Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Meet production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Health staple food flour special for diabetes patients and preparation method thereof

InactiveCN101564162AStrong targetingNutritional balanceDough treatmentFood preparationDiabetes mellitusDisease

The invention discloses a health staple food flour special for diabetes patients, which is prepared from full wheat flour taken as a raw material, and tartary buckwheat swelling powder, oat swelling powder, soybean protein powder, young oat powder, wheat gluten and stevia rebaudiana taken as accessories in certain proportion. The preparation method for the health staple food flour special for the diabetes patients comprises that: high-quality full wheat flour, the tartary buckwheat swelling powder, the oat swelling powder, the soybean protein powder, the young oat powder, the wheat gluten are firstly selected and baked respectively, weighted in proportion, mixed evenly, screened and packaged into a finished product. The health staple food flour special for the diabetes patients and the preparation method thereof have scientific formula and strong pertinency, change the current situation that more diseases are generated due to nutrition deficiency and physical condition deterioration caused by depending on the control of the staple food in the prior diabetic treatment, and provide a novel food therapy concept of sufficient staple food, balanced nutrition and systematic interference.

Owner:田向东

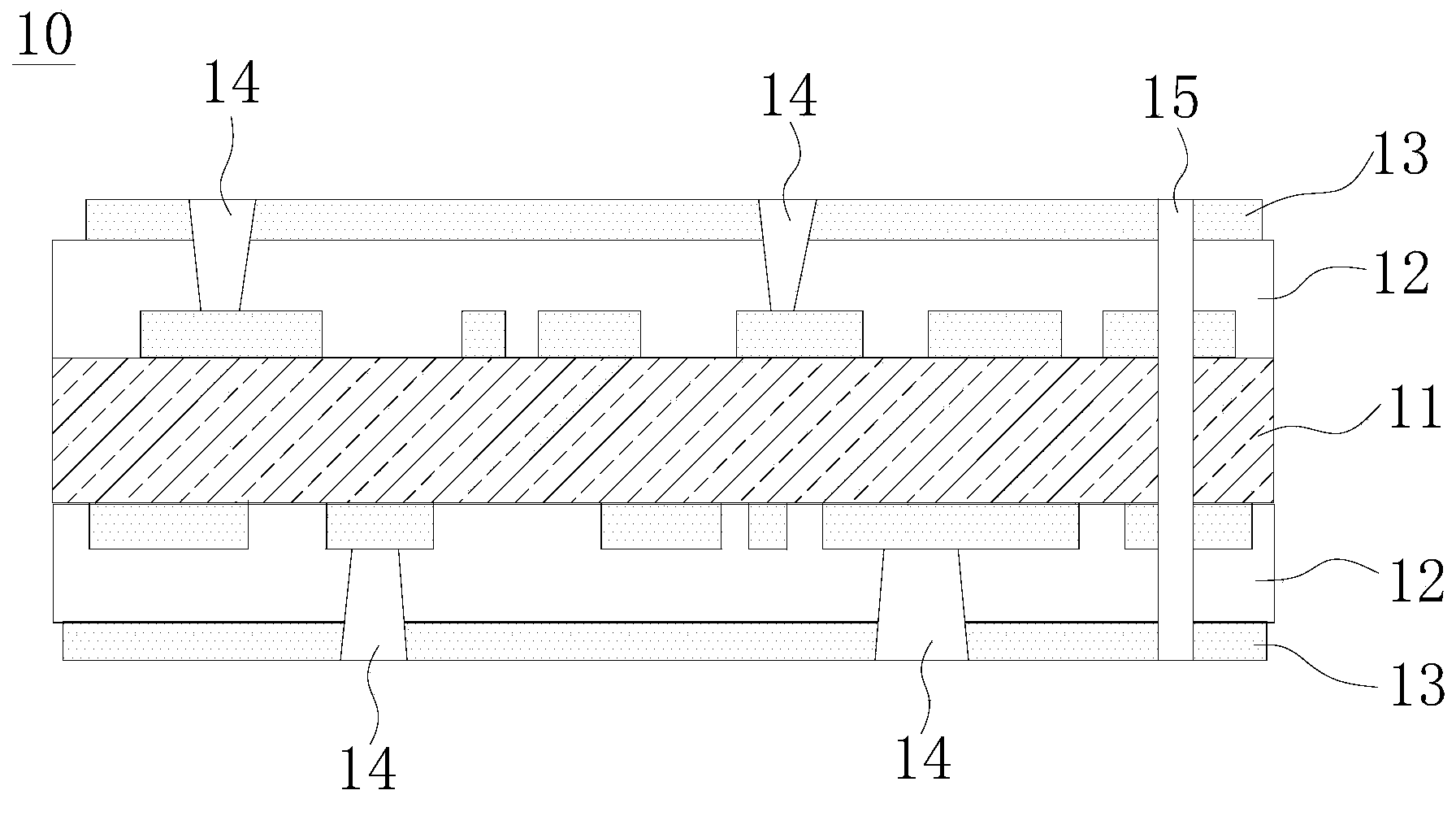

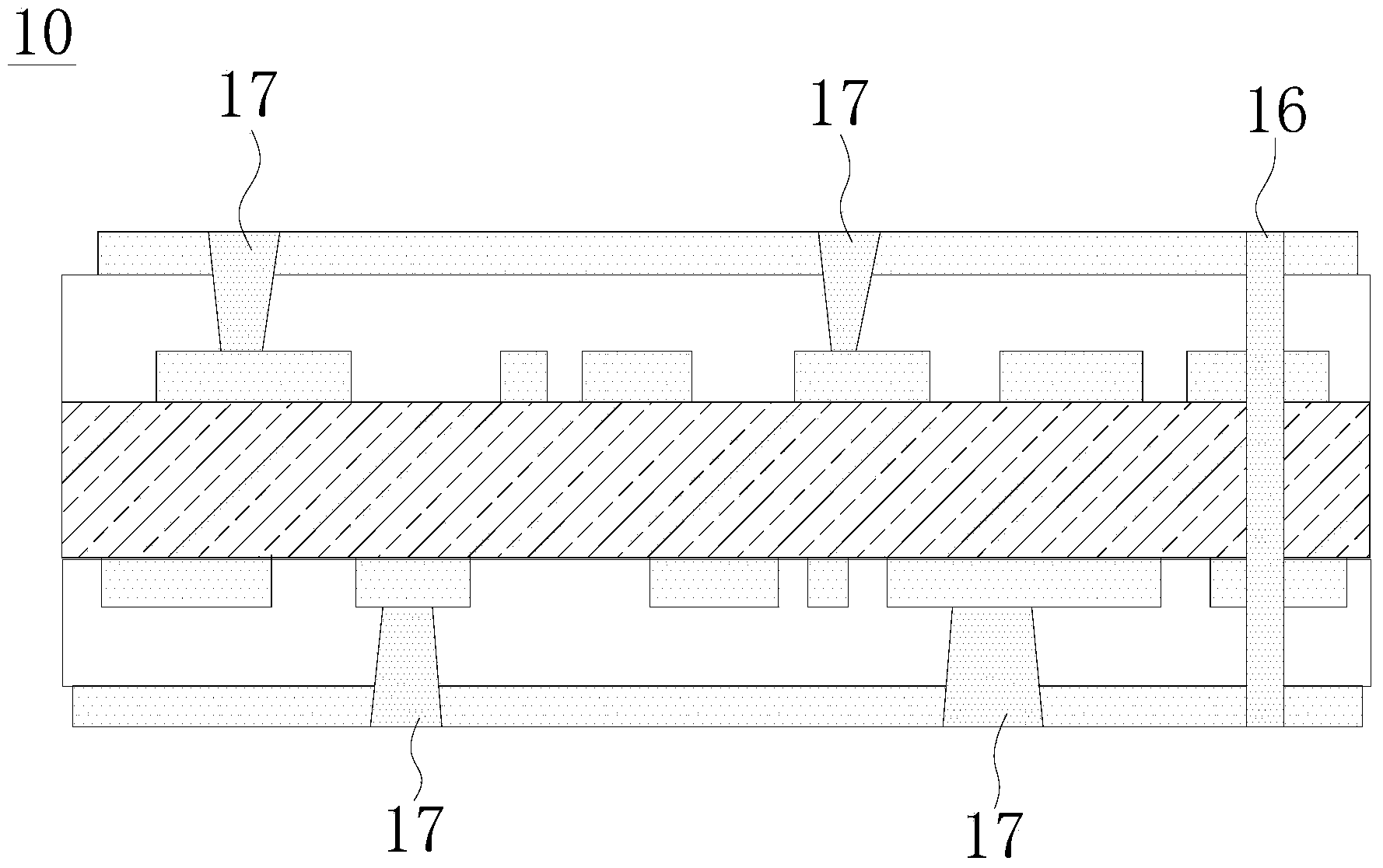

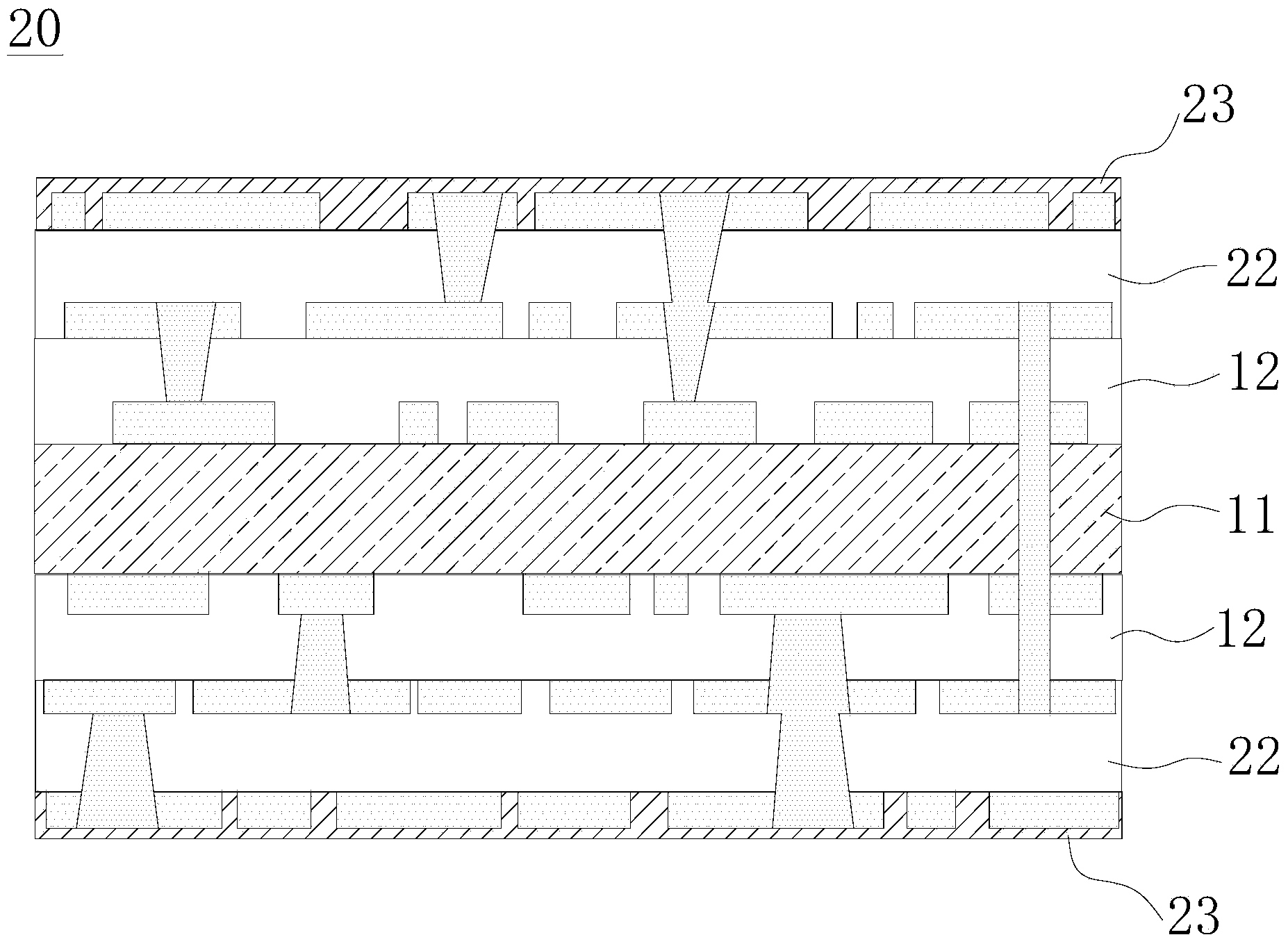

Method for manufacturing plated-through holes in HDI plate

InactiveCN104244613AImprove qualityFulfil requirementsPrinted element electric connection formationMicrometerEngineering

The invention relates to the technical field of circuit board production, in particular to a method for manufacturing plated-through holes in an HDI plate. After blind holes and through holes are drilled in multiple inner-layer plates, inner-layer copper deposition and whole-plate hole filling electroplating are conducted so that the blind holes and the through holes can be metallized at the same time. A horizontal copper deposition electroplating wire is used during inner-layer copper deposition, a perpendicular continuous electroplating wire is used during whole-plate hole filling electroplating, the blind holes and the through holes can be metallized at the same time when the horizontal copper deposition electroplating wire and the perpendicular continuous electroplating wire are used in cooperation, and therefore the technological process can be simplified, production efficiency can be improved, and production cost can be reduced. Specific electroplate liquid is used during whole-plate hole filling electroplating, and therefore the quality of the metallized blind holes and the metallized through holes can be remarkably improved, and the metallized blind holes are prevented from cavities, fractures, poor hole filling and the like, the thickness of hole wall copper layers of the metallized through holes is 25 micrometers or higher, the thickness of electroplated copper on the surfaces of the inner-layer plates ranges from 35 micrometers to 45 micrometers, the requirements of a client are completely met, and manufacturing of circuits in the later procedure is completely achieved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

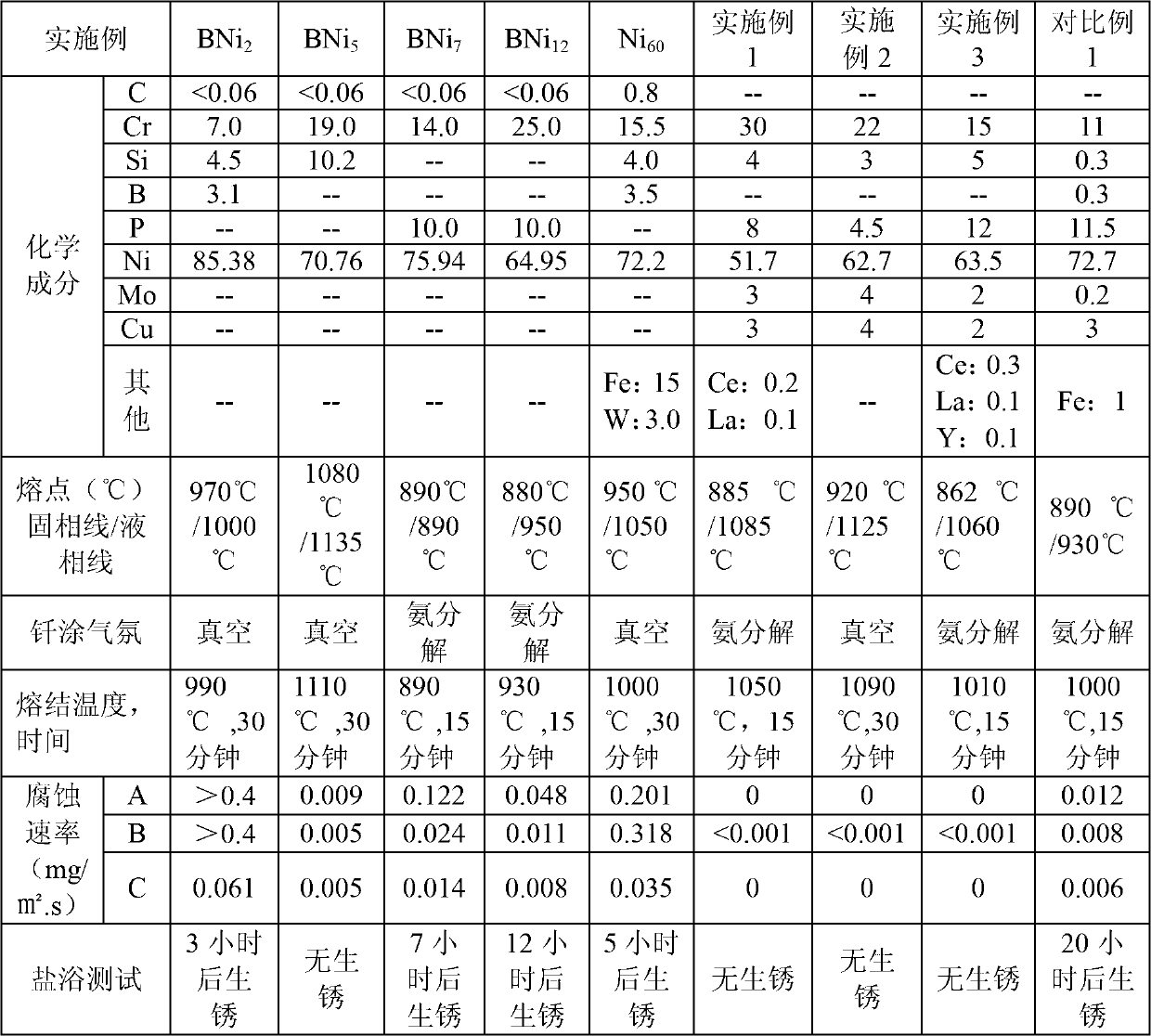

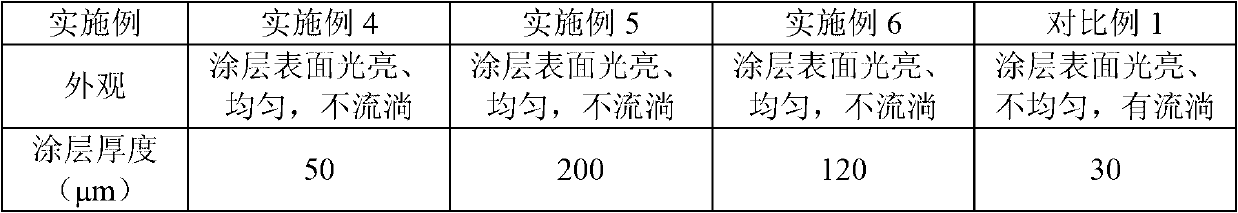

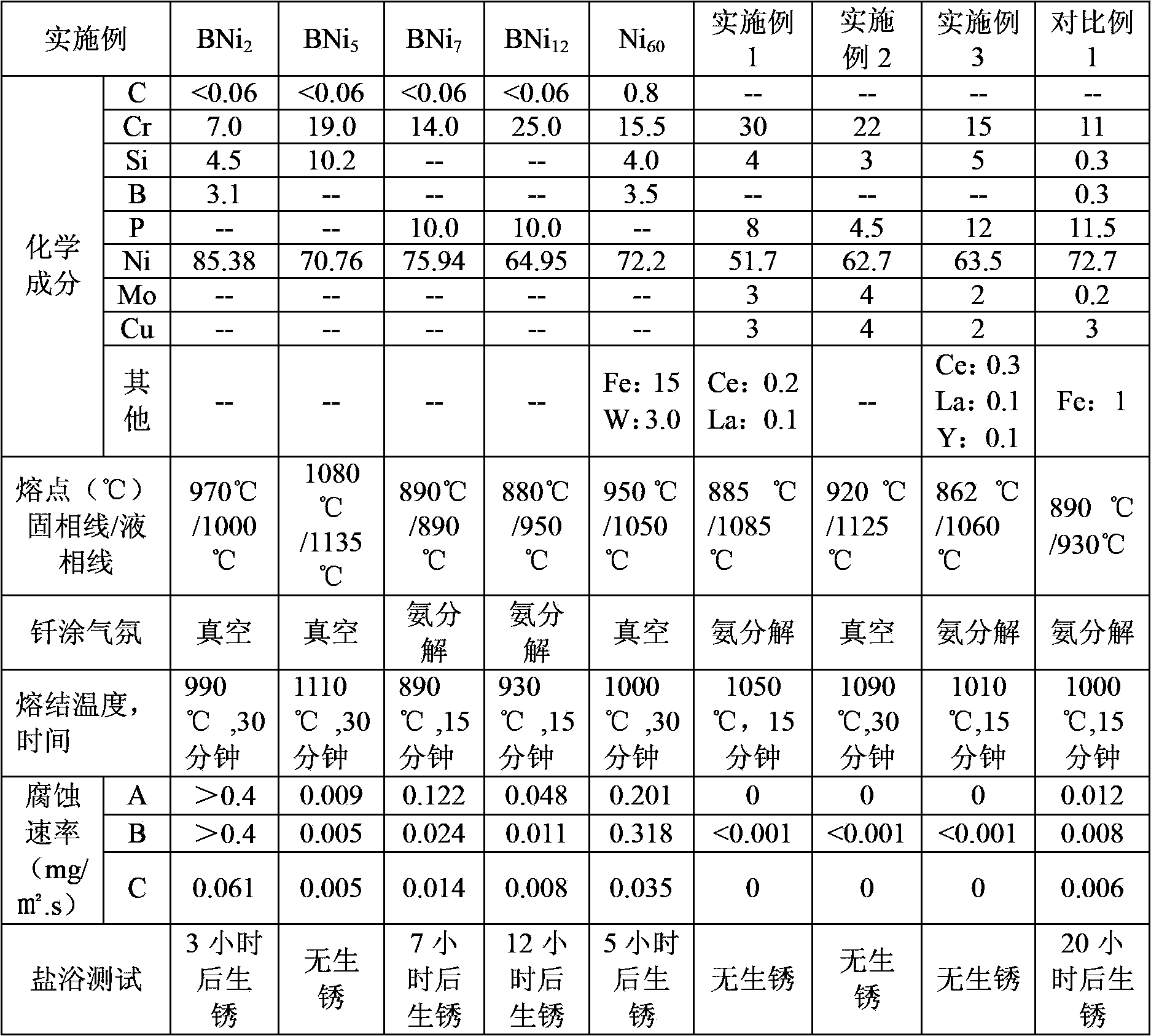

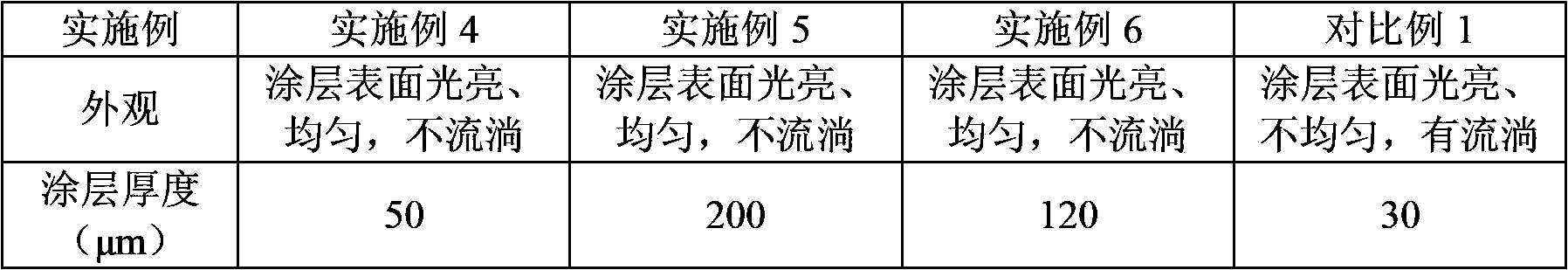

Nickel-based brazing material and method for preparing alloy coating by nickel-based brazing material

ActiveCN102941418AImprove corrosion resistanceImprove brazing process performanceWelding/cutting media/materialsSoldering mediaMischmetalRare earth

The invention provides a nickel-based brazing material, which comprises 15-30 wt% of Cr, 4.5-12wt% of P, 3-5wt% of Si, 2-4wt% of Mo, 2-4wt% of Cu, 0-0.5wt% of rare earth metal and the balance of Ni. The invention solves the technical problem that in the prior art, the nickel-based brazing material is single in the corrosion-resisting environment, so that a thicker and uniform coating is difficult to form on the surface of a workpiece.

Owner:湖南新光环科技发展有限公司

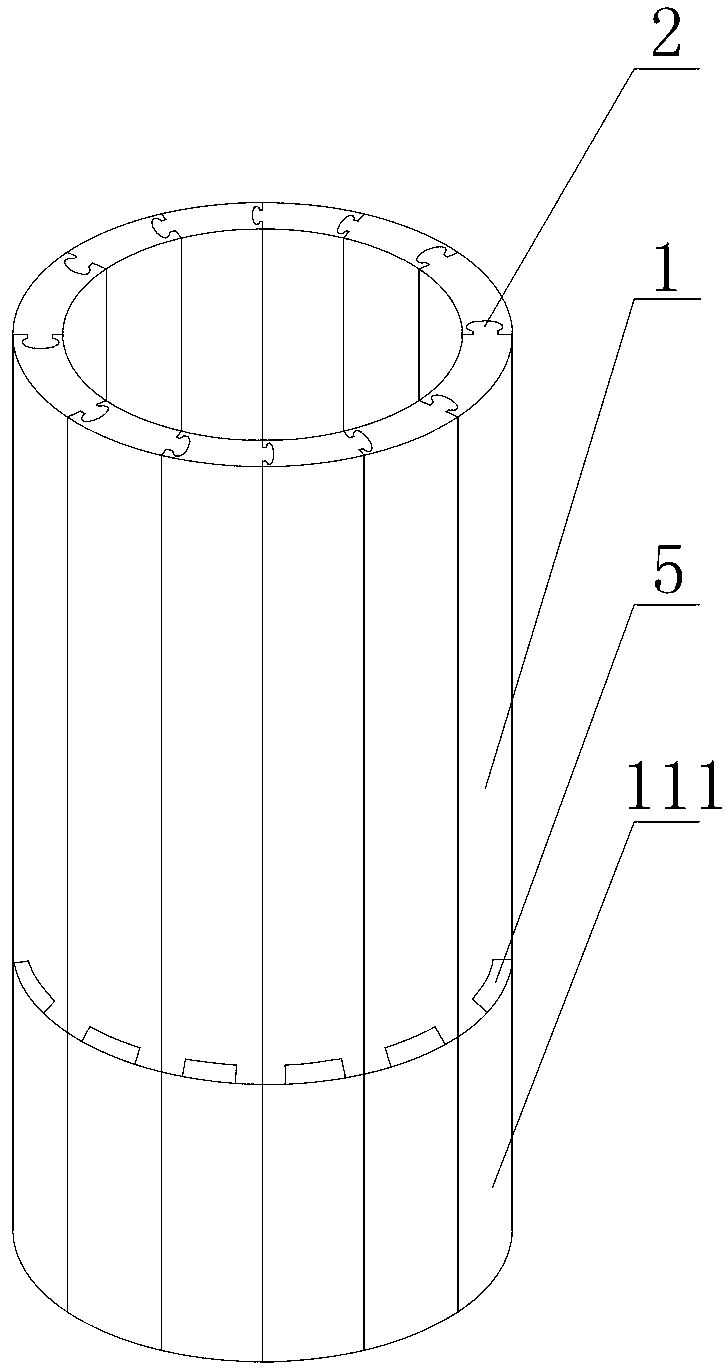

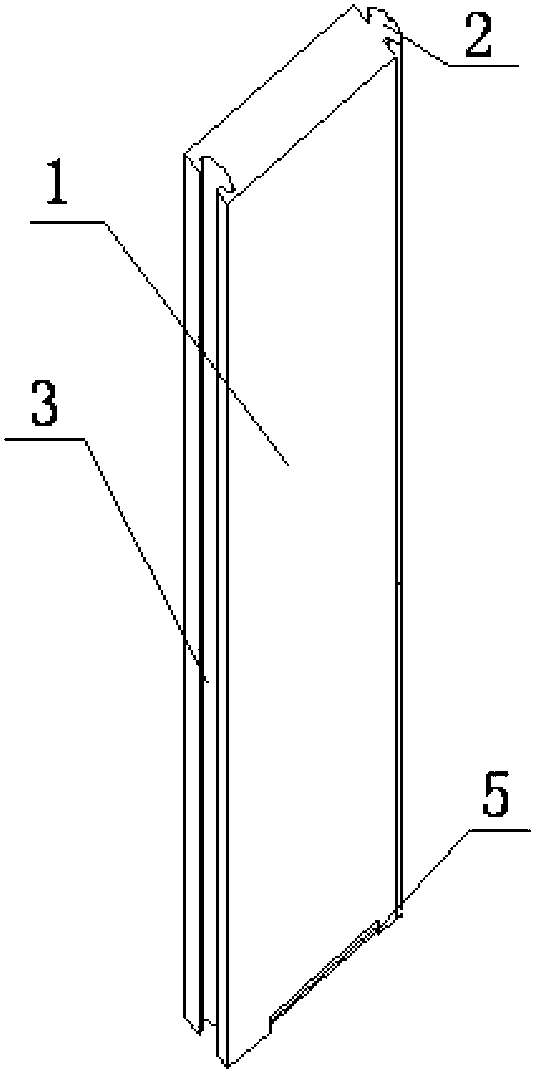

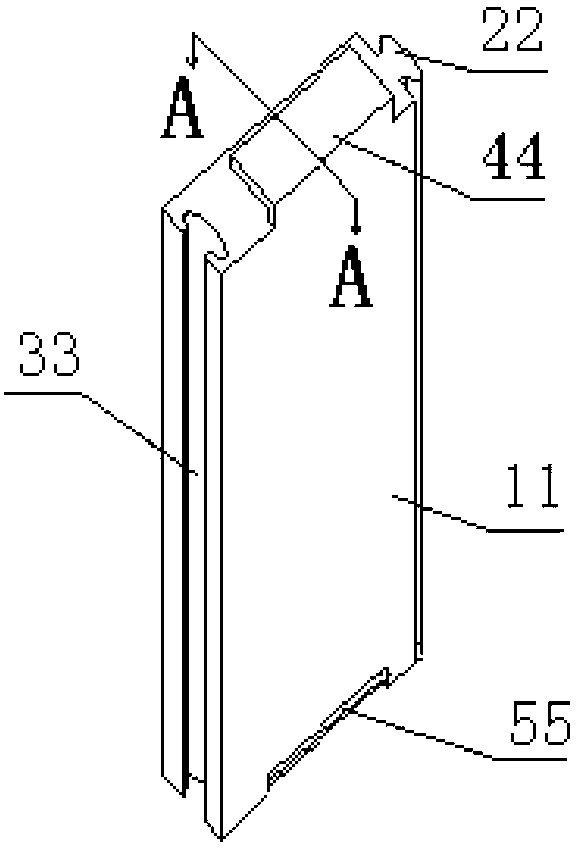

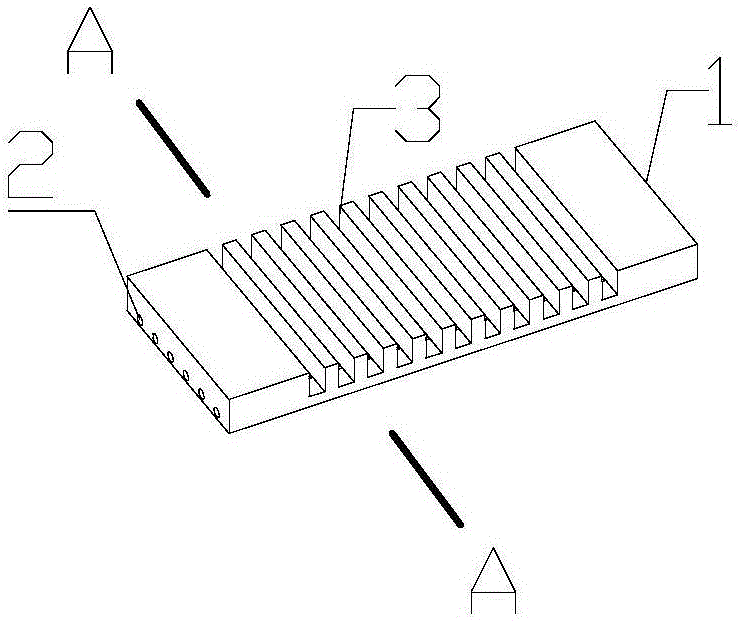

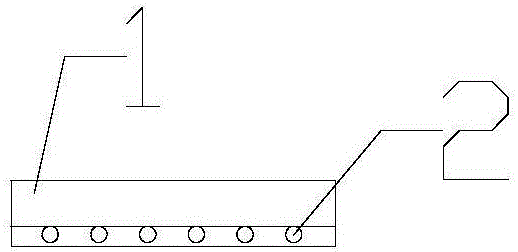

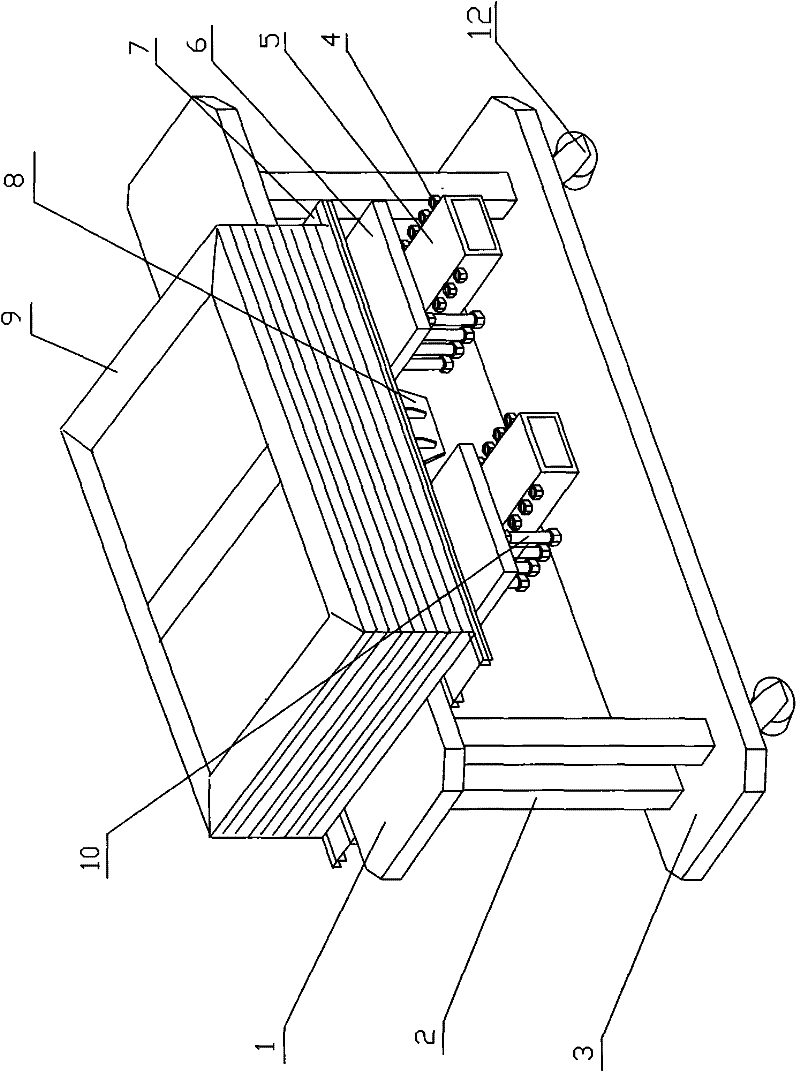

Circular miniature slide-resistant pile die with adjustable height and adjustable sectional area

ActiveCN103252832AHigh impact strengthImprove toughnessMould separation apparatusTransverse grooveJoints number

The invention relates to a circular miniature slide-resistant pile die with an adjustable height and an adjustable sectional area. Plug boards are utilized as parts for forming the die in a split joint mode, and the plug boards are divided into major plug boards, minor plug boards and bottom plug boards according the positions where the plug boards are located on a cylinder structure when the plug boards are assembled, the major plug boards are located on the upper layer positions on the cylinder structure, the minor plug boards are located on the middle layer positions on the cylinder structure, and the bottom plug boards are located on the lower layer positions on the cylinder structure. The lengths and widths of all the plug boards in the same die are the same, the heights of the major plug boards are the same, the heights of the minor plug boards are the same, and the heights of the bottom plug boards are the same. One edge of each plug board in the vertical direction is machined with a vertical plug bar, and a vertical plug groove is formed in the other edge of each plug board. A transverse plug groove is formed in the transverse lower side edge of each major plug board, and a transverse plug groove is formed in the transverse lower side edge of each minor plug board. A transverse plug bar is formed in the upper side edge of each major plug board, and a transverse plug bar is formed in the upper side edge of each minor plug board. Each transverse plug bar on each upper side edge is matched with each transverse groove in each lower side edge. When the plug boards are assembled, the major plug boards, the minor plug boards and the bottom plug boards are connected in an up-and-down left-and-right split joint mode to form the die which is in a nearly cylindrical shape. According to the circular miniature slide-resistant pile die with the adjustable height and the adjustable sectional area, the sectional area can be adjusted through changing of a left-and-right split joint number of the plug boards, the height can be adjusted through changing of an up-and-down connecting layer number of the plug boards, the circular slide-resistant pile die with the adjustable height and the adjustable sectional area can be spliced through only one set of plug boards, and the circular miniature slide-resistant pile die with the adjustable height and the adjustable sectional area is simple in structure, easy to splice and low in use cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

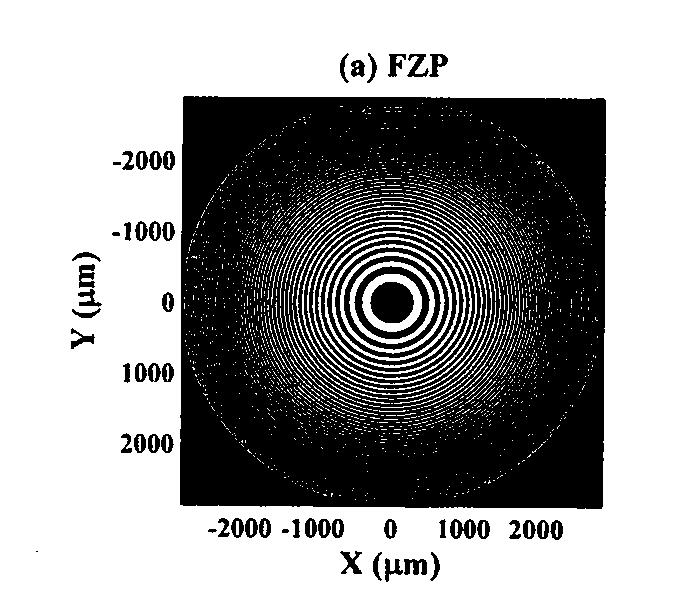

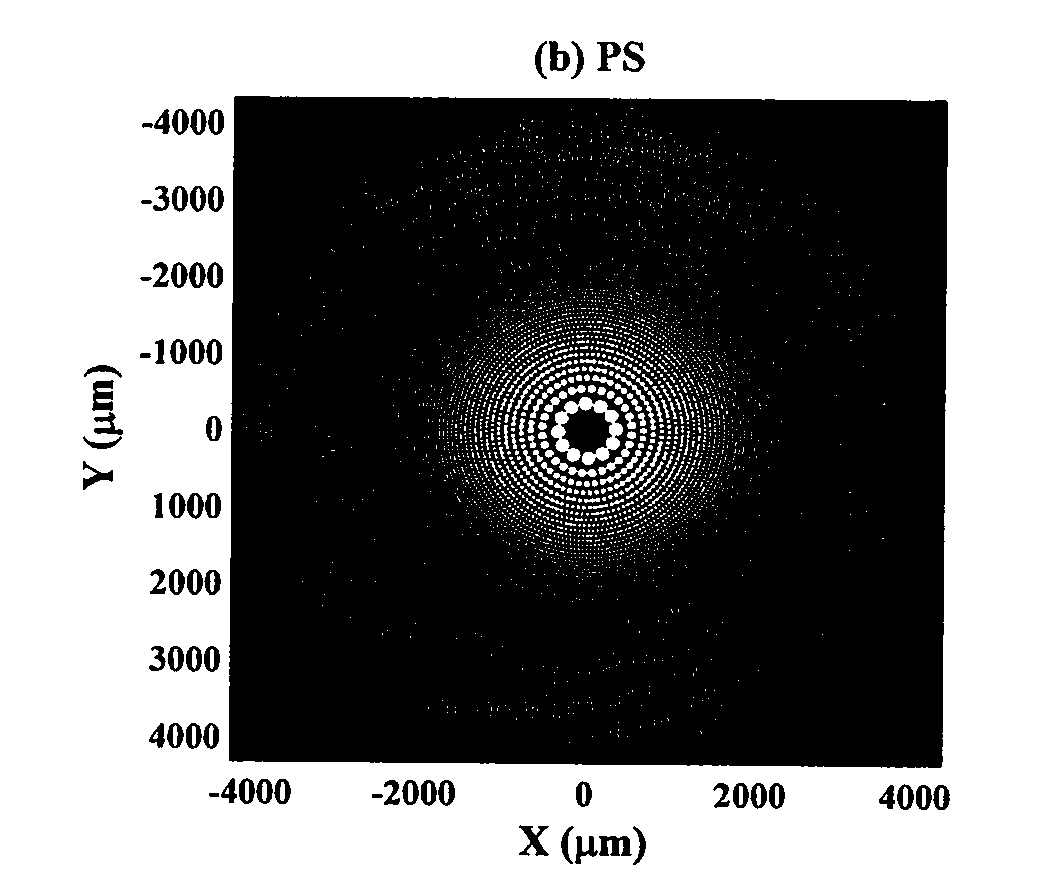

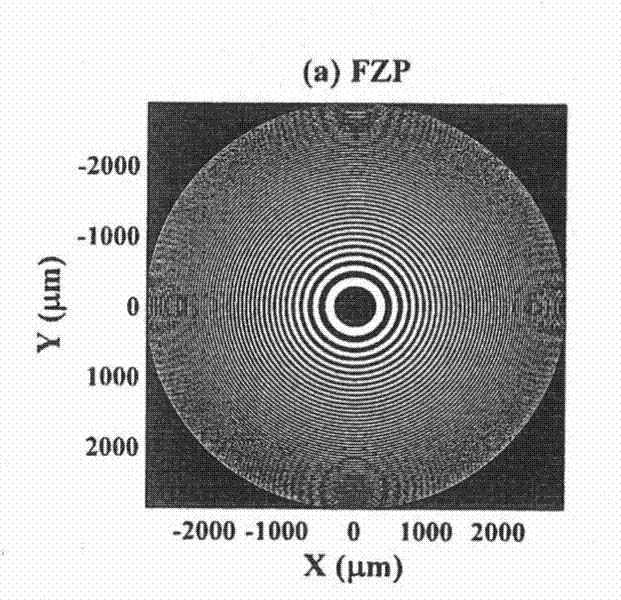

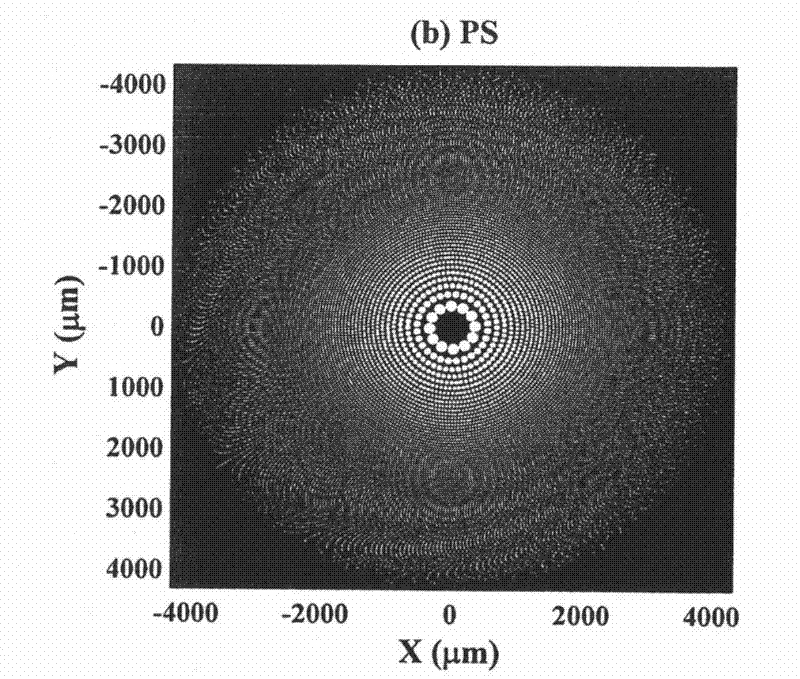

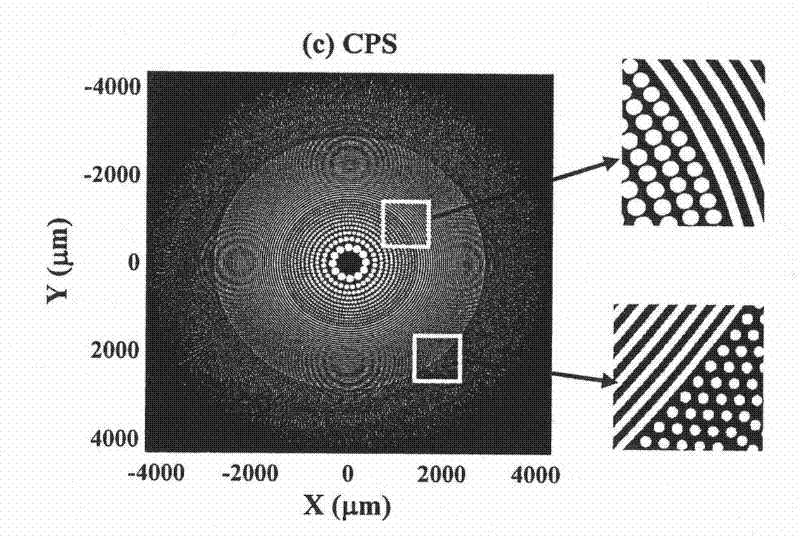

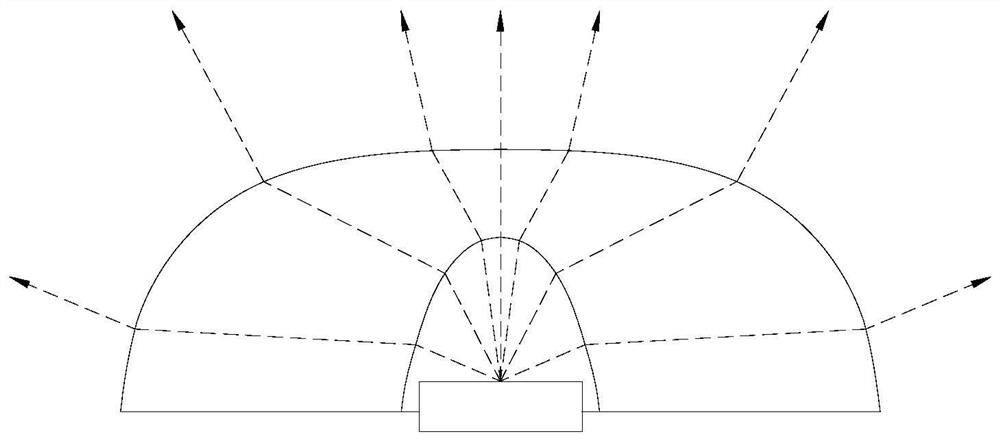

Compound photon sieve for large-caliber imaging and manufacturing method thereof

ActiveCN102043178AHigh-resolutionSharp focal spotPhotomechanical apparatusDiffraction gratingsOrganic glassBlocking layer

The invention discloses a compound photon sieve for large-caliber imaging and a manufacturing method thereof and belongs to the technical field of diffractive optical elements. The compound photon sieve comprises a transparent substrate and a lightproof metal film plated on the pervious substrate; a series of transparent girdles and pervious apertures which are randomly distributed are designed on the lightproof film; a pervious plane can be made of transparent materials such as fused quartz, common glass, organic glass and the like; the lightproof film is a metal light-blocking layer of chromium, gold, aluminum, copper and the like prepared on the transparent substrate; and the transparent girdles and the transparent apertures are not provided with the metal light-blocking layer. Compared with Fresnel wave zone plates, the compound photon sieve provided by the invention can improve numerical aperture and imaging resolution and can effectively restrain side-lobe effect and high-order diffraction in the direction of an optical axis; and compared with a common photon sieve, the compound photon sieve can improve imaging contrast, effectively reduces data volume of geometry data standard II (GDSII) map files, and reduces the difficulty in processing large-caliber imaging photon sieves.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

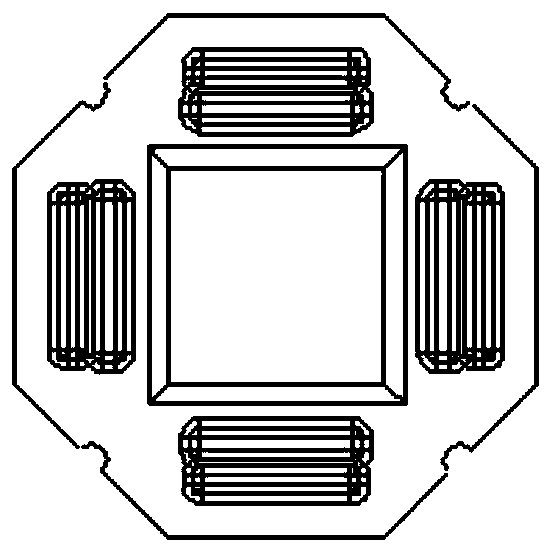

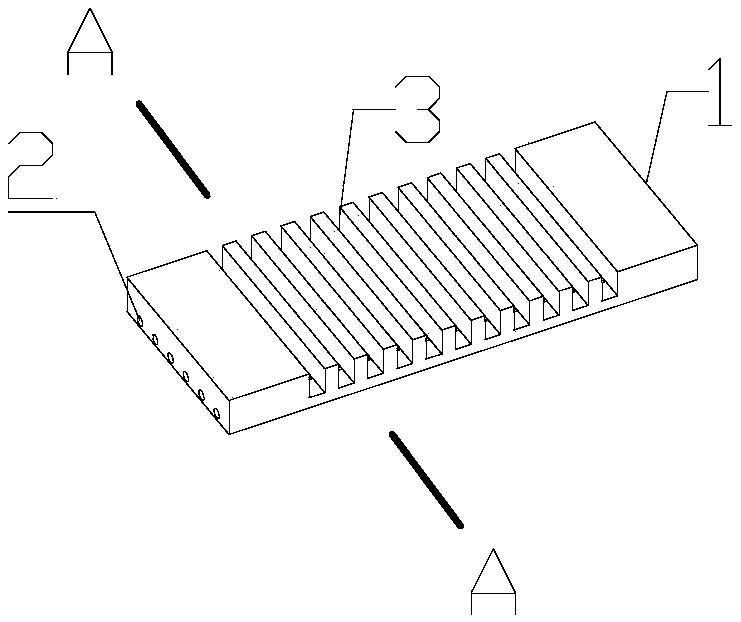

Through bar type concrete composite floor slab structure and manufacturing and assembling method thereof

The invention relates to the field of assembled concrete buildings, in particular to a through bar type concrete composite floor slab structure and a manufacturing and assembling method thereof. The structure comprises prefabricated base plates, longitudinal stressed steel bars, reserved transverse stressed steel bar grooves, hogging moment steel bars, transverse stressed steel bars and the like. Due to the fact that transverse stressed steel bars of the unique prefabricated base plates are continuous, additional connecting measures and additional connecting steel bars are not needed for connection of the prefabricated base plates, construction is simplified, materials are saved, and the integrity of composite slabs is greatly strengthened. The reserved transverse stressed steel bar grooves of the through bar type concrete composite floor slabs reinforce shear resisting and tensile resisting connection of a cast-in-place concrete layer and the prefabricated base plates, and the overall performance of the composite slabs is greatly improved. The transverse stressed steel bars of the through bar type concrete composite floor slab structure are placed in the reserved transverse stressed steel bar grooves formed in the prefabricated base plates, maximum approximating to the prefabricated base plates is achieved, and the anti-bending stress performance of the prefabricated base plates can be same as the performance of cast-in-place slabs.

Owner:SHENYANG SANXIN IND

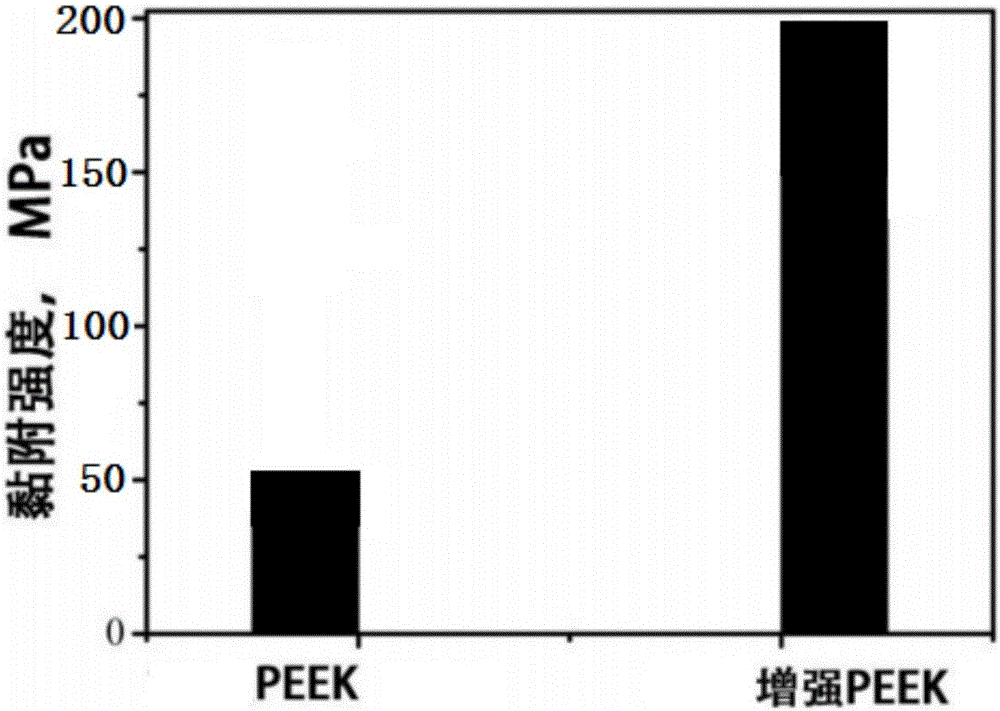

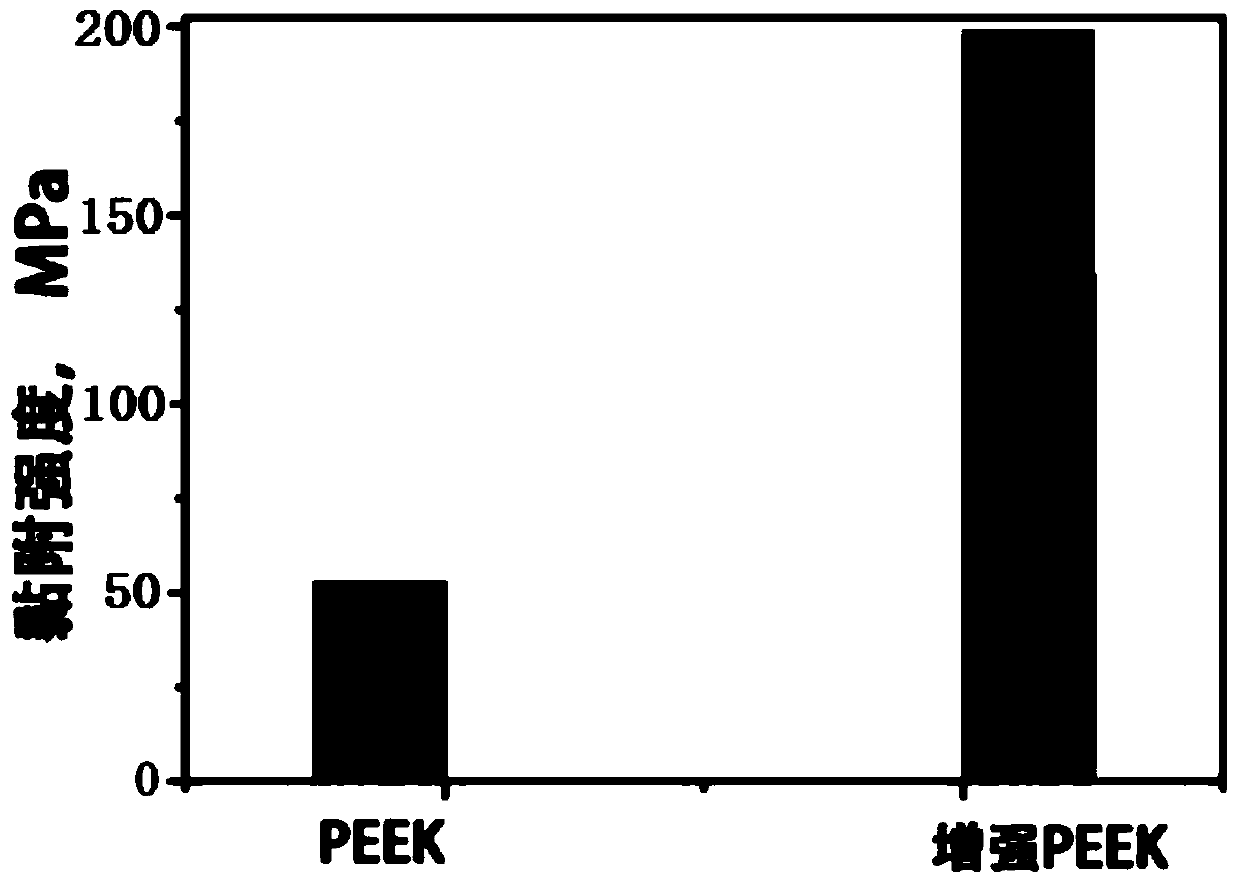

PEEK false tooth composite and preparation method thereof

The invention discloses a PEEK false tooth composite. The PEEK false tooth composite is prepared from, by weight, 110-150 parts of polyether-ether-ketone, 10-20 parts of nano calcium silicate, 8-12 parts of hydroxyl hydroxyapatites, 4-8 parts of barium glass short fibers, 15-22 parts of organic solvent, 8-18 parts of refined paraffin, 1-4 parts of co-binding agent, 8-12 parts of binder, 2-6 parts of antibacterial agent, 6-10 parts of carbide and / or 8-15 parts of oxide. The invention further discloses a preparation method of the PEEK false tooth composite. The preparation method includes the steps that firstly, the raw materials of nano calcium silicate, hydroxyl hydroxyapatites, carbide and / or oxide are mixed, the mixture is heated to 150-220 DEG C, the situation is kept for 10-30 min, cooling is carried out, the refined paraffin is added, mixing and stirring are carried out, and after the mixture is crushed ultrasonically, the organic solvent, polyether-ether-ketone, the co-binding agent, the binder and the antibacterial agent are added to be stirred till uniform paste is obtained; finally the barium glass short fibers are added, ball-milling and drying are carried out, and the finished composite powder is obtained.

Owner:广西深雅医疗科技股份有限公司

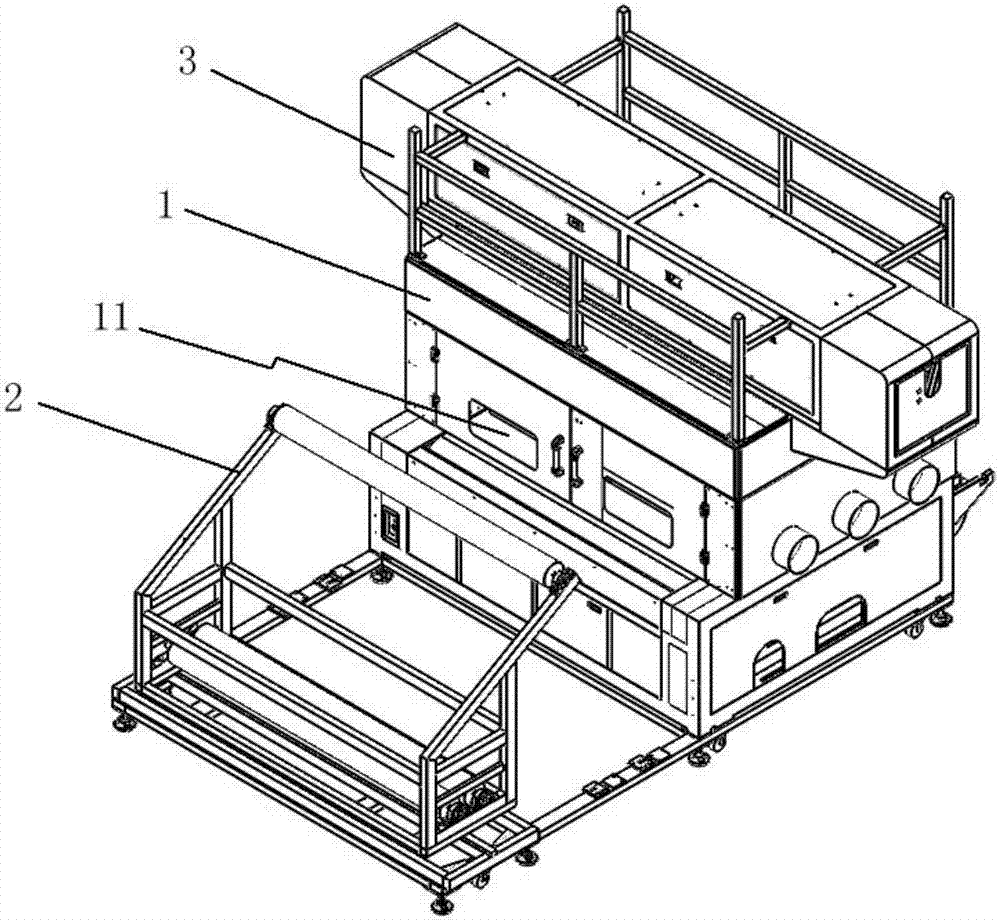

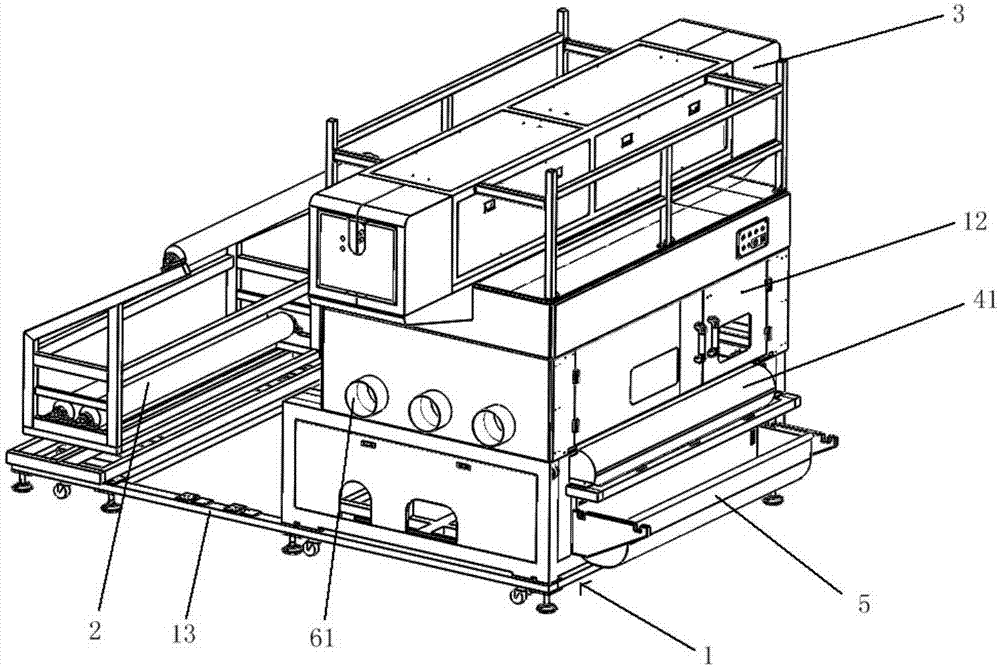

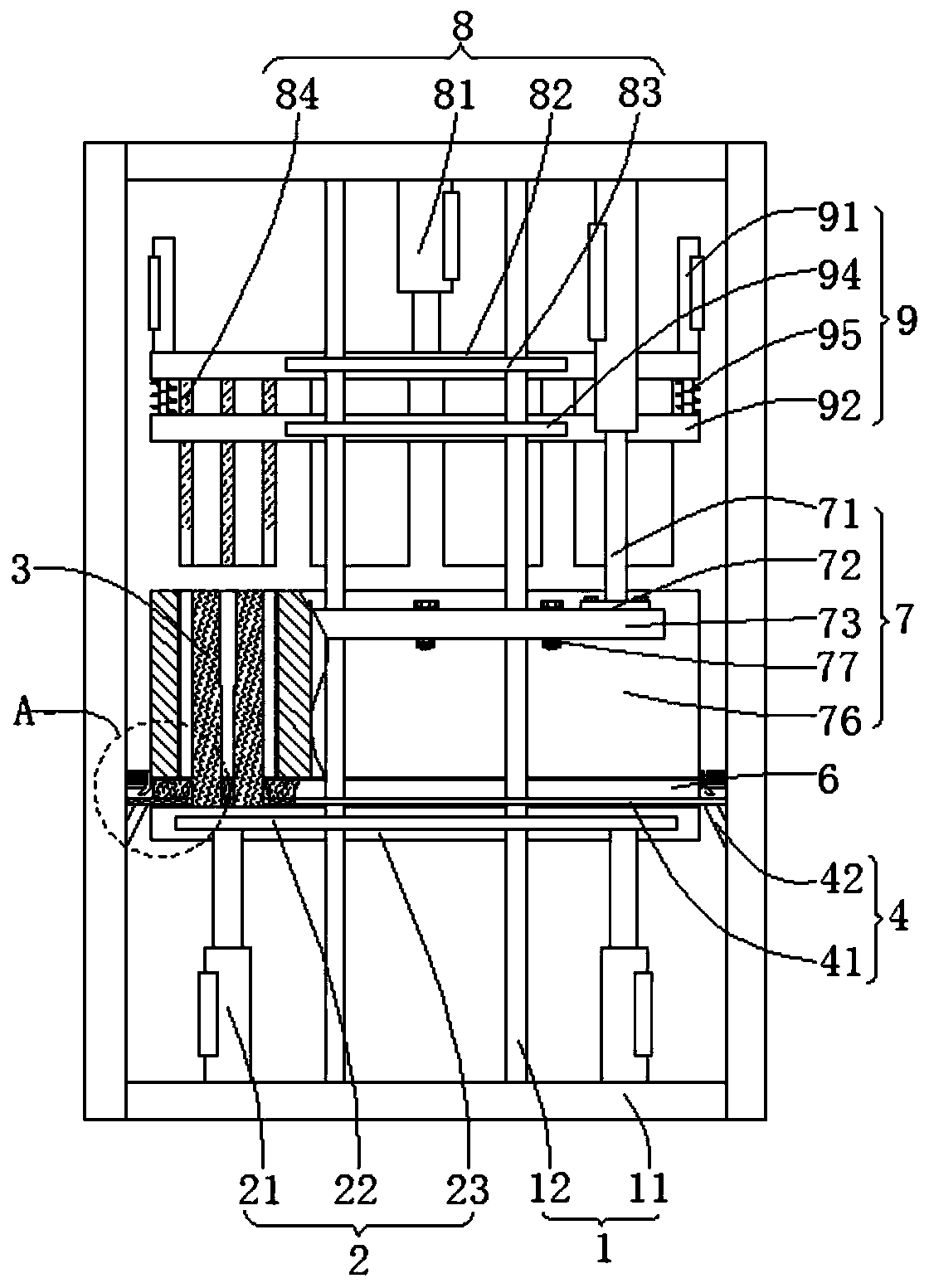

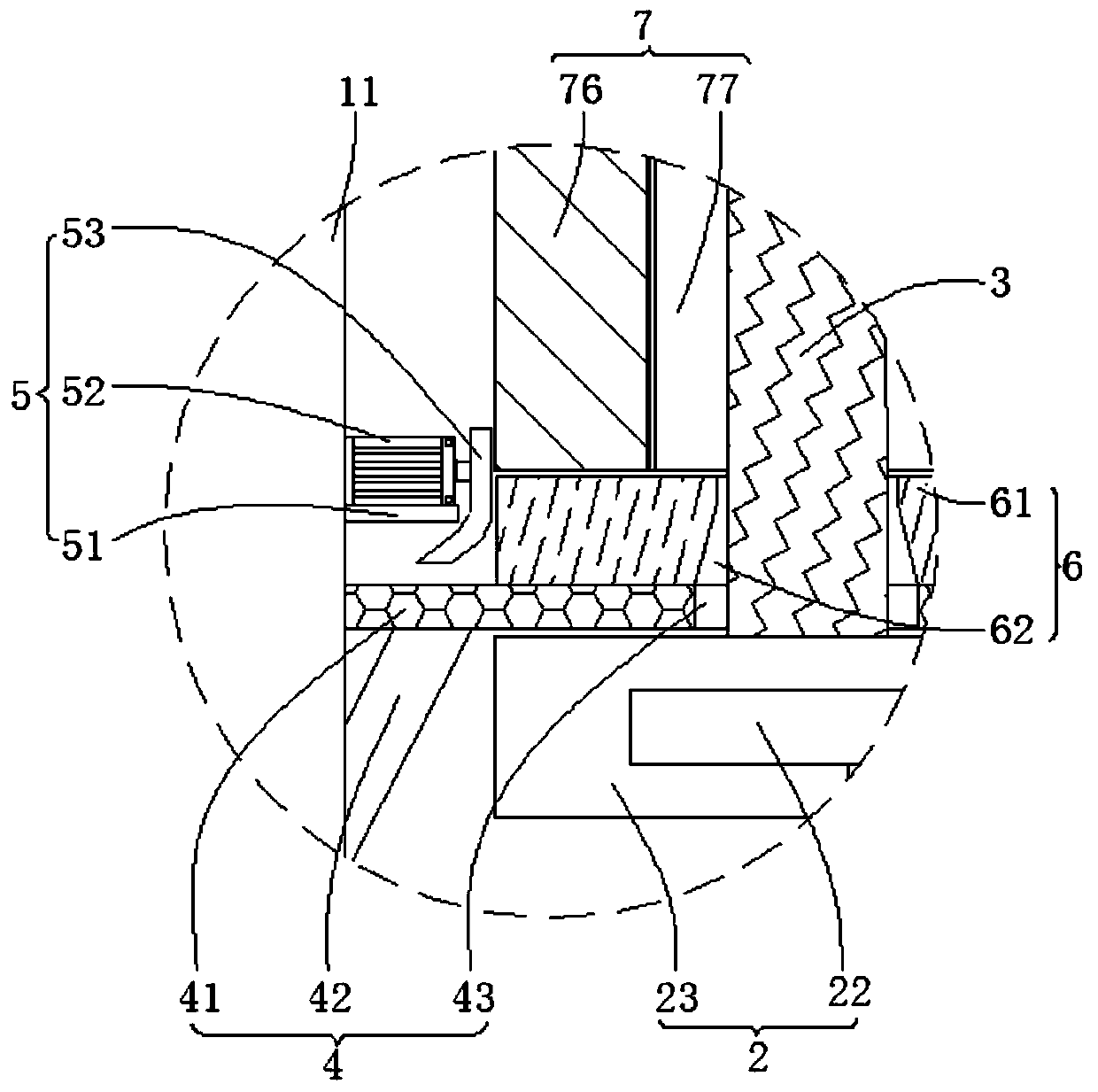

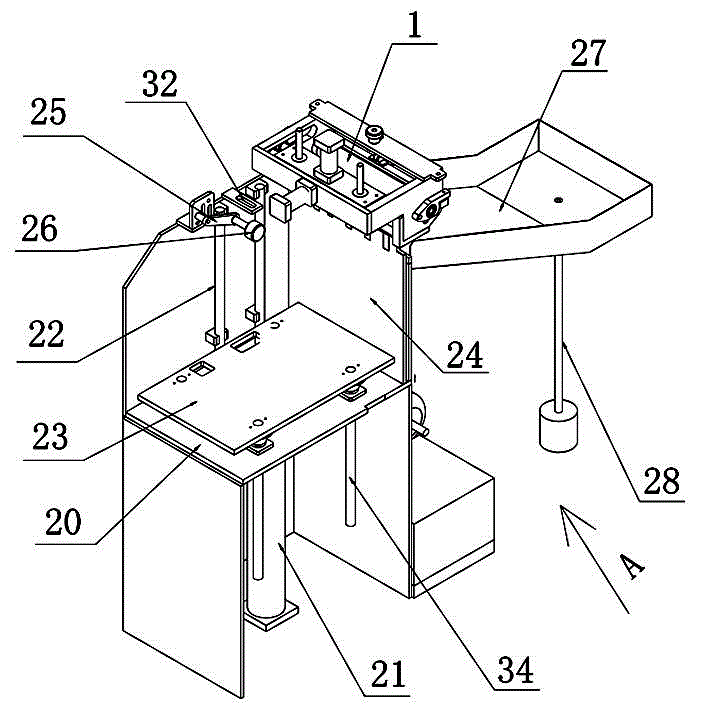

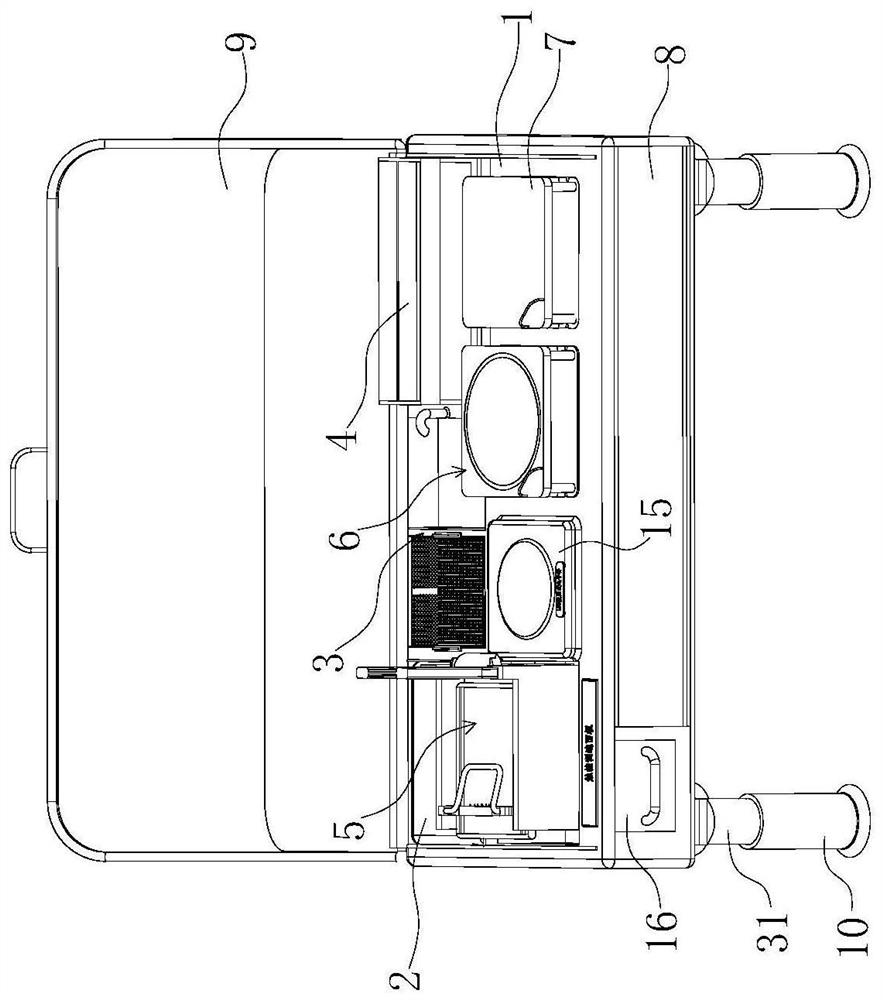

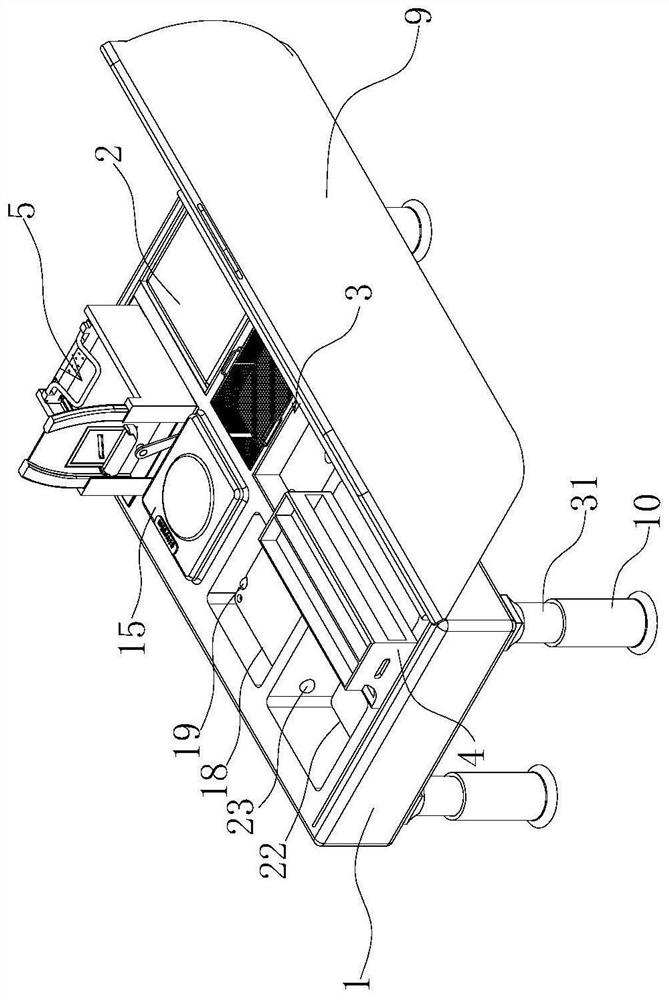

Hydraulic brick making machine and brick making method

ActiveCN110434983AMeet productionExtended service lifeDischarging arrangementFeeding arrangmentsBrickEngineering

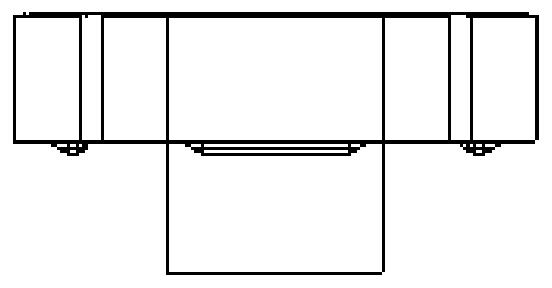

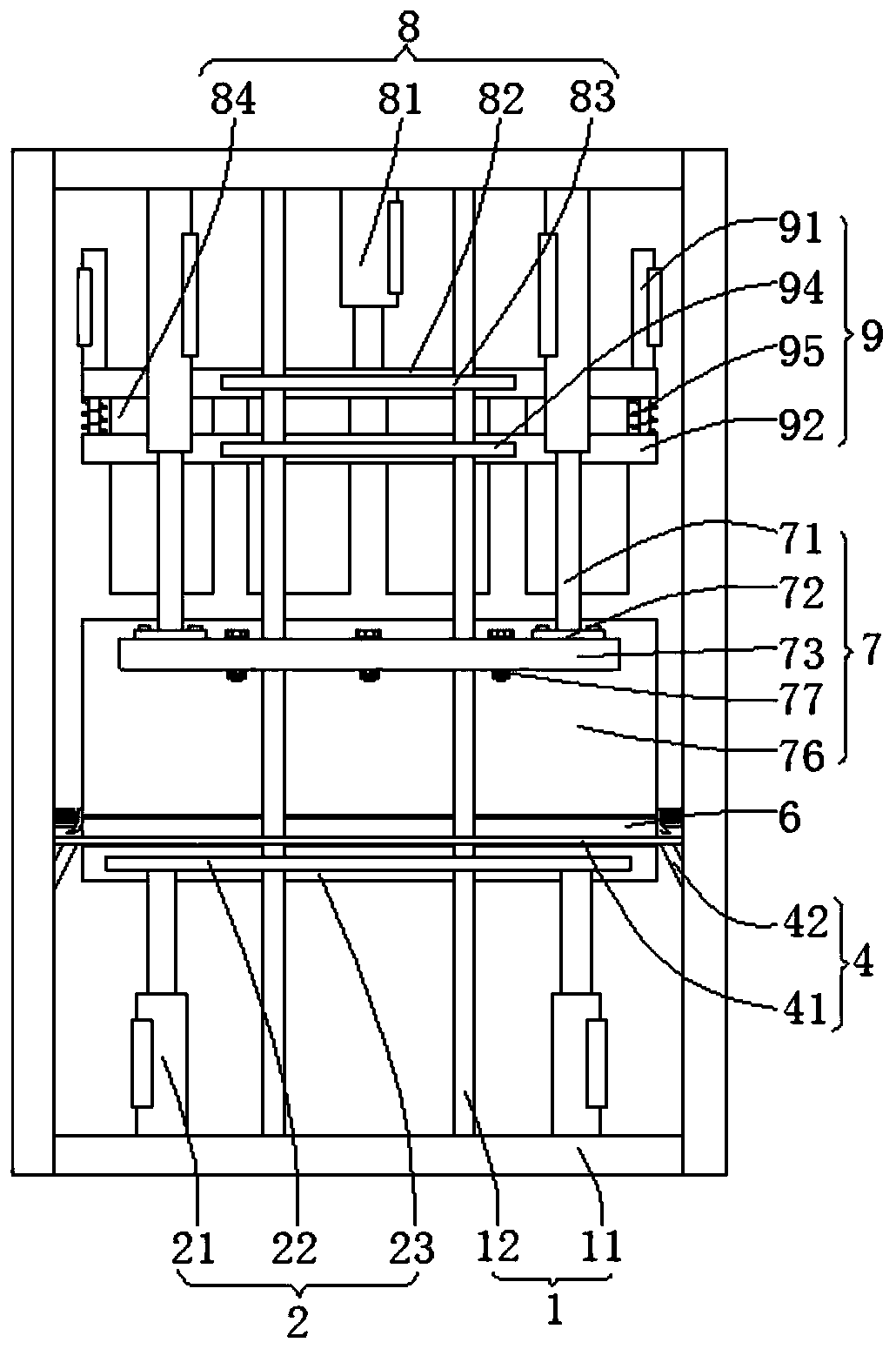

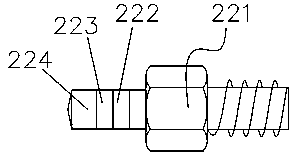

The invention relates to a hydraulic brick making machine and a brick making method. An upper fixing beam of the brick making machine is fixedly installed on a guide upright post, a connecting deviceis positioned between the upper fixing beam and a base, a distributing mechanism is installed on the connecting device, and a mould frame fixing piece for fixing a mould frame is detachably arranged on the connecting device; an upper die assembly is mounted on the upper fixing beam; a lower die assembly is mounted on the base; and a die frame assembly is detachably mounted on the lower die assembly. During use, a lower die and a die frame synchronously move upwards to a first position, and the die frame is continuously moved upwards to form a first filling cavity; and primary material distribution is performed, the lower die moves downwards, and secondary material distribution is performed. According to the hydraulic brick making machine and the brick making method, secondary distributioncan be realized, and the manufacture of brick bodies with different structures can be met; adjustment is carried out according to different types of brick making requirements, different configurationscan be selected according to required functions, different brick type requirements are met, the brick making cost is reduced, and the service life of the brick making machine is effectively prolonged.

Owner:CRRC DALIAN CO LTD

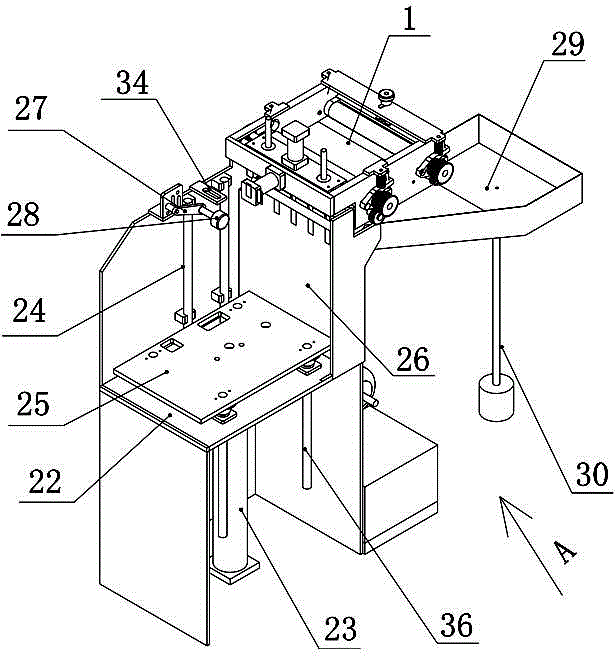

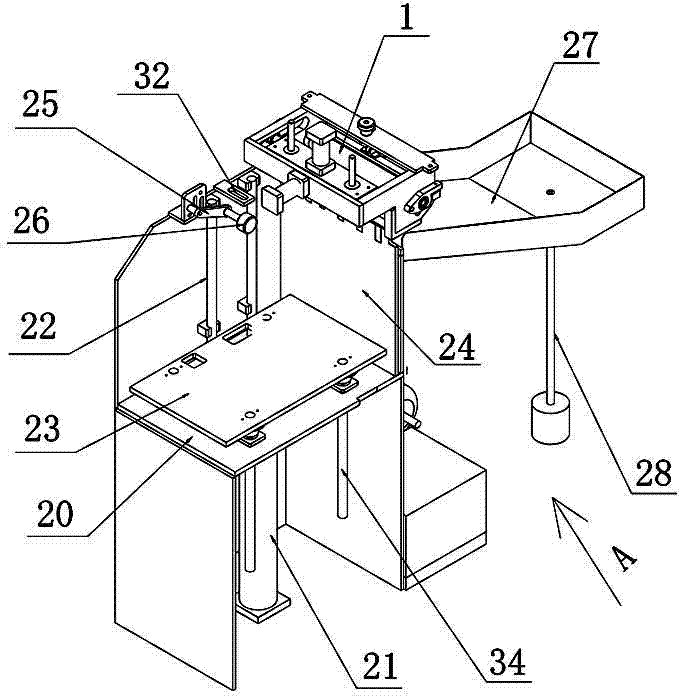

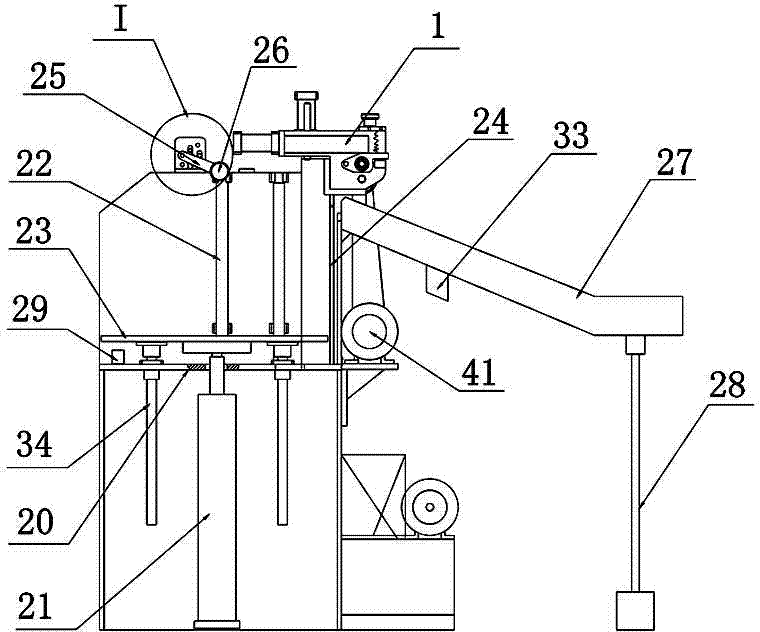

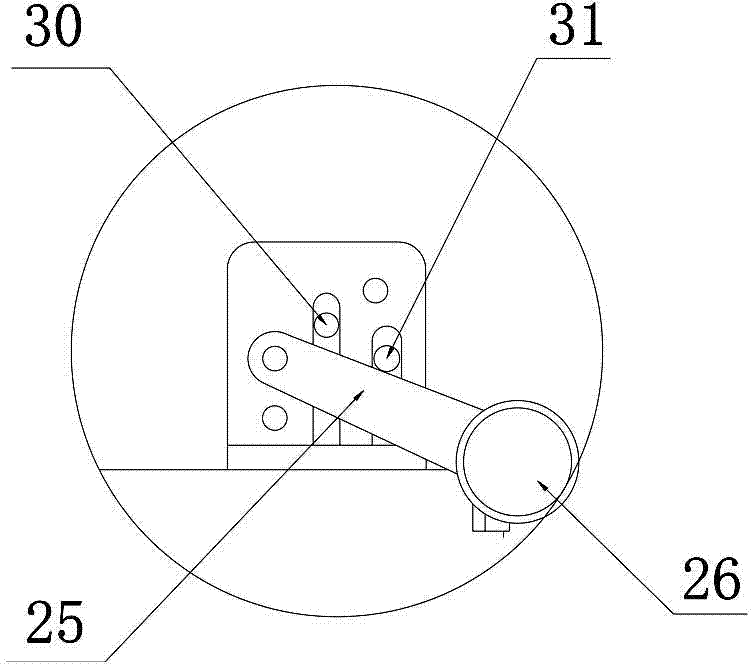

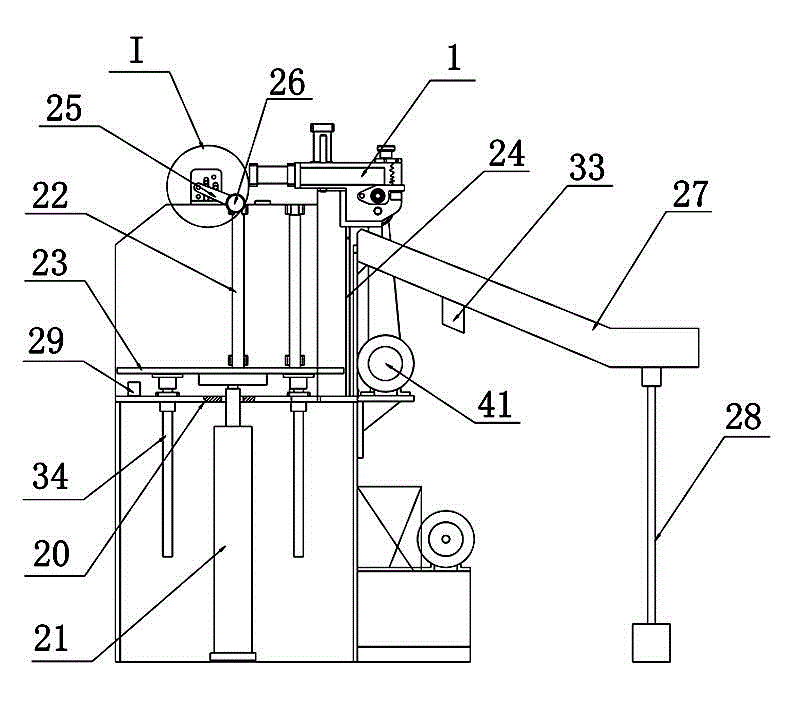

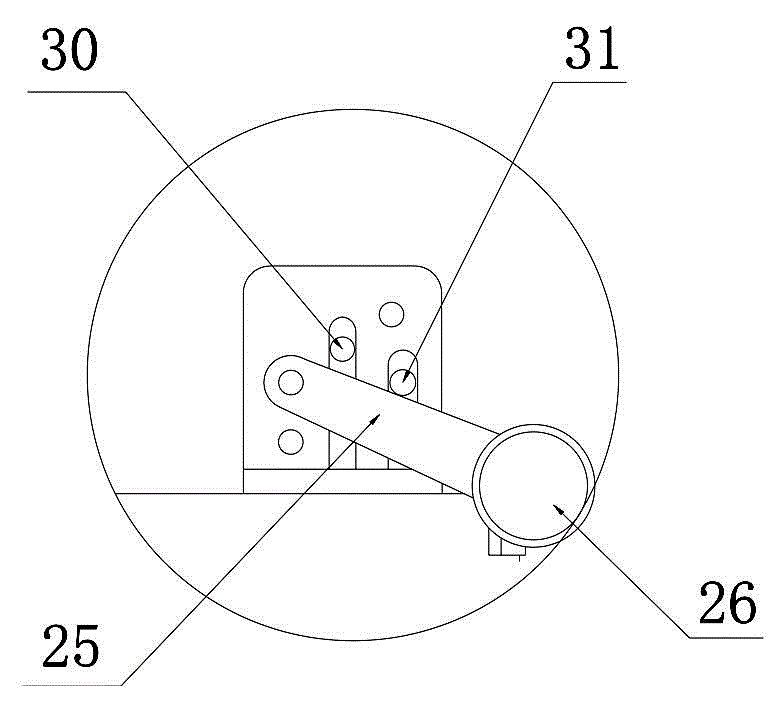

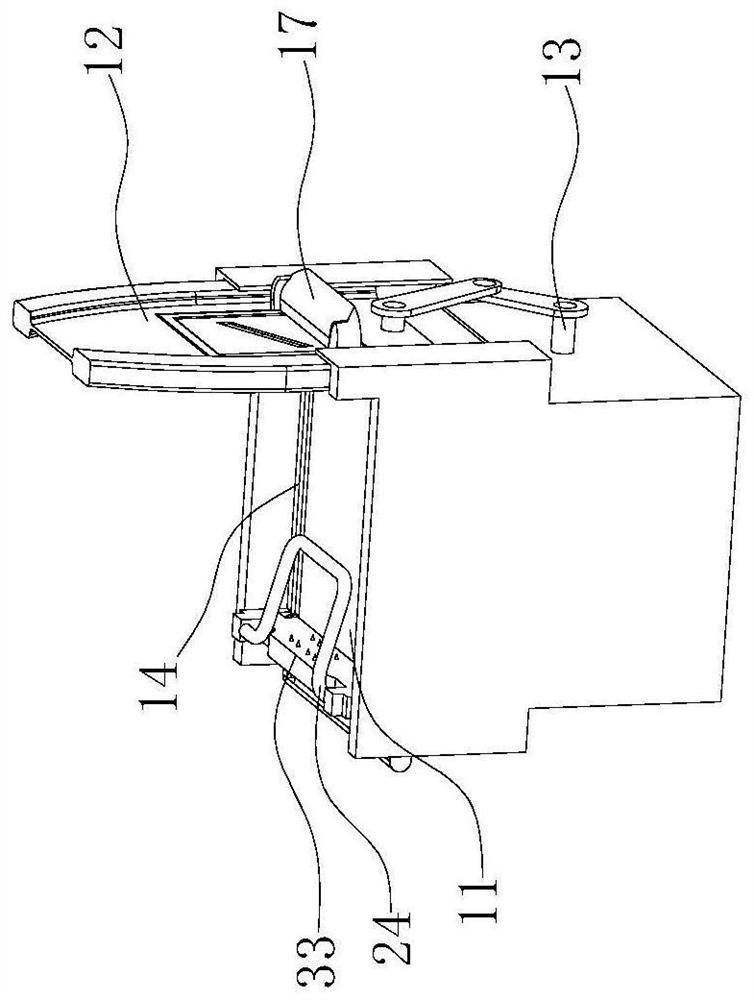

Five-axis full-automatic rounding machine

ActiveCN103495625BEasy to replaceMeet productionMetal-working feeding devicesPositioning devicesDrive wheelRounding

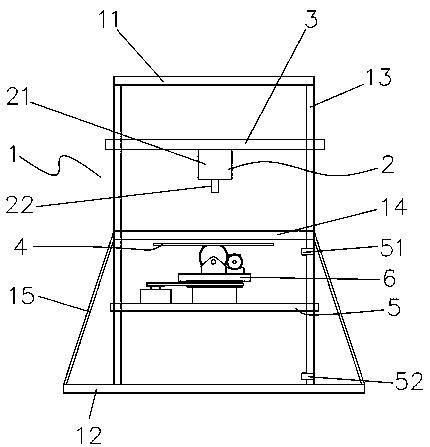

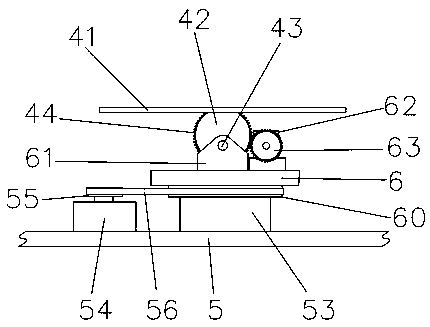

The invention discloses a five-axis full-automatic rounding machine which comprises a machine body, a handpiece, a power driving system and a control system, wherein a charging mechanism and a discharging mechanism are arranged on positions, at a charging port and a discharging port of the handpiece, of the machine body, and the handpiece comprises a feeding mechanism and a rounding mechanism which are arranged on the machine frame. A front roller pair and a back roller pair are arranged between the feeding mechanism and the rounding mechanism, the front roller pair is formed by a front upper roller and a front back roller, the back roller pair is formed by a back upper roller and a back lower roller, the front roller pair and the back roller pair are connected through a synchronous belt, a guide plate is arranged on the joint between the front roller pair and the back roller pair, the front lower roller is connected with a driving wheel, and the back upper roller is matched with the rounding mechanism in use. The five-axis full-automatic rounding machine has the advantages that the structure is simple, components are fast and convenient to replace, maintenance is facilitated, full-automatic mechanical rounding is achieved, production efficiency is greatly improved, production cost is reduced, the application range is wide, and manufacturing of workpieces of different diameters can be achieved.

Owner:河南金泰容器科技有限公司

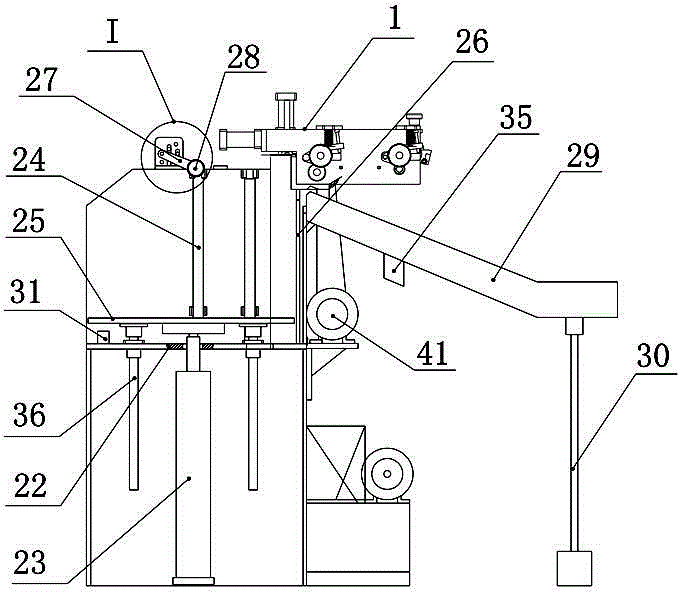

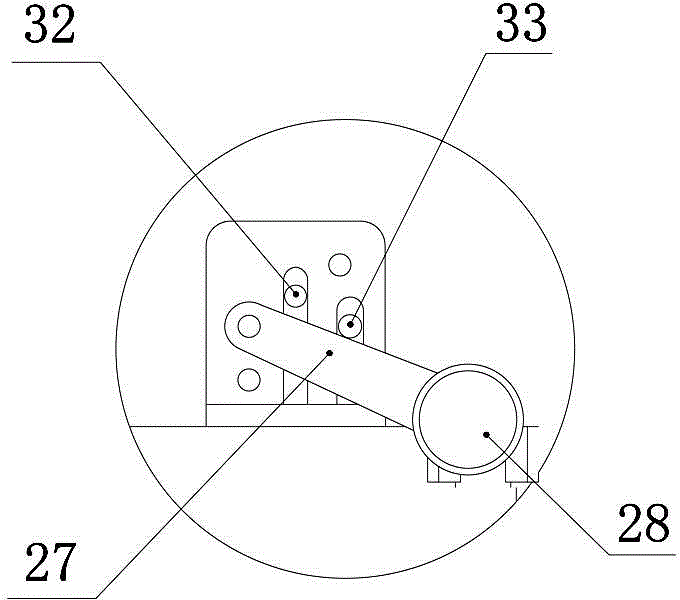

Three-shaft full-automatic edge rolling machine

ActiveCN103495628AEasy to replaceMeet productionMetal-working feeding devicesPositioning devicesControl systemMechanical engineering

The invention discloses a three-shaft full-automatic edge rolling machine which comprises a machine body, a machine head, a power driving system and a control system. An emptying mechanism and a discharging mechanism are arranged at the positions, located at the positions of a feeding opening and a discharging opening of the machine head, on the machine body respectively, the machine head comprises a feeding mechanism and a edge rolling molding mechanism, the feeding mechanism and the edge rolling molding mechanism are arranged on a machine frame, a guiding plate is arranged at the joining position of the feeding mechanism and the edge rolling molding mechanism, the feeding mechanism comprises a sucking device which is driven by a sucking air cylinder to move up and down, the sucking air cylinder is perpendicularly arranged on the machine frame, and a pushing air cylinder for driving the sucking device to horizontally move is arranged on the front portion of the sucking device. The three-shaft full-automatic edge rolling machine has the advantages that the structure is simple, parts are conveniently and rapidly replaced, maintenance is conveniently achieved, full-full-automatic mechanical edge rolling is achieved, the production efficiency is greatly improved, the production cost is reduced, the use range is wide, and the manufacturing requirements of workpieces with different diameters can be met.

Owner:河南金泰容器科技有限公司

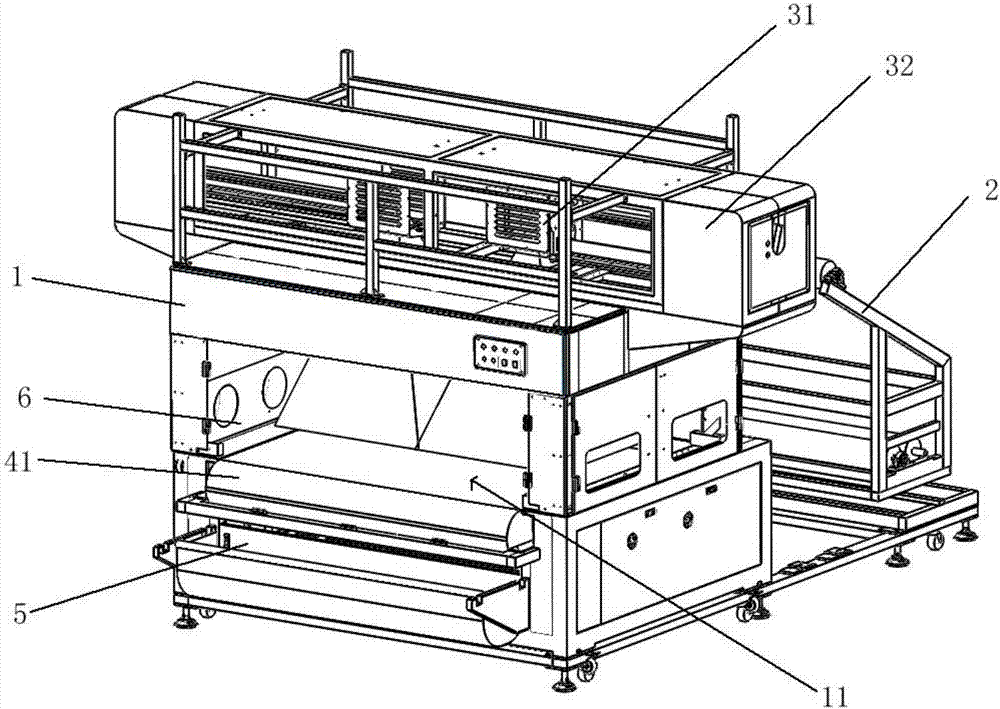

Laser equipment for automatically processing shoe and boot components

InactiveCN107030380AMeet productionAvoid wrinklesLaser beam welding apparatusLaser scanningEngineering

The invention discloses laser equipment for automatically processing shoe and boot components. The laser equipment comprises an equipment body, a conveying device, an adsorption device and a laser operation device, wherein the laser operation device comprises two laser scanning mechanisms forming corresponding first scanning area and second scanning area with a working area; the laser scanning mechanisms control two different directions separately; and the working path of laser is controlled during a process of processing shoe and boot fabrics in the first scanning area and the second scanning area, of the laser scanning mechanisms. The laser equipment disclosed by the invention is capable of meeting the production needs of various technique styles of shoes and boots, and greatly increasing the production efficiency; the whole processing and production process has no need of the co-operation of workers, and is high in automation degree, time-saving and labour-saving, and capable of lowering the labour cost and the production cost; and the technical treatment is high in the control degree and accuracy, and capable of avoiding errors, lowering the rejection rate and improving the quality requirements of the products.

Owner:巨一集团有限公司 +1

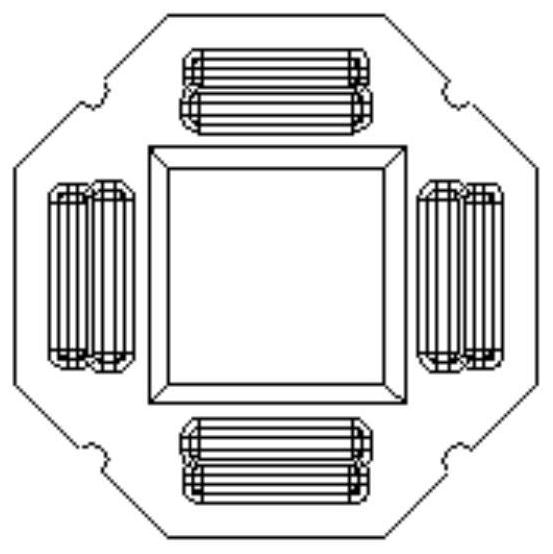

Sound-insulation heat-insulation hollow brick forming grinding tool

ActiveCN110712272AMeet productionEasy to shapeAuxillary shaping apparatusShaping press ramBrickMechanical engineering

The invention provides a sound-insulation heat-insulation hollow brick forming grinding tool which comprises a support device, a first adjusting device, forming rods and a positioning device. The first adjusting device is arranged on the bottom part of the inner side of the support device; the forming rods are arranged on the top part of the first adjusting device; and the positioning device is arranged on the inner side of the support device and located above the first adjusting device. According to the sound-insulation heat-insulation hollow brick forming grinding tool provided by the invention, the forming rods can move to be above a tray through first communicating holes in a fixed plate and second communicating holes in the tray; hollow brick forming die holes are formed between the forming rods and forming holes in a forming frame; and after materials fall into the inner parts of the hollow brick forming die holes, forming and pressing dies can press and form the materials in theforming die holes, so that the convenience in forming is realized, the convenience in discharging is realized, the requirement on manufacturing porous hollow bricks can be met, multiple groups of hollow bricks can be prepared at the same time, and the production efficiency is improved.

Owner:ANHUI KUNMENG NEW TYPE BUILDING MATERIAL CO LTD

High dimensional model 3D printer and 3D printing method

InactiveCN108724716AMeet productionCompact structureManufacturing platforms/substratesManufacturing driving meansLower limitEngineering

The invention discloses a high dimensional model 3D printer comprising a frame, a printing head, a moving bracket component and a loading tray. The moving bracket component is installed at the upper part of the frame, and can be used for driving the printing head to move up and down or right and left; a horizontal stiffening connecting rod is connected between the middle parts of upright columns of the frame, and the part, located below the stiffening connecting rod, of the frame is provided with a liftable bracket which is provided with a rotary table through a bearing pedestal; the rotary table is driven to rotate by a stepping motor installed on the liftable bracket, and the upright columns are provided with an upper limit switch and a lower limit switch for limiting the movement of theliftable bracket; and the loading tray is hinged to the rotary table, and can be driven by a servo motor to swing. The high dimensional model 3D printer is compact in structure, and the printing of ahigh dimensional product model can be finished. Specifically, through design of the stable frame, the printing head and the loading tray can be separately moved upwards and downwards, and the longitudinal printing space can be maximized; and the manufacturing requirement of a large-size product model is met.

Owner:茂名森源电子科技有限公司

Microwave dielectric ceramic material with near-zero temperature coefficient at high temperature and preparation method thereof

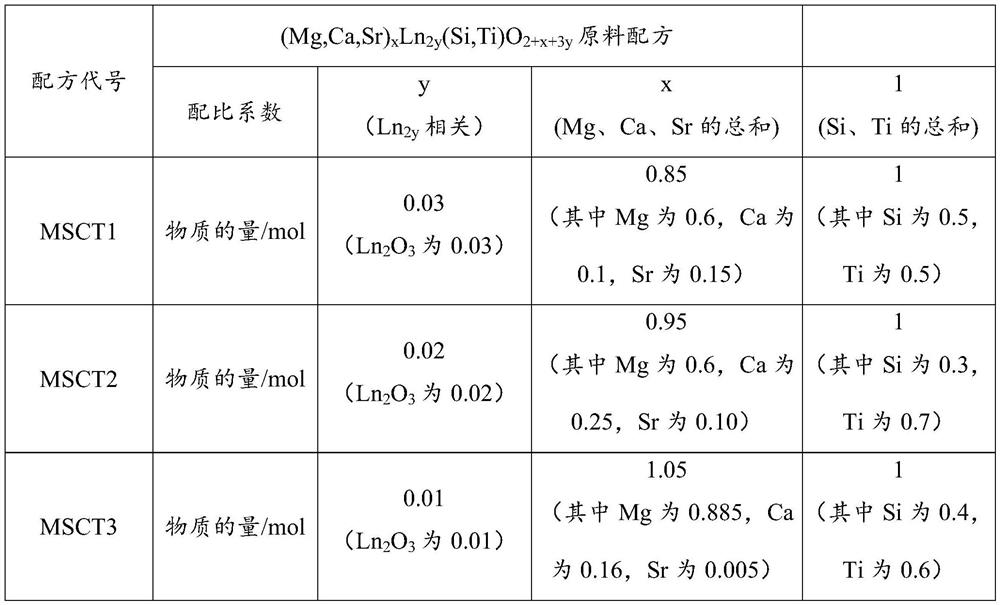

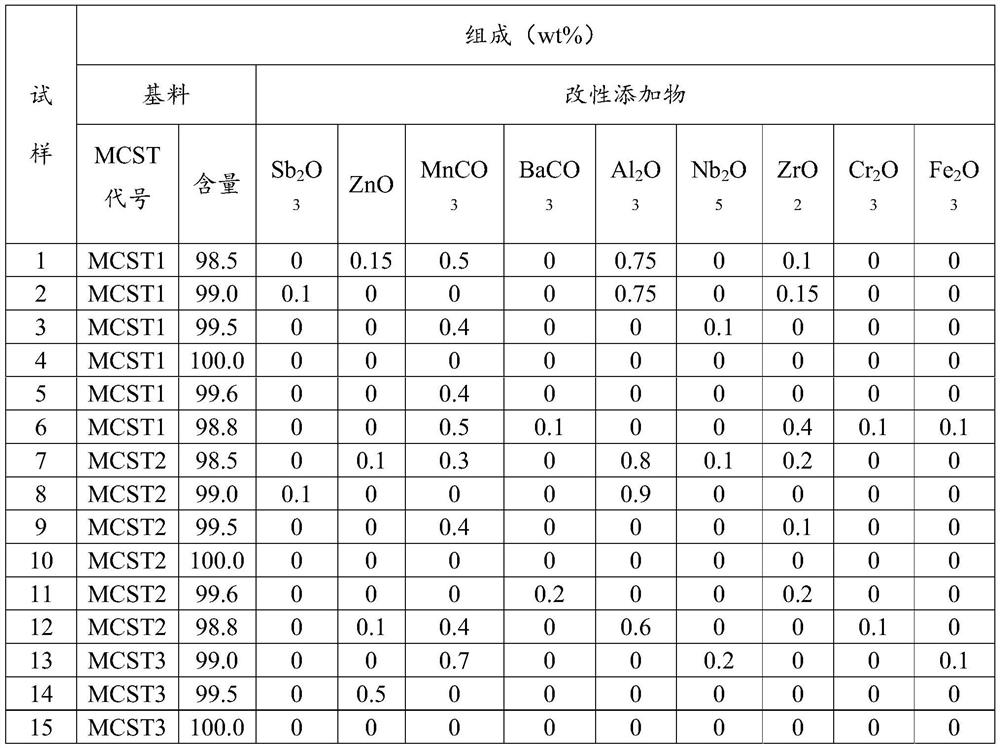

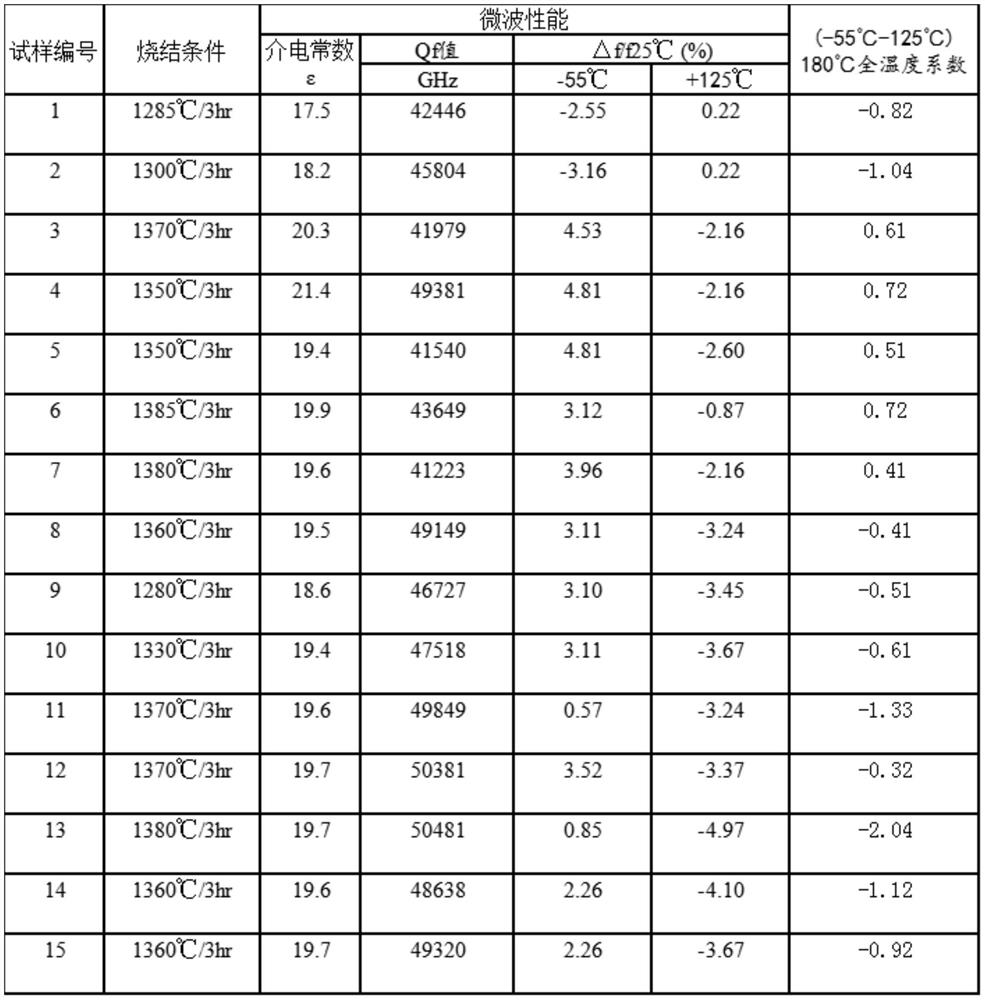

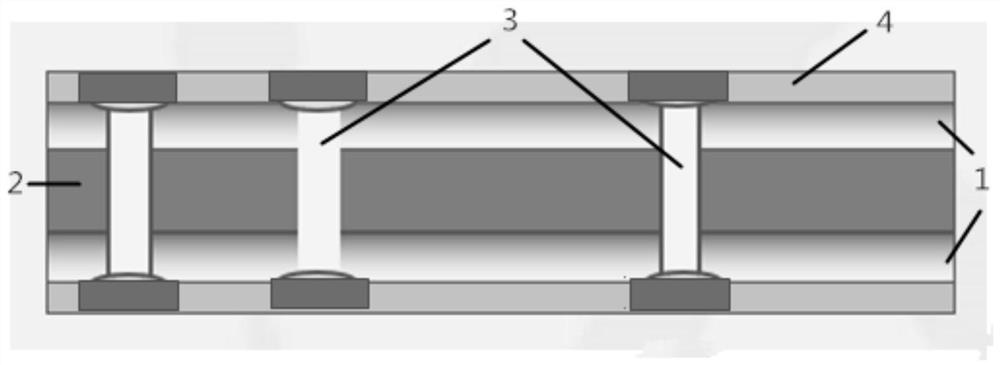

The invention provides a microwave dielectric ceramic material with a near-zero temperature coefficient at a high temperature and a preparation method thereof, and relates to the field of information function materials. The ceramic material comprises a base material and a modified additive. The chemical expression of the base material is (Mg,Ca,Sr)xLn2y(Si,Ti)O2+x+3y, the x is more than or equal to 0.80 and less than or equal to 1.20, the y is more than 0.00 and less than or equal to 0.03, and the Ln is selected from one or more of La, Y, Ce, Sm, Dy, Ho, Er and Nd; the base material is 98.5-100 wt% of the microwave dielectric ceramic material by mass fraction; and the modified additive is 0-1.5 wt% of the microwave dielectric ceramic material by mass fraction. The ceramic material is a lead-free environment-friendly material, the ceramic base material is synthesized through solid-phase synthesis by one time, and is supplemented by the certain doping modification additive, the dielectric constant of a prepared electronic ceramic device is 17-25, the quality factor is larger than or equal to 40000 GHz, the temperature coefficient tauf (-55 to 125 DEG C) is smaller than + / -5 ppm / DEG C, and the temperature coefficient tauf is smaller than + / -5 ppm / DEG C within the full temperature range of 180 DEG C. The ceramic material has good uniformity, is suitable for manufacturing microwave devices, and is particularly suitable for being used in an environment with large temperature difference.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

Micro-etching processing technology for resin plug hole of dry film cover

ActiveCN113709981AAvoid etchingMeet productionConductive material chemical/electrolytical removalEngineeringMechanical engineering

The invention relates to the technical field of circuit board processing, in particular to a dry film cover resin plug hole micro-etching processing technology. The technology comprises the following steps: directly windowing on a graphic resin plug hole, pasting films on two sides of a board surface, exposing the two sides of the board surface, performing copper reduction on a board at a micro-etching line after determining that a dry film completely covers the position of the resin plug hole, determining that the resin hole plugging position is not corroded, after the plate surface is ground to be flat, developing an outer layer by adopting data of small-size line width / line spacing, a positive film and double-sided exposure data, and after determining that the line width, the line spacing, the BGA, the IC and the MI are consistent, turning to the next process for production. According to the method, hole copper of the resin plug hole can be effectively prevented from being etched in the micro-etching copper reduction process by covering the hole covering dry film on the resin plug hole, the hole opening quality is good, the requirement for manufacturing a circuit board with small line width / line distance can be met, and the effect is good.

Owner:江西志浩电子科技有限公司

Art ceramic with machine-made Ding kiln engraved effect and preparation technology of art ceramic

InactiveCN109927158ATightly boundMeet productionSpecial ornamental structuresCeramic shaping apparatusManufacturing technologyEconomic benefits

The invention relates to the technical field of ceramic manufacturing, in particular to art ceramic with a machine-made Ding kiln engraved effect and a preparation technology of the art ceramic. The art ceramic with the machine-made Ding kiln engraved effect comprises a ceramic body, a ground coat layer, an engraved layer and a cover glaze layer, wherein the engraved layer and the ground coat layer are arranged on the same plane outside the ceramic body, the engraved layer is formed by a glaze missing part on the ground coat layer, and the ground coat layer and the engraved layer are covered with the cover glaze layer. The art ceramic with the machine-made Ding kiln engraved effect adopts a three-layer structure comprising the ground coat layer, the engraved layer and the cover glaze layer, and is formed by two times of glazing and one time of firing. A brand-new preparation method of the art ceramic with the Ding kiln engraved effect is provided, improves production efficiency substantially, can meet the manufacturing requirement of different types of ceramics, has positive significance of promoting development of Ding kiln ceramic products and has positive economic benefit.

Owner:福建省德化县全丰陶瓷有限公司

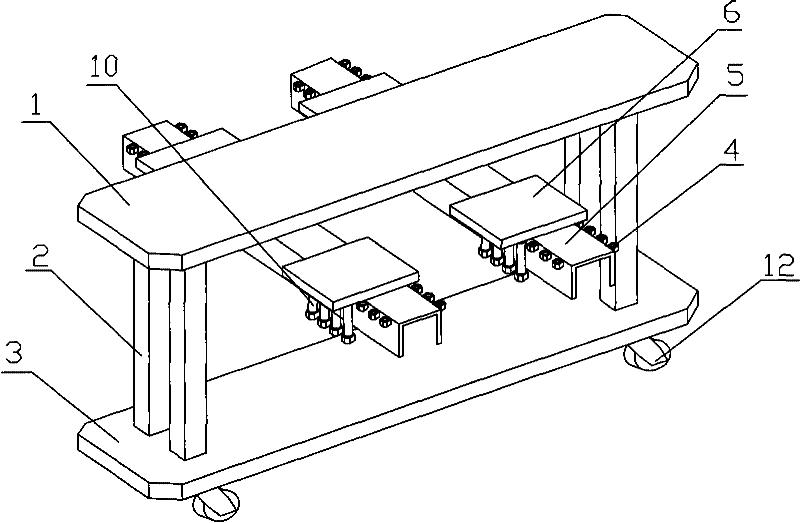

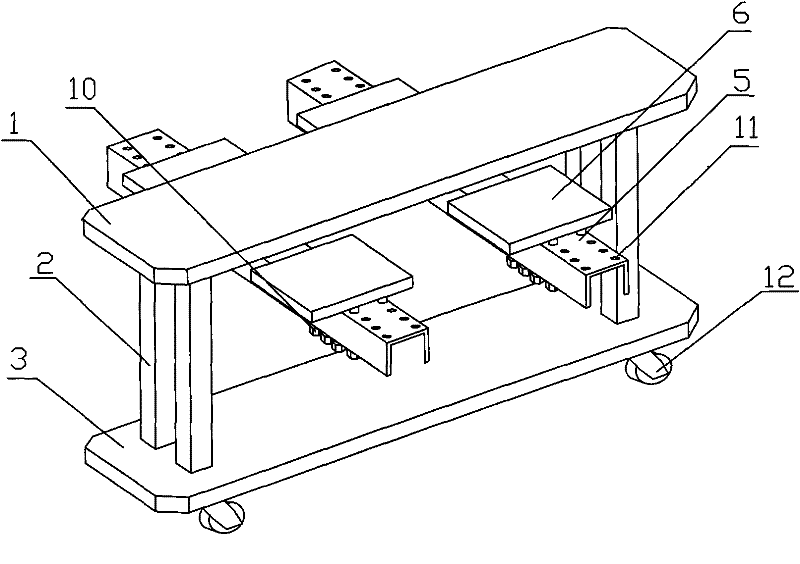

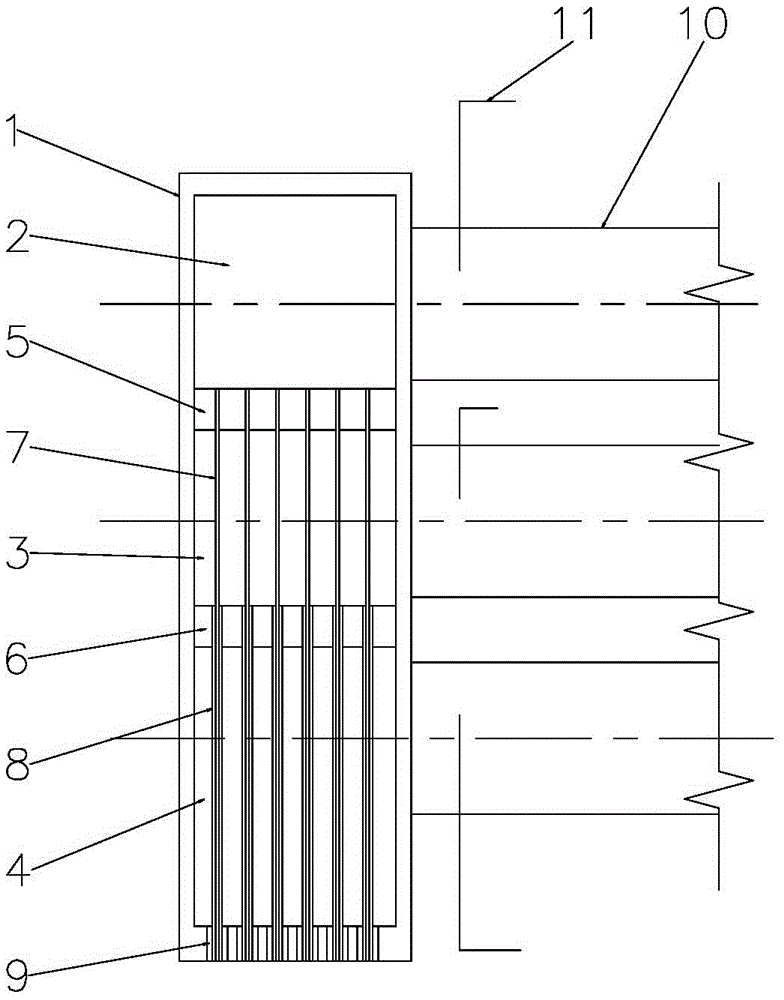

Adjustable transformer core assembly table

InactiveCN101996764BAdjustable lengthAdjustable widthInductances/transformers/magnets manufactureSurface mountingTransformer

The invention relates to an adjustable transformer core assembly table special for manufacturing a power transformer core. The conventional transformer core has nonadjustable length and width and low universality, when silicon sheets are overlapped on the assembly table, a raised supporting surface is needed so as to increase the operating difficulty and intensity, and the overlapping speed and even the quality stability and consistency of the core are influenced. The adjustable transformer core assembly table comprises a table plate and a bottom plate which is parallel to the table plate, wherein the two plates are connected through a group of supporting pins; a roller is arranged on the lower surface of the bottom plate; at least two transverse beams at intervals are arranged on the lower surface of the table plate; the transverse beams pass through the lower surface of the table plate and are parallel and vertical to the table plate and the supporting pins; and a supporting flat plate capable of lifting and translating is arranged at outer ends of the transverse beams extending out of two sides of the table plate. The invention provides an adjustable transformer core assembly table, which is adjustable in length and width, high in universality and easy and convenient to operate, and can effectively improve the working efficiency and improve the quality stability and consistency of the core.

Owner:浙江连成环保科技有限公司

A kind of peek denture tooth composite material and preparation method thereof

The invention discloses a PEEK false tooth composite. The PEEK false tooth composite is prepared from, by weight, 110-150 parts of polyether-ether-ketone, 10-20 parts of nano calcium silicate, 8-12 parts of hydroxyl hydroxyapatites, 4-8 parts of barium glass short fibers, 15-22 parts of organic solvent, 8-18 parts of refined paraffin, 1-4 parts of co-binding agent, 8-12 parts of binder, 2-6 parts of antibacterial agent, 6-10 parts of carbide and / or 8-15 parts of oxide. The invention further discloses a preparation method of the PEEK false tooth composite. The preparation method includes the steps that firstly, the raw materials of nano calcium silicate, hydroxyl hydroxyapatites, carbide and / or oxide are mixed, the mixture is heated to 150-220 DEG C, the situation is kept for 10-30 min, cooling is carried out, the refined paraffin is added, mixing and stirring are carried out, and after the mixture is crushed ultrasonically, the organic solvent, polyether-ether-ketone, the co-binding agent, the binder and the antibacterial agent are added to be stirred till uniform paste is obtained; finally the barium glass short fibers are added, ball-milling and drying are carried out, and the finished composite powder is obtained.

Owner:广西深雅医疗科技股份有限公司

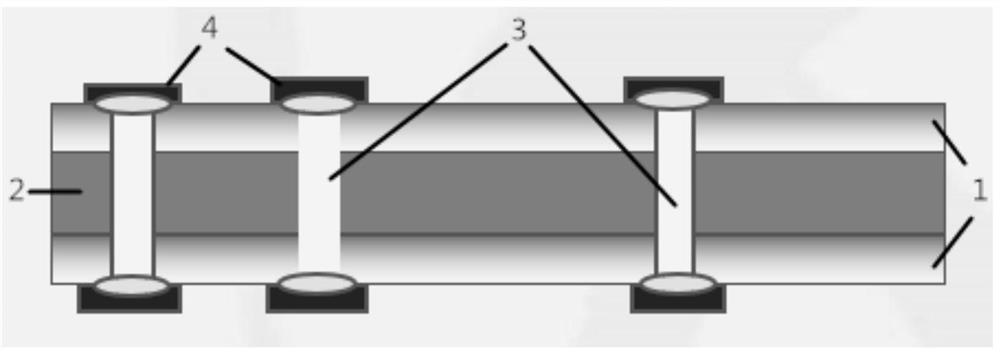

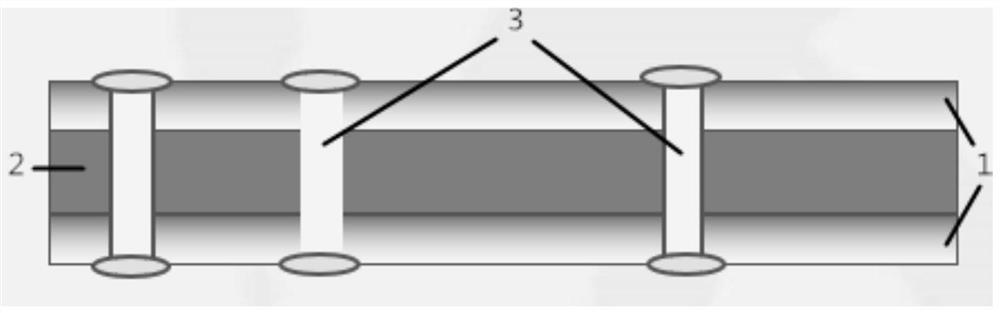

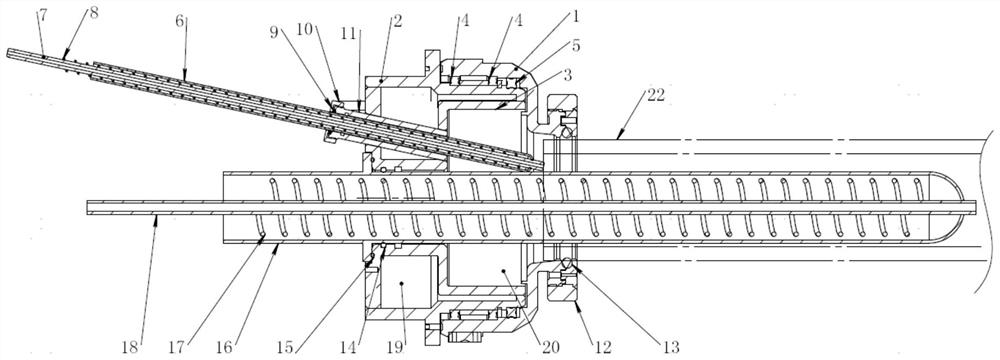

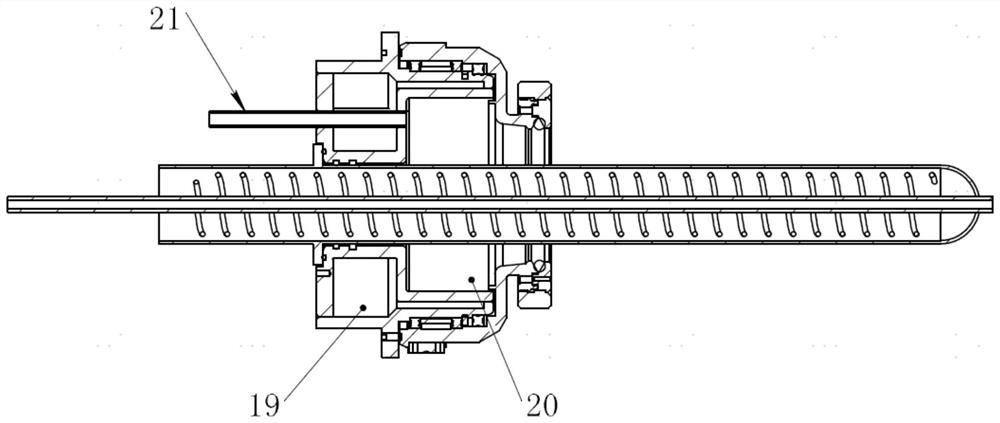

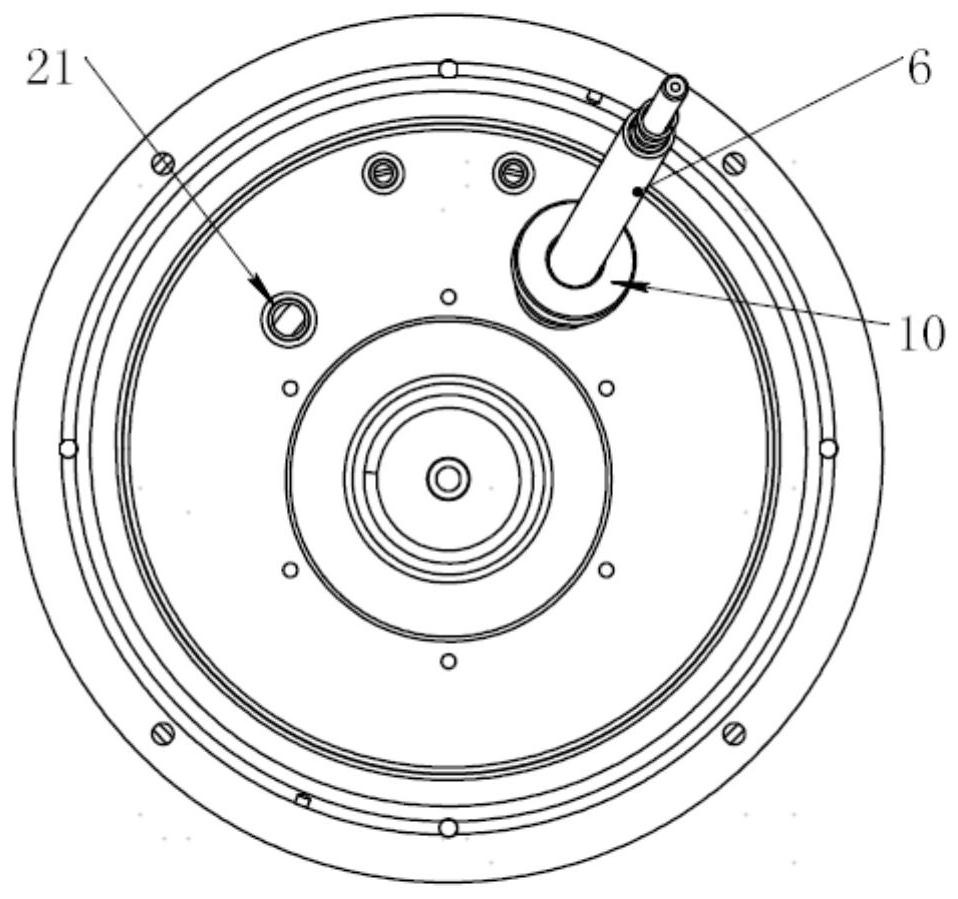

A kind of pcvd lathe multi-channel rotary chuck

ActiveCN112499957BImprove profile accuracyGuaranteed transmission performance requirementsGlass making apparatusEngineeringGas heating

The invention relates to a multi-channel rotary chuck of a PCVD lathe, comprising a fixed seat and a rotary jacket, the front end of the fixed seat is connected with the rotary jacket through a bearing, and a sealing device is arranged between the fixed seat and the rotary jacket, so that the The fixed seat is provided with a raw material gas mixing chamber and is connected to a basic mixed raw material gas pipeline, characterized in that the fixed seat is connected with a rare earth raw material heating gas pipeline and an auxiliary raw material gas heating pipeline, and the rare earth raw material heating gas pipeline and The auxiliary raw gas heating pipeline passes through the fixed seat and enters the inner cavity of the rotating chuck. The invention can provide the required rare earth doped raw materials for the PCVD deposition system, so that different raw materials can smoothly reach the reaction deposition area, so as to complete the PCVD deposition of the rare earth doped optical fiber preform, not only the doping uniformity is good, but also the optical fiber section precision is high , which can meet the production of various complex optical fiber profiles and ensure the transmission performance requirements of the optical fiber.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

A forming abrasive tool for sound-insulating and heat-insulating hollow bricks

ActiveCN110712272BMeet productionEasy to shapeAuxillary shaping apparatusShaping press ramBrickHeat conservation

The invention provides a forming abrasive tool for a sound-insulating and heat-resisting hollow brick, comprising: a supporting device; a first adjusting device, the first adjusting device is arranged at the bottom inside the supporting device; a forming rod, and the forming rod is arranged at the top of the first adjusting device; a positioning device , the positioning device is disposed on the inner side of the supporting device and above the first adjusting device. The forming abrasive tool of the sound-insulating and heat-insulating hollow brick. The forming abrasive tool of the sound-insulating and heat-resisting hollow brick provided by the present invention can be moved to the top of the tray through the first communication hole on the fixed plate and the second communication hole on the tray, and the hollow brick is formed between the forming rod and the forming hole inside the forming frame. Die hole, when the material falls into the hollow brick forming die hole, the forming pressure mold can press and shape the material inside the forming die hole, which is convenient for forming and discharging, and can meet the production of porous hollow hollow bricks, and at the same time Prepare multiple groups of hollow bricks to improve production efficiency.

Owner:ANHUI KUNMENG NEW TYPE BUILDING MATERIAL CO LTD

Three-shaft full-automatic edge rolling machine

ActiveCN103495628BEasy to replaceMeet productionMetal-working feeding devicesPositioning devicesControl systemEngineering

Owner:河南金泰容器科技有限公司

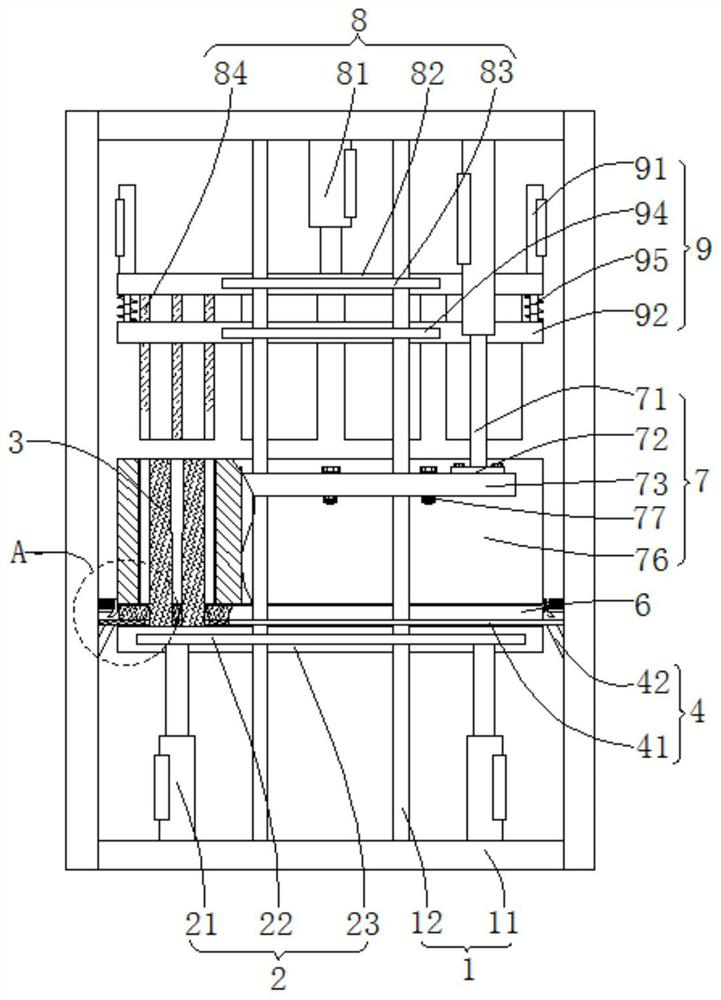

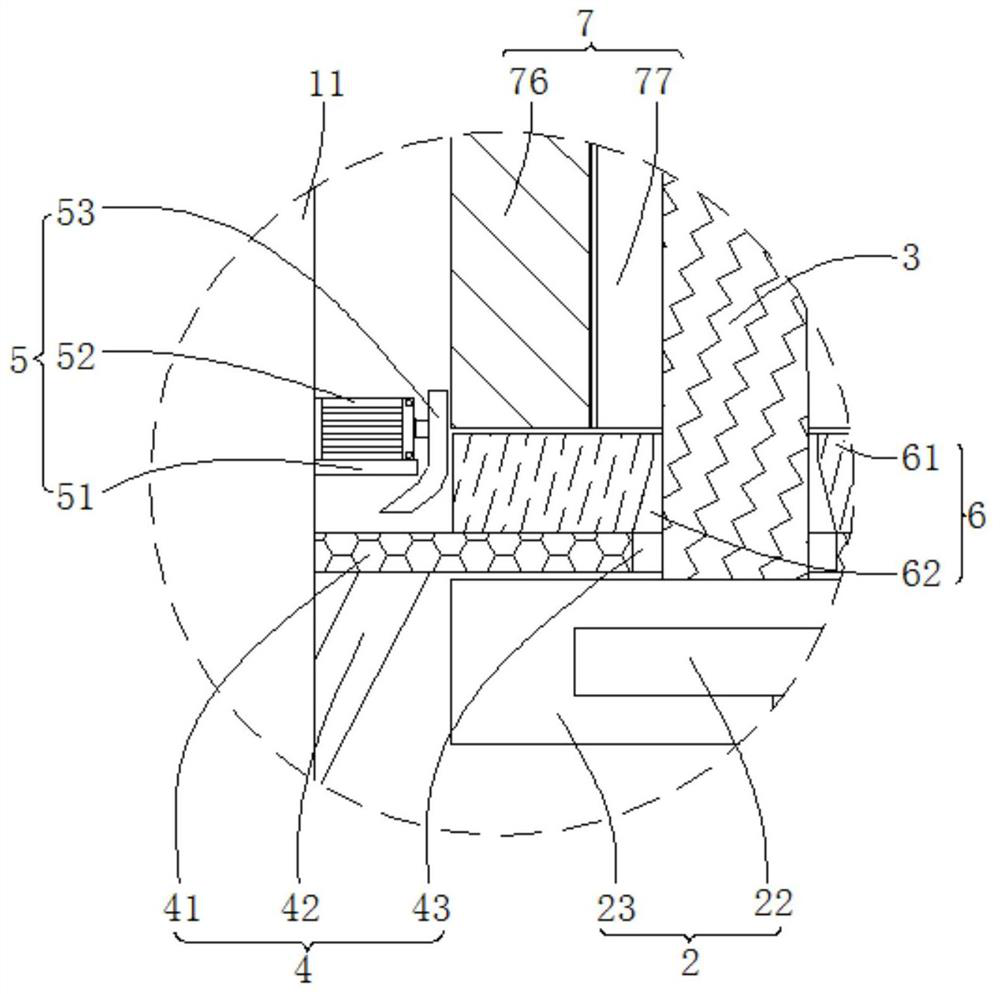

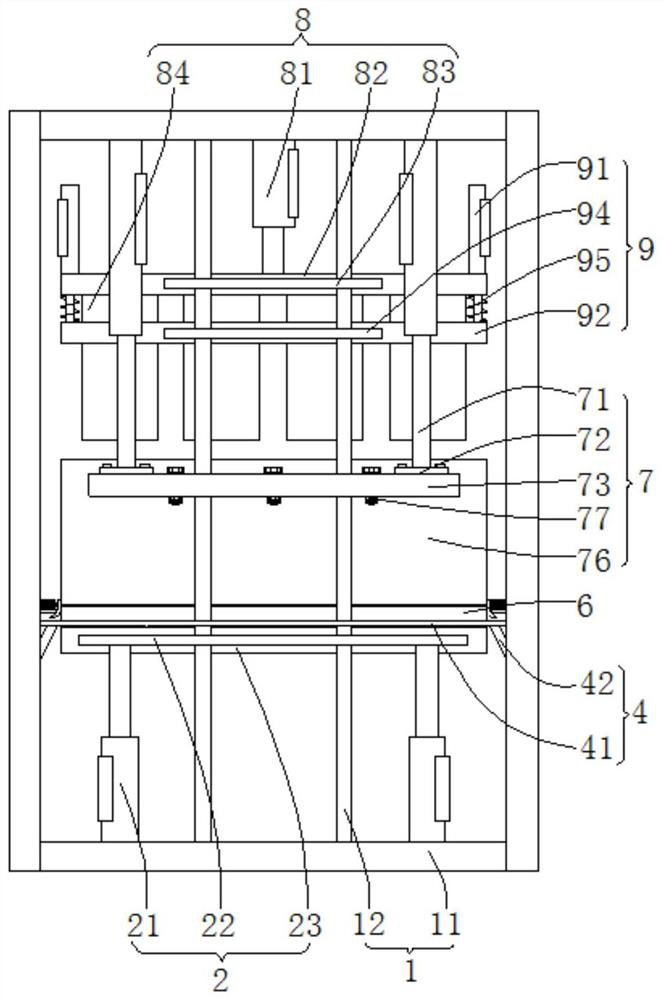

Hydraulic brick making machine and brick making method

ActiveCN110434983BMeet productionExtended service lifeDischarging arrangementFeeding arrangmentsBrickEngineering

A hydraulic brick making machine and a brick making method. The upper fixed beam of the brick making machine is fixedly installed on the guide column, the connecting device is located between the upper fixed beam and the base, the material distributing mechanism is installed on the connecting device, and the connecting device is detachably A mold frame fixture for fixing the mold frame is provided; the upper mold assembly is installed on the upper fixing beam; the lower mold assembly is installed on the base; the mold frame assembly is detachably installed on the lower mold assembly. When in use, the lower mold and the mold frame are moved up to the first position synchronously, and the mold frame continues to be moved up to form the first filling cavity; for the first time of material distribution, the lower mold is moved down for the second time of material distribution. The invention can realize secondary material distribution to meet the production of bricks with different structures; it can be adjusted according to the requirements of different types of bricks, and different configurations cannot be selected according to the required functions, so as to meet the needs of different brick types, reduce the cost of bricks, and effectively improve the production efficiency. The service life of the brick machine.

Owner:CRRC DALIAN CO LTD

Compound photon sieve for large-caliber imaging and manufacturing method thereof

ActiveCN102043178BHigh-resolutionSharp focal spotPhotomechanical apparatusDiffraction gratingsOrganic glassBlocking layer

The invention discloses a compound photon sieve for large-caliber imaging and a manufacturing method thereof and belongs to the technical field of diffractive optical elements. The compound photon sieve comprises a transparent substrate and a lightproof metal film plated on the pervious substrate; a series of transparent girdles and pervious apertures which are randomly distributed are designed on the lightproof film; a pervious plane can be made of transparent materials such as fused quartz, common glass, organic glass and the like; the lightproof film is a metal light-blocking layer of chromium, gold, aluminum, copper and the like prepared on the transparent substrate; and the transparent girdles and the transparent apertures are not provided with the metal light-blocking layer. Compared with Fresnel wave zone plates, the compound photon sieve provided by the invention can improve numerical aperture and imaging resolution and can effectively restrain side-lobe effect and high-order diffraction in the direction of an optical axis; and compared with a common photon sieve, the compound photon sieve can improve imaging contrast, effectively reduces data volume of geometry data standard II (GDSII) map files, and reduces the difficulty in processing large-caliber imaging photon sieves.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Nickel-based brazing material and method for preparing alloy coating by nickel-based brazing material

ActiveCN102941418BImprove corrosion resistanceImprove brazing process performanceWelding/cutting media/materialsSoldering mediaMischmetalRare earth

The invention provides a nickel-based brazing material, which comprises 15-30 wt% of Cr, 4.5-12wt% of P, 3-5wt% of Si, 2-4wt% of Mo, 2-4wt% of Cu, 0-0.5wt% of rare earth metal and the balance of Ni. The invention solves the technical problem that in the prior art, the nickel-based brazing material is single in the corrosion-resisting environment, so that a thicker and uniform coating is difficult to form on the surface of a workpiece.

Owner:湖南新光环科技发展有限公司

Aluminum material for power station air cooling system and preparation method thereof

ActiveCN110760766BAchieve final mechanical propertiesImprove cooling efficiencyPower stationMetallurgy

The invention discloses an aluminum material for a power station air-cooling system and a preparation method thereof in the technical field of aluminum material preparation, and aims to solve the problem of high production cost and insufficient production capacity in the prior art of using hot-rolled blanks to prepare aluminum materials for a power station air-cooling system technical problem. The method includes the following steps: performing step-by-step annealing treatment on the finished aluminum product prepared from the cast-rolled slab, and the step-by-step annealing treatment includes: heating up to 170-220°C at a rate of 0.8-2.0°C / min ℃, and keep it warm for 60-600 minutes; raise the temperature to 230-270 ℃ at a rate of 0.5-3.0 ℃ / min, and keep it warm for 480-1850 minutes.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Multifunctional stove

PendingCN113405122ASimple structureLow priceStoves/ranges foundationsDomestic stoves or rangesKitchen utensilsFood material

The invention belongs to the technical field of kitchen utensils, and provides a multifunctional stove. The multifunctional stove comprises a kitchen range panel, an auxiliary device, a cutting device, an electronic scale, a first article basket, a second article basket, an auxiliary chopping board, a dustproof cover and sleeve columns. The auxiliary device is formed by sequentially and adjacently arranging a projector, a dish washing tank and a storage rack, and the auxiliary device is arranged on the kitchen range panel. The cutting device is arranged on the kitchen range panel, and the cutting device is used for cutting vegetable and fruit food materials. The electronic scale is arranged on the kitchen range panel, and the electronic scale is used for weighing the weight of vegetable and fruit food materials. The first article basket is movably arranged on the kitchen range panel. The second article basket is movably arranged on the kitchen range panel, and the second article basket is adjacent to the first article basket. The auxiliary chopping board is rotationally arranged on the kitchen range panel. The dustproof cover is rotationally arranged on the kitchen range panel. The sleeve columns are arranged below the kitchen range panel. Compared with the prior art, the stove has the advantages that cooking utensils daily required are integrated by the stove, and diversified operations can be selected by users.

Owner:NINGBO POLYTECHNIC

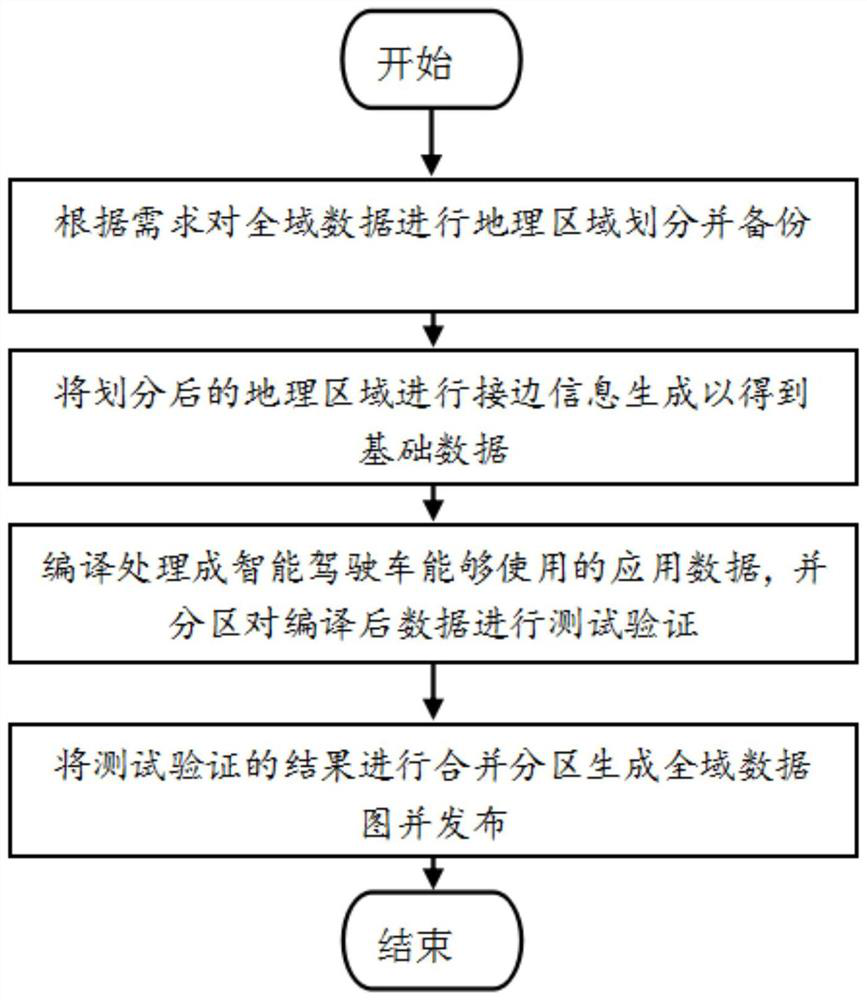

High-precision map regional compiling method and system

PendingCN114413913AImprove freshnessImplement Partition PublishingInstruments for road network navigationGeographic regionsData graph

The invention belongs to the technical field of high-precision electronic map making, and particularly provides a regional compiling method and system for a high-precision map, and the method comprises the following steps: carrying out the geographic region division of global data according to demands, and carrying out the backup; performing edge matching information generation on the divided geographic region to obtain basic data; compiling and processing the data into application data which can be used by the intelligent driving vehicle, and testing and verifying the compiled data in a partitioned manner; and merging and partitioning test verification results to generate a global data graph and publishing the global data graph. According to the scheme, global data are divided into a plurality of regions, and then basic vector data are compiled into application data which can be used by an intelligent driving vehicle in a regional manner. By means of the method, partition publishing and all-region publishing of data can be achieved at the same time, meanwhile, the all-region data publishing period is greatly shortened, and the freshness of a high-precision map in an intelligent driving automobile is improved to a certain degree. Wide application prospects are realized.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

Through-reinforced concrete laminated floor structure and its fabrication and assembly method

The invention relates to the field of assembled concrete buildings, in particular to a through bar type concrete composite floor slab structure and a manufacturing and assembling method thereof. The structure comprises prefabricated base plates, longitudinal stressed steel bars, reserved transverse stressed steel bar grooves, hogging moment steel bars, transverse stressed steel bars and the like. Due to the fact that transverse stressed steel bars of the unique prefabricated base plates are continuous, additional connecting measures and additional connecting steel bars are not needed for connection of the prefabricated base plates, construction is simplified, materials are saved, and the integrity of composite slabs is greatly strengthened. The reserved transverse stressed steel bar grooves of the through bar type concrete composite floor slabs reinforce shear resisting and tensile resisting connection of a cast-in-place concrete layer and the prefabricated base plates, and the overall performance of the composite slabs is greatly improved. The transverse stressed steel bars of the through bar type concrete composite floor slab structure are placed in the reserved transverse stressed steel bar grooves formed in the prefabricated base plates, maximum approximating to the prefabricated base plates is achieved, and the anti-bending stress performance of the prefabricated base plates can be same as the performance of cast-in-place slabs.

Owner:SHENYANG SANXIN IND

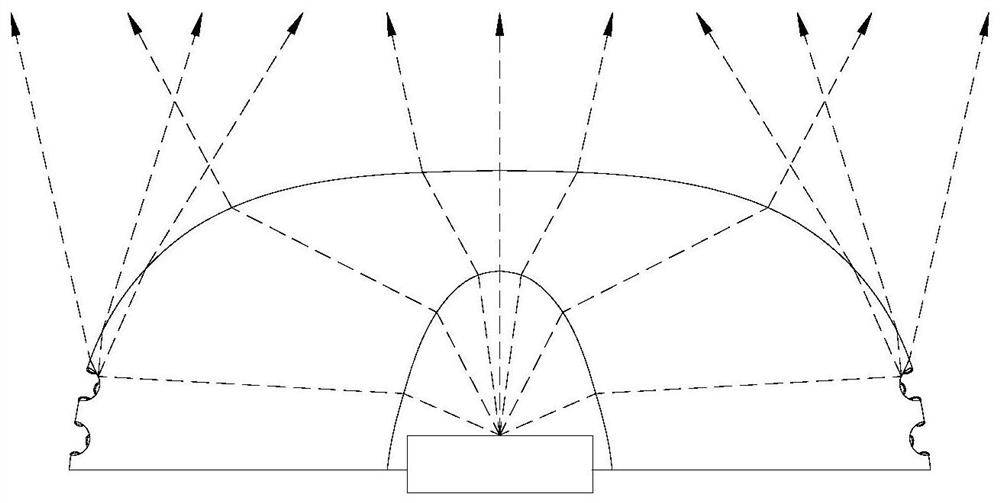

Preparation method of direct type backlight lens

ActiveCN113820764AImprove energy utilizationAchieving a cumulative effectNon-linear opticsLensSputteringLaser processing

The invention provides a preparation method of a direct type backlight lens. The preparation method comprises the following steps: injection molding: the two sides of the lens body are respectively provided with a mounting plane and a light emitting curved surface, and the center of the mounting plane is provided with a light accommodating cavity; the lens body is coated with positive photoresist to obtain a mask protection layer; dimming hole grooves are carved on the light emitting curved surface of the lens body by laser, an included angle alpha is formed between the connecting line of the dimming hole grooves and a light containing groove and the optical axis of the light containing cavity, and alpha is larger than or equal to 60 degrees and smaller than 90 degrees; metal materials are sputtered on the dimming hole grooves through magnetron sputtering, and metal matrixes are formed on the inner walls of the dimming hole grooves; the surfaces of the metal matrixes react with a reflecting salt solution to form a reflecting layer; and a mask protection layer is removed by using a UV lamp. A plurality of dimming hole grooves are formed in the edge area of the light emitting curved surface, the metal substrates and the reflecting layers are formed in the dimming hole grooves, incoming light can be reflected and refracted for multiple times, and the brightness is sufficient; the dimming hole grooves obtained through laser processing are used as basic positioning, and high-precision processing can be formed.

Owner:YEJIA OPTICAL TECH GUANGDONG CORP

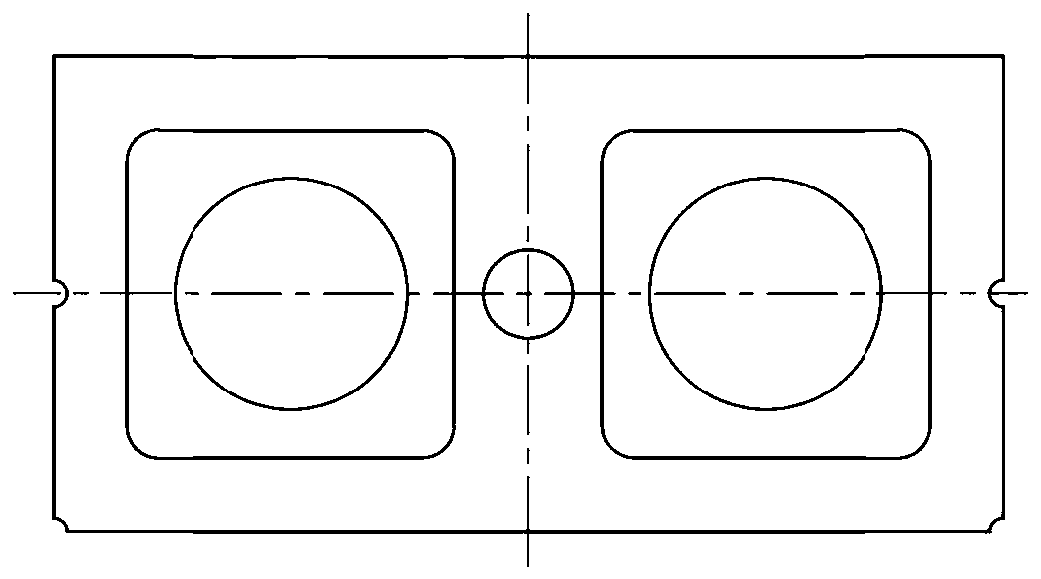

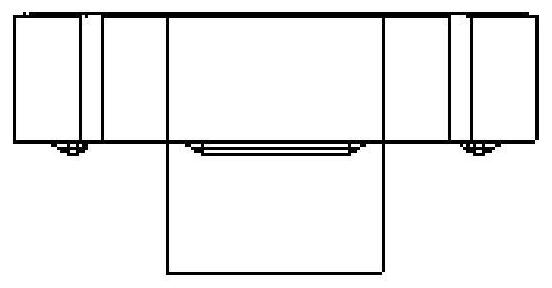

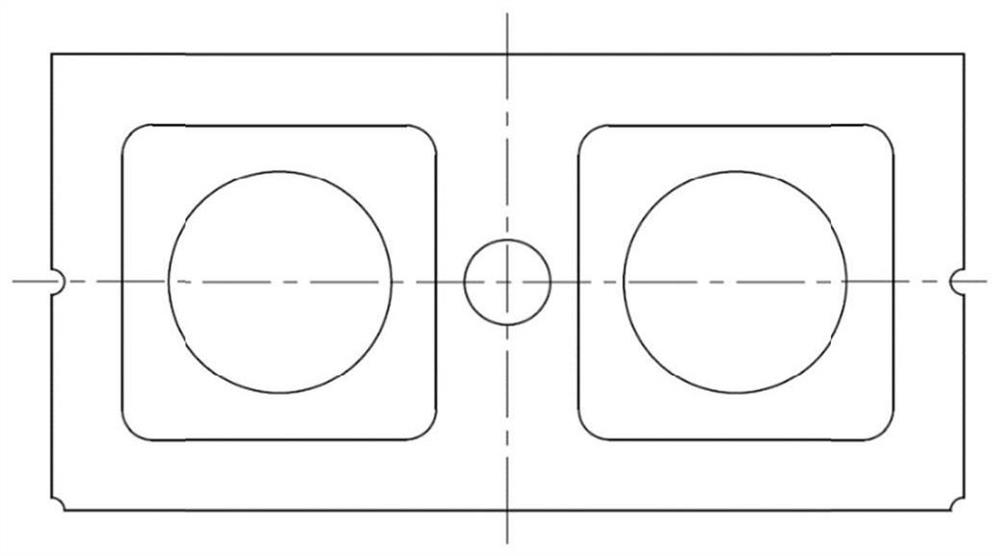

Head mold of double-layer sandwiched vermicelli maker

Owner:重庆市黄海食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com