Two-in-parallel elastic driver

A driver and spring-driven technology, which is applied in transmission devices, manufacturing tools, manipulators, etc., can solve the problems of increasing the moment of inertia of the load, decreasing the ability to resist impact loads, and reducing the accuracy of the output force of the driver, so as to increase the output bandwidth and improve Shock load resistance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

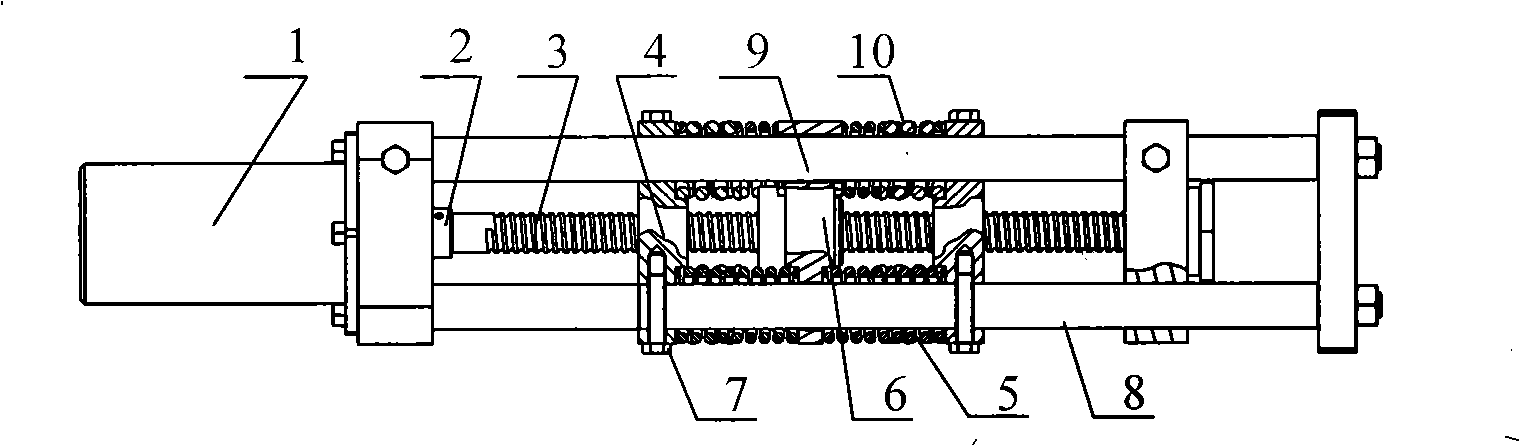

[0022] combine Figure 1 to Figure 3 , the first embodiment of the present invention is a motor-driven double-parallel elastic driver, its main components include two guide rods 9 fixed on the bracket at both ends, two through holes on the bracket at one end, and two push rods 8 is worn in the through hole, two spring baffles 4 are fixed on the push rod by bolt 7, there are holes on the two spring baffles, the spring baffles are passed on the guide rod, and a spring baffle is arranged between the two spring baffles. Spring drive plate 6, spring drive plate links to each other with the driver 1 that is installed on the support by drive rod, is provided with spring between spring drive plate and the spring baffle plate of both sides, and spring comprises soft spring 5 and hard spring 10, and soft spring and The hard springs are arranged in parallel, the soft spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com