Mesoporous silicon dioxide molecular sieve and preparation method thereof

A mesoporous silica and molecular sieve technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve problems such as limiting industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 3g of PEO-PPO-PEO (F127, molecular weight 12600) into 120ml of water, 2 SO 4 The pH of the solution was adjusted to 1.0, 5 g of methyl orthosilicate was added, and stirred at 25° C. for 1 hour. to obtain a homogeneous colloidal solution

[0024] (2) Add 25 mM carbonate buffer solution (pH 9.23) to the sol mixture obtained in step 1 under stirring at room temperature, adjust the pH value of the solution to 5.0, and obtain white silica precipitate.

[0025] (3) Calcining the precipitated product in step 2 at a high temperature of 600° C. at a rate of 2° C. / min for 5 hours to obtain a white mesoporous silica mesoporous molecular sieve.

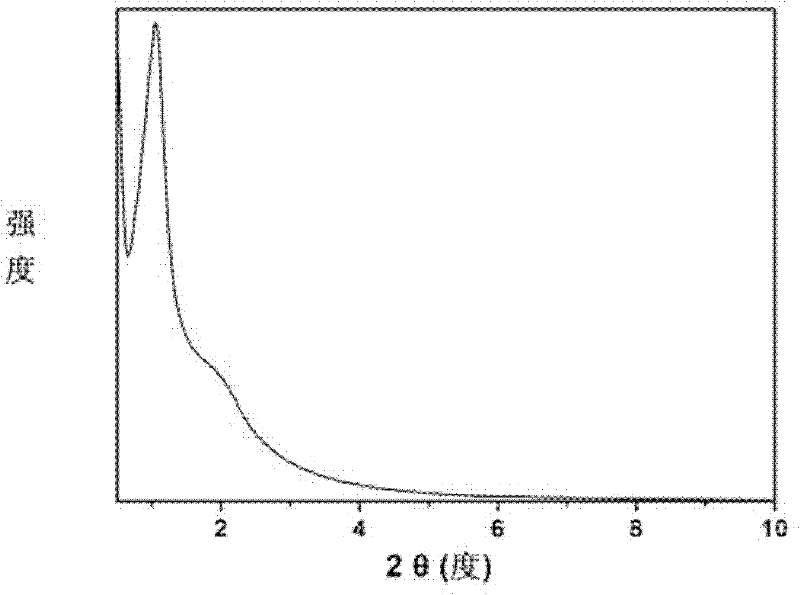

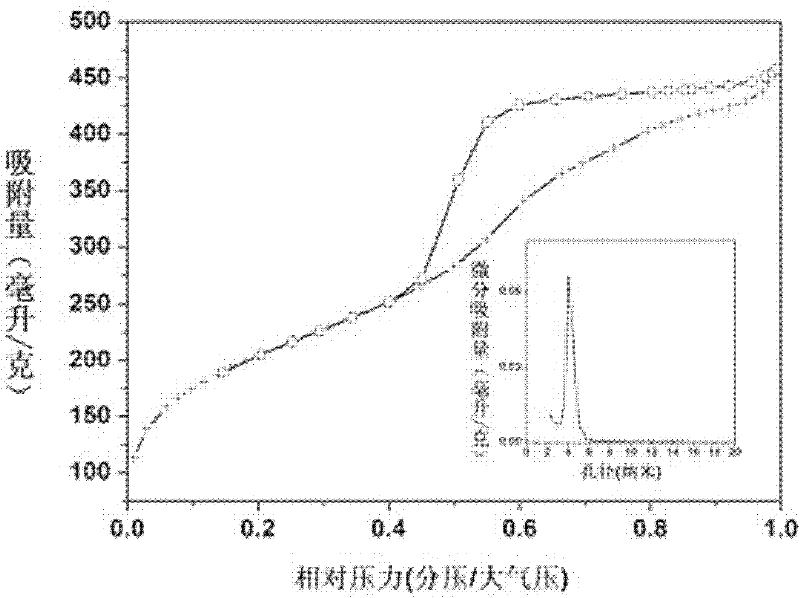

[0026] The main physical and chemical properties of the product: the specific surface area is 665m 2 / g, the mesopore diameter is 4.0nm~4.2nm, and the pore volume is 0.75cm 3 / g.

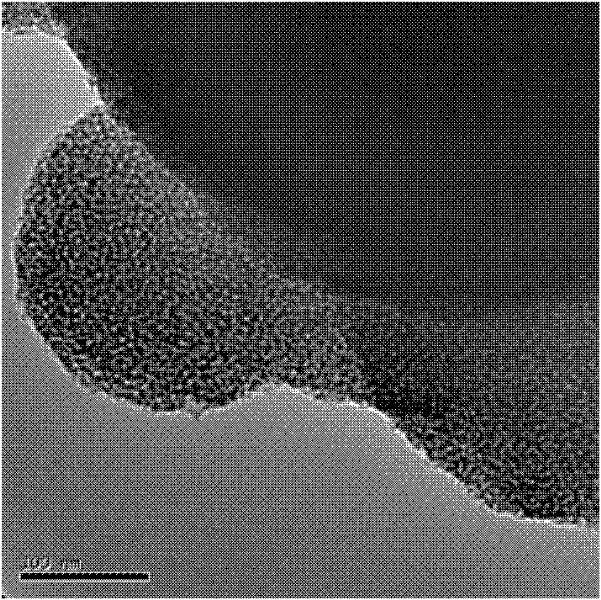

[0027] image 3 The TEM pattern of the product is shown. It can be seen from the graph that the product obtained in Example 1 is a TJU-1 worm-lik...

Embodiment 2

[0029] (1) 1.5g of EO 20 po 70 EO 20 (P123, molecular weight 5700-5800) was added into 100ml of water, the pH of the solution was adjusted to 2.0 with 1M HCl, 3.3g of tetraethyl orthosilicate was added, and stirred at 45°C for 1 hour. to obtain a homogeneous colloidal solution

[0030] (2) The sol mixture obtained in step 1 was stirred at room temperature, and 250 mM carbonate buffer solution (pH. 10.56) was added to adjust the pH value of the solution to 6.4 to obtain a white silica precipitate.

[0031] (3) Calcining the precipitated product in step 2 at a high temperature of 550° C. at a rate of 1.5° C. / min for 5 hours to obtain a white mesoporous silica mesoporous molecular sieve.

[0032] The main physical and chemical properties of the product: the specific surface area is 750m 2 / g, the mesopore diameter is about 4.0nm, and the pore volume is 0.70cm 3 / g.

[0033] Figure 4 The TEM spectrum of the embodiment product shown. The structural information shown in the...

Embodiment 3

[0035] (1) 1.5g of EO 20 po 70 EO 20 (P123, molecular weight 5700-5800) was added into 100ml of water, with 3M H 3 PO 4 The pH of the solution was adjusted to 3.0, 3.3 g of ethyl orthosilicate was added, and stirred at 40° C. for 3 hours. to obtain a homogeneous colloidal solution

[0036] (2) The sol mixture obtained in step 1 was stirred at room temperature, and added with 100 mM phosphate buffer solution (pH 7.9) to adjust the pH value of the solution to 6.7 to obtain a white silica precipitate.

[0037](3) Calcining the precipitated product in step 2 at a high temperature of 550° C. at a rate of 1.5° C. / min for 4 hours to obtain a white mesoporous silica mesoporous molecular sieve.

[0038] The main physical and chemical properties of the product: the specific surface area is 495m 2 / g, the mesopore diameter is about 5.6nm, and the pore volume is 0.88cm 3 / g. The TEM pattern of this embodiment product shown in Fig. 54. The structural information shown in the spect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com