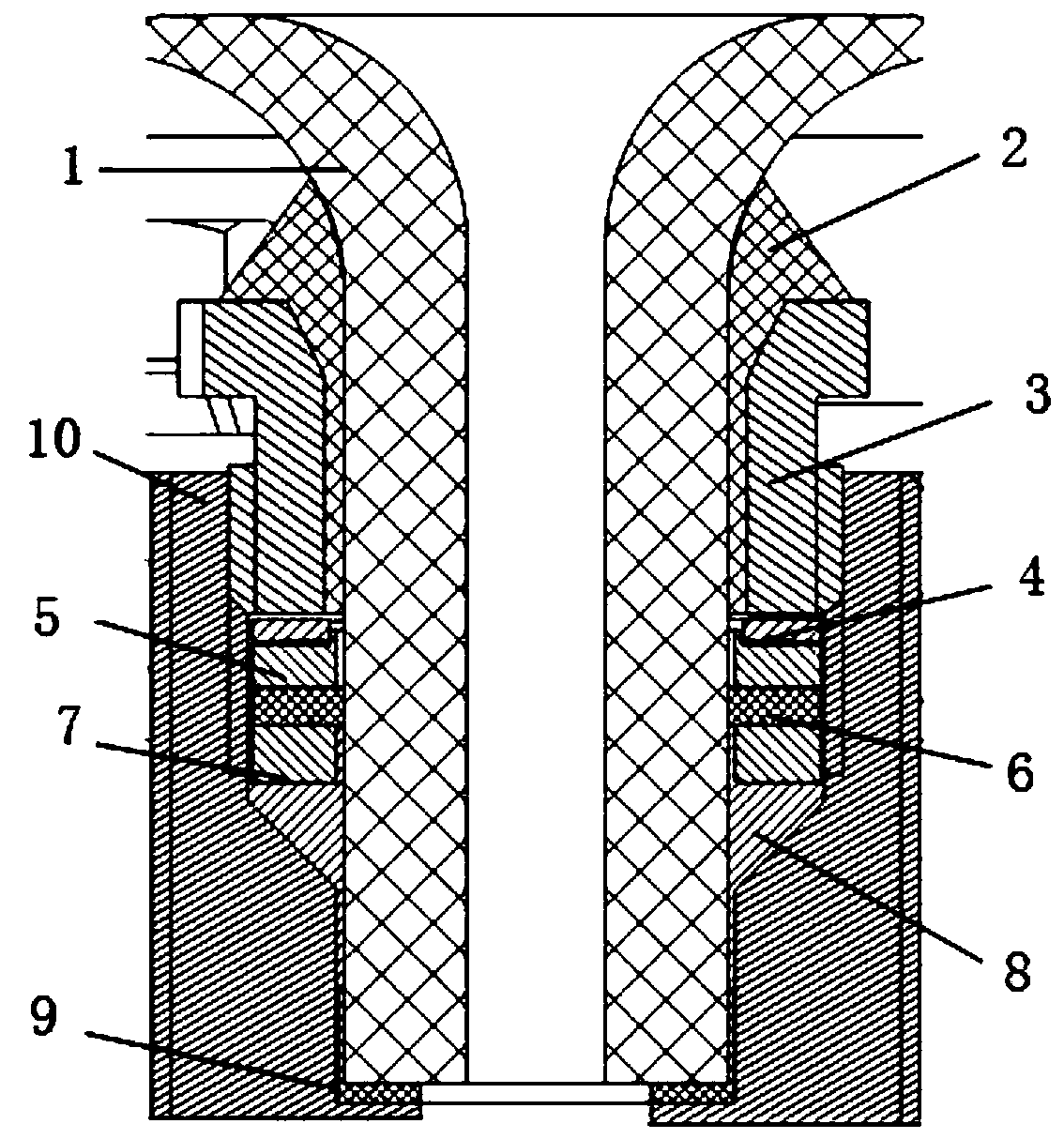

[0024] A hydrogen atom frequency standard storage bubble mouth vacuum sealing device, see figure 1 The hydrogen atomic frequency standard storage bubble mouth vacuum sealing device includes a copper nut 3 sleeved outside the upper part of the longitudinal tubular storage bubble mouth 1, and a longitudinal tubular glue is arranged between the storage bubble mouth 1 and the copper nut 3 Layer 2, the bottom of the copper nut 3 is provided with an annular wave spring washer 4, a first titanium ring 5, a polytetrafluoroethylene ring 6, a second titanium ring 7 and an indium wire ring sleeved outside the storage bubble opening 1 in sequence. 8. The lower end of the storage bubble port 1 is provided with a ring-shaped polytetrafluoroethylene cap 9, the lower part of the copper nut 3, and the wave spring washer 4, the first titanium ring 5, the polytetrafluoroethylene ring 6, and the second titanium ring 7 , the indium coil 8 and the polytetrafluoroethylene cap 9 are provided with a l...

Embodiment 2

[0034] A vacuum sealing method of a hydrogen atom frequency standard storage bubble mouth vacuum sealing device as described in embodiment 1, comprising the following steps,

[0035] Assemble the titanium connector 10 to the corresponding position of the hydrogen atom frequency standard;

[0036] Take the storage bubble to be sealed, and place a copper nut 3, a wave spring washer 4, a first titanium ring 5, a polytetrafluoroethylene ring 6, and a second titanium ring at the storage bubble opening 1 of the storage bubble to be sealed in sequence 7. Indium coil 8 and polytetrafluoroethylene cap 9;

[0037] Place the storage bubble port 1 into the titanium connector 10, and confirm that the storage bubble port 1 is pressed to the bottom end of the titanium connector 10;

[0038] Tighten the copper nut 3;

[0039] Connecting the hydrogen atomic frequency standard to a leak detector through a valve for leak detection;

[0040] When the leak rate is higher than the leak rate set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com