Process for manufacturing middle frame of mobile phone by liquid metal die-casting molding technology

A technology of liquid metal and mobile phone middle frame, which is applied in the technical field of design/production of mobile phone middle frame parts with liquid metal technology, which can solve the problems of high manufacturing cost and achieve the effect of easy manufacturing process and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

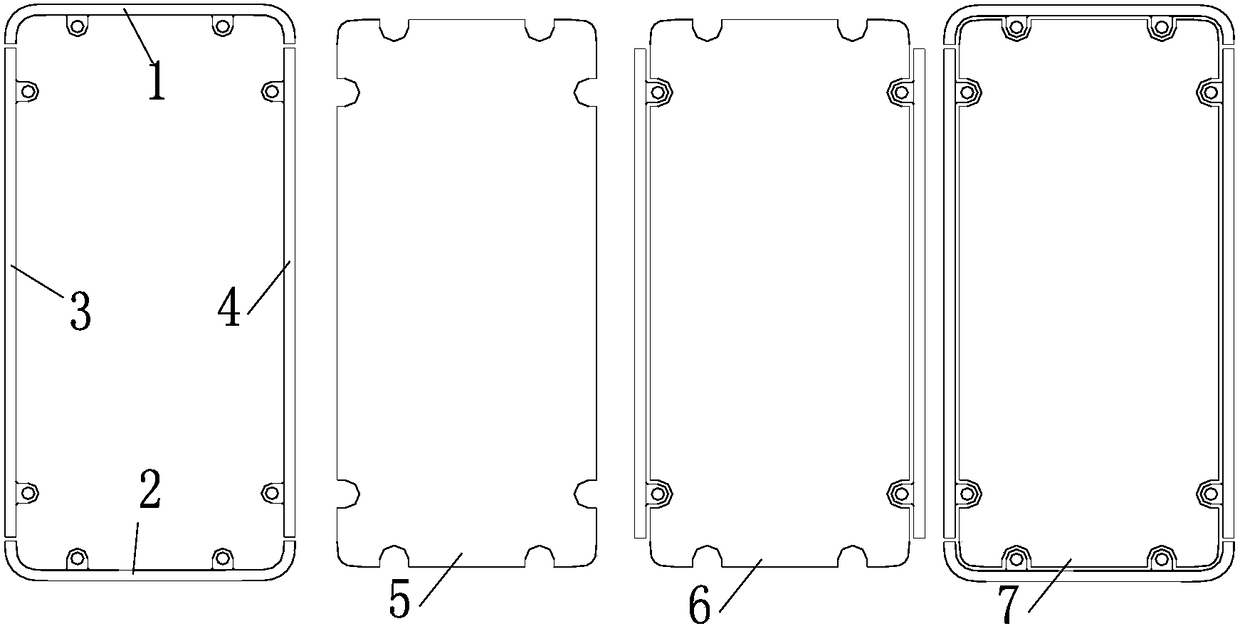

[0030] 1) Liquid metal full vacuum die-casting: Put the raw material alloy balls into the crucible of the vacuum die-casting machine, the vacuum degree of the die-casting machine is below 10pa, and the crucible is heated to 800 degrees by induction to form alloy molten soup, pour the molten soup into the sprue sleeve of the mold, The mold temperature needs to be raised to 210 degrees through the high-temperature oil circuit. After the mold is closed, the punch connected to the cylinder pushes the molten soup into the mold for 3 seconds, and the pressure is maintained for 20 seconds. After the mold is cooled by the mold water circuit, the ejector pin ejects the product , The special retrieving device catches the product and sends it out of the die-casting machine, that is, the liquid metal side strips 1, 2, 3, 4 of the middle frame of the mobile phone are obtained.

[0031] 2) Machining treatment 1: Use CNC to remove scraps, slag, and burrs of liquid metal edge strips 1, 2, 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com