Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201results about "Thiocyanic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

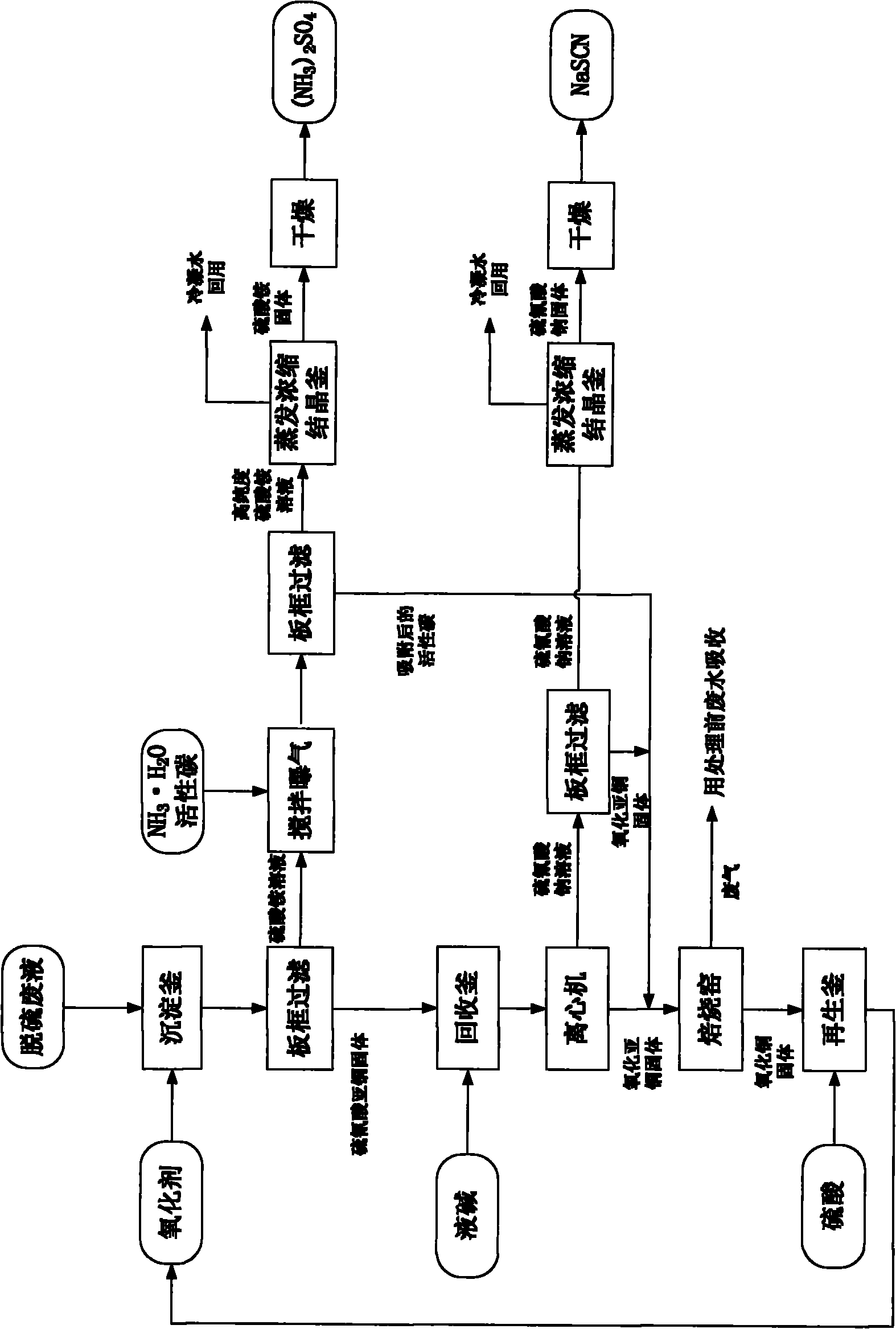

Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

ActiveCN101985359AReduce consumptionReduce lossesThiocyanic acidSulfate preparationActivated carbonSulfate

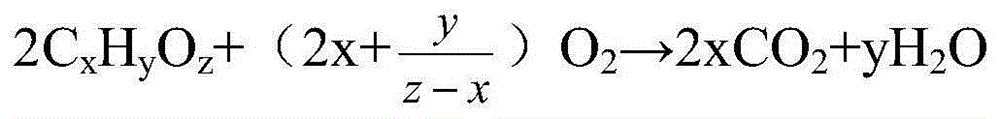

The invention relates to a method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in a coking plant, which comprises the following steps of: preparing saturated solution of copper sulfate, mixing the saturated solution with desulfuration waste liquor, and heating and stirring; performing solid-liquid separation to obtain a solid and sulfate liquid; adding aqueous alkali into the solid, heating at the temperature of between 50 and 98 DEG C, and stirring and reacting for 10 to 120 minutes; performing solid-liquid separation on slurry obtained by heating; concentrating the obtained liquid, and freezing for crystallizing and drying to obtain a high-purity thiocyanate product; calcining the obtained solid, adding solution of sulfuric acid, and stirring to produce the copper sulfate for circular use; adding activated carbon into the sulfate liquid, and aerating and oxidizing to purify sulfate; and concentrating the sulfate, and crystallizing and drying to obtain a high-purity sulfate product. The method solves the problem of pollution of the desulfuration waste liquor to the environment, and simultaneously, pollutants can become value products through the production of the high-purity thiocyanate product and the high-purity sulfate product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

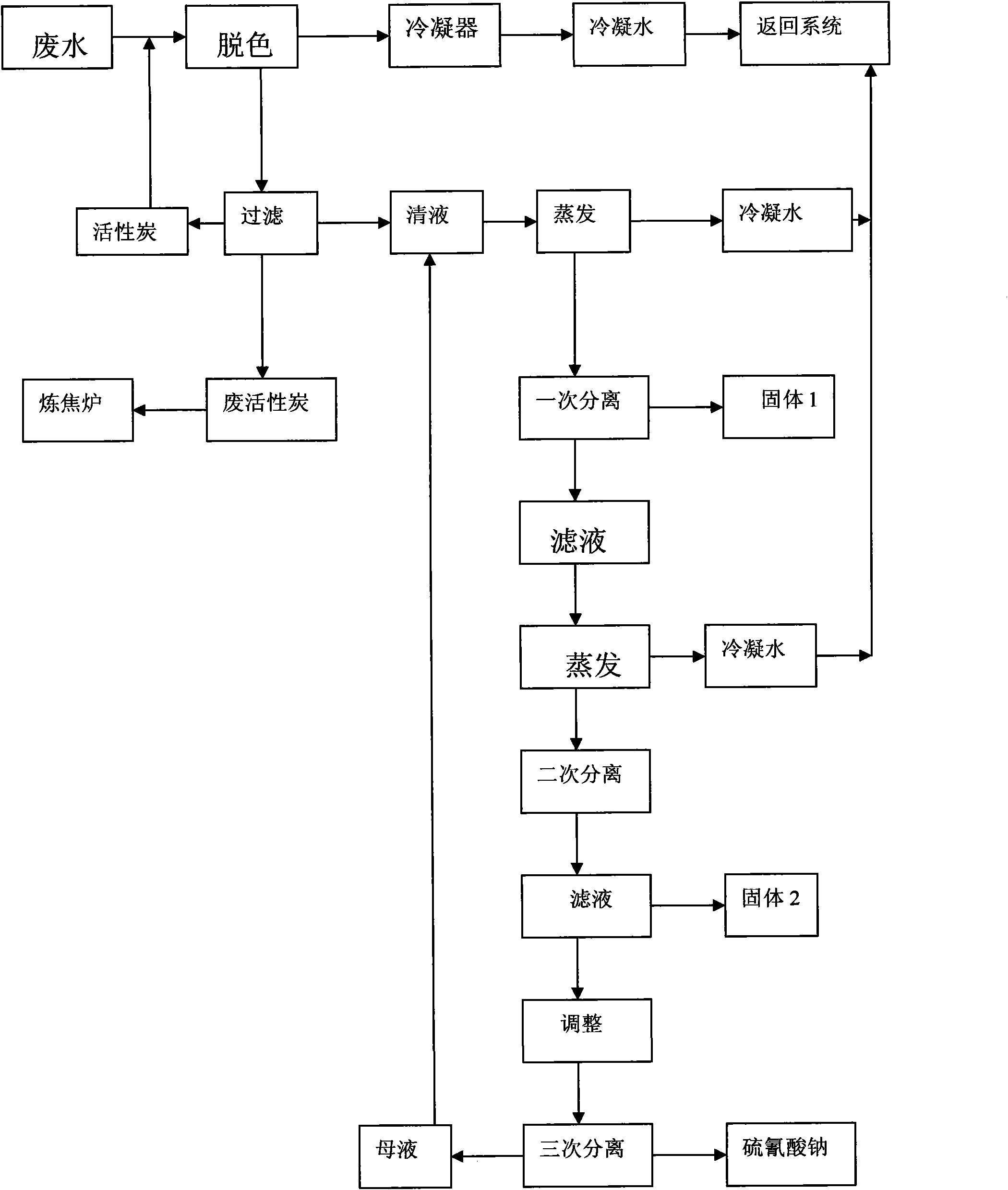

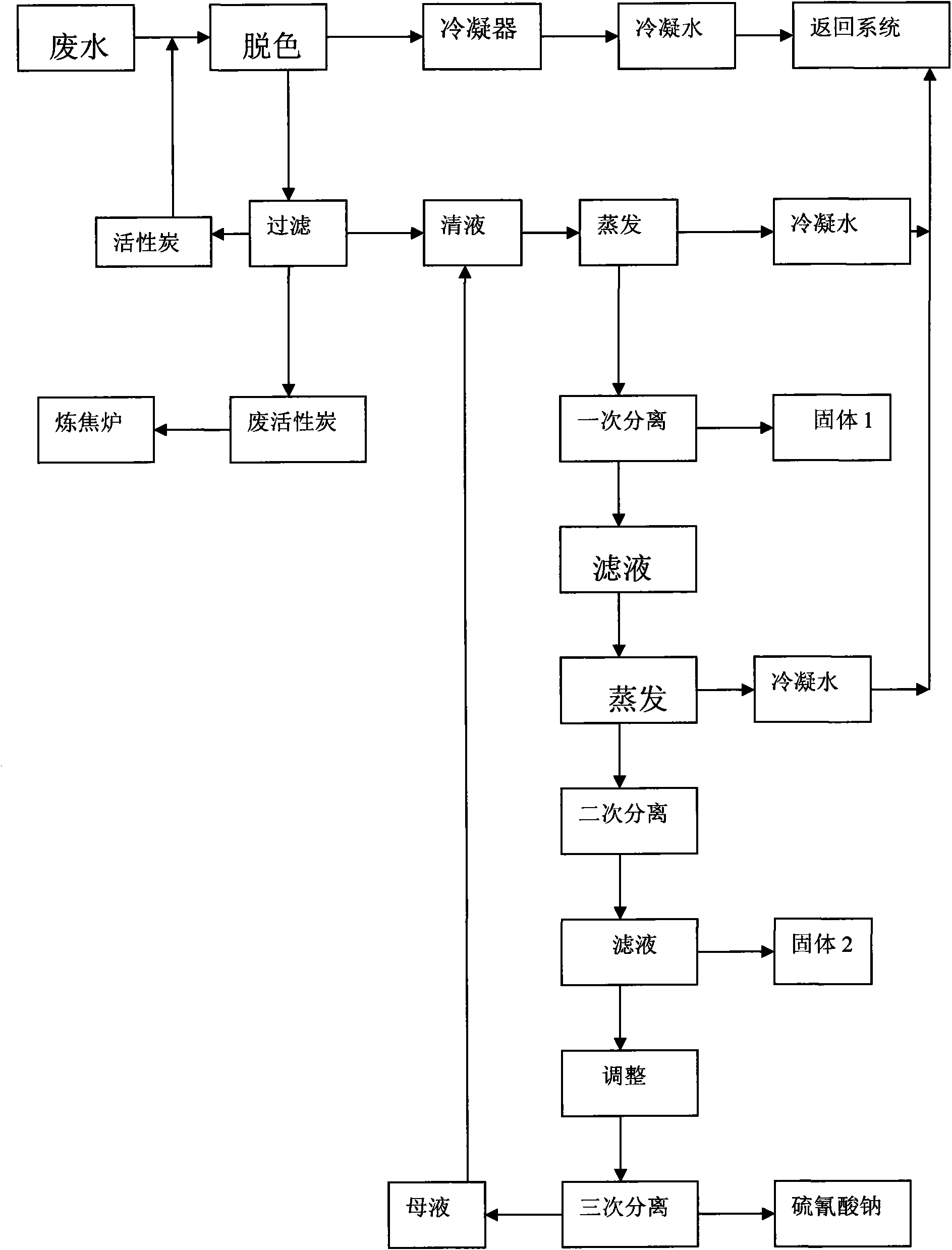

Method for treating desulfurization waste liquid of wet oxidation method

ActiveCN102295379AReduce manufacturing costNot easily decomposed by heatThiosulfates/dithionites/polythionitesThiocyanic acidSodium thiocyanateEvaporation

A method for treating desulfurization waste liquid of a wet oxidation method. The method comprises the following steps: firstly adding a decolorant into desulfurization waste liquid for decolorizing treatment, filtering after decolorization, adding alkali into the filtrate, controlling the PH to be 8-9, performing evaporation concentration under a condition with a negative pressure, condensing the evaporated ammonia gas and water vapor to obtain concentrated ammonia liquor which can be returned to the system for recycle or be used to produce ammonium sulfate, performing fractional crystallization of the concentrated desulfurization liquid to respectively obtain high-purity sodium thiocyanate and sodium hyposulfite. The invention has a simple process, and stable operations, and effectively solves the problem of difficult HPF desulfurization waste liquid treatment in coking enterprises; the method not only reduces the discharge of the waste liquid, but also recovers a lot of chemical products with economic value, and the method has quite significant economic benefits and environmental benefits.

Owner:SHOUGANG CORPORATION

Method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas

InactiveCN101597073AHigh purityHigh selectivityChemical industryThiocyanic acidLiquid wasteSodium thiocyanate

The invention discloses a method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas, and belongs to the technical field of utilization of desulphurization waste liquid of the coke oven gas. The method comprises the following steps: using the desulphurization waste liquid of the coke oven gas as a raw material, firstly, filtering the waste liquid in vacuum, using tributyl phosphate to extract thiocyanate radicals in the waste liquid, then using sodium hydroxide solution to back-extract the extract, and finally concentrating and crystallizing the extract, and washing and drying the crystals to obtain sodium thiocyanate crystals. The method uses the desulphurization waste liquid of the coke oven gas to prepare a sodium thiocyanate product with the purity as high as 93 to 95 percent so as to change waste into valuable and makes full use of waste resources; and the method is simple, saves energy, has no three-waste discharge, is favorable for environmental protection, has low production cost and good economic benefit, and develops a new path for the utilization of the desulphurization waste liquid resources of the coke oven gas. The sodium thiocyanate product prepared by the method can be widely applied in the industries of medicaments, textile, printing and dyeing, pesticide, chemistry and the like.

Owner:CHONGQING UNIV

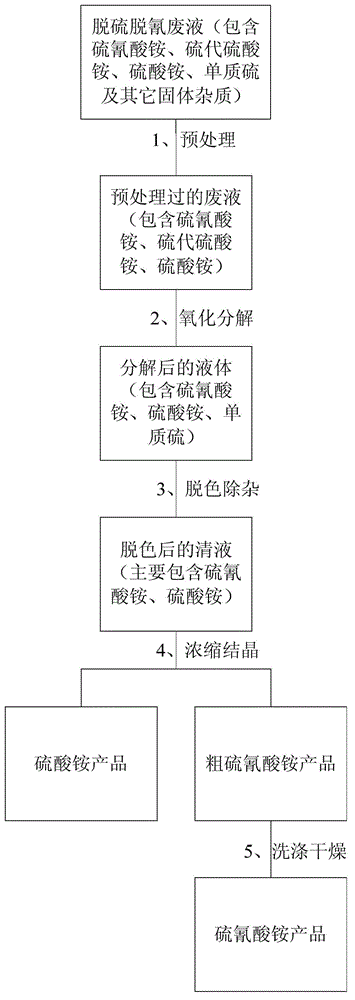

Method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization/decyanation waste liquor

InactiveCN102976361AEfficient decompositionHigh purityThiocyanic acidAmmonium sulfatesPollutionAmmonium sulfate

The invention provides a method for recycling ammonium salt from chemical waste liquor generated in the desulfurization / decyanation process of coke oven gas, and particularly, the invention provides a method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization / decyanation waste liquor. The purities of ammonium thiocyanate and ammonium sulphate produced by using the method disclosed by the invention are greatly improved in comparison with those of products produced by contrasted embodiments. According to the method disclosed by the invention, high-purity products can be prepared under the condition of only carrying out one-time step-by-step concentration, so that the wastewater discharge amount is reduced and the environment pollution of coking plants is alleviated; and high-purity and high-added-value chemical raw materials are recycled, thereby increasing the economic benefits of enterprises.

Owner:BEIJING RISUN TECH CO LTD

Method for extracting secondary salt from coking desulphurized waste liquid

InactiveCN102502709ARealize water savingReduce manufacturing costThiocyanic acidEnvironmental chemistryEngineering

The invention discloses a preparation method for extracting secondary salt (ammonium salt or sodium salt) from coking desulphurized waste liquid, wherein, coking desulphurized waste liquid is processed through the steps such as decolorization, filtration, concentration, filtration, crystallization (purification is carried out if the secondary salt is sodium salt), filtration, drying and the like. The preparation method is characterized in that a one-step crystallization (purification) method is adopted; the preparation method is simple to operate; and simple technology, less equipment, low investment, high content, advanced technology, environmental protection and energy conservation can be achieved.

Owner:泰安金塔化工机械有限公司

Method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater

ActiveCN102424401AMeet the requirements of green circular economyEasy to handleThiocyanic acidPersulfateThiocyanate

The invention discloses a method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater. The method comprises the steps of: adding persulfate or sulfuric acid to polyamine salt wastewater for reacting with ammonium thiosulfate so as to generate ammonium sulfate and ammonium sulfite, and further oxidizing into ammonium sulfate and sulfur, thus the wastewater is changed into a two-component mixed liquid which contains ammonium thiocyanate and ammonium sulfate and is easy to separate by crystallization from a three-component mixed liquid, and high-efficiency separation is realized. The purity of the obtained ammonium thiocyanate crystal can reach 99%.

Owner:江苏燎原环保科技股份有限公司

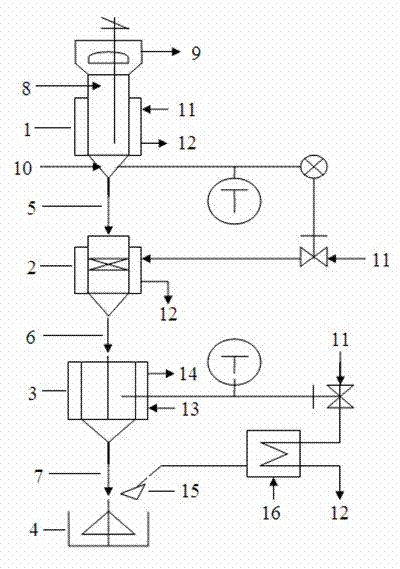

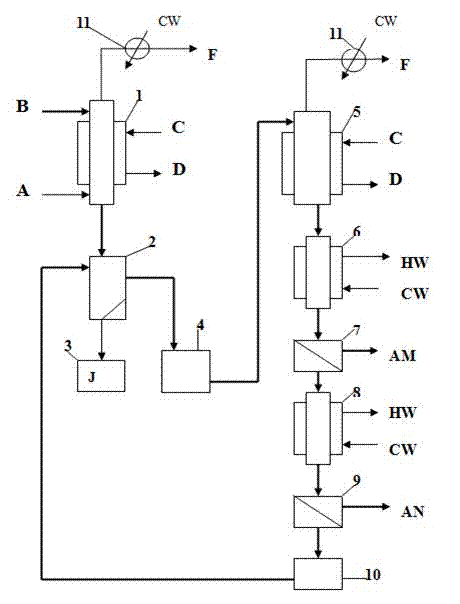

Method for extracting salt from coking desulphurization waste solution and special device thereof

InactiveCN102161541AEffective interceptionAvoid diversionThiocyanic acidWater/sewage treatment bu osmosis/dialysisFiltrationDecomposition

The invention discloses a method for extracting salt from coking desulphurization waste solution and a special device thereof. The method comprises the following steps of: heating raw material waste solution for decomposition, adsorbing and decolorizing, then heating, evaporating and concentrating to obtain concentrated solution, performing heat filtration at constant temperature to remove fine sulfur particles, cooling and crystallizing in a crystallizer, filtering at constant temperature, separating filtrate to obtain crystals, washing the crystals to obtain high-purity ammonium thiocyanate, dissolving mixed salt crystals in ammonium sulfate mother liquor, regulating the acidity to be below 20 percent, preheating to ensure that the temperature is between 90 and 110 DEG C, blowing air oroxygen, performing oxidative transformation for 1min to obtain ammonium sulfate transformation liquid, and adding ammonium sulfate production mother liquor to obtain an ammonium sulfate product. By the method, a high-purity product can be extracted from the waste solution through one-time operation, so that processing and treatment times are reduced; solid-phase impurities are effectively intercepted and prevented from transferring to the crystals at constant temperature; and the mixed salt is subjected to oxidative transformation treatment, all ammonium thiosulfate is transformed into the ammonium sulfate product with high nitrogen content, the process is simple, operation cost is low, and product marketing is broad.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

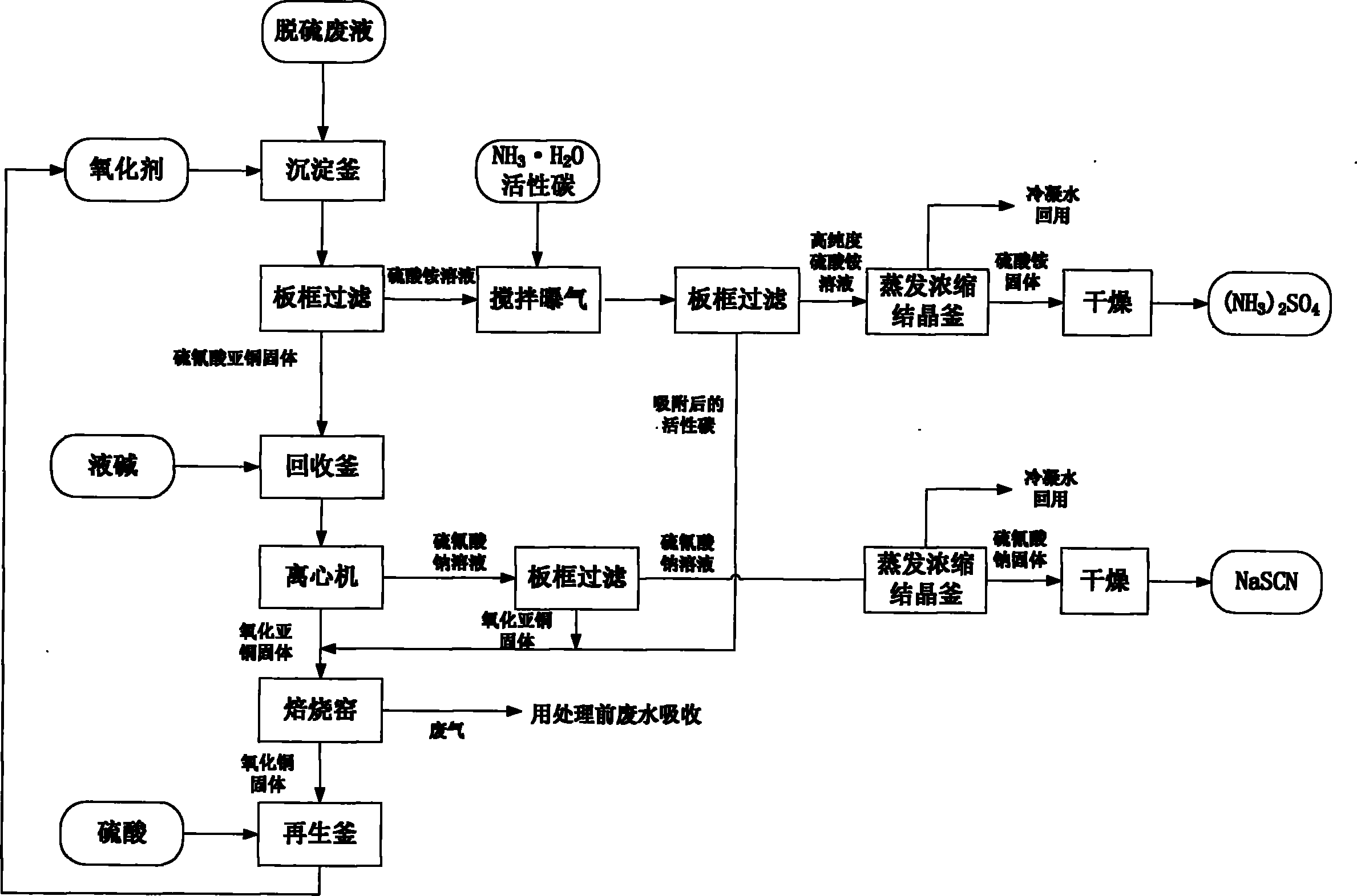

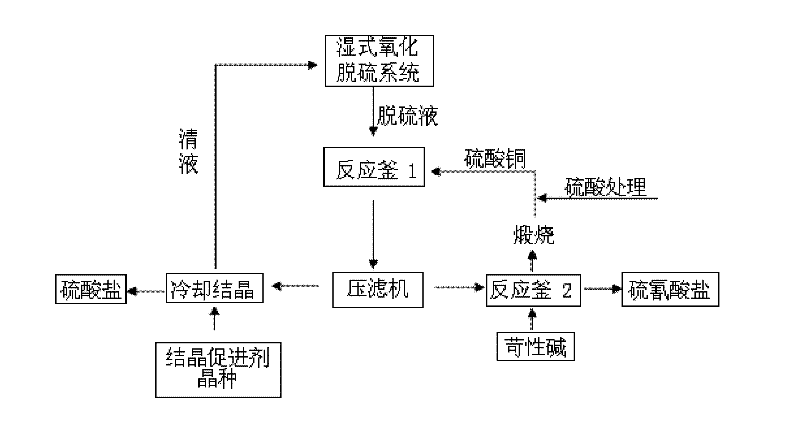

Method for recovering secondary salts from desulfurization liquid and recycling desulfurization liquid

ActiveCN102225816AAchieve recyclingHigh crystallinityThiocyanic acidMultistage water/sewage treatmentSulfatePollutant emissions

The present invention relates to a method for recovering secondary salts from a desulfurization liquid and recycling the desulfurization liquid, which comprises the following steps of: adding CuSO4 to the desulfurization liquid discharged from a wet oxidative desulfurization system for treatment, filtering to obtain CuSCN precipitates and a sulfate solution; adding the CuSCN precipitates to caustic alkali for treatment to recover thiocyanate; and cooling and crystallizing the sulfate solution to recover sulfates and returning the clear liquid to the desulfurization system. The method provided by the present invention simplifies the treatment process of desulfurization liquid wastewater, reduces pollutant emission, recovers the secondary salts from the desulfurization liquid and realizes the recycling of the desulfurization liquid, has a simple process, is environmentally-friendly, realizes the recycling of resources and has a good application prospect.

Owner:BEIJING BAIAONA HI TECH

Method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor

ActiveCN102674398AImprove desulfurization efficiencyEconomicalThiocyanic acidAmmonium sulfatesPhthalocyanineCobalt

The invention relates to a method for recycling chemical wastewater, in particular to a method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor. By the method, inorganic salt in the desulfuration waste liquor generated by a phthalocyanine cobalt sulfonate (PDS) method in a coking plant is extracted by a two-stage concentration and fractional crystallization separation method. The method is easy to operate and control, the purity of the ammonium thiocyanate which is finally recovered reaches more than 98 percent, and the yield reaches more than 80 percent. By the method, the circulation volume of desulfuration liquor in a desulfuration working section and the total salt content in the desulfuration liquor are reduced, and the desulfuration efficiency of the desulfuration working section is improved; environmental problems generated by wastewater discharge pollution of coking plants are solved; and useful chemical raw materials are recovered from the desulfuration waste liquor, so that social, environmental and economic benefits for enterprises are increased.

Owner:邢台旭阳科技有限公司

Method for processing secondary salt in desulphurization waste liquid

InactiveCN103058442AHigh salt contentNo emissionsThiosulfates/dithionites/polythionitesThiocyanic acidInorganic saltsWastewater

The invention relates to a method for processing secondary salt in desulphurization waste liquid, comprising the following steps: a, carrying out pre-treatment on the desulphurization waste liquid, and removing the impurities in the desulphurization waste liquid; b, conveying the desulphurization waste liquid to a de-coloring kettle via a centrifugal pump; c, after atomizing via the nozzle of a spray dryer, drying the desulphurization waste liquid, so that Na2S2O3, Na2SO4 and NaCNS secondary salts can be separated by a manner of solid salts, and recycling the secondary salts which are adopted as inorganic salts to realize the discharge without wastewater. The method for processing the secondary salt in the desulphurization waste liquid disclosed by the invention can rationally process the waste liquid which is produced in the desulphurization step in gas production factories and has a high content of the secondary salt, realizes the discharge without wastewater, effectively recycles the waste heat of systems, realizes the reuse of the heat, reduces the production cost, has simple process and has performance of environmental-friendliness.

Owner:甘肃银光聚银化工有限公司

Method of separating multi-ammonium compound salt

InactiveCN101012065ANon-flammableNon-explosiveThiosulfates/dithionites/polythionitesThiocyanic acidAmmonium compoundsWastewater

The invention discloses a separating method of multi-ammonia composite salt, which comprises the following steps: separating ammonia thiocyanate under low temperature (0-25 deg.c); enriching ammonium thiosulfate and ammonium sulfate under middle temperature (40-65 deg.c); separating ammonium sulfate under high temperature (80-90 deg.c); separating enriched ammonium thiosulfate at 20-40 deg.c; dissolving, crystallizing and separating solid from liquid for several times under different temperature to separate ammonium thiocyanate, ammonium thiosulfate and ammonium sulfate one by one.

Owner:苏州久王环保科技股份有限公司

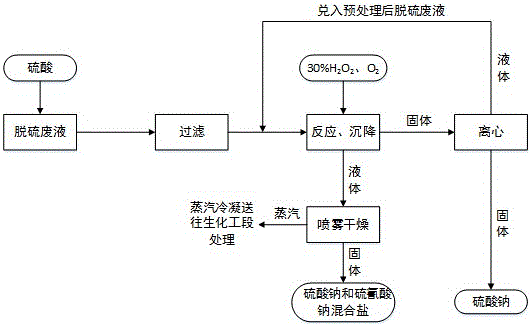

Harmless treatment method for sodium alkali desulfurization waste solution

ActiveCN105036438ADecompose thoroughlyMild reaction conditionsThiocyanic acidMultistage water/sewage treatmentSodium thiocyanateWater vapor

The invention discloses a harmless treatment method for a sodium alkali desulfurization waste solution. The method comprises: the desulfurization waste solution is adjusted in pH value by sulfuric acid and is filtered and pre-treated; then hydrogen peroxide is added to be uniformly mixed and oxygen is blown; wet oxidation reaction is carried out at high temperature and high pressure; sodium sulfite and elemental sulfur in the desulfurization waste solution are oxidized to sodium sulfate, organic matters are oxidized to carbon dioxide and water, and sodium thiocyanate is not oxidized and is continuously retained in the desulfurization waste solution; after reaction, the desulfurization waste solution is settled and separated to obtain solid sodium sulfate and a clean liquid, wherein the clean liquid is fed to a spraying drier for vacuum spraying and drying; water vapor generated by drying is condensed and fed to a biochemical treatment workshop section of an enterprise to be treated so as to obtain the solid which is mixed salt of sodium sulfate and sodium thiocyanate; and the mixed salt is evaporated and crystalized or extracted and crystalized by virtue of an organic solvent to obtain sodium sulfate and sodium thiocyanate, respectively. The method is simple in process, and chemical products with economical benefits are recovered while the waste solution is treated, so that harmless treatment for the sodium alkali desulfurization waste solution is realized.

Owner:山西恒鑫宇环保科技服务有限公司

Method for treating ammonia desulfurization waste liquid by oxidation method

InactiveCN103030207AEasy to separateSimple processDispersed particle separationThiocyanic acidThio-Catalytic oxidation

The invention provides a method for treating ammonia desulfurization waste liquid by an oxidation method, and belongs to the technical field of desulfurization waste liquid treatment. According to the method, oxidation reaction is conducted by blowing air or oxygen into the ammonia desulfurization waste liquid; ammonium thiosulfate in the desulfurization waste liquid is oxidized into ammonium sulfate in the oxidation reaction process; ammonium thiocyanate is not oxidized, but continues to be reserved in the desulfurization waste liquid; and then ammonium thiocyanate is extracted through evaporation and secondary crystallization. The method is suitable for treating desulfurization waste liquid generated in a gas desulfurization and decyanation technological process by a catalytic oxidation method, and suitable for waste liquid treatment in the desulfurization technology field of hydrogen sulfide such as coke oven gas, natural gas, coalbed methane and refinery gas. With the adoption of the method, ammonium thiosulfate salt in the waste liquid can be converted to ammonium sulfate salt, ammonium thiocyanate salt can be protected, and ammonium sulfate salt and ammonium thiocyanate salt can be separated and purified from the waste liquid into a product.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for extracting sodium thiocyanate from coking desulfurization waste liquid

The invention relates to a method for extracting sodium thiocyanate from desulfurization waste liquid in a coking plant, which is characterized by comprising the following steps of: adding 2 to 6 weight percent of activated carbon into the desulfurization waste liquid, heating to the temperature of between 70 and 90 DEG C, and keeping stirring for 1 to 2 hours; filtering, adding sulfuric acid into filtrate in a closed container until pH is 3.5 to 4.5, heating to the temperature of between 60 and 80 DEG C, and keeping stirring for 1 to 2 hours; leading escaping sulfur dioxide gas out by using a guide pipe and absorbing by using dilute ammonia water; filtering after reaction is finished, adding sodium hydroxide with the same mol as ammonium thiocyanate in filtrate and calcium hydroxide with the same mol as ammonium sulfate in the filtrate into the filtrate in the closed container, heating to the temperature of between 50 and 70 DEG C, and keeping stirring for 1 to 2 hours; and leading escaping ammonia gas out by using the guide pipe and absorbing by using water to obtain the dilute ammonia water, filtering after reaction is finished, and performing evaporation crystallization on filtrate to obtain a sodium thiocyanate product.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

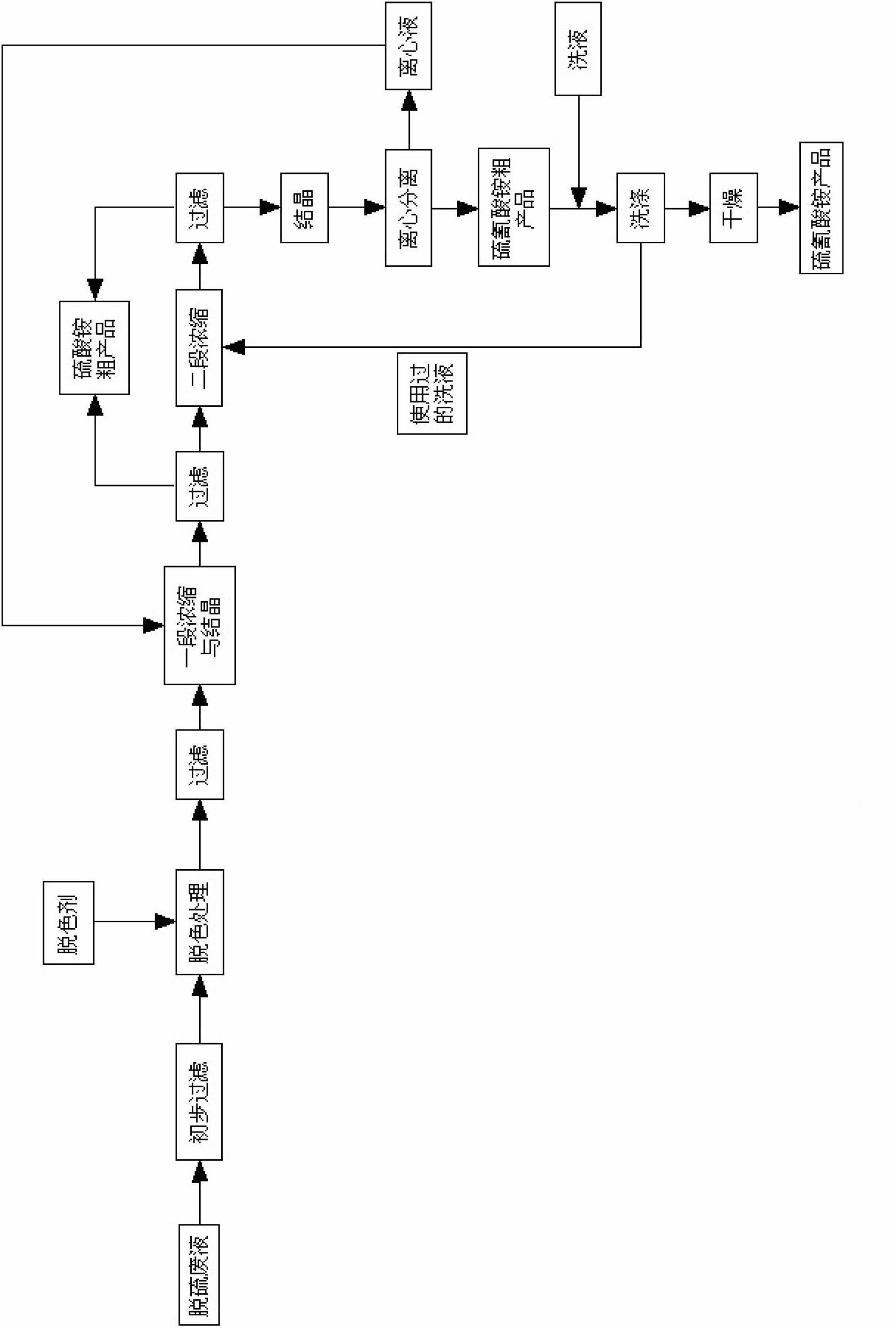

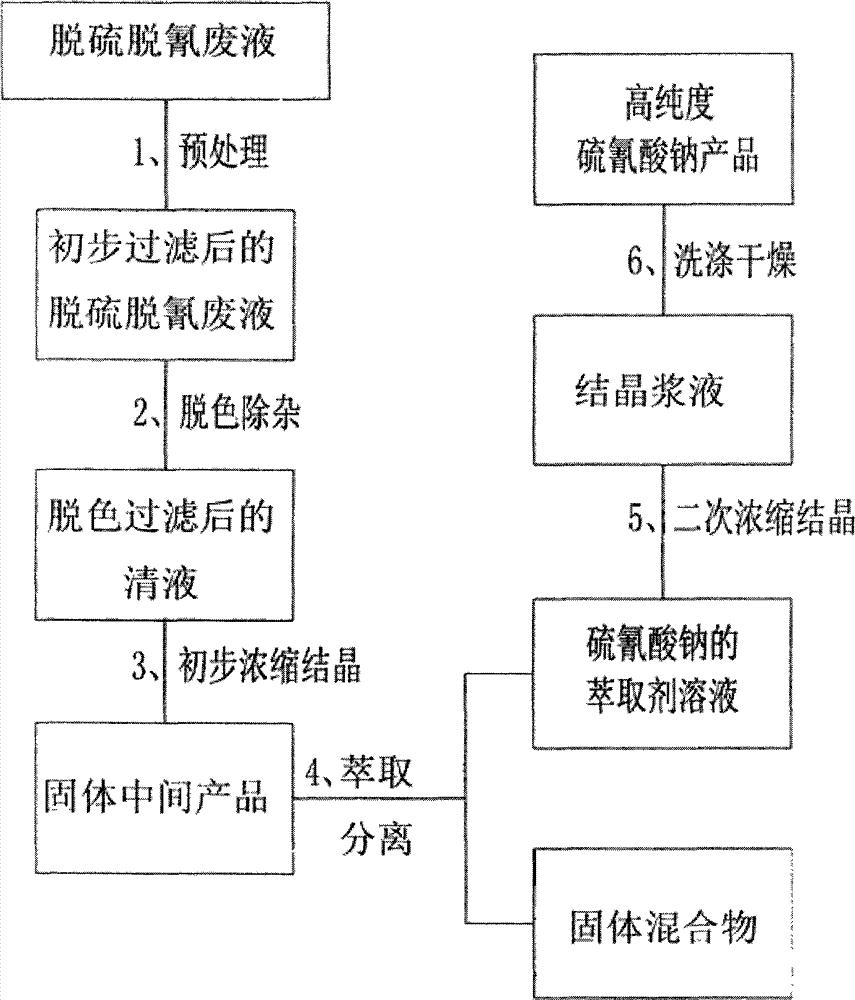

Method for improving purity of sodium thiocyanate in coking and desulfurizing waste liquid

The invention relates to a method for improving the purity of sodium thiocyanate in a coking and desulfurizing waste liquid, which comprises the following sequential steps: (1) pretreating; (2) decoloring and removing impurities; (3) performing primary concentrating crystallization; (4) performing extraction separation; (5) performing secondary concentrating crystallization; and (6) washing, and drying, wherein the sodium thiocyanate product obtained after drying has a purity of 98% or above. According to the invention, the extraction method is simple and convenient to operate, and the salt content in a desulfurizing and decyanation waste liquid generated in a PDS desulfurizing production process of a coke-oven plant is effectively extracted and separated, so that the high-purity sodium thiocyanate product is extracted through concentrating crystallization; and the discharge of waste water from the coke-oven plant and environmental pollution are reduced, the high-purity high-added-value chemical raw material is recovered at the same time, and economic benefits of the enterprise are increased.

Owner:北京艾思合众环保科技有限公司

Inorganic particles as a dental material and a method of producing the same

InactiveUS20030089276A1Reduced pore volumeReduce adhesionPigmenting treatmentImpression capsInorganic particleSilicic acid

The present invention provides amorphous inorganic particles as a dental material comprising silica and inorganic oxide(s) other than silica and having high x-ray impermeability. The inorganic particles as a dental material comprise silica with the content in the range from 70 to 98 weight % and oxide(s) of one or more elements selected from the group consisting of Zr, Ti, La, Ba, Sr, Hf, Y, Zn, AL, and B, wherein 5 to 70 weight % of the silica is originated from an acidic silicic acid solution and 30 to 95 weight % of the silica is originated from a sol of silica. This inorganic particles as a dental material have average particle diameter in the range from 1 to 10 mum, specific surface area in the range from 50 to 350 m2 / g, pore volume in the range from 0.05 to 0.5 ml / g, amorphous crystallinity as observed by x-ray diffraction, and the refractive index in the range from 1.47 to 1.60.

Owner:JGC CATALYSTS & CHEM LTD

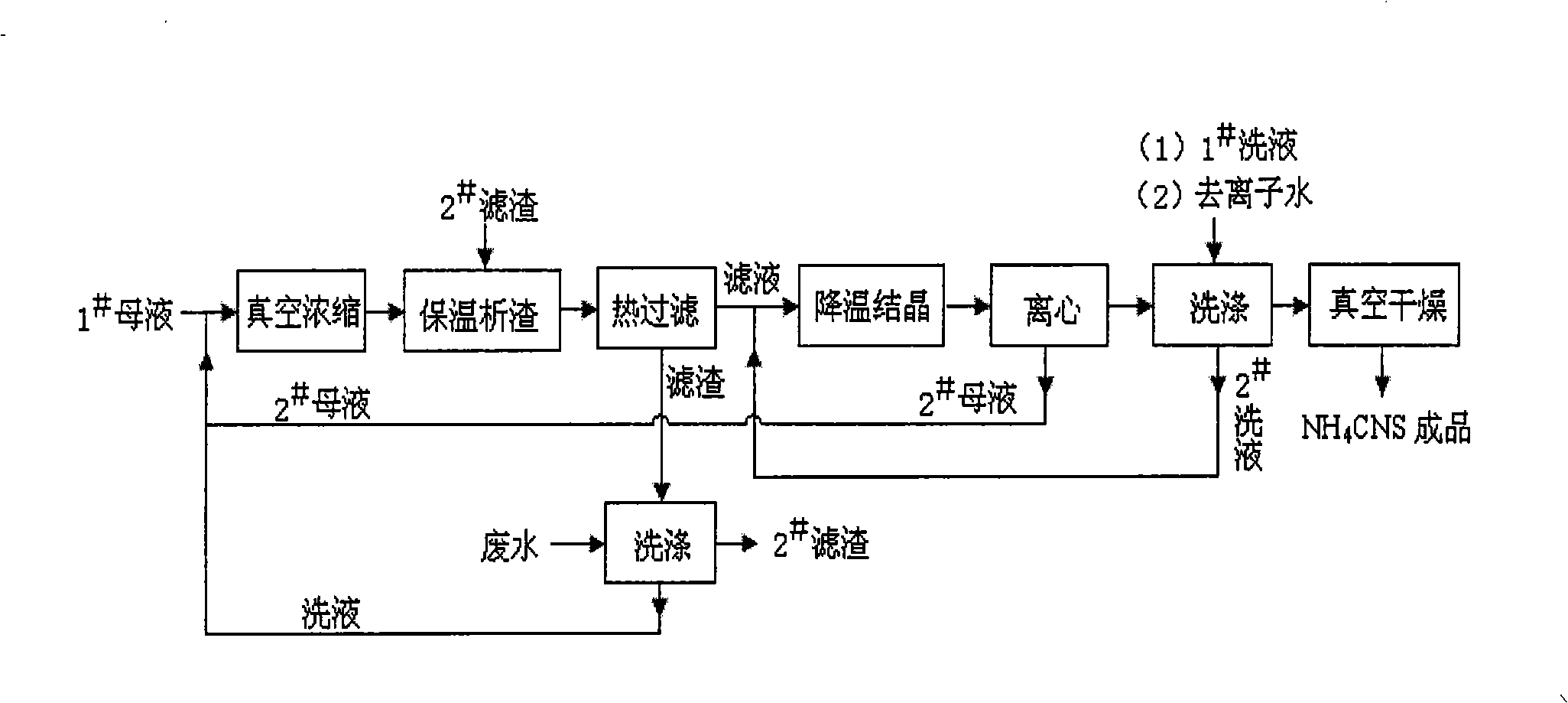

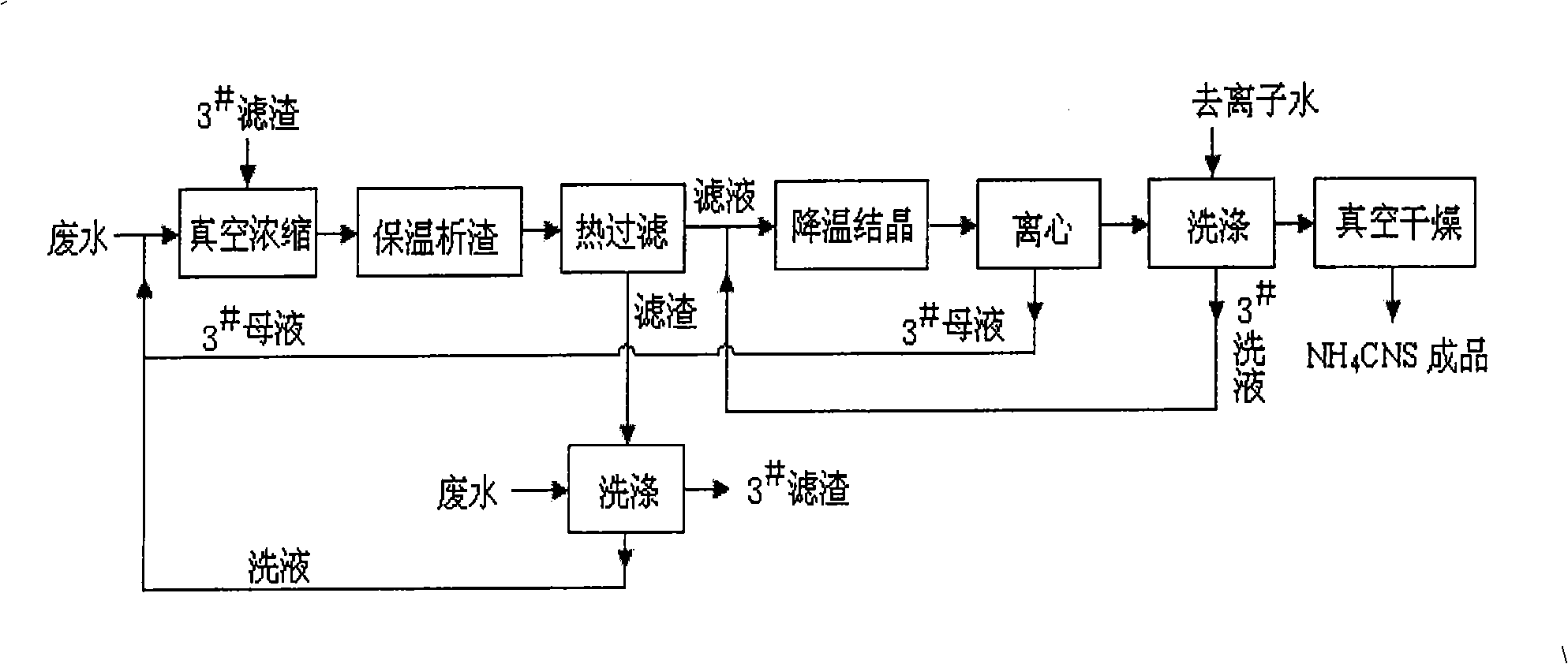

Process for recycling inorganic salt from wastewater for desulfurization and decyanation of coke oven gas

ActiveCN101402461AHigh recovery rateEasy to operateThiosulfates/dithionites/polythionitesThiocyanic acidCatalytic oxidationNo production

The invention provides a process for reclaiming inorganic salt from wastewater in the desulphurization and decyanation of coal gas of a coke furnace. The process aims at reclaiming ammonium thiocyanate (NH4CNS), ammonium thiosulfate ((NH4)2S2O3) and ammonium sulphate ((NH4)2SO4) from wastewater produced by a liquid-phase catalytic oxidation, desulphurization and decyanation process taking ammonia as an alkaline resource. In particular, the process comprises that the wastewater and a mother solution with the ratio of NH4CNS to (NH4)2S2O3 more than or equal to 1.0 (wt) and the ratio of NH4CNS to (NH4)2S2O3 less than 1.0 (wt) are separated to obtain finished products of NH4CNS, (NH4)2S2O3 and (NH4)2SO4 through a targeted process. The process is easy to operate and control parameter, has high salt reclaiming rate and high product quality, reaches the aim that the wastewater can be fully treated and has no production of three wastes, and has good economic and social benefits.

Owner:JINNENG SCI & TECH

Method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by oxidation process

InactiveCN103011201AEasy to separateSimple processThiocyanic acidMultistage water/sewage treatmentLiquid wasteEvaporation

The invention discloses a method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by an oxidation process, and belongs to the technical field of treatment of the desulfurization waste liquid. According to the method, an oxidation reaction is implemented by a way of blowing air or oxygen into ammonia-process desulfurization waste liquid; by the oxidation reaction, ammonium thiosulfate in the desulfurization waste liquid is oxidized into ammonium sulfate, but ammonium thiocyanate is not oxidized and is still reserved in the desulfurization waste liquid; and the ammonium thiocyanate is extracted by ways of evaporation and secondary crystallization. The method disclosed by the invention is applicable to the treatment of the desulfurization waste liquid which is generated from the process of desulfurization and decyanation of the gas by a catalytic oxidation process, and is suitable for the waste liquid treatment in the field of desulfurization process of hydrogen sulfide-containing gases such as coke oven gas, natural gas, coal-bed methane and refinery gas. By the method, the ammonium thiosulfate salt in the waste liquid is converted into the ammonium sulfate salt and the ammonium thiocyanate salt is protected, and the ammonium thiosulfate salt and the ammonium thiocyanate salt are separated from the waste liquid and purified into products.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for recovering sodium sulfocyanate from desulfurized and decyanated wastewater of coke-oven gas

InactiveCN102336417AEliminate pollutionAchieving a circular economyThiocyanic acidChemical reactionSodium sulfocyanate

The invention discloses a method for recovering sodium sulfocyanate from coke-oven gas wastewater that is desulfurized and decyanated through a sodium alkali method. Belonging to a pure physical separation technology, the method of the invention has no need for additional accessories to take part in a reaction and does not discharge any wastewater and waste material to the outside, thus really reaching the purposes of eliminating environmental pollution, utilizing waste materials, change waste materials into things of value and realizing circular economy. The method provided in the invention has the advantages of novel technology, simple process, low cost, advanced technique, and practical applicability.

Owner:苏州久王环保科技股份有限公司

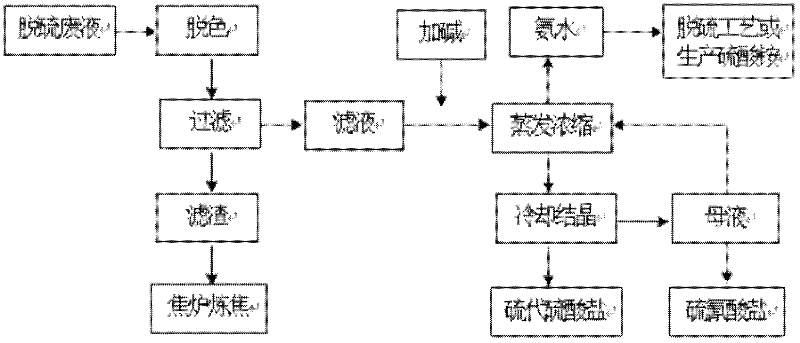

Production technique for extracting ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquor

InactiveCN101850952ASolving Recycling ProblemsEmission reductionThiosulfates/dithionites/polythionitesThiocyanic acidOrganic solventEconomic benefits

The invention discloses a production technique for extracting ammonium thiosulfate and ammonium thiocyanate from a desulfurization waste liquor, which comprises the following steps: settling, filtering, decoloring, concentrating, crystallizing, separating, drying a sulfur-containing waste liquor generated in a desulfurization production process of HPF in a coke-oven plant, and finally, recovering ammonium thiocyanate and ammonium thiosulfate by using a mixed organic solvent. The invention is a production technique for comprehensively treating waste water generated in the prior HPF desulfurization technique, and the mixed organic solvent is used for separating ammonium thiocyanate and ammonium thiosulfate. The invention effectively solves the problem of waste water recovery in the desulfurization process, reduces discharge and environmental pollution of waste water, recovers important chemical raw materials (ammonium thiocyanate and ammonium thiosulfate), and can increase the economic benefit.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

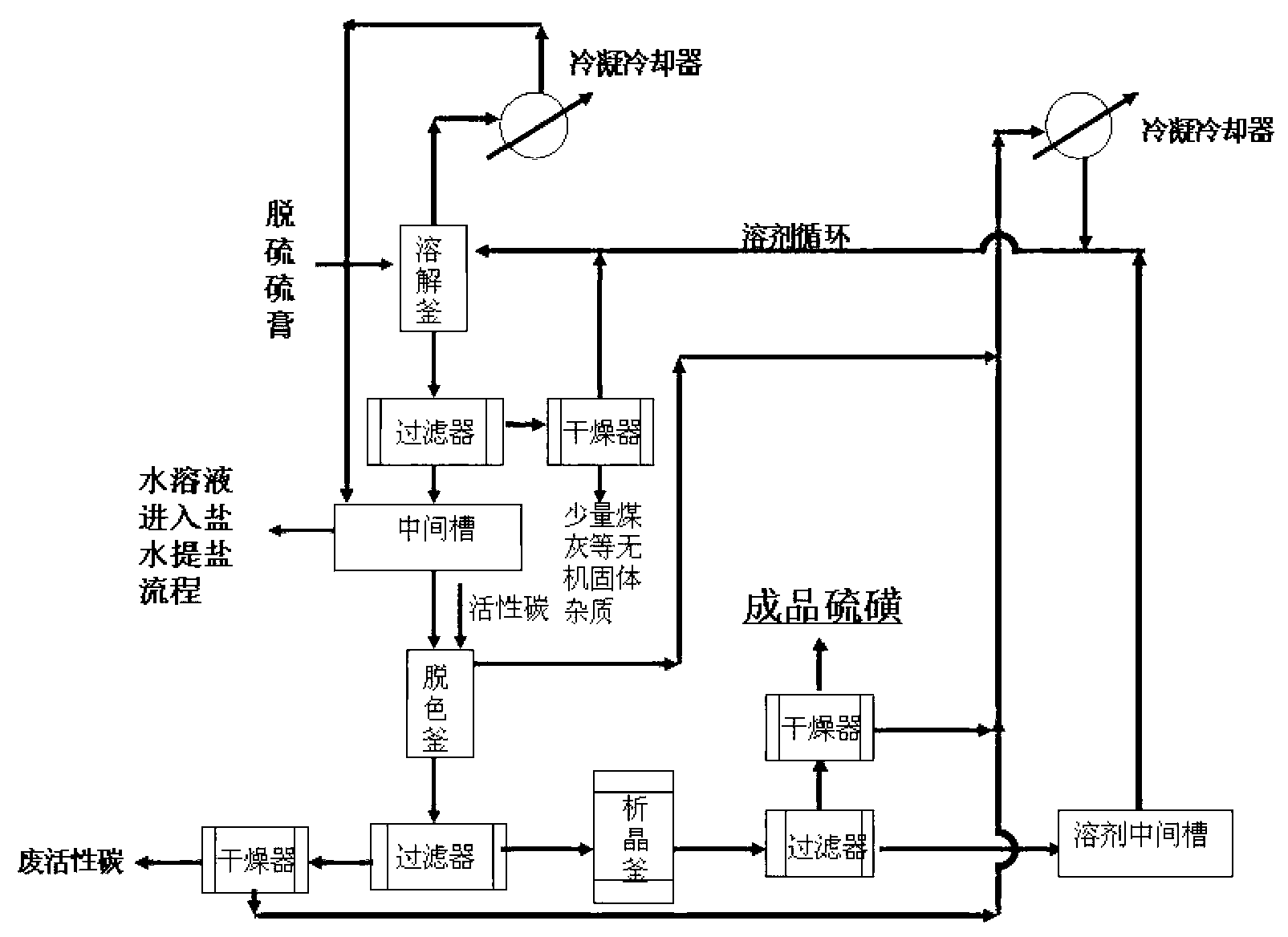

Method for processing sulfur paste as coke oven gas desulfuration by-product

ActiveCN103264991AThorough treatmentNo secondary pollutionCalcium/strontium/barium sulfatesThiosulfates/dithionites/polythionitesResource utilizationImpurity

The invention relates to a method for processing sulfur paste as a coke oven gas desulfuration by-product. The method is characterized in that a sulfur paste processing procedure comprises the steps of dissolving sulfur and removing impurities, decoloring and removing impurities, lowering temperature and crystallizing, drying the product and the like; and a waste liquid treatment procedure comprises the steps of decoloring and removing impurities, carrying out vacuum concentration on filtrate containing salt, separating ammonium thiocyanate, concentrating the ammonium thiocyanate ethyl alcohol filtrate for crystallization, drying an ammonium thiocyanate product, separating ammonium sulfate, concentrating the ammonium thiosulfate filtrate for crystallization, drying the ammonium thiosulfate product, and the like. The method can be used for thoroughly processing the sulfur paste and the waste liquid containing sulfur, the recycling rate of the product is high, no mixed salt and waste water are discharged without cause secondary pollution, so that the method is clean and environment-friendly. The method also has the outstanding characteristics of strong adaptive capacity, large production elasticity, high resource utilization ratio and the like.

Owner:张建利

Method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas

ActiveCN103274367AThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteResource utilization

The invention relates to a method for extracting two secondary salts from a desulfurized salt-containing waste liquid of coke oven gas. The waste liquid treatment and secondary salt extraction process comprises the following steps: decolorizing, removing impurities, performing reduced pressure concentration on the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, drying the ammonium thiosulfate product and the like. According to the invention, the desulfurized waste liquid is thoroughly treated, the products are high in recovery rate, no mixed salts or waste water is discharged, no secondary pollution is caused, and the process is clean and environment-friendly. Meanwhile, the invention also has the remarkable characteristics of high adaptability, high production elasticity, high resource utilization rate and the like.

Owner:张建利

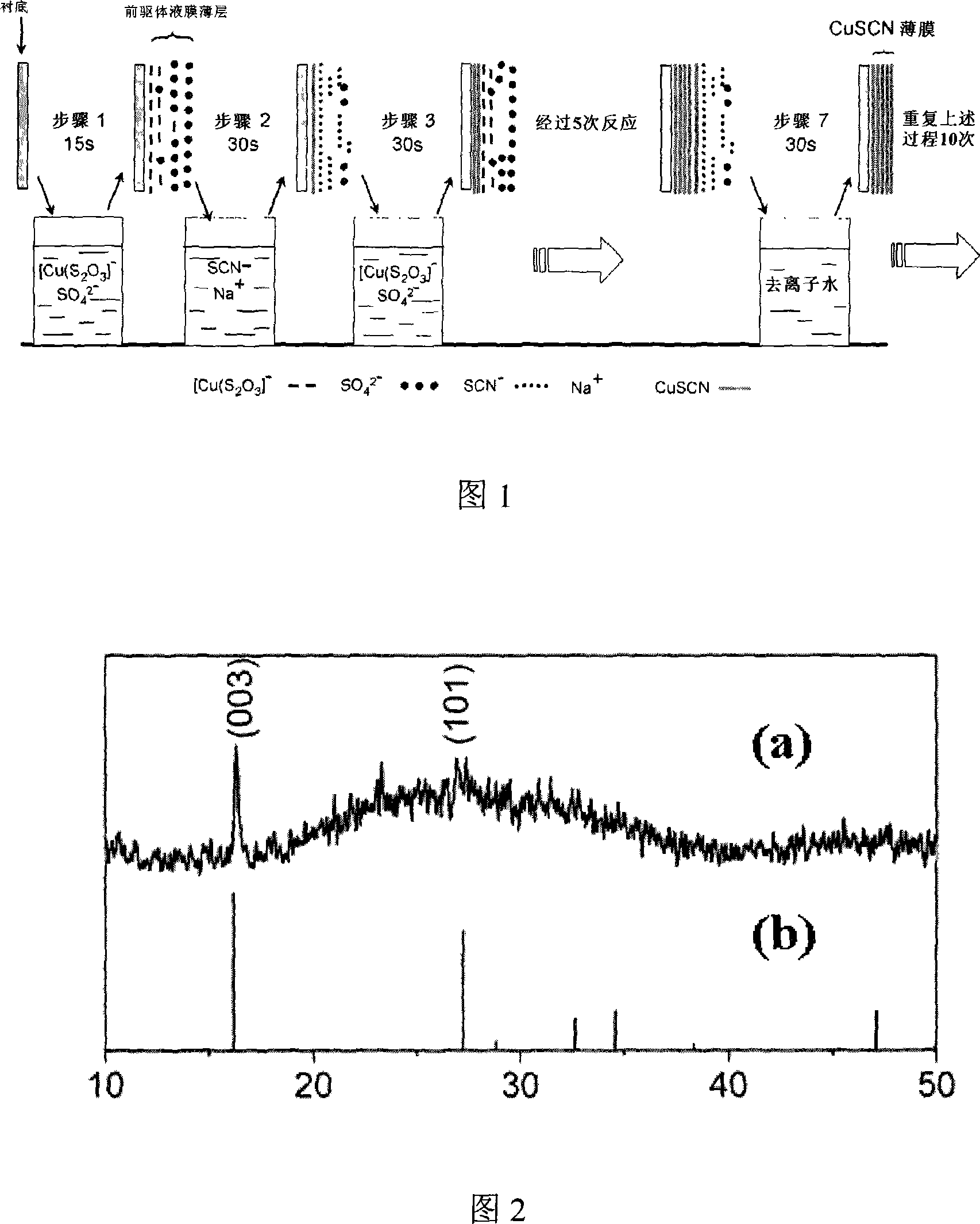

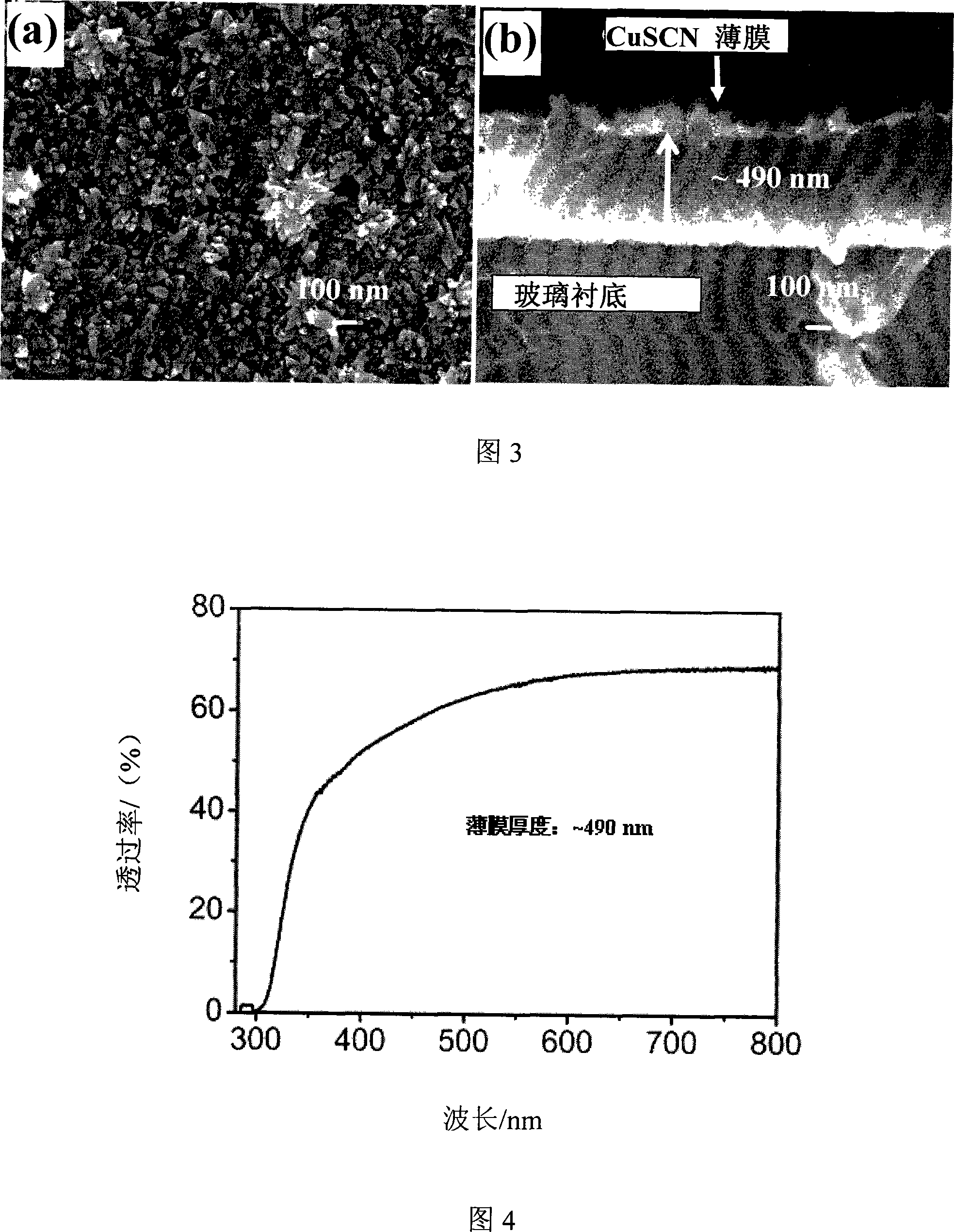

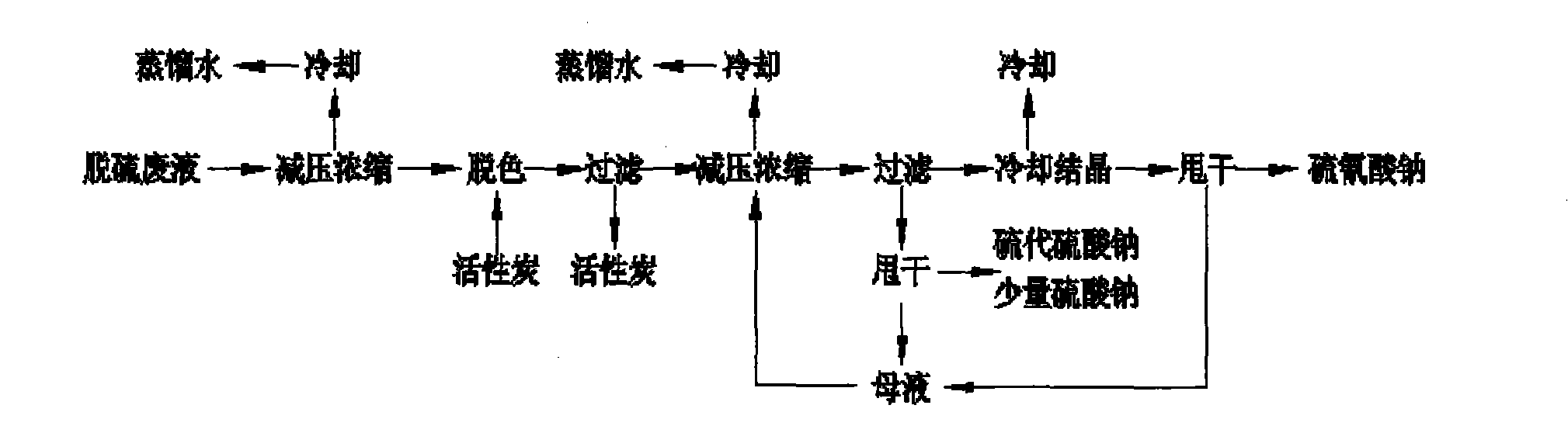

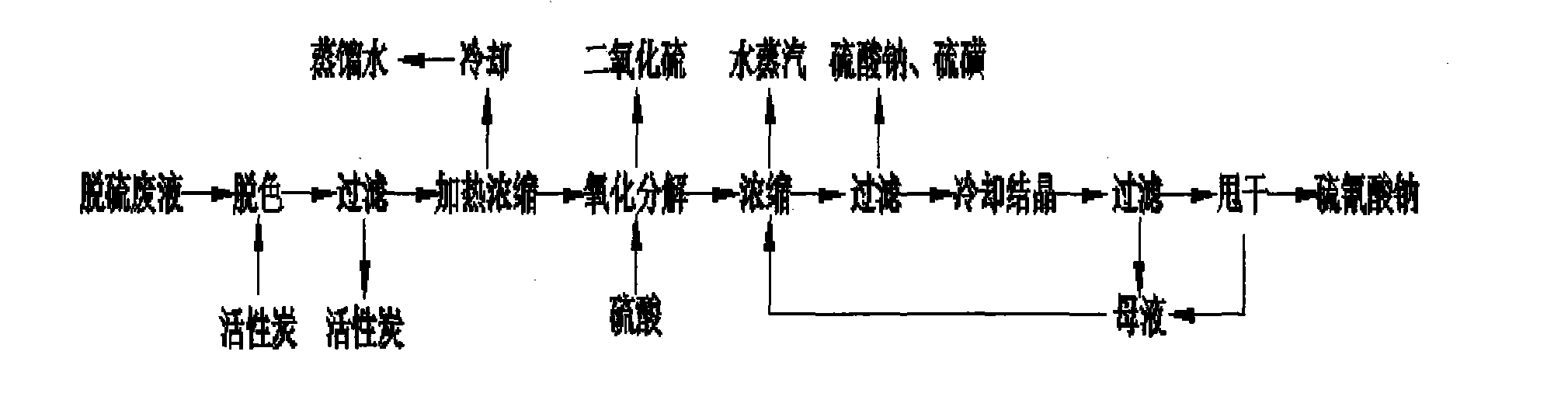

Method for manufacturing cuprous thiocyanate membrane in liquid phase condition

InactiveCN101109101AImprove stabilityQuality improvementFrom normal temperature solutionsThiocyanic acidConcentration ratioPhysical chemistry

The invention relates to a method for preparing CuSCN film under room temperature and liquid phase, which is characterized in that: (1) inorganic copper salt is selected as a precursor, the concentration of Cu2+ is 0.001-0.1mol / L; (2) Na2S2O3 is used as complex, the mole concentration with copper ion is 2 swung dash 5; (3) sulfocyanide of alkaline metal is used as SCN- ion precursor, in concentration 0.002-0.2mol / L, and the concentration ratio of SCN- to Cu2+ is 1-15; (4) deposition of film is carried out by way of ''serial ion layer absorption and reaction'' (SILAR), the liner is first immersed in Cu2+ precursor solution; then the liner is placed in SCN- precursor solution for reaction; the liner is immersed in Cu2+ precursor again; above operation is repeated; finally the liner is fully washed by de-ionizing water. The CuSCN film prepared has dense and even film layer, the grain size is as small as 20-50 nm; and the optic transmissivity of 400-800 nm wavelength is 50-70%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

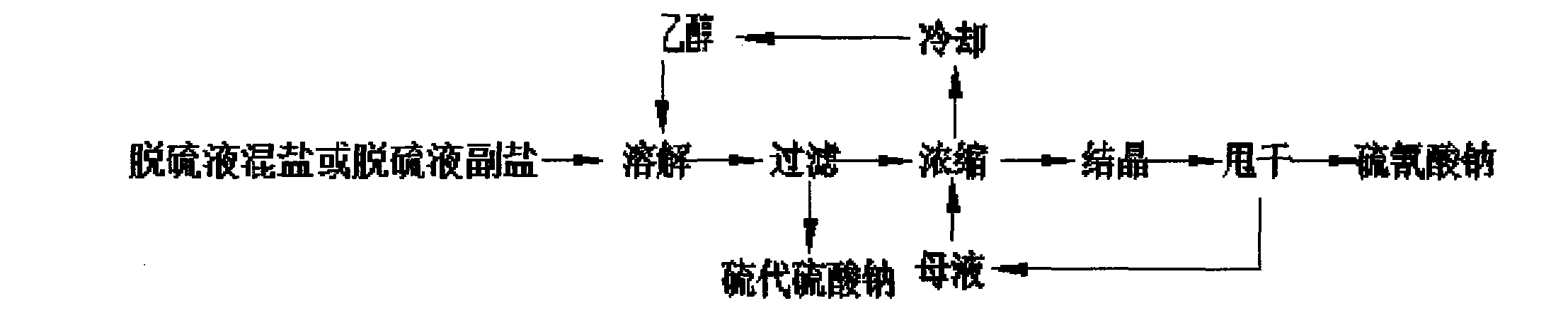

Method for extraction of high purity sodium thiocyanate from desulfurization waste liquid or desulfurization liquid mixed salt

InactiveCN103723744AReduce production energy consumptionCraft fluency shortThiocyanic acidSolventChemistry

The invention discloses a method for extraction of high purity sodium thiocyanate from a desulfurization waste liquid or a desulfurization liquid mixed salt. The method comprises the steps of: 1) subjecting the desulfurization waste liquid to preliminary evaporation, conducting cooling to lower than certain temperature when reaching certain concentration, then taking alcohol as a solvent, and injecting the alcohol thereinto, and keeping the temperature above 48DEG C in the process; 2) then performing cooling to less than 48DEG C so as to make sodium thiosulfate therein and free water generate sodium thiosulfate of crystal water and make the generated product precipitate in the alcohol solution, and then separating the sodium thiosulfate from a small amount of impurities by filtration; and 3) concentrating the alcohol solution, cooling and recovering the evaporated alcohol, returning the product to the system to undergo recycling, and carrying out evaporation, concentration and crystallization, thus obtaining the high purity sodium thiocyanate. The method provided by the invention has the advantages of low production energy consumption, short process, simple operation, good product quality, and obvious economic benefits.

Owner:秦飞

Method for preparing high-quality sodium thiocyanate from desulfurized and decyanated waste liquid of coke oven gas

The invention discloses a method for preparing high-quality sodium thiocyanate from a desulfurized and decyanated waste liquid of coke oven gas, which comprises the following steps: decolorizing and filtering the desulfurized and decyanated waste liquid through activated carbon, and adding an assistant A into the waste liquid while stirring, wherein the specific quantity of the assistant A is 50-200% of the molal quantity of sodium thiosulfate in the waste liquid; removing sodium thiosulfate ions in the waste liquid system, filtering to remove insoluble substances, and then adding a small quantity of assistant C into the filtrate to regulate the pH value to 5-10; distilling and concentrating to remove the moisture, and centrifuging to separate out inorganic salt impurities based on the difference of various substances in solubility under different temperatures and concentrations; and decolorizing through activated carbon, and further concentrating and crystallizing to produce the sodium thiocyanate finished product. According to the invention, the process is simple, the cost is low, and the weight content of the produced potassium thiocyanate is more than 99%.

Owner:江苏燎原环保科技股份有限公司

Method for selectively absorbing and separating thiocyanates and thiosulfates in water solution

ActiveCN101857282AEasy to recycleSolve pollutionThiocyanic acidSulfur-trioxide/sulfuric-acidSorbentAbsorption effect

The invention provides a method for selectively absorbing and separating thiocyanates and thiosulfates in water solution. The invention uses the difference absorption effect of the layered bihydroxide mixed metal oxide roasted products (LDO) on the ion absorption quantity of thiosulfate radicals and thiocyanate radicals, the LDO is used as absorbing agents to be placed into the water solution containing thiosulfates and thiosulfates, firstly, the thiosulfates in the solution are absorbed into the LDO, then, the replacement and the purification are carried out, and next, the thiosulfates in the rest solution are separated, so the goal of separating and purifying two salts is reached. The used LDO is obtained through roasting Mg-Al hydrotalcites with the constitutional formula of Mg<1-x>Alx(OH)2(An<->)x / 2.yH2O at 400 to 500 DEG C for 3 to 4 h. The method can be used for treating waste water in the solution containing the thiosulfates and the sulfates for solving the problem of water body and soil pollution by the thiosulfates and the sulfates, and at the same time, the two salts can be perfectly recovered.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting NaSCN from thiocyanate-containing wastewater solution

InactiveCN101966996ALow priceHigh purityThiocyanic acidMultistage water/sewage treatmentElutionWastewater

The invention specifically relates to a method for extracting NaSCN from thiocyanate-containing wastewater solution. The technical scheme comprises the following steps: adsorbing the thiocyanate-containing wastewater solution by active carbon and filtering to obtain primary filtrate; adding elution agent into the primary filtrate under normal pressure at 10 to 50 DEG C, wherein the volume of the added elution agent is 1 to 8 times of that of the primary volume, and the addition seed of the elution agent is 50 to 600 mL / h; stirring at a speed of 100 to 600 r / min during the addition of the elution agent; after adding the elution agent, standing for 15 to 30 min and filtering to obtain secondary filtrate; and evaporating and crystallizing the secondary filtrate to obtain the NaSCN crystal. The method has the characteristics of low cost, environmental protection and the like, and the purity of extracted NaSCN reaches 87 to 96%.

Owner:WUHAN UNIV OF SCI & TECH

Method for extracting ammonium thiocyanate from coking desulfurization waste liquid

InactiveCN102126732ASimple processEasy to operateThiocyanic acidWater/sewage treatmentActivated carbonLiquid waste

The invention discloses a method for extracting ammonium thiocyanate from coking desulfurization waste liquid. The method comprises: adding 3-5% of activated carbon to the coking desulfurization waste liquid, heating the mixture to 70-90 DEG C, stirring the mixture for 1-3 hours and filtering the mixture; adding sulfuric acid to the filtrate in a closed container to ensure the pH value of the filtrate to be 3.5-4.5, heating the mixture to 60-80 DEG C and stirring the mixture for 1-3 hours, leading out the escaping SO2 with a conduit and absorbing the escaping SO2 with dilute ammonia water; filtering the reaction liquid, adding barium hydroxide octahydrate with mass being equal to the mass of ammonium sulfate in the filtrate, heating the mixture to 60-80 DEG C in a closed container, stirring the mixture for 1-3 hours, leading out the escaping ammonia with a conduit and absorbing the escaping ammonia with water; and carrying out filtering after completing reaction, and heating, evaporating and crystallizing the filtrate to obtain the ammonium thiocyanate product with purity being more than 97%.

Owner:陈琳

Inorganic particles as a dental material and a method of producing the same

InactiveUS6849112B2High x-ray impermeabilityControl refractionPigmenting treatmentImpression capsInorganic particleSilicic acid

Amorphous inorganic particles as a dental material includes silica and inorganic oxide(s) other than silica and has high x-ray impermeability. The inorganic particles as a dental material includes silica with the content in the range from 70 to 98 weight % and oxide(s) of one or more elements selected from the group of Zr, Ti, La, Ba, Sr, Hf, Y, Zn, AL, and B, wherein 5 to 70 weight % of the silica is originated from an acidic silicic acid solution and 30 to 95 weight % of the silica is originated from a sol of silica. The inorganic particles as a dental material have an average particle diameter in the range from 1 to 10 μm, specific surface area in the range from 50 to 350 m2 / g, pore volume in the range from 0.05 to 0.5 ml / g, amorphous crystallinity as observed by x-ray diffraction, and the refractive index in the range from 1.47 to 1.60.

Owner:JGC CATALYSTS & CHEM LTD

Device and method for extracting refined salt from waste liquid generated during wet ISS-J desulfurization

PendingCN107128950AAchieving zero emissionsOrganic compound preparationThiosulfates/dithionites/polythionitesSodium thiocyanateEvaporation

The invention discloses a device and a method for extracting refined salt from waste liquid generated during wet ISS-J desulfurization. The device comprises a coarse salt drying assembly, a sodium thiocyanate separating and refining assembly, a sodium thiosulfate separating and refining assembly, a sodium sulfate separating and refining assembly and a solvent recycling assembly. The coarse salt drying assembly comprises a desulfurization waste liquid tank, a heat exchanger, an evaporation kettle, a crystallization kettle and a centrifugal machine; the sodium thiocyanate separating and refining assembly comprises a dissolving kettle, a filter-press kettle, an evaporation kettle, a crystallization kettle, a centrifugal machine, a drying machine and a packaging machine; the sodium thiosulfate separating and refining assembly comprises a dissolving kettle, a condensate tank, a filter-press kettle, a crystallization kettle, a centrifugal machine and a packaging machine; the sodium sulfate separating and refining assembly comprises a dissolving kettle, a concentrate sulfuric acid elevated tank, an evaporation kettle, a centrifugal machine, a drying machine and a packaging machine. The device and the method have the advantages that the waste liquid which can originally pollute environments and is generated by desulfurization systems can be thoroughly treated by the aid of the device and the method, industrial-grade products can be produced from the waste liquid, accordingly, wastewater emission can be truly prevented, and waste can be truly turned into wealth.

Owner:沂州科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com