Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1003results about How to "Fully protected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

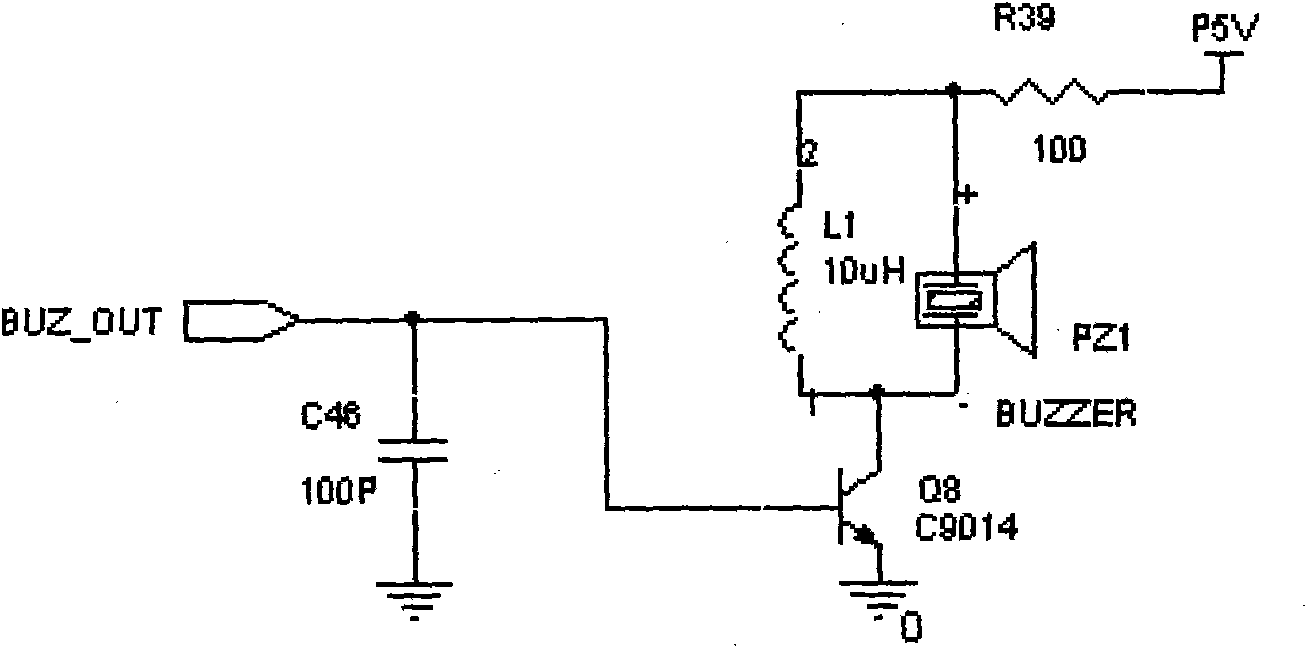

Serial and parallel switching and charging method and charging device for lithium dynamic battery unit

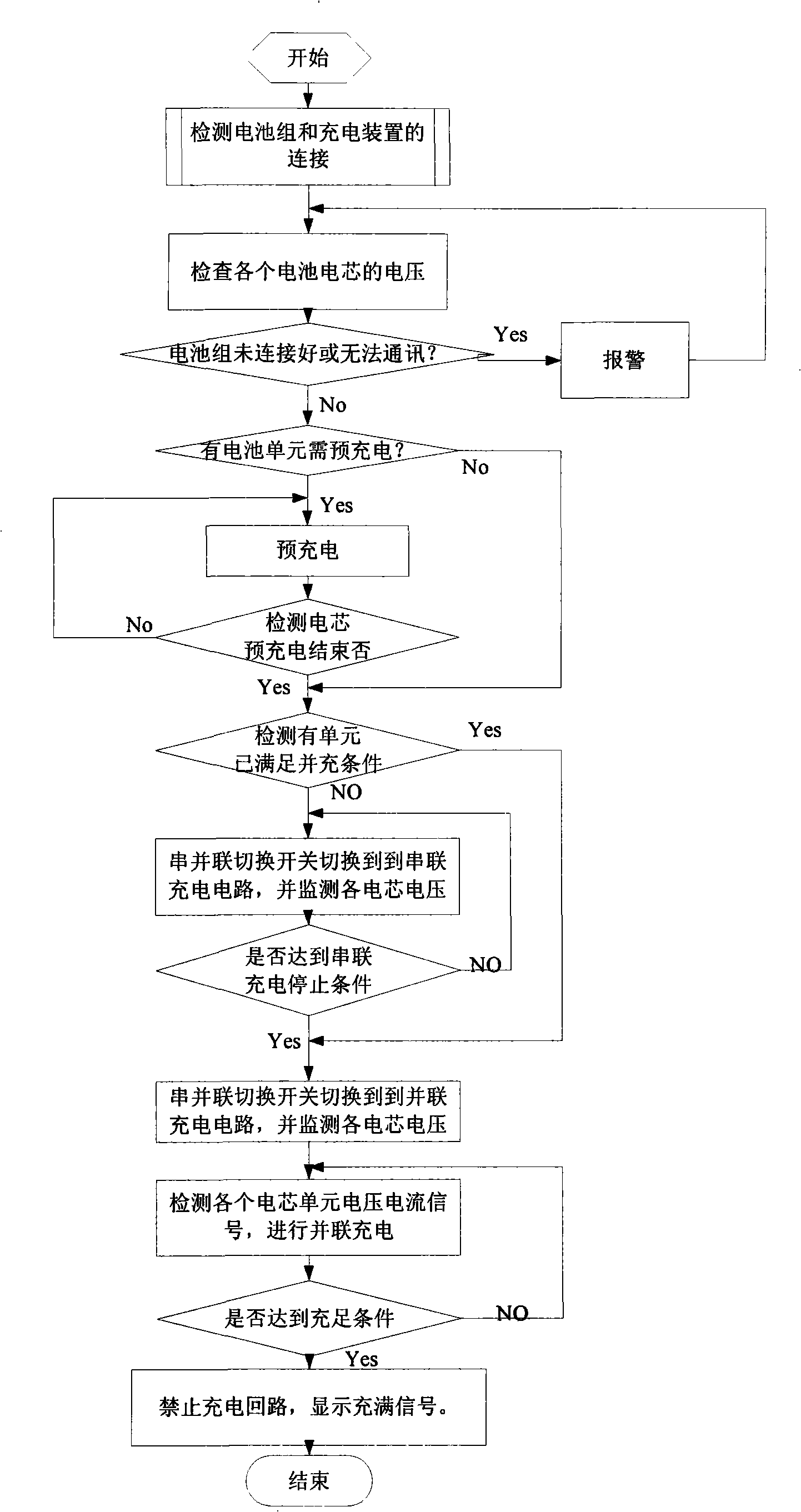

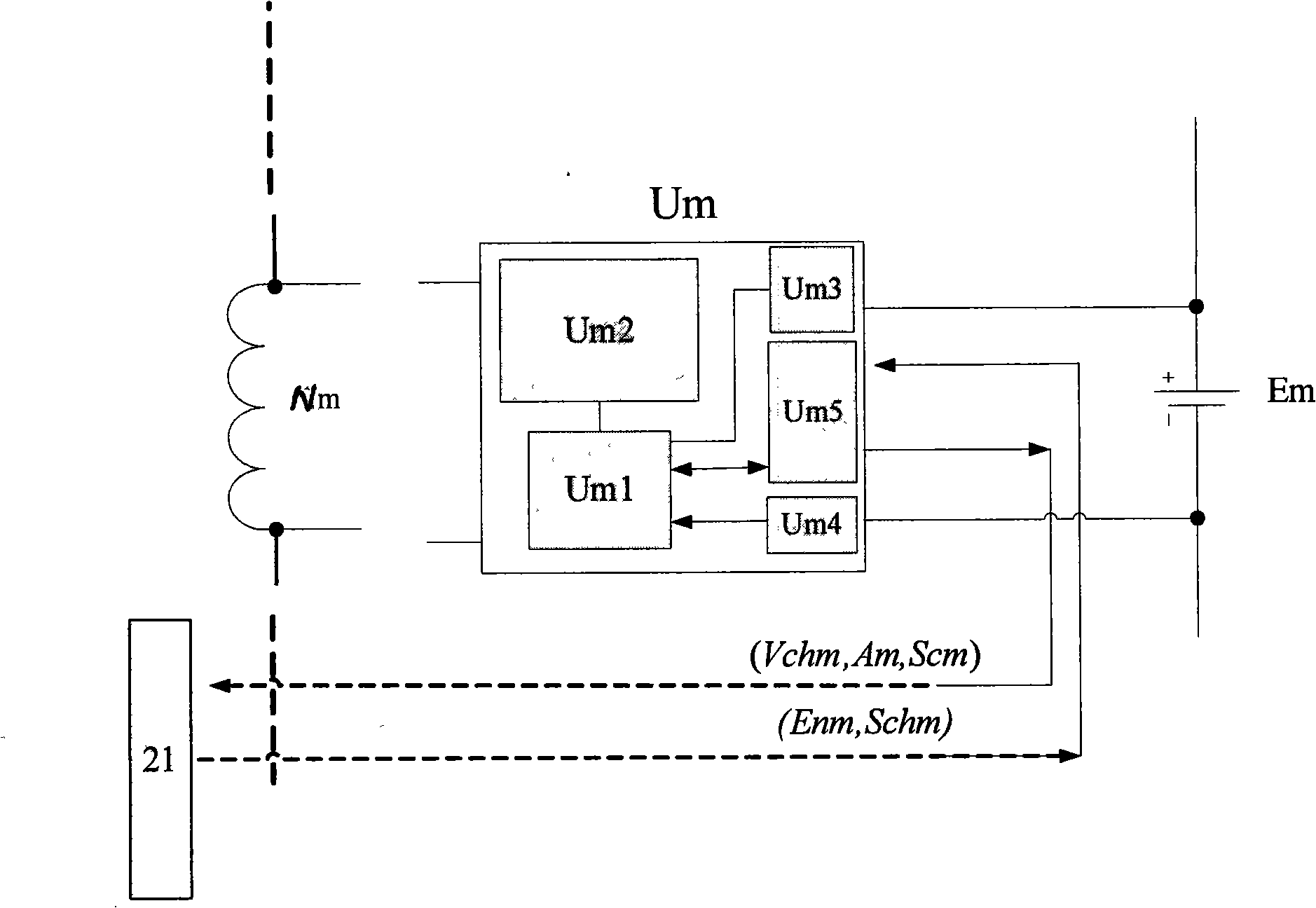

InactiveCN101262140ALow costReduce volumeBatteries circuit arrangementsEmergency protective circuit arrangementsTransformerPre-charge

The invention discloses an Li traction battery series parallel change-over charging method and a charging device. The charging device comprises a power main loop comprising a rectifier circuit, a DC filtering capacitor, a pre-charging circuit, a voltage sensor, a switch bridge circuit, a charging current sensor and a series parallel change-over switch, a control circuit board comprising a parallel branch signal unit, a switch signal drive control unit, a coil signal circuit, a voltage current signal circuit, a control processor and a signal display unit, a serial charging circuit comprising a filter inductor, a filter capacitor and an output voltage sensor, and a parallel charging circuit comprising a primary coil, a feedback coil, an iron core, a plurality of secondary coils of a multi-winding transformer and a plurality of series parallel charging unit. The pre-charging, serial charging and parallel charging are carried out by the charging method according to a set pre-charging voltage value and an end voltage value. The method and the device provided by the invention reduce the cost and volume of charging devices, maintain the balance of charging capacity of every Li traction battery electrical core, ensure adequate protection and best working status for each battery unit and improve safety and service life cycle of Li traction battery.

Owner:刘云海 +2

Procesing equipment capable of improving plate part formation limitation and method therefor

Owner:HARBIN INST OF TECH

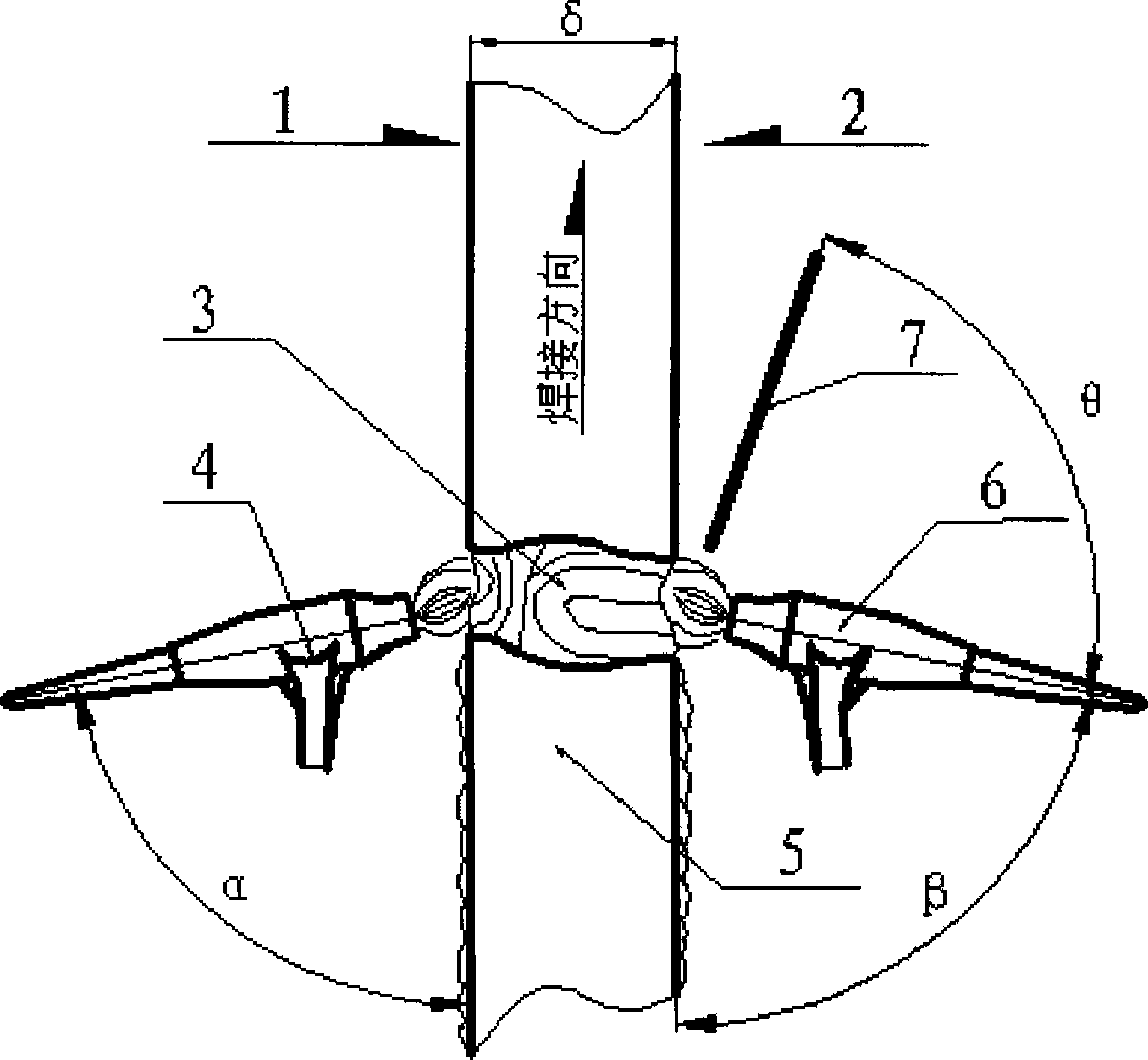

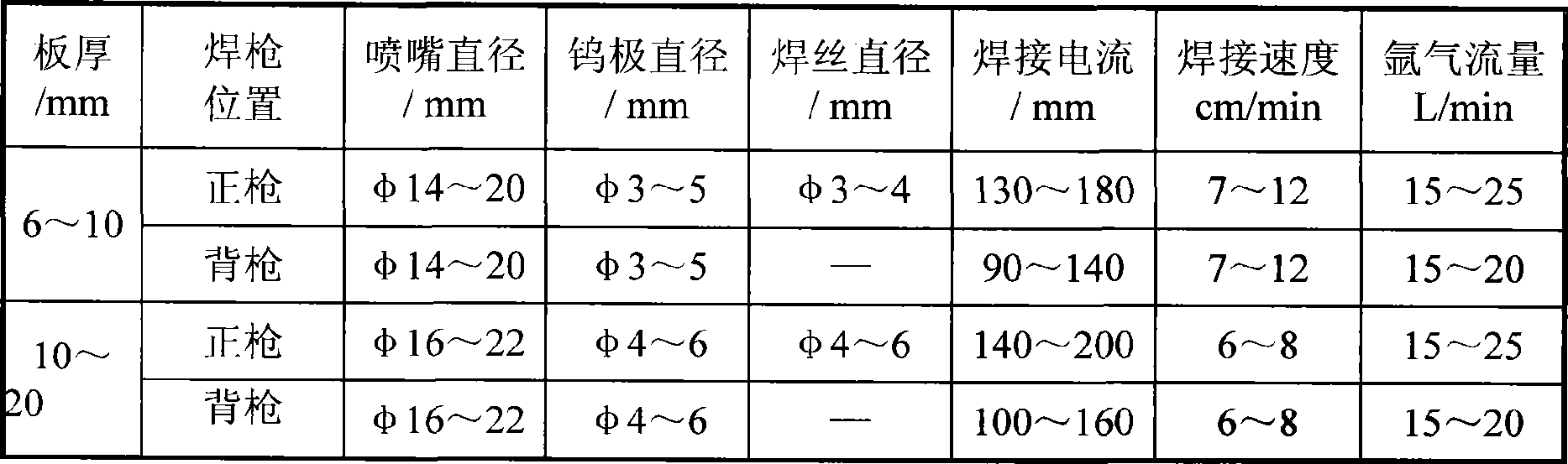

Aluminum and aluminum alloy handwork double-gun double-face TIG welding technique

InactiveCN101474709AFlexible approachAdaptableArc welding apparatusWelding/soldering/cutting articlesAluminium alloyWelding joint

The invention introduces a manual double-torch double-side TIG welding technology for welding aluminum and aluminium alloy. The welding process comprises the following steps: a vertical upward welding technique is adopted, two manual welding torches simultaneously and respectively initiate arc and weld at the front side and the reverse side of welding joints to be welded; two tungsten electrodes are basically aligned; the two welding torches move simultaneously and share a melting bath; the front side of welding lines are filled with welding sticks while the reverse side is not. Welding parameters such as the reverse side welding torch current and the like are less than the welding parameters of the front side welding torch; once weld penetration is achieved and both sides are shaped; argon shield is adopted in the process of welding; inclination angles Alpha and Beta are controlled within the range of 70-100 degrees, the included angle Theta between the welding sticks and the welding torches is maintained within the range of 80-110 degrees. According to the welding technology of the invention, irregular space curve welding lines of medium wall are welded, the applied technology is flexible and the adaptability is high, thus simplifying production procedures and process steps, greatly improving welding efficiency, avoiding possibility of causing interlayer defects due to multilayer welding and improving interior quality of welding lines and appearance quality thereof.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

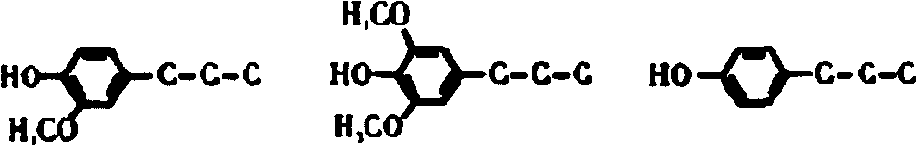

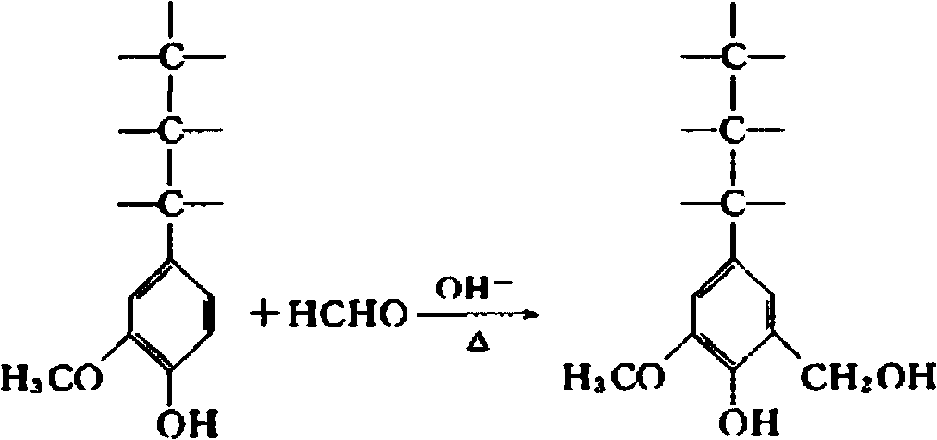

Preparation method of modified phenolic resin binder for casting

InactiveCN101607297ALow costImprove practicalityFoundry mouldsFoundry coresSodium BentoniteEconomic benefits

The invention provides a preparation method of a modified phenolic resin binder for casting, belonging to the technical field of binder for casting. The preparation method comprises the following steps of: carrying out hydroxymethylation modification to lignin, then carrying out cocondensation of hydroxymethylation lignin, phenol and formaldehyde, finally adding organic bentonite for composition and preparing the modified phenolic resin binder. The lignin molecule has phenolic hydroxyl and aldehyde group, uses lignin, not only improves the property of the binder, but also saves using amount of the phenol, reduces the releasing amount of formaldehyde and achieves the purposes of fully utilizing waste and protecting environment. Simultaneously, the adding of the organic bentonite further improves the strength and stability of the binder. The binder product has high strength and good comprehensive performance, can replace synthetic fat oil or partial resin sand to manufacture II level mud core, have the advantages of low cost, low content of free formaldehyde and good storage and stability and the like, have obvious economic benefit and can be widely applied in the casting field.

Owner:FUZHOU UNIV

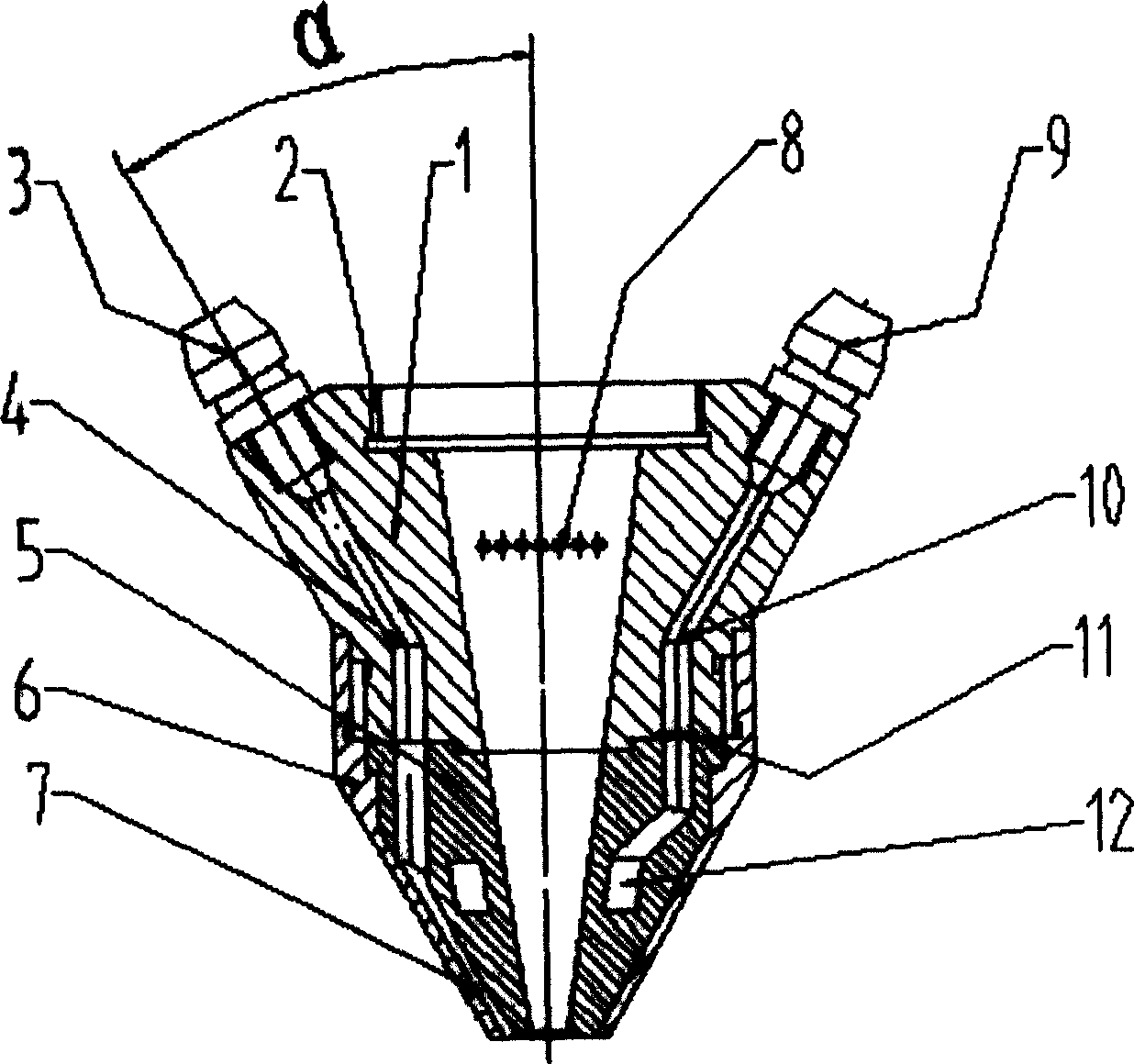

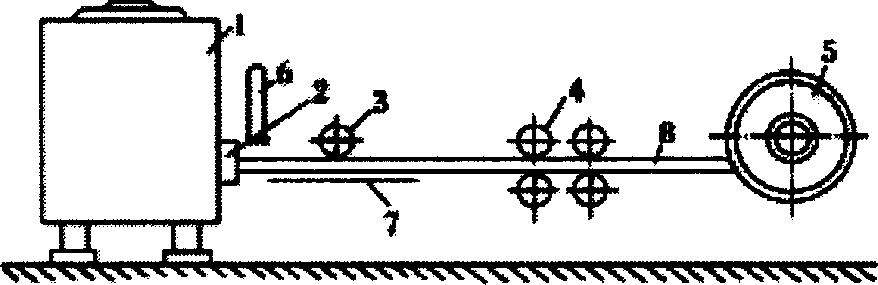

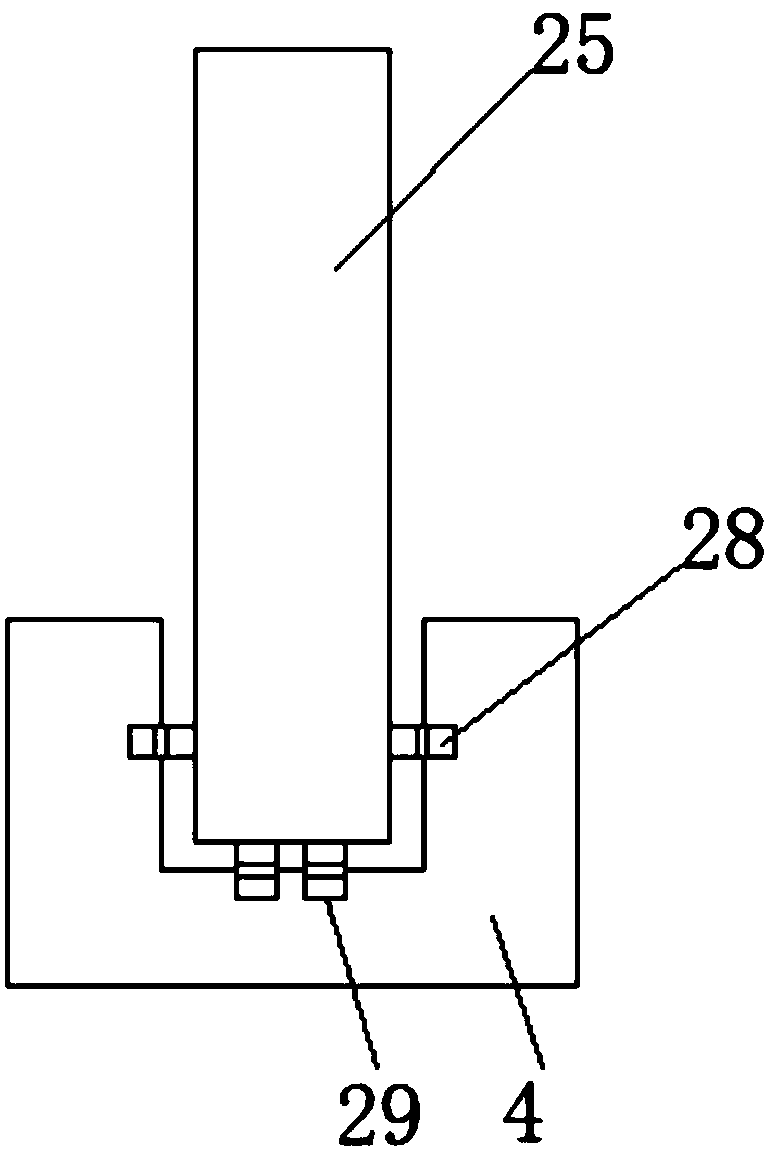

Built-in type jet nozzle for laser melting and coating

ActiveCN1570190ASuitable for laser cladding applicationsFully protectedMolten spray coatingLaser beam welding apparatusCarbon Dioxide / HeliumShielding gas

The invention discloses a built-in laser cladding nozzle. A powder channel, a cooling water way and a shielding gas channel are arranged in the wall of the tapered drum; the outlets of the power channel are distributed uniformly on the bottom circle of the tapered drum, and the other outlets and inlets are arranged uniformly on the upper circle of the tapered drum; the included angle Alpha between the axis of the powder and the axis of the nozzle center is in a range of between 30 degree and 70 degree; a cooling water ring connected with the cooling water way is arranged in the bottom wall of the tapered drum; and the horizontal shielding gas screen for protecting the condensing lens system consists of an air inlet, a connection channel, an air box, exhaust holes, and an air outlet. The nozzle can be used as not only side axial powder-feeding nozzle, but also coaxial powder-feeding nozzle.

Owner:TECH LASER TECH SHANGHAI CO LTD

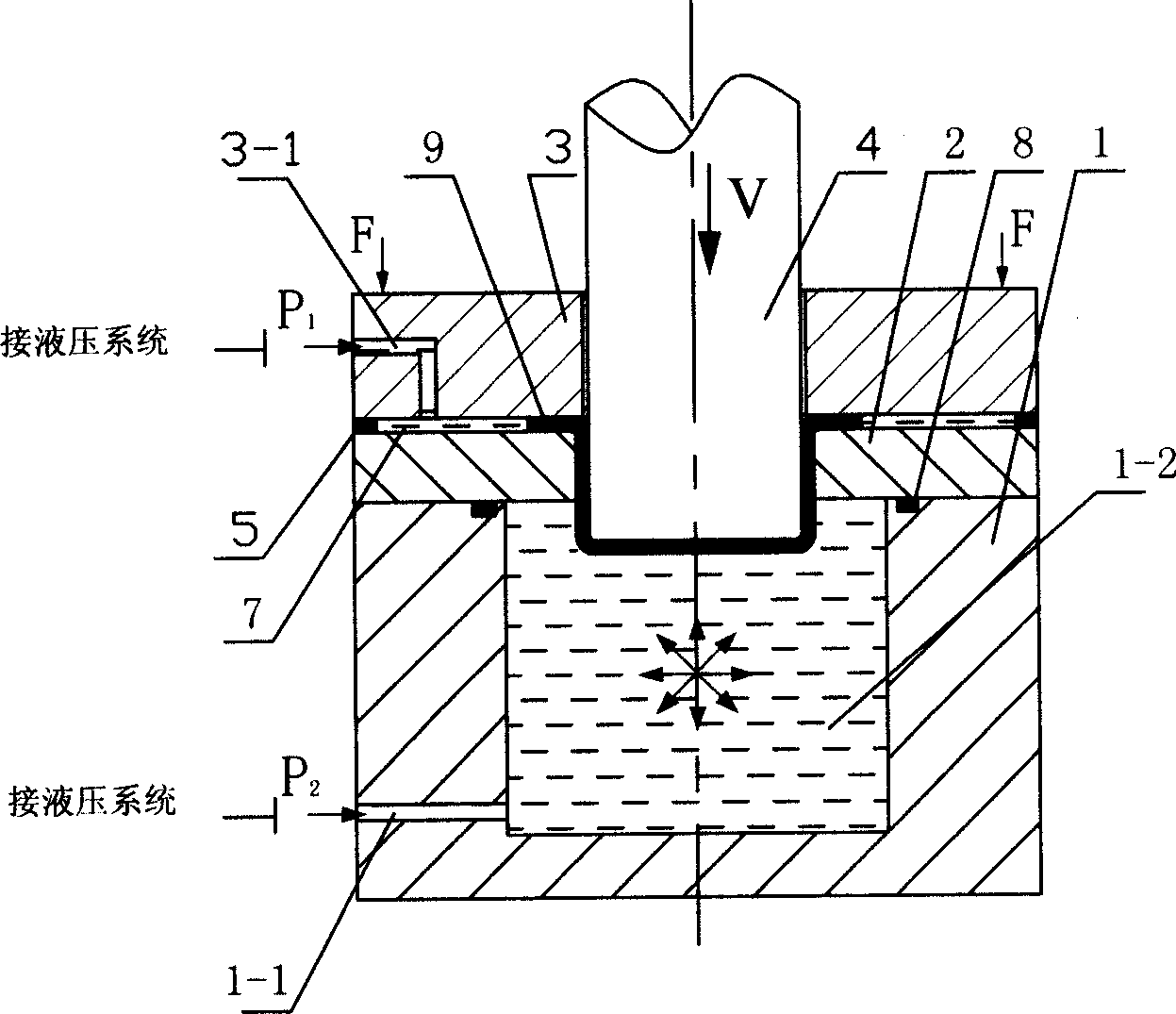

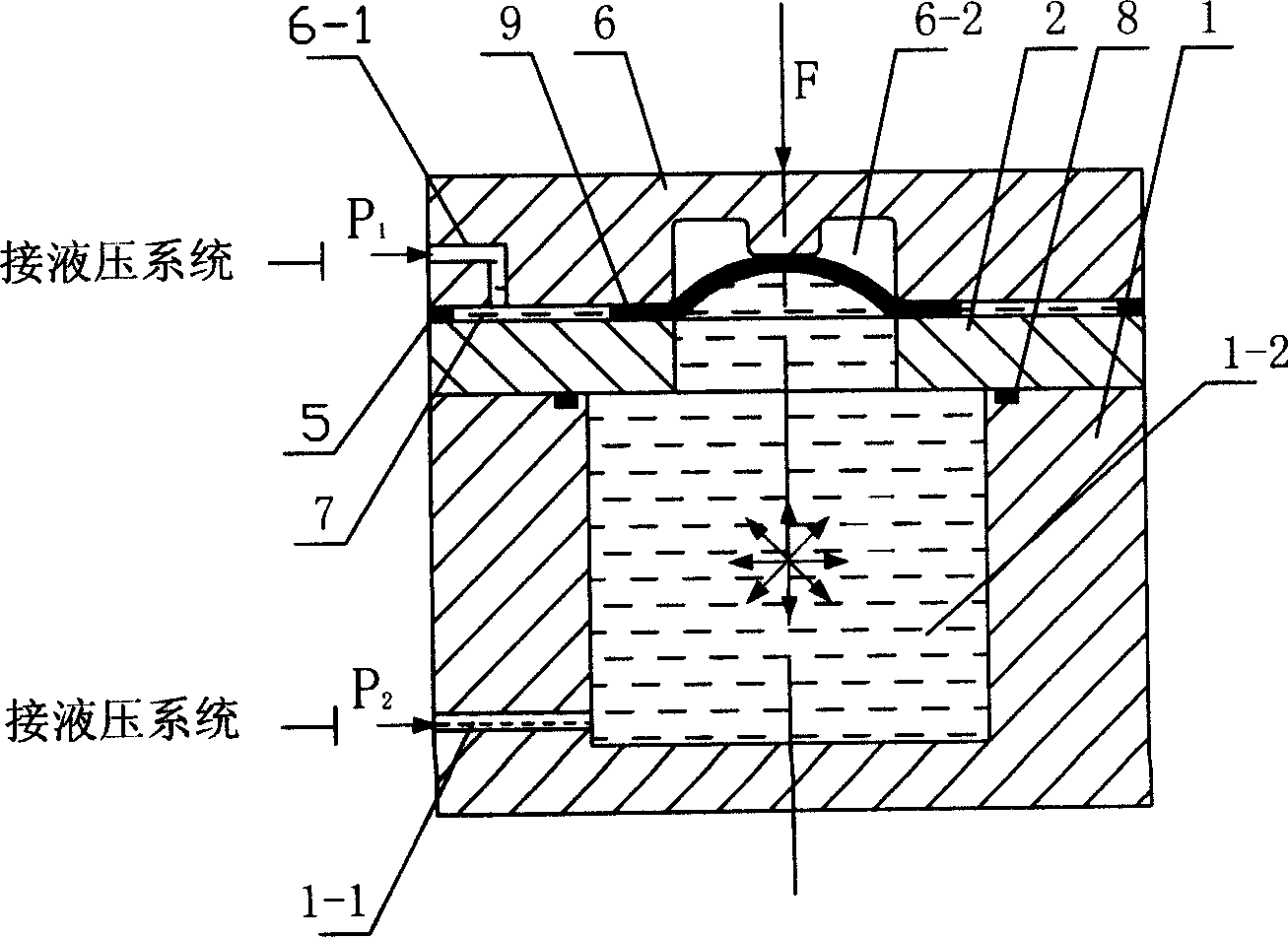

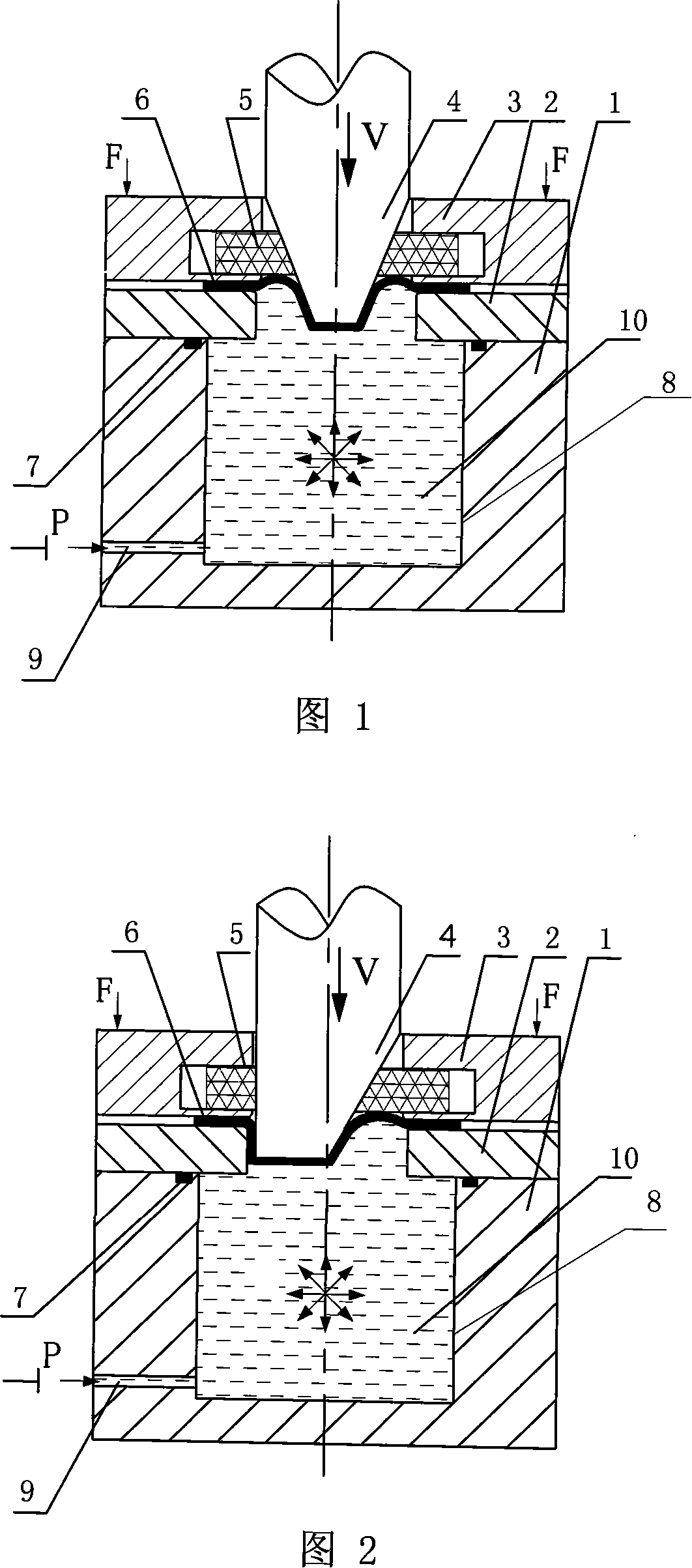

Device for preventing suspension area from breaking while taper piece filling liquid and drawing deep forming and forming method

InactiveCN101147940AReduce frictionReduce friction, so that the surface of the billet is fully protectedShaping toolsEngineeringMechanical engineering

The present invention relates to a conical component forming device capable of preventing floating zone from being broken when the conical component is formed by adopting liquid-charging and drawing process and its forming method. Said conical component forming device is characterized by that its rigid edge-pressing ring is set over a concave die, in said rigid edge-pressing ring interior a recessed groove is cut, a flexible supporting ring is placed in the recessed groove interior, said concave die is placed on the fluid medium cavity, and its liquid-injecting hole is connected with its hydraulic system. Its forming method includes the following steps; (1), making the liquid-injecting hole on the cavity body be communicated with the hydraulic system; (2), placing a plate blank on the concave die; (3), making the rigid edge-pressing ring be moved downwards and apply edge-pressing force; and (4), making convex die be downwards moved until the plate blank is drawn into the concave die interior with the convex die so as to obtain a formed conical component.

Owner:HARBIN INST OF TECH

Boron-iron and iron-titanium composite cored wire and application thereof

The invention relates to a boron-iron and iron-titanium composite cored wire and the application thereof. The powdery raw materials of the boron-iron and iron-titanium composite cored wire include boron iron and iron titanium, wherein the boron content of boron iron is not less than 9wt%, the titanium content of iron titanium is not less than 25wt%, and the mixing ratio of boron iron to iron titanium depends on the actual needs. The boron-iron and iron-titanium composite cored wire is manufactured by adding boron iron and iron titanium to molten steel at the same time, thereby simplifying the alloying operation in boron steel smelting and stabilizing the control of boron content in steel. Compared with the prior boron iron cored wire, the boron-iron and iron-titanium composite cored wire has the advantages of low proportion of boron iron, small fluctuation of deviation of the addition amount of boron iron, less loss, adequate protection of each boron iron fine particle by titanium element, and stable boron recovery rate (over 93%). The boron-iron and iron-titanium composite cored wire achieves the effect that the deviation of boron content in smelting components between furnaces for manufacturing the same boron-containing steel grades is less than 2ppm.

Owner:SHANDONG IRON & STEEL CO LTD +1

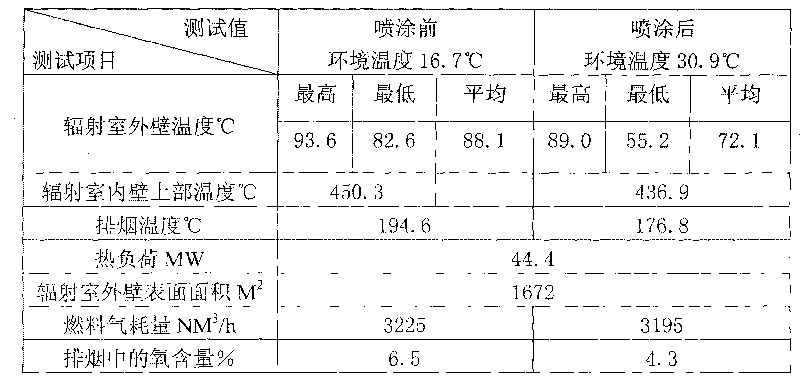

High-temperature counter radiation resistant inorganic coating and preparation method thereof

InactiveCN101760058AImprove thermal shock resistanceImprove thermal efficiencyFireproof paintsAlkali metal silicate coatingsPhosphateOxidation resistant

The invention relates to an energy-saving high-temperature counter radiation resistant inorganic coating for coating the liner of a kiln and a preparation method thereof. The coating mainly comprises oxides, such as cobalt oxide, zirconium oxide powder, aluminum oxide and chromic oxide, and silicon powder, silicon carbide, sodium silicate, aluminium dihydrogen phosphate, silica flour, graphite powder, boron oxide and other components and is prepared by grinding, soaking, heating reaction, stirring and mixing. The coating has high thermal shock resistance, high radiation utilization rate, high corrosion resistance, high cracking resistance, high oxidization resistance and high thermal stability. The inorganic coating of the invention has the advantages of allowing for normal construction without making special modification of the basal body of the kiln, along with small investment, quick response, no toxicity, no corrosion and desirable social and economic benefits.

Owner:上海乐恒石油化工集团有限公司

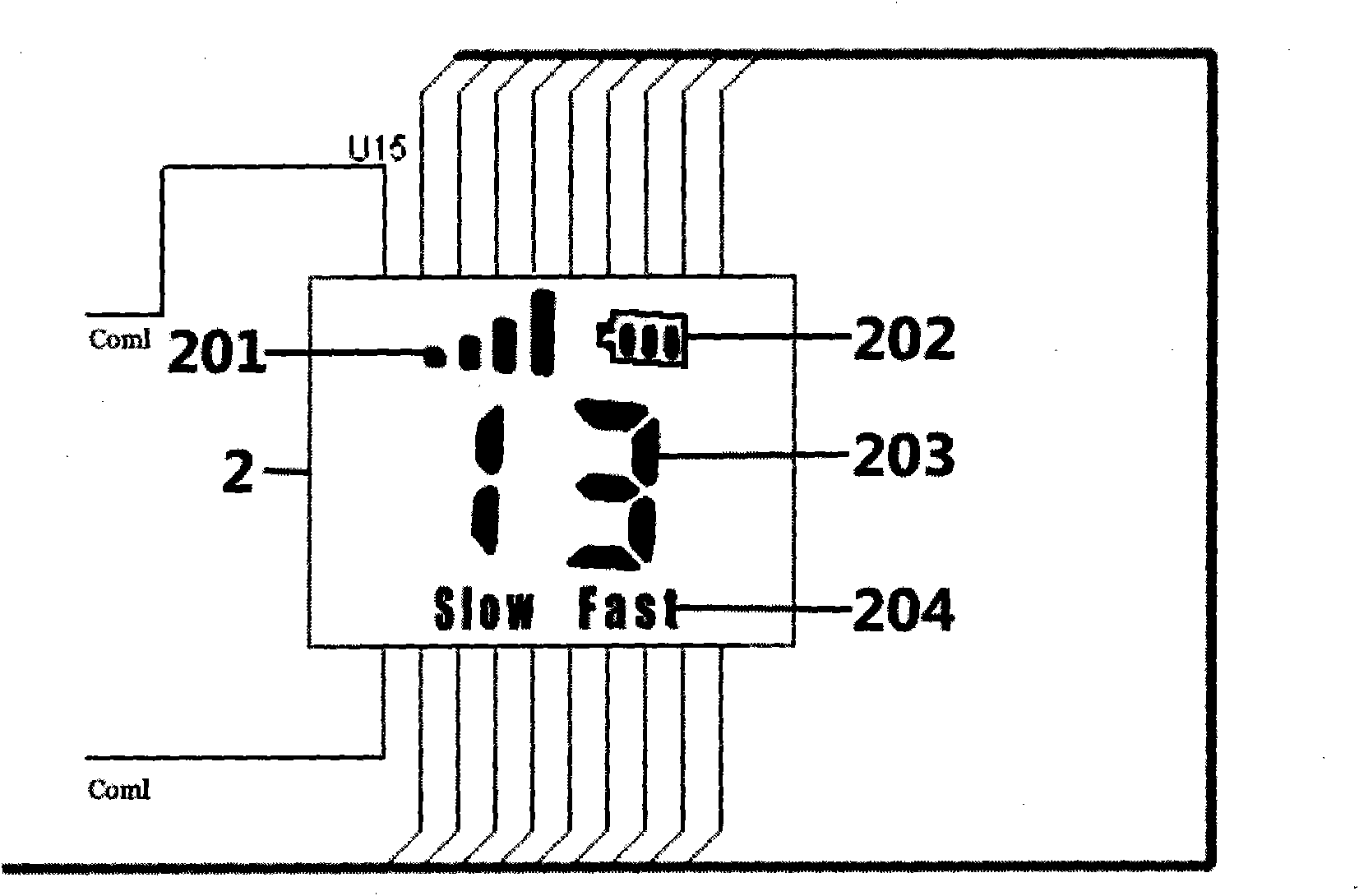

Auto-darkening welding filter capable of automatically setting shade number

ActiveCN101785725AReduce inconvenienceLower technical barriersGogglesEye-masksMicrocontrollerAutomatic control

The invention discloses an auto-darkening welding filter capable of automatically setting a shade number, comprising a liquid crystal lens group, light sensitive tubes, a trigger circuit and a singlechip. Two groups of light sensitive tubes are provided, one group includes infrared light sensitive tubes and the other group includes green light sensitive tubes, wherein, the infrared light sensitive tubes are used for detecting welding arc light and controlling the work of the singlechip through the trigger circuit; the green light sensitive tubes are used for detecting green light signals in the welding arc light and transmitting the detected signal to a matched light intensity processing circuit; the detected signal is processed into a light intensity signal by the light intensity processing circuit and is then transmitted to the singlechip; and the singlechip automatically controls the darkening of the liquid crystal lens group according to the green light intensity value. The filterovercomes the problem of damage to the users by the existing darkening welding filter owning to using complexity and easy misoperation.

Owner:DAHENG NEW EPOCH TECH

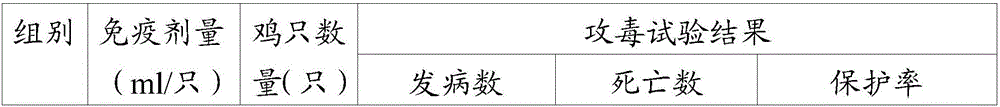

Livestock adenovirus strain, vaccine composition and application thereof

ActiveCN107523556AImproving immunogenicityFully protectedViral antigen ingredientsMicroorganism based processesSerum igeAvian adenovirus

The invention provides a serum type-4 livestock adenovirus strain FAV-HN. The strain has good immunogenicity. A vaccine composition prepared from an antigen of the strain can rapidly generate antibodies after immune, and chickens can be completely protected by using a low-content vaccine composition. In addition, the antigen has combined action with multiple other antigens, and the immunity effects are not affected by the antigens.

Owner:PU LIKE BIO ENG

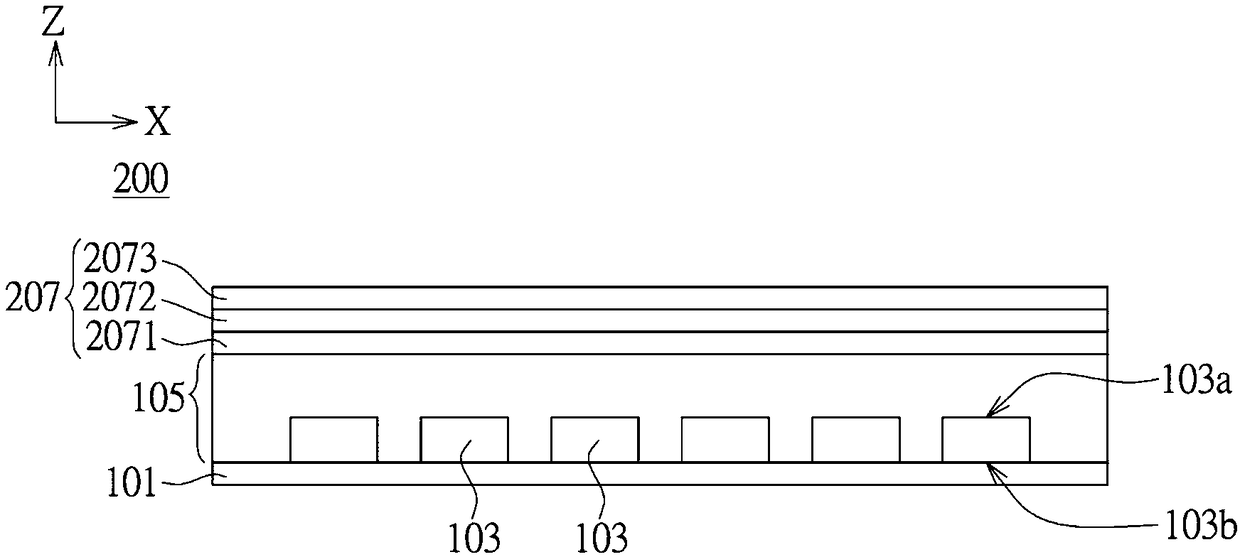

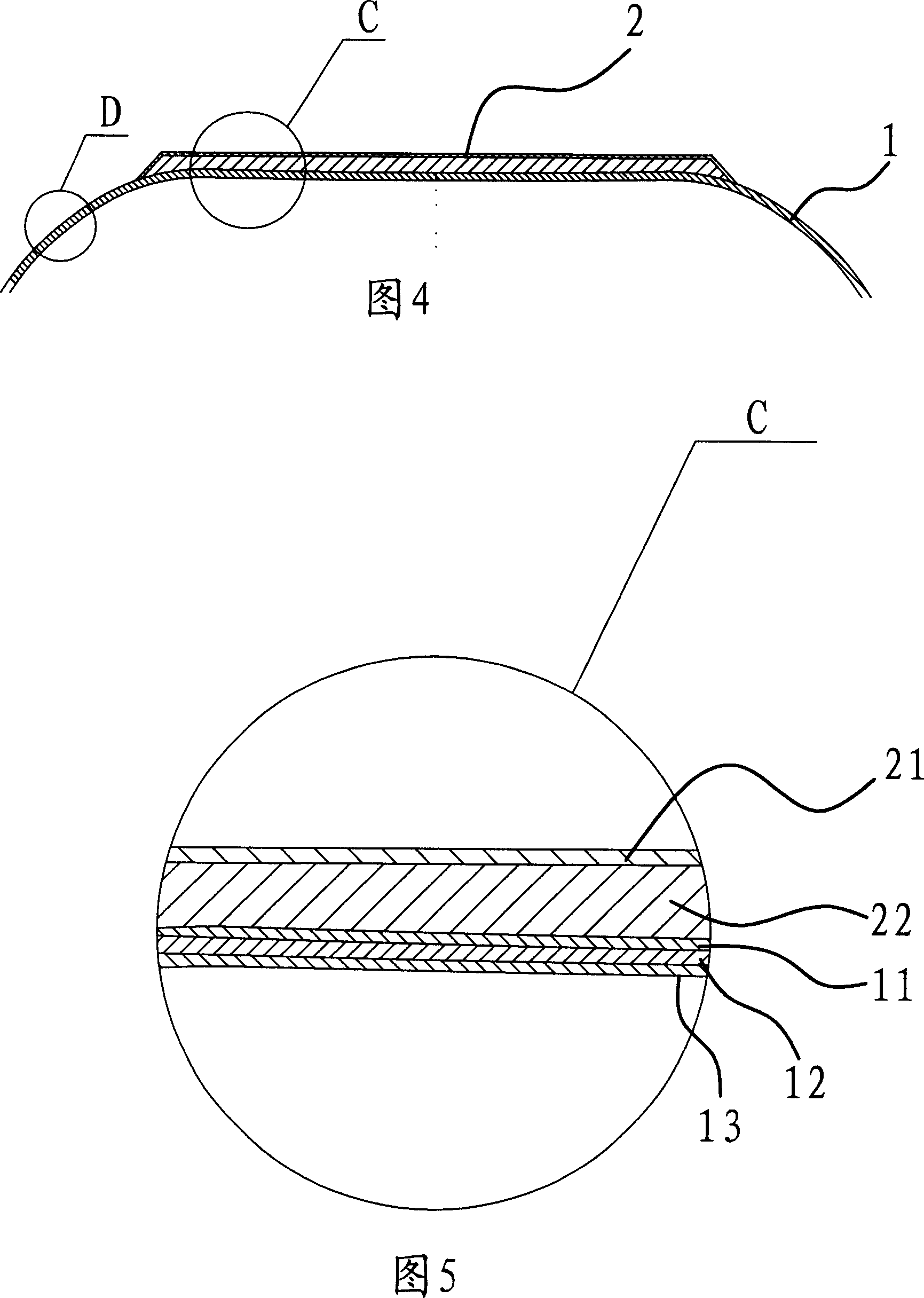

Backlight module, panel comprising same, and manufacturing method of backlight module

ActiveCN109254451AFully protectedExcellent optical propertiesNon-linear opticsOptical propertyLight-emitting diode

The invention discloses a backlight module, a panel comprising the same, and a manufacturing method of the backlight module. The backlight module comprises a light emitting unit, an adhesive layer, and an optical film layer. The light emitting unit is covered on the adhesive layer. The optical film layer is arranged on the adhesive layer. The adhesive layer is arranged between the optical film layer and the light emitting unit. The light emitting unit is a light emitting diode, which is a sub-millimeter light emitting diode or a micro light emitting diode. The size of the light emitting diodeis less than 500 millimeters. The light emitting diode is covered by the adhesive layer and the optical film layer, is protected, and is not exposed to the air directly. Due to the special optical design of the adhesive layer or / and the optical film layer, the optical characteristics of the light emitting diode are improved.

Owner:SUMIKA TECH

Method for using fungi to elicit Aquilariasinensis tree to produce agilawood

InactiveCN101781623ATake advantage ofFully protectedFungiMicroorganism based processesChemical compositionAquilaria

The invention relates to a method for using fungi to elicit an Aquilariasinensis tree to produce agilawood, belonging to the biotechnological field. Two used fungi comprise a Fusaria (Fusarium sp.) fungus A-11 and a Cephalosporium (Cephalos porium sp.) fungus A-17. The content comprises the culture method and the inoculation method of the fungi. By adopting the method, the trunk of the Aquilariasinensis tree to elicited to secrete yellow brown substances similar to the chemical ingredients of agilawood. The invention has the advantages that the method is simple and convenient, the production cost is low, the period is short, the Aquilariasinensis tree resources are fully utilized and protected, and the popularization and the application are facilitated.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

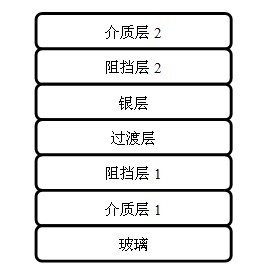

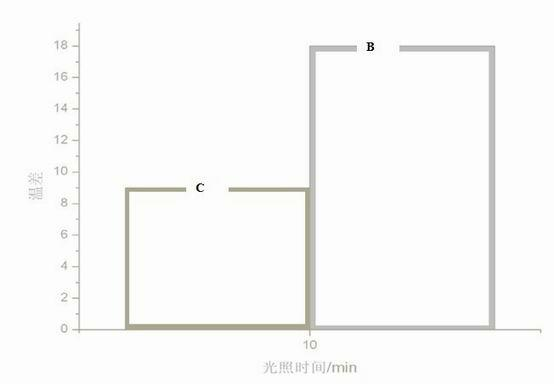

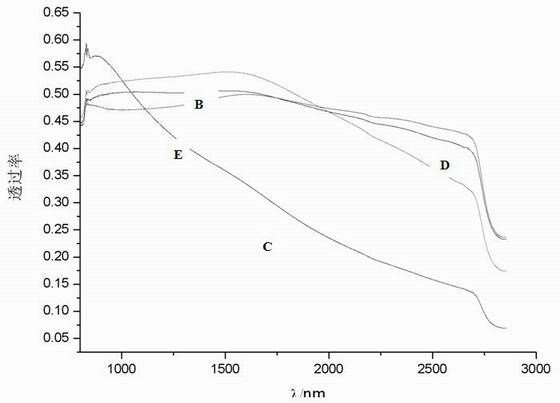

Low emissivity glass

The invention discloses low emissivity glass. The low emissivity glass contains a glass substrate, a first dielectric layer, a first barrier layer, a transition layer, a metal layer and a second barrier layer in turn from bottom to top, wherein preferably, a second dielectric layer can be plated on the second barrier layer; the transition layer is adopted to promote the growth of the metal layer and ensure that the metal layer can grow to form a continuous structure, thus the glass can have high infrared reflectivity and visible light transmittance; and the barrier layers can fully protect the metal layer to ensure that the high infrared reflectivity of the metal layer can be utilized. The low emissivity glass has low production cost and very good industrial application prospect; and the energy can be effectively saved.

Owner:HUAZHONG UNIV OF SCI & TECH

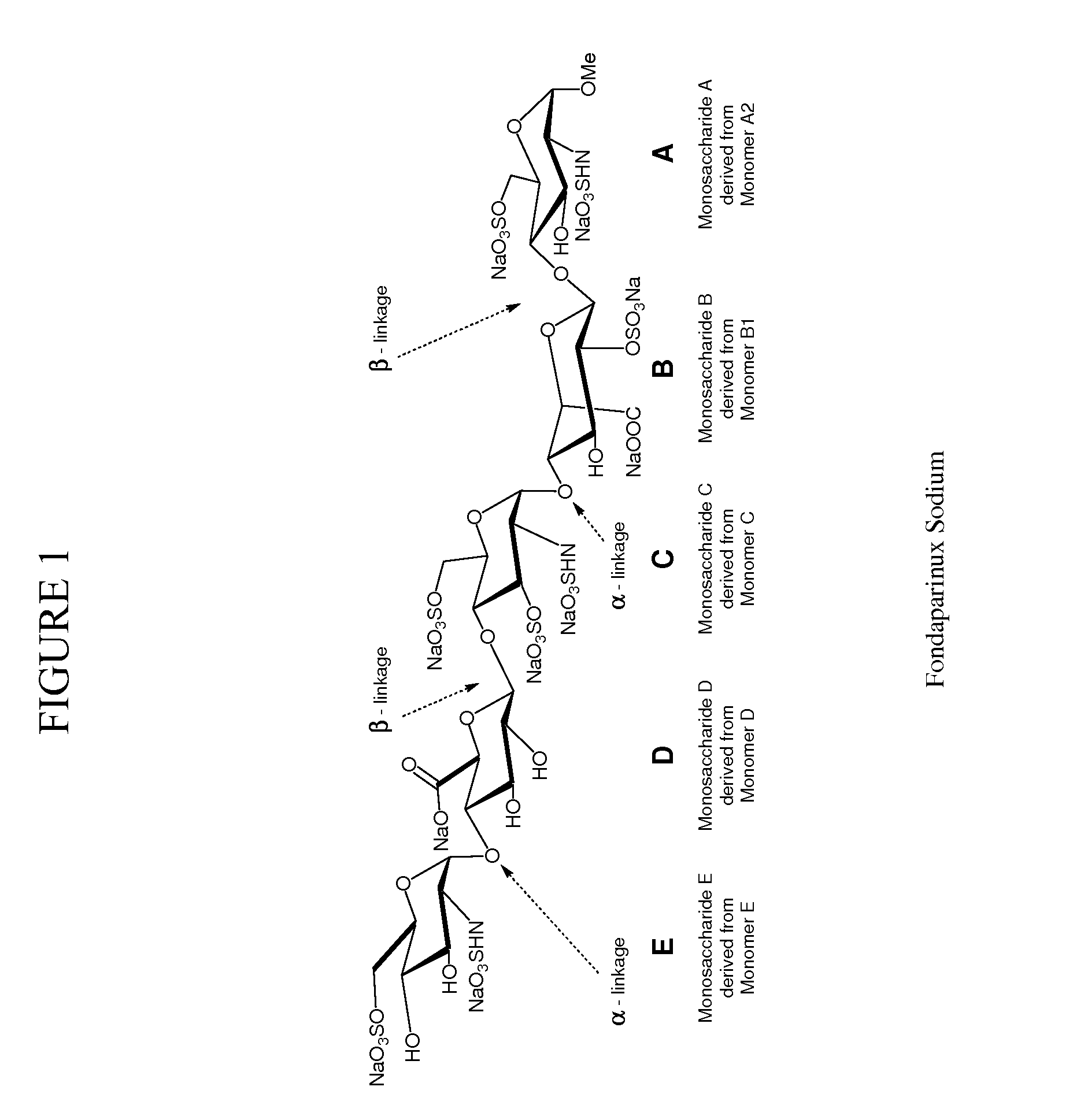

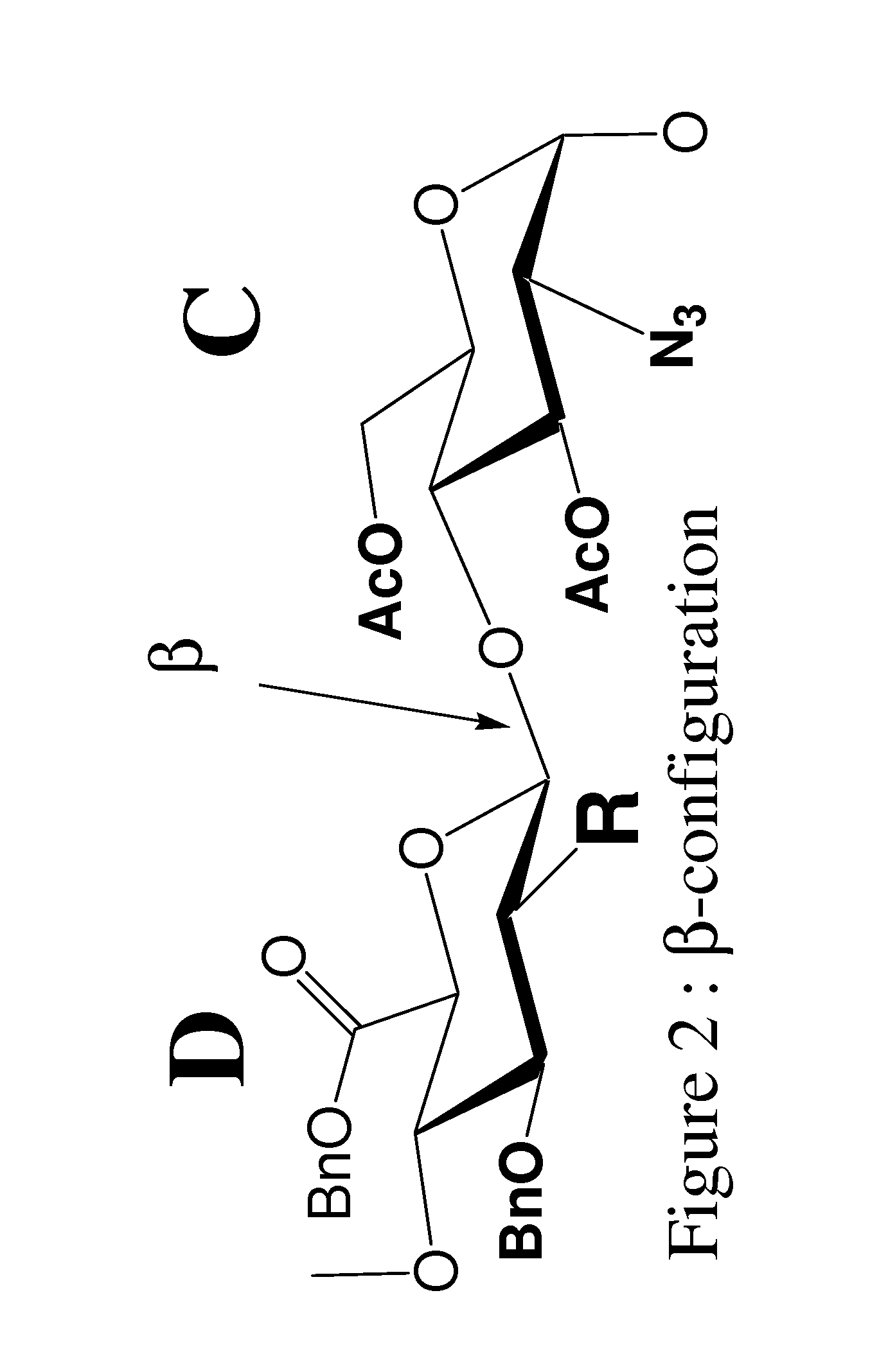

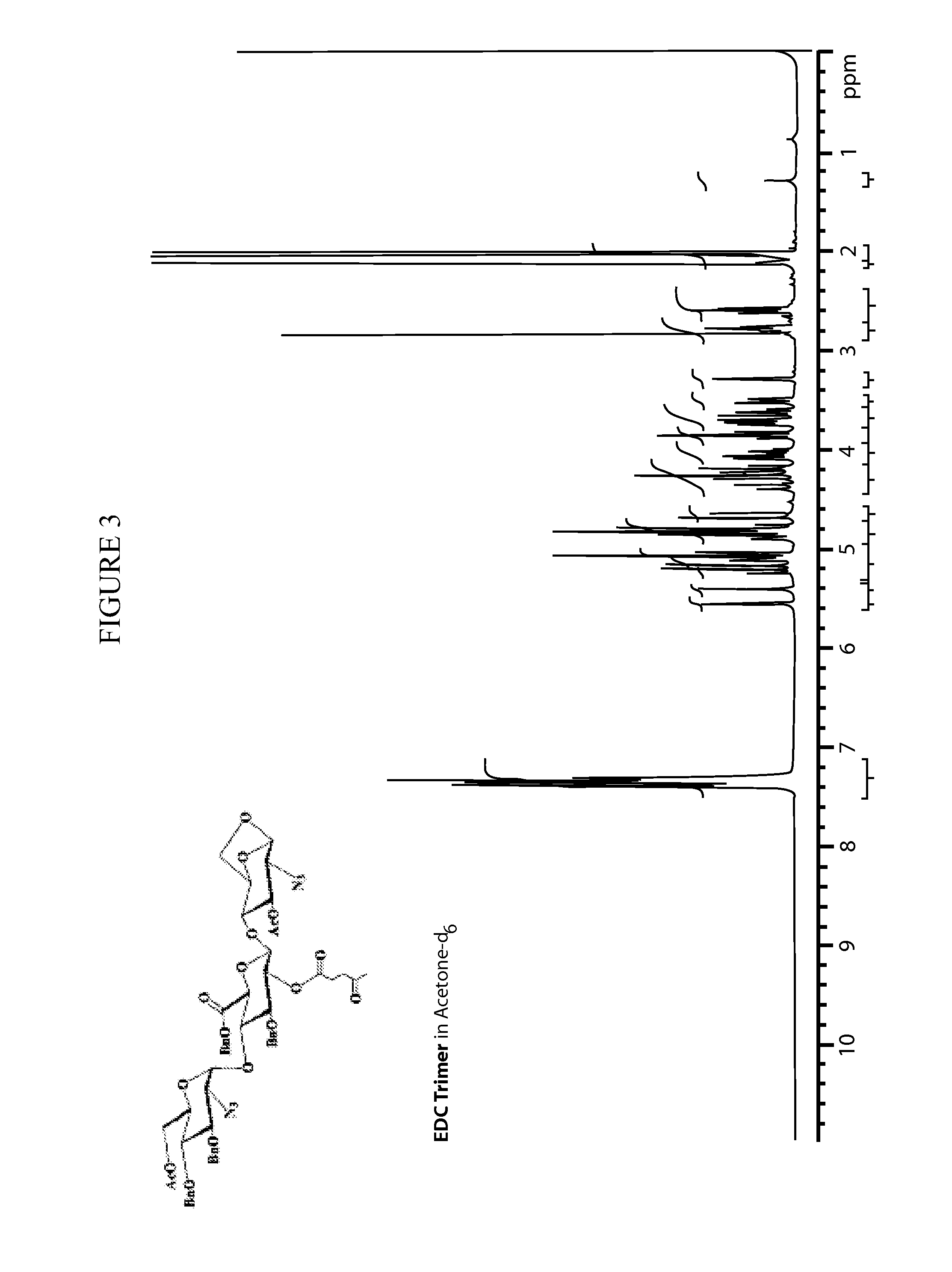

Process for preparing Fondaparinux sodium and intermediates useful in the synthesis thereof

ActiveUS8288515B2Highly efficient glycosylation reactionGood yieldEsterified saccharide compoundsOrganic active ingredientsAnticoagulant AgentCombinatorial chemistry

Processes for the synthesis of the Factor Xa anticoagulent Fondaparinux, and related compounds are described. Also described are protected pentasaccharide intermediates as well as efficient and scalable processes for the industrial scale production of Fondaparinux sodium by conversion of the protected pentasaccharide intermediates via a sequence of deprotection and sulfonation reactions.

Owner:RELIABLE BIOPHARM LLC

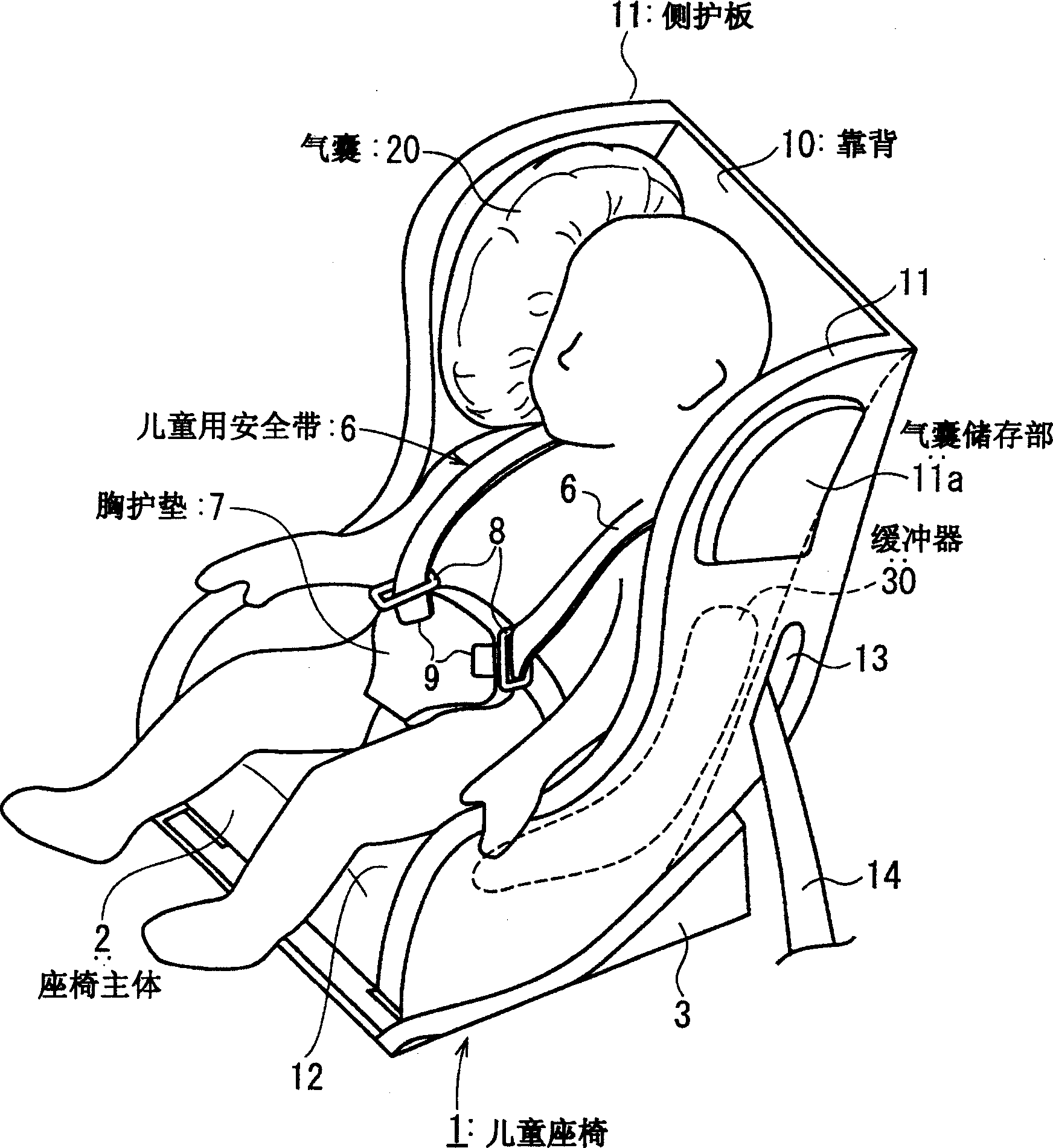

Child seat

InactiveCN1572601ASimple structureFully protectedPedestrian/occupant safety arrangementKids chairsEngineeringAirbag deployment

In order to provide a child seat that has a simple structure and that achieves thorough protection of a child, a child seat (1) includes side panels (11) whose upper portions facing the sides of the head of a child seated in the seat (1) are provided with airbags (20), and whose inner surfaces below the airbags (20) are provided with cushions (30). Each cushion (30) and its corresponding airbag (20) communicate with each other through a duct. When the child's body comes into contact with the cushion (30) during a collision and the pressure inside the cushion (30) rises, the gas inside the cushion (30) is discharged towards the airbag (20) so as to inflate the airbag (20) over the side of the child's head.

Owner:JOYSON SAFETY SYST JAPAN KK

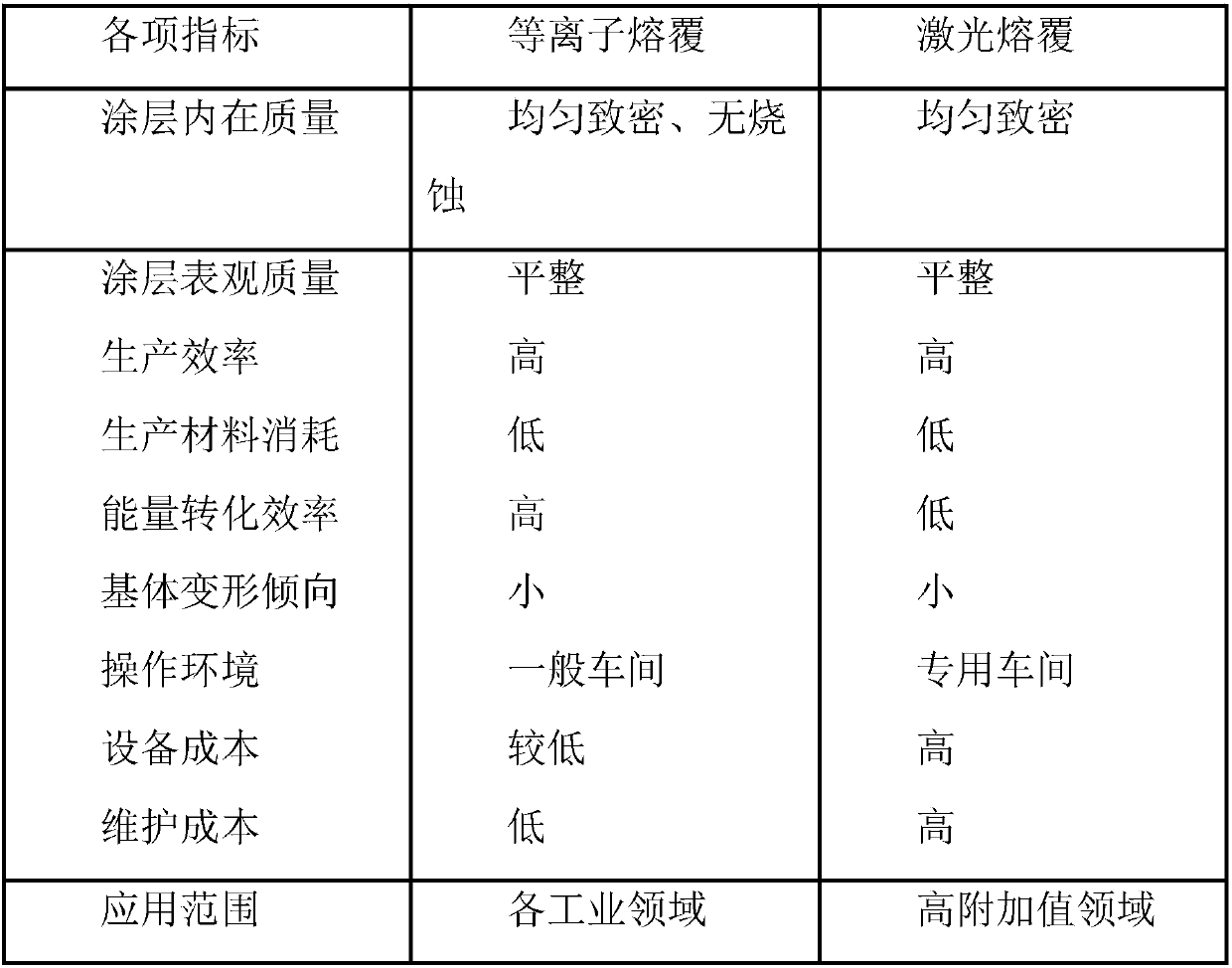

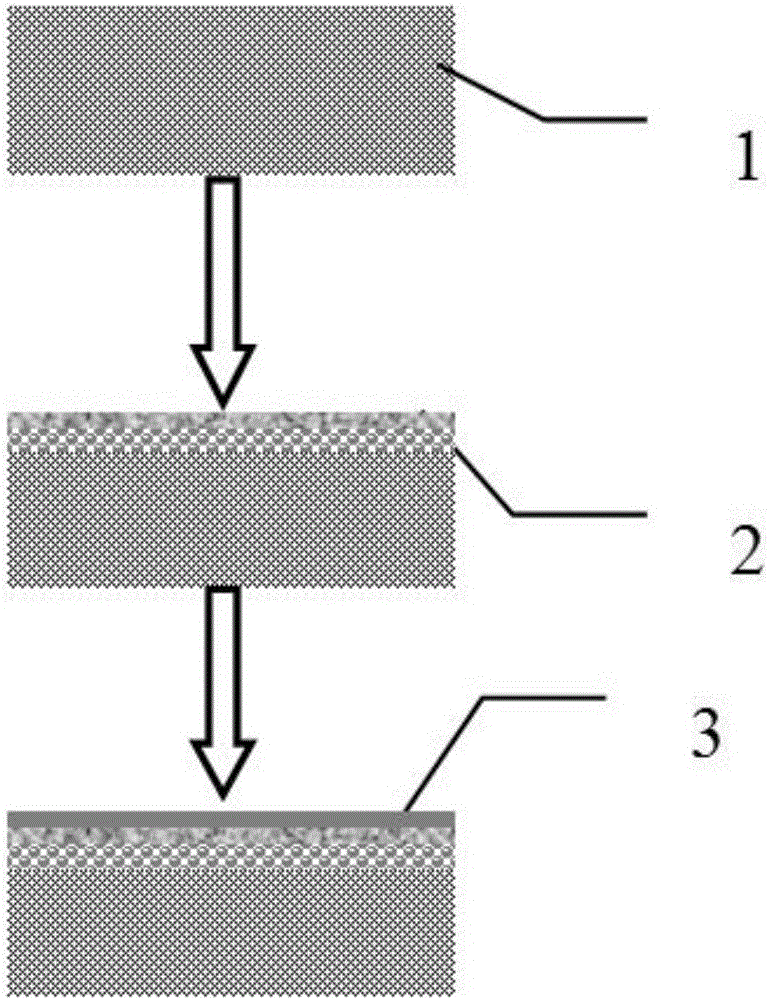

Method for preparing wear-resistance toughening coating layer on surface of high-manganese steel

ActiveCN107815682AReduce pollutionImprove wear resistanceMetallic material coating processesSolution treatmentCoated surface

The invention discloses a method for preparing a wear-resistance toughening coating layer on a surface of high-manganese steel. The method is characterized by comprising the steps of: (S1) pretreatment of a basal body before cladding, (S2) pretreatment of powder before cladding, (S3) cladding, and (S4) heat treatment after cladding. A plasma cladding technology, solid solution treatment and a coating layer surface aging process are adopted to prepare the Fe-Ni base alloy coating layer with high hardness, high wear resistance and high impact toughness; the surface hardness and the wear resistance of the basal body material are improved; the problem of easy cracking of a traditional hard particle reinforcing metal base wear-resistance coating layer under such conditions as medium and high stress is solved; and the prepared coating layer is excellent in metallurgical bonding with the basal body material, so that the comprehensive performance of the coating layer is greatly improved, the basal body material is protected more sufficiently, the service life of the basal body material is prolonged, and the application prospect is broad.

Owner:梧州啟润机械有限公司

Capacitive touch sensor

InactiveCN103399677AFully protectedSimple structureInput/output processes for data processingElectrical conductorEngineering

The invention discloses a capacitive touch sensor comprising a base with an accommodating cavity, a light-transmitting panel laid on the base, an indicating light source and a circuit board. The indicating light source and the circuit board are positioned in the accommodating cavity, the base comprises a top board and a bottom board, and the accommodating cavity is located between the top board and the bottom board. A light-transmitting hole is formed at the position, corresponding to the indicating light source, of the top board. A condensation barrel is arranged in the accommodating cavity around the indicating light source. A light-transmitting conducting layer is arranged at the position, corresponding to the light-transmitting hole, at the bottom of the light-transmitting panel and is connected to the circuit board through a conductor. The capacitive touch sensor is high in sensitivity, good in sealing effect and high in environmental adaptability.

Owner:浙江新涛电子科技有限公司

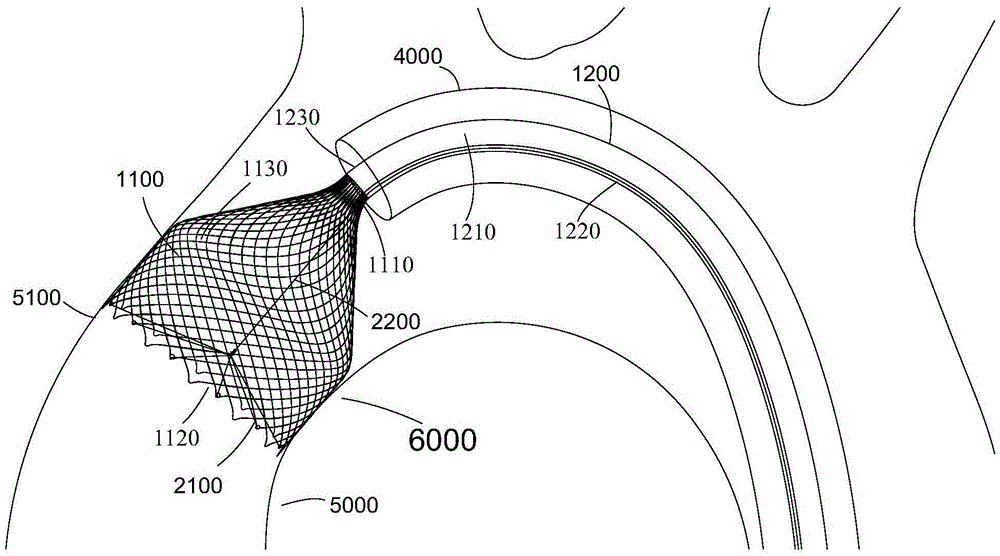

Thrombus filter

The invention discloses a thrombus filter which comprises a handle, a filter umbrella for capturing thrombi, a push catheter, and a folding device for shrinking and folding the filter umbrella, wherein the filter umbrella adopts a meshy elastically-recoverable funnel-shaped structure; a neck part of the filter umbrella is fixedly connected with the push catheter; an inner cavity is axially formed in the push catheter; a cavity enclosed by the filter umbrella is communicated with the inner cavity of the push catheter; the folding device comprises a take-up unit and a drawing mechanism for drawing the take-up action; the take-up unit is connected with an opening part of the filter umbrella and draws the opening part to be folded, so that the filter umbrella becomes a closed space; the drawing mechanism penetrates the inner cavity of the push catheter, extends towards the opening part of the filter umbrella and is connected with the take-up unit; the push catheter and the drawing mechanism are connected with the handle; the actions of the push catheter and the drawing mechanism are controlled by the handle. The thrombus filter can effectively block exfoliated plaques or emboli, and is simple in structure, small in push resistance and smooth in operation.

Owner:VENUS MEDTECH (HANGZHOU) INC

Stabilized oil-in-water emulsion of vinca alkaloids for vein and production thereof

InactiveCN1679576ALow toxicityLess irritatingOrganic active ingredientsEmulsion deliveryAdditive ingredientVinorelbine

A stable oil-in-water emulsion of vinorelbine for intravenous injection is prepared from vinorelbine, the oil for injection, emulsifier, and the water for injection. Its advantages are high tageting function, low poison, and high safety.

Owner:JIANGSU QINGJIANG PHARMA

Hot spraying aluminium-zinc alloy wire rod and method for making same

The invention relates to a heat spraying aluminium zinc alloy wire rod composition and its preparing process, wherein the constituents (by weight percentage) of the wire rod include Al 54-56%, 0.004%<=M<=1.08%, impurity whose total amount is less than 1%, and balancing Zn, M is any one or the combination of RE, Mg, Ti or B.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Producing method of composite cooking-vessel and product thereof

ActiveCN101015892AIncrease acceptanceIncrease profitCooking-vessel materialsSoldering apparatusSurface finishingThermal efficiency

The invention provides a method for producing composite cooking tool, and relative method, for resolving the problems as low thermal efficiency, long cooking time and short service life. The inventive method comprises that A, producing body of cooling tool as a, material selection, cold rolling, b, washing, drying, c, roller pressing, d, drawing, B, returning bottom as a, washing, drying, b, thermally forging or solder welding, c, surface treatment. The inventive composite cooking tool comprises a body and a bottom plate, wherein the bottom plate has welded metal plate and metal sheets from inner to outer via thermal forging or solder welding, the body has two or three metal layers welded via thermal forging or solder welding, and the body and the bottom plate are welded together via thermal forging or solder welding. The invention has simple process, low cost, uniform heated and long service life.

Owner:ZHEJIANG SUPOR

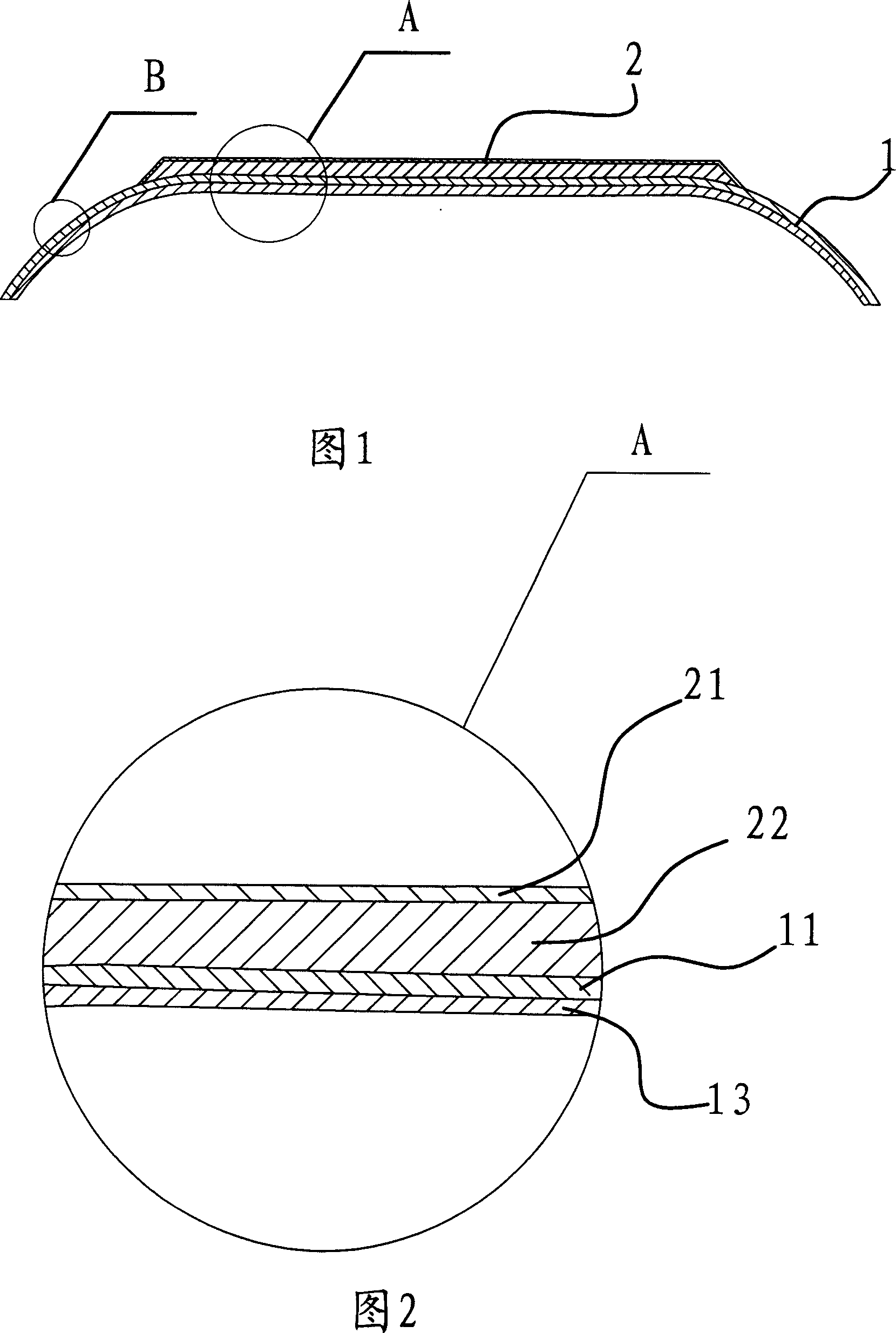

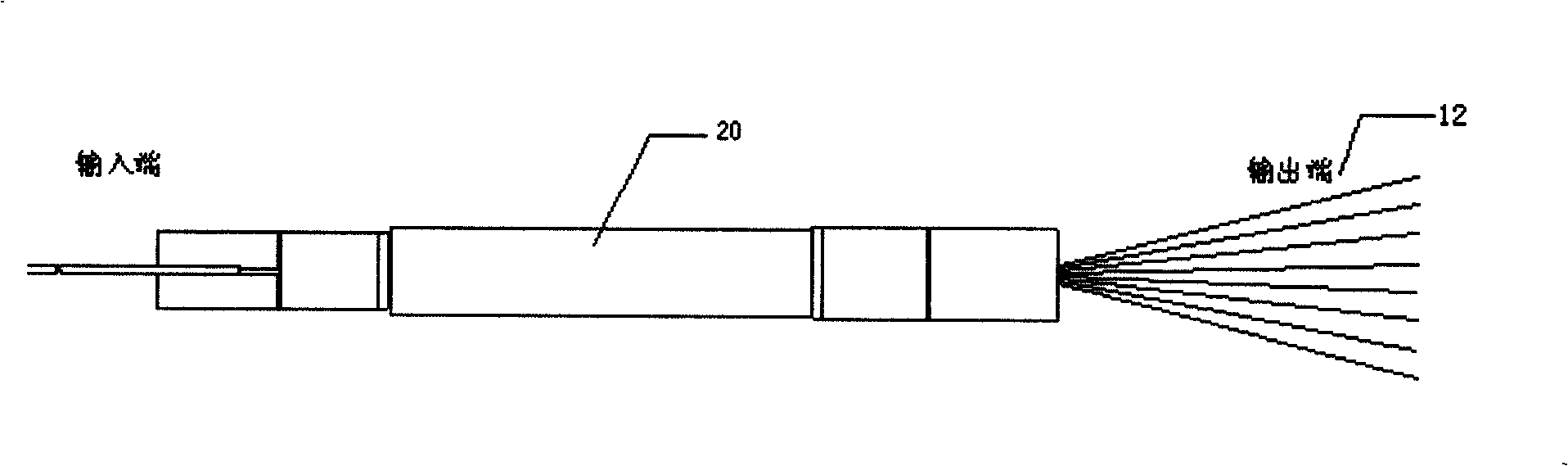

Packaging structure of plane waveguide light shunt and preparation method thereof

InactiveCN101256254AFully protectedReduce production processCoupling light guidesHigh volume manufacturingEngineering

The invention relates to a packaging structure of plane waveguide optical branching device and preparation method. A plane waveguide optical branching device core (20) is fixed in the lower casing (18) of the outer casing. A rubber cap module (15) of input end and rubber cap module (17) of output end respectively pass through from the two ends of the branching device core (20) and are fixed at the port of the lower casing (18) to directly output the optical fiber loose sleeve (13). The optical fiber of input end and optical fiber of the output end are all protected by the loose sleeve (13). The top casing (19) of the outer casing is fixed on the lower casing (18) of the outer casing. The new optical fiber loose sleeve is directly output, therefore the method can effectively increase the production efficiency of the optical branching device and reduce the production step of the traditional branching device, and the optical fiber of input end and optical fiber of the output end obtain the protection of the whole loose sleeve, with compact whole structure, safety, reduced cost, suitable for production in enormous quantities.

Owner:BROADEX TECH

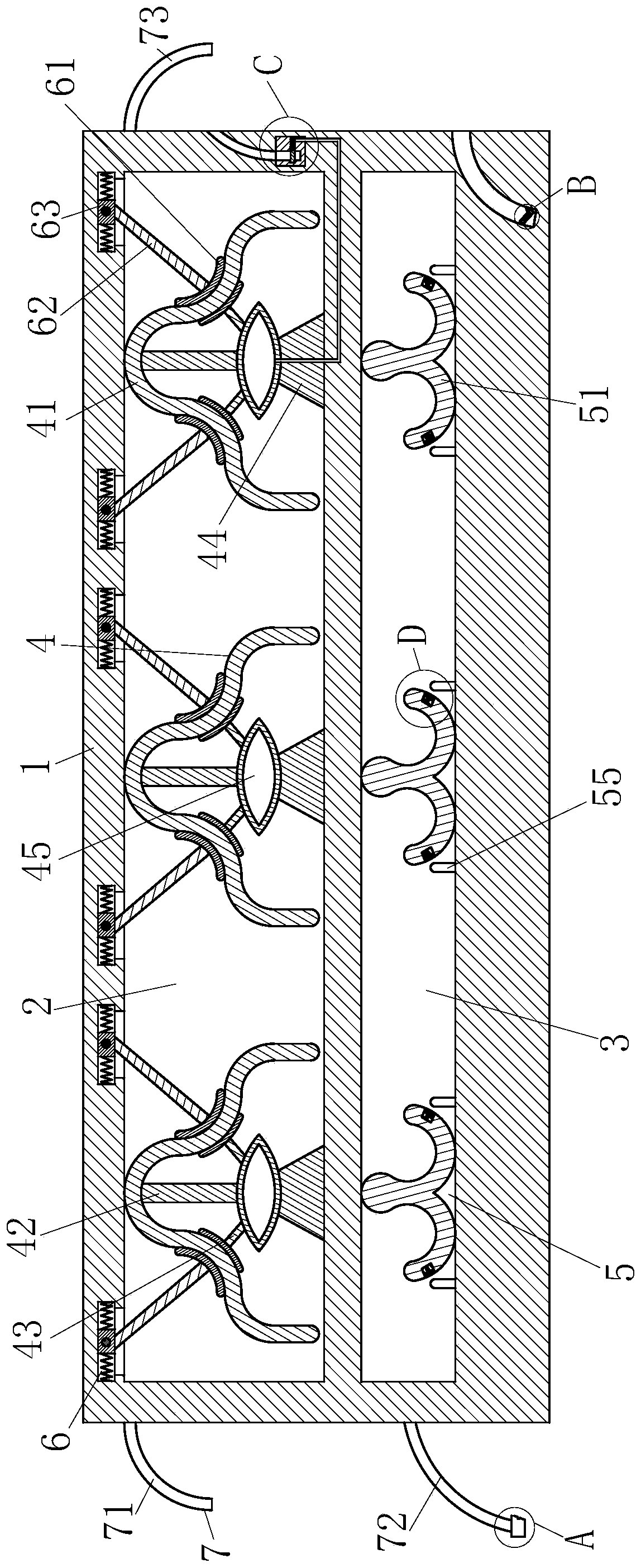

Double-layer anti-pressure acrylic floor

ActiveCN109826400AExtended service lifeAchieve installationResiliently-mounted floorsProtection mechanismEngineering

The invention belongs to the field of acrylic plates, and particularly relates to a double-layer anti-pressure acrylic floor. The floor comprises a main plate body, a first cavity, a second cavity, aforce dividing mechanism, a buffer supporting mechanism, a sliding protection mechanism and a mounting mechanism; the force dividing mechanism is disposed in the first cavity, and the force dividing mechanism comprises convex cover plates, first support bars, second support bars, third support bars and metal elastic frames; the three convex cover plates are arranged, and the first support bars arefixedly connected to the upper ends of the inner walls of the convex cover plates; the lower ends of the first support bars are fixedly connected with the upper surfaces of the outer ends of the metal elastic frames; the metal elastic frames are disposed in closed shapes, two ends of the upper surfaces of the outer ends of the metal elastic frames are symmetrically fixedly connected with the second support bars, and the third support bars are fixedly connected to the lower surfaces of the outer ends of the metal elastic frames; the upper ends of the second support bars are fixedly connected to the arc portions of both sides of the inner walls of the convex cover plates; the floor is mainly used for solving the problem of insufficient bearing capacity and pressure resistance of the acrylicplates in existing floors.

Owner:宏耐地板(宿迁)有限公司

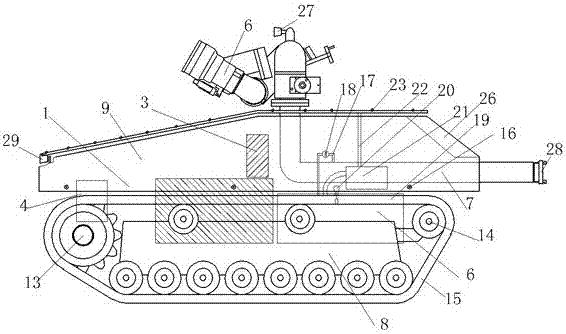

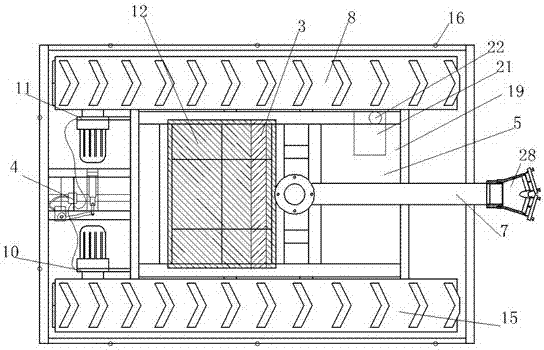

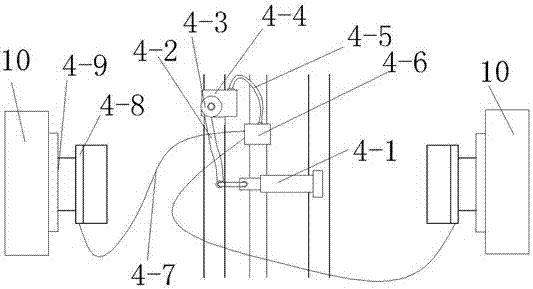

Teleoperation intelligent monitoring fire fighting robot

The invention relates to a teleoperation intelligent monitoring fire fighting robot, and belongs to the field of fire fighting robots. The teleoperation intelligent monitoring fire fighting robot comprises a vehicle body, a movement mechanism, a control mechanism, a brake mechanism, a cooling mechanism, a fire fighting spraying nozzle and a fire fighting water inlet pipe. According to the teleoperation intelligent monitoring fire fighting robot, remote control can be achieved through the control mechanism, and operation through a control panel can be achieved; and meanwhile, the cooling mechanism connected with the water inlet pipe of the fire fighting spraying nozzle is used, water in a water tank can be supplemented in time, and sufficient protection on the robot is carried out while fire fighting is carried out.

Owner:TAIZHOU XIANGDA FIRE EQUIP CO LTD

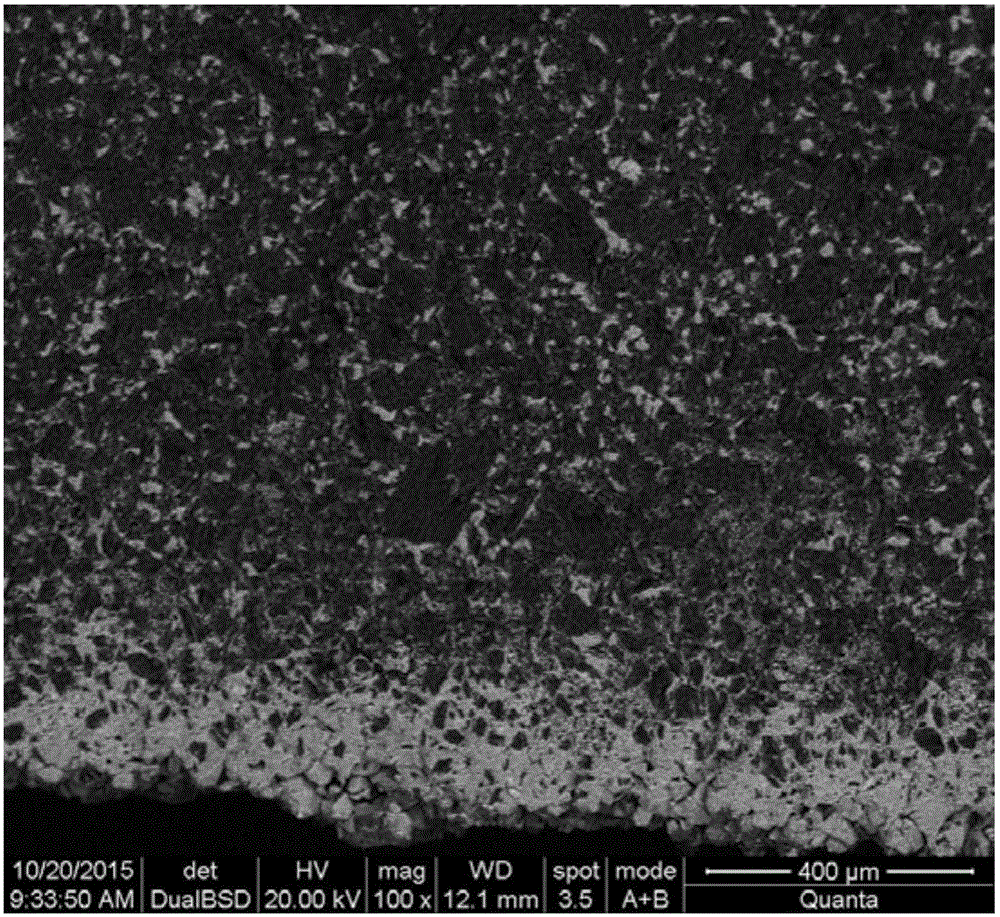

Graphite material with SiC coating and preparation method thereof

The invention discloses a graphite material with a SiC coating and a preparation method thereof. The graphite material comprises a graphite base and a SiC coating. The SiC coating comprises a primary SiC layer and a secondary SiC layer. The primary SiC layer permeates into the graphite base from the surface of the graphite base and is formed by an in-situ reaction of gaseous silicon and the graphite base. The secondary SiC layer is located on the primary SiC layer. The preparation method comprises 1, carrying out vapor silicon infiltration sintering on a graphite material to obtain a graphite material with the primary SiC layer and 2, carrying out vapor deposition of the secondary SiC layer. The graphite material with the SiC coating has the advantages that the SiC coating has good cohesiveness to the graphite material, has no thermal expansion coefficient mismatch, is compact and has high oxidation resistance. The preparation method effectively solves the problem of thermal expansion coefficient mismatch in preparation of the SiC coating on the surface of the graphite material directly through a CVD technology, and guarantees high bonding strength between the coating and graphite.

Owner:NAT UNIV OF DEFENSE TECH

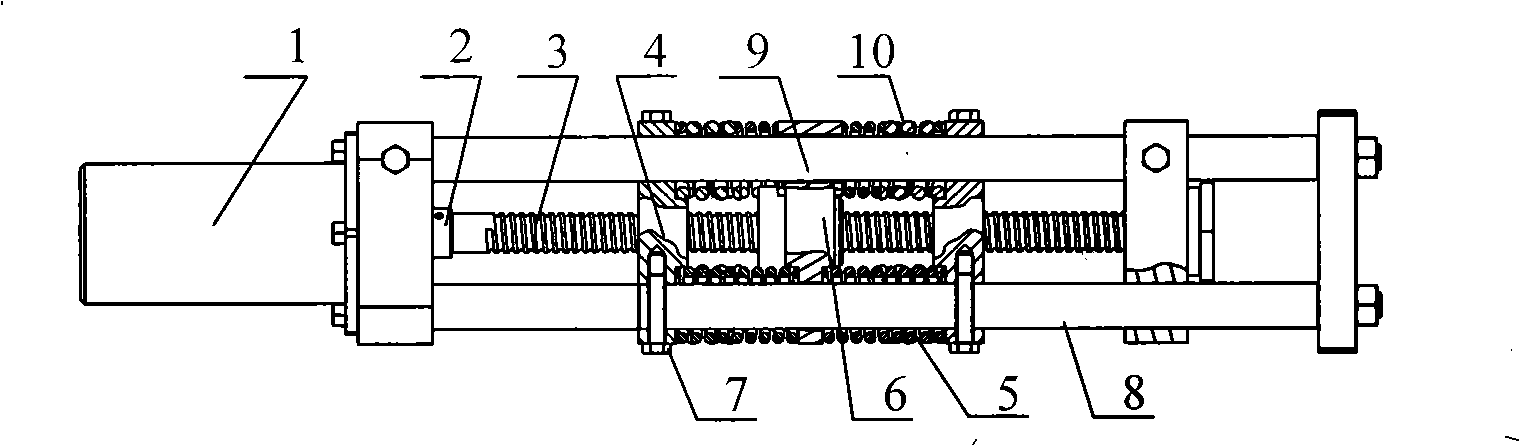

Two-in-parallel elastic driver

InactiveCN101318330AImproved ability to resist shock loadsSimple structureGearingManipulatorEngineeringMechanical engineering

The invention relates to a double-series connection elastic driver and comprises two guide bars, two ends of which are fixed on brackets; wherein, the bracket of one end is provided with two through holes, and two push rods go through the through holes; two spring baffles which are provided with holes are fixed on the push rods and go through the guide bars; a spring driving plate is arranged between the two spring baffles and is connected with a driver arranged on the bracket through a driving rod; springs are positioned between the spring driving plate and the spring baffles on two sides, and the springs comprise a soft spring and a hard spring which are distributed in a parallel way; the soft spring is sheathed on the push rod and the hard spring is sheathed on the guide bar and a passage of gap exists between the hard spring and the spring driving plate. The elastic driver has the advantages that when the driving load is smaller, the spring with smaller rigidity has the buffering effect to avoid the overlarge impact force; when the driving load is bigger, the spring with smaller rigidity is totally compressed and then the spring with larger rigidity plays the buffering role, thus preventing the driving belt width from being over influenced.

Owner:HARBIN ENG UNIV

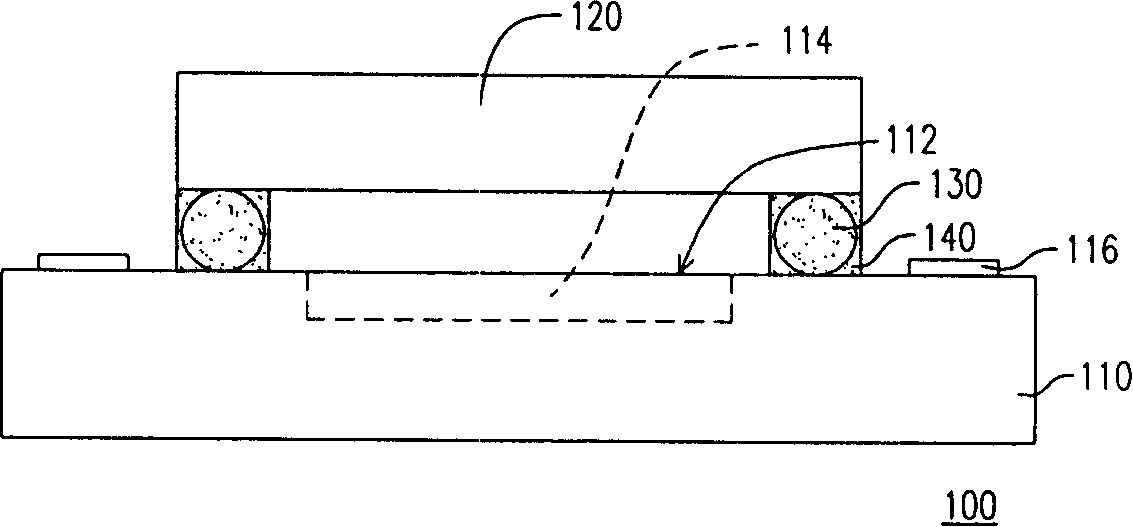

Wafer-grade chip packaging process and chip packaging structure

ActiveCN101211791AProtect the photosensitive areaReduce the numberSemiconductor/solid-state device detailsSolid-state devicesConductive materialsElectrical and Electronics engineering

A process for encapsulating a wafer level chip comprises the following steps that: first, a wafer is provided and a plurality of chip units are contained in the wafer, and the wafer has an active surface and a back facing to the active surface; each chip unit is provided with a plurality of connective cushions on the active surface and then a plurality of through holes are formed below the connective cushions, and then the conductive materials are stuffed in the through holes and are electrically connected with the connective cushions; moreover, the conductive materials are exposed and convex out from the back of the wafer. Then a transparent adhesive layer is formed on the active surface and then a transparent cover plate is configured on the transparent adhesive layer so as to bond the transparent cover palte with the wafer through the transparent adhesive layer. Then a step of monomerisation is carried out so as to separate the chip units from the transparent cover plate corresponding to the chip units, thereby forming a plurality of independent chip package structure.

Owner:ADVANCED SEMICON ENG INC

Overwintering and cold-proof method of outdoor grape

InactiveCN101822190AUnique methodEasy to makeCultivating equipmentsPlant protective coveringsFrostNorth china

The invention relates to a cold-proof method of grape, in particular to an overwintering and cold-proof method of outdoor grape. The method is characterized by comprising the following steps of: a. preparing a polystyrene foam grain carpet; and b. paving the polystyrene foam grain carpet under an outdoor grape bracket. The method is unique, is applied to the outdoor grape in the rest period in the North China, adopts the material which is low in price, good in heat preservation, light in weight, low in water absorption, labor-saving, time-saving, and easily paved and furled for preventing late frost in winter, prevents the buds of branches of the outdoor grape in rest period from being frozen and covered, prevents the branches and tendrils of the outdoor grape in rest period from losing water, and prevents the roots of the outdoor grape from being frozen due to the temperature in the covering material.

Owner:NINGXIA UNIVERSITY

Hot sprayed zinc-aluminium alloy wire rod and its preparing method

The hot sprayed Zn-Al alloy wire consists of Al 10-20 wt%, one or several of RE, Mg, Ti and B 0.006-1.5 wt% and impurity less than 1 wt%, except Zn. The preparation process of the hot sprayed Zn-Al alloy wire includes melting zinc ingot and aluminum ingot in an alloy smelting furnace and refining; adding intermediate alloy under stirring, letting stand, eliminating slag and continuous horizontal casting to obtain coarse Zn-Al alloy wire; homogenizing annealing and drawing to form Zn-Al alloy wire product. Spraying with the Zn-Al alloy wire can well protect base steel and prolong its service life.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

A new energy solar photovoltaic power generation panel with a protective device

InactiveCN109067336AFully protectedEasily dodge the impactPhotovoltaic supportsSolar heating energyNew energyEngineering

The invention provides a new energy solar photovoltaic power generation panel with a protective device, which relates to the technical field of the new energy solar photovoltaic power generation panel. The new energy solar photovoltaic power generation panel with the protective device, includes the base, a level gauge is fixedly installed in front of the base, a threaded through hole is arranged near the edge of the base, a side plate is fixedly installed on both sides of the base, an electric telescopic device is fixedly installed on the top of the base, an expansion rod is fixedly installedon the top of the electric telescopic device, a lifting plate is fixedly installed on the top of the expansion rod, and a first wheel rod and a second wheel rod are fixedly installed on both sides ofthe lifting plate. The new energy solar photovoltaic power generation panel with the protective device can make the sliding cover open and close smoothly when the sliding cover slides in the groove ofthe inner wall of the side plate through the side pulley and the bottom pulley of the groove of the inner wall of the side plate, and when the sliding cover is closed, the magnetic suction strip canmake the sliding cover close completely.

Owner:芜湖寅越信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com