Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Short range order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Short range order refers to the regular and predictable arrangement of atoms over a short distance, usually with one or two atom spacings. However, this regularity does not persist over a long distance. Examples of materials with short range order include amorphous materials such as wax, glass and liquids as well as the collagen fibrils of the stroma in the cornea.

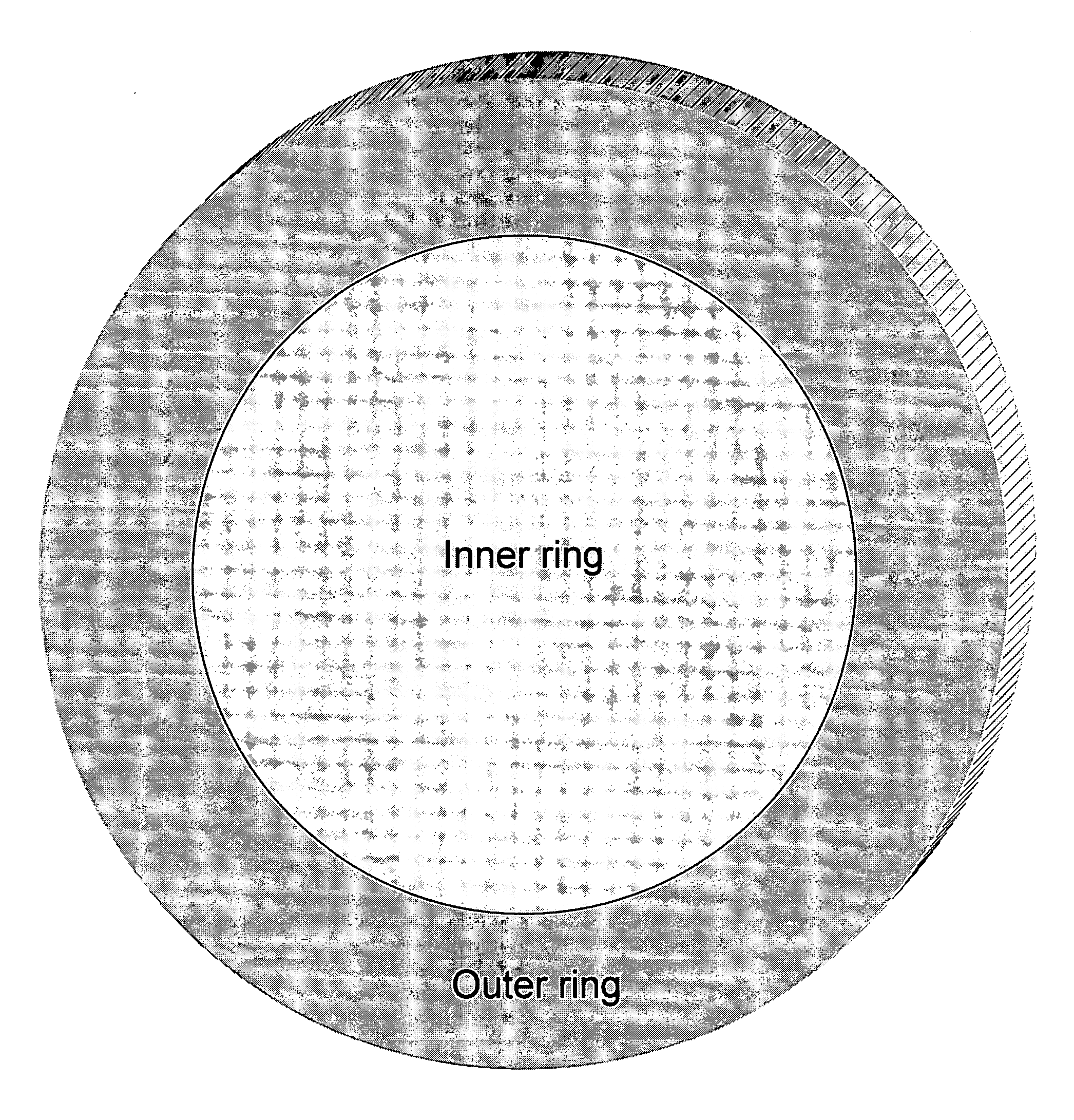

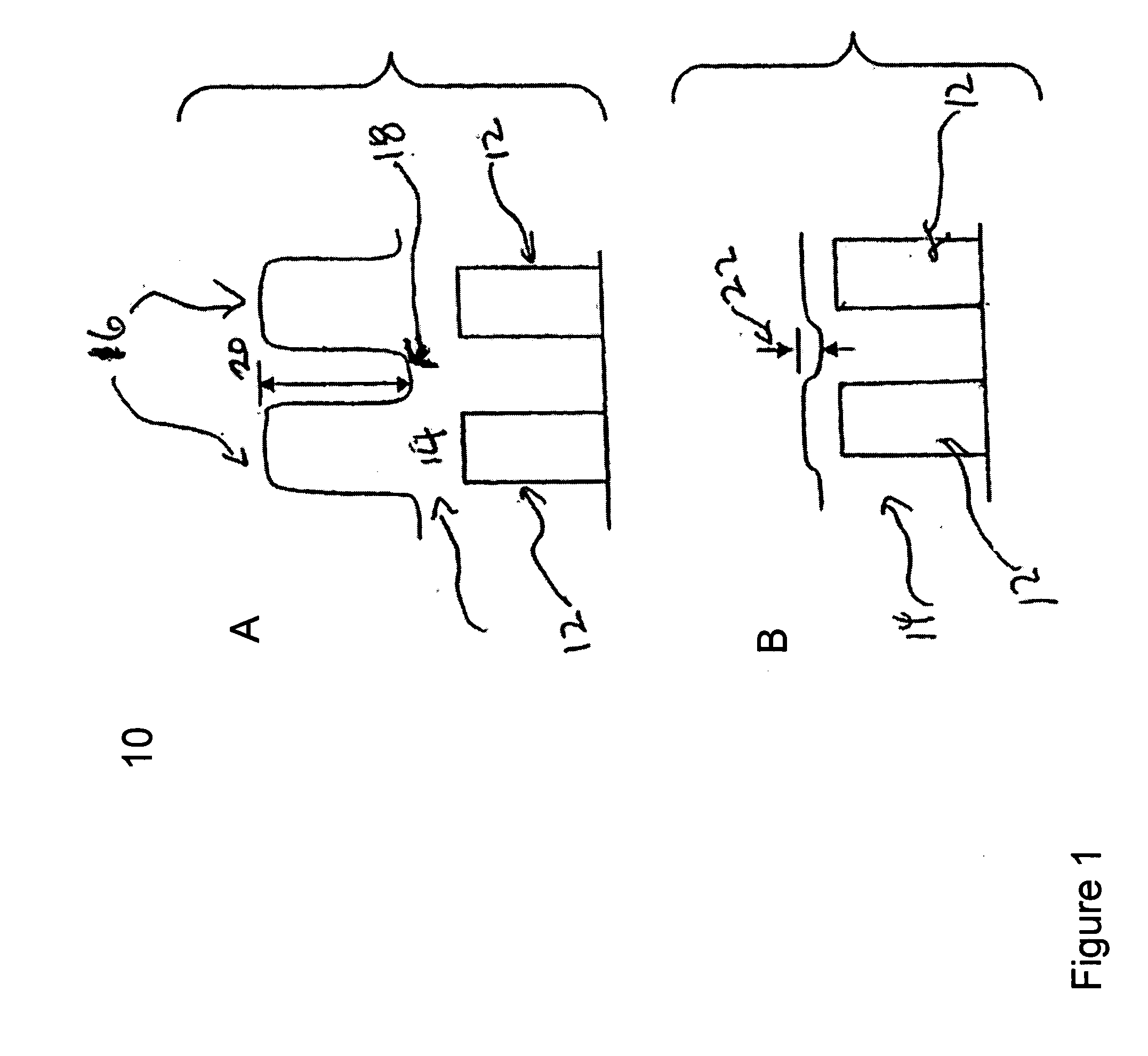

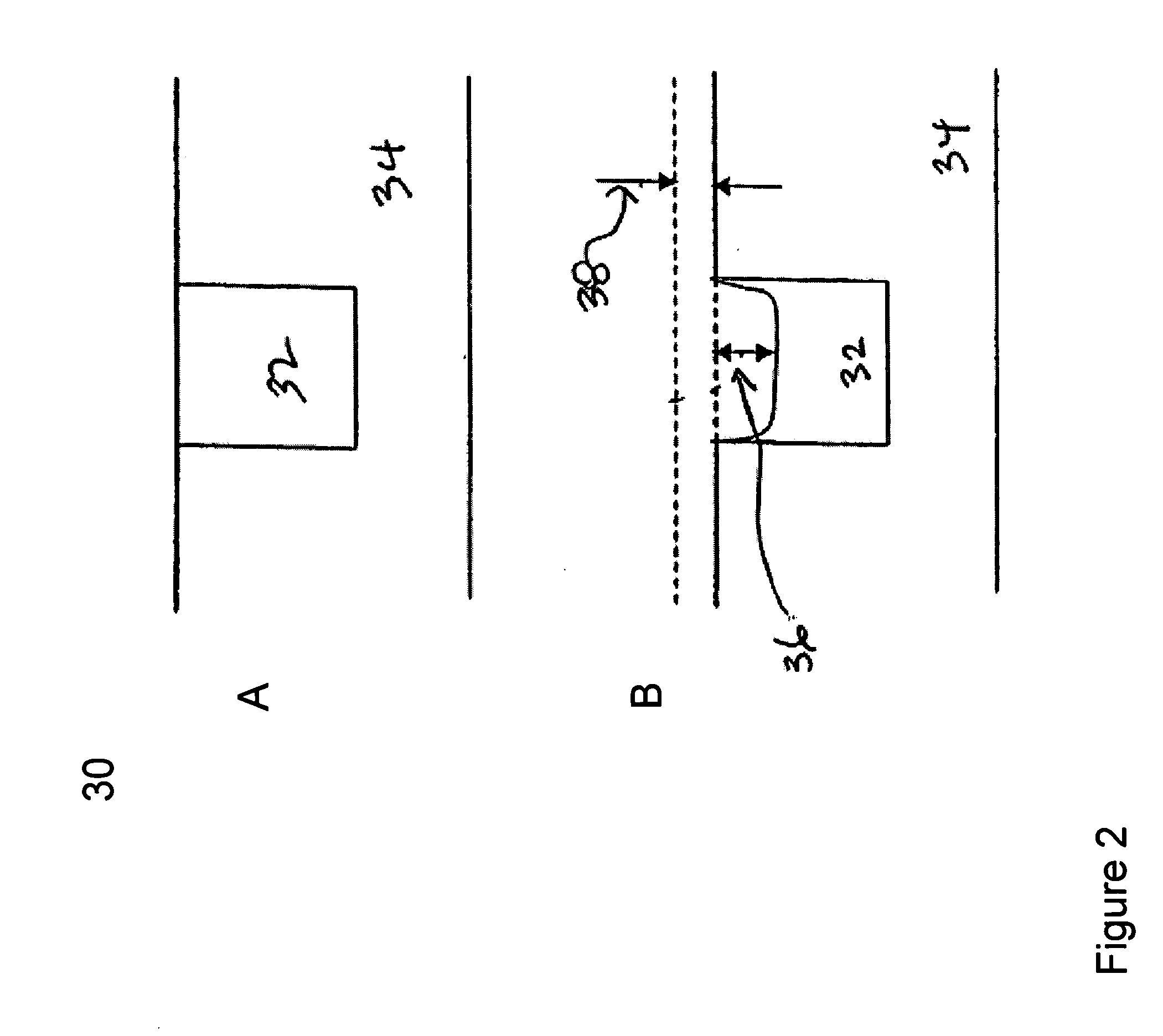

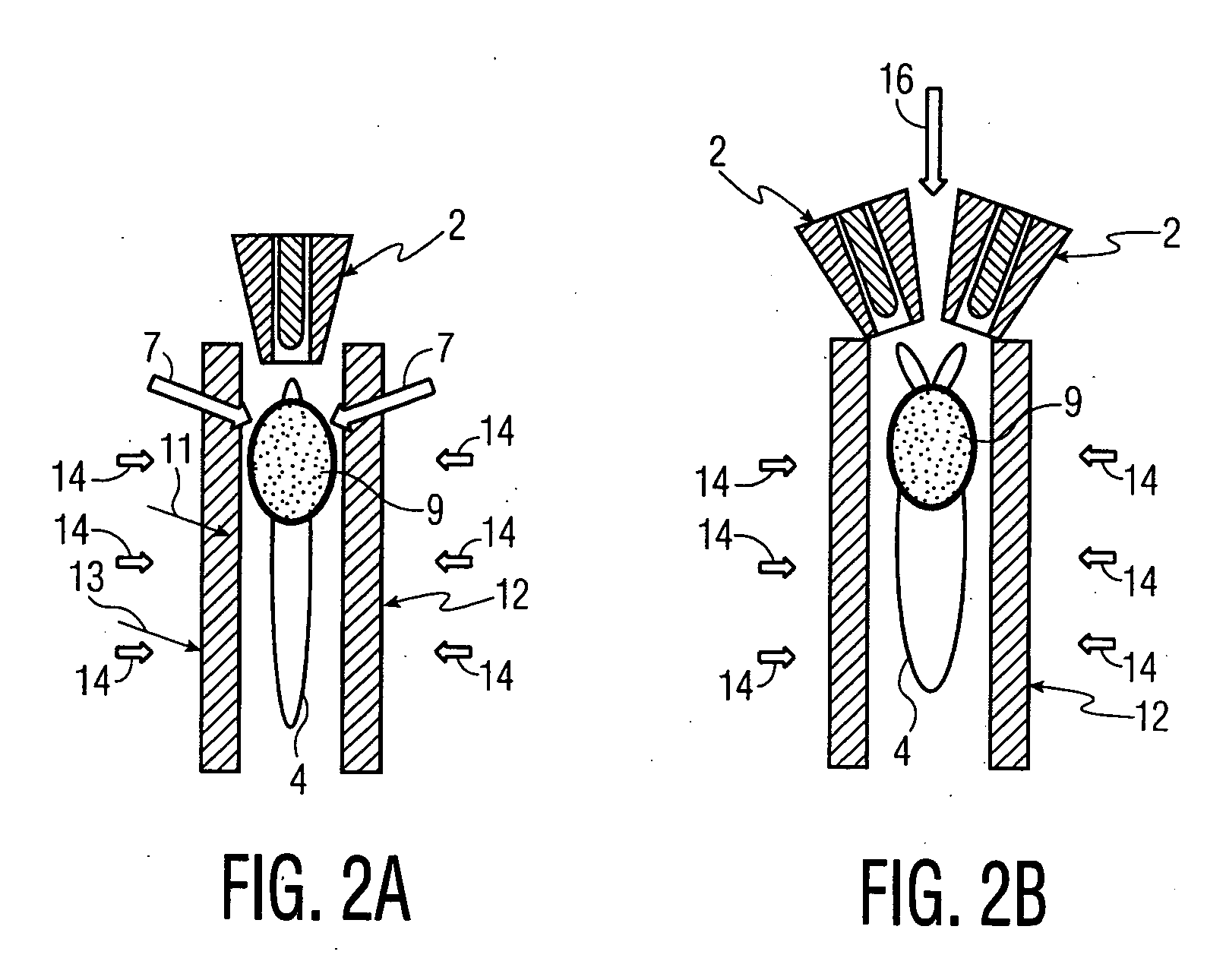

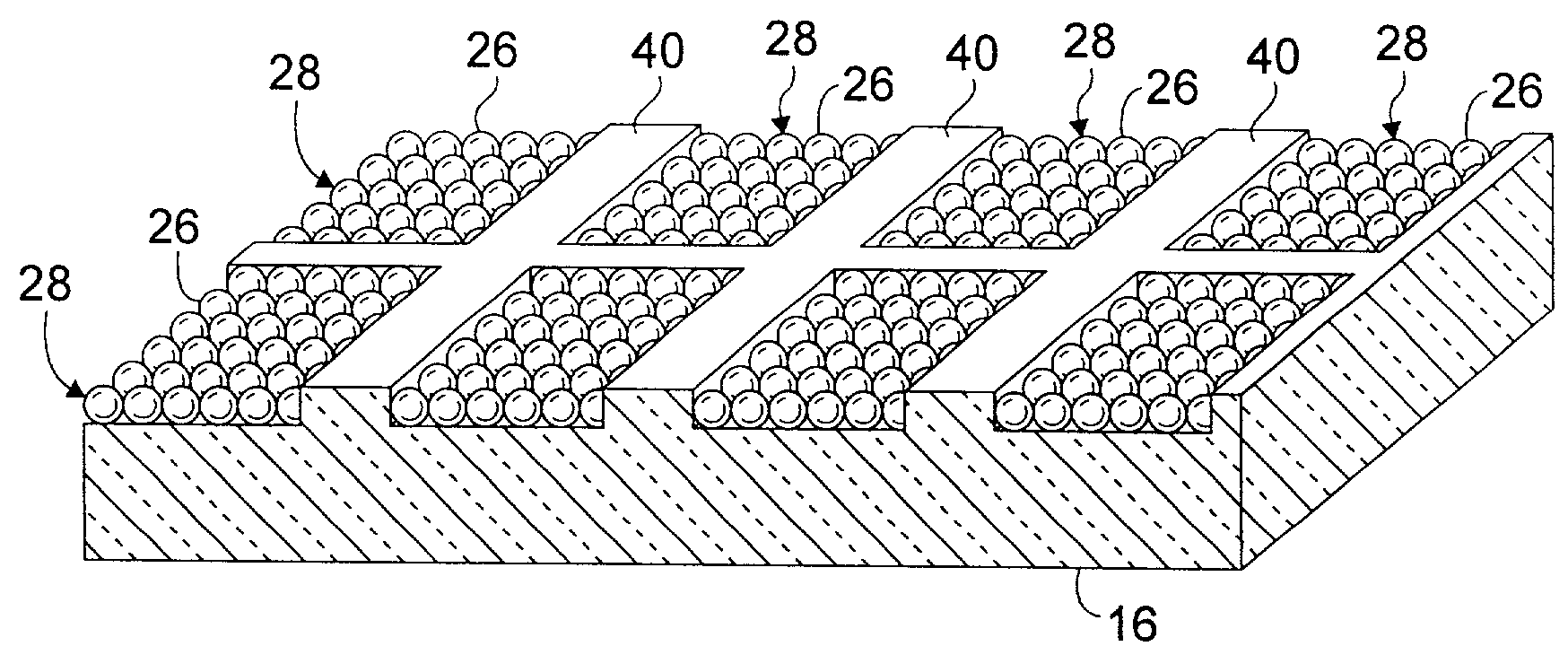

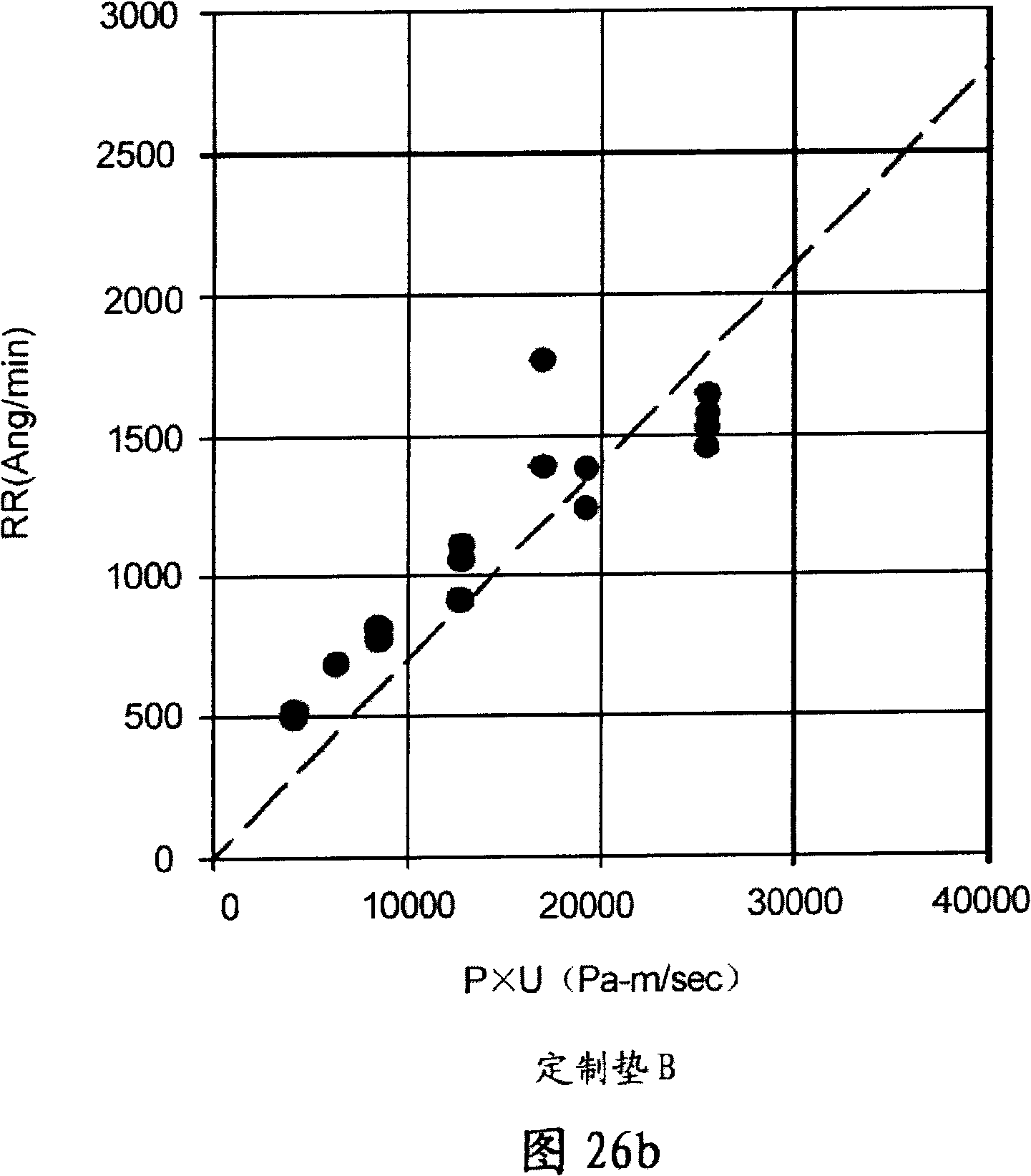

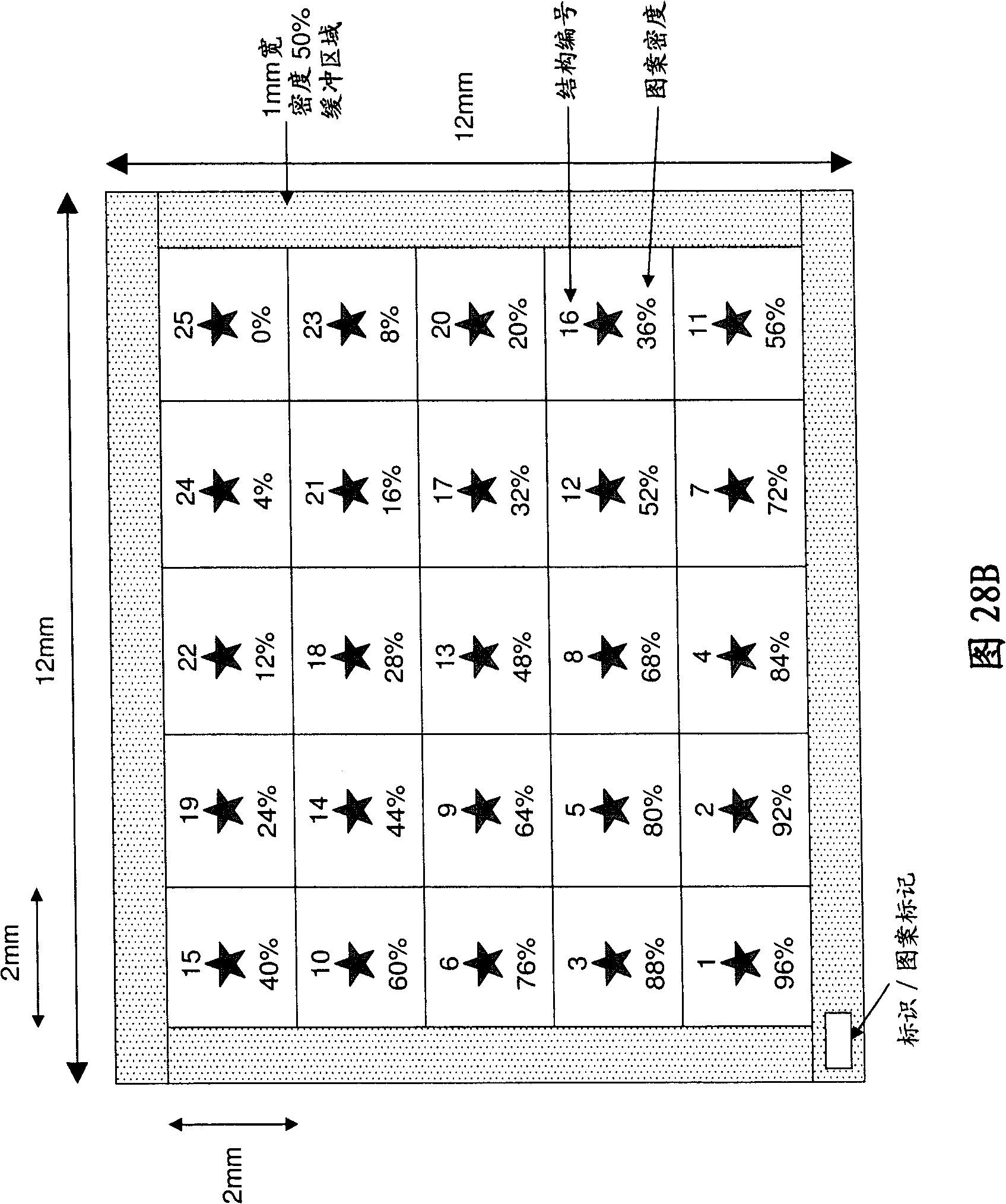

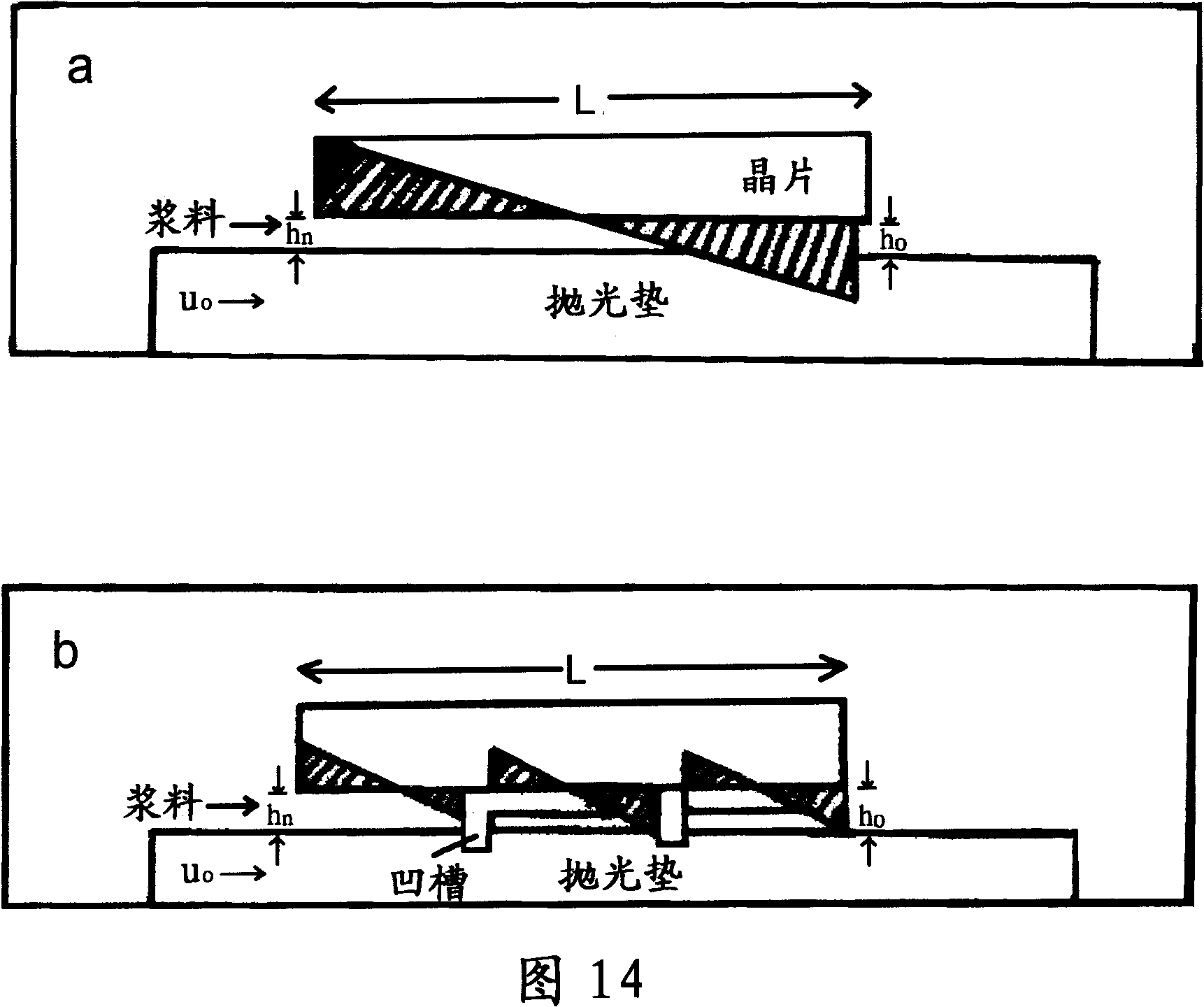

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

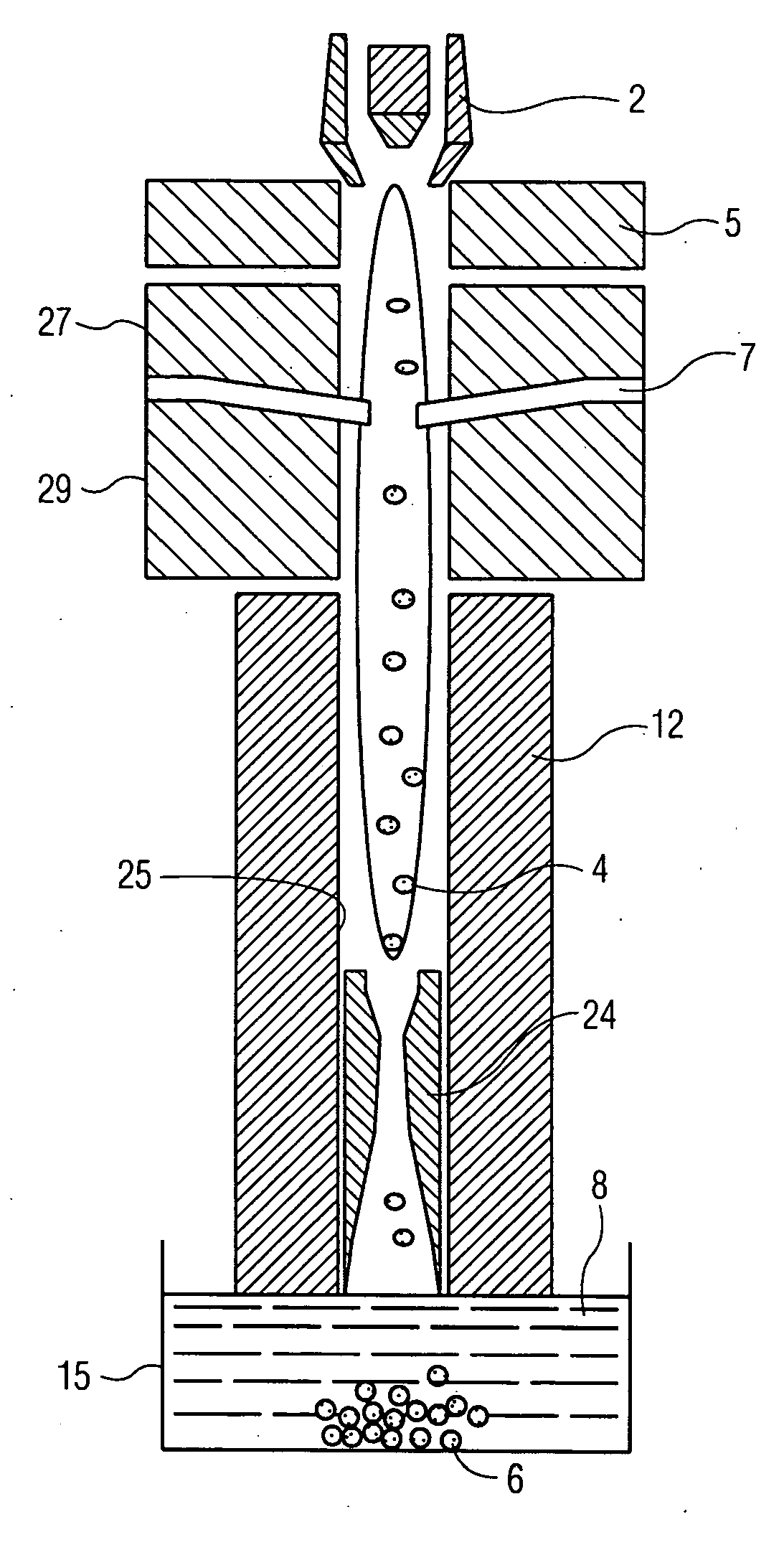

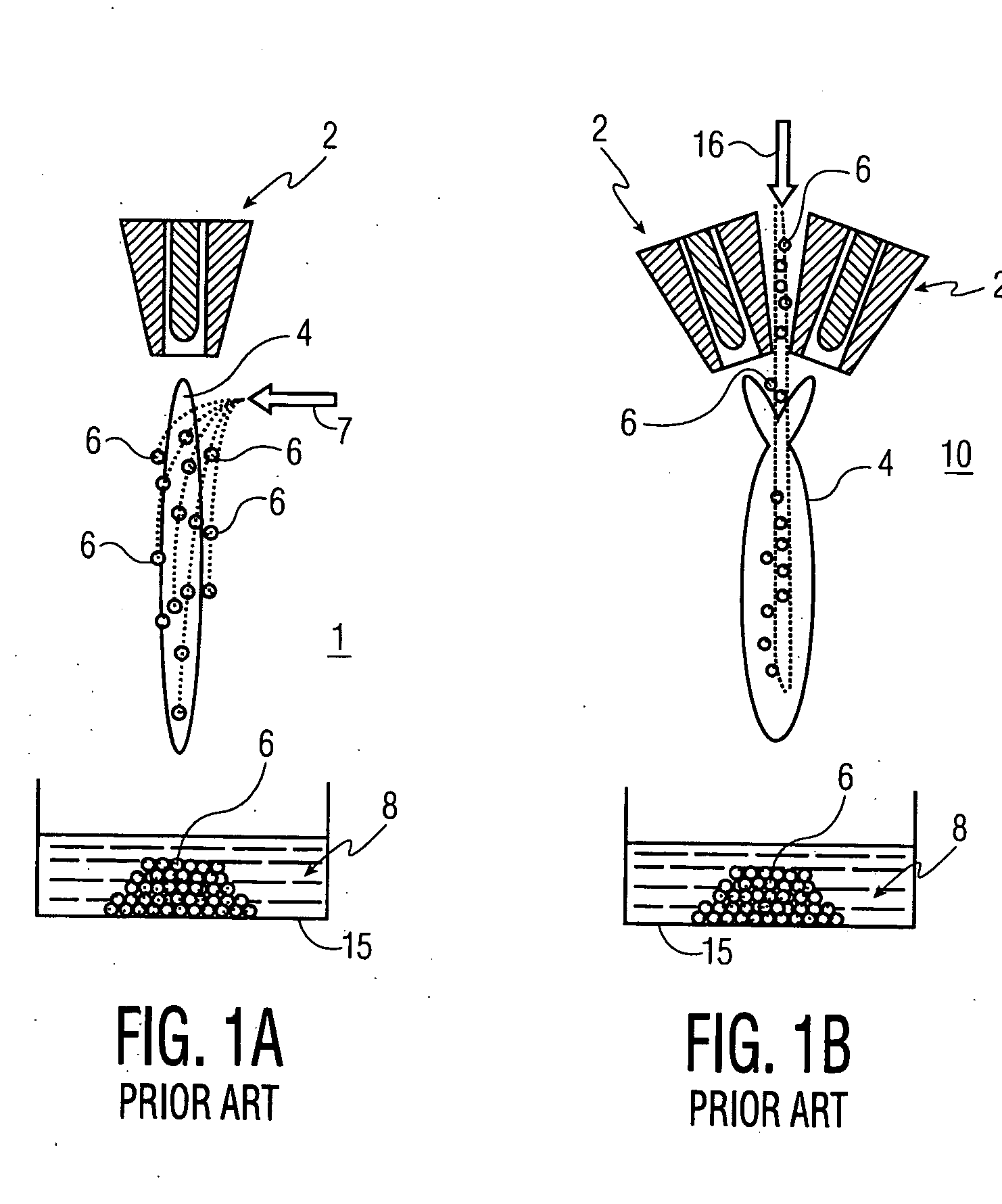

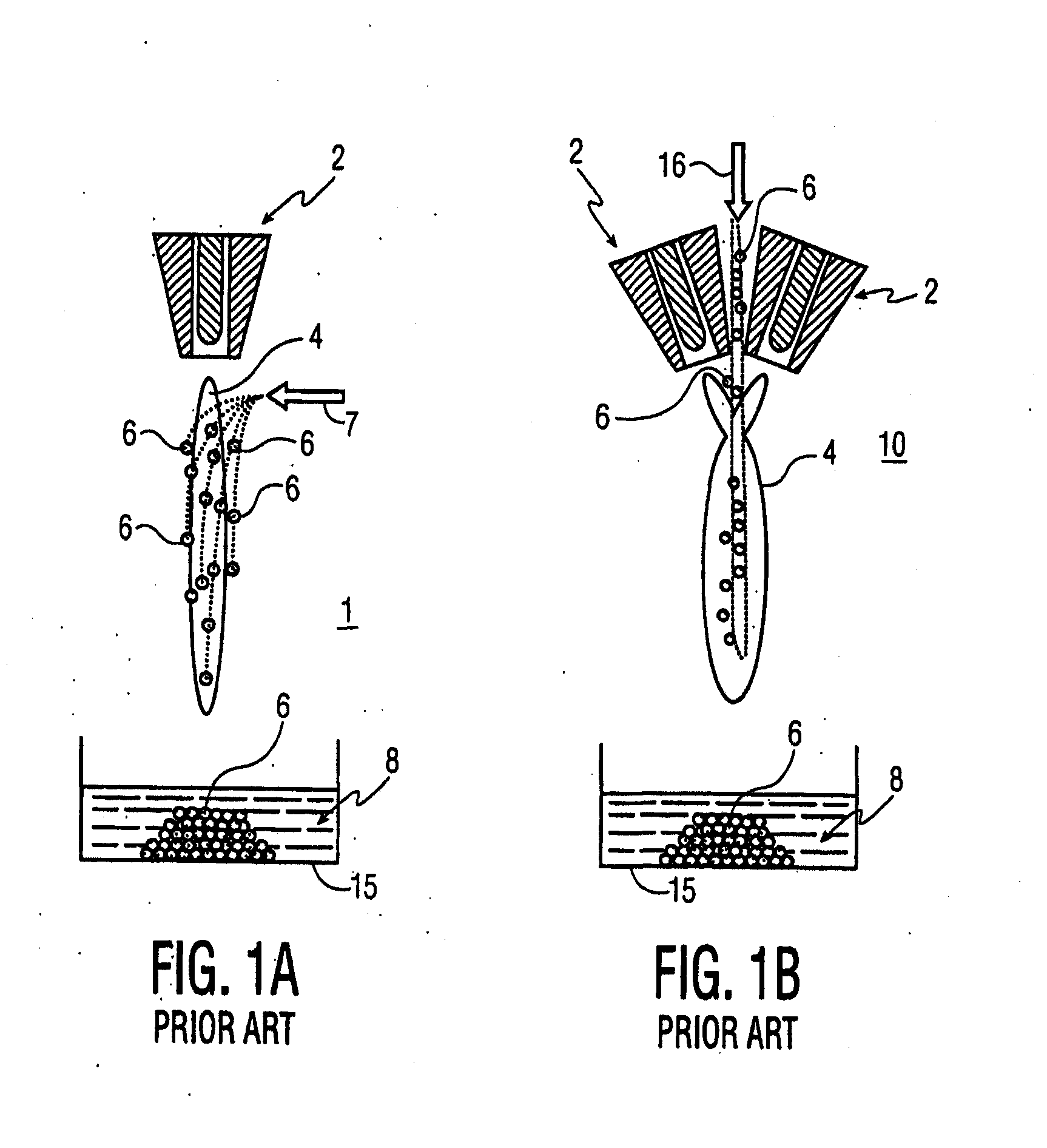

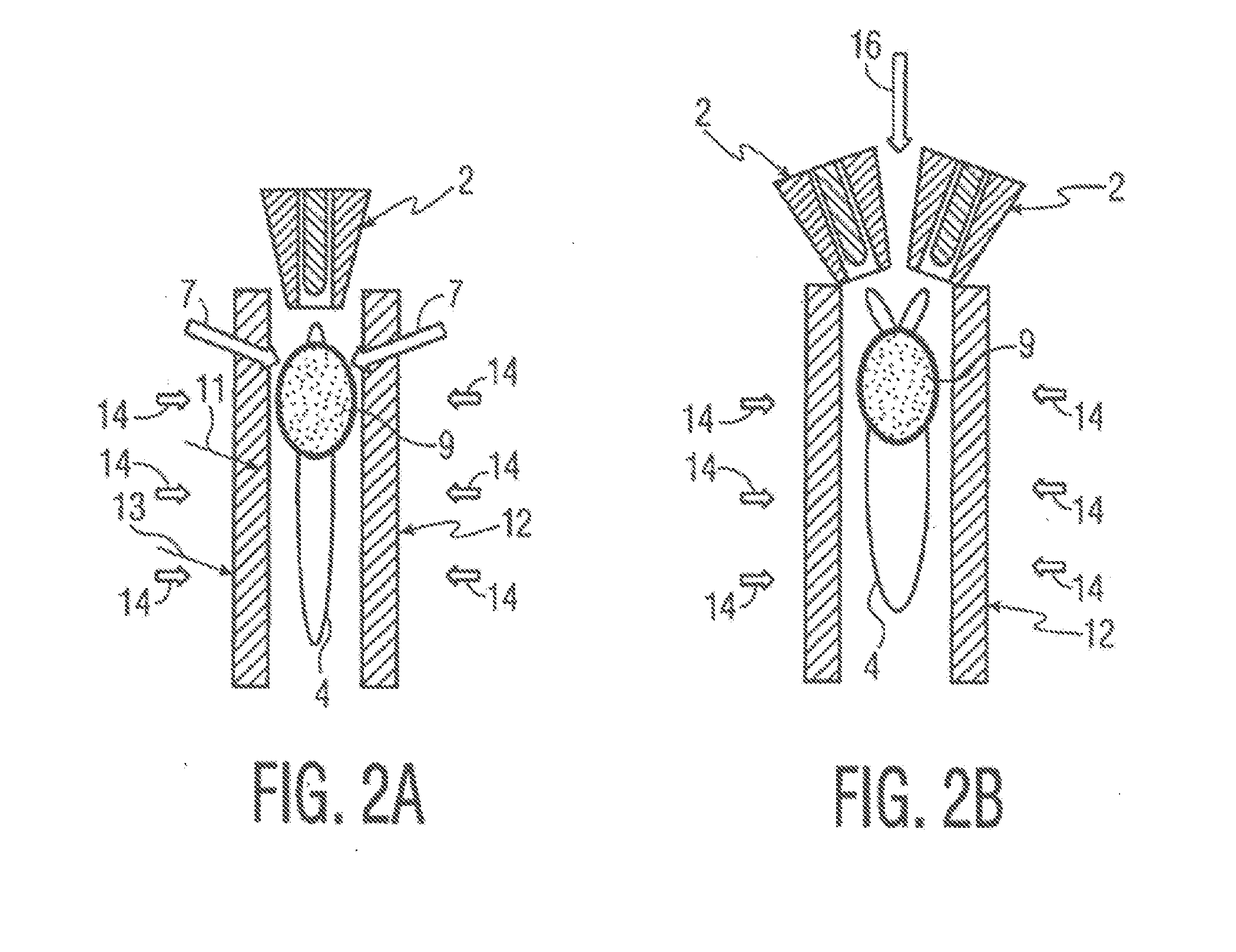

Shrouded-plasma process and apparatus for the production of metastable nanostructured materials

InactiveUS20070044513A1Improve compactnessImprove sintering performanceMaterial nanotechnologyNitrogen compoundsLiquid jetShort range order

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:RUTGERS THE STATE UNIV

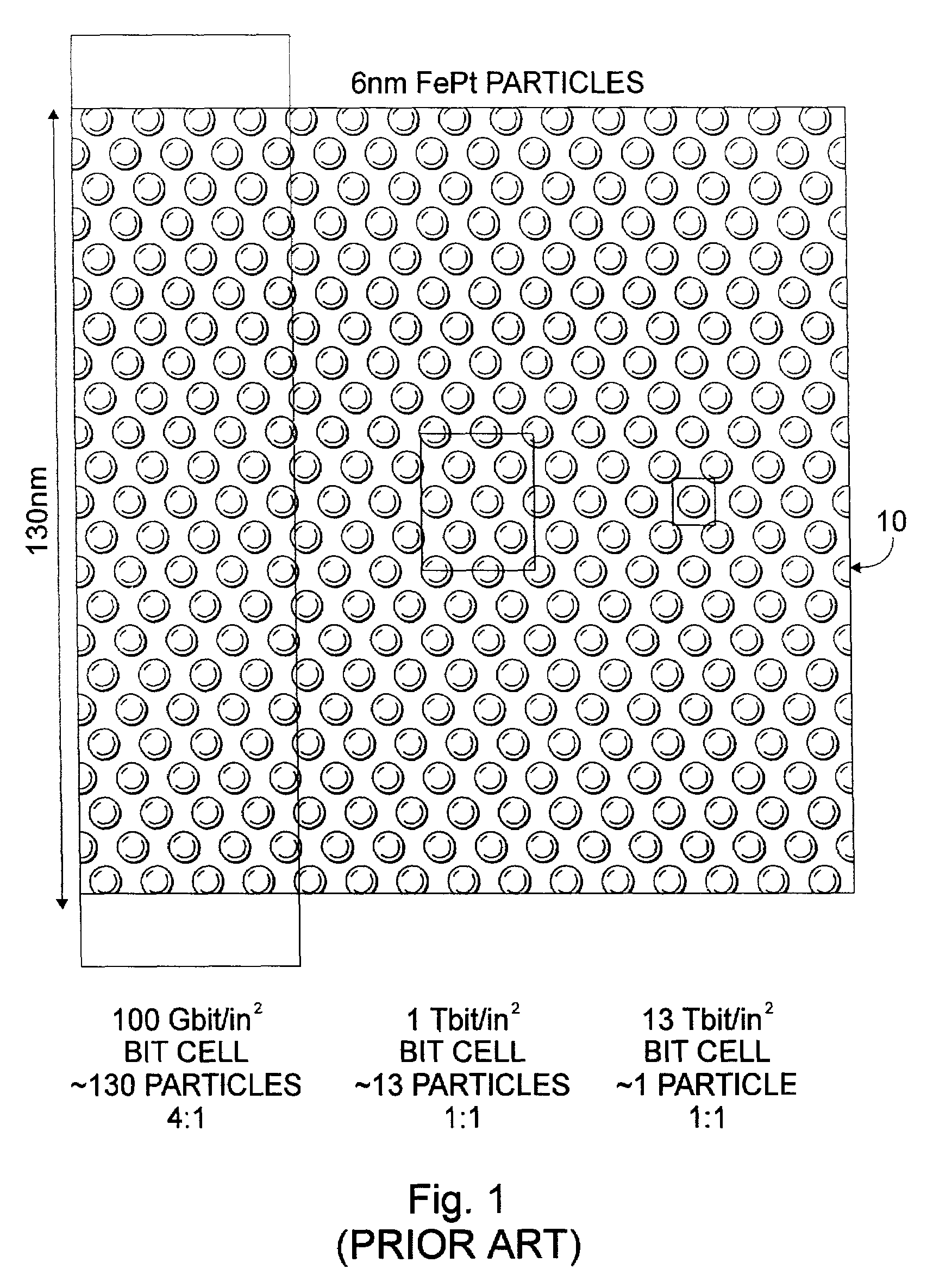

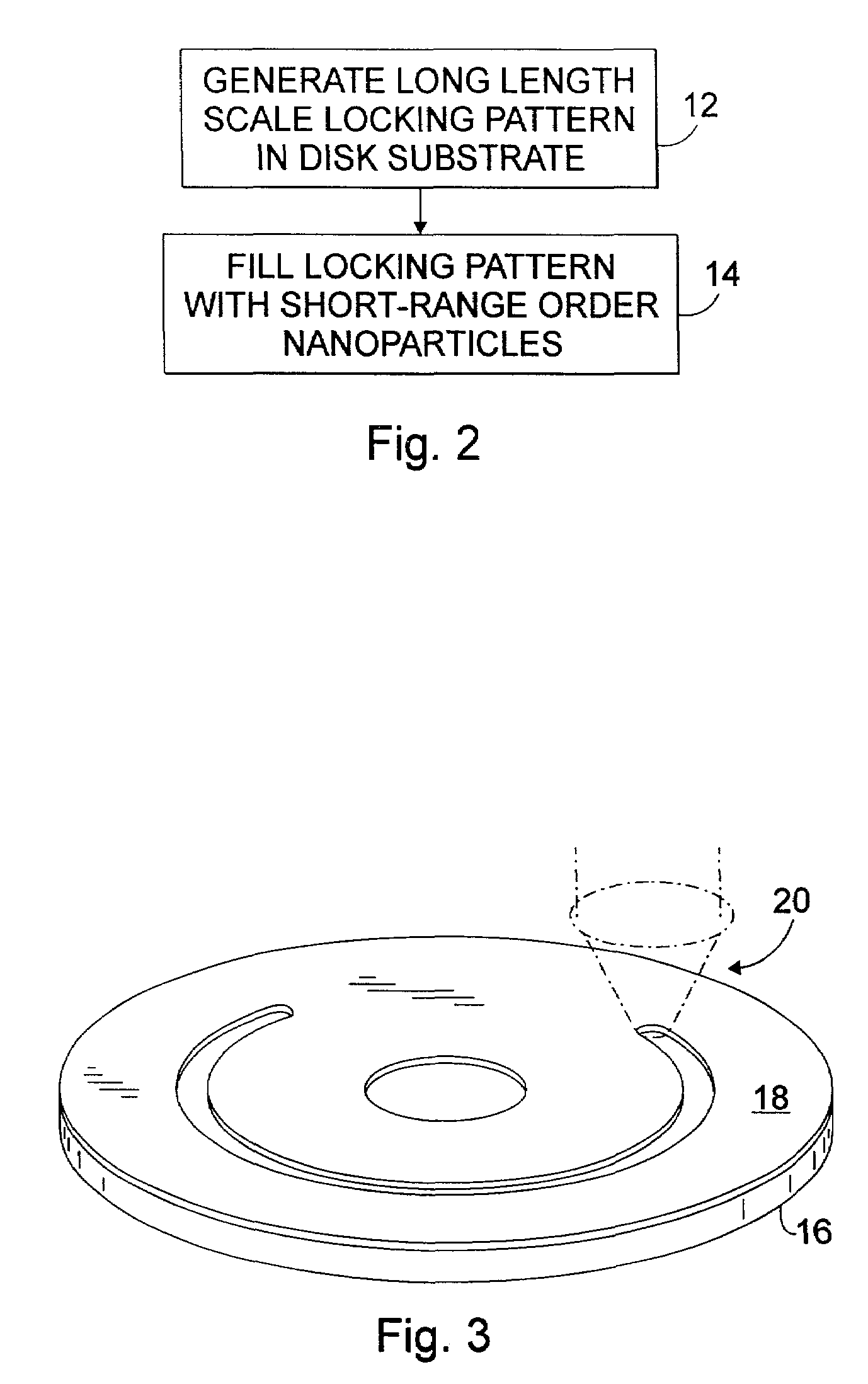

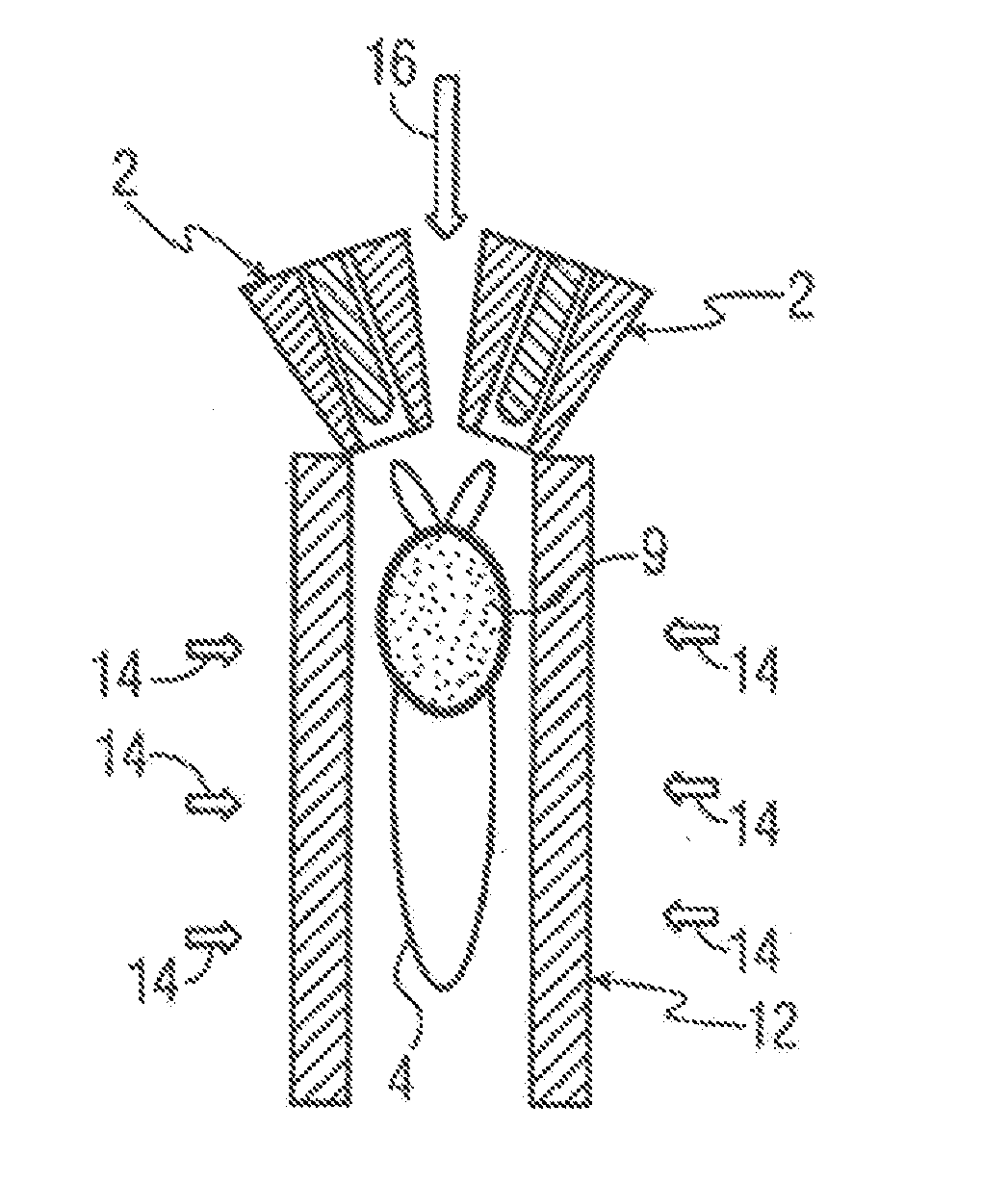

Magnetic recording media having self organized magnetic arrays

InactiveUS7041394B2Magnetic materials for record carriersPatterned record carriersChemical synthesisShort range order

A magnetic recording disc is provided according to the present invention for magnetic recording. The magnetic recording disc includes a disc substrate having a locking pattern etched therein. Chemically synthesized iron-platinum particles are provided in the locking pattern and completely fill the locking pattern. The chemically synthesized iron-platinum nanoparticles exhibit short-range order characteristics forming self organized magnetic arrays.

Owner:SEAGATE TECH LLC

Shrouded-Plasma Process and Apparatus for the Production of Metastable Nanostructured Materials

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:KEAR BERNARD H +2

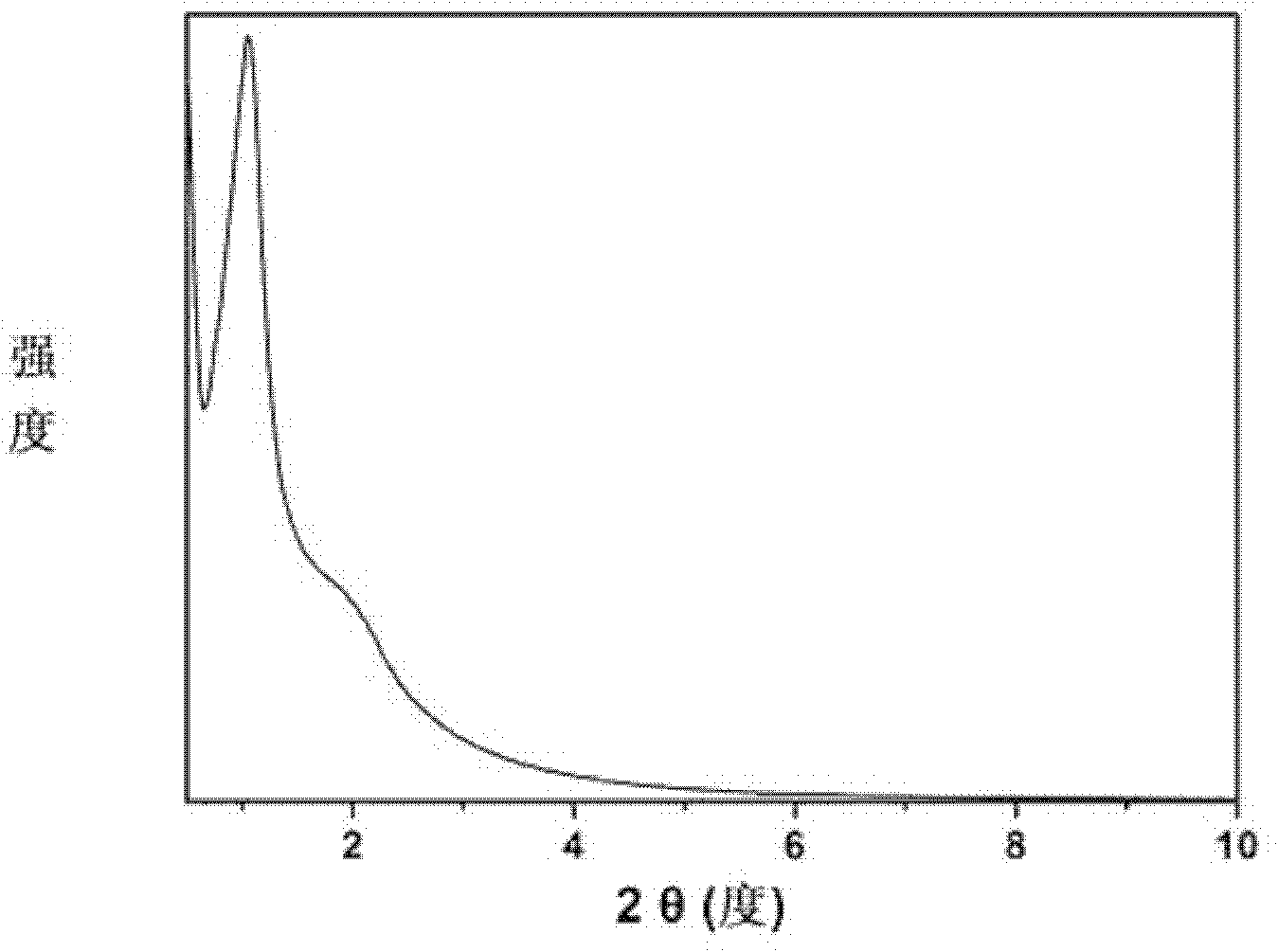

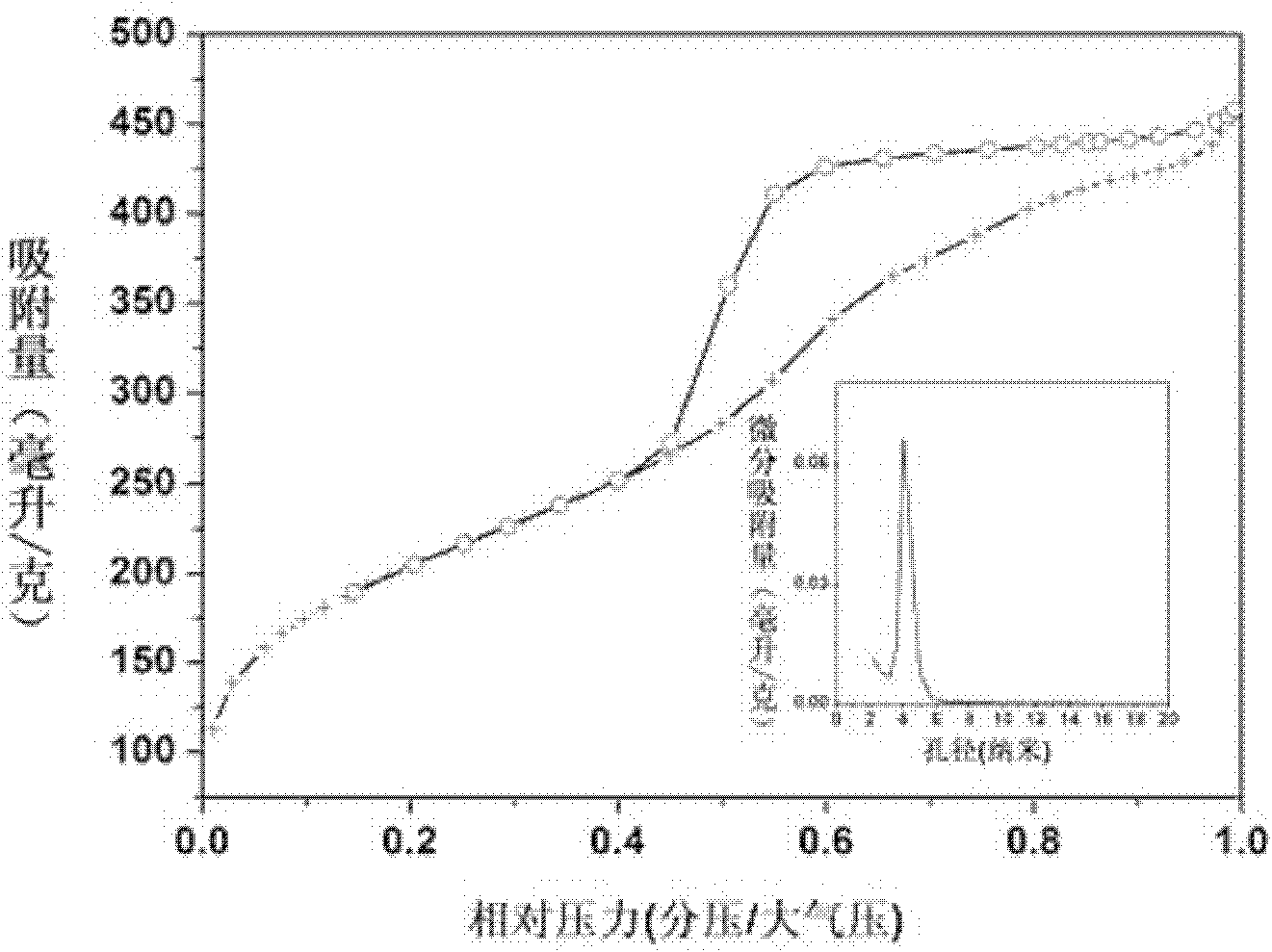

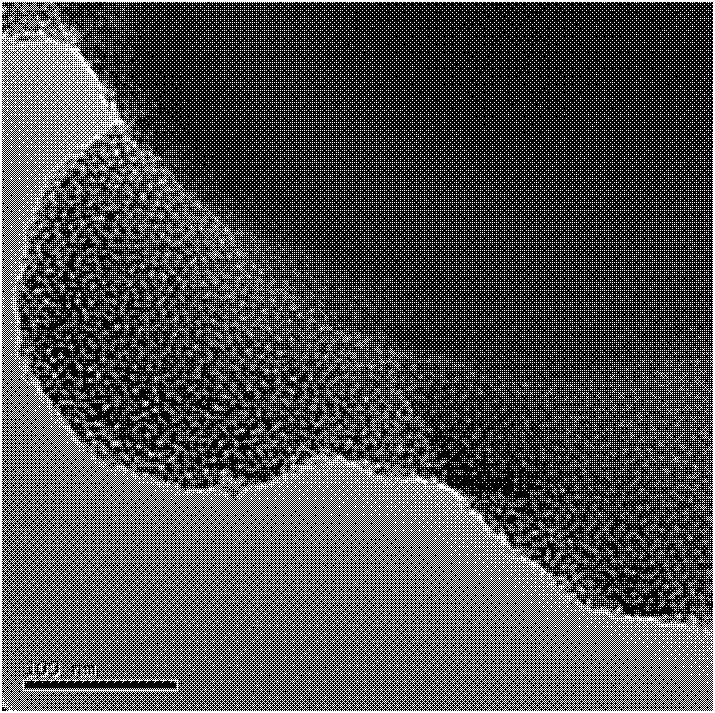

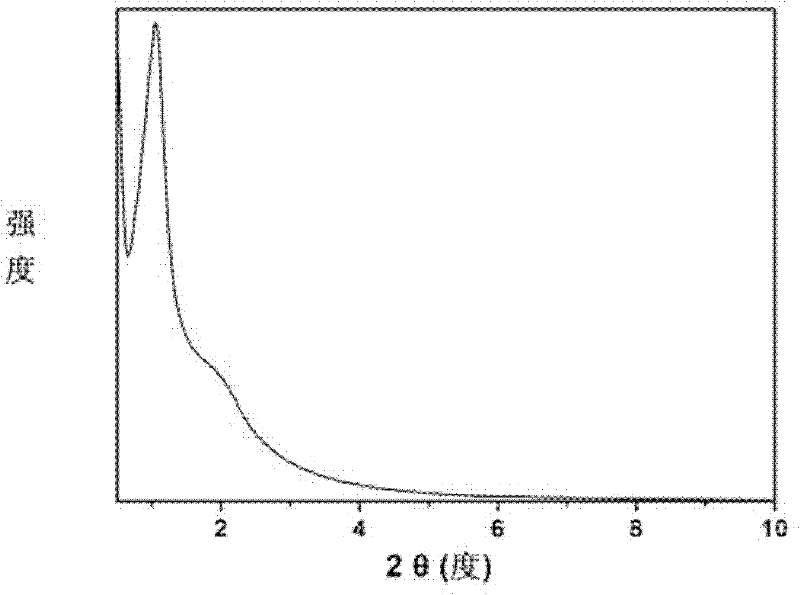

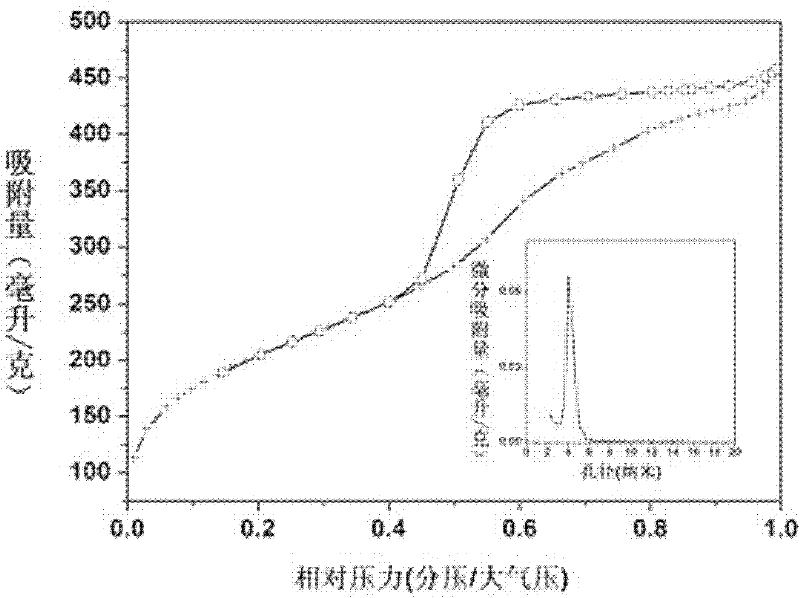

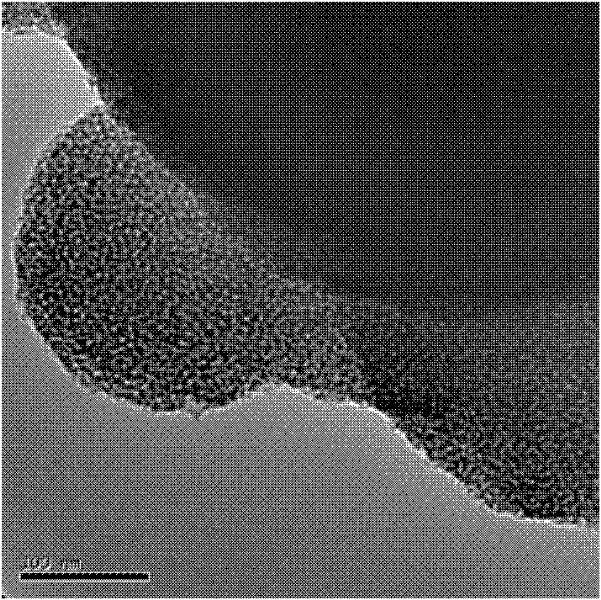

Mesoporous silicon dioxide molecular sieve and preparation method thereof

InactiveCN101786639ASimple processRapid responseCatalyst carriersOther chemical processesMolecular sieveShort range order

The invention relates to a mesoporous silicon dioxide molecular sieve and a preparation method thereof. The method comprises the following synthesis steps: 1), mixing a nonionic surfactant, a silicon source and water in a molar ratio of (0.01-0.1): (300-500): (1-3), regulating the pH value of the solution to 1.0 to 3.0 with an acid, and stirring the solution at 20 to 80 DEG C for 1 to 3 hours to form a sol mixture; 2) stirring the sol mixture obtained by the step 1 at room temperature, adding an alkaline buffer solution and regulating the pH value of the solution to 5 to 7.5 to obtain a white silicon dioxide precipitate; and 3) roasting the precipitate obtained by the step 2 at 500 to 600 DEG C for 3 to 5 hours to obtain a white mesoporous silicon dioxide material. The white mesoporous silicon dioxide material has an order hexagonal phase structure, a local short range order hexagonal phase structure, a multilayer onion-like structure, a worm-like structure or a foam-like hollow vesica structure. The method for synthesizing the mesoporous silicon dioxide molecular sieve of the invention is a real green biomimic synthesis method. The application of the method can promote the industrial production of like materials.

Owner:TIANJIN UNIV

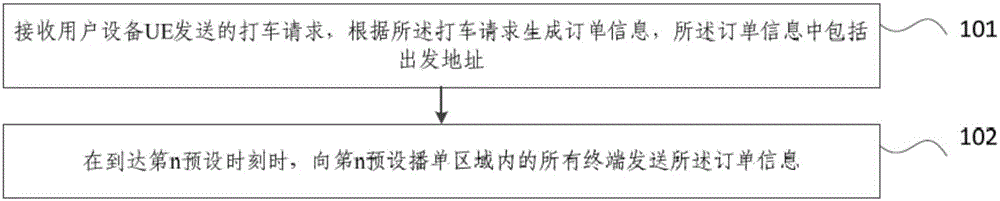

Order pushing method and device

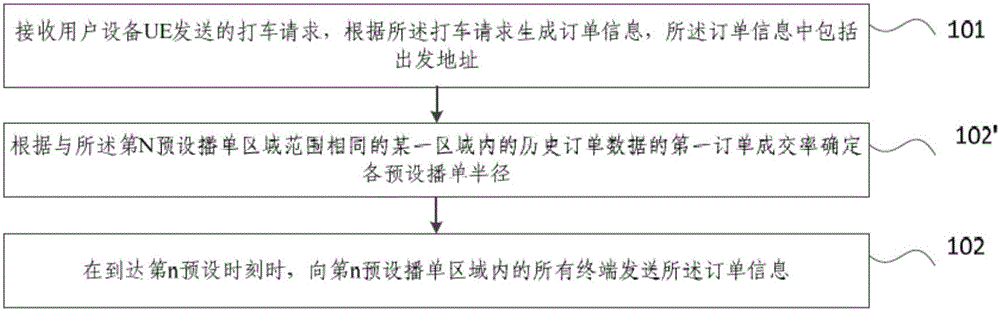

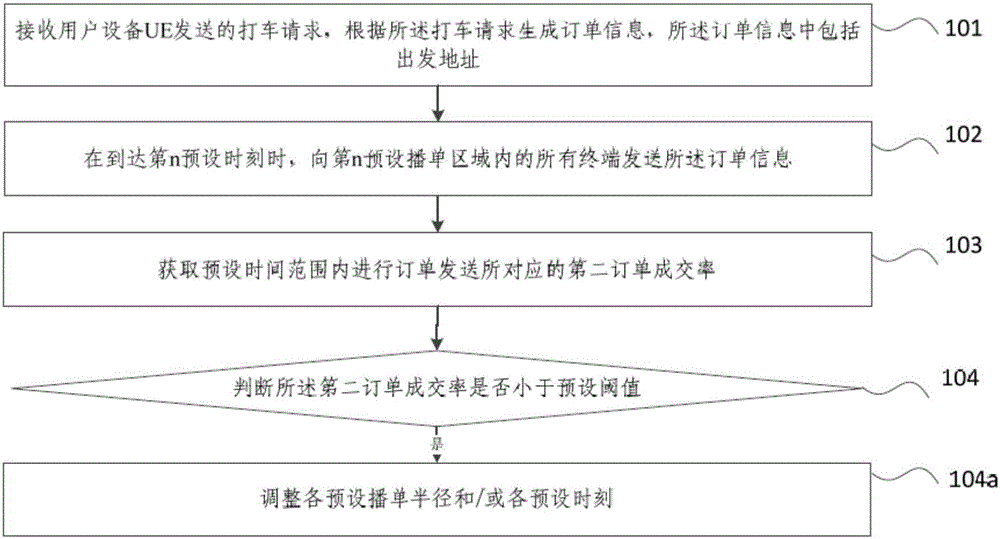

The invention provides an order pushing method and device. The method comprises the steps that receiving a user equipment (UE) taxi request generates order information request according to the taxi, the order information includes a starting address; n in reaching the first preset when the time to send the n-th preset to all terminals within the broadcast single region order information, n is an integer of not less than 1 and not more than N, said N being an integer greater than 1; wherein, the first preset time n + 1 night n in the first preset time; the first pre-sowing single region n to the starting address location for the center, according to the n-th pre-sowing single radius determined area; the first n + 1 pre-sowing single radius greater than the first n pre-sowing single radius. The present invention can effectively shorten the distance of order execution, increase the turnover rate of the short-range order, while reducing the rate of order cancellation.

Owner:BEIJING DIDI INFINITY TECH & DEV

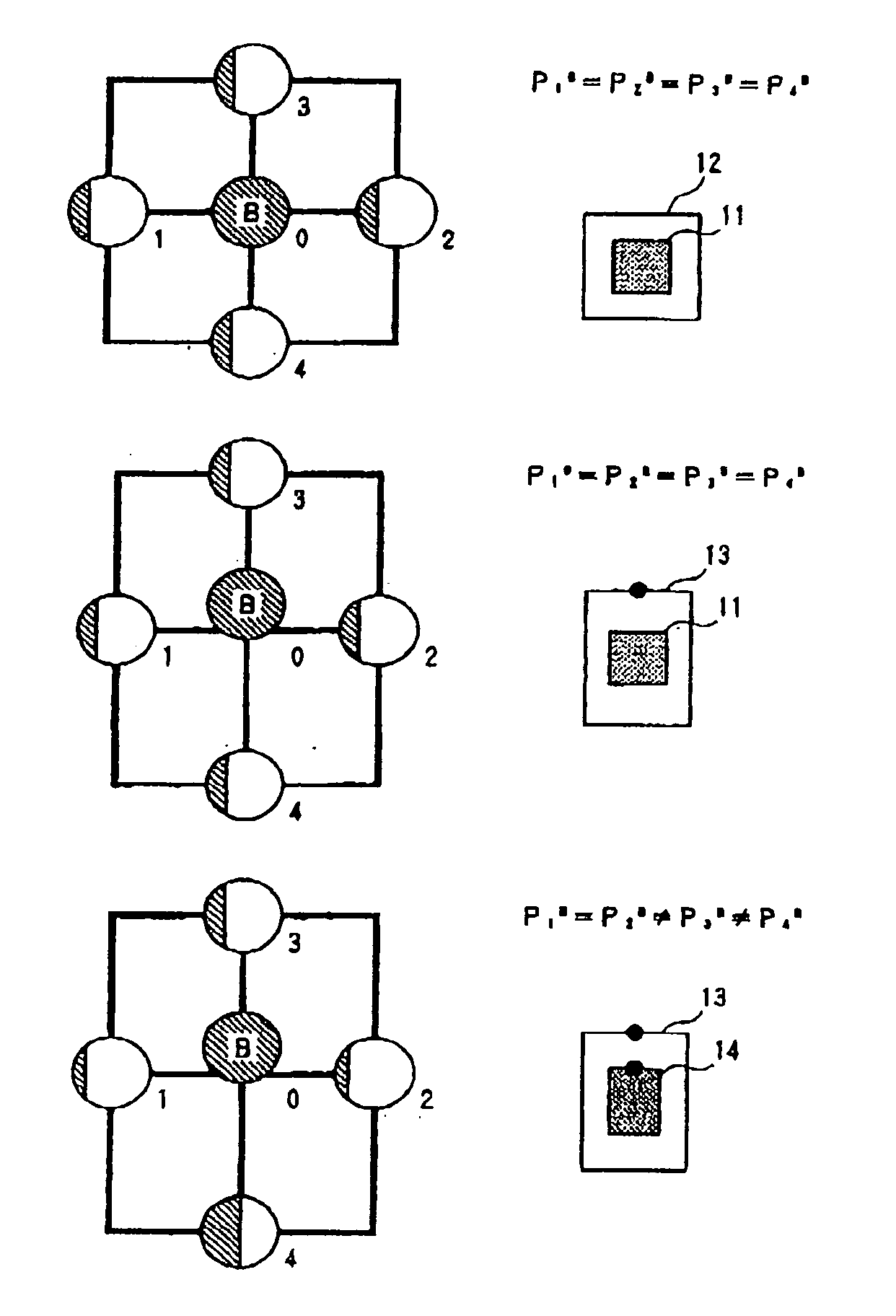

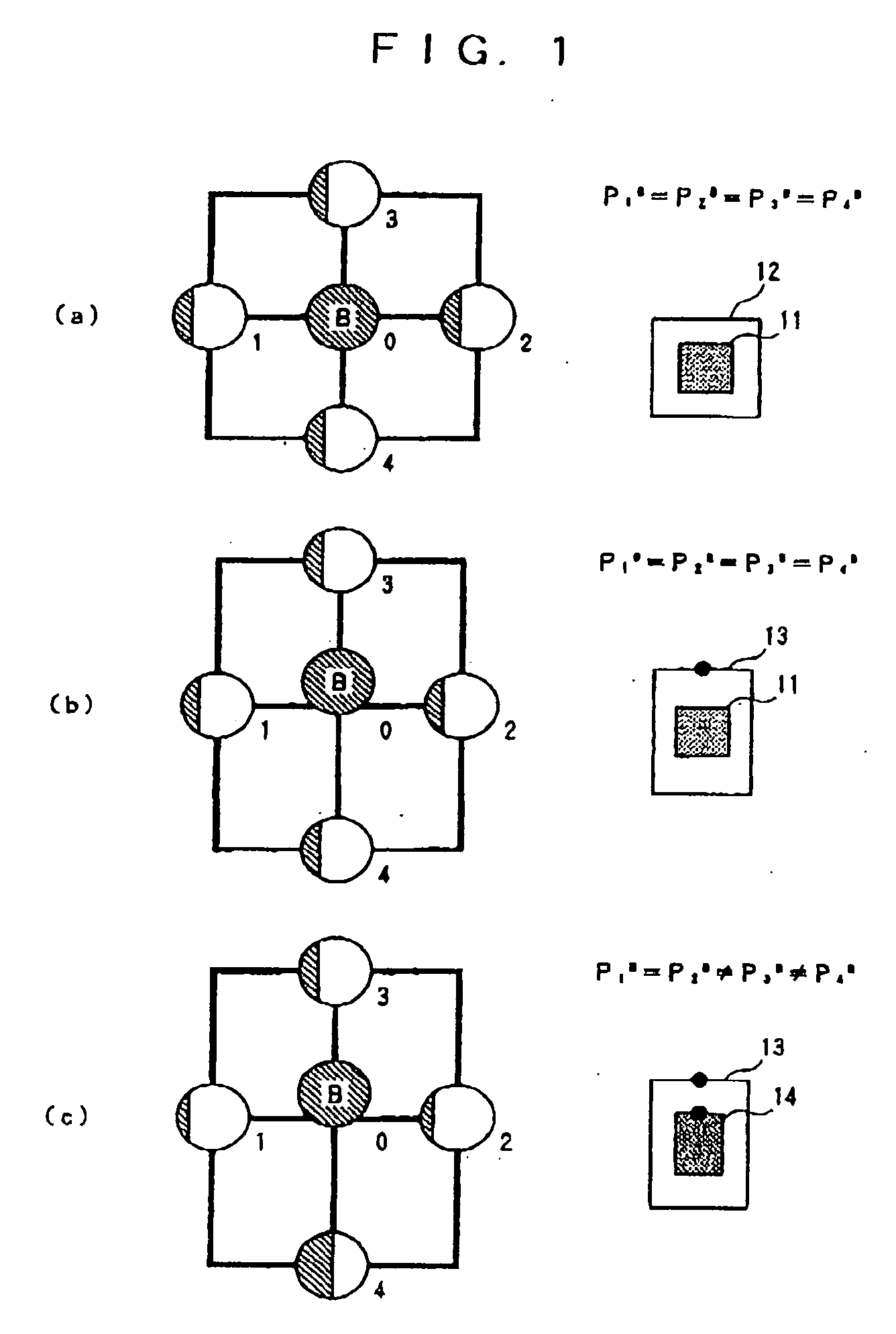

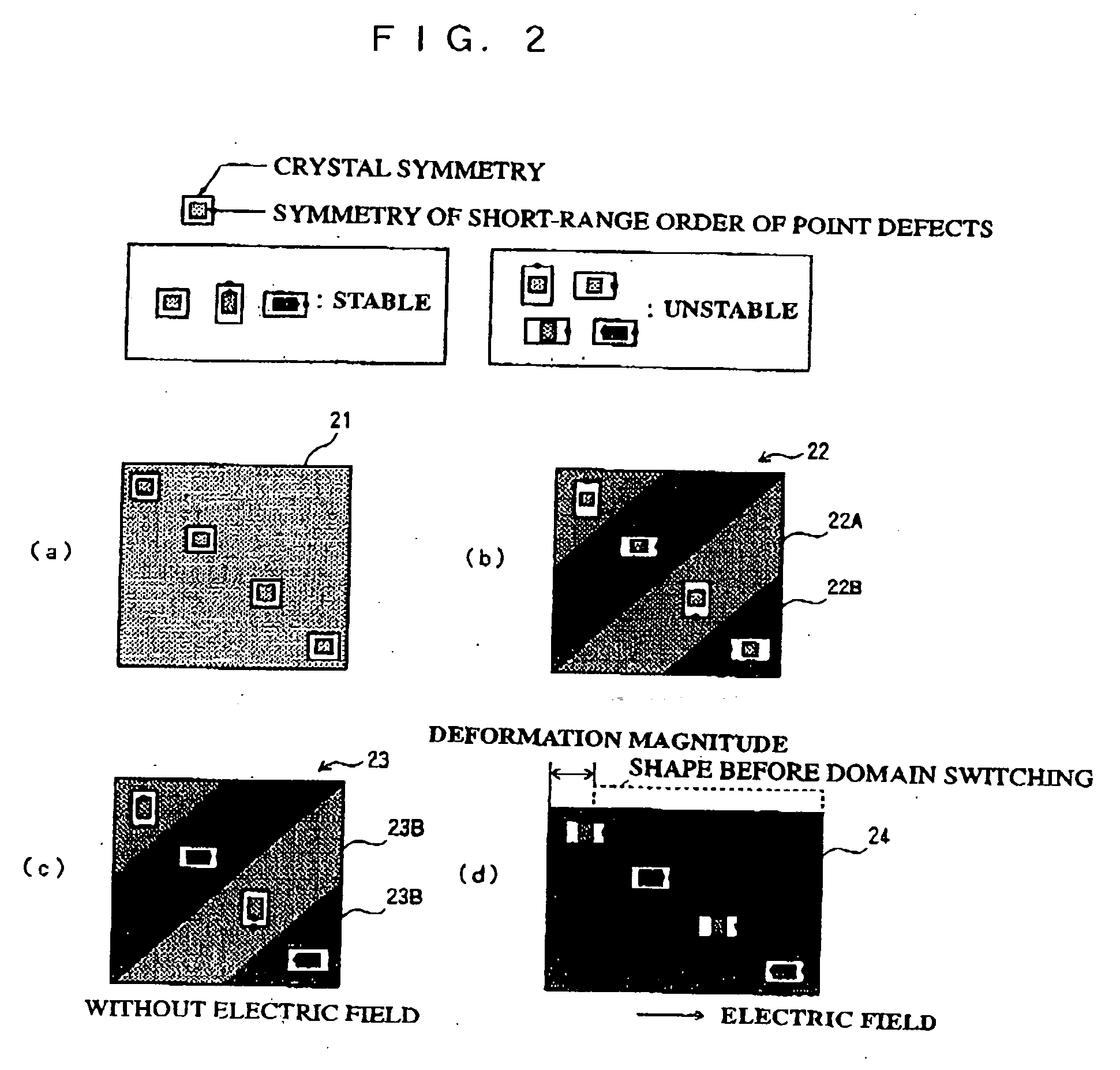

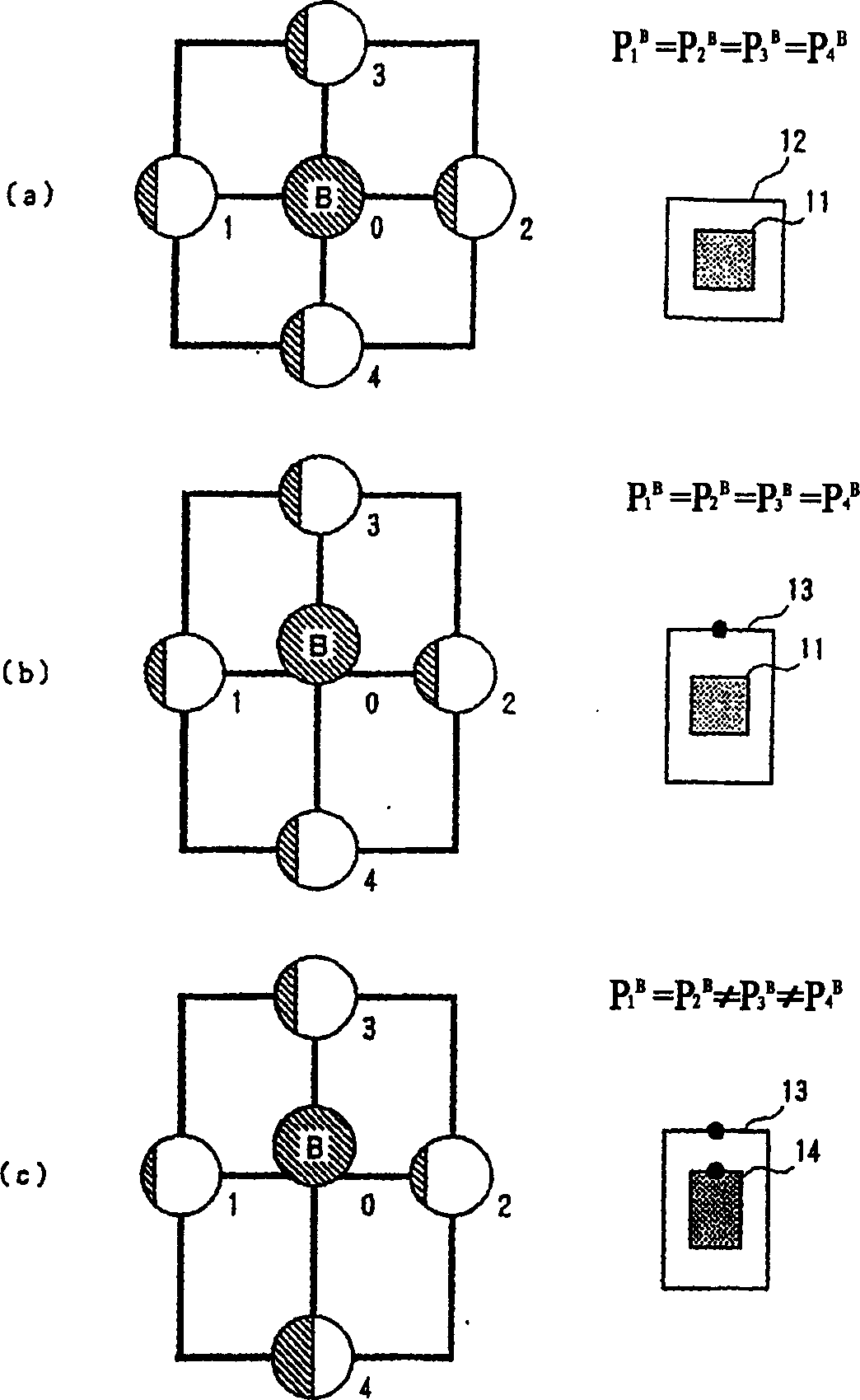

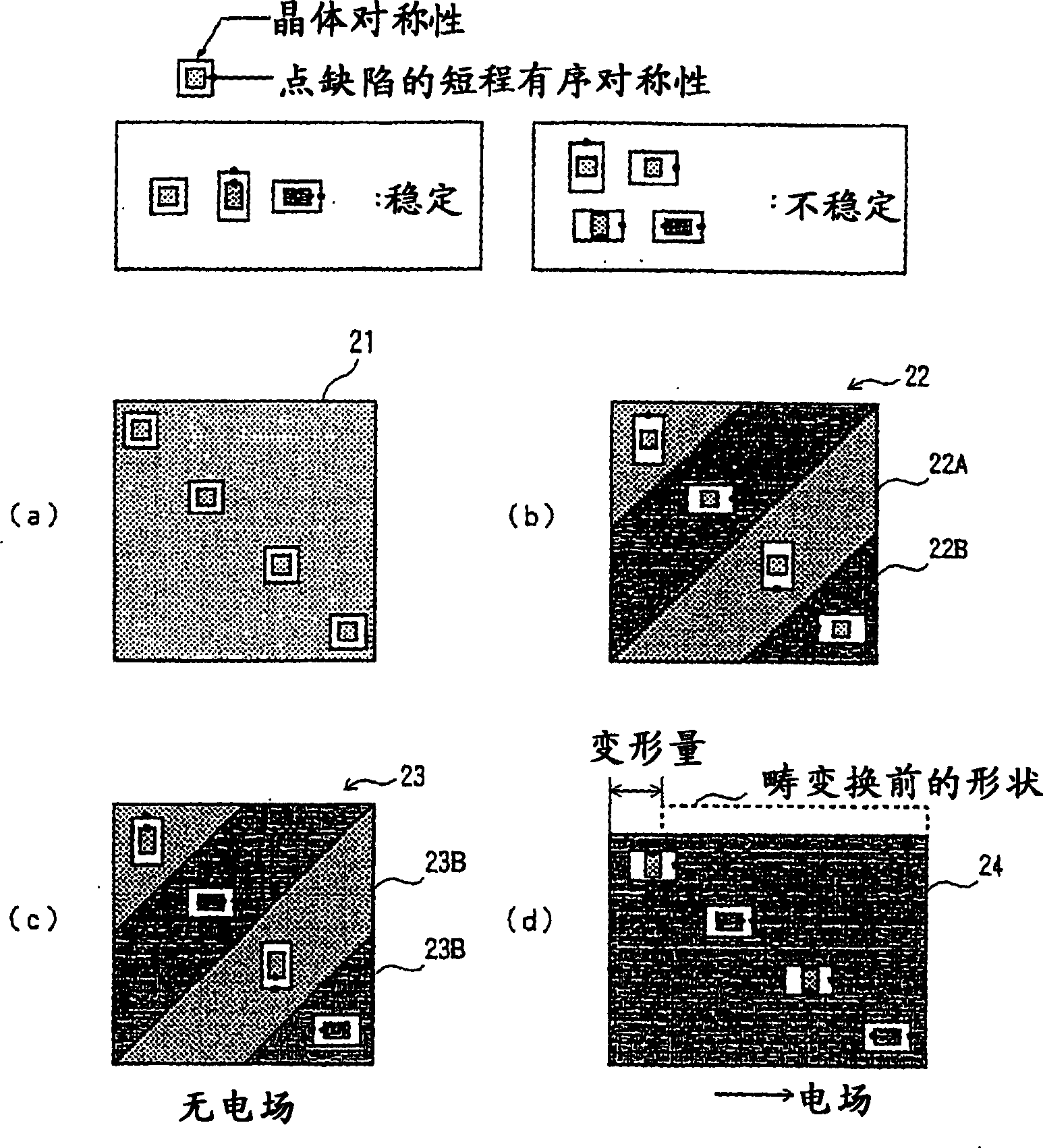

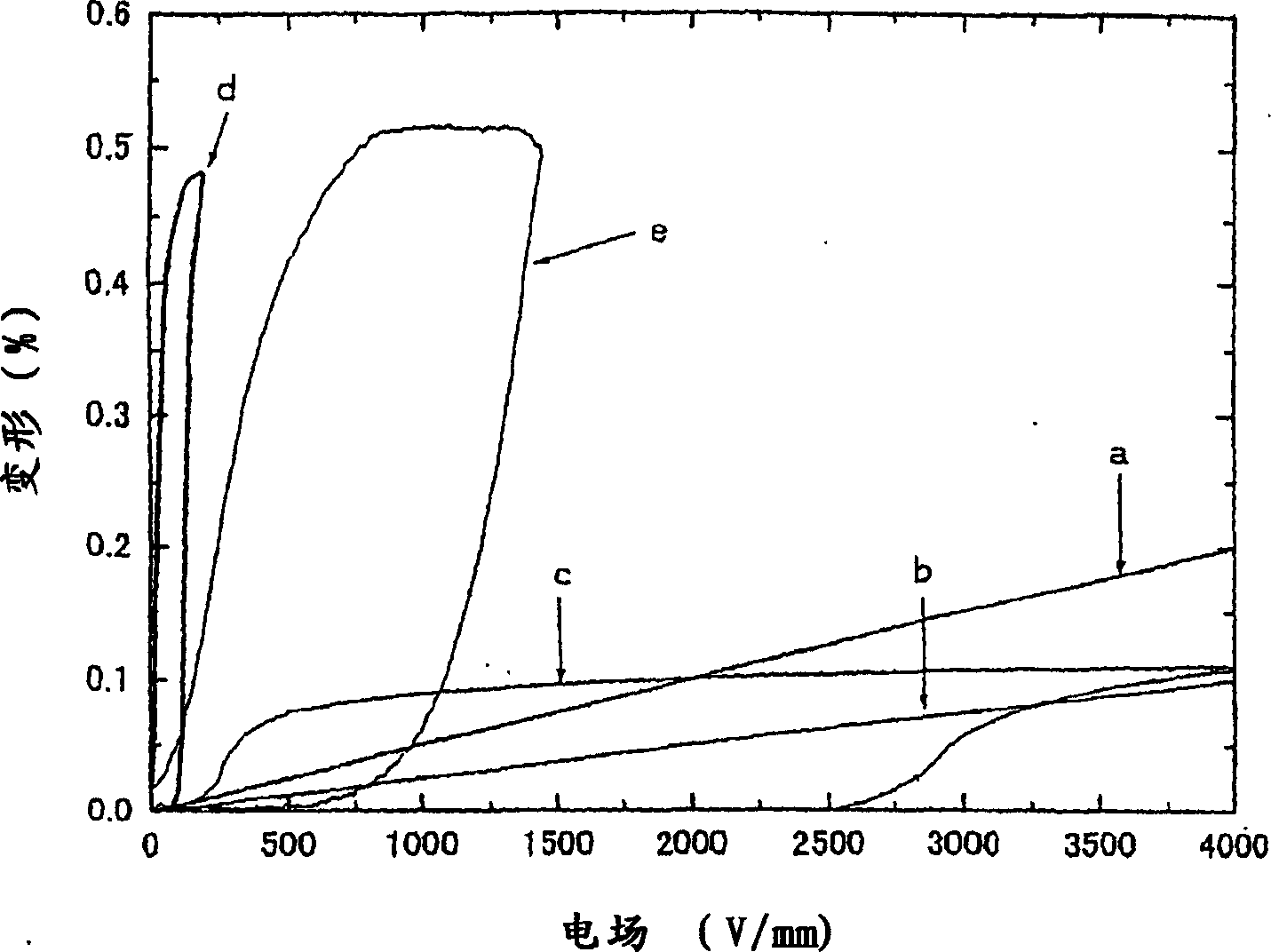

Piezoelectric material, manufacturing method thereof, and non-linear piezoelectric element

InactiveUS20060279178A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesShort range orderLow voltage

A piezoelectric material is provided that has mobile point defects which are arranged so that the short-range order symmetry is matched with the crystal symmetry of the ferroelectric phase. A large non-linear electrostrain effect is obtained by the reversible domain switching under electric field in the ferroelectric material. Thus, it is possible to provide a piezoelectric material and its element having a large and steep deformation even at low voltage. Its manufacturing method is also disclosed.

Owner:JAPAN SCI & TECH CORP +1

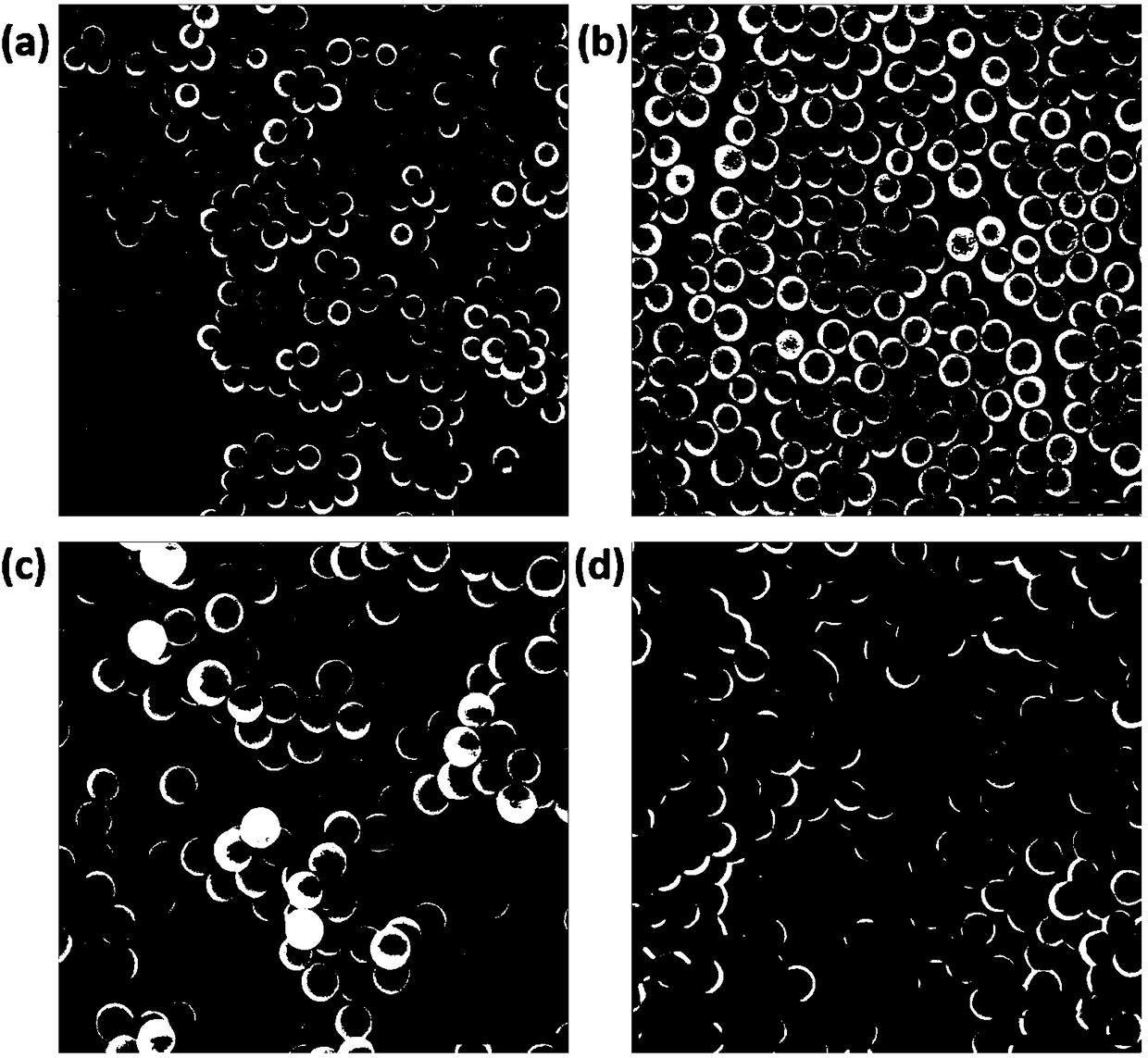

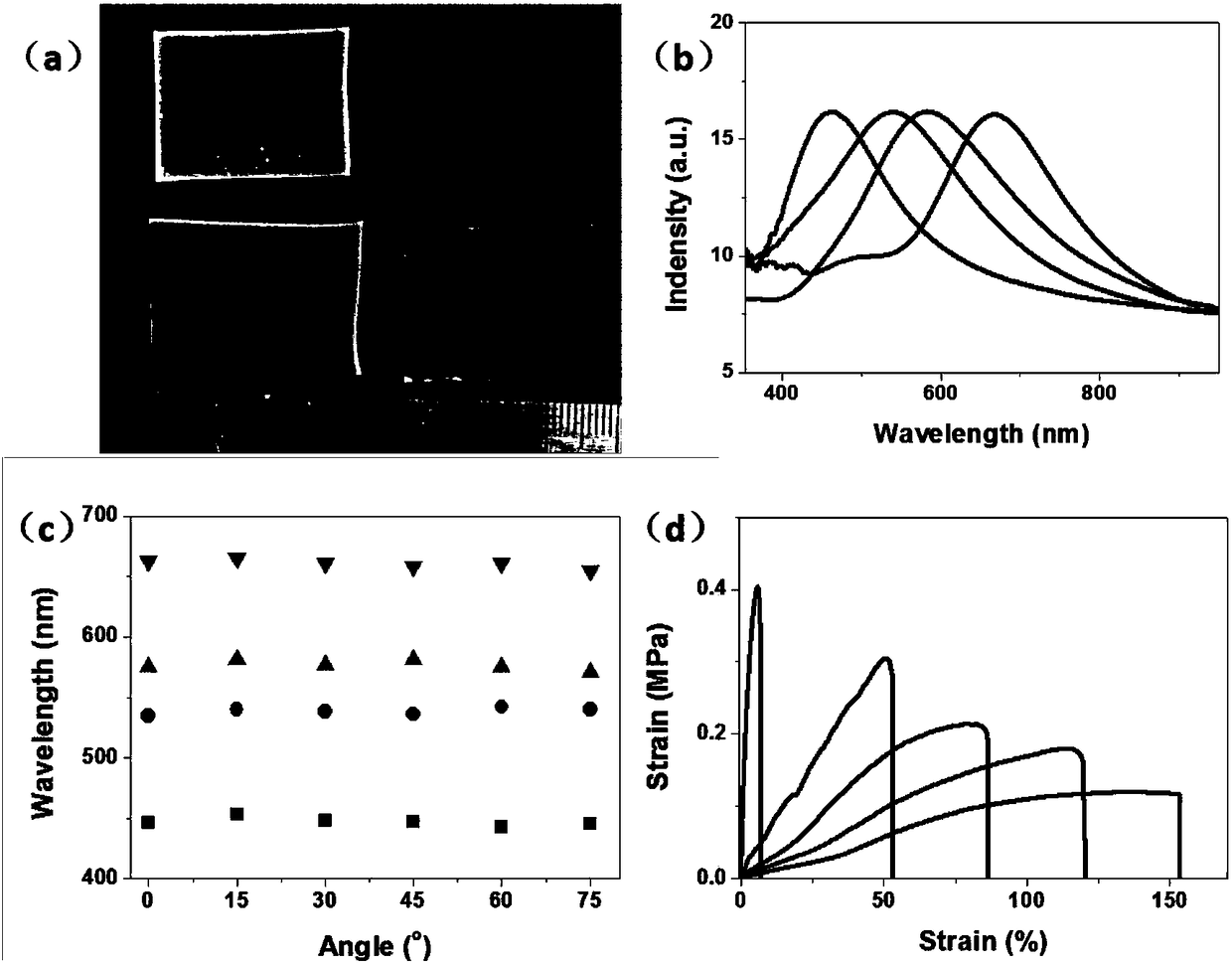

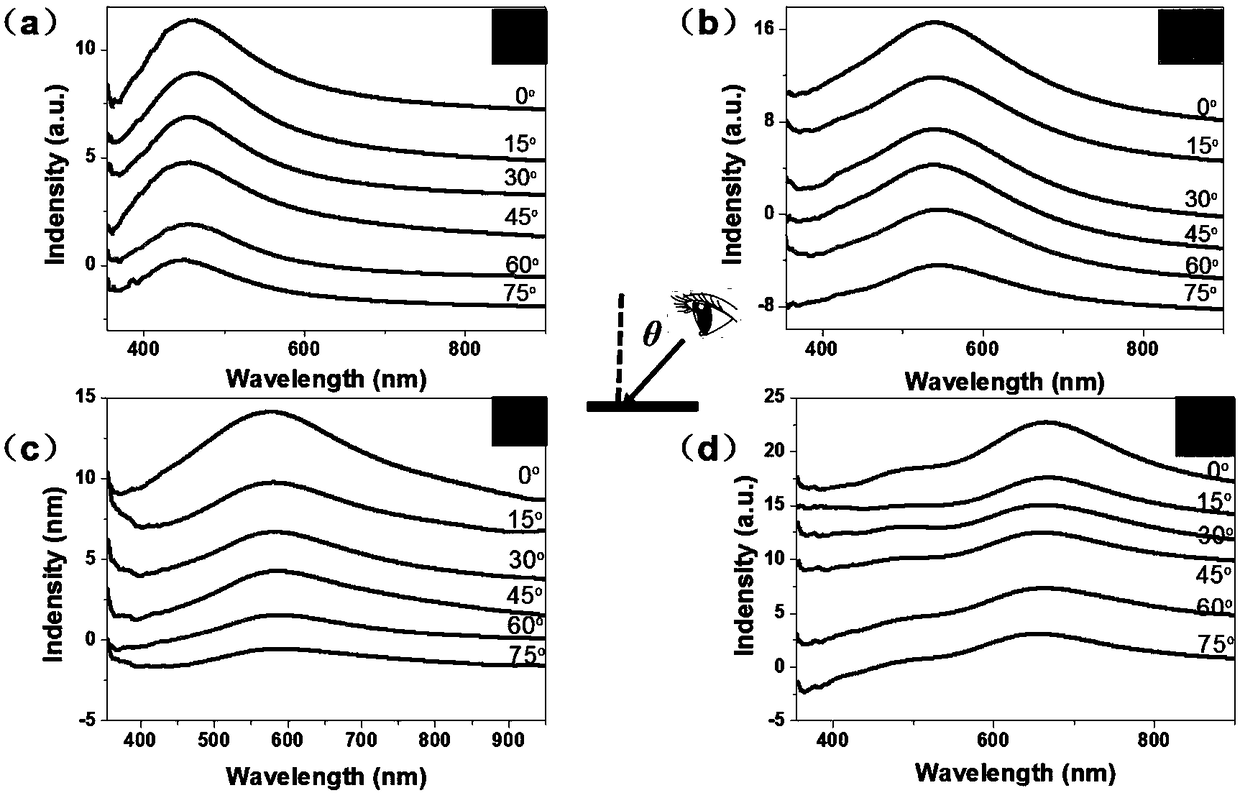

Responsive photonic crystal elastomer membrane material, preparation and application thereof

The invention belongs to the Polymer function material field, and specifically relates to a responsive, self-restorative and display angle dependence-free photonic crystal elastomer membrane material,and preparations and applications thereof; the responsive photonic crystal elastomer membrane material comprises a crosslinking Polymer matrix material, a modified nanoparticle and a light absorptivenano-material, wherein mol ratio of said three materials is (1-200):100:(0-5); the modified nanoparticle and the light absorptive nano-material are arranged and dispersed in the crosslinking Polymermatrix material in a short range order structure; the color of the photonic crystal elastomer membrane material cannot change with the observation angles; the photonic crystal elastomer membrane material is self-restorative under mechanical damages, and has elasticity in a stretching process.

Owner:HUAZHONG UNIV OF SCI & TECH

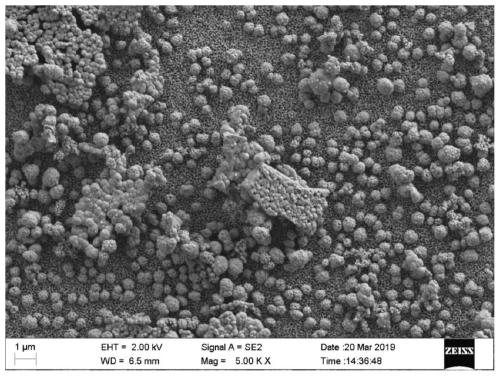

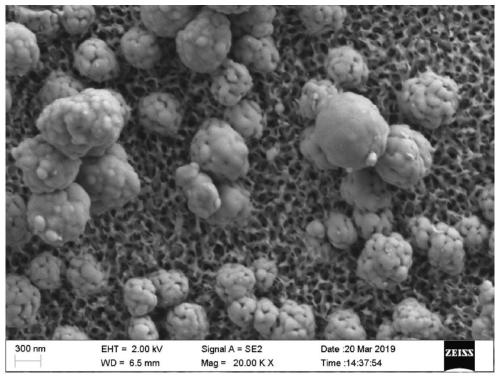

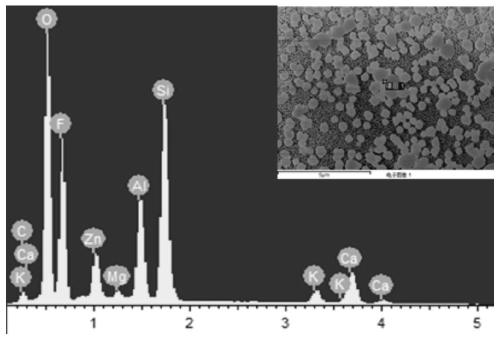

Low-angle-dependence violet zinc-sulfide structural color film and preparing method thereof

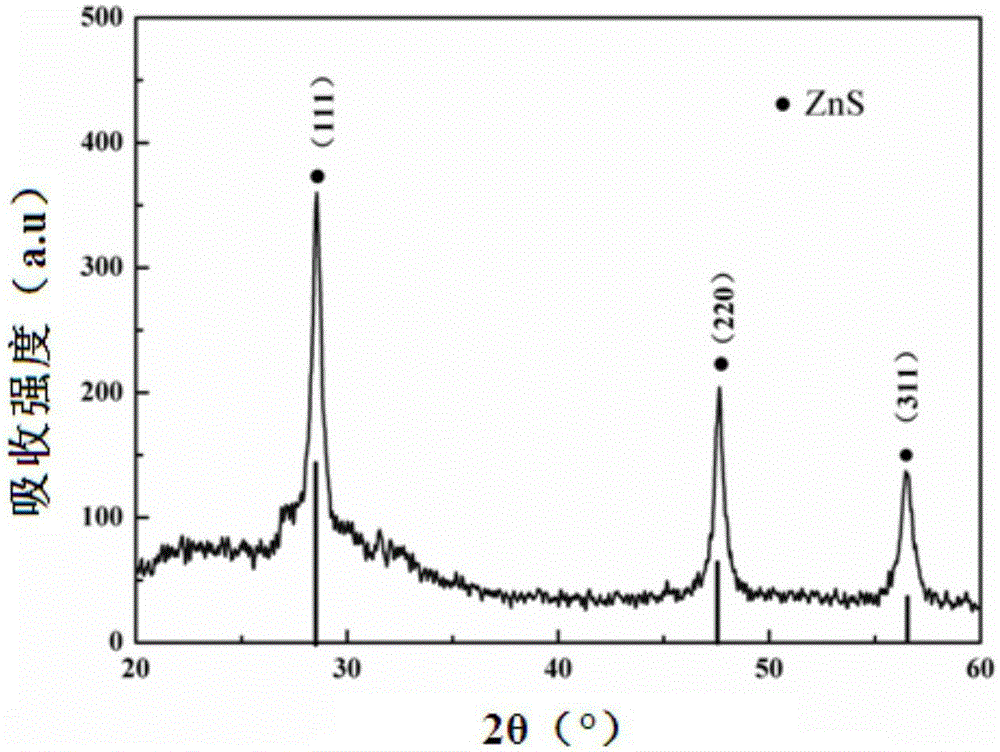

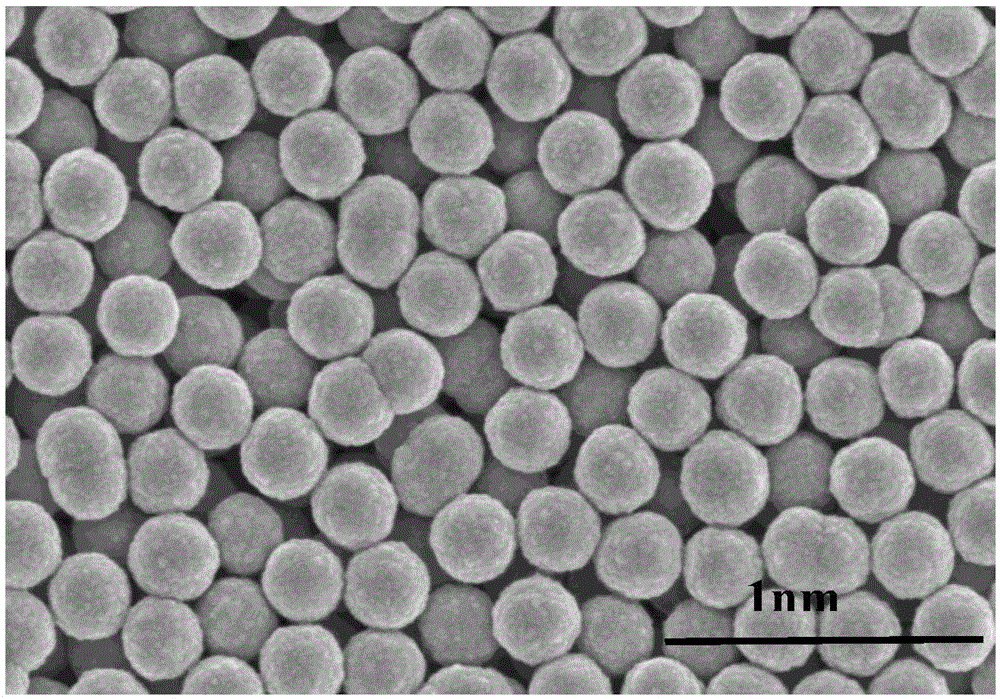

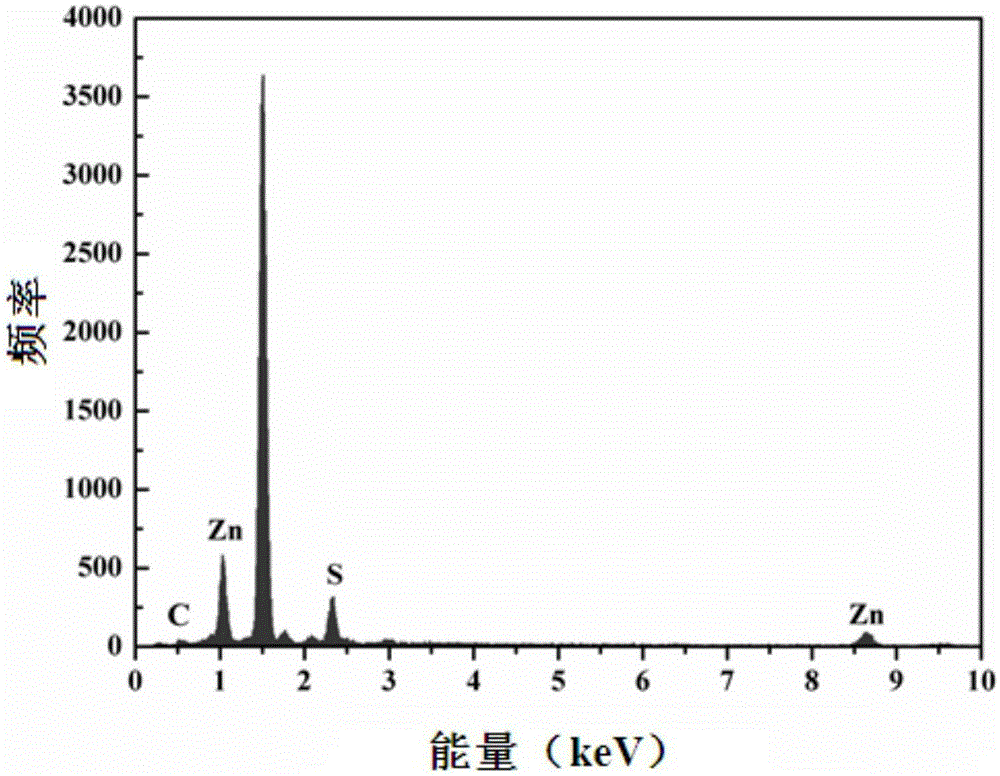

InactiveCN105175015ALow roughness requirementsHigh color saturationAngle dependenceShort range order

The invention discloses a violet zinc-sulfide photonic crystal structural color film and a preparing method thereof, and belongs to the technical field of photonic crystal material preparing. The preparing method includes the steps that zinc sulfide microsphere nano-particles with uniform particle sizes are firstly prepared with a chemical homogeneous precipitation method, a short-range order film is prepared and then roasted in protection atmosphere to enable a trace of organic substances to be carbonized, and therefore the violet structural color film with evenly-distributed carbon black is obtained. The preparing method is simple, repeatability is high, the technical problems that chemical organic pigment is prone to fading and is harmful to the human body are solved, and meanwhile the problems that the requirements of opal structure photonic crystals for a substrate are high, and film coating conditions are strict are solved. The operating process is simple and practicable, large-scale industrial production can be achieved, the preparing method is suitable for building optically-variable-free structural color pigment on the surfaces of various materials, and the broad application prospects are achieved. The prepared violet zinc-sulfide photonic crystal structural color film is even in carbon black distribution, free of angle dependence, good in sphericity degree and uniform in particle size.

Owner:SHAANXI UNIV OF SCI & TECH

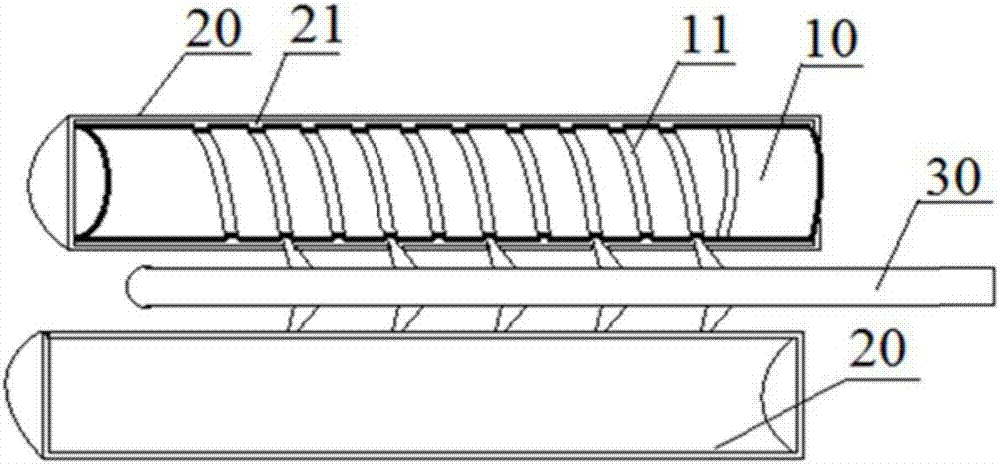

Spring, preparation method thereof and mold assembly used for preparing spring

InactiveCN107541682AEasily brokenFailure to be foundFoundry mouldsFoundry coresShort range orderMultiple use

The invention discloses a spring, a preparation method thereof and a mold assembly used for preparing the spring. The spring is an integrally formed amorphous alloy element. Compared with conventionalcrystal materials, by utilizing structural characteristics of short range order and long range disorder of an amorphous alloy, the spring has the excellent mechanical properties of relatively high elastic limit, high strength, high hardness and the like, and therefore the phenomenon of flabby stiffness is not prone to occurring after the spring is used many times. Meanwhile, by utilizing the characteristics of no typical deformation mechanism such as dislocation slipping and twin crystal of the integrally formed amorphous alloy, the spring is broken rapidly once exceeding use limit so that anoperator can easily find out and timely handle with the situation that the spring fails.

Owner:BYD CO LTD

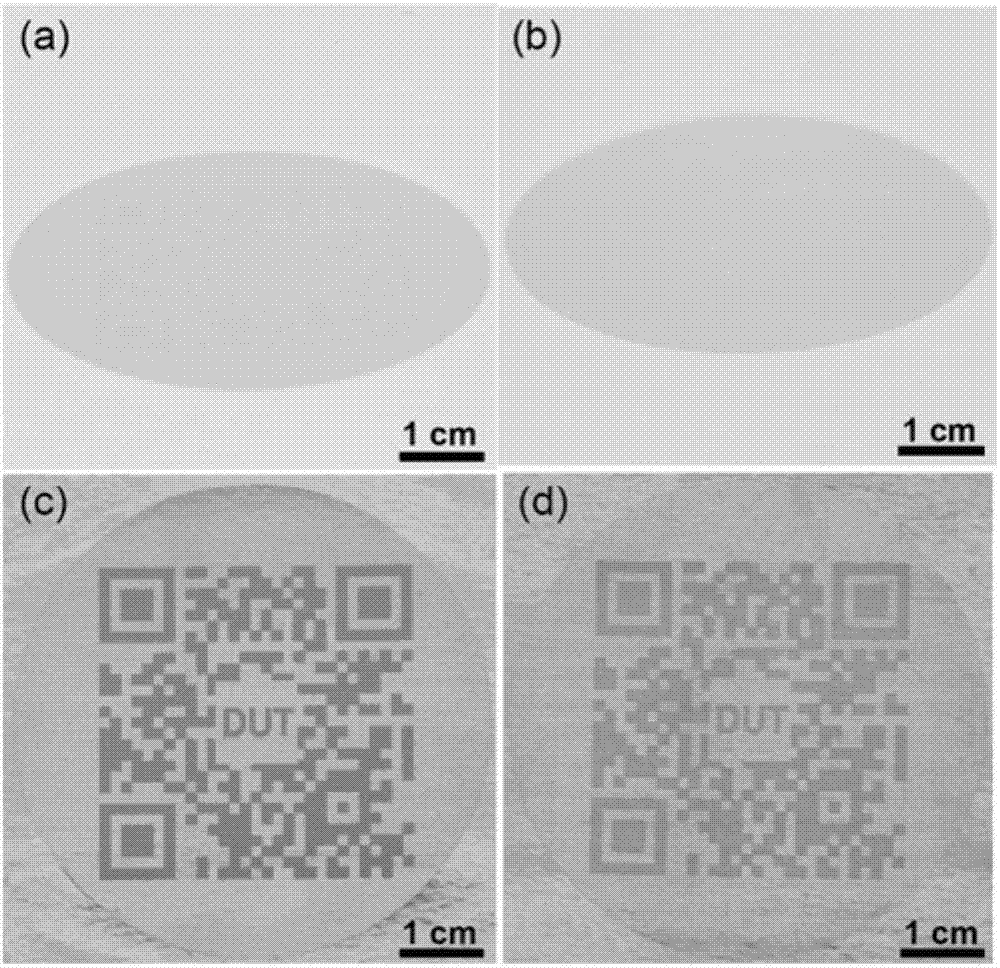

Method for preparing large-area structural coloration pattern by ink-jet printing

The invention discloses a method for preparing a large-area structural coloration pattern by ink-jet printing. According to the method, high-reflective-index monodisperse colloidal microspheres, a high-boiling additive, ethanol, glycerol, a surfactant, a defoamer, adhesive, a pH adjusting agent and deionized water are mixed, and ink obtained through ultrasonic dispersion is injected into an ink cartridge of an ink jet printer for printing. According to the method, the high-reflective-index monodisperse colloidal microspheres are evenly deposited on paper through a common ink jet printer, and a short-range order and long-range disordered microstructure is obtained; and due to the mutual effect of the nanometer microspheres with different grain diameters and light, the structural color pattern with different colors can be obtained, the preparation of the large-area structural color pattern is achieved, the method is high in expansibility, and the method has the wide application prospects on the aspects of the display, security and the like.

Owner:DALIAN UNIV OF TECH

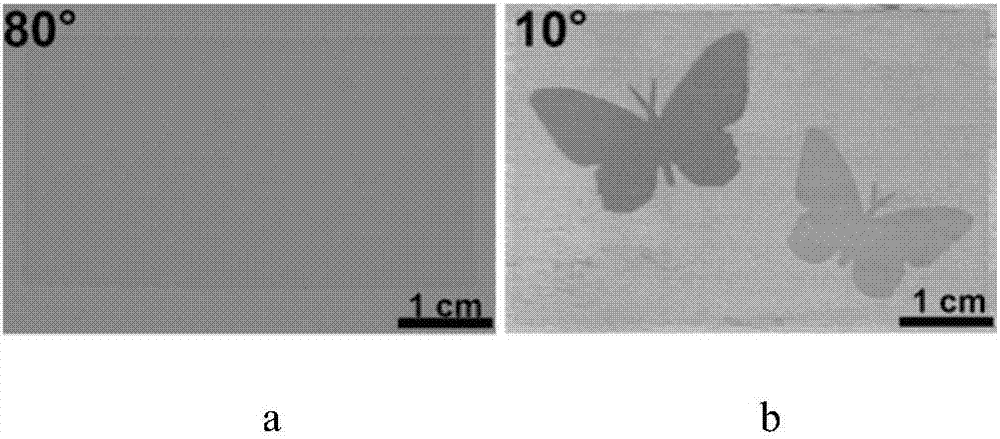

Anti-counterfeiting method based on structural color change

InactiveCN107020853AAchieve hiddenRealize the display effectPattern printingShort range orderMicrosphere

The invention discloses an anti-counterfeiting method based on structural color brightness change. Dispersion liquid containing monodisperse nano-microspheres is printed on paper by utilizing an ink-jet printer, and the nano-microspheres are arrayed and assembled on the paper to obtain short-range order. According to a microstructure of long-range disorder, due to the interaction effect of the structure and light, the bright structural color can be observed, the display of patterns is realized, an observation angle is changed, the brightness of the structural color is reduced, and patterns or quick response matrix codes are hidden. The method is simple and convenient, external stimulation is not needed, and anti-counterfeiting can be quickly realized.

Owner:DALIAN UNIV OF TECH

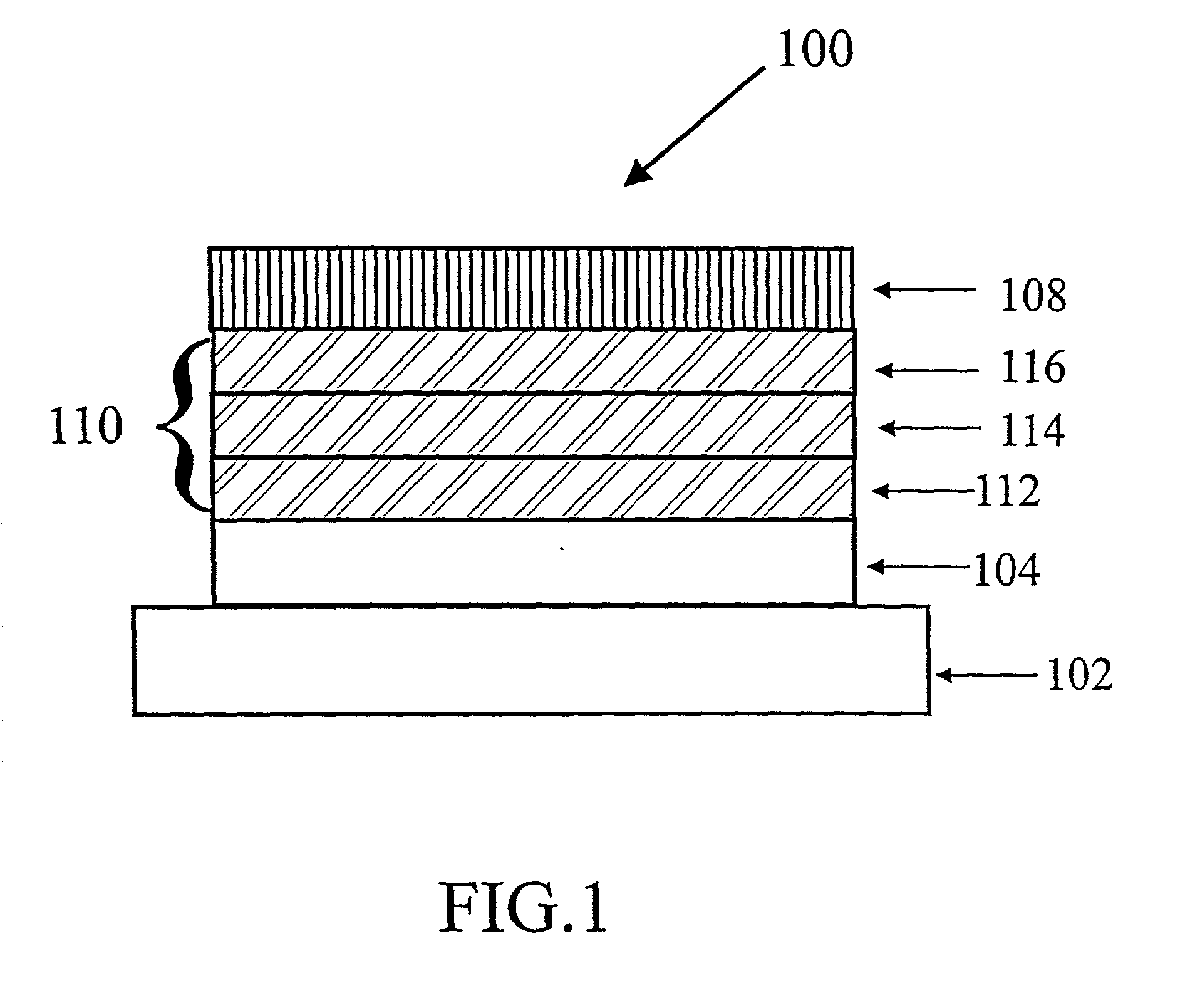

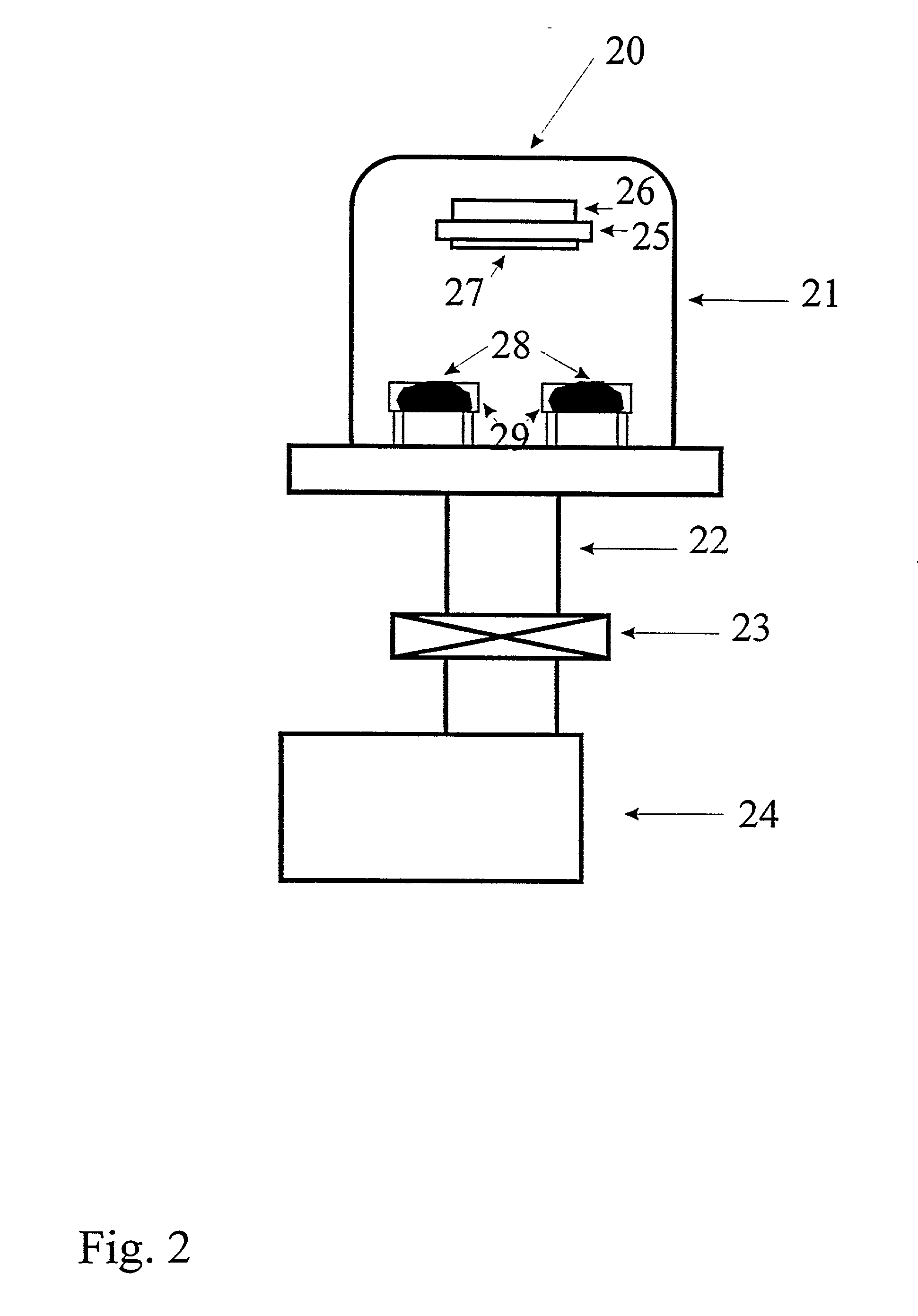

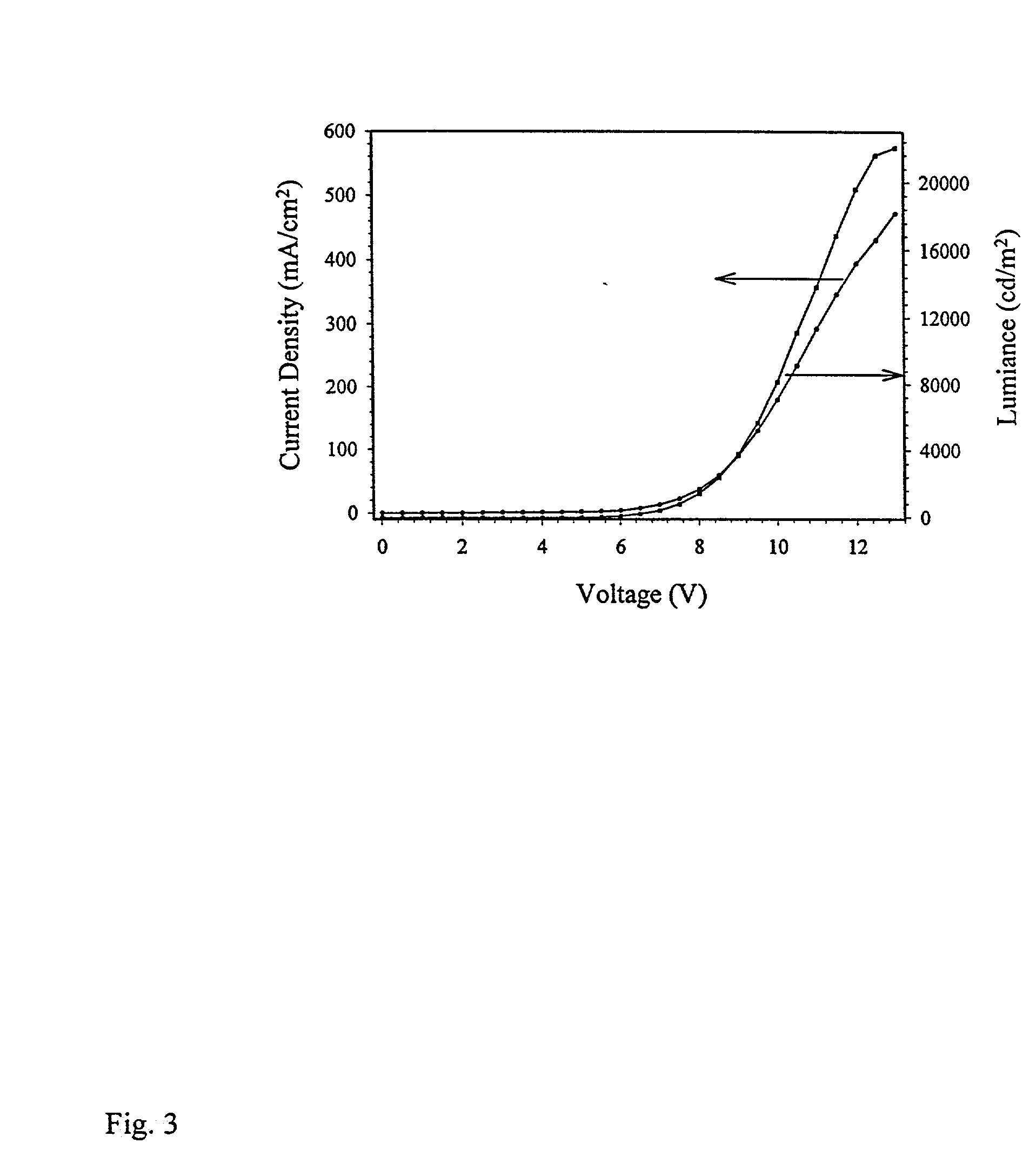

Organic electroluminescent devices with organic layers deposited at elevated substrate temperatures

InactiveUS20020182307A1Improve performanceShort range orderDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmShort range order

An organic light-emitting diode has been disclosed, in which crystalline organic films were utilized to increase device stability upon operation. Correspondingly, a novel method has been developed to improve device performance through depositing organic electroluminescent materials at elevated substrate temperatures. The improvements are attributed to the formation of crystalline films or amorphous films with a better short range order.

Owner:CITYU RES

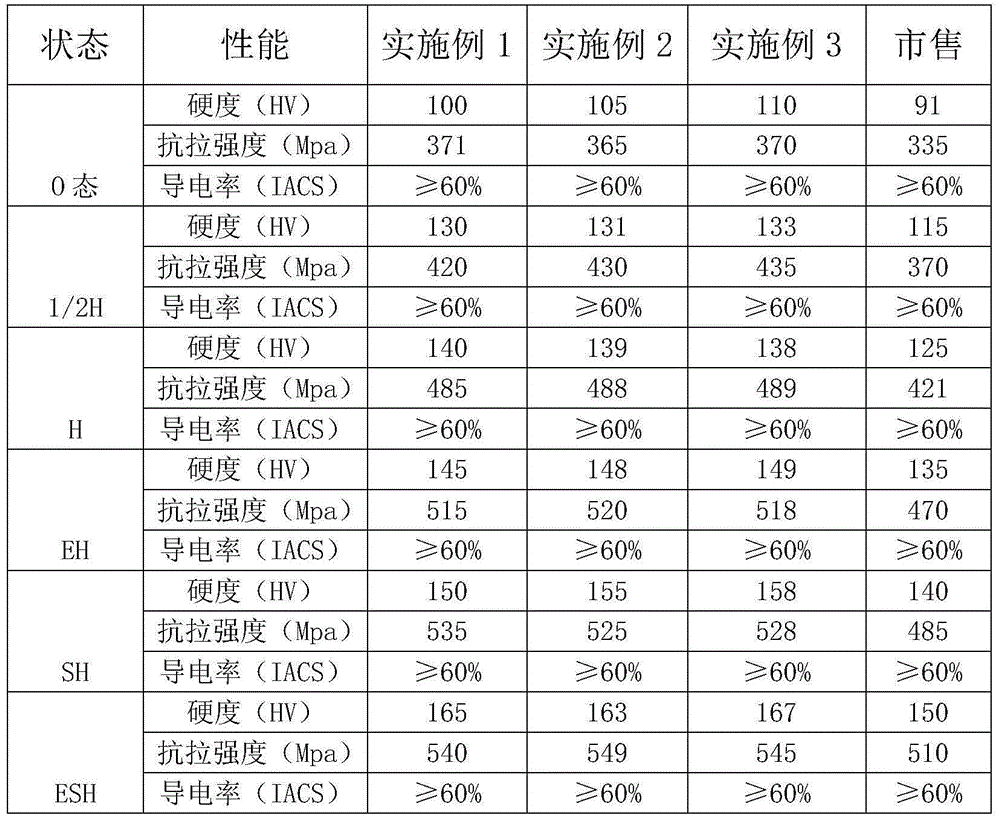

High-strength copper-iron-phosphorus alloy and production method thereof

InactiveCN105220007AHigh hardnessSolid solution strengtheningShort range orderSolid solution strengthening

The invention discloses a high-strength copper-iron-phosphorus alloy and a production method thereof. The formula of the copper-iron-phosphorus alloy comprises the following elements in percentage: 2.1-2.6% of Fe, 0.015-0.15% of P, 0.05-0.20% of Zn, Pb of which the percentage is smaller than or equal to 0.03%, 0.01-0.1% of Ni, 0.01-0.1% of Sn, and the balance being Cu. Compared with the prior art, according to the copper-iron-phosphorus alloy disclosed by the invention, trace amounts of Sn elements and Ni elements, which play a solution strengthening role in the alloy, are added in the raw material formula, so that the hardness of the materials under various states can be improved by nearly 5-10%. During the production of the copper-iron-phosphorus alloy disclosed by the invention, the condition of low-temperature annealing is adopted, so that on one hand, atoms of solution strengthening elements Sn and Ni are clustered at the periphery of a dislocation generated after being processed and hardened so as to perform dislocation pinning, and the strength of the alloy is improved; on the other hand, through low-temperature annealing, a short-range ordered structure formed in an organization and the dislocation perform interaction, so that the alloy is hardened.

Owner:安徽鑫科铜业有限公司

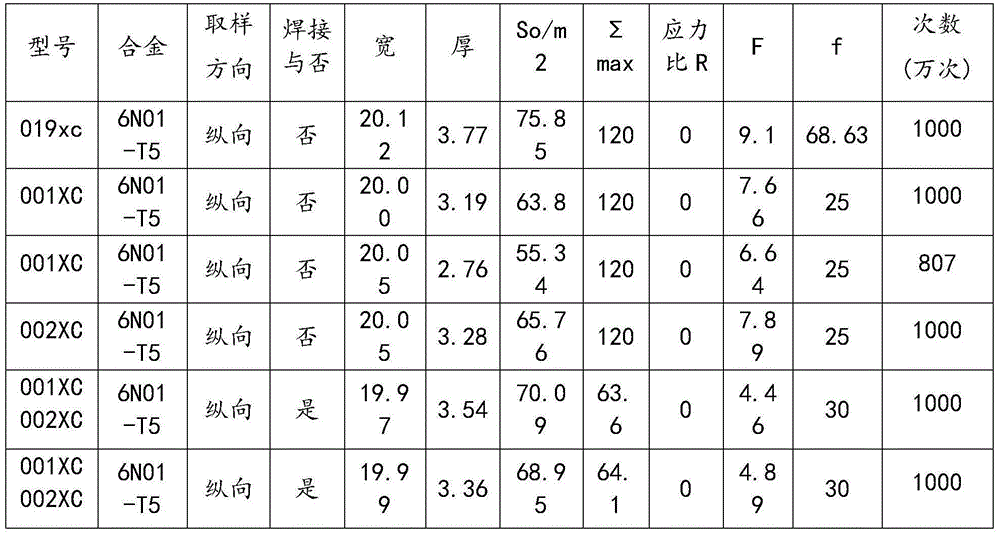

Manufacturing method of aluminum alloy for railway vehicle body

The invention relates to a manufacturing method of aluminum alloy for a railway vehicle body. The manufacturing method of the aluminum alloy sequentially includes the steps of prepurging, smelting, primary refining, secondary refining, standing, casting and homogenizing, and further includes the superheating treatment process and the quenching process. After primary refining, aluminum alloy melt is subjected to superheating treatment and quenching and then subjected to secondary refining. By performing superheating treatment on the aluminum alloy melt, the melt structure is switched into a disordered state from a short-range ordered state similar to a solid phase; then, by performing quenching rapidly, molten aluminum alloy is rapidly cooled to a casting temperature without loosing effects. In this way, the number of active crystal nucleuses generated by non-spontaneous crystallization of the molten aluminum alloy is reduced; although spontaneous crystal nucleuses are small, the structure of a cast ingot can be better refined, and a more compact cast ingot structure can be obtained. The performance of the aluminum profile produced by the cast ingot in the method is better than that of aluminum profiles produced by cast ingots in traditional methods.

Owner:龙口市丛林铝材有限公司

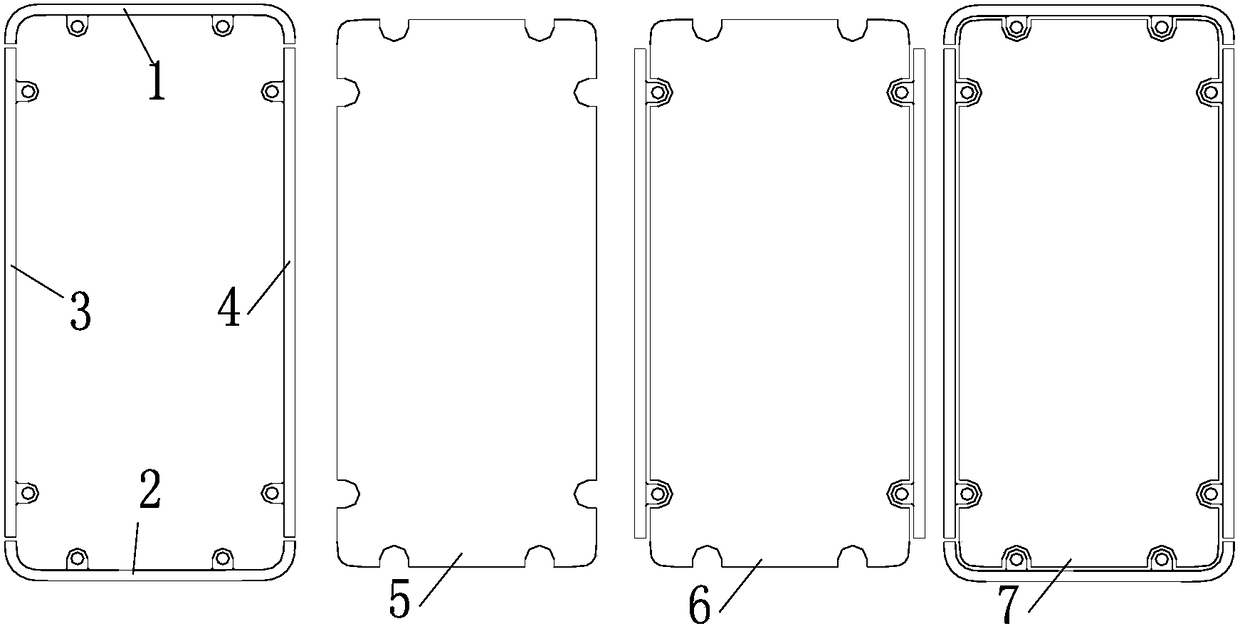

Process for manufacturing middle frame of mobile phone by liquid metal die-casting molding technology

The invention discloses a process for manufacturing a middle frame of a mobile phone by liquid metal die-casting molding technology. The appearance structure of the middle frame of the mobile phone ismade of a bulk amorphous alloy, namely, liquid metal. The glass forming ability (GFA) of the bulk amorphous alloy is more than 1 mm during copper mold pouring, the solid microstructure of the bulk amorphous alloy is of a short-range ordered and long-range disordered arrangement structure, and the solid microstructure is similar to microstructure in liquid and similar to the microstructure of theglass, so the bulk amorphous alloy is further called liquid metal or metallic glass. The process for manufacturing the middle frame of the mobile phone by the liquid metal die-casting molding technology comprises main technological processes of full vacuum die casting of the liquid metal, machining treatment 1, combination of aluminum / magnesium middle plate, machining treatment 2, NMT, machining treatment 3, polishing, and PVD. According to the process for manufacturing the middle frame of the mobile phone by the liquid metal die-casting molding technology, the middle frame of the liquid metalmobile phone has high strength, high hardness, high elasticity, abrasion resistance, corrosion resistance, almost no plastic deformation, low thermal conductivity and attractive and high-grade appearance, and the production of high performance, high efficiency and low cost is achieved.

Owner:上海驰声新材料有限公司

Ceramic blank crystalline glaze and preparation process thereof

The invention provides a ceramic blank crystalline glaze, and discloses a preparation process capable of treating at medium temperature. The ceramic blank crystalline glaze is prepared only by takingfour raw materials of glass powder, zinc oxide, potassium feldspar and calcite to be matched in proportion, glazing a ceramic blank with a high iron content and firing. Due to the abandonment of quartz and clay and combination of a slow cooling heat preservation firing system, long-range disorder and short-range order amorphous photonic crystal structures are easy to form in a glaze glass phase. The phases in the glaze layer generate a large amount of metastable micro-nano spherical particles and unstable spongy structures, and physical coloring is generated, so that the pottery embryo glaze surface presents a beautiful blue, purple or blue-purple double-color bottom glaze effect. Through selective enrichment, doping or substitution of colored ions in zinc silicate crystals, crystal flowers exhibit cyan and bright gold and other prominent effects. The ceramic blank crystalline glaze is fired at the highest firing temperature of 1200-1230 DEG C. The crystal flowers have obvious boundaries, and are radial inside, the diameter can reach 3-4 cm, and multi-color matching is extremely beautiful.

Owner:WUXI INST OF ARTS & TECH

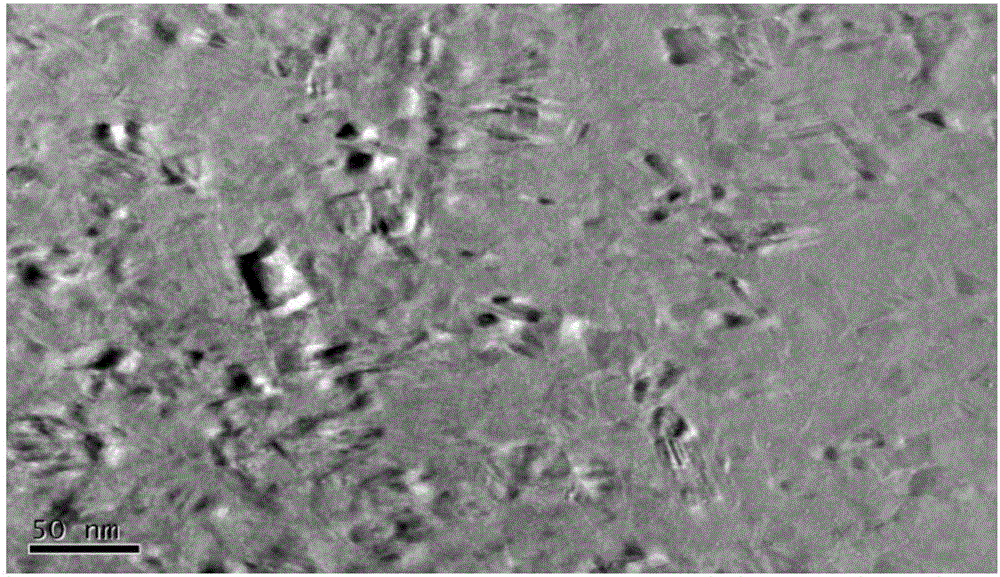

Fe-Ni magnetically soft alloy with short-range order structure and Fe-Ni magnetically soft alloy part

ActiveCN106756579ANo need to change ingredientsImprove magnetismTransportation and packagingMetal-working apparatusRare-earth elementShort range order

The invention discloses a Fe-Ni magnetically soft alloy with a short-range order structure and a Fe-Ni magnetically soft alloy part. The Fe-Ni magnetically soft alloy is prepared by mixing Fe-50%Ni coarse powder with the average particle size ranging from 20 microns to 50 microns and Fe-50%Ni fine powder with the average particle size ranging from 1 micron to 5 microns according to the mass ratio of 7:3; and due to the adding of the fine powder, an L10 phase of the short-range order can be better formed in the alloy, and therefore the saturation magnetic induction density of the material is improved, the saturation magnetic induction density of the material can reach 1.55 T to 1.57 T to the maximum degree, and the magnetic performance is obviously improved. A method is easy to operate, components of the alloy do not need to be changed, the cost is low, and the technology is simple. Heat treatment heat preservation is conducted on the magnetically soft alloy material after forming, and then fast cooling is conducted, so that the grain size can be controlled, stress can be eliminated at the same time, the magnetic performance of the magnetically soft alloy is easily and conveniently improved, expensive rare earth elements do not need to be added, and the Fe-Ni magnetically soft alloy part provided with nanoscale L10 phase particles and having good magnetic performance is obtained.

Owner:HUNAN HENGJI POWDER TECH

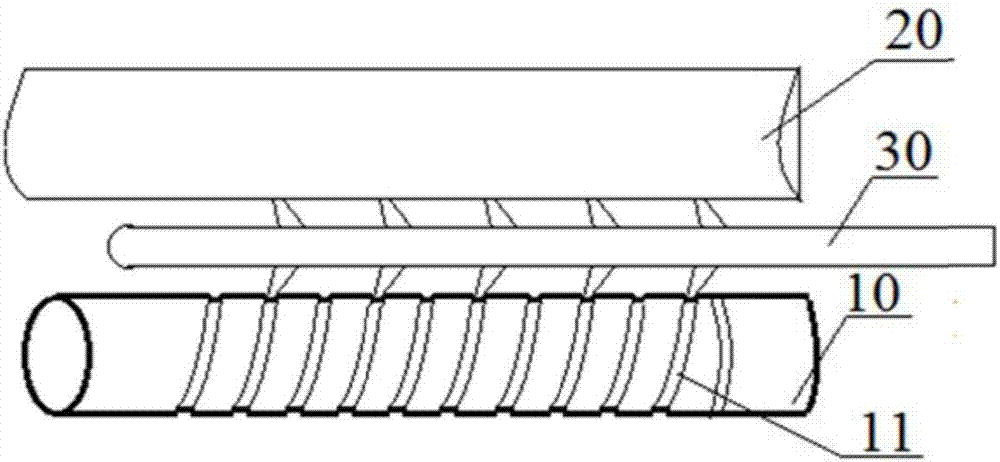

Short-range repositioning system for unmanned trains

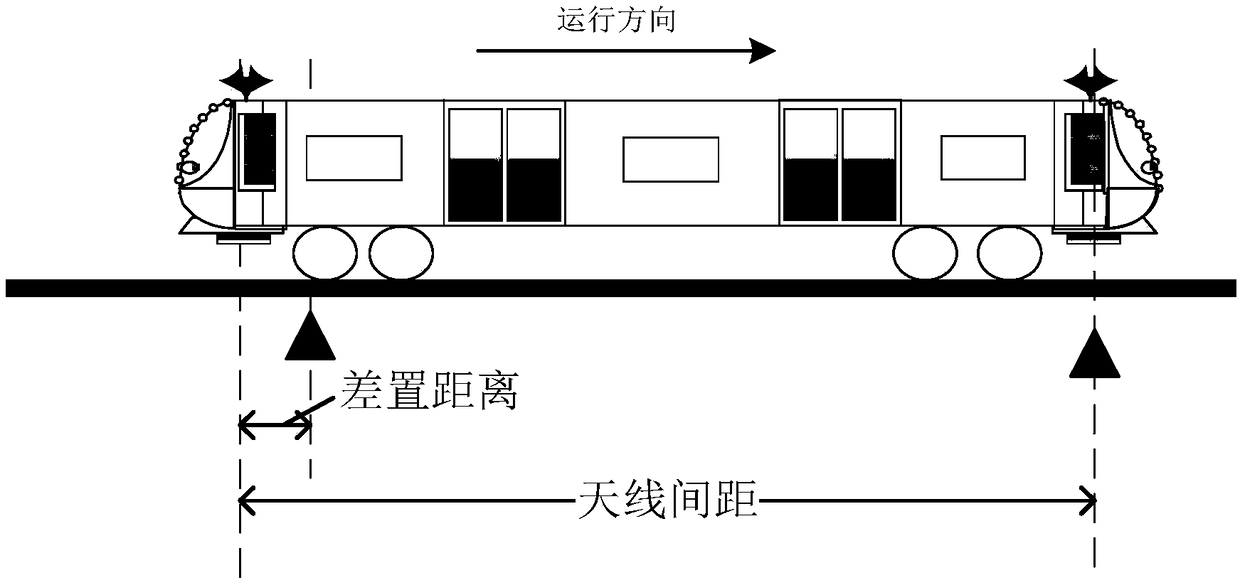

The invention discloses a short-distance repositioning system of an unmanned train. The system includes a plurality of beacons arranged along the extending direction of the ground track and two beaconreaders arranged on the train, the adjacent two beacons have a difference distance and the difference distance needs to be greater than twice the distance of the beacon reading sidelobe plus the train passing in the reading information delay time. The double beacon differential arrangement, and a short-range positioning technology scheme in which the double beacon reader reads the beacons in short-range order are adopted, so that the vehicle-mounted equipment can continuously read two beacons in a short range, thereby completing positioning.

Owner:浙江众合科技股份有限公司

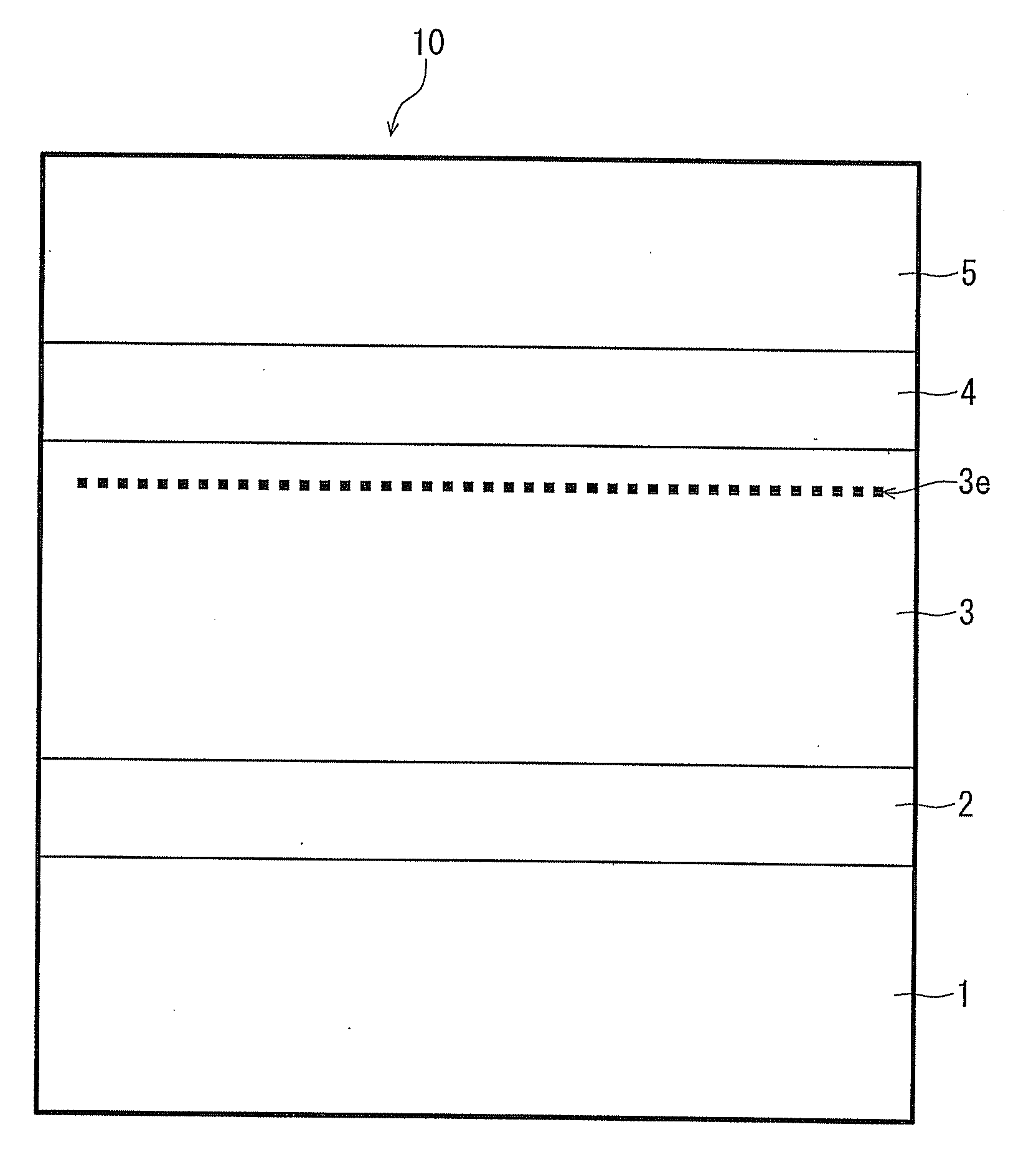

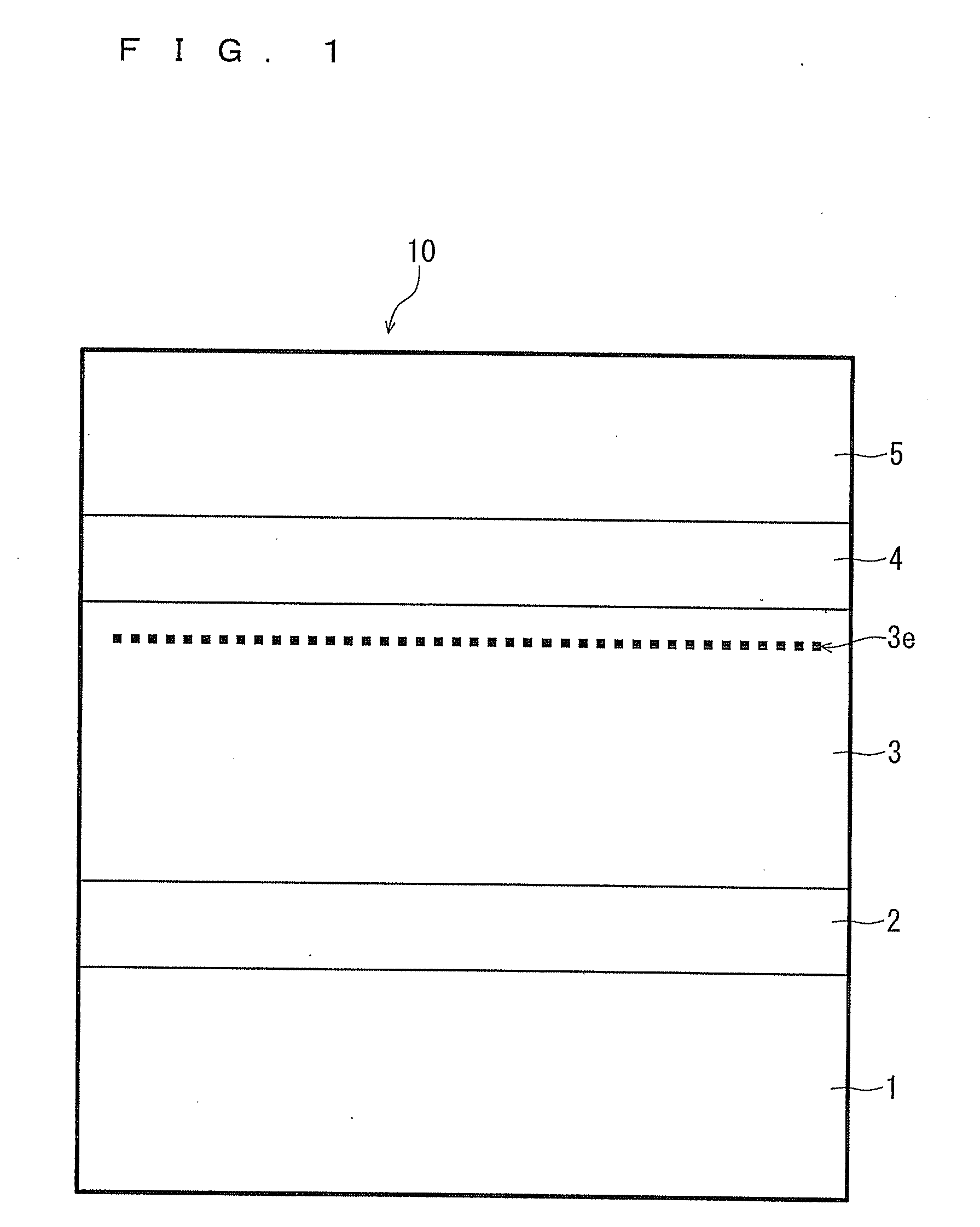

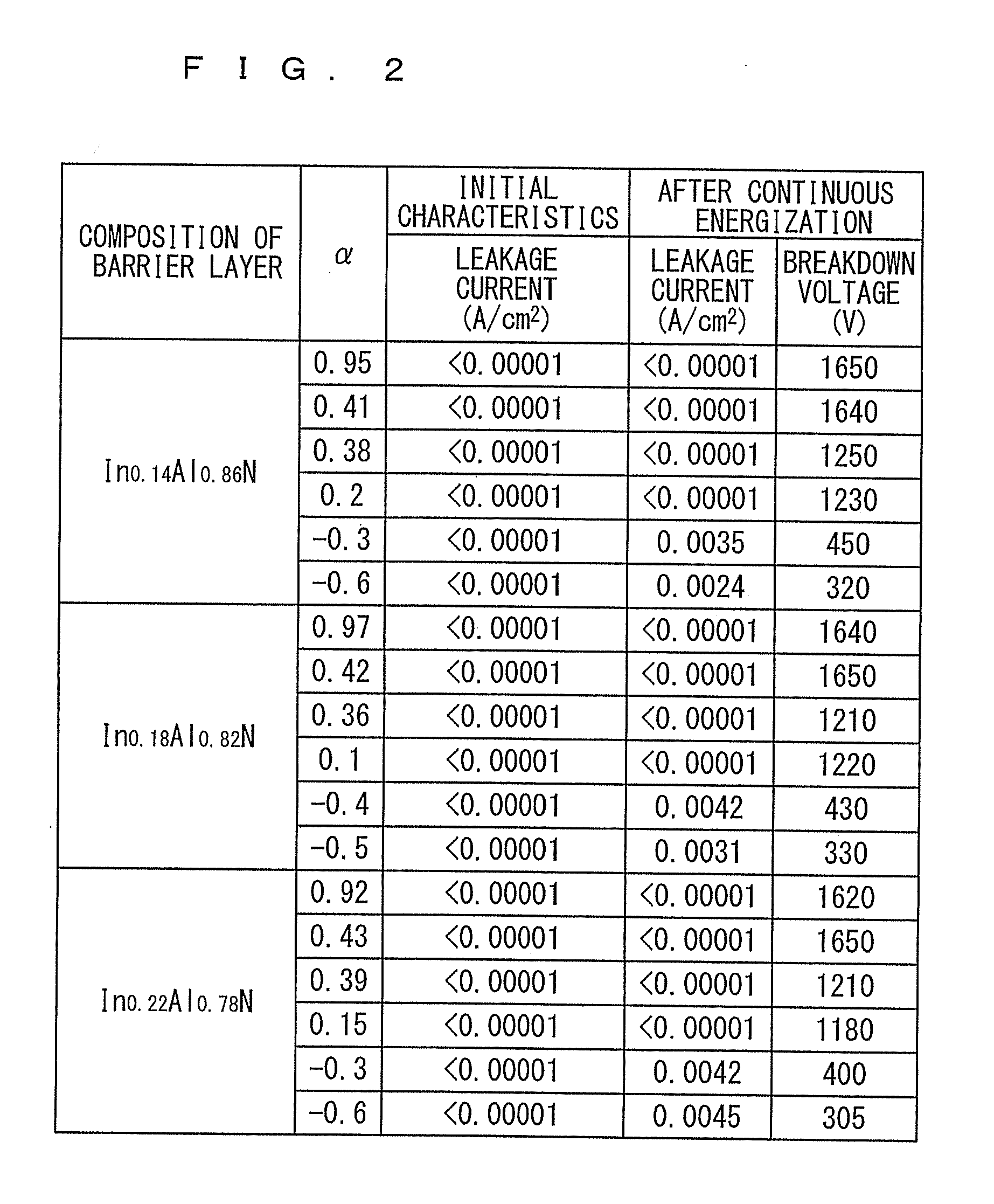

Epitaxial substrate for semiconductor device, schottky junction structure, and leakage current suppression method for schottky junction structure

ActiveUS20110062493A1Improve reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesShort range orderCrystal plane

Provided is an epitaxial substrate for semiconductor device that is capable of achieving a semiconductor device having high reliability in reverse characteristics of schottky junction. An epitaxial substrate for semiconductor device obtained by forming, on a base substrate, a group of group III nitride layers by lamination such that a (0001) crystal plane of each layer is approximately parallel to a substrate surface includes: a channel layer formed of a first group III nitride having a composition of Inx1Aly1Gaz1N (x1+y1+z1=1, z1>0); and a barrier layer formed of a second group III nitride having a composition of Inx2Aly2N (x2+y2=1, x2>0, y2>0), wherein the second group III nitride is a short-range-ordered mixed crystal having a short-range order parameter α satisfying a range where 0≦α≦1.

Owner:NGK INSULATORS LTD

Piezoelectric material, manufacturing method thereof, and non-linear piezoelectric element

InactiveCN1788365APiezoelectric/electrostrictive/magnetostrictive devicesShort range orderLow voltage

The present invention provides a piezoelectric material, its element, and its manufacturing method. It is a piezoelectric material having movable point defects arranged in such a way that its short-range order symmetry coincides with the crystal symmetry of the ferroelectric phase, using the ferroelectric The reversible switching under the electric field of the domains in the material achieves a large nonlinear piezoelectric effect, and the displacement is large and sharp even at low voltage.

Owner:JAPAN SCI & TECH CORP +1

Palladium molybdenum precision resistance alloy and preparing method thereof

ActiveCN110453105AReduce oxidationReduce volatilityFurnace typesHeat treatment furnacesShort range orderHeat treated

The invention discloses a palladium molybdenum precision resistance alloy and a preparing method thereof. Chemical components of the alloy comprise, by mass, 30-40% of Mo, 0.5-6% of M (at least one ofZr, Cr and Y), and the balance Pd. Cast ingots are prepared through high-frequency induction smelting, and a finished product is prepared through the procedures of high-temperature forging, short-range order transition heat treatment and the like. The alloy has high specific resistance and tensile strength, a low temperature coefficient of resistance, high oxidation resistance and high abrasive resistance, is a precision resistance alloy material with good comprehensive performance, and has wide application prospects in the cutting-edge technical fields of computer technology, aerospace and aviation, and the like.

Owner:SINO PLATINUM METALS CO LTD

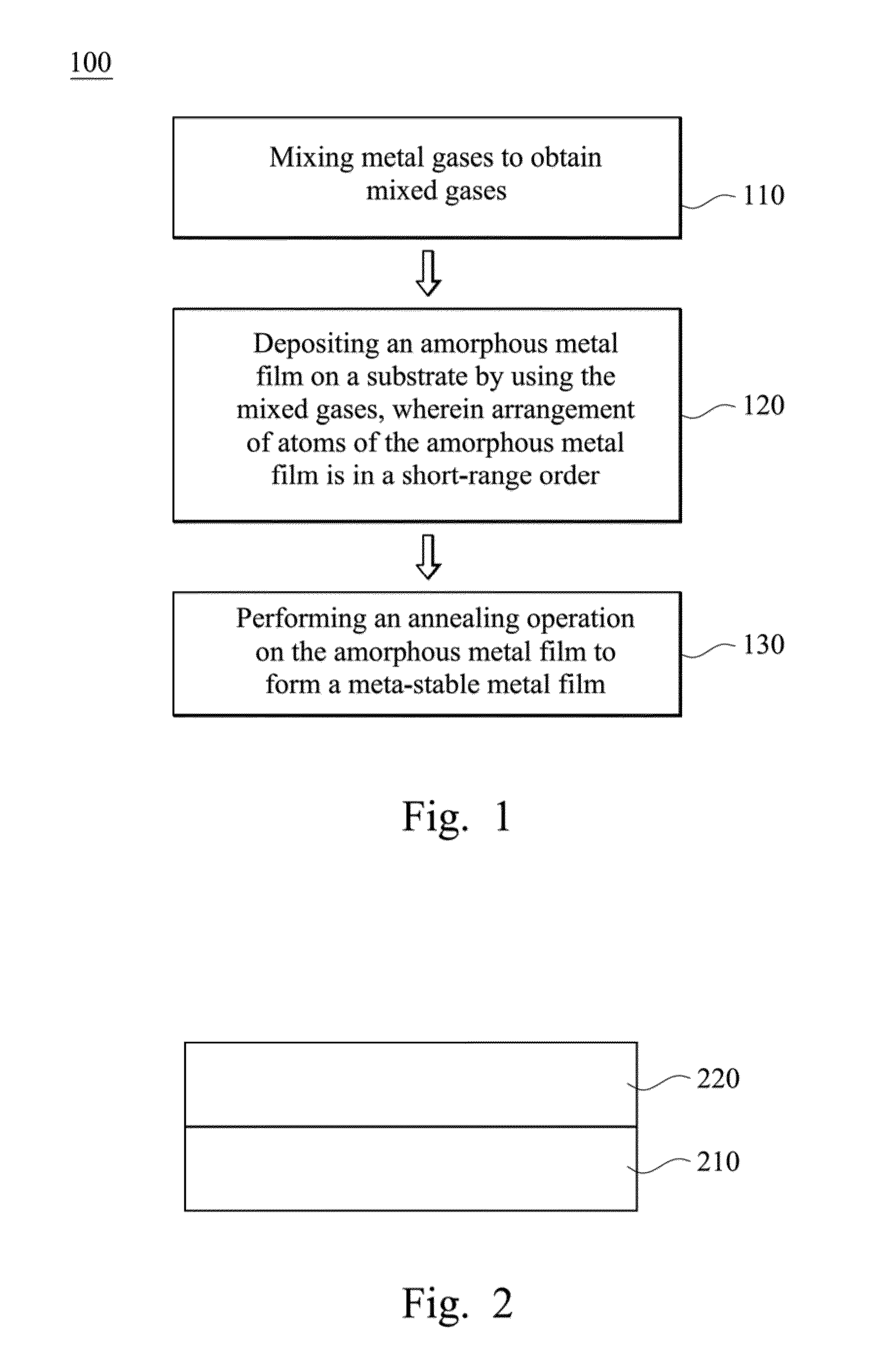

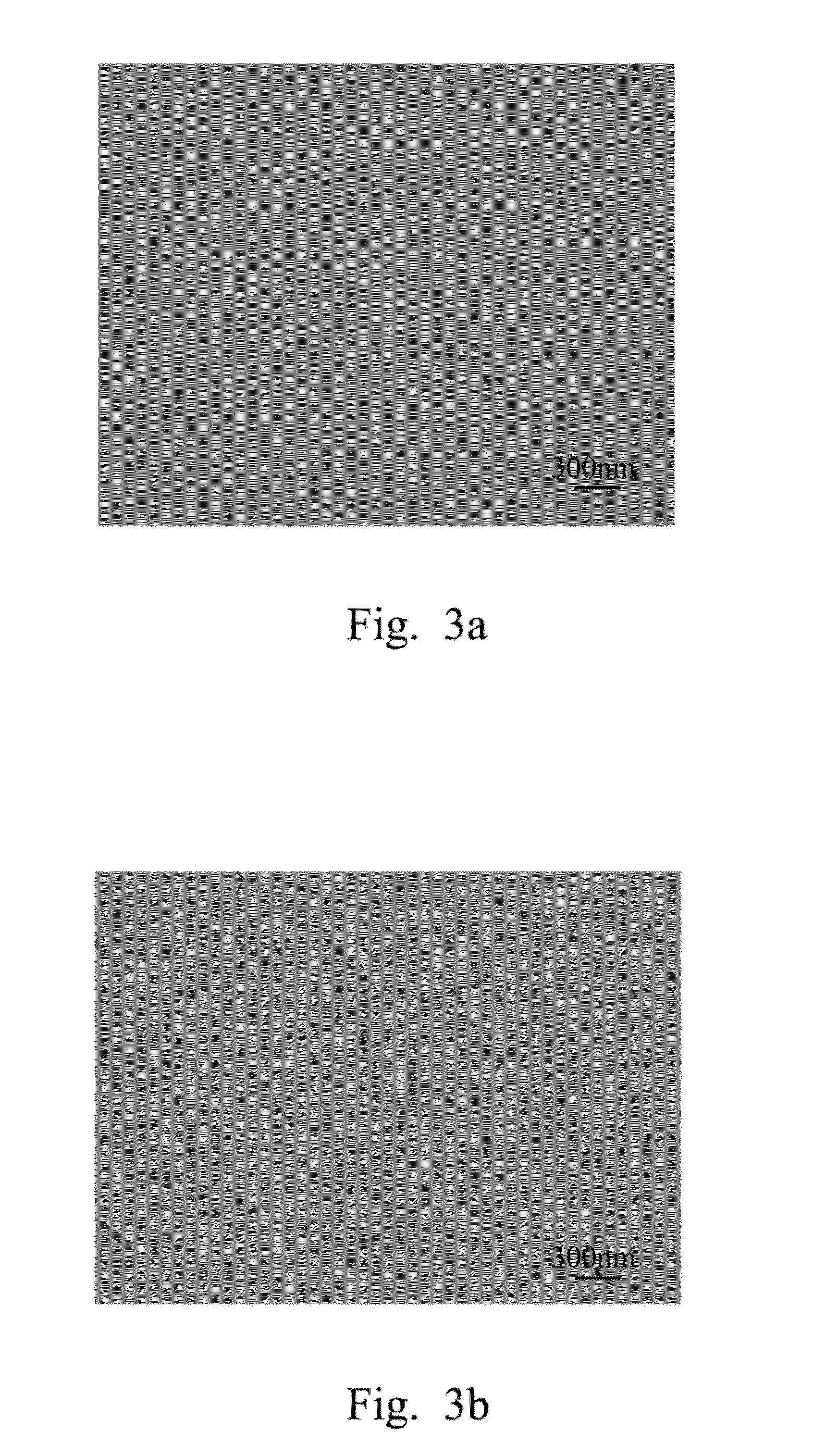

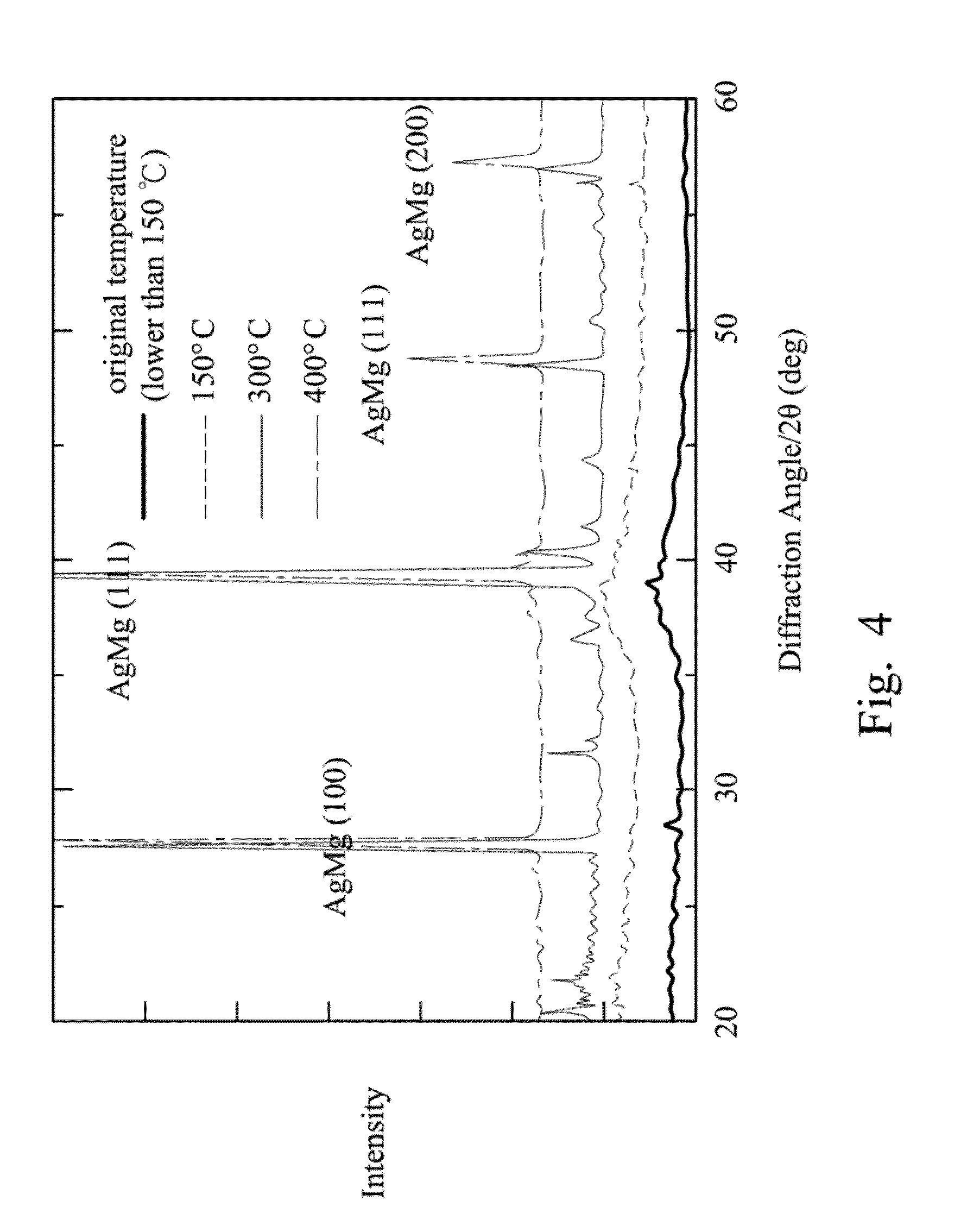

Protection film and method for depositing the same

InactiveUS20160145734A1Low resistivityReduce the cost of protectionVacuum evaporation coatingSputtering coatingTectorial membraneShort range order

A protection film and a method for depositing the protection film are provided. The method is used to form a protection film having low resistivity on a substrate. In the method, at first, a mixing operation is performed to mix a plurality of metal gases. The metal gases consist of silver, magnesium, and aluminum, or consist of silver, copper, and aluminum, or consist of copper, Nickel, and aluminum. The metal gases have two or more atom sizes. Thereafter, a depositing operation is performed to deposit an amorphous metal film on the substrate by using the mixed metal gases. The atoms of the amorphous metal film are arranged in a short-range order. Then an annealing treatment is performed to anneal the amorphous metal film to form a meta-stable metal film having averagely distributed grains to be used as the protection film.

Owner:METAL INDS RES & DEV CENT +1

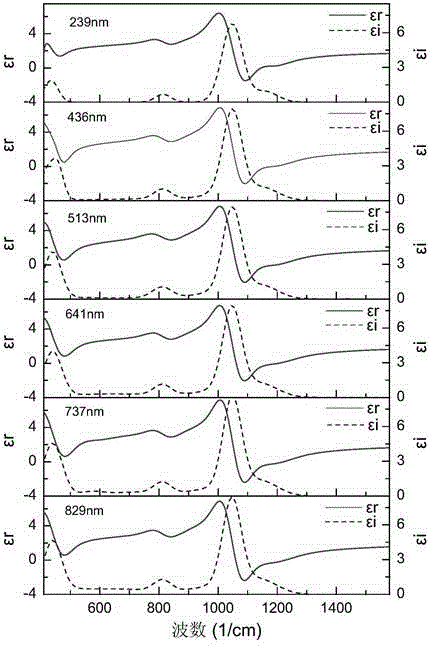

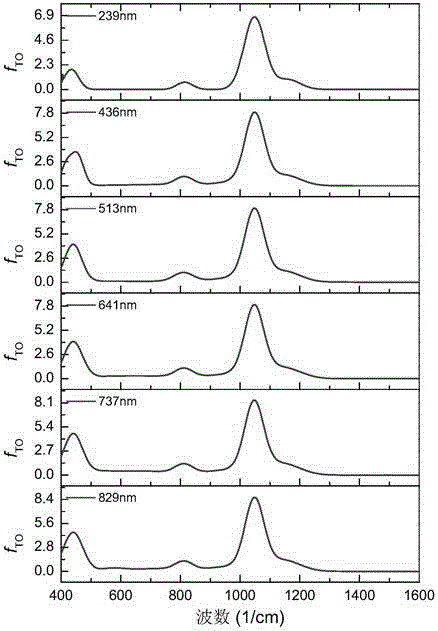

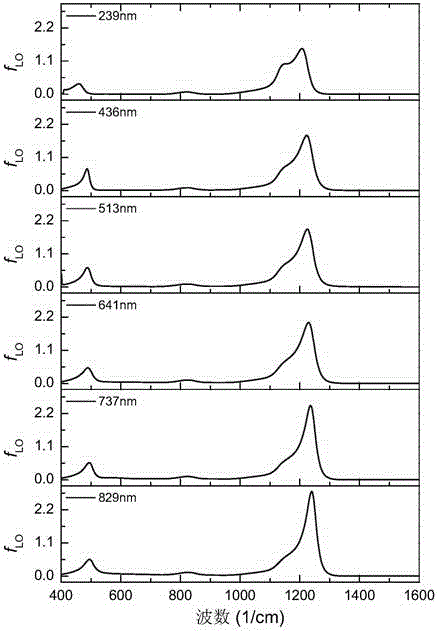

Research method on microstructure evolution in SiO2 thin film growth process

InactiveCN104361257APreparing sample for investigationSpecial data processing applicationsDielectricShort range order

The invention belongs to the field of reverse research on the performance evolution in a thin film growth process, and particularly relates to a research method on microstructure evolution in an SiO2 thin film growth process. The research method can be used for evaluating an evolution rule of a microstructure in the SiO2 thin film growth process. According to the research method, layered corrosion is performed on an SiO2 thin film by adopting a chemical solution corrosion method, so that infrared dielectric constant testing is performed on the corroded SiO2 thin film respectively, and a short-range ordered structure of the SiO2 thin films with different thicknesses can be evaluated; the research method has an important significance on deep understanding of the microstructure in the thin film growth process; a reverse research method is provided for the research on the performance evolution rule of the growth process of a thin film material. According to the method, the defects of long period, high cost and the like of a conventional layered preparation method are overcome, and a novel method is provided for the reverse research on the growth process of the thin film.

Owner:THE 3RD ACAD 8358TH RES INST OF CASC

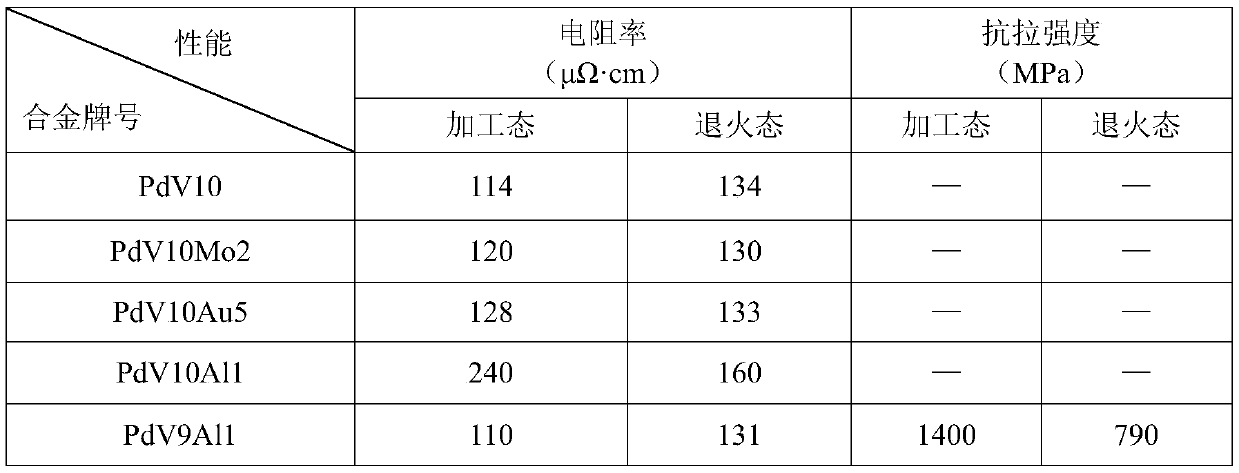

Palladium vanadium precision high-resistance alloy and preparation method thereof

The invention discloses a palladium vanadium precision high-resistance alloy and a preparation method thereof. The alloy comprises the chemical components, by mass percentage, of 28-32 of V, 1-4 of M(M is at least one of Cr and Al), 0-2 of Ru and the balance Pd. High-frequency induction melting is carried out to prepare ingots, and homogenization heat treatment, high-temperature forging, rolling,thick wire drawing, intermediate annealing, fine wire drawing and short-range order transformation heat treatment are performed to prepare wires with the diameter larger than phi0.03 mm. The alloy has high resistivity and tensile strength and low temperature coefficient of resistance, is a precision high-resistance alloy material with excellent comprehensive performance, and has broad applicationprospects in the field of high-resistance or small precision wire-wound potentiometers and resistors.

Owner:SINO PLATINUM METALS CO LTD

Mesoporous silicon dioxide molecular sieve and preparation method thereof

InactiveCN101786639BSimple processRapid responseCatalyst carriersOther chemical processesMolecular sieveShort range order

The invention relates to a mesoporous silicon dioxide molecular sieve and a preparation method thereof. The method comprises the following synthesis steps: 1), mixing a nonionic surfactant, a silicon source and water in a molar ratio of (0.01-0.1): (300-500): (1-3), regulating the pH value of the solution to 1.0 to 3.0 with an acid, and stirring the solution at 20 to 80 DEG C for 1 to 3 hours to form a sol mixture; 2) stirring the sol mixture obtained by the step 1 at room temperature, adding an alkaline buffer solution and regulating the pH value of the solution to 5 to 7.5 to obtain a whitesilicon dioxide precipitate; and 3) roasting the precipitate obtained by the step 2 at 500 to 600 DEG C for 3 to 5 hours to obtain a white mesoporous silicon dioxide material. The white mesoporous silicon dioxide material has an order hexagonal phase structure, a local short range order hexagonal phase structure, a multilayer onion-like structure, a worm-like structure or a foam-like hollow vesica structure. The method for synthesizing the mesoporous silicon dioxide molecular sieve of the invention is a real green biomimic synthesis method. The application of the method can promote the industrial production of like materials.

Owner:TIANJIN UNIV

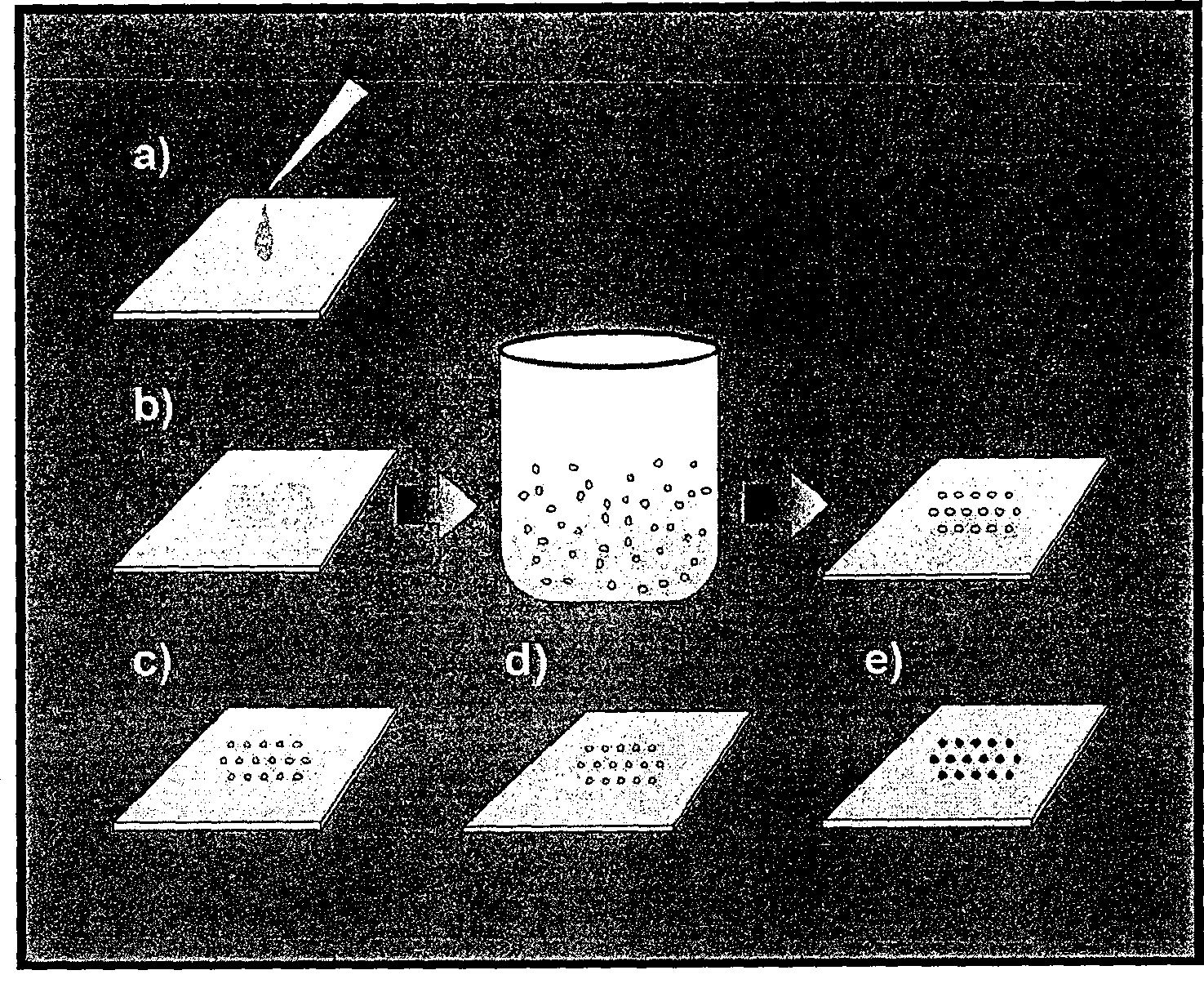

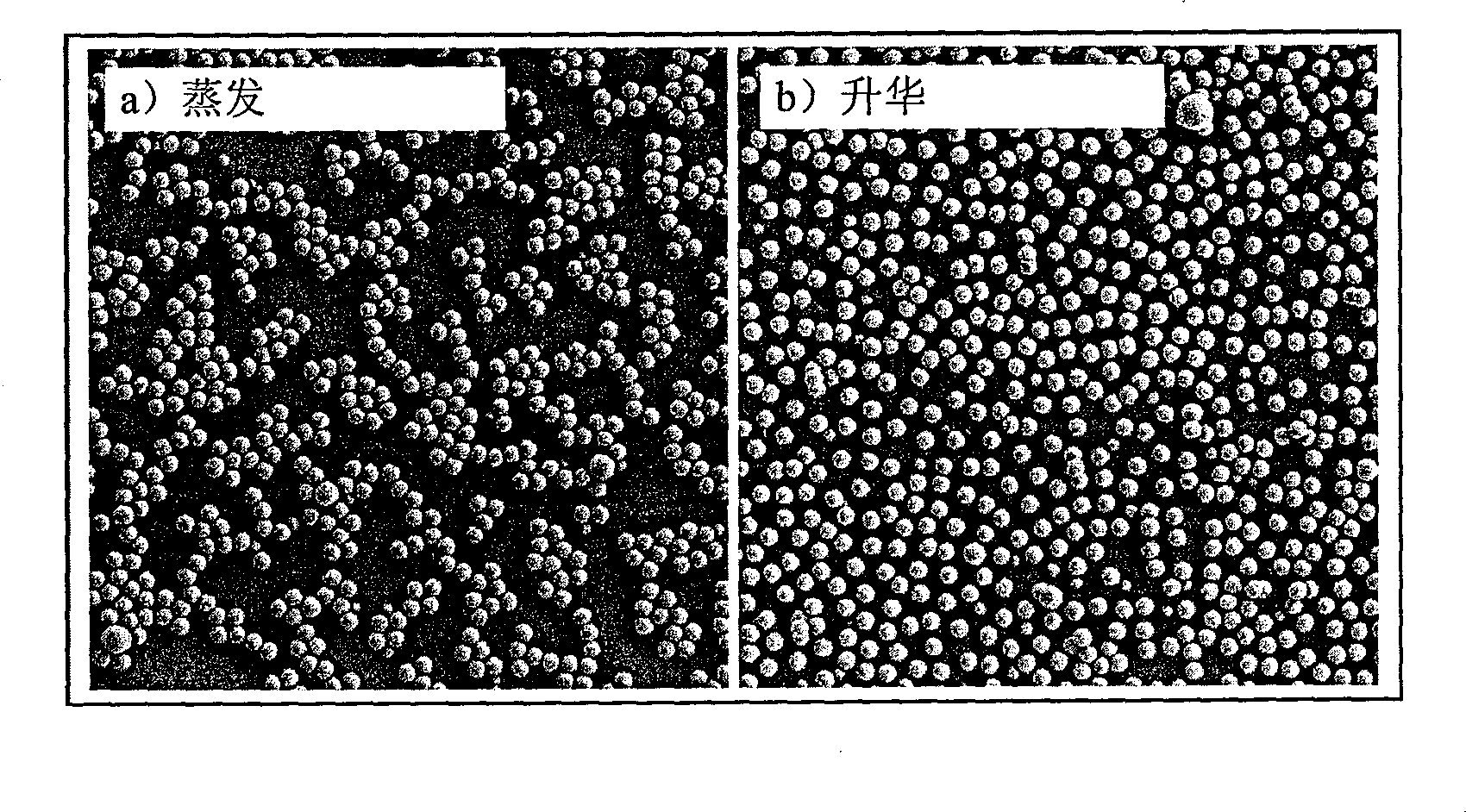

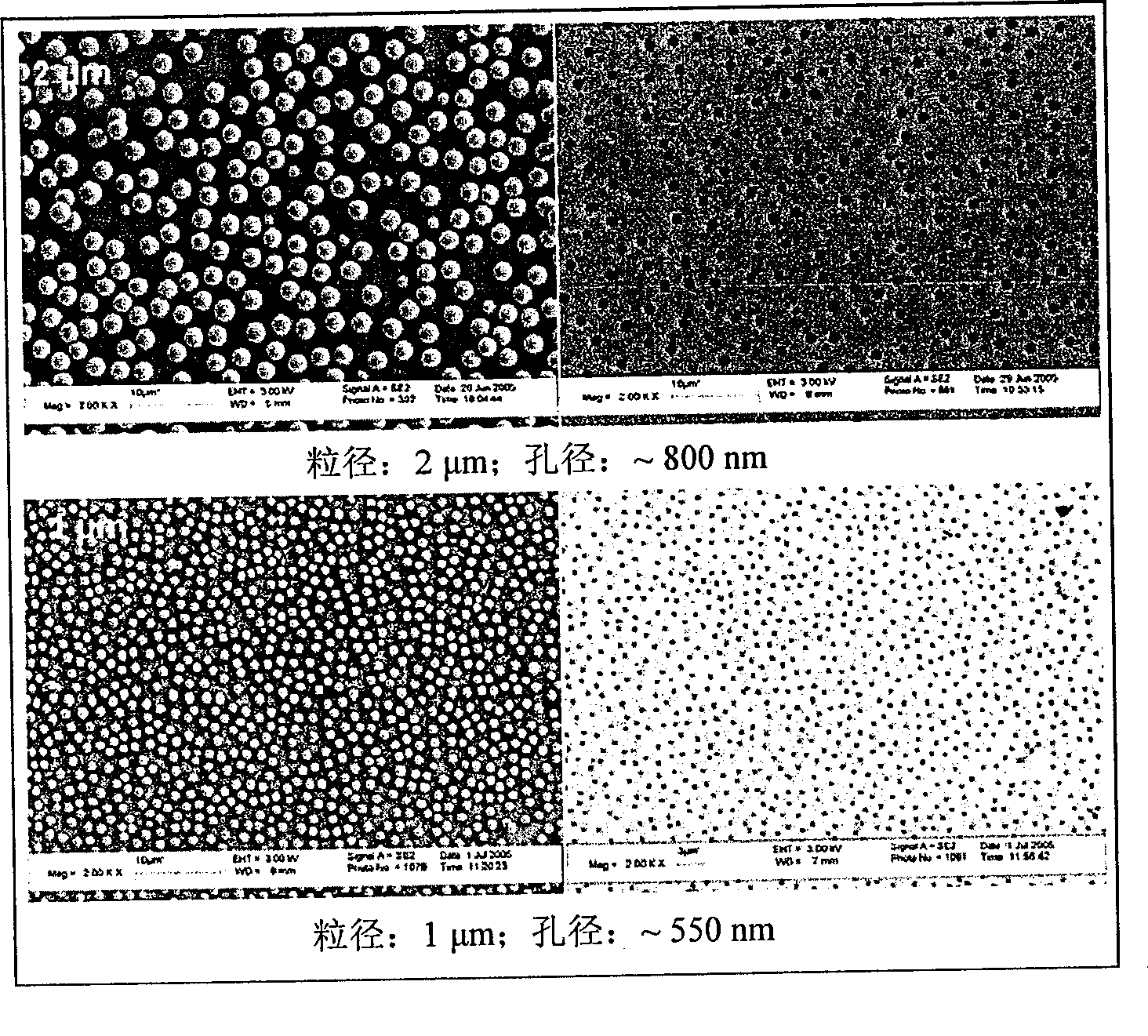

Production of micro- and nanopore mass arrangements by self-organization of nanoparticles and sublimation technology

The invention relates to a method for producing micro- and / or nanopore mass arrangements on a substrate, comprising the following steps: functionalizing the substrate surface in selected areas by applying a bonding agent; depositing, from an aqueous dispersion on the substrate surface, colloid particles which are capable of selectively binding to the functionalized areas of the substrate surface, an ordered monolayer of the particles forming on the substrate surface; removing non-bound colloid particles; freezing the substrate; and sublimating the residual water on the substrate in vacuo, the short-range order of the particle monolayer remaining intact.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

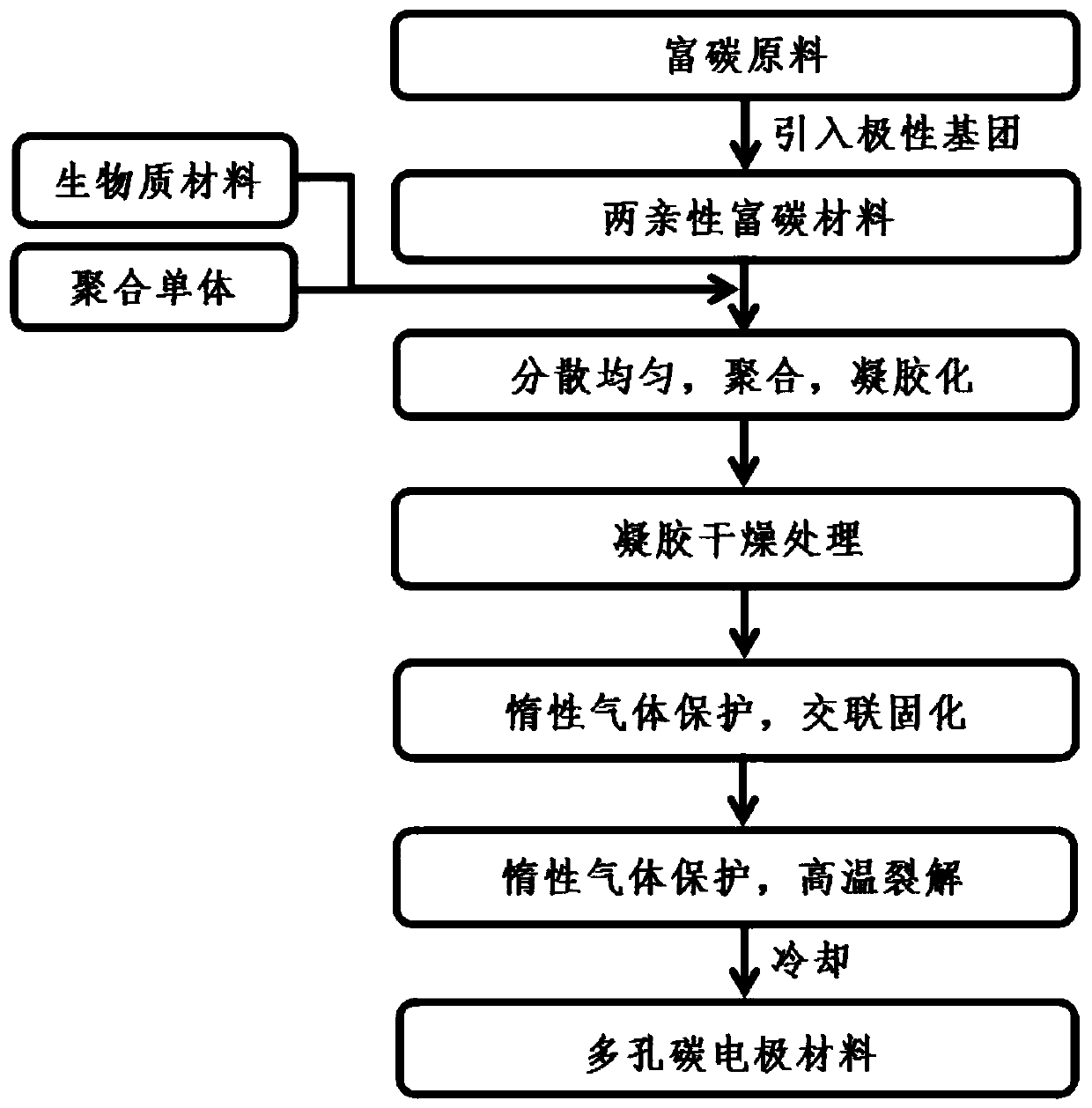

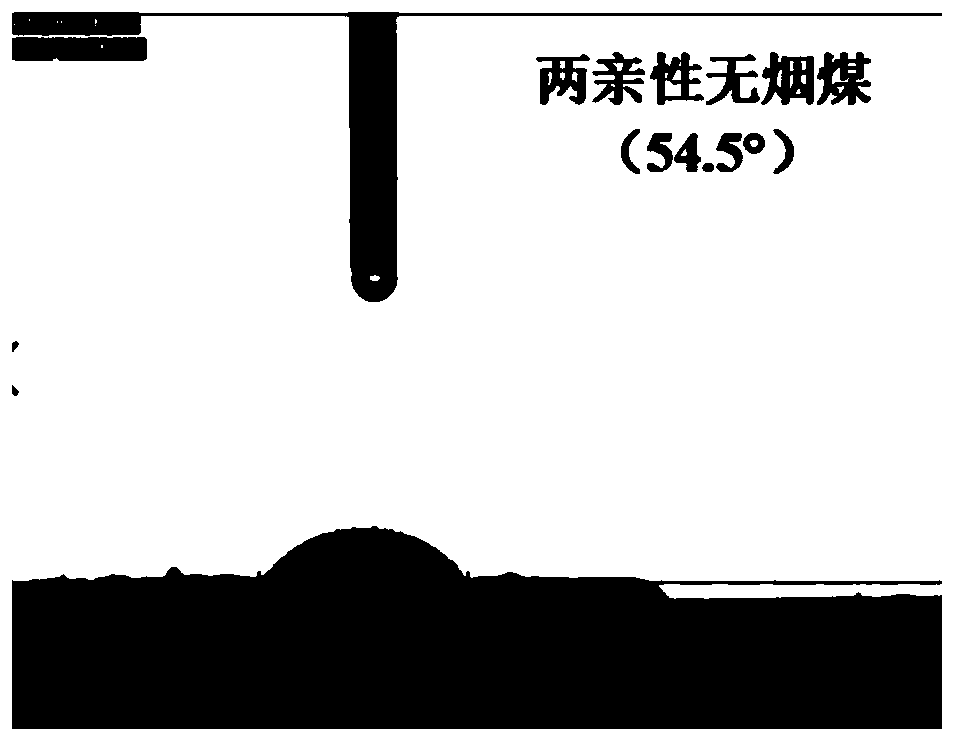

Porous carbon electrode material with easily-regulated microstructure as well as preparation method and application of porous carbon electrode material

ActiveCN110240142AEasy to prepareLow costHybrid capacitor electrodesSecondary cellsShort range orderPorous carbon

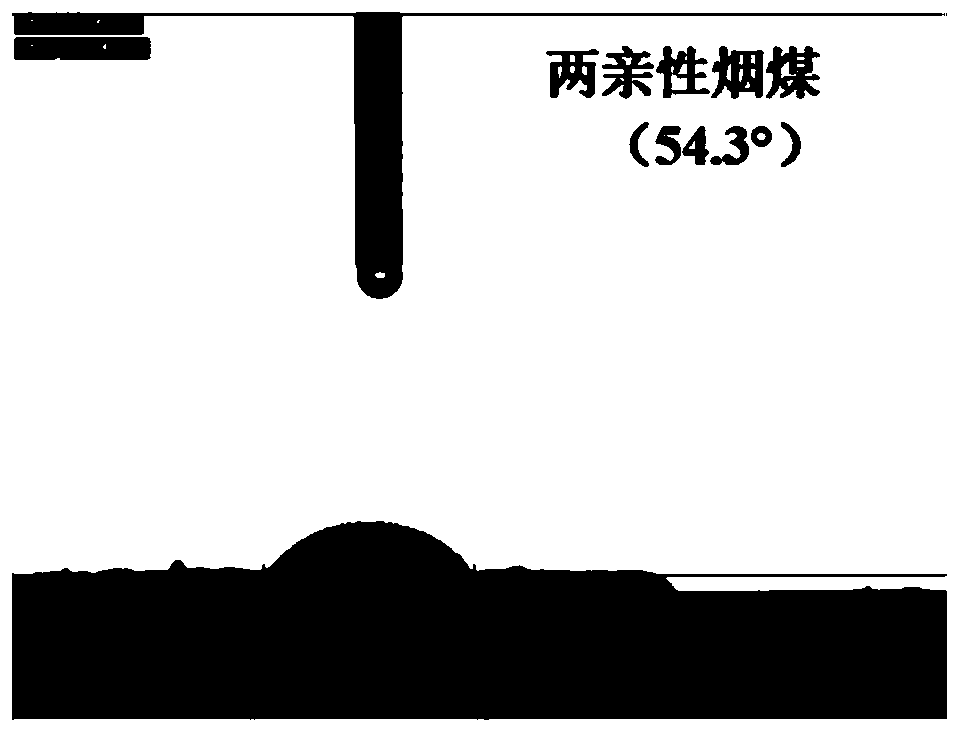

The invention relates to a porous carbon electrode material with an easily-regulated microstructure as well as a preparation method and application of the porous carbon electrode material. The porous carbon electrode material has the characteristics of long-range disorder and short-range order and is prepared by introducing a polar group to a carbon-rich raw material to prepare an amphipathic carbon-rich material, then, adding water to mix the amphipathic carbon-rich material with a biomass material and / or an amphipathic polymer material, then, carrying out gelatination, and then, carrying out crosslinking, curing and high-temperature pyrolysis. The microstructure of the porous carbon electrode material can be regulated by regulating the ratio of the raw materials, the moisture content of a gel as well as the treatment temperature during crosslinking, curing and high-temperature pyrolysis. The porous carbon electrode material disclosed by the invention is high in carbon yield and excellent in conductivity so as to be particularly used as an anode material of a sodium-ion battery or an electrode material of a supercapacitor; and the porous carbon electrode material is simple in preparation method, available in raw materials and low in cost so as to be suitable for large-scale production.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Customized polishing pads for CMP and methods of fabrication and use thereof

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior thermo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC材料有限责任公司

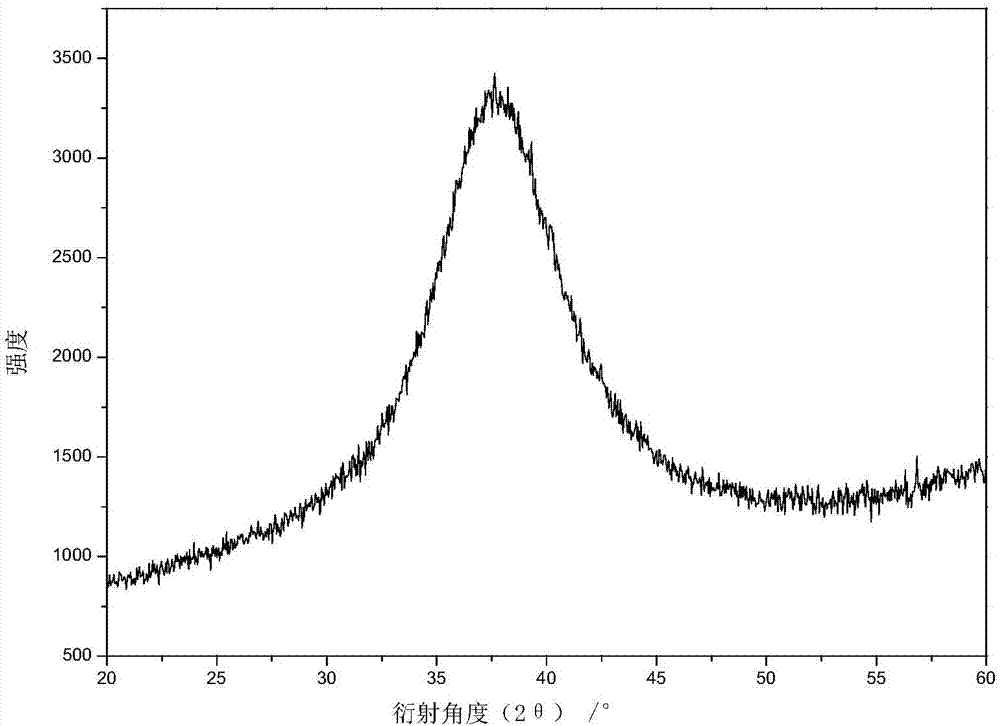

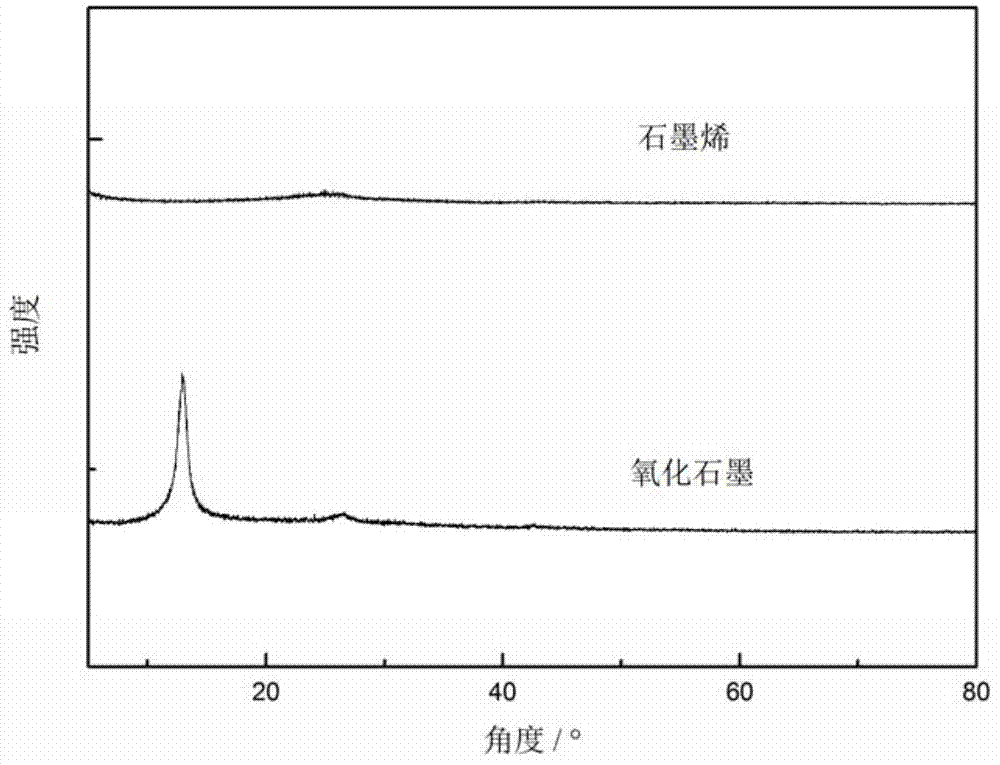

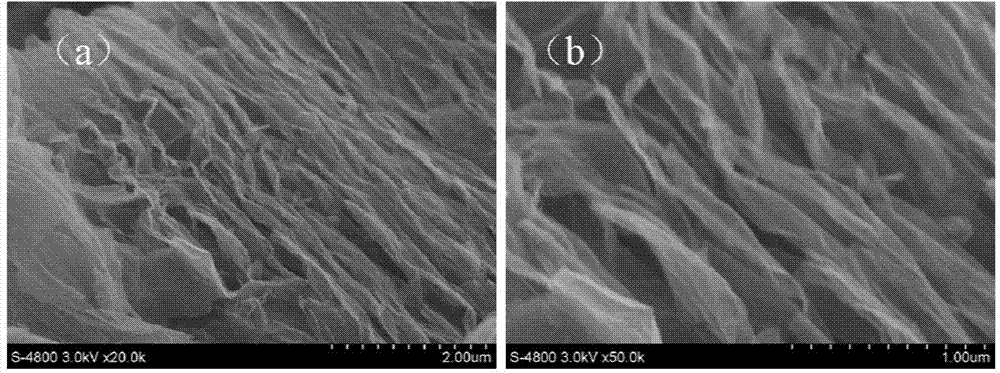

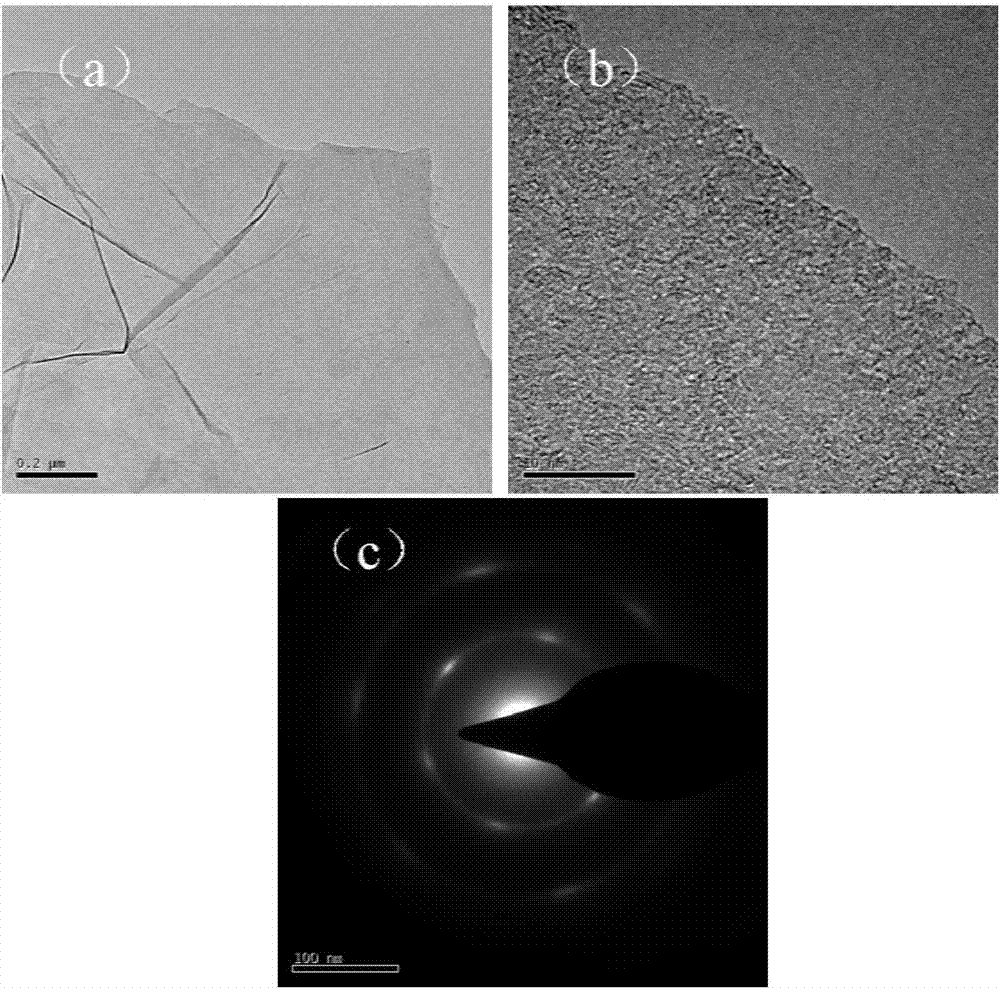

Simple thermal expansion method for preparing thin graphene

InactiveCN104724698ASuitable for large-scale productionIncrease productivityHydrogenShort range order

The invention discloses a simple thermal expansion method for preparing thin graphene. The method comprises the following step: scattering graphite oxide powder into a furnace body of 250-400 DEG C to suddenly raise the temperature of the graphite oxide powder, so as to expand graphite oxide to obtain the thin graphene powder. The thermal expansion process of graphite oxide is directly completed under a simple condition without additional conditions mentioned in known reports such as graphite oxide pre-treatment, expansion in a hydrogen environment, expansion in a vacuum environment and the like. The number of laminates of graphene is less than 10, and graphene has no obvious diffraction peaks in an x-ray diffraction spectrum and belongs to short-range order and long-range disorder. The production cost is lowered while the production efficiency is improved, and the method is quite suitable for large-scaled production of graphene.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com