Piezoelectric material, manufacturing method thereof, and non-linear piezoelectric element

A technology of piezoelectric materials and manufacturing methods, applied to electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of very sensitive temperature and low usefulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

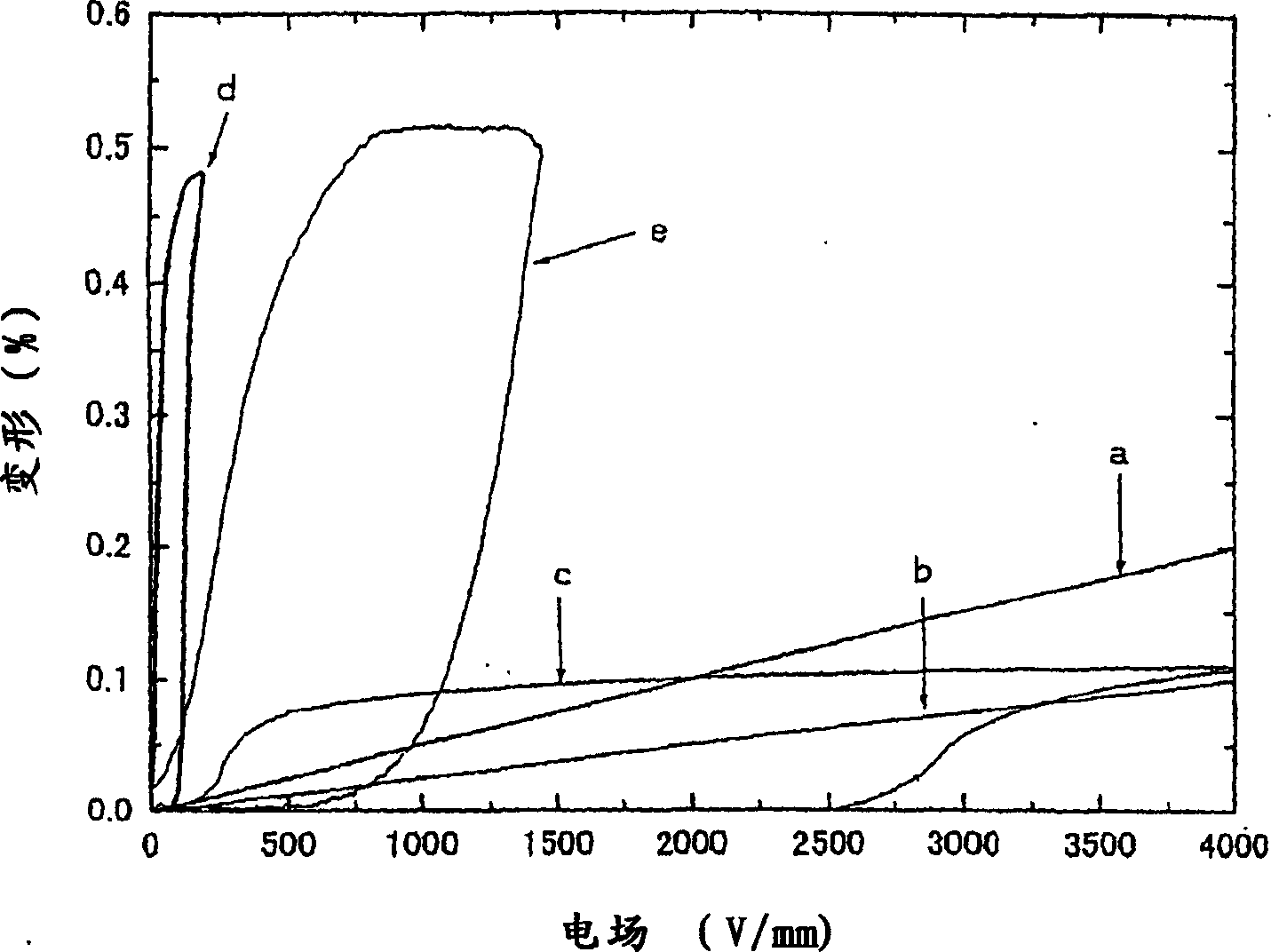

[0083] Fabrication of BaTiO by Flux Method 3 A single crystal, after cooling, was aged at a temperature at or below the Curie point (3 days at 80°C). The electric field-displacement characteristics of the obtained piezoelectric material were taken as image 3 The curve d shows. and, image 3 In , the displacement characteristics of the conventional piezoelectric material as described above are shown as curves a, b, and c.

[0084] from the image 3 It can be clearly seen from the curve d of the present application that the piezoelectric material invented by the present application can realize reversible domain switching under a low electric field, showing a huge nonlinear piezoelectric effect.

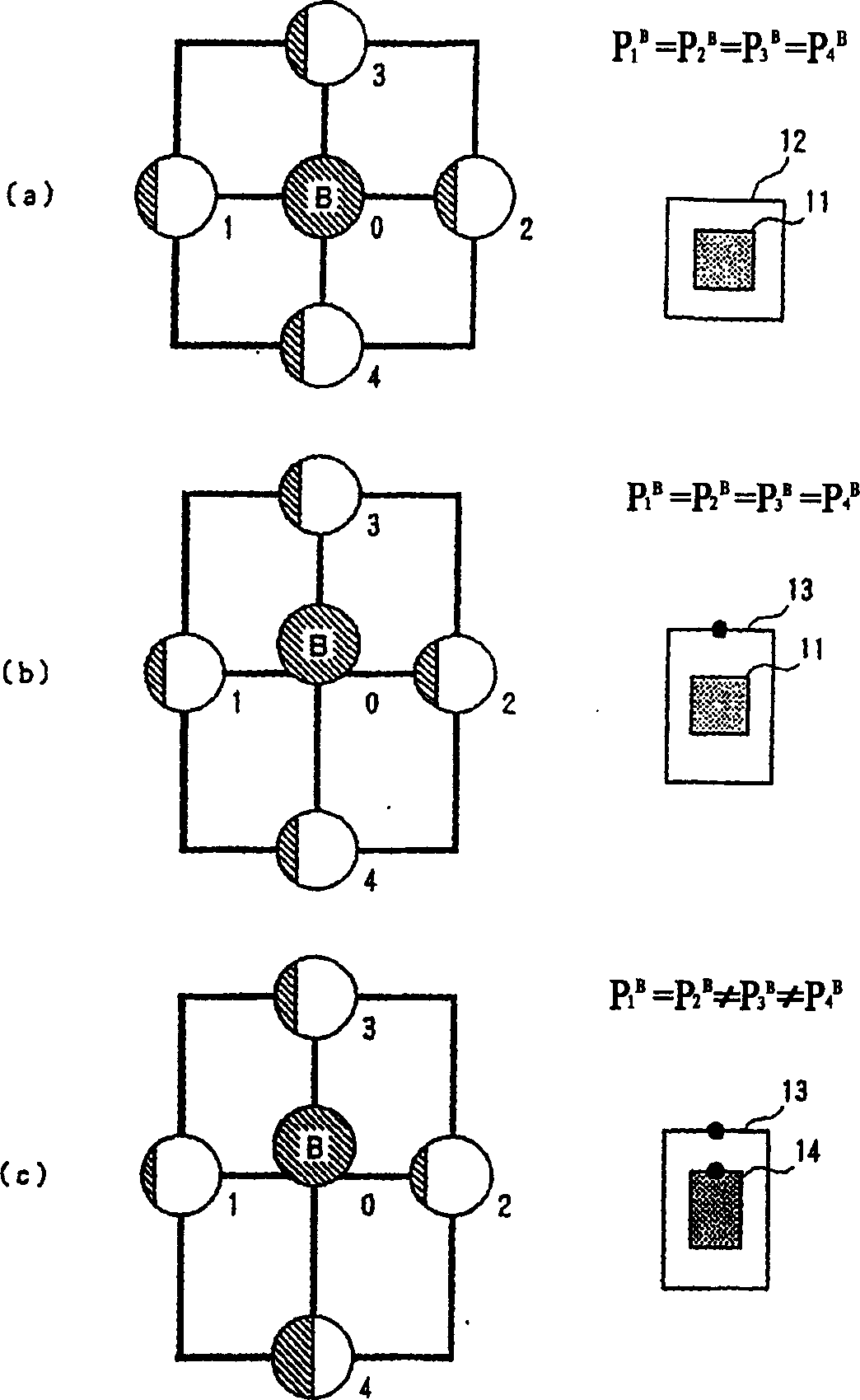

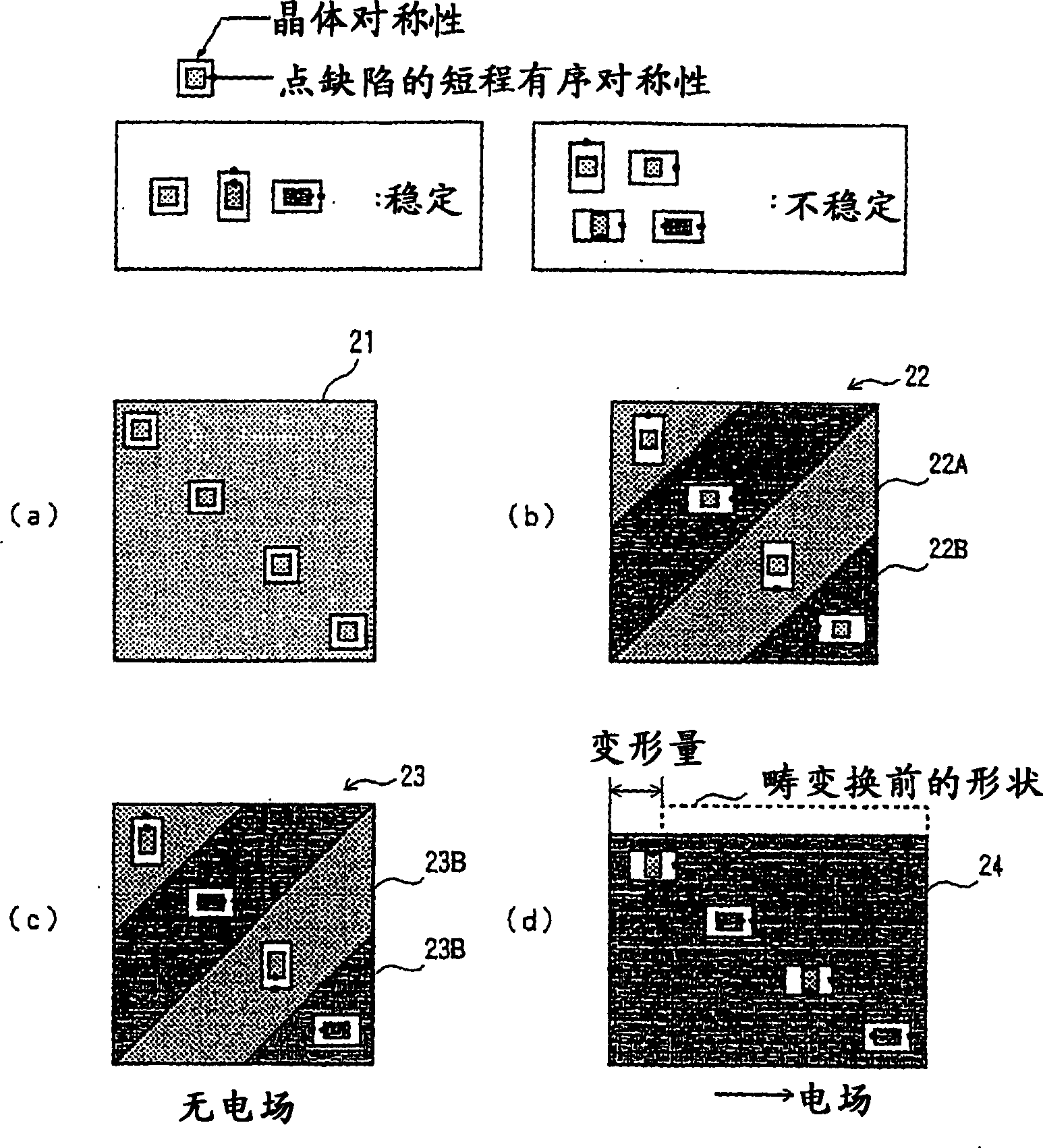

[0085] Using BaTiO 3 The rearrangement of a small amount of oxygen vacancies (point defects) naturally contained in the single crystal due to aging treatment (making the short-range order symmetry of point defects consistent with the crystal symmetry) can be achieved in a low electri...

Embodiment 2

[0088] (BaK)TiO with a small amount (0.7 mol%) of K added by the flux method 3 single crystal.

[0089] Then, after cooling, an aging treatment was performed at a temperature equal to or lower than the Curie point (room temperature 18° C. to 22° C., 1 month).

[0090] In this case, point defects are generated by the addition of K ions, and an aging treatment at or below the Curie temperature is performed to make the short-range order symmetry of the point defects coincide with the crystal symmetry. The piezoelectric displacement characteristics of the resulting piezoelectric material are expressed in image 3 in the curve e.

[0091] According to the image 3 In the curve e, a large piezoelectric displacement of 0.52% can be obtained with an electric field of 1470V / mm. This displacement is the same as the result under the same electric field of the conventional PZT piezoelectric element ( image 3 When compared with the curves a~c), it is a huge displacement. Furthermore, i...

Embodiment 3

[0094] The following three types of ceramic (polycrystalline) samples were prepared as the piezoelectric material of the invention of the present application.

[0095] 1) (Pb, La) (Zr, Ti) O 3 = PLZT ceramic aged for 30 days at room temperature (no polarization).

[0096] 2) Mn-(Ba, Sr)TiO 3 : Mn-BST (Mn 1mol%) ceramic aged at 70°C for 5 days.

[0097] 3) Mn-BaTiO 3 : Mn-BT (Mn 1mol%) ceramic aged for 3 months at room temperature.

[0098] For the above three ceramic piezoelectric materials, the electric field-displacement characteristics were measured, and the results are expressed in Figure 4 middle.

[0099] The measurement results of conventional hard PZT and soft PZT for comparison are also shown in Figure 4 middle.

[0100] from the Figure 4 It can be clearly seen from the results that the PLZT ceramic piezoelectric material of the invention of the present application exhibits several times the amount of deformation at low voltage compared with the conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com