Method for manufacturing plated-through holes in HDI plate

A technology of metallized holes and manufacturing methods, which is applied to the formation of electrical connections of printed components, etc., can solve the problems of high production cost, long production process, and low efficiency, and achieve the effects of improving quality, increasing production efficiency, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

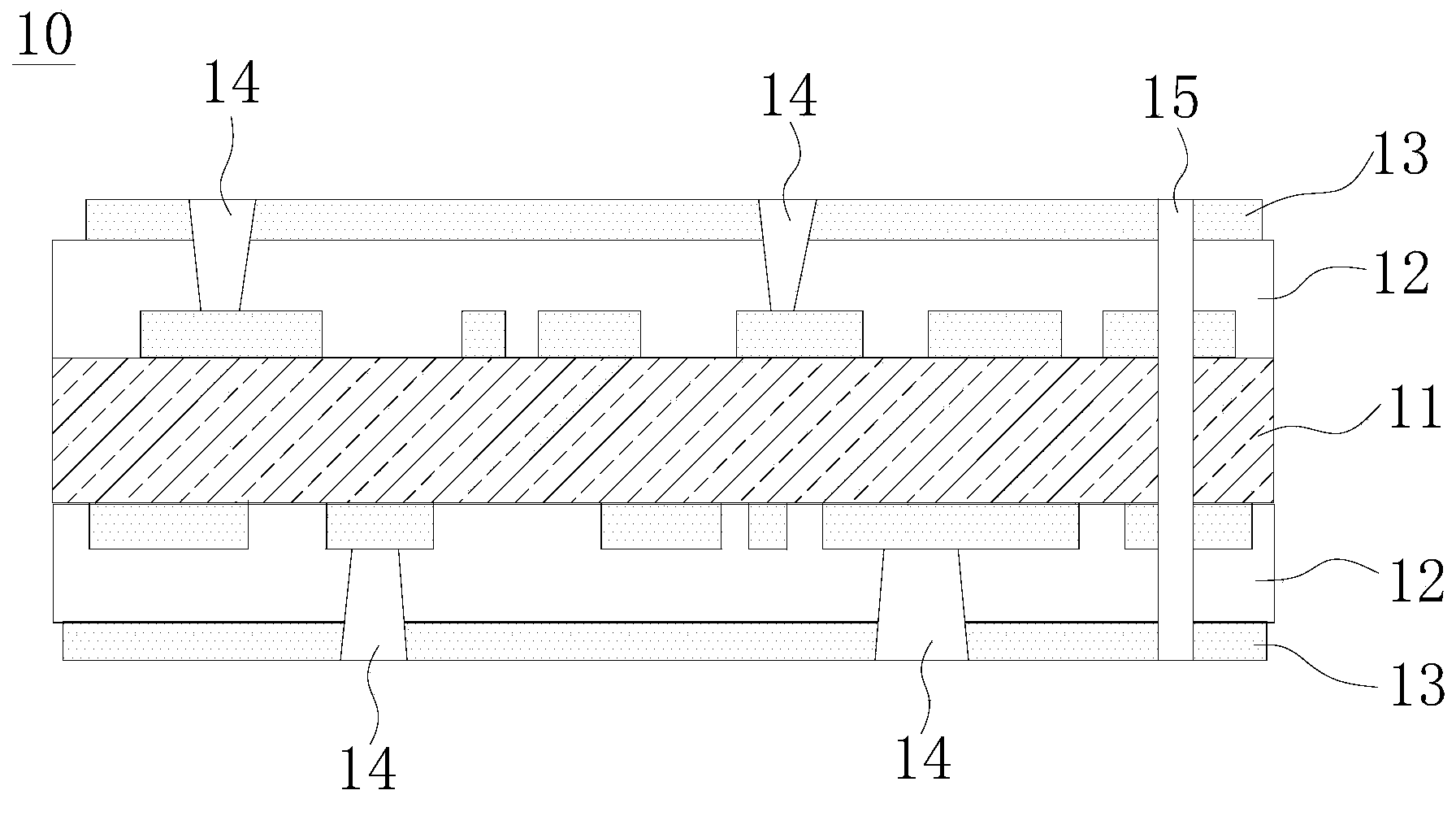

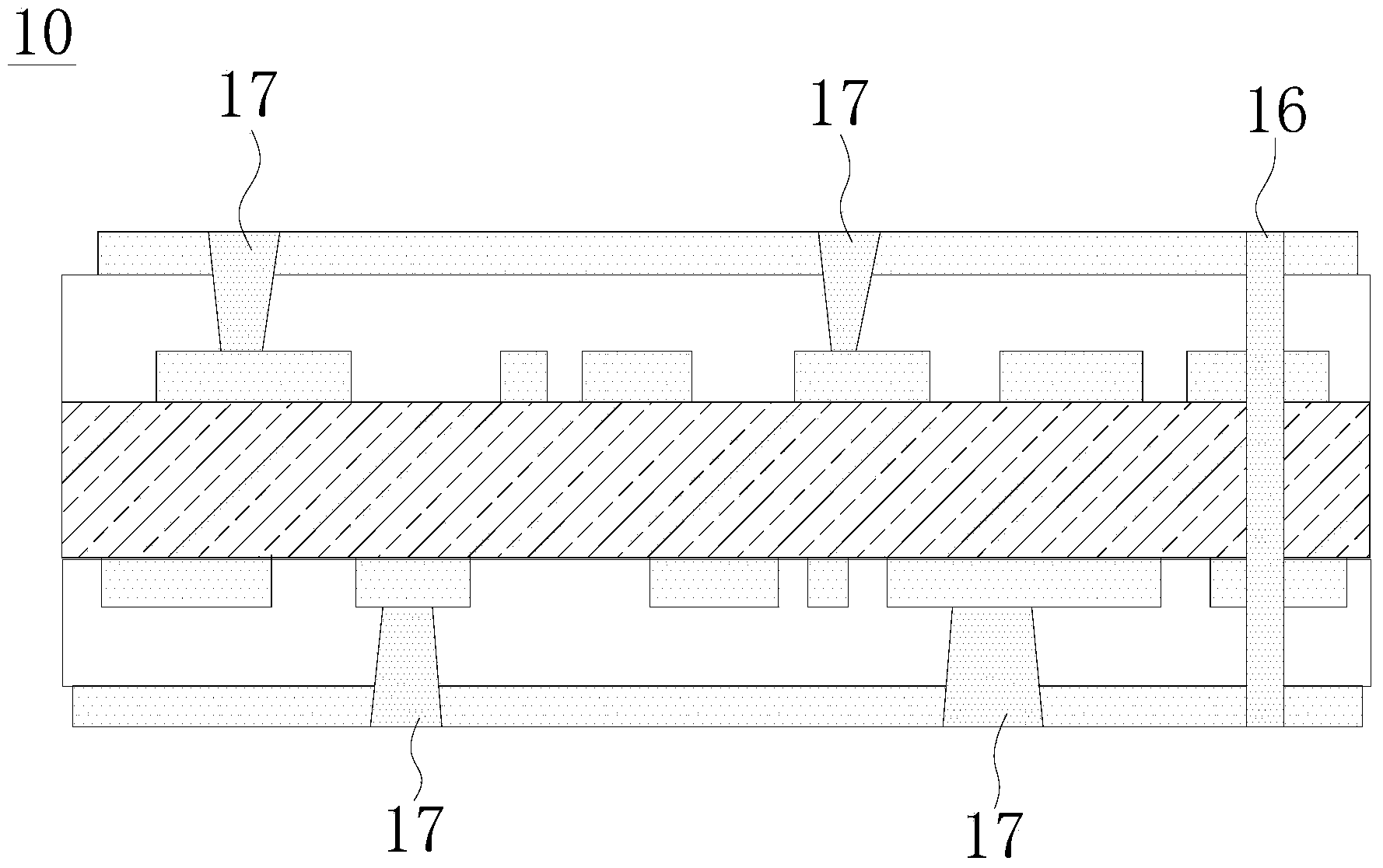

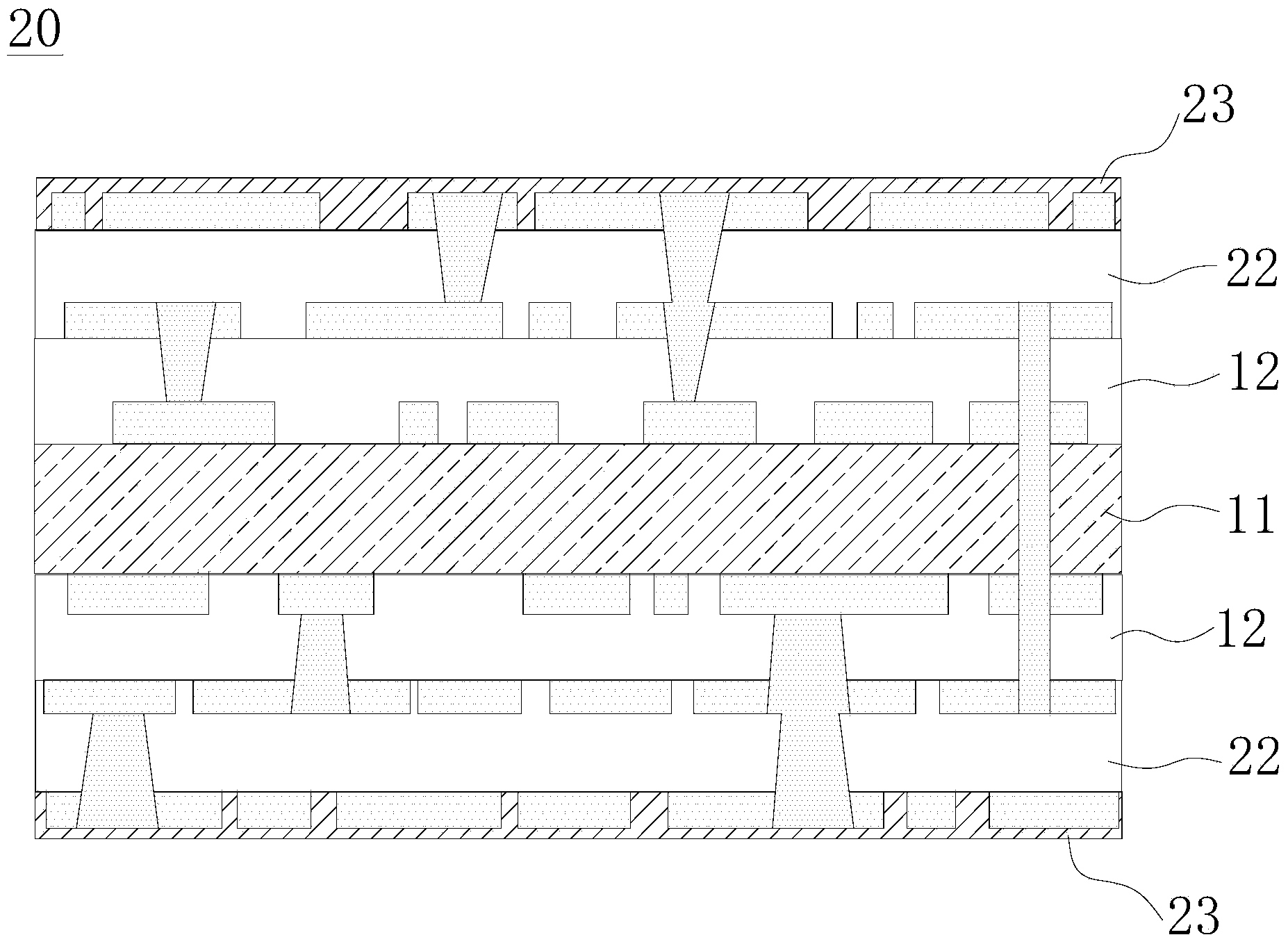

[0020] refer to Figure 1-3 , the preparation method of a kind of HDI plate 20 (six layers) that present embodiment provides, wherein included the method (the length and breadth of the metallized blind hole 17 of metallized blind hole 17) to make the method for metallized blind hole 17 and metallized through hole 16 simultaneously on HDI board 20 The ratio is 1.2:1, and the aspect ratio of the metallized via 16 is 10:1). The method specifically includes the following steps:

[0021] (1) According to the circuit board production process of the prior art, the circuit board raw material is cut to obtain the substrate, and then the inner layer pattern is transferred and etched on the substrate to form the inner layer circuit on the substrate to obtain the inner layer board 11 . After the inner layer board 11 is pre-pressed, the inner layer board 11 and the copper foil 13 are pressed together through the prepreg 12 to form the first multi-layer inner layer board 10 .

[0022] (2)...

Embodiment 2

[0039] This embodiment provides a method for preparing an HDI board (eight layers), which includes a method of simultaneously manufacturing metallized blind holes and metallized through holes on the HDI board. The method specifically includes the following steps:

[0040] Steps (1), (2) and (3) in this embodiment are the same as steps (1), (2) and (3) in Embodiment 1.

[0041] (4) After the first multi-layer inner layer board is pre-pressed, the first multi-layer inner layer board and the copper foil are pressed together through a prepreg to form a second multi-layer inner layer board. Then repeat the above step (2) to make metallized blind holes and metallized through holes on the second multilayer inner layer board. After making metallized blind vias and metallized through holes, slice analysis is done to inspect and evaluate the condition of metallized holes. Then repeat the operation of the above step (3) to make the inner layer circuit on the second multilayer inner lay...

Embodiment 3

[0046] This embodiment provides a method for manufacturing an HDI board (six layers), which includes a method of simultaneously manufacturing metallized blind holes and metallized through holes on the HDI board. The specific operation steps of this embodiment are basically the same as those of Embodiment 1, the difference being that in step (2), when using a vertical continuous electroplating line to perform electroplating for hole filling of the entire board, in the electroplating solution, Cu 2+ The concentration is 90g / L; H 2 SO 4 The concentration is 195g / L; Cl - The concentration of the lightening agent is 80ppm; the concentration of the leveling agent is 4mL / L, and the concentration of the brightening agent is 1.5mL / L.

[0047] According to the method of Example 3, 1000 HDI boards were produced, and the first multi-layer inner layer board after the whole board was filled and electroplated in the production process of each HDI board was sliced and analyzed. The analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com