Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

575results about How to "Economical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

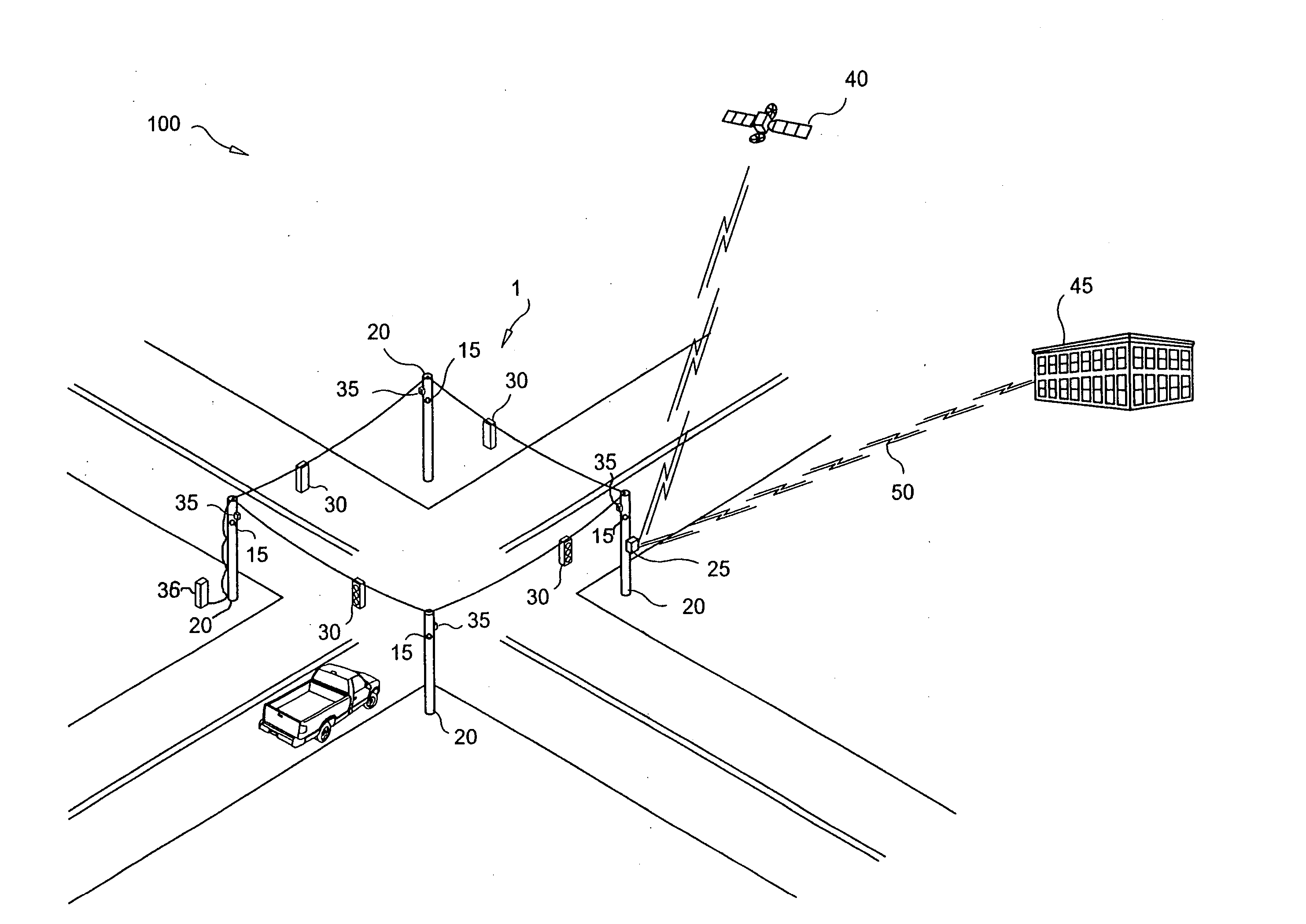

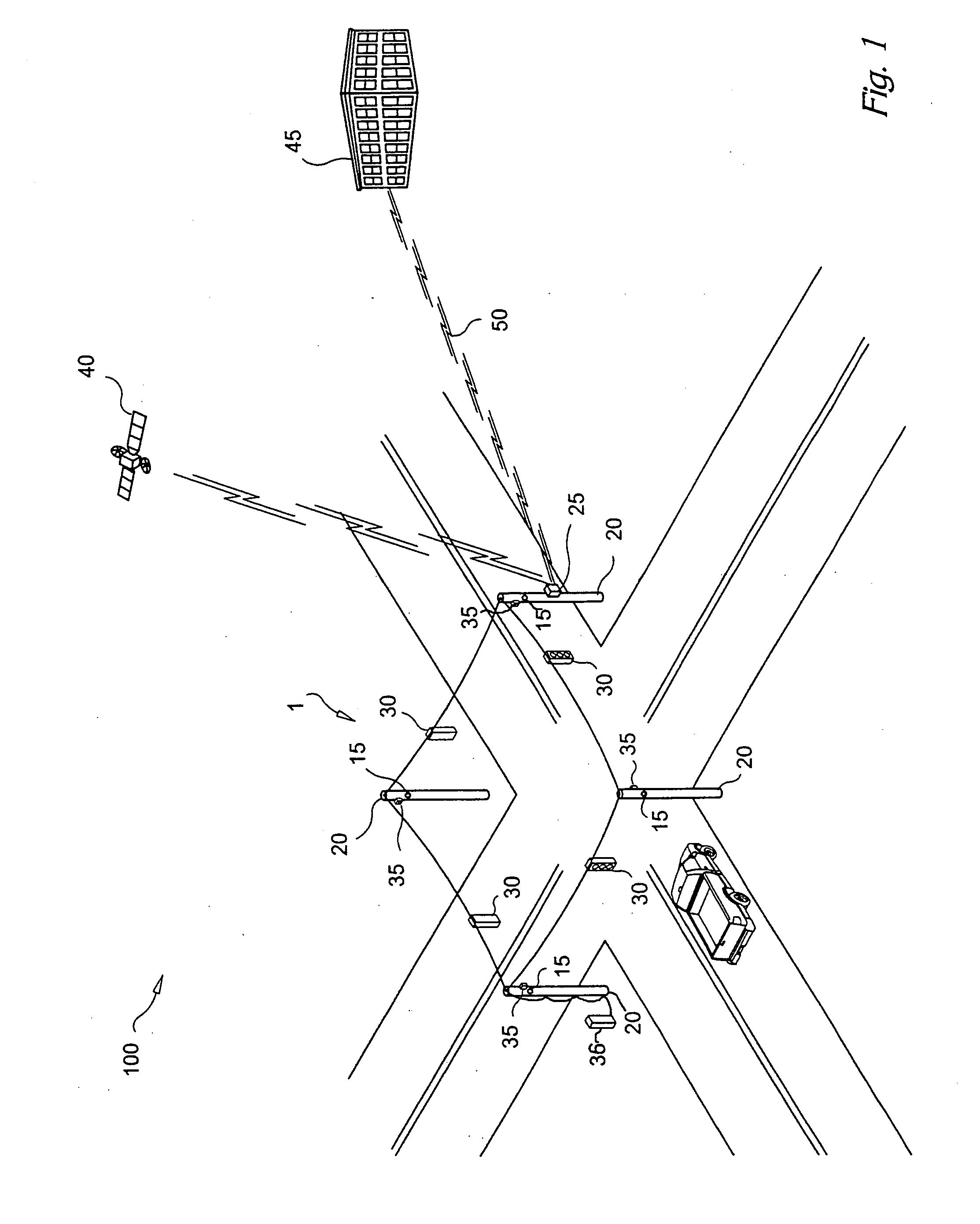

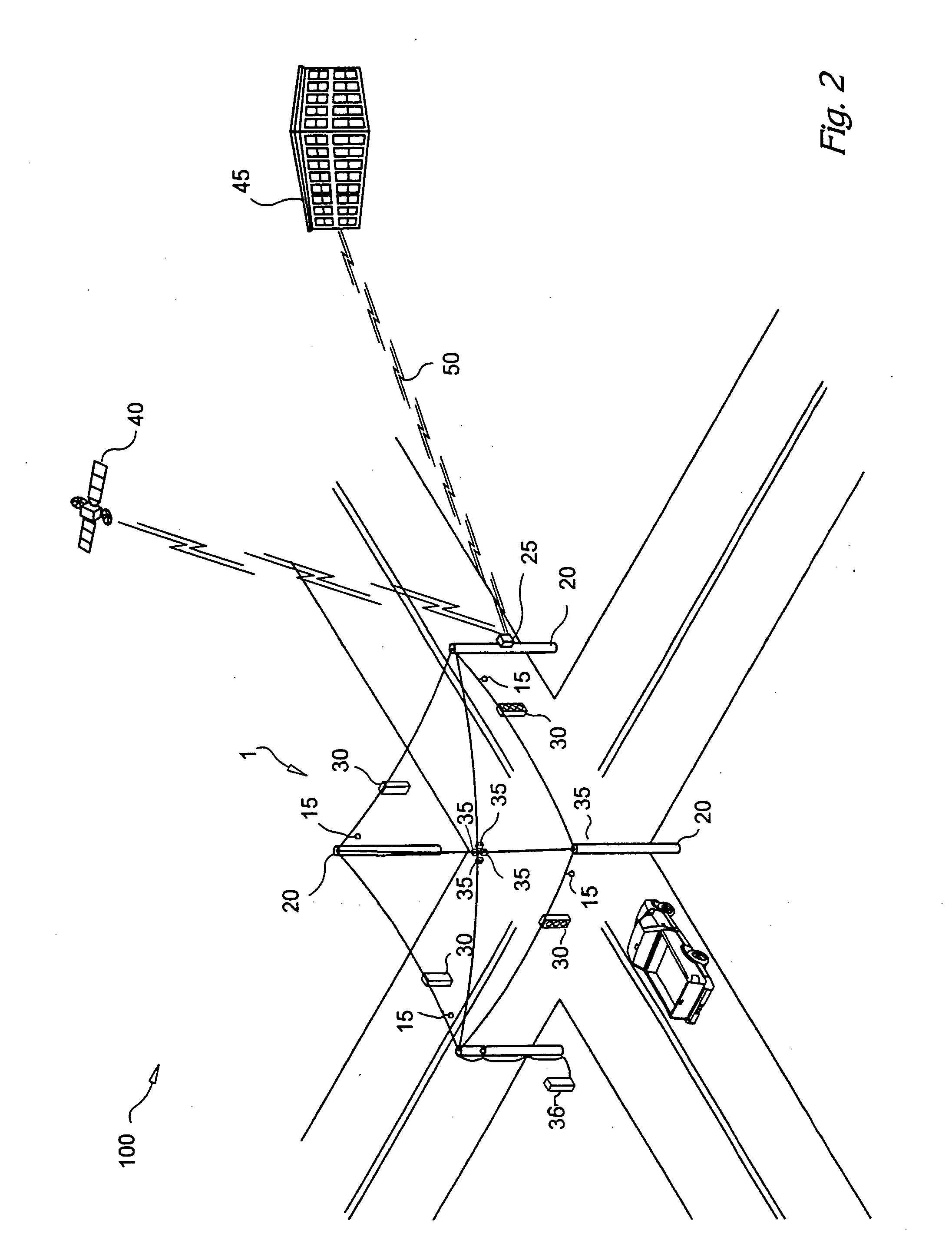

Advanced automobile accident detection, data recordation and reporting system

InactiveUS20060092043A1Additional revenue opportunityEconomicalControlling traffic signalsRegistering/indicating working of vehiclesReceiptTelecommunications link

A system for monitoring a location to detect and report a vehicular incident, comprising a transducer for detecting acoustic waves at the location, and having an audio output; a processor for determining a probable occurrence or impending occurrence of a vehicular incident, based at least upon said audio output; an imaging system for capturing images of the location, and having an image output; a buffer, receiving said image output, and storing at least a portion of said images commencing at or before said determination; and a communication link, for selectively communicating said portion of said images stored in said buffer with a remote location and at least information identifying the location, wherein information stored in said buffer is preserved at least until an acknowledgement of receipt is received representing successful transmission through said communication link with the remote location.

Owner:LAGASSEY PAUL J

Vitreoretinal silicone tamponades made by supercritical fluid extraction

InactiveUS7276619B2EconomicalHighly effectiveSilicon organic compoundsSilicon compound active ingredientsSupercritical fluid extractionOligomer

A process for the purification of a silicone oil or fluid using neat supercritical carbon dioxide or a supercritical carbon dioxide mixture extraction to produce vitreoretinal silicone tamponades. The subject process is an economical, highly effective, reproducible, contaminant-free method by which unreacted relatively low molecular weight cyclic siloxanes and oligomers are removed from relatively high molecular weight silicone oil or fluid.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

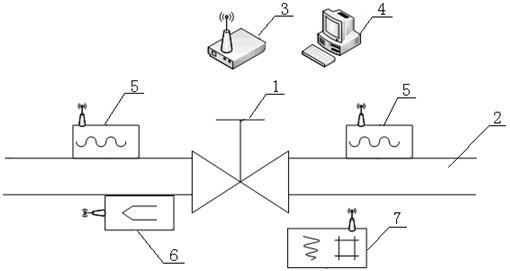

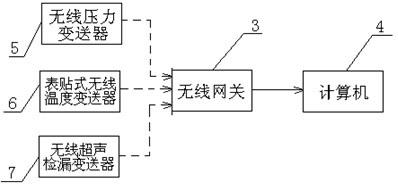

Detecting system used for leakage of gas valve

InactiveCN102095083AConsiderable wasteFlexible installation and deploymentEnergy efficient ICTPipeline systemsWireless sensor networkingEngineering

The invention relates to a detecting system used for the leakage of a gas valve, which mainly utilizes the arrangement of a wireless sensor network. The detecting system provided by the invention comprises a wireless pressure transmitter, a bonding wireless temperature transmitter and a wireless ultrasonic leakage sensor, wherein the wireless pressure transmitter and the bonding wireless temperature transmitter are installed on the front and rear pipelines of the gas valve; the wireless ultrasonic leakage sensor is installed at the lateral side of the valve, thereby uploading signals with little change in pressure and temperature passing the front and rear section of the valve and ultrasonic leakage signals obtained by the wireless ultrasonic leakage sensor to a wireless gateway; the gateway is communicated with a computer through a wire mode; and the analysis software of the computer comprehensively utilizes a pressure distributing method, a temperature detecting method and an ultrasonic leakage detecting method to analyze the leakage of the valve, and analyzes and judges the leakage conditions of the valve through data. The detecting system provided by the invention has the advantages that the adopted methods have higher accuracy and sensitivity and the wireless transmitters are convenient and rapid to install, does not need to additionally lay a signal cable, can repair the leakage in time and has great significance on enhancing the production efficiency of enterprises and saving energy sources.

Owner:SHANGHAI INST OF PROCESS AUTOMATION & INSTR

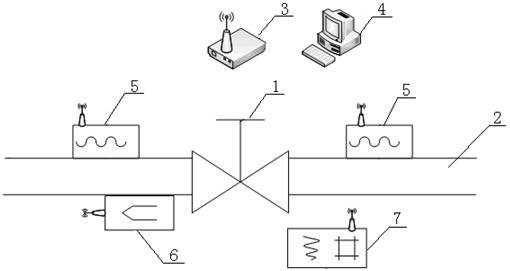

Method for preparing active carbon from straw stalk

The invention relates to a method for preparing active carbon from rice straw. The method comprises taht: (1) the collected rice straw is subjected to alkali cleaning, cleaned to neutrality, dried, and cut or pulverized; (2) the rice straw is added into an activator solution, evenly stirred, soaked for 12 to 24 hours, subjected to solid-liquid separation, cleaned and dried; (3) the rice straw prepared in step (2) is put in a barrate type oven and pre-oxygenated for 1 to 2 hours; (4) the pre-oxygenated rice straw is put in a tube-type carbide furnace, heated for temperature rise under the protection of nitrogen gas, and activated; and (5) the activated rice straw is washed by water till pH is between 6.5 and 7.5, and dried at 105 DEG C to prepare the active carbon. The active carbon prepared by the method has good adsorption performance; the adsorptive value of methylthionine chloride reaches between 200 and 300 mL / g; and the preparation process is simple, economical and environment-friendly, meets requirement of clean production and circular economy development, and has good industrial application prospect.

Owner:DONGHUA UNIV

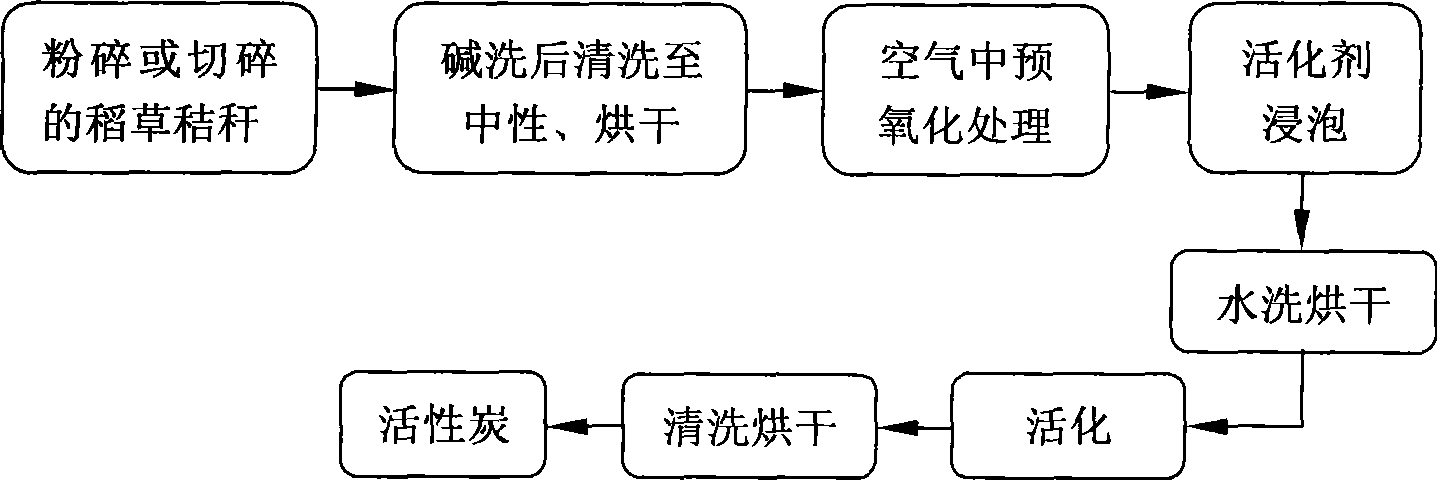

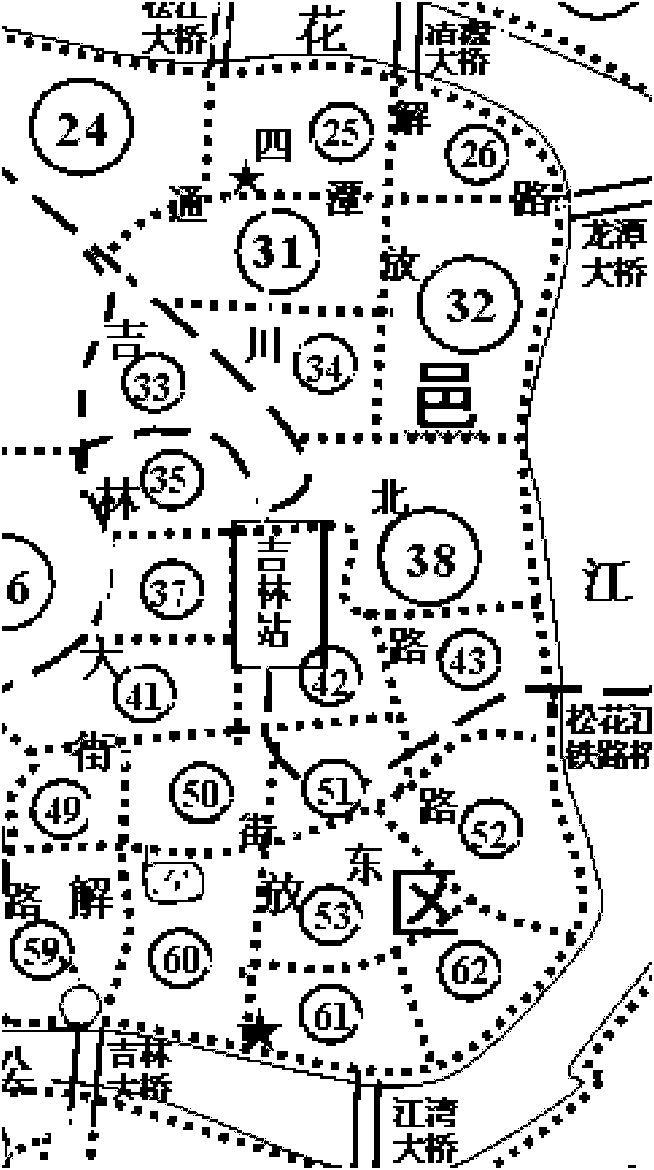

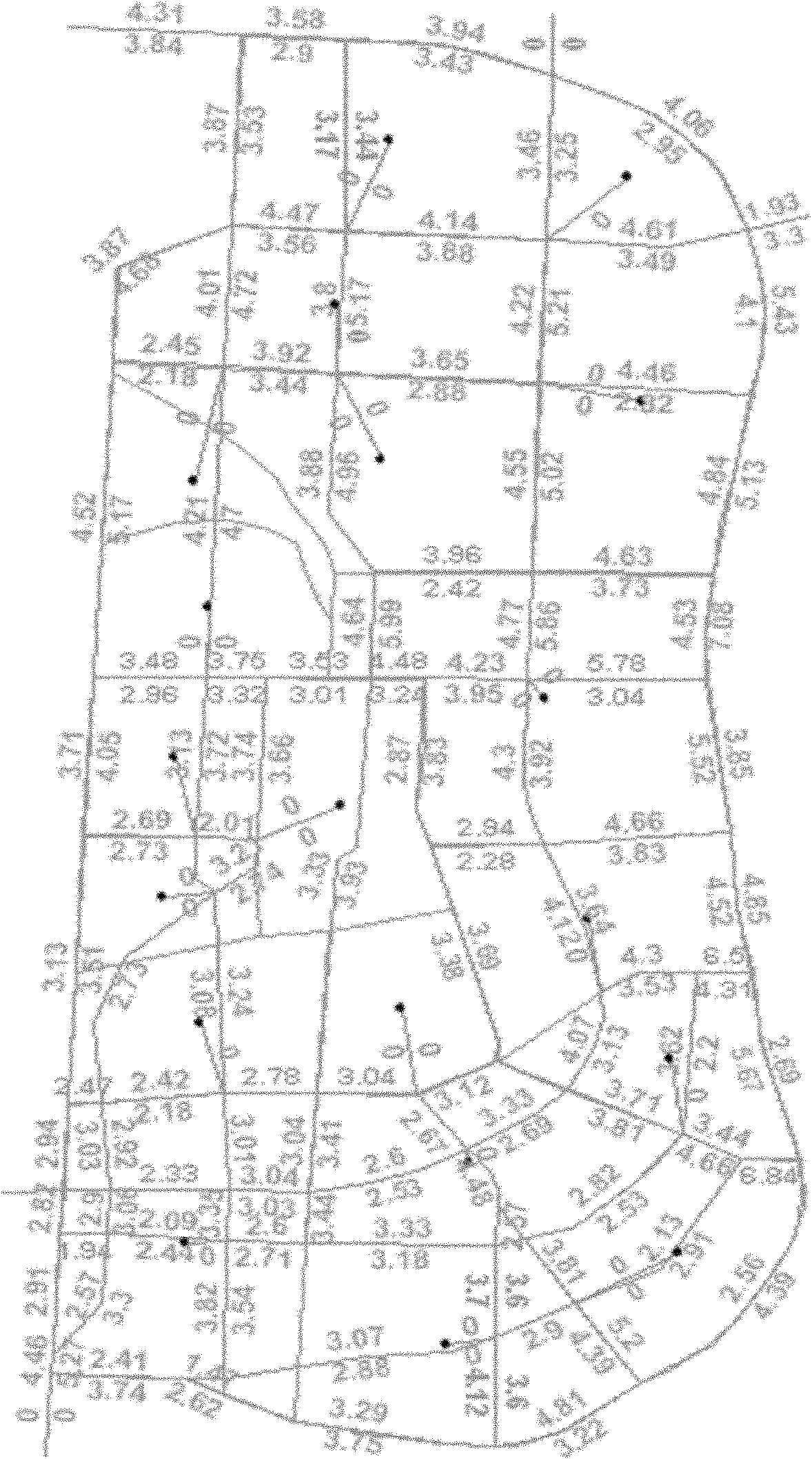

Method for quantizing urban motor vehicle emission load based on resident trip analysis

InactiveCN102054222AEconomicalGreat social effectData processing applicationsPollutant emissionsDecision taking

The invention discloses a method for quantizing urban motor vehicle emission load based on resident trip analysis, belonging to the technical field of intelligent traffic. The method comprises the following steps: analyzing resident trip characteristics; predicting traffic volume; determining an emission factor by means of a road experiment; calculating the emission load of motor vehicle pollutants; and evaluating environment. In the method, the practical resident trip situation information obtained by investigation is combined with a vehicle emission model, and traffic investigation data is reasonably linked with motor vehicle environment evaluation so as to calculate the motor vehicle emission load within a certain area in the urban; and by utilizing the method, necessary basic data and important parameters for total wide-zone emission load estimation of the urban traffic can be accurately and objectively provided, and practical data and decision support can be provided for controlling traffic pollution and realizing the urban traffic planning for sustainable development and the like. The method has the advantages of high accuracy and high efficiency, and is convenient to implement on the basis of fully utilizing the existing traffic investigation data.

Owner:JILIN UNIV

Method for manufacturing embedded type multi-layer compound film cutting temperature sensor

InactiveCN101324472AExtended service lifeEconomicalThermometers using electric/magnetic elementsUsing electrical meansRadio frequencyEngineering

The invention relates to a method for manufacturing an embedded multi-layer composite thin-film cutting temperature sensor, in particular to a method for measuring the transient cutting temperature of a cutter point during cutting and manufacturing, and belongs to the temperature sensor field. SiO2 insulating film deposition on a cutter body is carried out for a plurality of times, so as to form a multi-layer composite thin film; then a thin-film thermocouple is formed through sputtering deposition of a NiCr thin-film electrode and a NiSi thin-film electrode; and then the prepared thin-film thermocouple is embedded into a protective layer. The radio-frequency reactive unbalanced magnetron sputtering technology is enhanced by adopting a microwave ECR plasma; the prepared thin-film thermocouple is embedded into the protective layer, so as to be prepared into an embedded multi-layer composite thin-film temperature measurement sensor integrating the cutting and the temperature measurement. The sensor has the advantages of long service life and cost-effectiveness. The thermocouple has the advantages of minimum size of a hot end and short response time, thereby achieving the submicrosecond level. A compensation conducting wire is hidden in a cutter head, so that the anti-interference capability is strong. Therefore, the cutting temperature of the cutter point can be measured rapidly, accurately and stably by the method.

Owner:DALIAN UNIV OF TECH

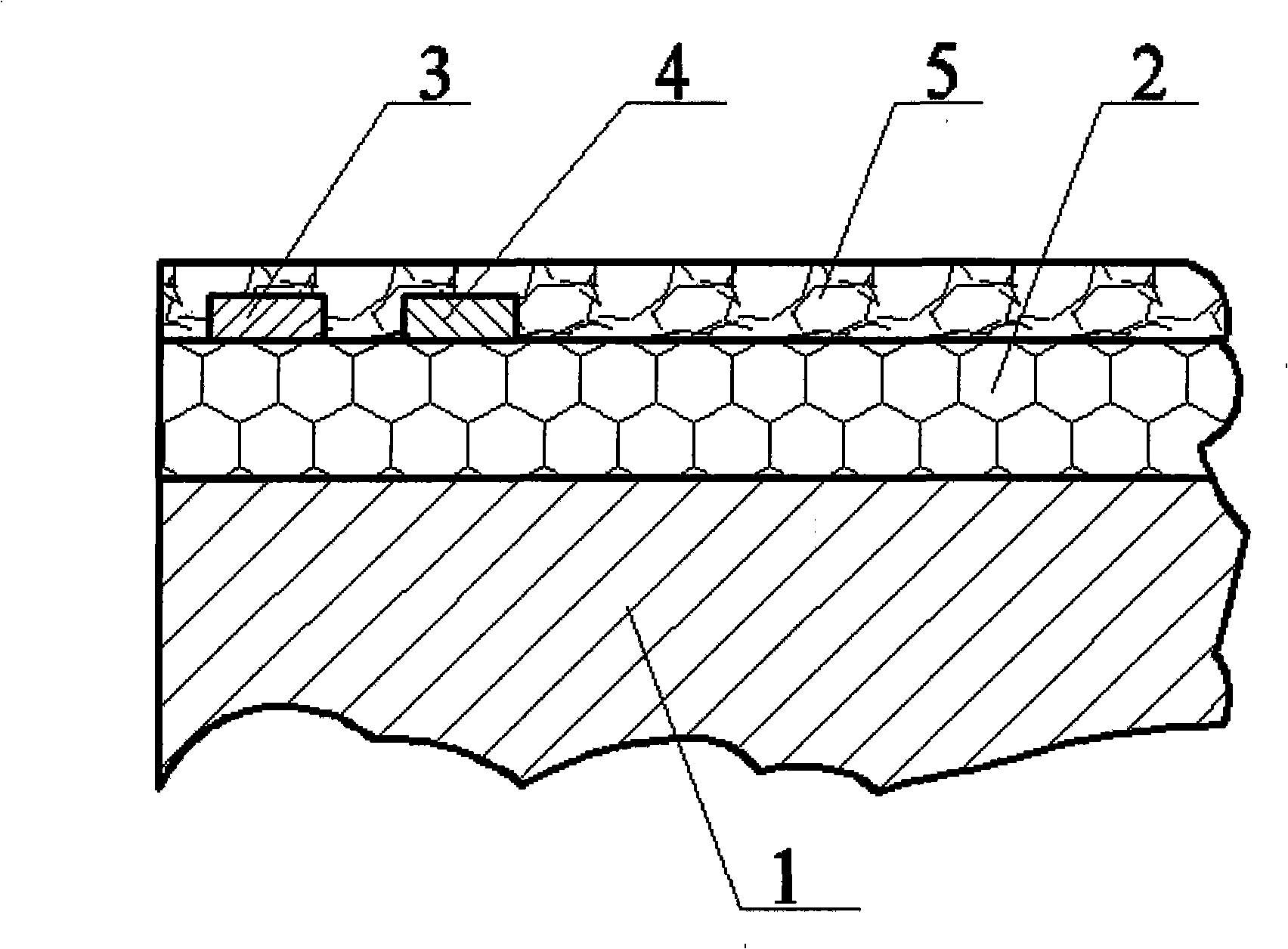

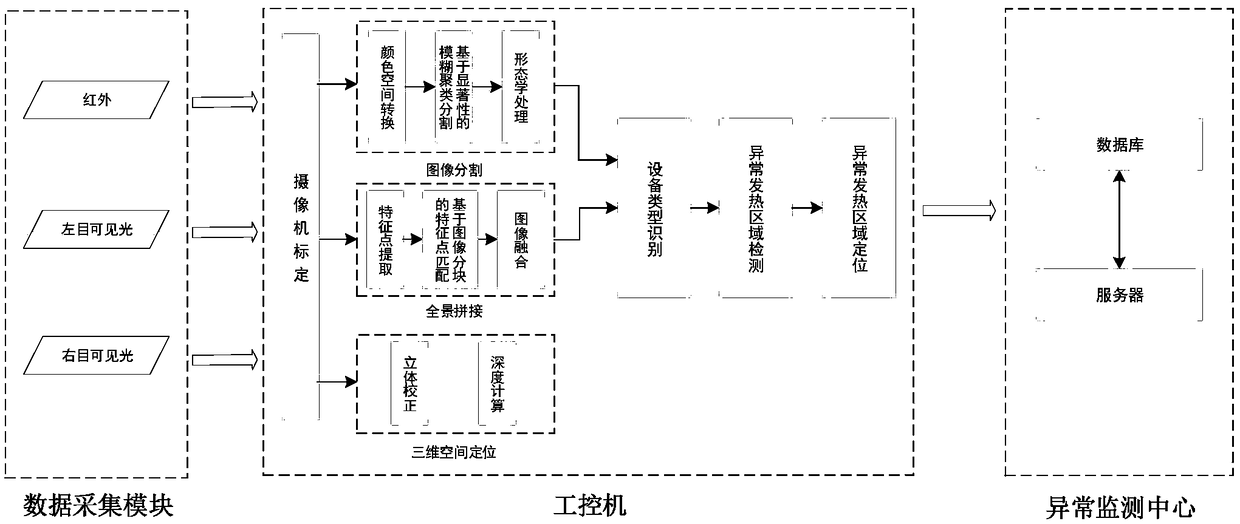

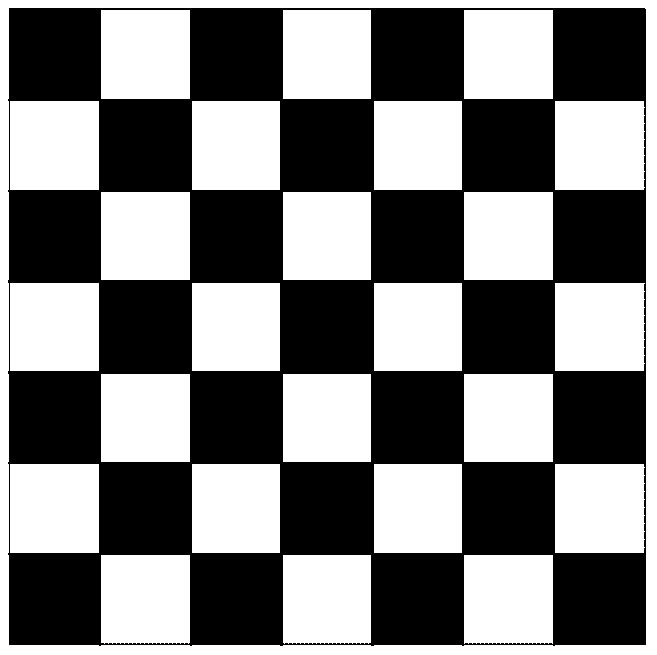

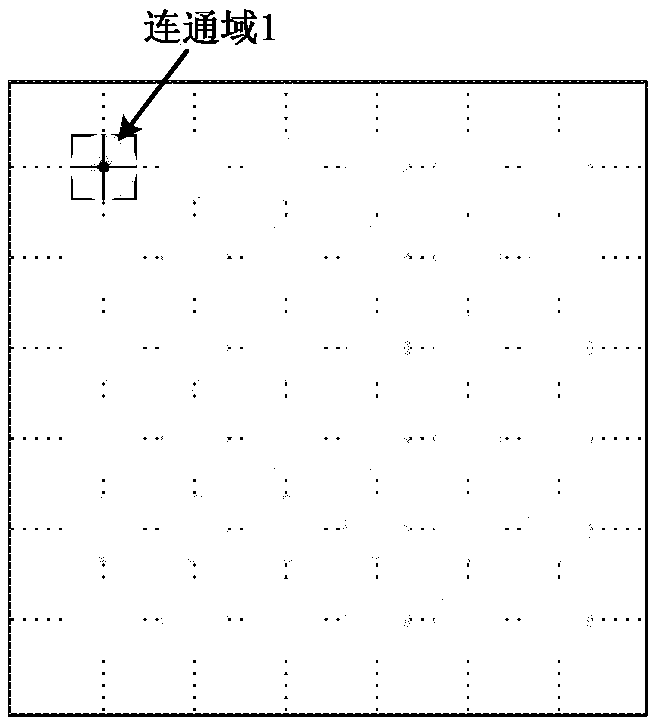

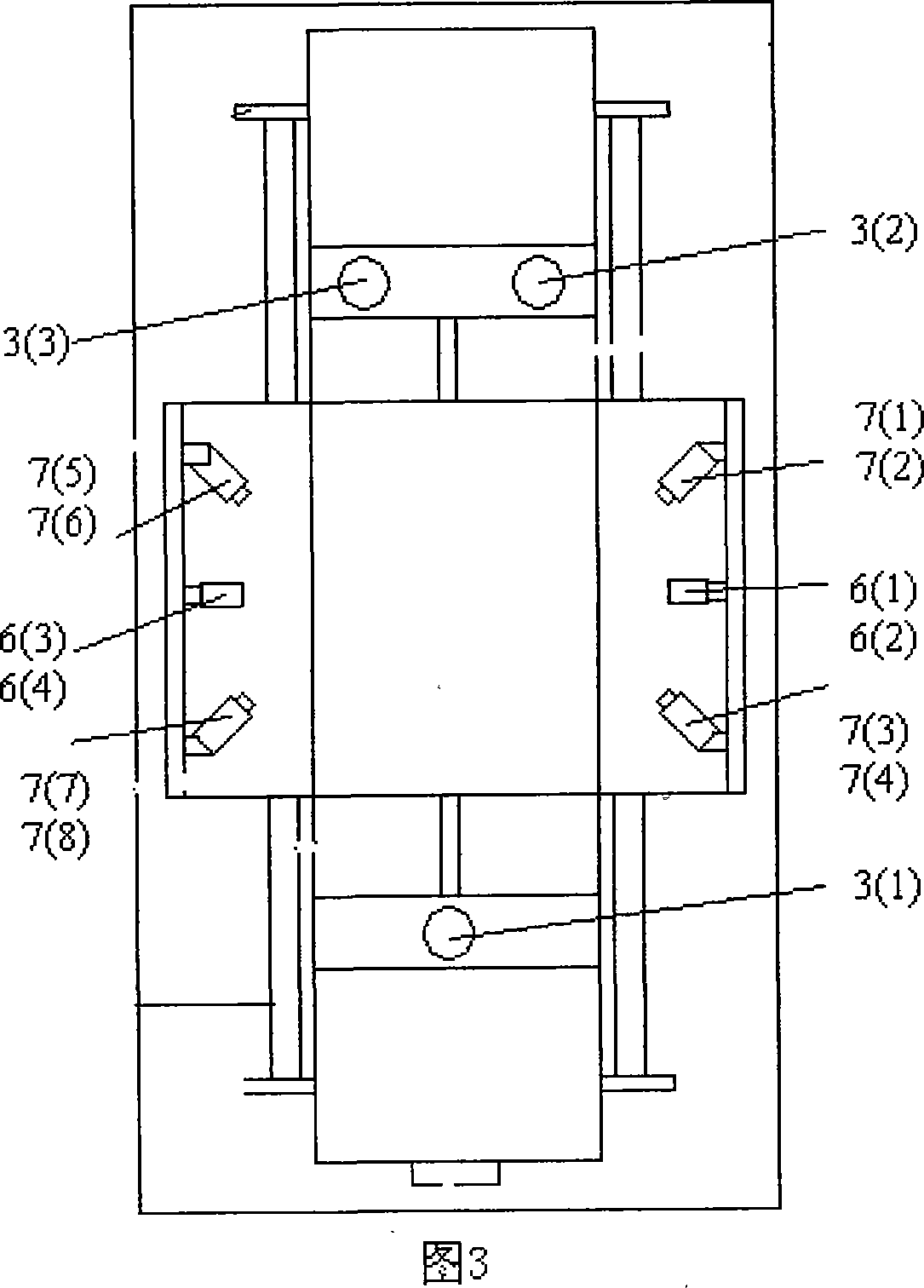

Power equipment abnormality monitoring system and method based on multi-vision

InactiveCN109029731AAccurate detectionPrecise positioningTelevision system detailsRadiation pyrometryMonitoring systemData acquisition

The invention discloses a power equipment abnormality monitoring system and method based on multi-vision. The monitoring system comprises a data acquisition device, an industrial personal computer andan abnormality monitoring center. The data acquisition device comprises an infrared camera for collecting an infrared image of a region where a power device is located, and a left-view visible lightcamera and a light-view visible light camera for collecting visible light images of the region where the power device is located; the industrial personal computer analyzes and processes the infrared image and the visible light image, detects an abnormal heating region of the power device, locates the abnormal heating region, and sends the abnormal heating information to the anomality monitoring center; and the abnormality monitoring center outputs early warning information after receiving the abnormal heating information. The power equipment abnormality monitoring system and method based on multi-vision in the invention can accurately and quickly detect the abnormal heating region of the power equipment and accurately locate the abnormal heating position, and performs early fault warning timely, thereby effectively avoiding the occurrence of the power equipment failure and reducing economic loss.

Owner:HOHAI UNIV CHANGZHOU

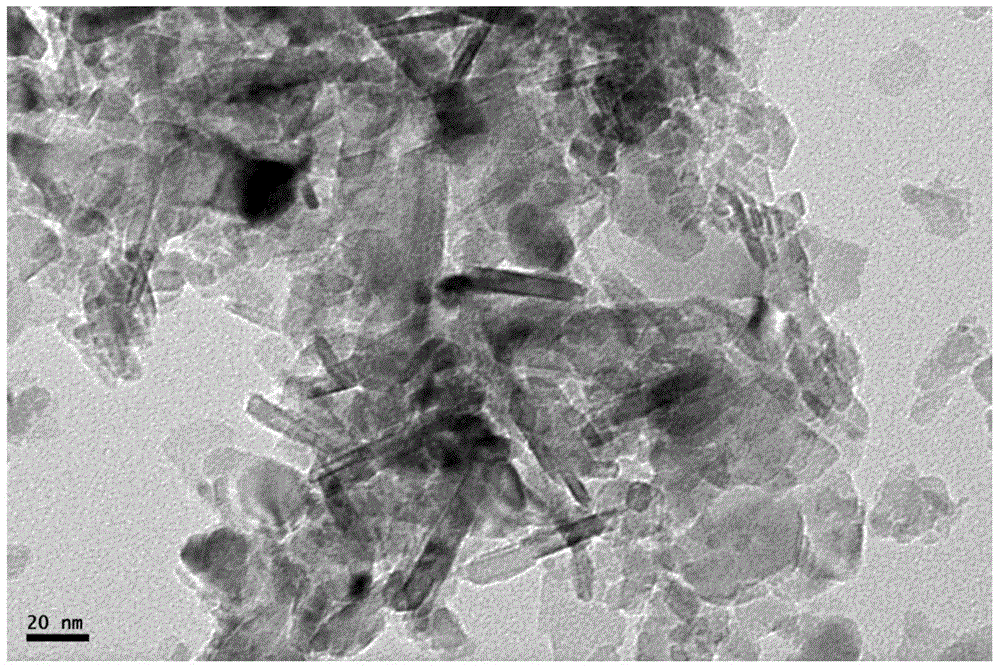

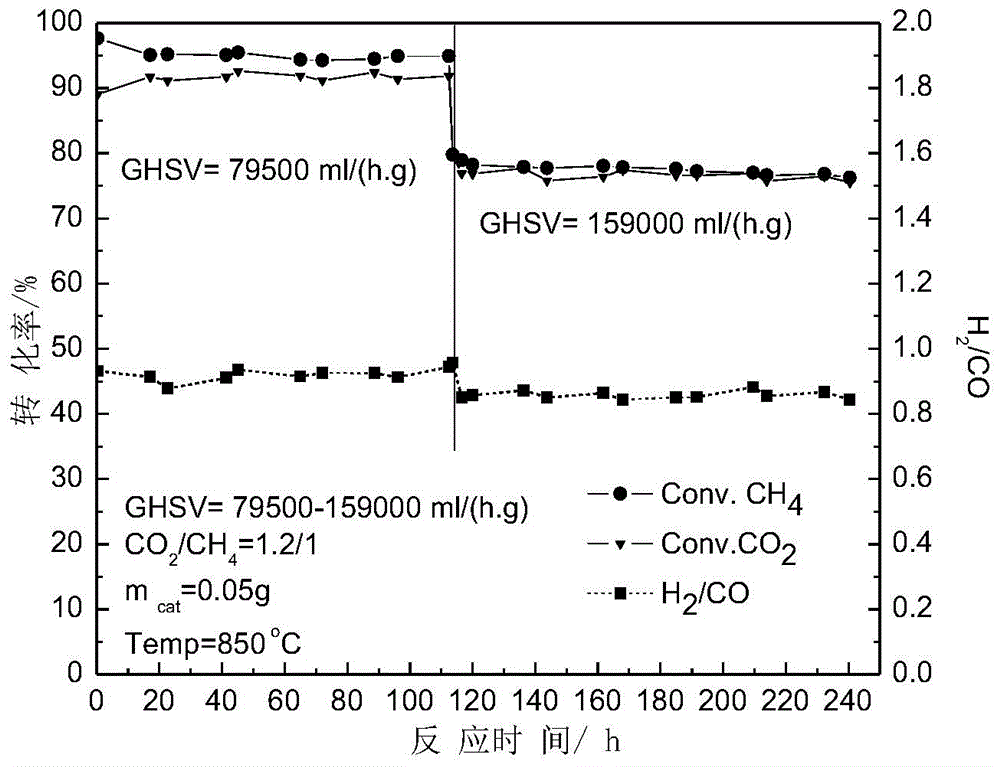

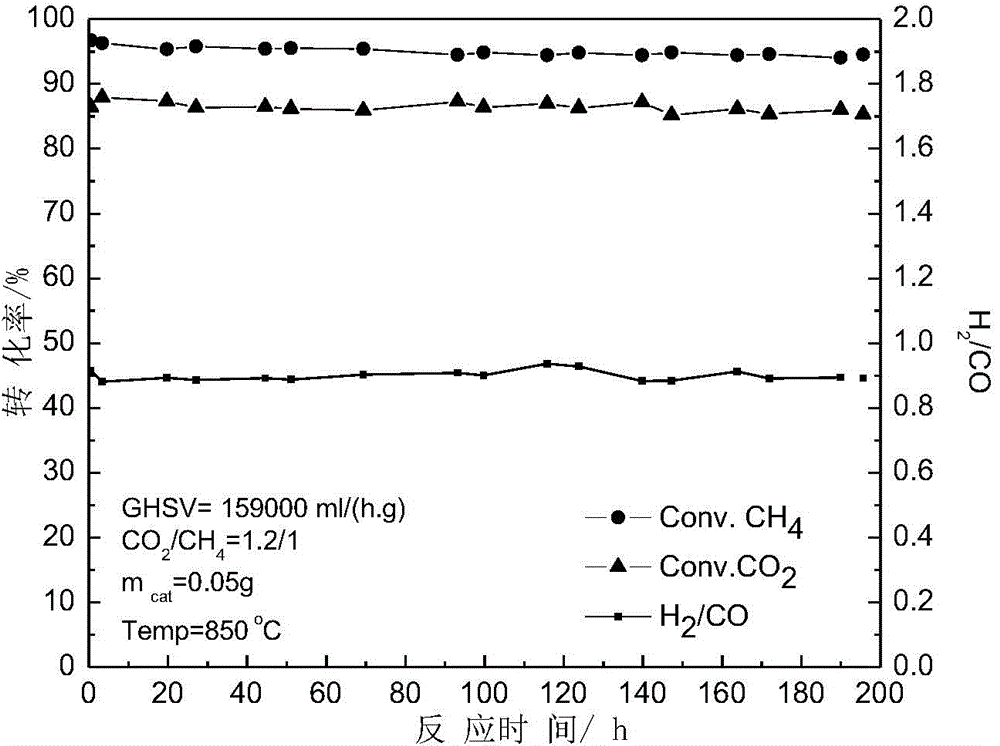

Catalyst for preparing synthesis gas or hydrogen and preparation method and application thereof

ActiveCN104084211AImprove thermal stabilityNo decrease in activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogenFlue gas

The invention discloses a catalyst for preparing synthesis gas or hydrogen and a preparation method and application of the catalyst. The catalyst comprises an active ingredient and an assistant, and is loaded on a carrier. The preparation method comprises the following steps: uniformly mixing raw materials for preparing the catalyst through a coprecipitation, impregnation or mixed-grinding manner, and roasting to obtain the catalyst. The catalyst is applied to reaction of producing synthesis gas by reforming of natural gas or reaction of producing hydrogen by reforming of natural gas, or reaction of producing the synthesis gas or hydrogen by reclaiming coalbed methane, purge gas and flue gas with methane ingredient being 5-50 percent by mole. The catalyst has the characteristics of high activity, high stability, high temperature resistance and the like, and overcomes defects of poor stability, high probability of inactivation and the like of an existing methane reforming catalyst.

Owner:高潞空气化工产品(上海)能源科技有限公司

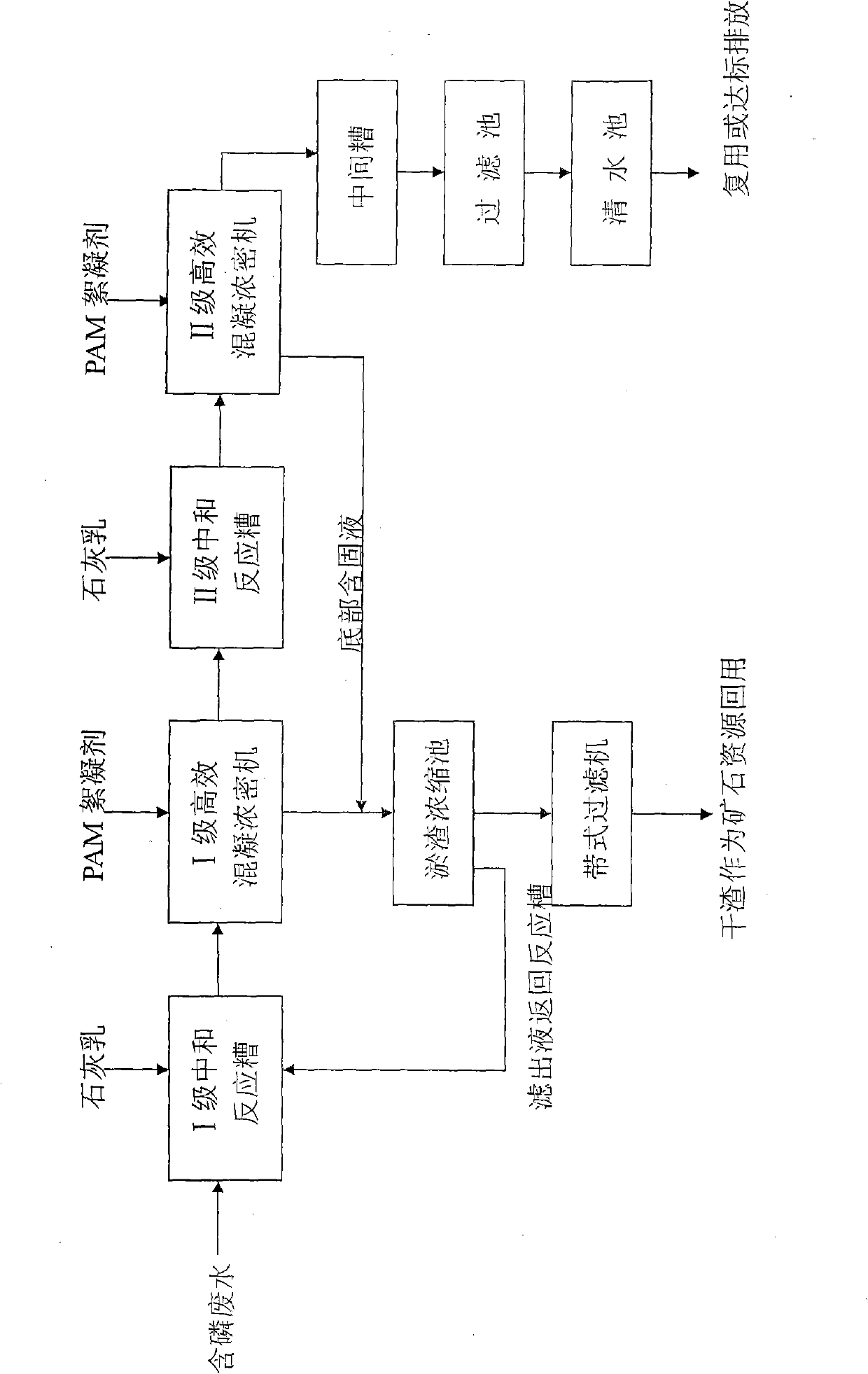

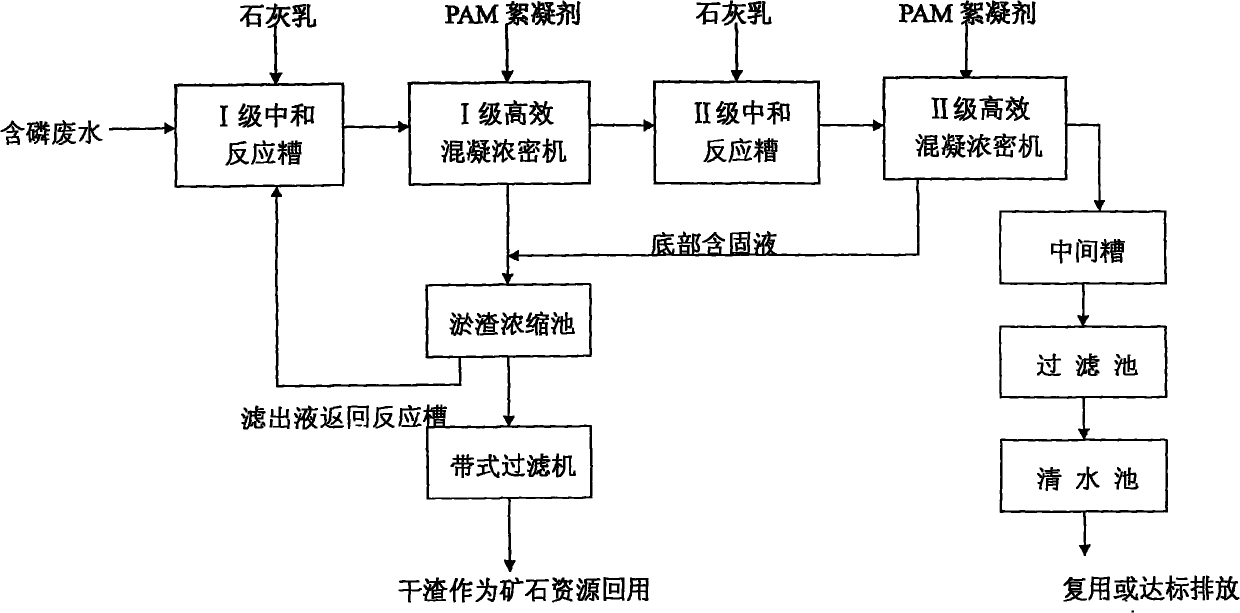

Treating method for phosphoric waste water and sludge generated in production process of phosphatic compound fertilizer

InactiveCN101905933AConform to energy savingEconomicalMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeFiltration

The invention discloses a treating method for phosphoric waste water and sludge generated in the production process of a phosphatic compound fertilizer, which comprises the following steps: adding lime milk into the phosphoric waste water to be treated firstly, and controlling a pH value to be 5-6; carrying out neutralization reaction for the first time; adding a PAM flocculating agent for flocculation reaction and then carrying out separation of mud and water; adding the lime milk in the aqueous phase again, and controlling the pH value to be 10-11 for the neutralization reaction for the second time; and adding the PAM flocculating agent again for the flocculation reaction and then carrying out the separation of mud and water, wherein the aqueous phase reaches a effluent standard after filtration. The invention realizes the multiplexing or the standard-reaching discharge of the waste water, the zero release of the sludge, accords to the developing direction of the energy saving and emission reduction and circular economy. The clear liquid treated by the process of the invention contains 0.4-0.5mg / L of phosphate (calculated by being based on P2O5), 8-9mg / L of F and 60-80mg / L of COD, meets the primary standard emission requirement of GB8978-1996, the ultimate clear liquid can be returned to a phosphoric acid device for multiplexing, and also be directly discharged after reaching standards; and the sludge produced by the filtration comprises the following main components: calcium phosphate, calcium fluoride, calcium carbonate and calcium sulfate, which can be totally reused as phosphorite resources.

Owner:中化重庆涪陵化工有限公司

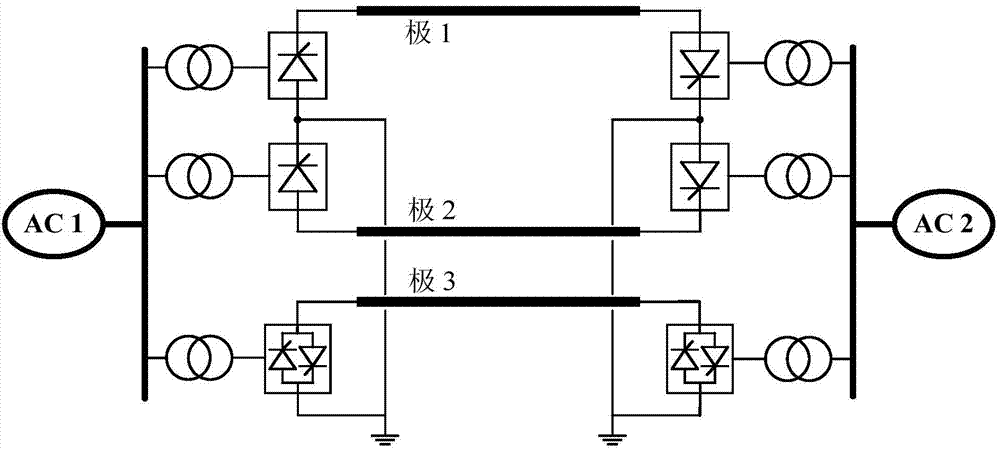

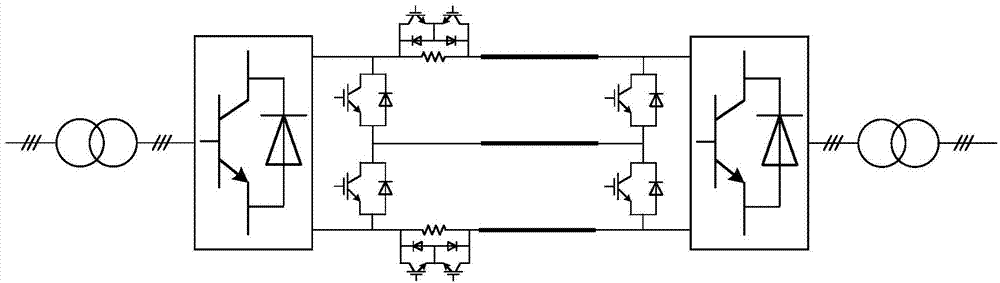

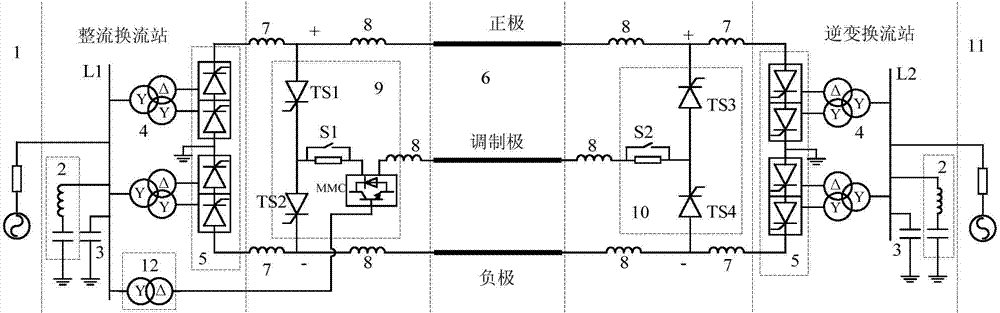

Expansion double-electrode direct current transmission system

ActiveCN103595064AEconomicalGood engineering applicabilityElectric power transfer ac networkCapacitanceTransmission line

The invention discloses an expansion double-electrode direct current transmission system which comprises a rectification convertor station, a rectification side current conversion unit, a three-electrode power transmission circuit, an inversion side current converting unit and an inversion convertor station. When the expansion double-electrode direct current transmission system normally works, the rectification convertor station controls the magnitude of direct currents by controlling the triggering angle of a thyristor and converts the three-phase alternating currents into double-electrode direct currents in a rectification mode; afterwards, the double-electrode direct currents are converted into three-electrode direct currents through current conversion processing, flow through three transmission lines respectively and undergo current conversion reverse processing. The three-electrode currents are converted into the double-electrode direct currents and the direct currents are converted into three-phase alternating currents through the inversion action of an inversion side thyristor converter and a received end alternating current system is filled with the three-phase alternating currents. Thus, power is transmitted from a sending end alternating current system to the received end alternating current system. Thus, the investment cost is much less than that of a three-electrode direct current transmission system, the transmission capacitance is 1.37 times that of a double-electrode system, consumption loss of extra power will not be introduced into a direct current side, good economical efficiency is achieved and engineering application is facilitated.

Owner:ZHEJIANG UNIV

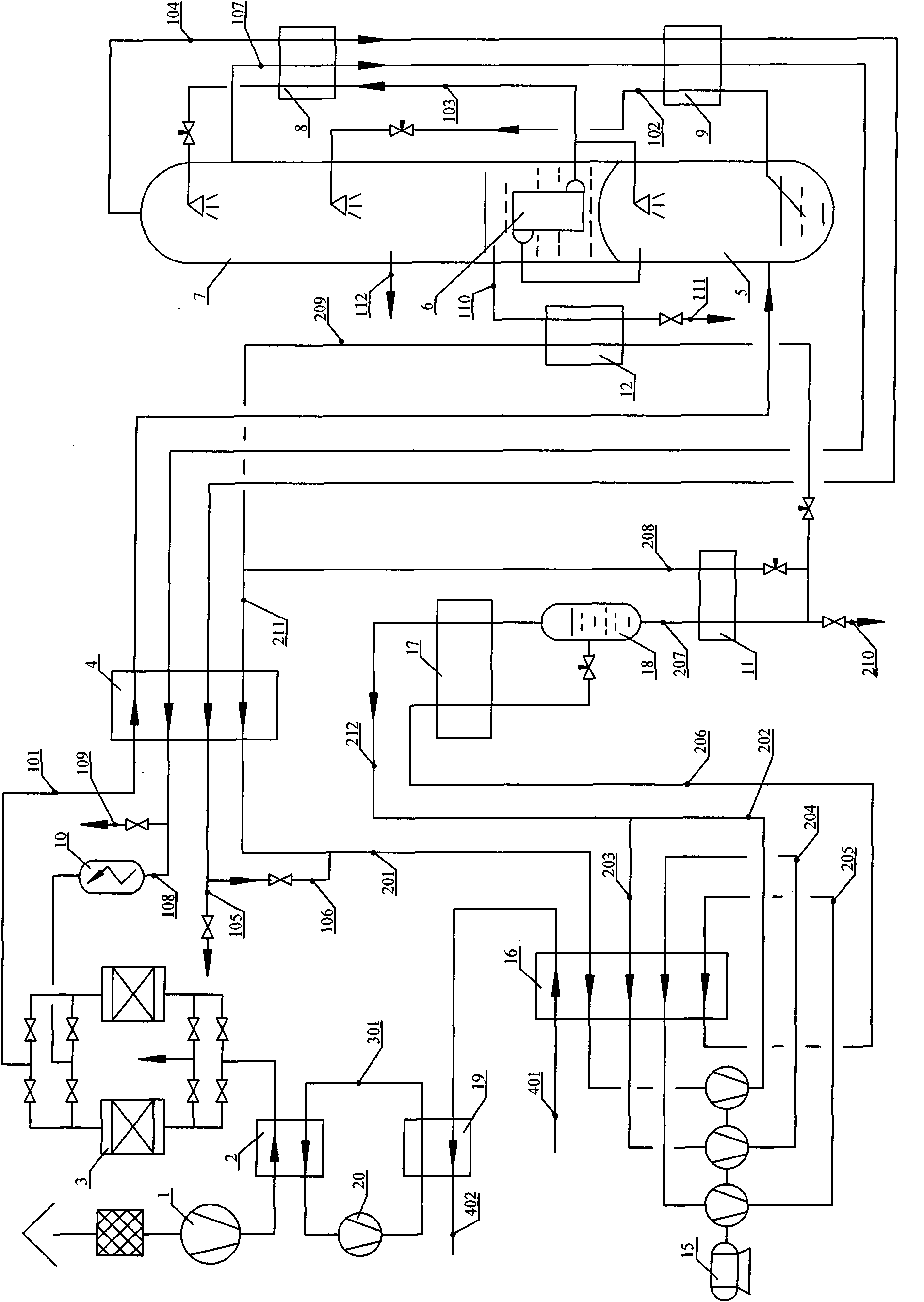

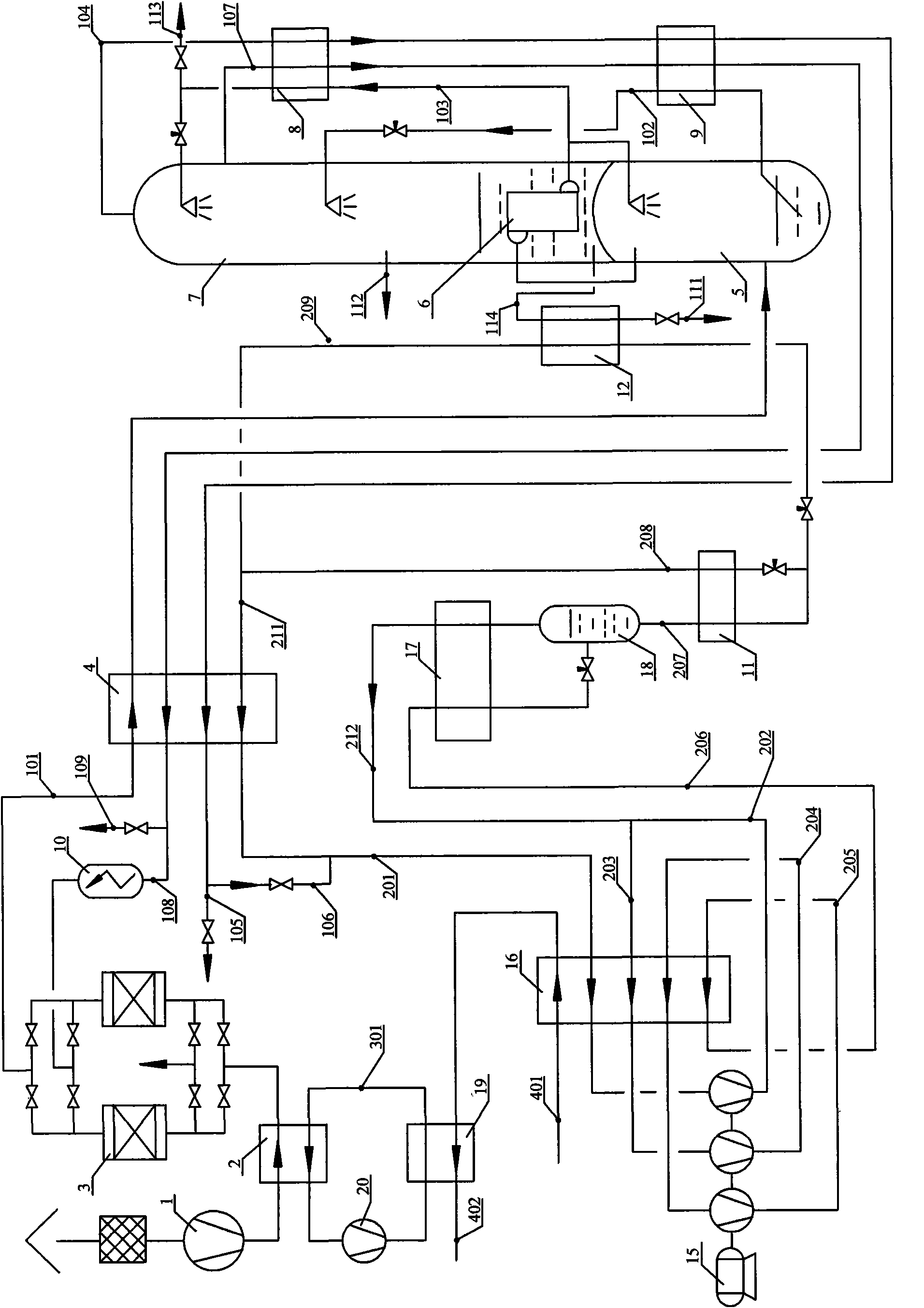

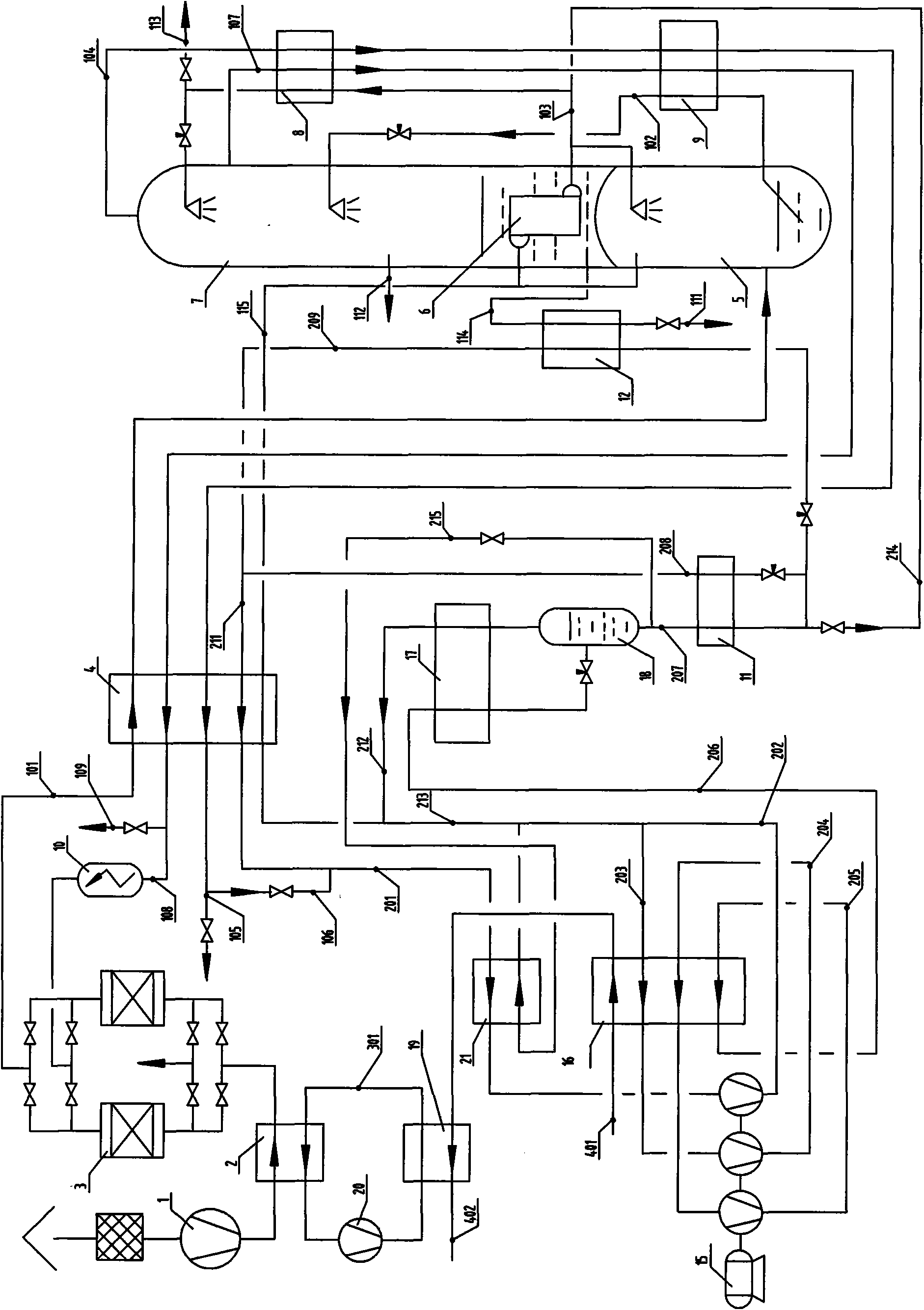

Air separation method utilizing liquefied natural gas cold energy

ActiveCN101571340AReduce unit power consumptionConform to energy savingSolidificationLiquefactionLiquefied natural gasSocial benefits

The invention discloses an air separation method utilizing liquefied natural gas cold energy, comprising an air separation unit, an LNG cold energy utilization unit providing refrigeration energy for the LNG cold energy utilization unit and a glycol water solution circulation unit utilizing NG high temperature cold energy. In the invention, low temperature cold energy of the LNG is applied to the air separation system, thus unit power consumption of a liquid air separation product can be reduced to about 0.30kwh / m, which is one third of the unit power consumption of a liquid air separation product in conventional process production; and unit power consumption of the internal compressed gas product also can be greatly reduced, and meanwhile a large number of cooling water can be saved, thus being in accordance with the trend of energy saving, consumption reduction and circular economy developing and having obvious social benefit and economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +3

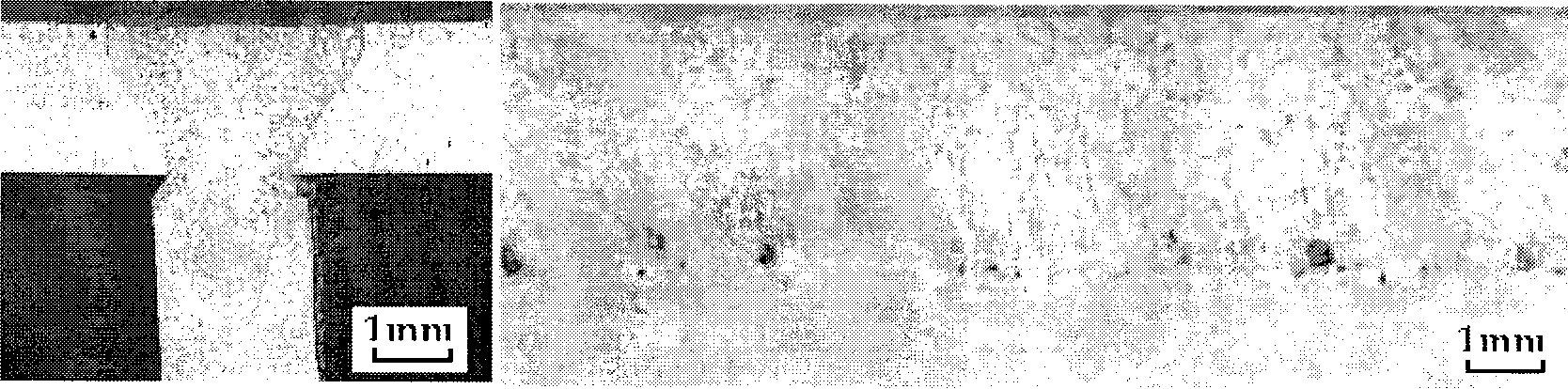

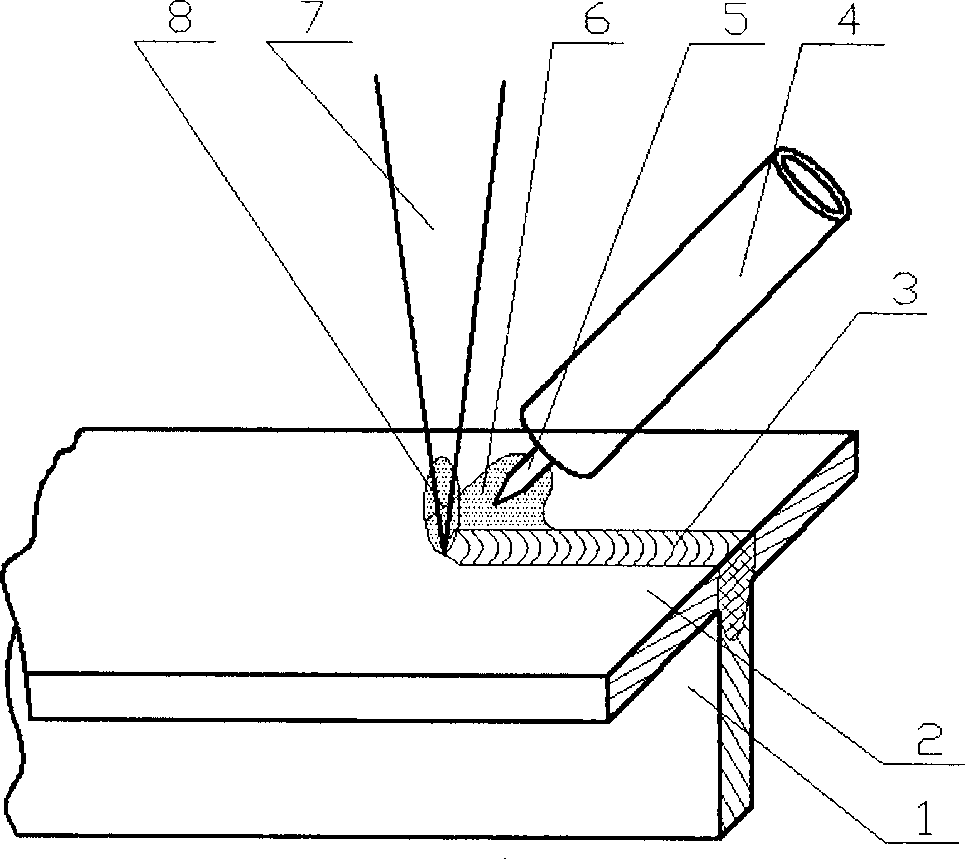

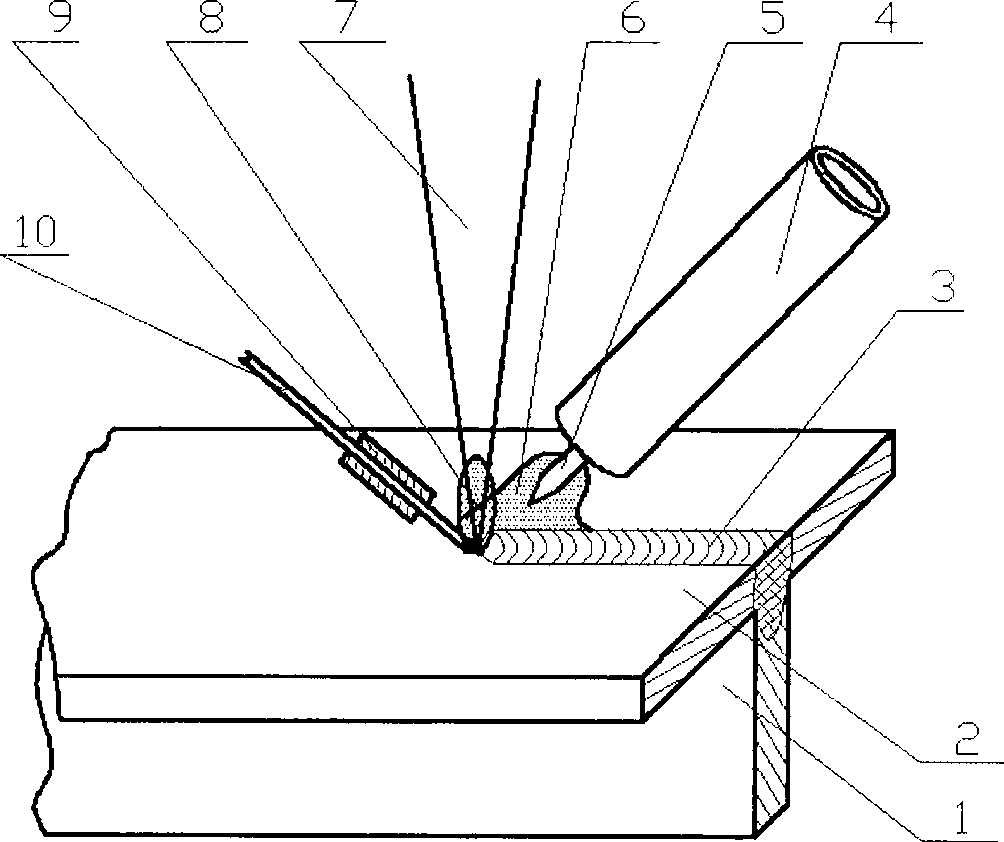

Laser-arc hybrid welding method of light sheet T type joint

InactiveCN101474727AEasy to shapeImproved weld toe transitionLaser beam welding apparatusLight beamEngineering

The invention relates to a laser-arc composite welding method for a T-shaped joint of a thin plate, belonging to the technical field of laser materials processing. The method adopts a laser-arc composite thermal source to complete the welding of the T-shaped joint on the lateral face of a bottom plate, a laser bean enters from the top face of the bottom plate, an electric arc is in paraxial arrangement at the front part or the rear of the laser bean, and the composite thermal source accomplishes the penetration fusion welding from the lateral face of the bottom plate of the T-shaped joint. The welding seam of the joint welded by the method is favorably shaped, a weld toe of the connection part of a rib plate and the bottom plate is uniformly and smoothly transited, and air holes, cracks and other defects are not presented after the welding seam is anatomized. The method fully utilizes the characteristics of the composite thermal source; and under the mutual actions of laser and arc, the stability of a welding process is obviously improved, the welding efficiency is increased, and the welding deformation can be lessened.

Owner:BEIJING UNIV OF TECH

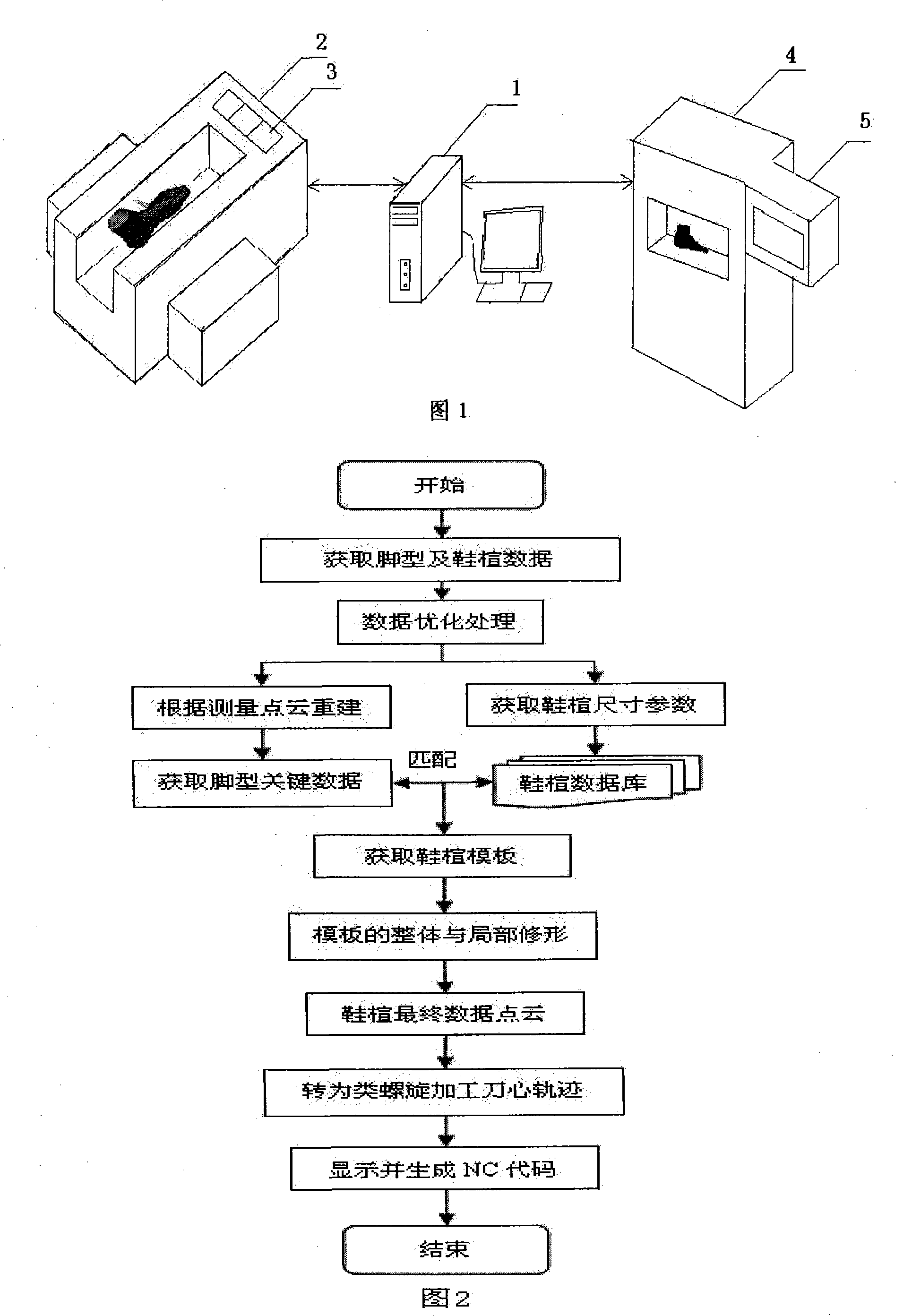

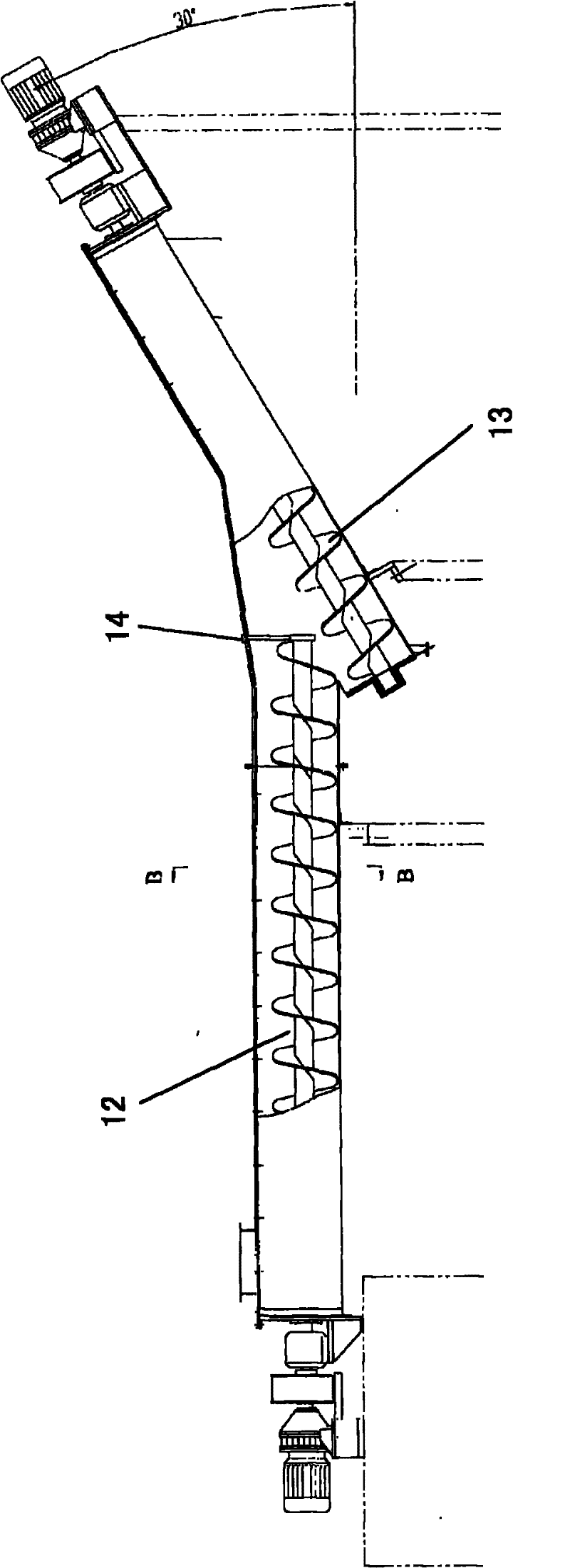

Digitalized sneakers tree customizing production apparatus and process

InactiveCN101088728AReasonable spatial distributionComprehensive foot dataWood working apparatusControl systemTemplate based

The present invention belongs to the field of numerically controlled machining technology, and is especially digitalized sneakers tree customizing production apparatus and process. The digitalized sneakers tree customizing production apparatus consists of a main control computer, a 3D foot form scanning instrument and a numerically controlled shoe tree machine connected together. The main control computer forms the sneakers tree template based on the foot form parameters obtained through measuring the loaded foot form with the 3D foot form scanning instrument, zooms and trims the tree template, converts the shoe tree data into an NC file suitable for machining and feeds the NC file to the numerically controlled shoe tree controlling system for driving the shoe tree machine. The present invention may be applied widely in customizing production of different shoes.

Owner:TSINGHUA UNIV

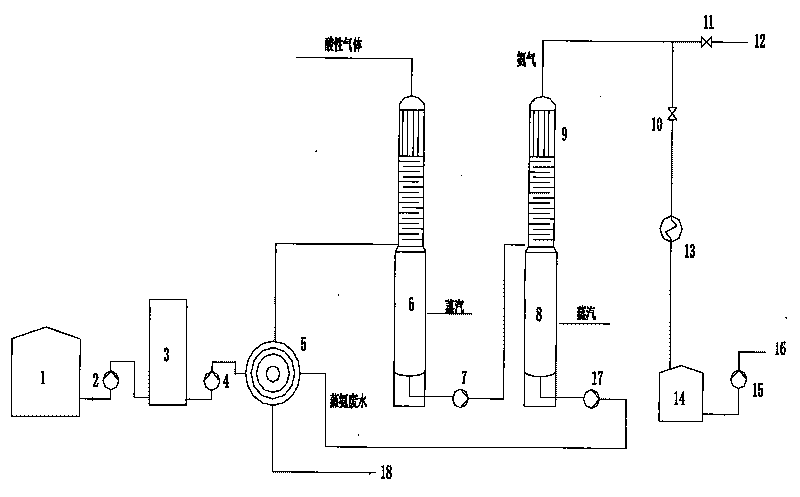

Technology for preparing desulfurizing agent ammonia water in sintering flue gas desulfurization by coking residual ammonia water

ActiveCN101717096AReduce the impactLow running costDispersed particle separationAmmonia preparation/separationCircular economyCoke oven

The invention relates to a technology for preparing desulfurizing agent ammonia water in sintering flue gas desulfurization by coking residual ammonia water. The technology cokes the residual ammonia water with an ammonia vaporizing tower 8 and an ammonia dephlegmator 9 in a coking gas purifying system, i.e. 15-20% of ammonia water which is generated by condensing ammonia vapour is taken as source of the desulfurizing agent ammonia water in the sintering ammonia flue gas desulfurization, has the advantages of mature technology, stable operation, stability, small modification work load, less investment and less influence to coking production, provides stable ammonia source for the sintering ammonia flue gas desulfurization, reduces the process cost of waste ammonia and the running cost of sintering desulfurization during the coking production, recycles harmful substance ammonia in residual ammonia water, and accords with the national circular economy and the sustainable development strategy.

Owner:中钢集团天澄环保科技股份有限公司

Preparation of transparent, multilayered articles containing polyesters comprising a cyclobutanediol and homogeneous polyamide blends

Disclosed is a process for the preparation of multilayered, shaped articles having high transparency and low haze and in which at least one layer contains at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol and a separate layer which contains a transamidized, homogeneous blend of a least two polyamides. The polyester component and the polyamide component have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into one or more of the layers of the article while maintaining high clarity. These articles can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into one or more layers to impart oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

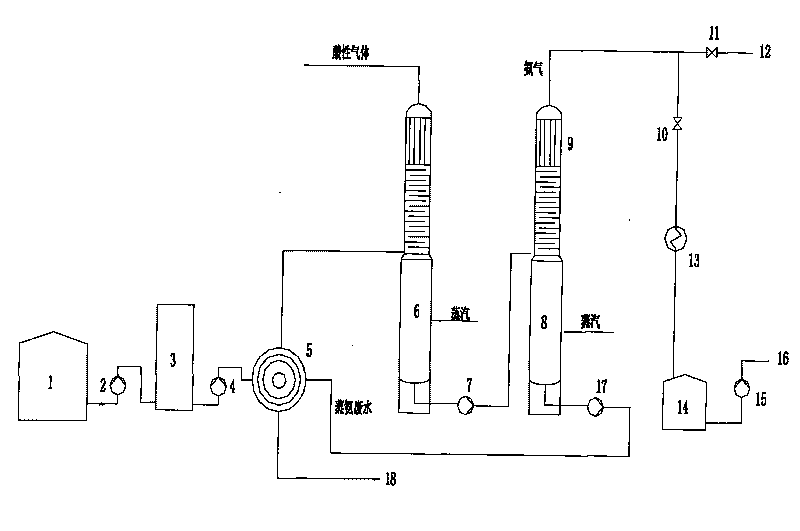

Method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor

ActiveCN102674398AImprove desulfurization efficiencyEconomicalThiocyanic acidAmmonium sulfatesPhthalocyanineCobalt

The invention relates to a method for recycling chemical wastewater, in particular to a method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor. By the method, inorganic salt in the desulfuration waste liquor generated by a phthalocyanine cobalt sulfonate (PDS) method in a coking plant is extracted by a two-stage concentration and fractional crystallization separation method. The method is easy to operate and control, the purity of the ammonium thiocyanate which is finally recovered reaches more than 98 percent, and the yield reaches more than 80 percent. By the method, the circulation volume of desulfuration liquor in a desulfuration working section and the total salt content in the desulfuration liquor are reduced, and the desulfuration efficiency of the desulfuration working section is improved; environmental problems generated by wastewater discharge pollution of coking plants are solved; and useful chemical raw materials are recovered from the desulfuration waste liquor, so that social, environmental and economic benefits for enterprises are increased.

Owner:邢台旭阳科技有限公司

Method for industrially culturing needle mushroom by utilizing soybean stalks

ActiveCN102037858AFull of nutritionLow priceHorticultureFertilizer mixturesBiotechnologyAdditive ingredient

The invention belongs to the field of edible mushroom production, and discloses a method for industrially culturing needle mushroom by utilizing soybean stalks, which comprises the following steps of: collecting and processing the soybean stalks; making a formula of a soybean stalk culture medium; preparing the culture medium; bottling and holing; sterilizing and inoculating; culturing mycelium; controlling temperature and compensating light for promoting buds; covering a plastic film; harvesting and packaging; and cleaning bottles. The method is characterized in that: the formula of the culture medium comprises 40 to 55 percent of soybean stalk, 25 to 35 percent of bran, 8 to 15 percent of corn meal, 8 to 12 percent of sawdust, 1 to 2 percent of light calcium carbonate and 55 to 65 percent of water. The utilized soybean stalks are rich in nutrition and low in price, and has the nutritional ingredient content not lower than that of cotton seed hulls and corncobs, but only costs 1 / 4-1 / 2 of the cotton seed hulls; and the soybean stalks instead of the cotton seed hulls for industrially culturing the needle mushroom can reduce the production cost by 28 to 35 percent and can be promoted and applied across the country.

Owner:江苏江南生物科技有限公司

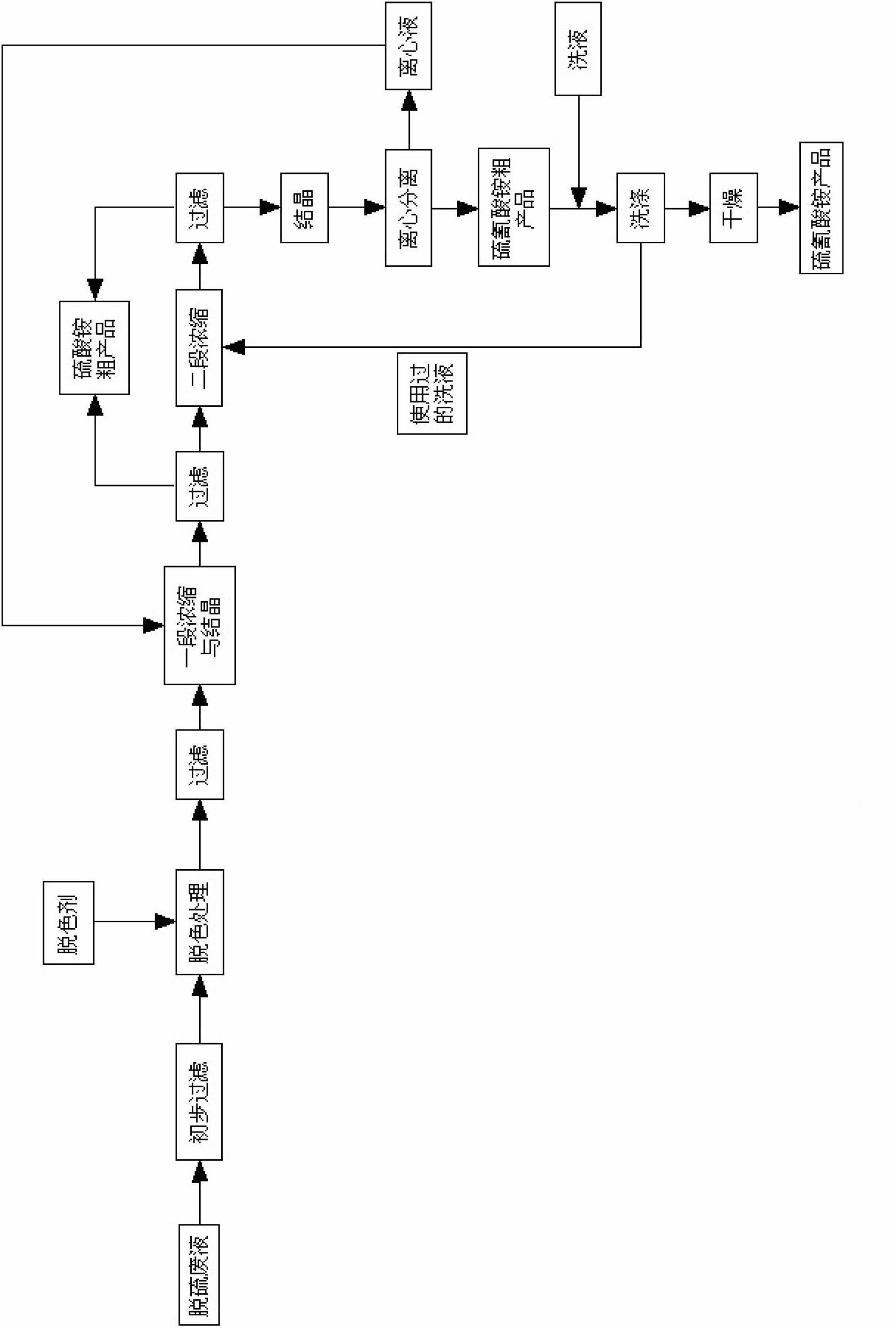

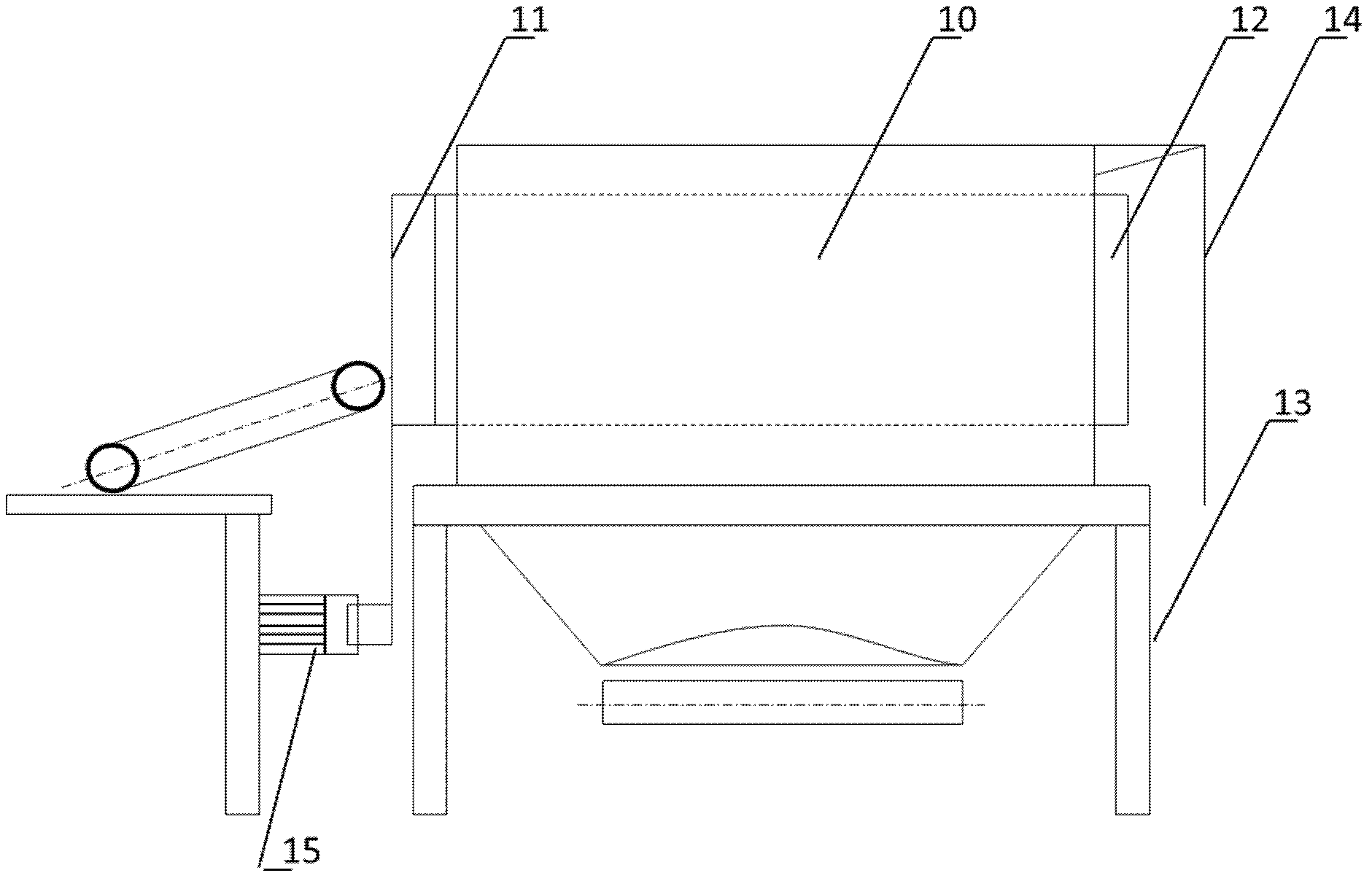

Successive separation method of aluminum-plastic composite packaging materials and device thereof

InactiveCN102206359ASmooth feedingContinuous dischargePlastic recyclingProcess efficiency improvementFormic acidSeparation method

A successive separation method of aluminum-plastic composite packaging materials comprises the following steps of: A) immersing the aluminum-plastic composite packaging materials in a formic acid remover, wherein the formic acid concentration of the formic acid remover is 2-6 mol / L; B) drying the separated aluminium foils and plastic to remove the residual remover; C) centrifuging and sifting thedried aluminium foils and plastic to spall and separate the plastic and aluminium foils, followed by collecting the plastic and aluminium foils. The invention also provides a device to accomplish theabove method. The method provided by the invention accomplishes the purpose of successive feeding and successive discharging with high separation efficiency and high separation speed, saves costs andis of economic and valid industrial value.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

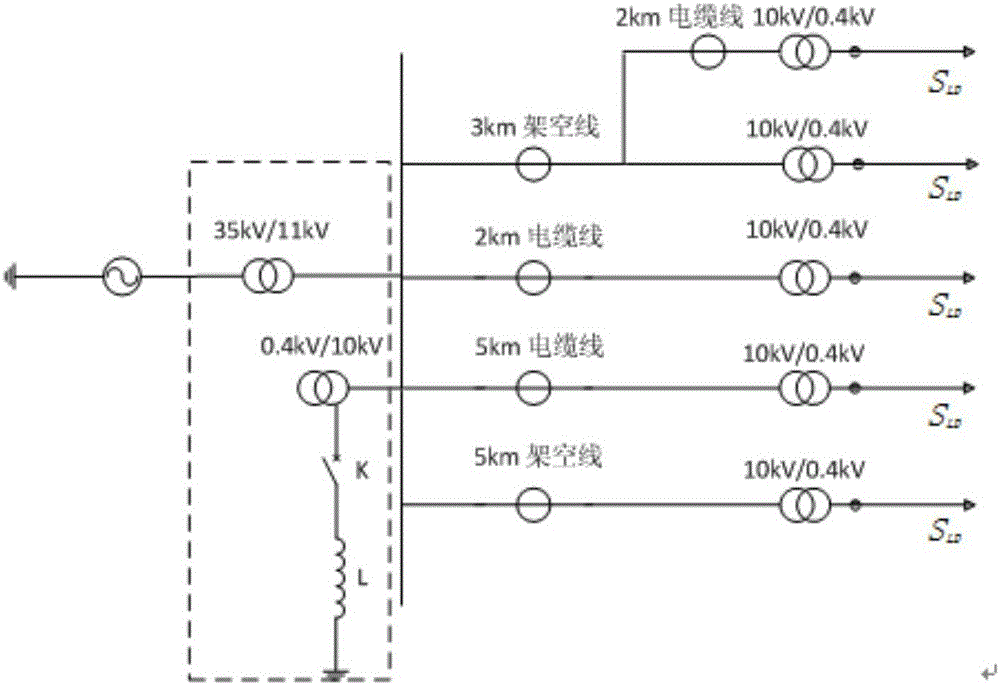

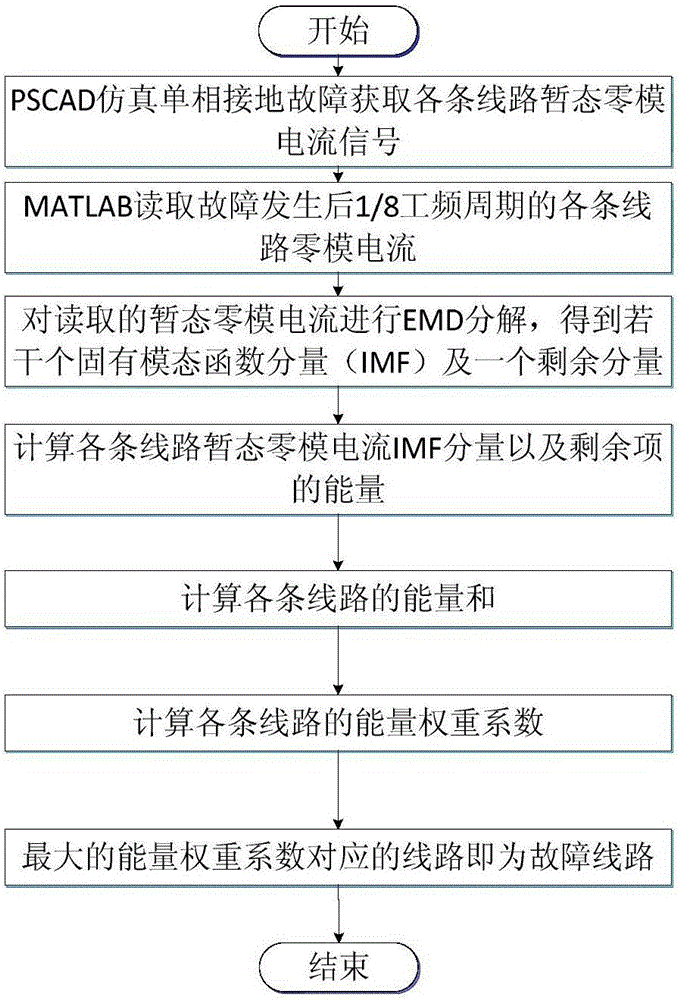

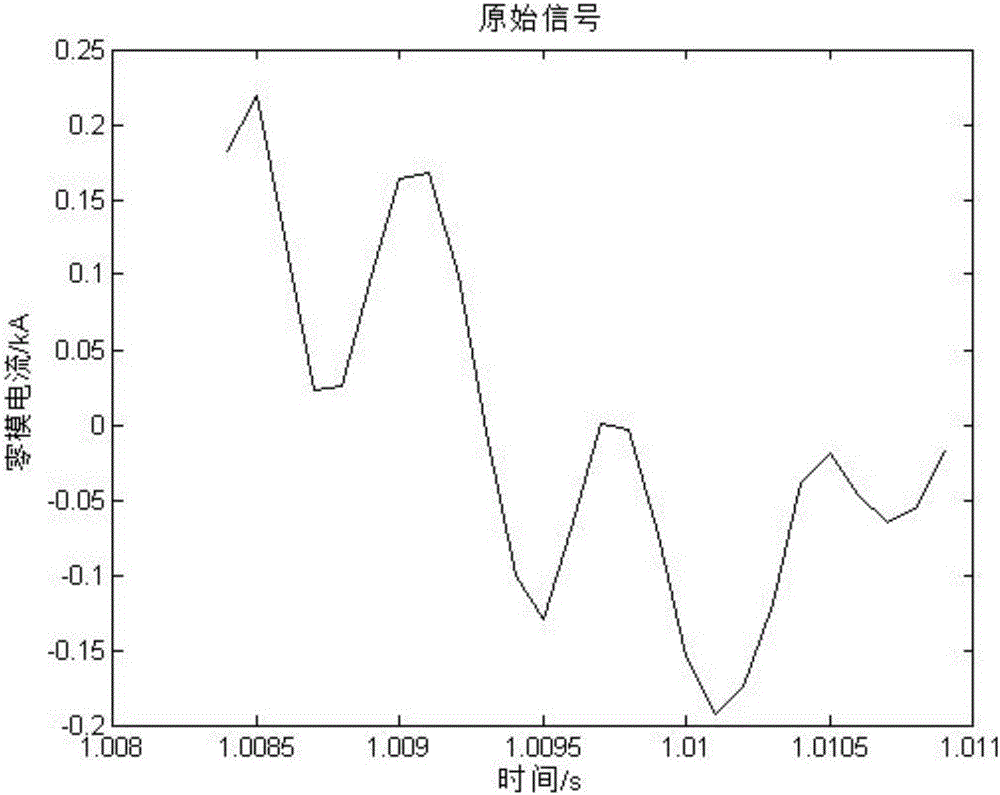

Small current grounding system single-phase grounding fault wire selection method based on transient zero-module current

InactiveCN105866634AEconomicalLine selection is accurateFault location by conductor typesSingle phasePower grid

The invention discloses a single-phase grounding fault line selection method for a small current grounding system based on transient zero-mode current. Three-phase modeling is performed on the power grid, and different fault conditions are selected for single-phase grounding fault simulation experiments to obtain various lines Transient zero-mode current; extract the above data; perform empirical mode decomposition EMD on the above data; calculate the time-domain energy of multiple IMFs and residual components; add the energy of IMF and residual components to obtain the energy sum of a line , repeat the above steps to obtain the energy sum of all lines; calculate the energy weight coefficients of each line, compare the energy weight coefficients of each line, and the line corresponding to the maximum energy weight coefficient is the faulty line. Comparing the peak value and polarity of the first zero-mode current pulse and the polarity of the first instantaneous power peak value, the zero-mode current amplitude of the faulty line is larger than that of the non-faulty line, and the polarity of the two is opposite. The invention is not affected by arc suppressing coils and fault conditions and can accurately select fault lines.

Owner:NARI TECH CO LTD +2

Inorganic powder plastic and preparation method

ActiveCN102432956AGood mechanical propertiesWide range of usesMicroballoon preparationPigment treatment with macromolecular organic compoundsLinear low-density polyethyleneLow-density polyethylene

The invention discloses inorganic powder plastic, which consists of superfine inorganic powder particle microcapsules wrapped by coatings and a macromolecular polymer. The inorganic powder plastic comprises the following components in part by weight: 75 to 85 parts of inorganic powder microcapsules, and 15 to 25 parts of macromolecular polymer. Wherein, the inorganic powder microcapsules consist of inorganic powder with the particle diameter of 2.5 to 5.0 microns and coatings consisting of an active agent, an initiator, an interface modifier and a dispersant; and the macromolecular polymer isat least one of polystyrene, polyethylene glycol terephthalate, lowed density polyethylene, high density polyethylene, metallocene polyethylene, linear low density polyethylene, acrylonitrile-butadiene-styrene copolymer, polypropylene and the like. The inorganic powder plastic (commonly called as stone plastic) has good flowability and thermal plastic processing property, greatly lowers the cost of a plastic product, and reduces the dependency of the plastic product on petroleum resources.

Owner:牧童集团(广东)实业有限公司

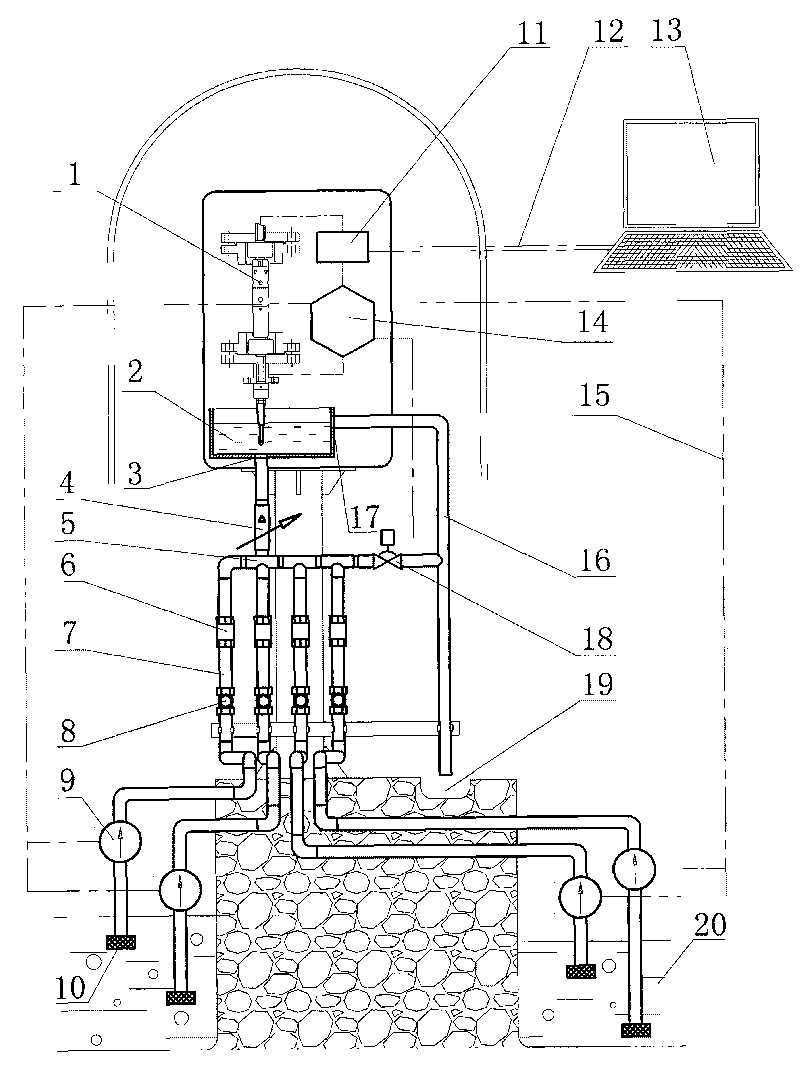

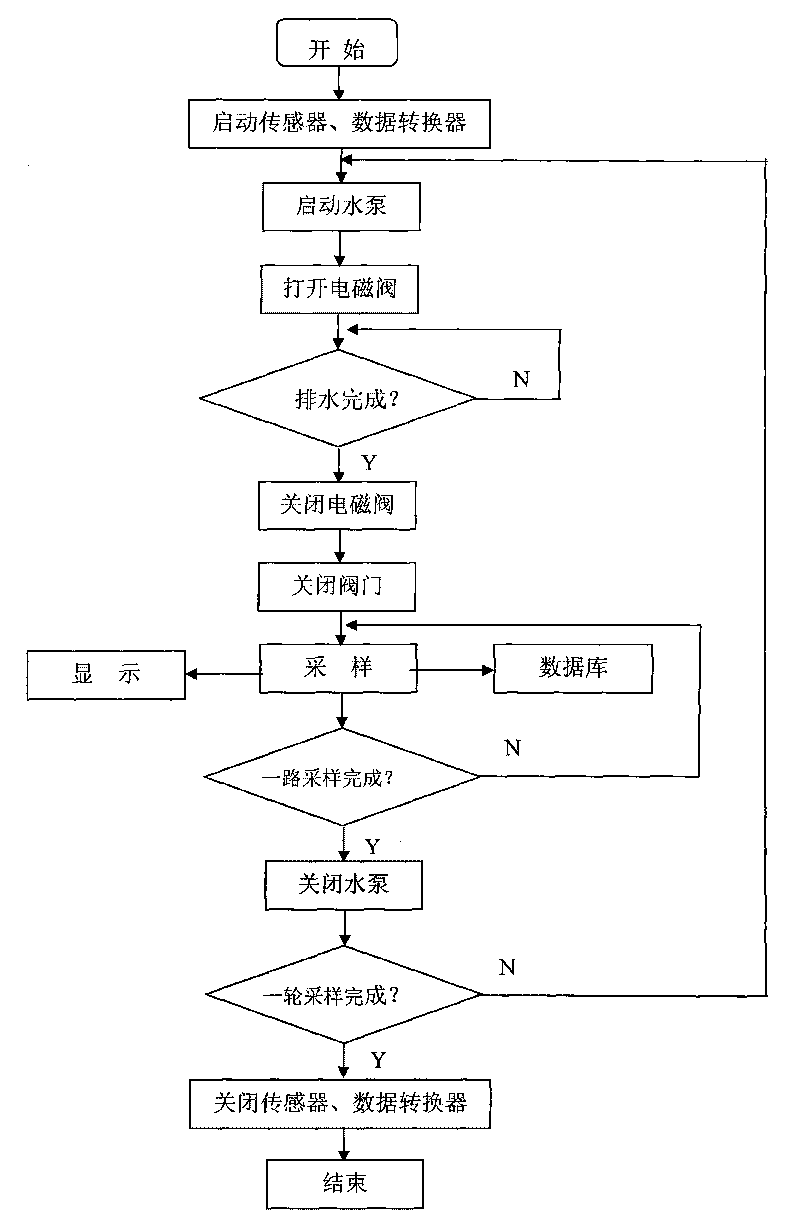

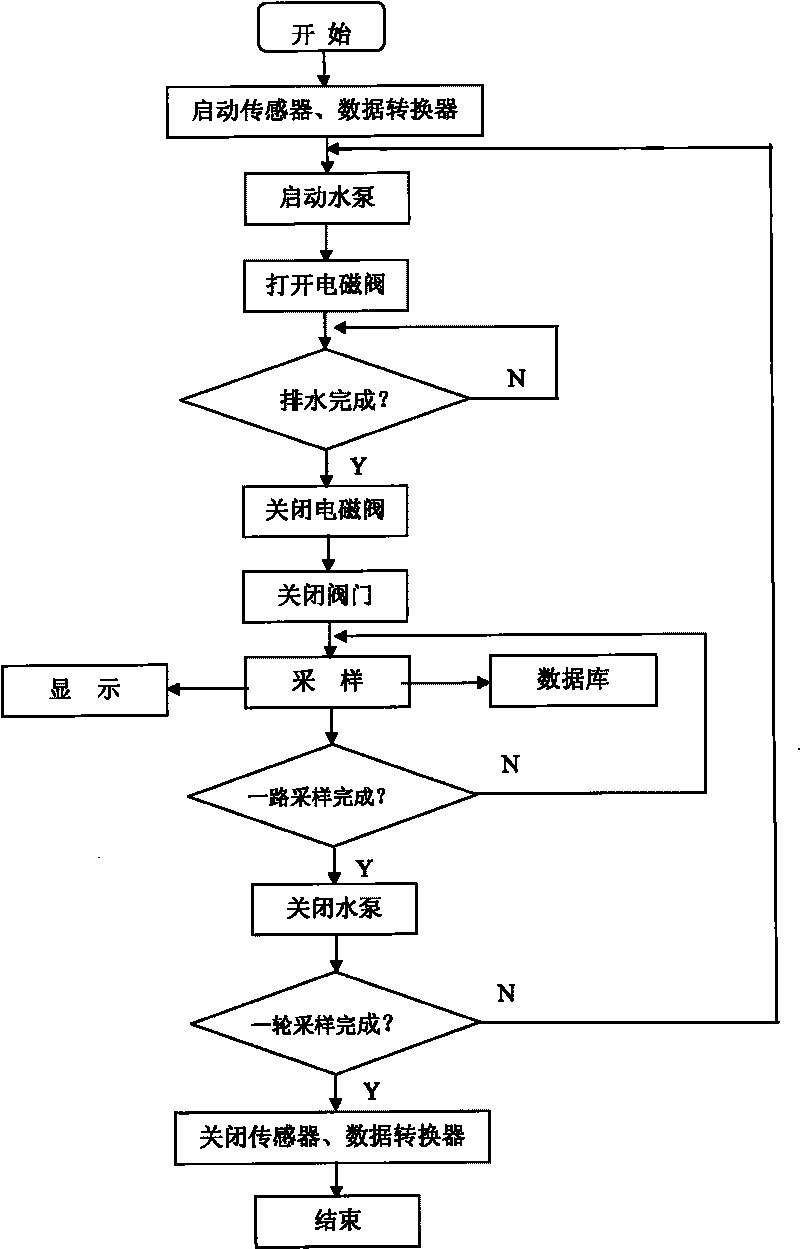

Method and system for sampling aquaculture waters in ponds in real time

InactiveCN101713710AControl inputEconomicalWithdrawing sample devicesMonitoring dataData acquisition unit

The invention discloses a method and a system for sampling aquaculture waters in ponds in real time. The method comprises that: a suite of data acquisition units orderly acquire a plurality of paths of fed samples of the different ponds and different sampling points, namely, orderly sample and monitor the second path and the next plurality of paths of fed samples after finishing sampling and monitoring the first path of fed samples, and start from the first path to perform the next round of sampling and monitoring after the first round of sampling and monitoring is finished; and the data acquisition units transmit monitoring data obtained by the sampling of each round and each path to a central control system in real time, wherein the sampling and monitoring data comprises the concentration of dissolved oxygen DO, a pH value, salinity Sal and temperature Tem. The method and the system have the characteristics of low input cost and good economical efficiency, are specifically suitable for aquaculture in the ponds, and can fully ensure that every time sampling data represents the actual conditions of the aquaculture waters in real time due to the adoption of the monitoring mode of in-vicinity sampling and monitoring and data remote transmission, enable managers to timely master real-time water quality data and take corresponding measures, and reduce the damage of the quality change of the aquaculture waters to aquatic products.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

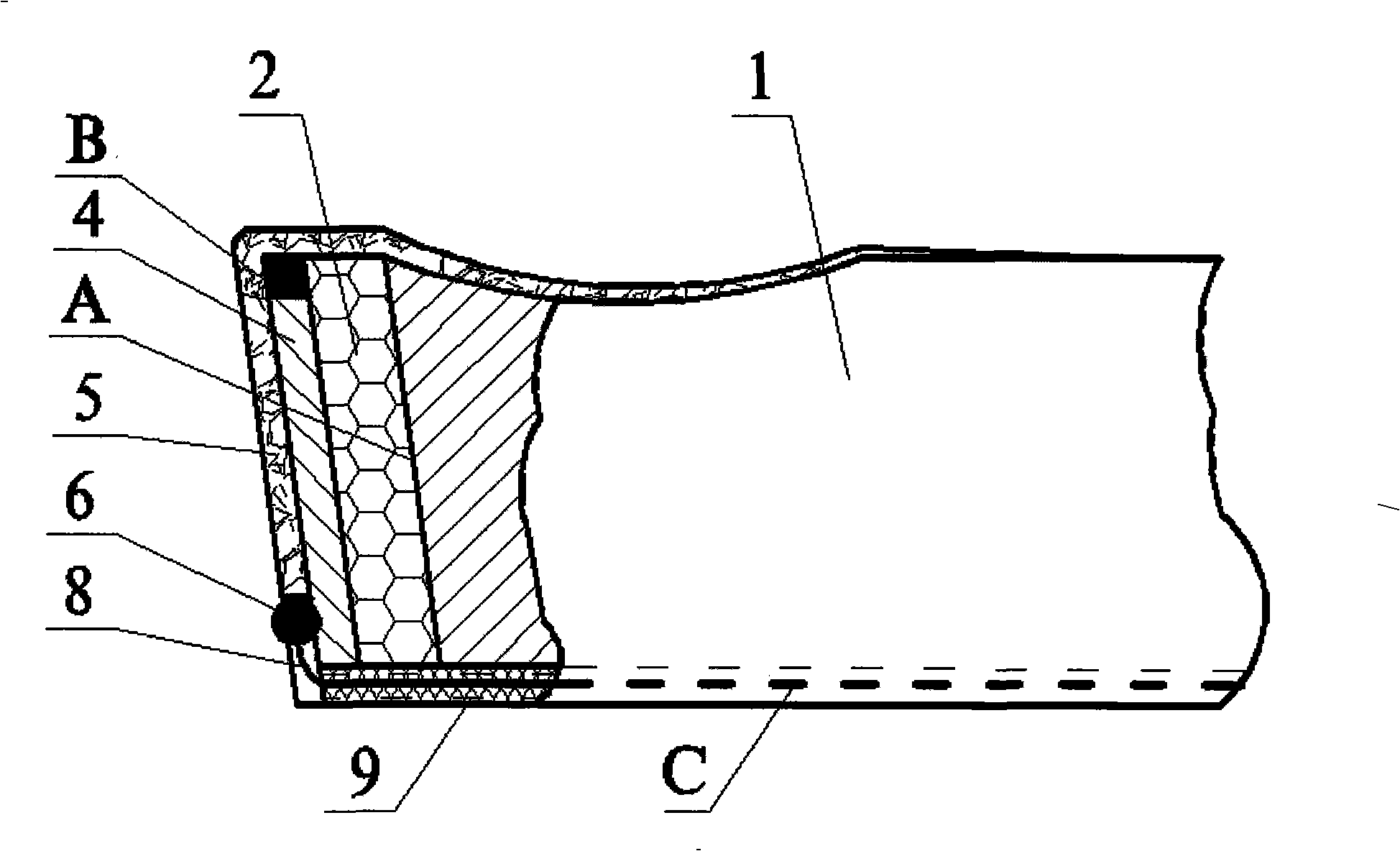

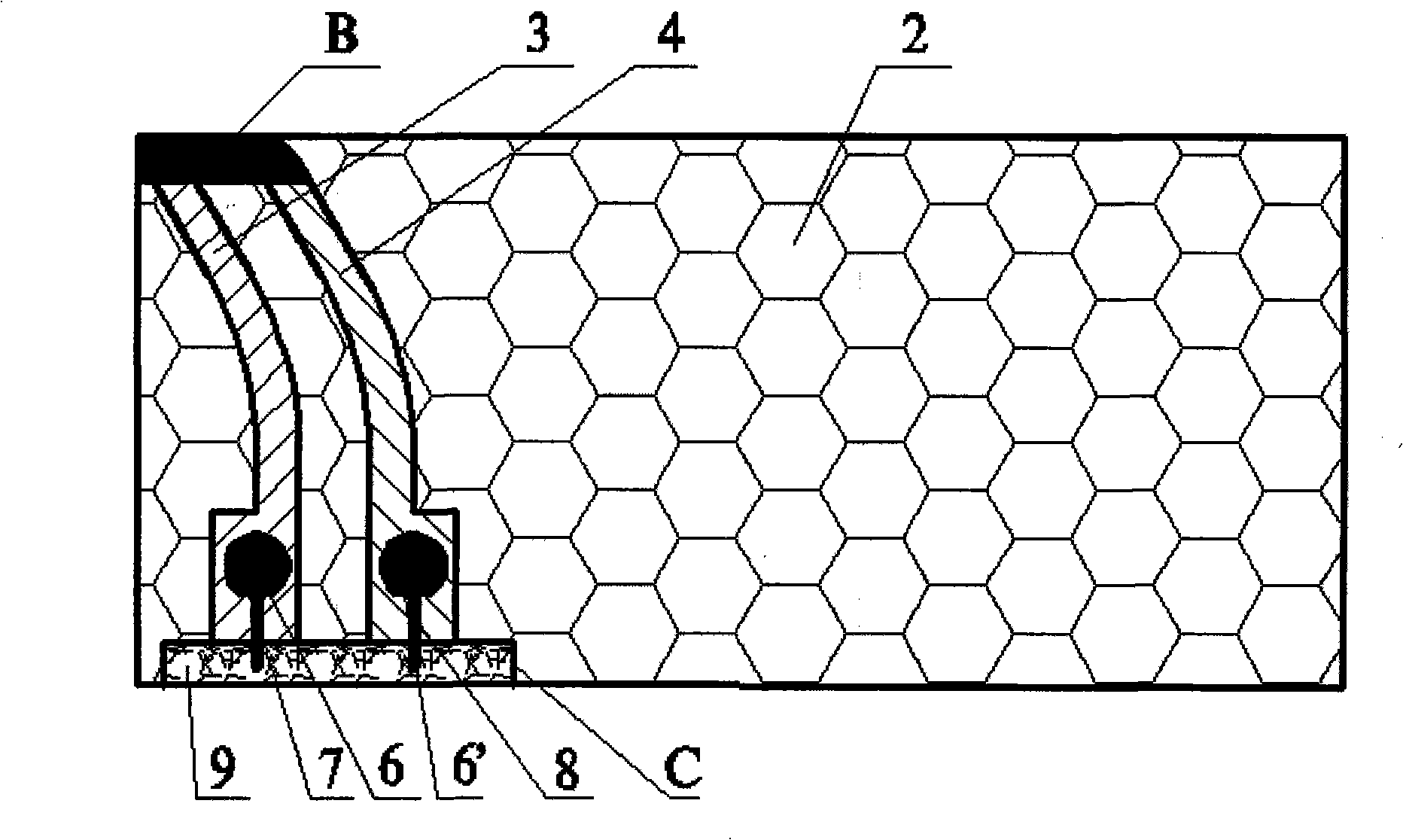

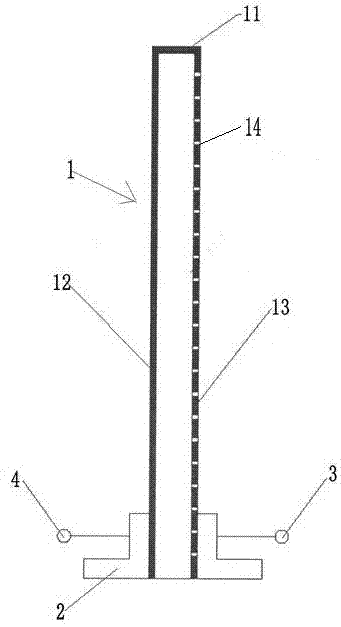

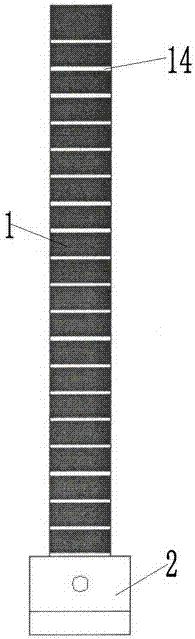

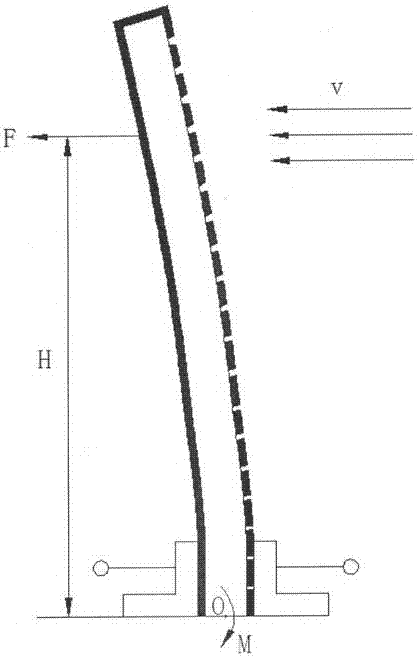

Bionic gas flow rate sensor of hair seam combination

The invention discloses a bionic gas flow rate sensor of hair seam combination. The sensor is formed by an embedded seam hair rod, a fixing pedestal, a first electrode lead wire and a second electrode lead wire. The embedded seam hair rod and the fixing pedestal are assembled into one body so as to form a cantilever beam structure. The first electrode lead wire is led out from a left side and the second electrode lead wire is led out from a right side. The first electrode lead wire and the second electrode lead wire are fixed to the fixing pedestal. The embedded seam hair rod is made of an elastic insulating material. An upper surface, the left side and the right side are coated with conductive material layers. A micro-nano seam is processed on the conductive material layer of the right side along a horizontal direction. When a gas with a slow flow rate flows through, a gas flow and the embedded seam hair rod are interacted so that the embedded seam hair rod generates a certain degree of deflection. When the micro-nano seam of the right side is stretched, a deflection angle is large, a seam width is increased and a resistance is large too. When the micro-nano seam is compressed, the deflection angle is large, the seam width is decreased and the resistance is small. Therefore, perception measurement of a gas flow rate is realized.

Owner:JILIN UNIV

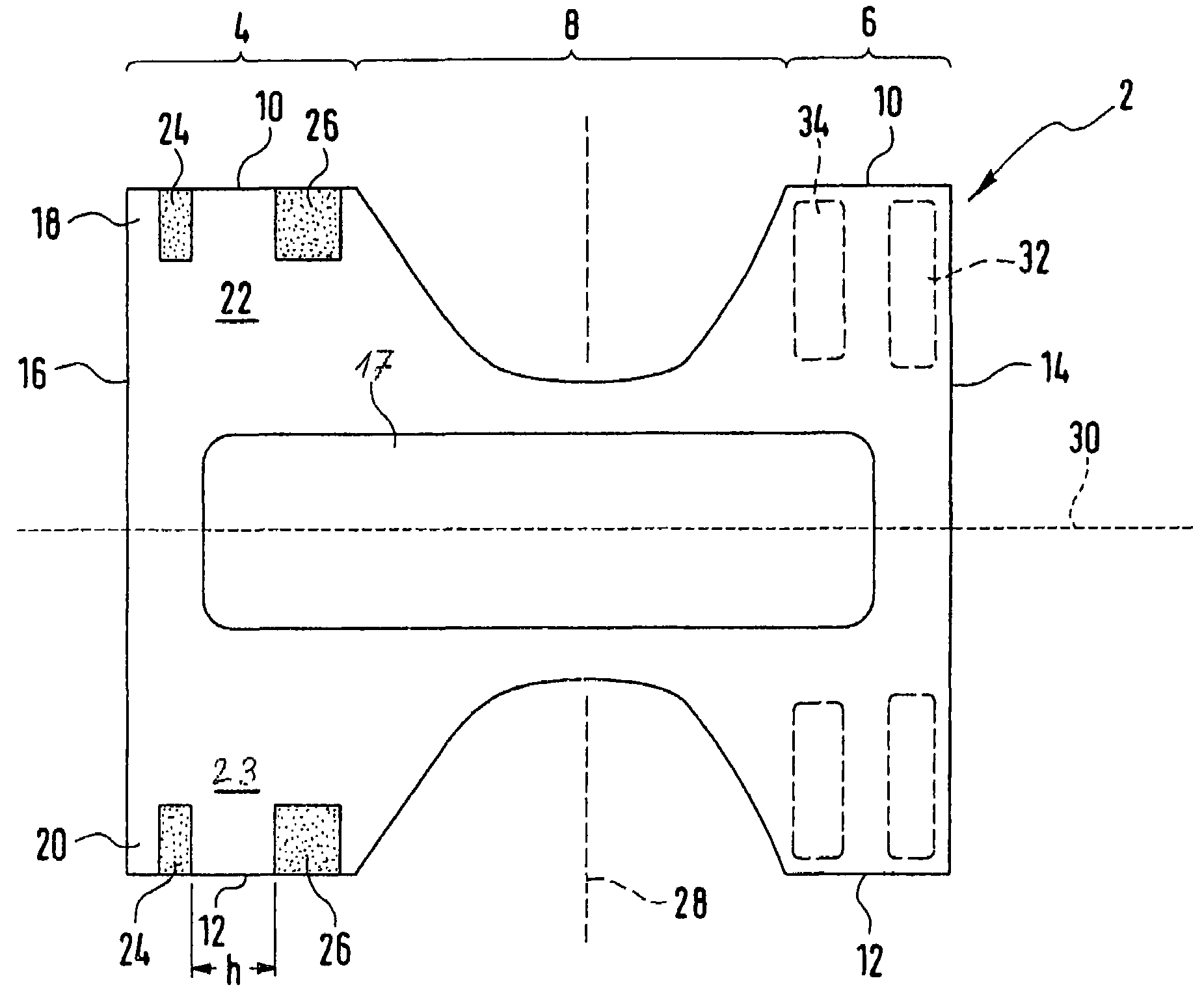

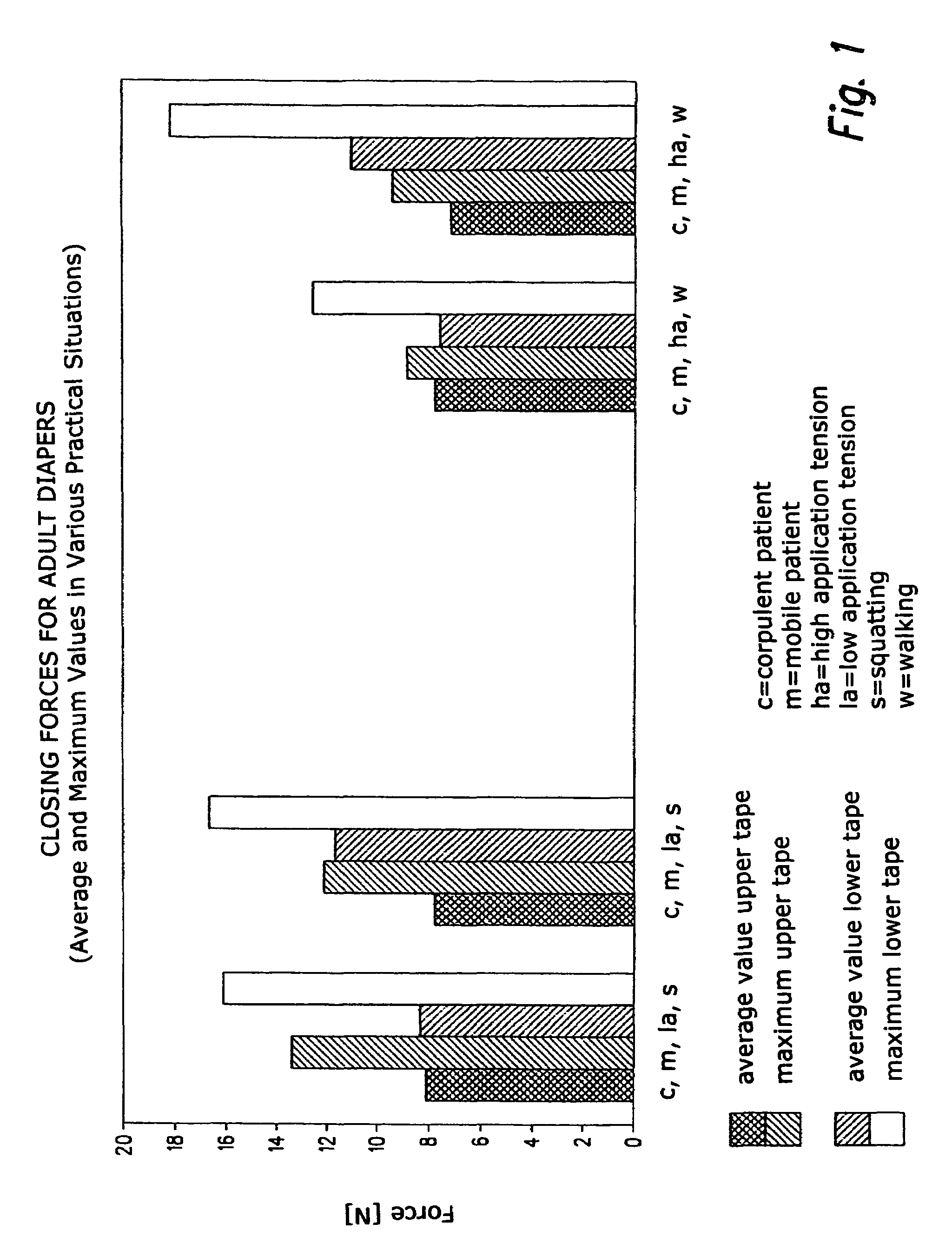

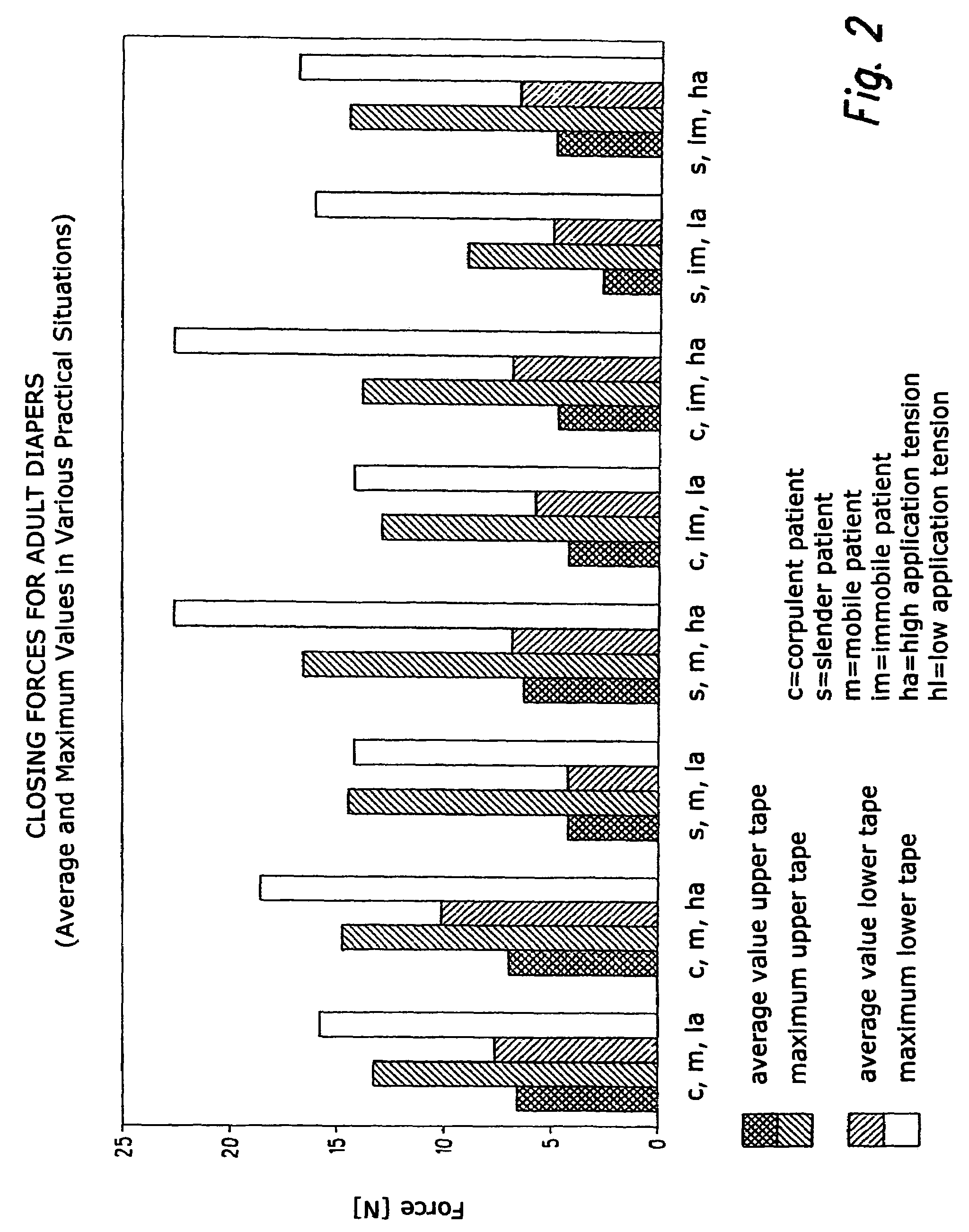

Incontinence diaper for adults

InactiveUS7201743B2Weaken adhesive bondEconomicalAbsorbent padsBaby linensUrinary incontinenceEngineering

The invention relates to disposable incontinence diapers for adults. At least two closure means (24, 26) are provided on each respective side section (22, 24) or longitudinal edge section (18, 20) and are distanced from each other in a longitudinal direction (30) in order to adapt the diapers in a more effective manner to the actual requirements made thereof. The invention is characterized in that the respective closure means (26) which is located further away from the edge of the hip (16) and the impact section (34) associated therewith are configured in such a way that the adhesive connection, beginning with the closed state of the diapers, only becomes detached when the force is higher than that of the adhesive connection of the closure means (24) located nearer to the edge of the hip (16) and the impact section (32) associated therewith.

Owner:PAUL HARTMANN AG

Gasoline of high proportion methanol directly used for vehicle

The invention discloses gasoline of high proportion methanol directly used for a vehicle. The methanol mass fraction is not less than 70%. The methanol gasoline comprises: 70-90% of methanol, 7-29% of component oil and 1 to 3% of additive, wherein, the component oil comprises C5-C7 saturated alkane, solvent oil, 90 # gasoline and toluene, the additive comprises C3-C8 monobasic alcohol, petroleum ether with distillation range of 30-60 degrees C., EGME, N, N'-2 salicylidene -1,2- propylene diamine and other raw materials which can be added or not. The provided gasoline of high proportion methanol directly used for the vehicle in the invention overcomes the existing technical problem of the gasoline of high proportion methanol under the circumstances that the existing engine is not required to be modified, and leads the gasoline of high proportion methanol to be well applied to the vehicle.

Owner:山西华顿实业有限公司

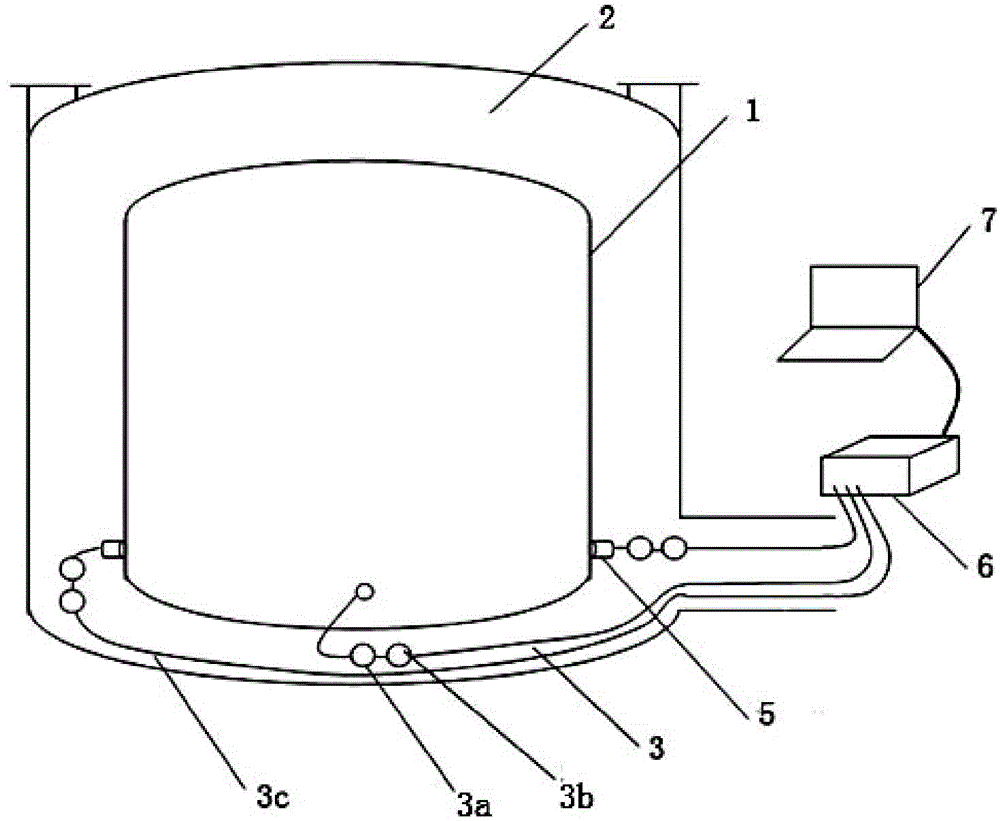

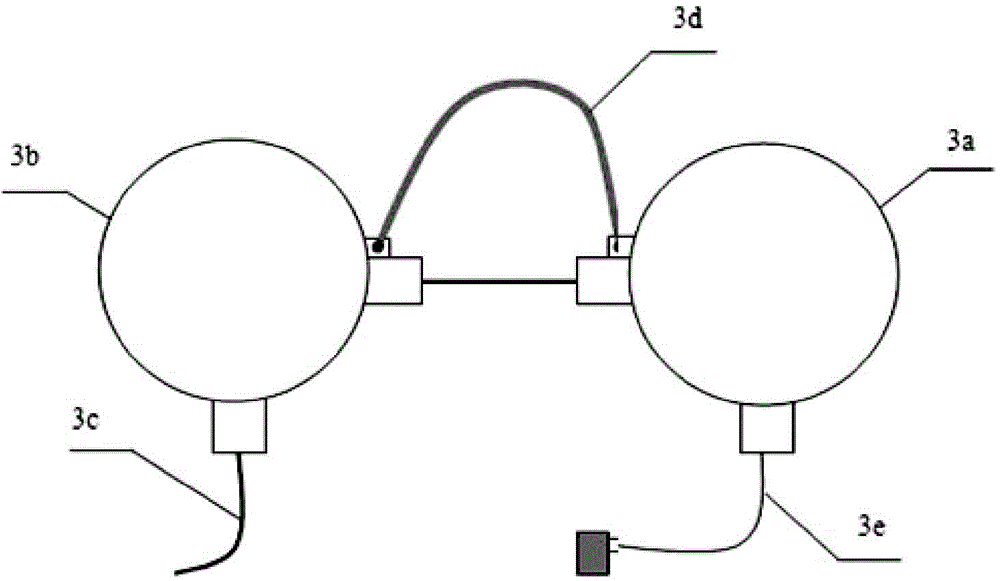

Acoustic emission detection device and method for detecting bottom of storage tank in confined space

InactiveCN102721749AImprove securityEconomicalMaterial analysis using acoustic emission techniquesUltrasound attenuationNondestructive testing

The invention discloses an acoustic emission detection device for detecting the bottom of a storage tank in a confined space. The acoustic emission detection device comprises a plurality of acoustic emission sensors uniformly arranged on the same circumference of the wall of the storage tank, explosion-proof cable devices connected with the acoustic emission sensors respectively, an acoustic emission host electrically connected with the explosion-proof cable devices, a computer electrically connected with the acoustic emission host, and a lead refill, wherein the computer is used for receiving signals of all the acoustic emission sensors, which are processed by the acoustic emission host and judging the situation that the acoustic emission sensors detect the bottom of the storage tank in the area; and the lead refill is broken on the wall of the storage tank and gives out a breakage signal to serve as an analog source capable of repeatedly sending elastic waves, so as to achieve calibration of the acoustic emission host, channel sensitivities of the explosion-proof devices and attenuation measurement and positioning. The acoustic emission detection device provided by the invention can achieve nondestructive detection on the bottom of the storage tank without influencing the normal operation of the storage tank, and has the advantages of high security, good economical efficiency and reliable detection result.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Needle mushroom culturing material and method for preparing needle mushroom culture medium by using same

ActiveCN102010236AFull of nutritionLow priceOrganic fertilisersFertilizer mixturesAgricultural scienceCorn flour

The invention belongs to the field of edible mushroom production and discloses a needle mushroom culturing material and a method for preparing a needle mushroom culture medium by using the same. The culturing material mainly comprises the following components: 36%-55% of pulverized cotton straws with the pulverized grain size of 0.1-6 mm, 26%-33% of rice bran, 8%-13% of corn flour, 8%-13% of sawdust and 0.8%-1.8% of light calcium carbonate with the water content of 58%-65%. The method for preparing the culture medium comprises the following steps of: stirring dry materials comprising the cotton straws, the sawdust and the like for 5-10 minutes by the proportions in a formula, adding a proper amount of water and then stirring for 15-20 minutes; adding the corn flour and the light calcium carbonat and stirring for 10-15 minutes; adding the water until the water accounts for 58%-65% and then stirring for 15-20 minutes so that various raw materials and the water are fully and uniformly stirred. The cotton straws utilized in the method has abundant nutriment and low prices, the nutrient components of the cotton straws are not lower than those of cotton seed hulls, and the price of the cotton straws is only 1 / 4-1 / 2 of the price of the cotton seed hulls, thereby the production cost of the needle mushroom can be reduced by using the cotton straws for replacing the cotton seed hulls toculture the needle mushroom.

Owner:江苏江南生物科技有限公司

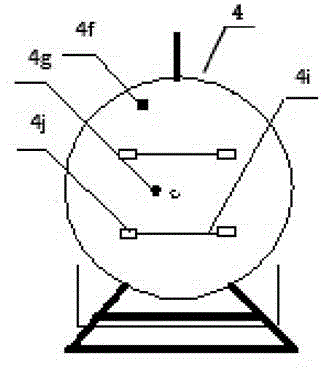

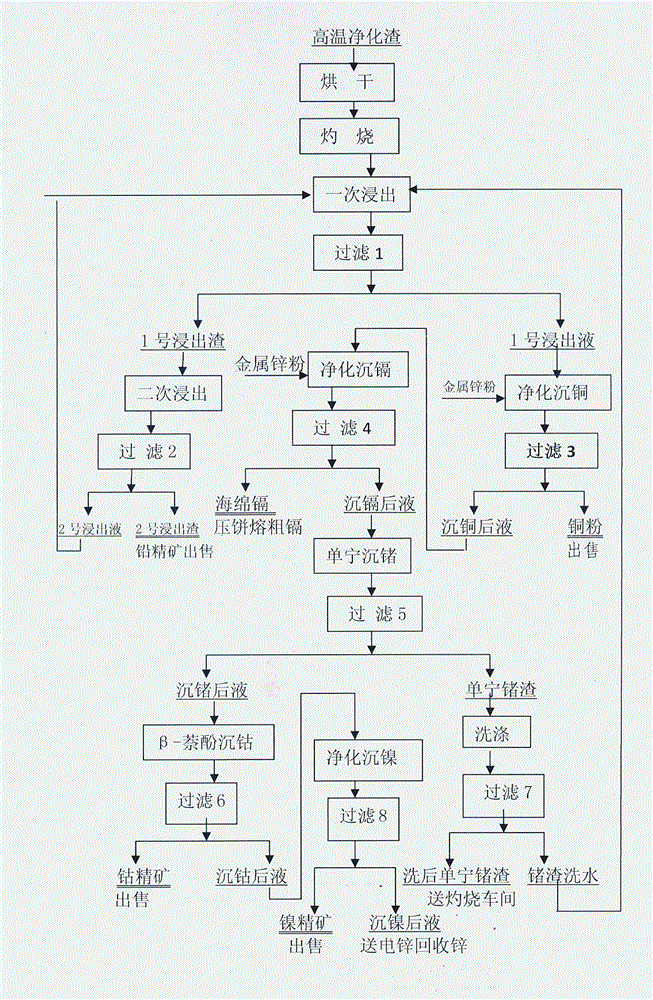

Method for comprehensively recovering valuable metals from zinc hydrometallurgy high-temperature purification slags

The invention discloses a method for comprehensively recovering valuable metals from zinc hydrometallurgy high-temperature purification slags. The method comprises the following steps: (1) drying and firing of the high-temperature purification slags; (2) first leaching; (3) second leaching; (4) purification and deposition of copper; (5) purification and deposition of cadmium; (6) deposition of tannin germanium; (7) deposition of cobalt; and (8) deposition of nickel and recovery of zinc by returning liquid obtained by deposition of nickel to a zinc hydrometallurgy system. The invention provides a method for leaching the zinc hydrometallurgy high-temperature purification slags twice after drying and firing to obtain the produced leaching slags, namely silver lead ore concentrate for sales, and comprehensively recovering copper, cadmium, germanium, cobalt, nickel and zinc from filtering liquid subjected to first leaching; the method is easy to carry out and simple in process; the recovery rate of the valuable metals is high, as the recovery rate of lead, silver, copper, cadmium, germanium, cobalt, nickel and zinc respectively reaches 98.50-99.50 percent, 99.10-99.70 percent, 94.40-97.80 percent, 95.10-96.90 percent, 93.50-96.70 percent, 94.70-95.70 percent, 94.80-96.80 percent, and 96.00-97.00 percent; moreover, the recovery of the valuable metals is more comprehensive, scientific and reasonable; waste water, waste gas and waste slags are avoided, and the requirement on national circular economy and sustainable development is met.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

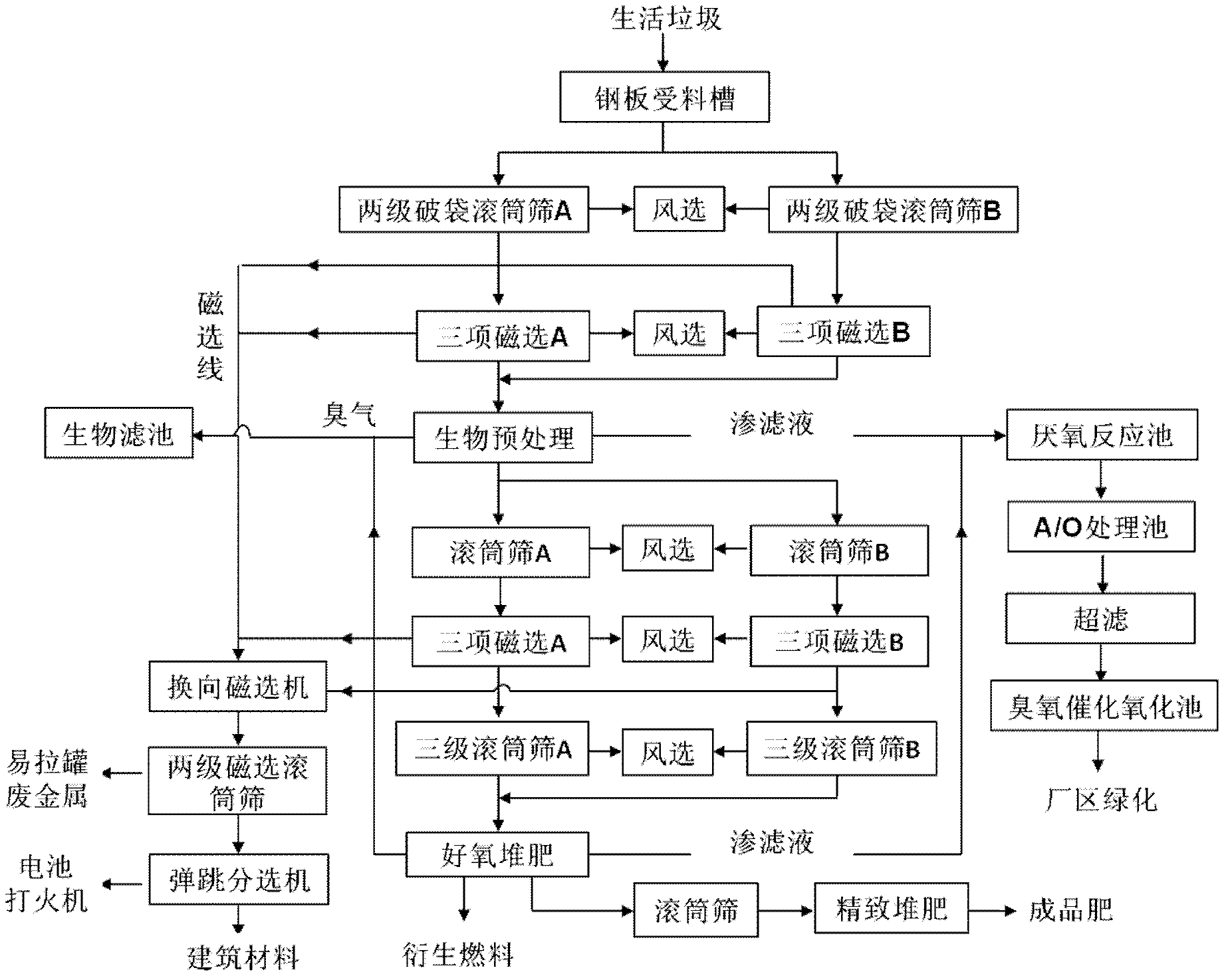

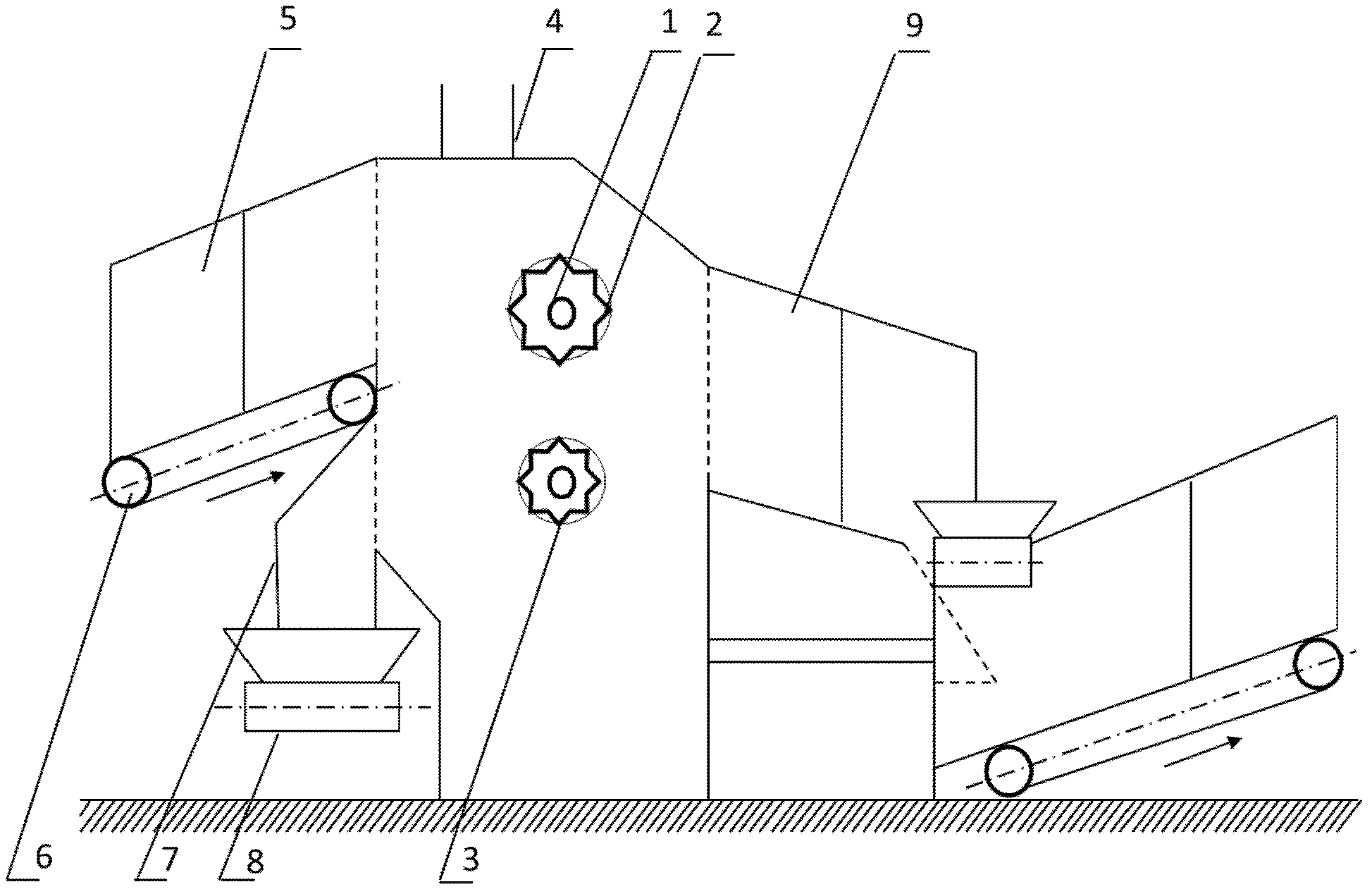

Method for comprehensive treatment of household refuses and secondary pollution control

ActiveCN103008326ACompact layoutReasonable configurationBio-organic fraction processingWaste processingRefuse-derived fuelUnit device

The invention provides a method for comprehensive treatment of household refuses and secondary pollution control. The method comprises the following procedures of: 1) coarse separation of the household refuses; 2) pretreatment of the household refuses; 3) fine separation of the household refuses; 4) aerobic composting of the household refuses; 5) biological organic fertilizer preparation; 6) fabrication of refuse derived fuels; and 7) secondary pollution control. The method employs parallel dual-separation lines which are compact in arrangement; each functional unit device is rational in configuration, easy to operate and mechanically control; the sorting efficiency and the energy source recovery effect are obviously improved; and minimization, harmless treatment, recycling and energy conversion of the household refuses can be realized.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

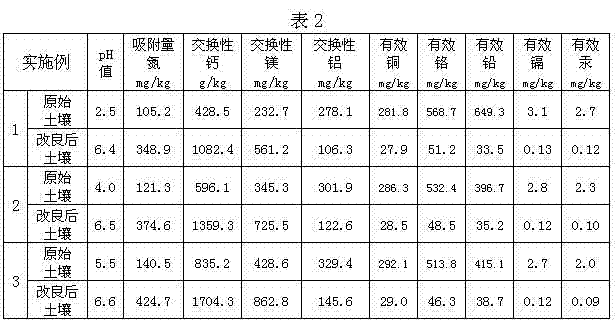

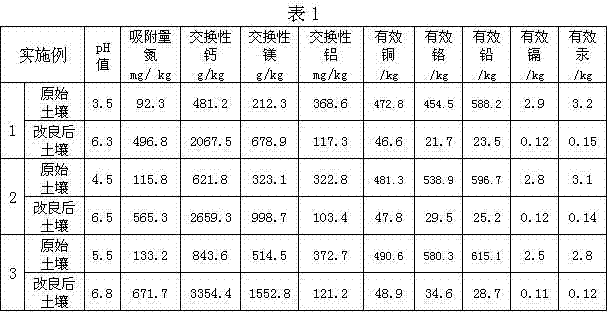

Acidic soil improving agent and application method thereof

InactiveCN104263379APromote circulationTurn waste into treasureAgriculture tools and machinesOther chemical processesPlant growthPolyacrylamide

The invention relates to an acidic soil improving agent and an application method thereof. The acidic soil improving agent is prepared by fully and uniformly mixing the following raw materials in percentage by weight: 80-90% of dry carbide slag, 5-15% of plant ash, 1-5% of polyacrylamide and 0.1-0.5% of chitosan, wherein the pH value of a mixture is 12-12.6. The main raw material of the acidic soil improving agent provided by the invention selects the dry carbide slag, thereby realizing comprehensive utilization of industrial solid wastes, having good benefits, turning the wastes into treasures and being in line with national environment-friendly and cyclic economy policies. When the acidic soil improving agent is applied during soil tillage, a soil top application way is adopted in a paddy field and a soil blending application way is adopted in a dry land. The pH value of soil to which the acidic soil improving agent provided by the invention is applied achieves 6-7, the absorption of soil available nutrients by crops is reinforced, the activity of heavy metal ions in the soil can be also inhibited, a soil environment is improved and growth and development of plants are promoted.

Owner:凌少青

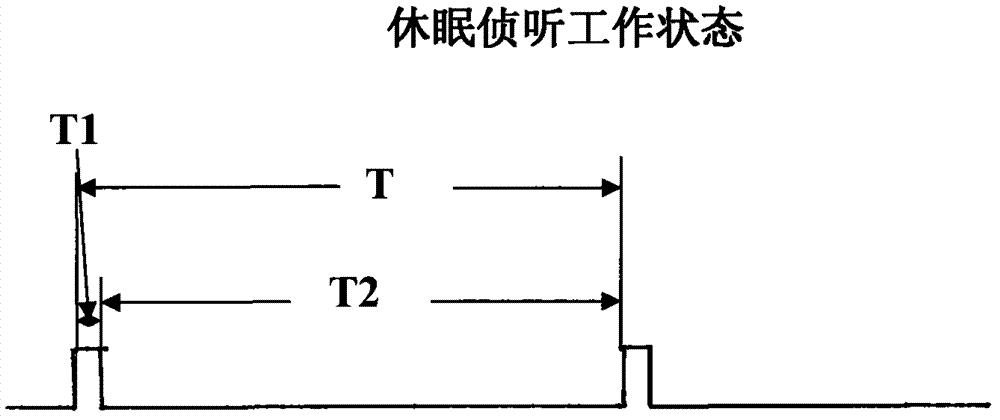

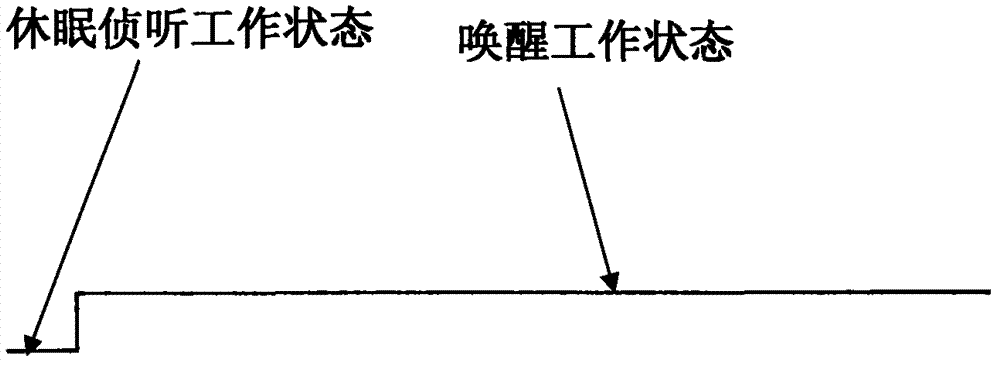

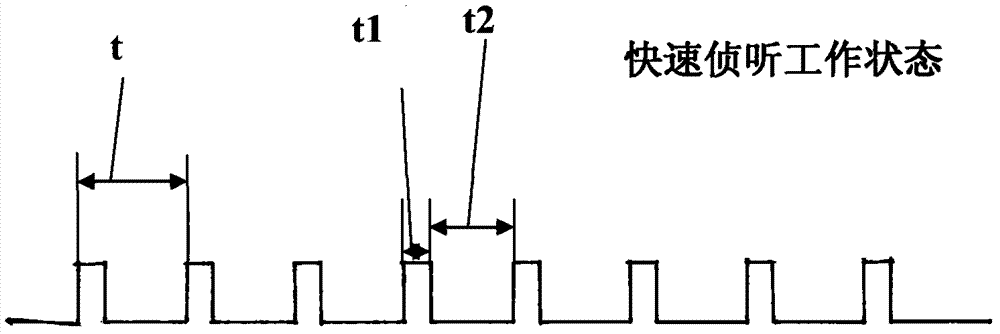

Wireless communication implantable medical system and wireless communication method thereof

ActiveCN102772852AExtended service lifeEconomicalEnergy efficient ICTHeart defibrillatorsElectricitySleep state

The invention discloses a wireless communication implantable medical system and a wireless communication method thereof. An implantable medical device has at least two operating states of a sleeping interception operating state and an awakening operating state, the implantable medical device is in the sleeping interception operating state once powered on, each cycle period of the sleeping interception operating state comprises at least one interception period and at least one sleeping period, a power source of a first wireless communication module in the sleeping state is in a low energy consumption operating state, so that electric energy consumption is greatly reduced, the service life is prolonged, and great economical and using values are provided. When a doctor needs to perform program control on the internal implantable medical device through an external control device, the external control device sends an awakening signal to the implantable medical device, the implantable medical device starts the awakening operating state and achieves wireless high speed communication with the external control device, energy consumption is saved, and real-time responsiveness of the implantable medical device is guaranteed simultaneously.

Owner:SCENERAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com