Fe-Ni magnetically soft alloy with short-range order structure and Fe-Ni magnetically soft alloy part

A technology of iron-nickel soft magnetic alloy and short-range order, which is applied in the field of soft magnetic alloy parts and iron-nickel soft magnetic alloy, can solve the problems of high saturation magnetic induction intensity, etc., and achieve the goal of increasing saturation magnetic induction intensity, simple process, and improving magnetic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

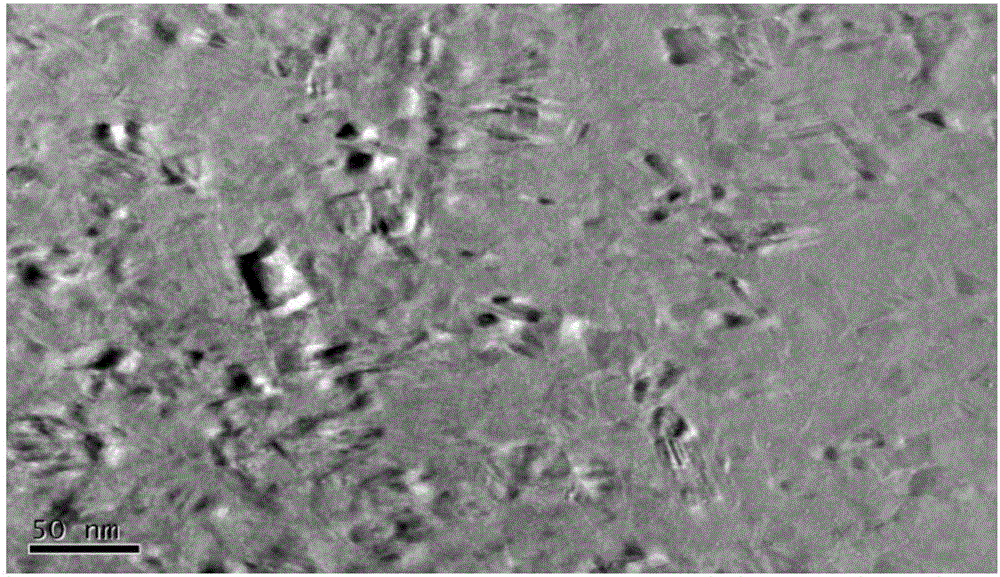

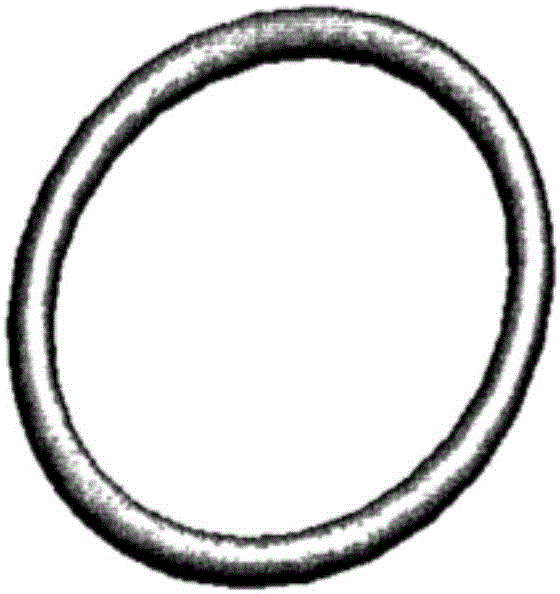

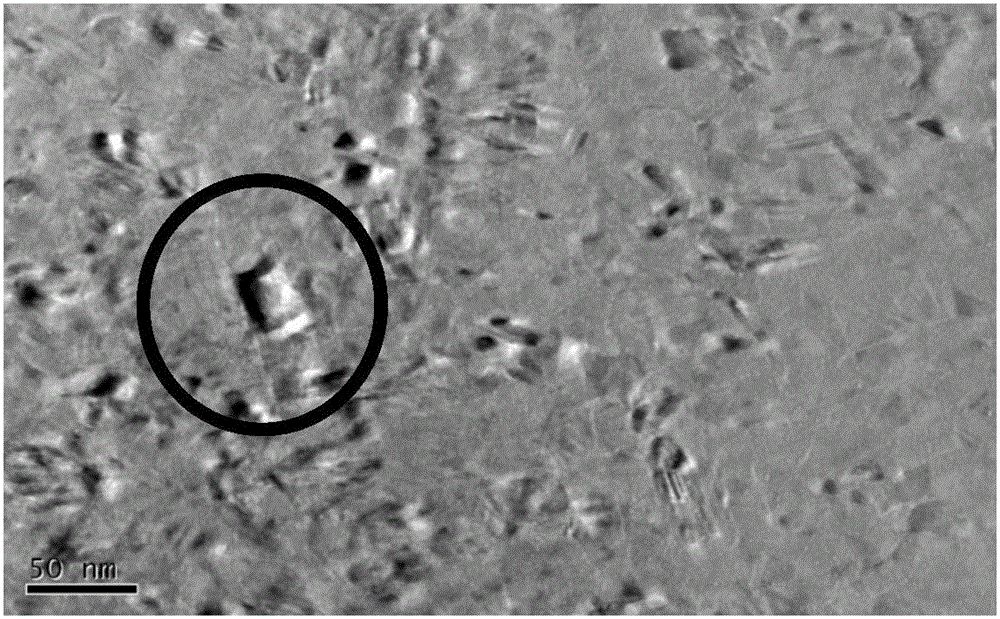

[0016] The Fe-50%Ni alloy powder with an average particle size of 35 microns is used, and the Fe-50%Ni alloy powder with an average particle size of 1 micron is added and mixed, and the mixing mass ratio is 7:3. Through dry mixing, feeding mixing, granulation, injection molding to produce such as figure 2 circle shown. Specific process: the two powders are mixed evenly by mechanical mixing, the mixing equipment is a four-tank dry mixer, and the dry mixing time is 2 hours. Add an appropriate amount of oil-based binder according to 55% of the powder loading, and make it evenly mixed by dry mixing for 1 hour. After the mixed powder with the binder added is dry-mixed evenly, it is put into the mixing equipment for mixing, so that the metal powder and the binder are mixed evenly, and the feed material with good fluidity is obtained. The sample is injected with an injection molding machine. By adjusting the injection temperature, mold temperature, injection pressure, and injectio...

Embodiment 2

[0021] Use Fe-50%Ni alloy powder with an average particle size of 20 microns, add Fe-50%Ni alloy powder materials with an average particle size of 3 microns, mix, and the mixing mass ratio is 7:3.

[0022] The two powders were mixed evenly by means of mechanical mixing, the mixing equipment was a four-tank dry mixer, and the dry mixing time was 2 hours. Add an appropriate amount of oil-based binder according to 55% of the powder loading, and make it evenly mixed by dry mixing for 1 hour. After the mixed powder with the binder added is dry-mixed evenly, it is put into the mixing equipment for mixing, so that the metal powder and the binder are mixed evenly, and the feed material with good fluidity is obtained. The sample is injected with an injection molding machine. By adjusting the injection temperature, mold temperature, injection pressure, and injection speed, a defect-free magnetic performance test ring injection blank is obtained. After the injection body is obtained, th...

Embodiment 3

[0027] Use Fe-50%Ni alloy powder material with an average particle size of 50 microns, add Fe-50%Ni alloy powder material with an average particle size of 5 microns, mix, and the mixing mass ratio is 7:3.

[0028] The two powders were mixed evenly by means of mechanical mixing, the mixing equipment was a four-tank dry mixer, and the dry mixing time was 2 hours. Add an appropriate amount of oil-based binder according to 55% of the powder loading, and make it evenly mixed by dry mixing for 1 hour. After the mixed powder with the binder added is dry-mixed evenly, it is put into the mixing equipment for mixing, so that the metal powder and the binder are mixed evenly, and the feed material with good fluidity is obtained. The sample is injected with an injection molding machine. By adjusting the injection temperature, mold temperature, injection pressure, and injection speed, a defect-free magnetic performance test ring injection blank is obtained. After the injection body is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com