High-strength copper-iron-phosphorus alloy and production method thereof

A production method, copper-iron-phosphorus technology, applied in high-strength copper-iron-phosphorus alloy and its production field, can solve problems such as difficulty in achieving hardness, performance deviation, and difficulty in reaching 540Mpa in tensile strength, so as to improve alloy strength and ensure electrical conductivity The effect of improving performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A high-strength copper-iron-phosphorus alloy comprises the following elements by weight percentage: Fe2.5%; P0.13%; Zn0.15%; Pb0.03%; Ni0.09%; Sn0.1%;

[0018] A production method of a high-strength copper-iron-phosphorus alloy, comprising the following steps: mixing raw materials according to the formula ratio, heating, casting, hot rolling, cold rolling, heat treatment, cleaning, stretching and straightening, and heat treatment to obtain a finished product; removing the finished product from annealing Except for the process, other processes are existing processes. The annealing process for the finished product is: heating to 200°C at a heating rate of 2°C / min, holding the heat for 3 hours, cooling with the furnace, and releasing it below 50°C. The annealing process maintains a hydrogen protective atmosphere.

Embodiment 2

[0020] A high-strength copper-iron-phosphorus alloy comprises the following elements by weight percentage: Fe2.3%; P0.15%; Zn0.2%; Pb0.02%; Ni0.04%; Sn0.06%;

[0021] A production method of a high-strength copper-iron-phosphorus alloy, comprising the following steps: mixing raw materials according to the formula ratio, heating, casting, hot rolling, cold rolling, heat treatment, cleaning, stretching and straightening, and heat treatment to obtain a finished product; removing the finished product from annealing Except for the process, other processes are existing processes. The annealing process for the finished product is: heating to 210°C at a heating rate of 3°C / min, holding the heat for 3 hours, cooling with the furnace, and releasing it below 50°C. The annealing process maintains a hydrogen protective atmosphere.

Embodiment 3

[0023] A high-strength copper-iron-phosphorus alloy, including the following elements by weight percentage: Fe2.1%; P0.1%; Zn0.1%; Pb0.01%; Ni0.06%; Sn0.07%;

[0024] A production method of a high-strength copper-iron-phosphorus alloy, comprising the following steps: mixing raw materials according to the formula ratio, heating, casting, hot rolling, cold rolling, heat treatment, cleaning, stretching and straightening, and heat treatment to obtain a finished product; removing the finished product from annealing Except for the process, other processes are existing processes. The annealing process for the finished product is: heating to 210°C at a heating rate of 4°C / min, holding the heat for 3 hours, cooling with the furnace, and releasing it below 50°C. The annealing process maintains a hydrogen protective atmosphere.

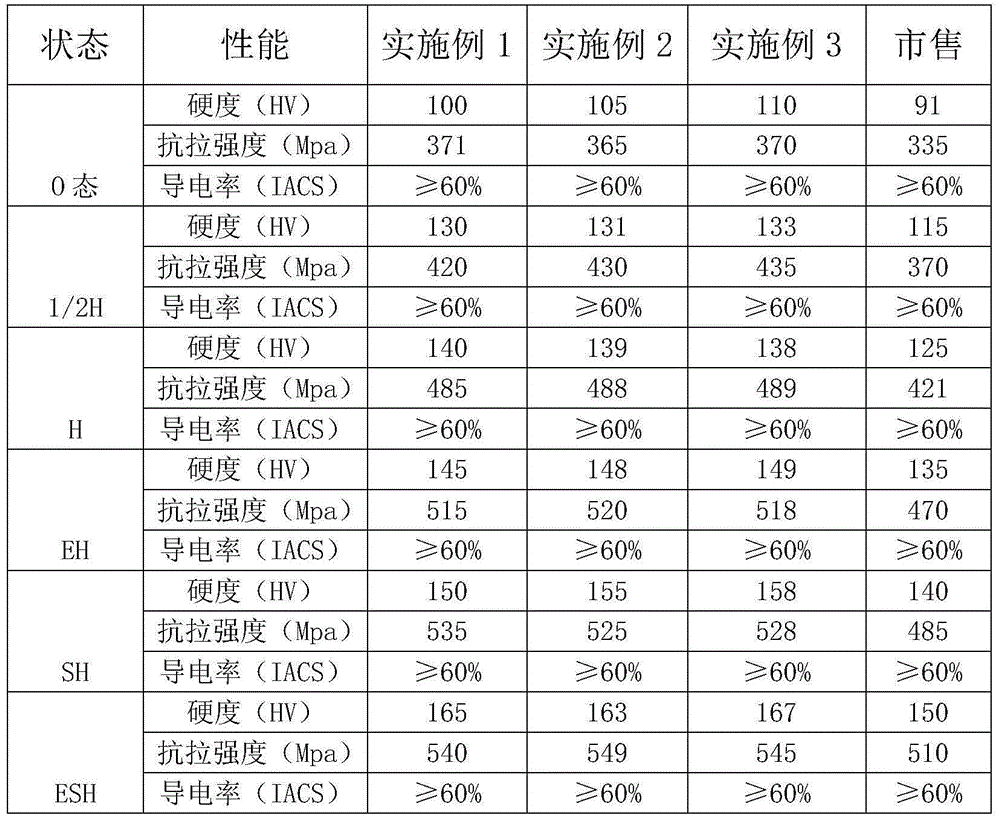

[0025] The mechanical properties of the products prepared in Examples 1-3 and the C19400 alloy in the traditional process were compared, and the results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com