Impact-type high-temperature hardness test method

A hardness testing and impact technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of low temperature upper limit and large test error, and achieve the effect of improving measurement accuracy, improving test accuracy and preventing temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

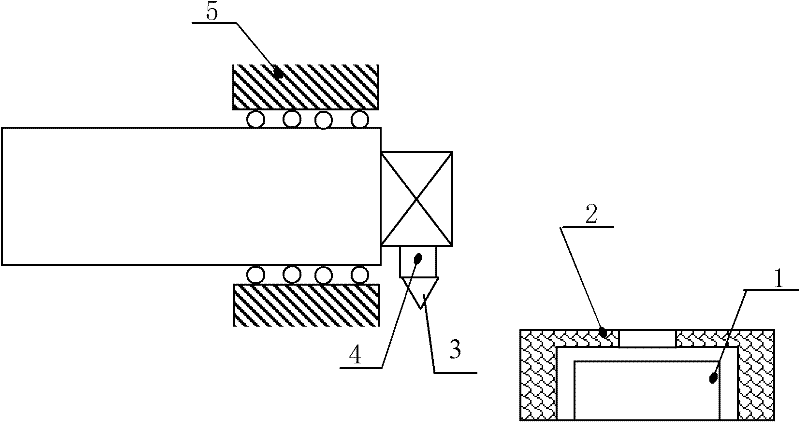

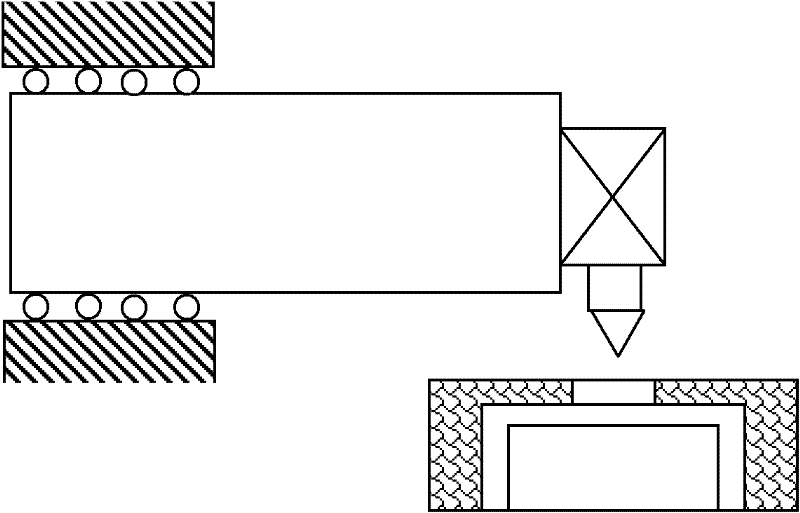

[0014] Specific implementation mode one: as Figure 1~2 As shown, an impact-type high-temperature hardness testing method described in this embodiment is based on a high-temperature hardness testing system including a vacuum device, a heating part, a probe moving mechanism, a water cooling system, and a hardness testing part. achieved;

[0015] The specific process of this high temperature hardness test method is:

[0016] Step 1. Place the sample 1 in the heater 2 with heat insulation function in the heating part, and maintain the vacuum degree in the heater 2 with heat insulation function by a vacuum device to be better than 2×10 -1 Pa; the sample 1 in it is heated to the set test temperature by the heater 2 with heat insulation function;

[0017] Step 2. Cool the outer surface of the vacuum device, the moving mechanism of the measuring head, the hardness testing part and the heater 2 with heat insulation function through the water cooling system, so that the hardness test...

specific Embodiment approach 2

[0022] Specific implementation mode two: as Figure 1~2 As shown, in the third step of this embodiment, after the second impact on the sample 1, a pulse current with an appropriate width twice the rated value is applied to the electromagnet of the electromagnetic mechanism, and the indenter bounced up for the second time Suction on the measuring head clamping mechanism 4; other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: as Figure 1~2 As shown, this embodiment also adds the following steps: when the indenter that pops up for the second time is sucked on the probe clamping mechanism 4, the probe clamping mechanism 4 and the probe 3 are immediately translated by the probe moving mechanism 5 Return to the preparation area away from the insulated heater 2. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com