Method for improving purity of sodium thiocyanate in coking and desulfurizing waste liquid

A technology of coking desulfurization waste liquid and sodium thiocyanate, which is applied in the direction of thiocyanate, etc., can solve the problems of restricting usage and price, affecting the purity of sodium thiocyanate, mixed crystals, etc., and achieves convenient operation, reduction of emissions and environmental protection Contamination, simple effect of extraction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

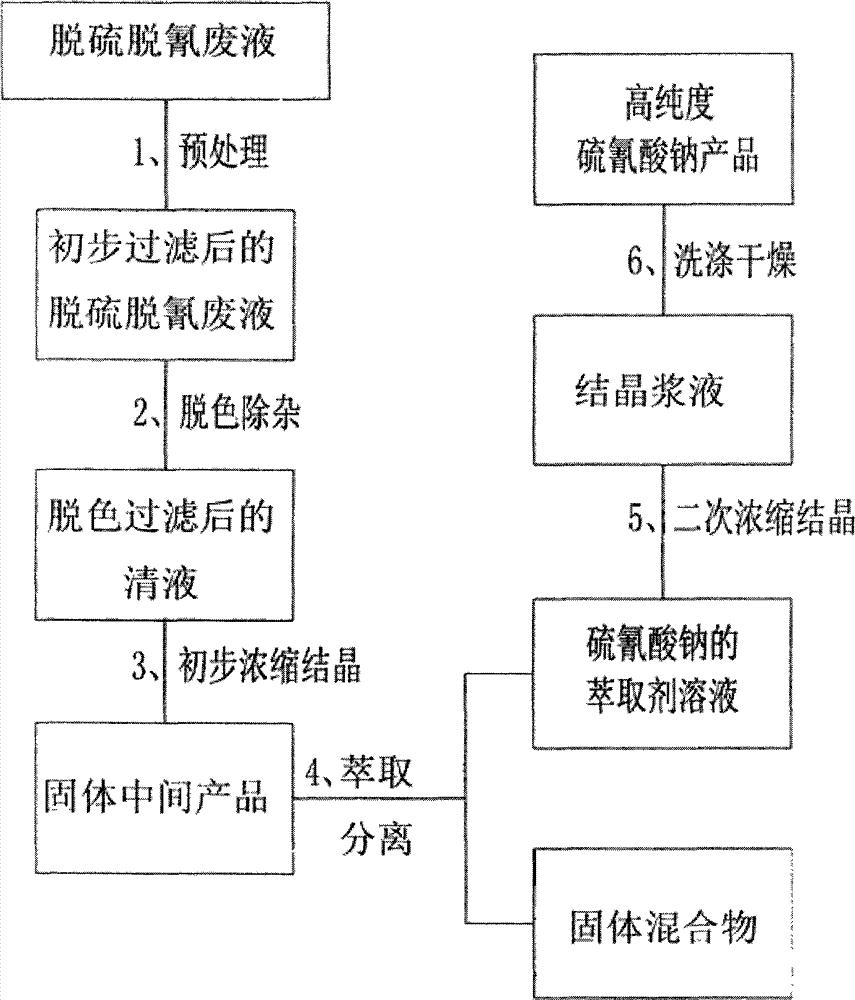

[0018] A method for improving the purity of sodium thiocyanate in coking desulfurization waste liquid, comprising the steps in sequence:

[0019] Pretreatment of desulfurization and decyanation waste liquid: take coke oven gas desulfurization and decyanation waste liquid 1000g, wherein sodium thiocyanate content is 10wt%, sodium sulfate content is 3.5wt%, sodium thiosulfate is 7.5wt%, filter to remove simple substance Sulfur and solid impurities;

[0020] Decolorization and impurity removal: place the desulfurization and decyanation waste liquid initially filtered in step (1) in a decolorization kettle, add 50 g of activated carbon, decolorize at 60° C. for 90 minutes, and then filter to obtain a clear liquid;

[0021] Initial concentration and crystallization: transfer the clear liquid filtered in step (2) to the concentration kettle for concentration under reduced pressure, the vacuum degree is 0.075Mpa, the concentration temperature is 75°C, after concentration, 750g of deh...

Embodiment 2

[0026] A method for improving the purity of sodium thiocyanate in coking desulfurization waste liquid, comprising the steps in sequence:

[0027] Pretreatment of desulfurization and decyanation waste liquid: take coke oven gas desulfurization and decyanation waste liquid 1000g, wherein sodium thiocyanate content is 10wt%, sodium sulfate content is 3.5wt%, sodium thiosulfate is 7.5wt%, filter to remove simple substance Sulfur and solid impurities;

[0028] Decolorization and impurity removal: place the desulfurization and decyanation waste liquid initially filtered in step (1) in a decolorization kettle, add 50 g of activated carbon, decolorize at 60° C. for 90 minutes, and then filter to obtain a clear liquid;

[0029] Initial concentration and crystallization: Transfer the clear liquid filtered in step (2) to a concentration kettle for concentration under reduced pressure, the vacuum degree is 0.075Mpa, the concentration temperature is 75°C, and the concentrated slurry is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com