Material web for the production of a bellows of a transitional section, particularly between two articulated vehicle parts

A technology of material width and transition part, applied in the direction of connecting vehicle passages, vehicle parts, railway car body parts, etc., can solve the problem of metal wire breakage of lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

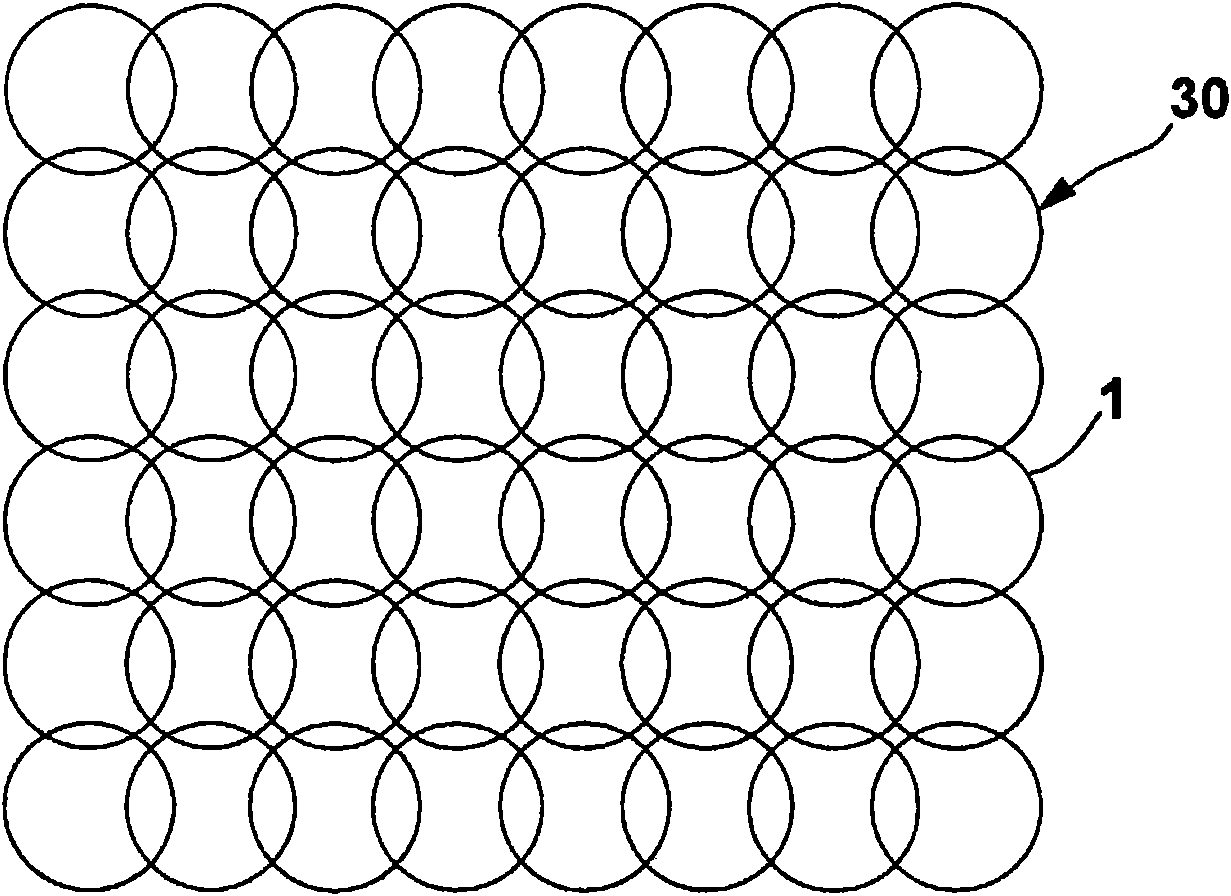

[0021] according to figure 1 , the loop fabric 30 features individual metal loops, where each loop is connected to an adjacent loop. To connect the rings, the openings of the individual rings are welded together, for example.

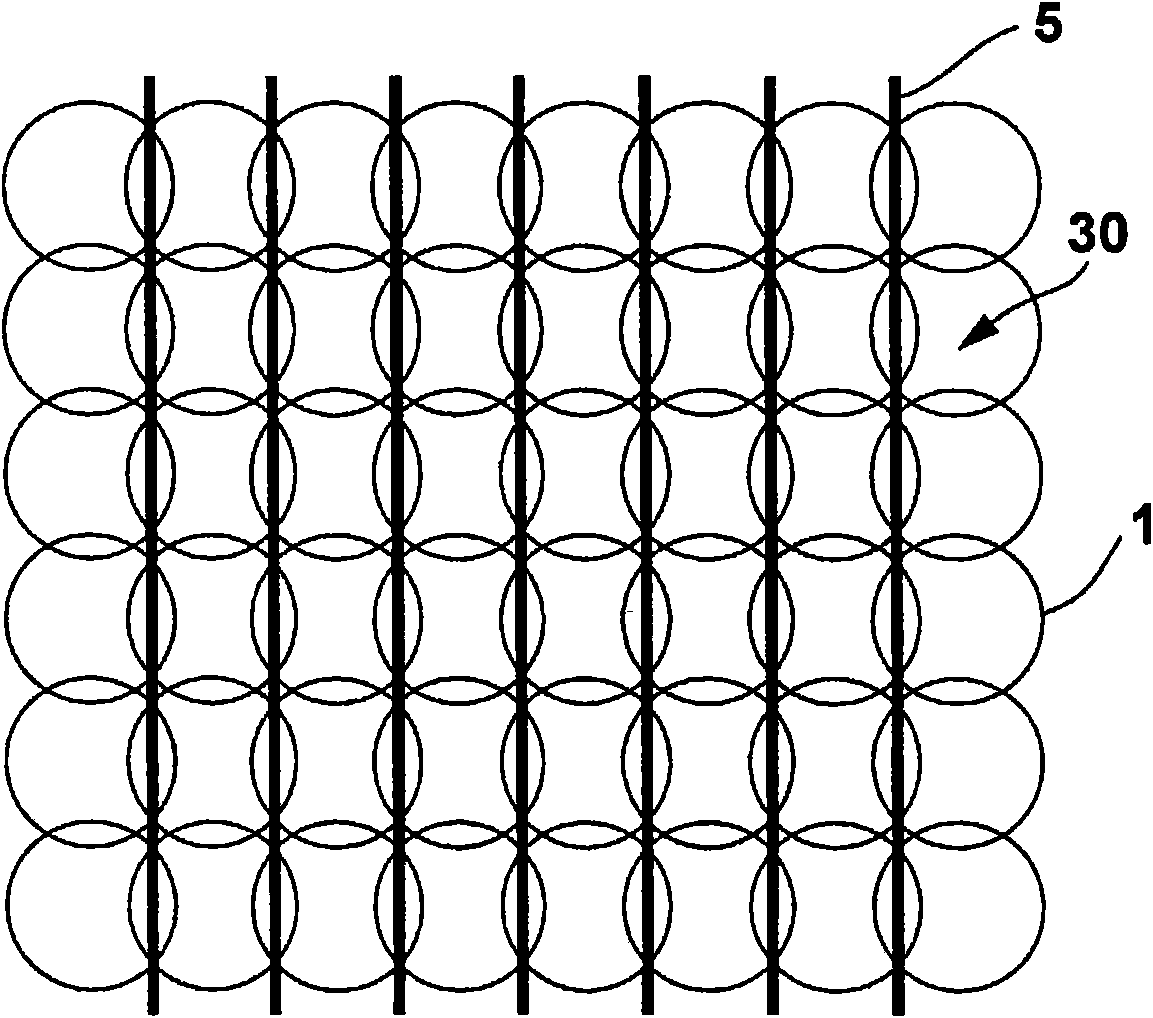

[0022] figure 2 A further embodiment of such a loop fabric 30 is shown, the loop fabric shown being characterized in that the individual loops 1 are connected to each other by threads 5 .

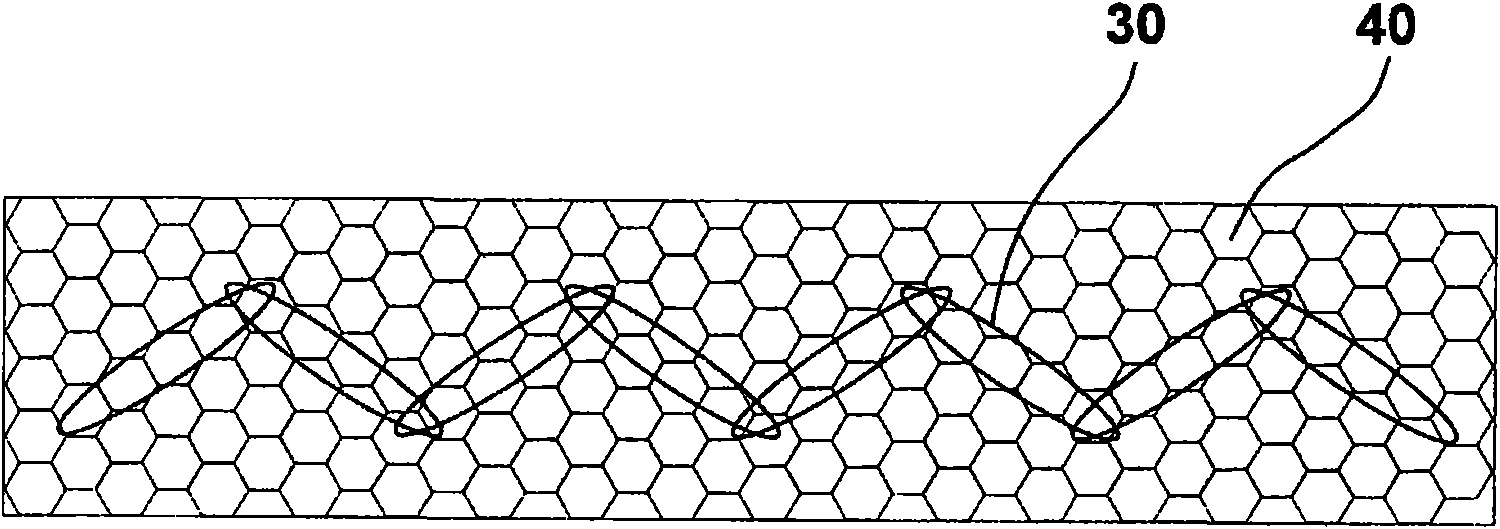

[0023] image 3 An embodiment is shown in which such a loop fabric 30 is embedded in a plastic layer 40 . The plastic layer can here be elastomer rubber or silicone rubber.

[0024] Figure 4 An example is shown, where according to image 3 The loop fabric 30 is embedded in the plastic layer and is provided with textile layers 50 on both sides, such as knitwear, knitted fabric or fabric. The textile layer can here be designed in one or more layers and can likewise be embedded in the foamed plastic. Such a textile layer serves, on the one hand, for reasons of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com