Aluminum and aluminum alloy handwork double-gun double-face TIG welding technique

A welding technology, aluminum alloy technology, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., to solve the effect of low welding efficiency, stable process parameters and process, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

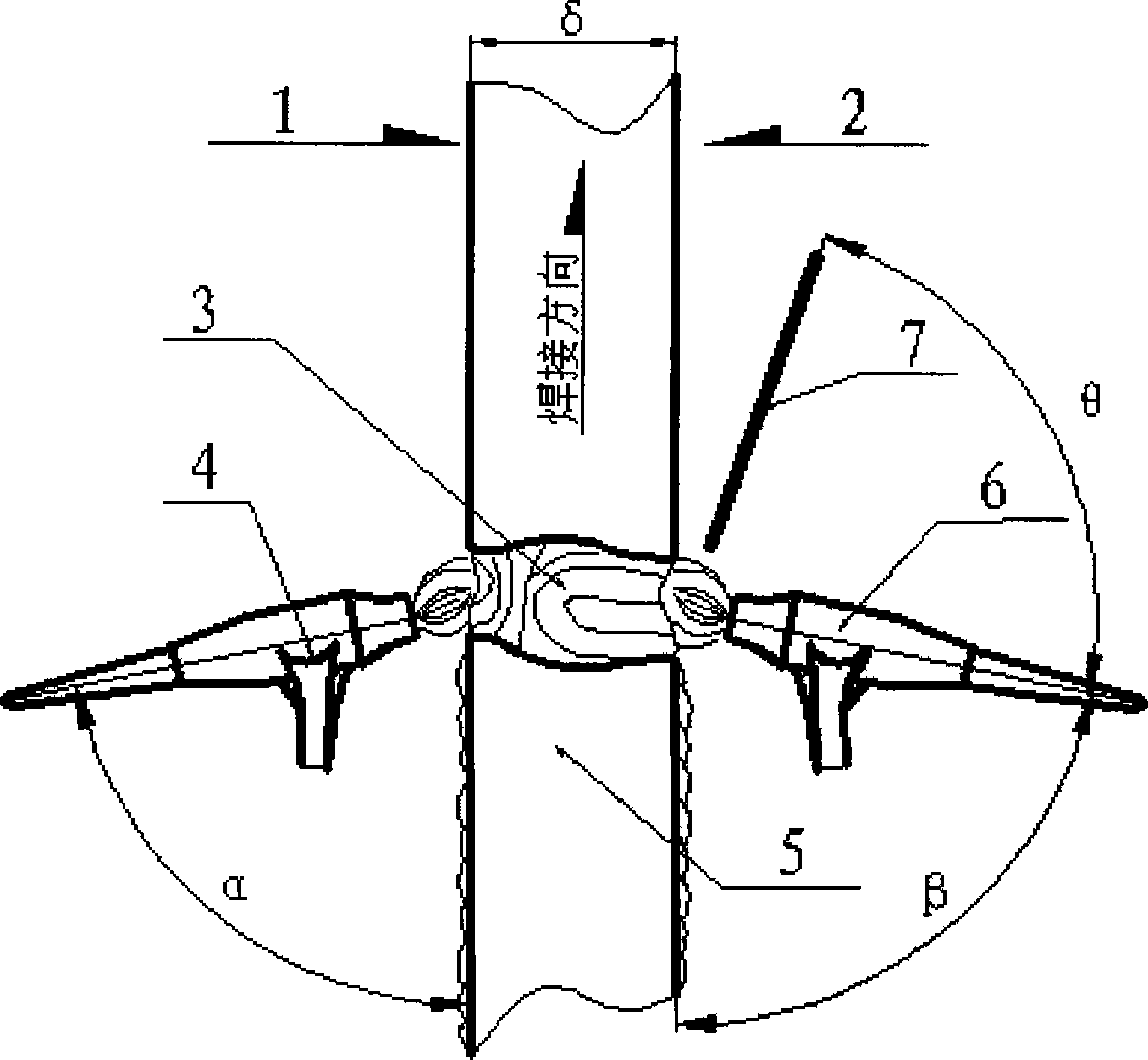

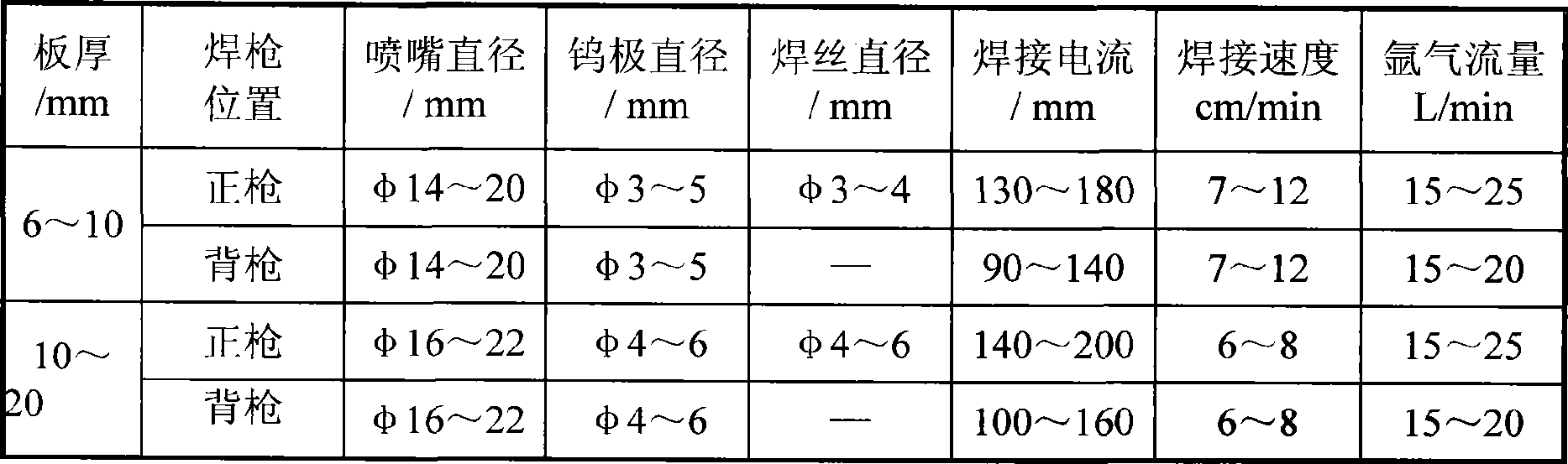

[0020] Using the invented double-gun double-sided TIG welding technology, the longitudinal welds of 5083-O aluminum alloy half elbows with wall thicknesses of 8mm, 10mm, 12mm, 16mm and 20mm series were welded. The upward vertical welding process is adopted, the welding wire is SALMg-3 welding wire, the welding joint is in the form of "I" type butt joint without groove, and the butt joint gap is 3mm to 8mm. Double torch welding adopts a high-frequency arc ignition device. Under the guidance of the front welding torch, the two torches basically start arcing at the same time. Welding wire is added to the front side, and the inclination angles α and β of the welding torch are controlled at 70° to 100° during the welding process, and the angle θ between the welding wire and the welding torch is kept at 80° to 110°. The tungsten electrode does not swing left and right; the welding current is attenuated when the arc is stopped, and the argon gas must be cut off with a delay of 5s to ...

Embodiment 2

[0025] Using the invented double-gun and double-sided TIG welding technology, the ring welds of 5A01 aluminum alloy shrimp joint elbow pipes with wall thicknesses of 6mm, 10mm, 12mm and 16mm were welded. The upward vertical welding process was adopted, and the welding wire was 5B01 welding wire. , Welded joints are in the form of non-groove corner joints, and the butt gap is 3mm to 8mm. Double torch welding adopts a high-frequency arc ignition device. Under the guidance of the front welding torch, the two torches basically start arcing at the same time. Welding wire is added to the front side, and the inclination angle α and β of the welding torch are controlled at 70°~100° during the welding process, and the angle θ between the welding wire and the welding torch is kept at 80°~110°; the tungsten electrode does not swing left and right; And the argon should be cut off after a delay of 5s to 7s. See Table 4 for other welding parameters preferred under this condition:

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com