Method for processing sulfur paste as coke oven gas desulfuration by-product

A technology of coke oven gas and by-products, which is applied in chemical instruments and methods, thiosulfate/dithionite/polythionate, thiocyanate, etc., and can solve the problem of heavy pollution in the purification process, poor economic benefits, Low extraction rate and other issues to achieve the effect of avoiding further pollution, ensuring clean production, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

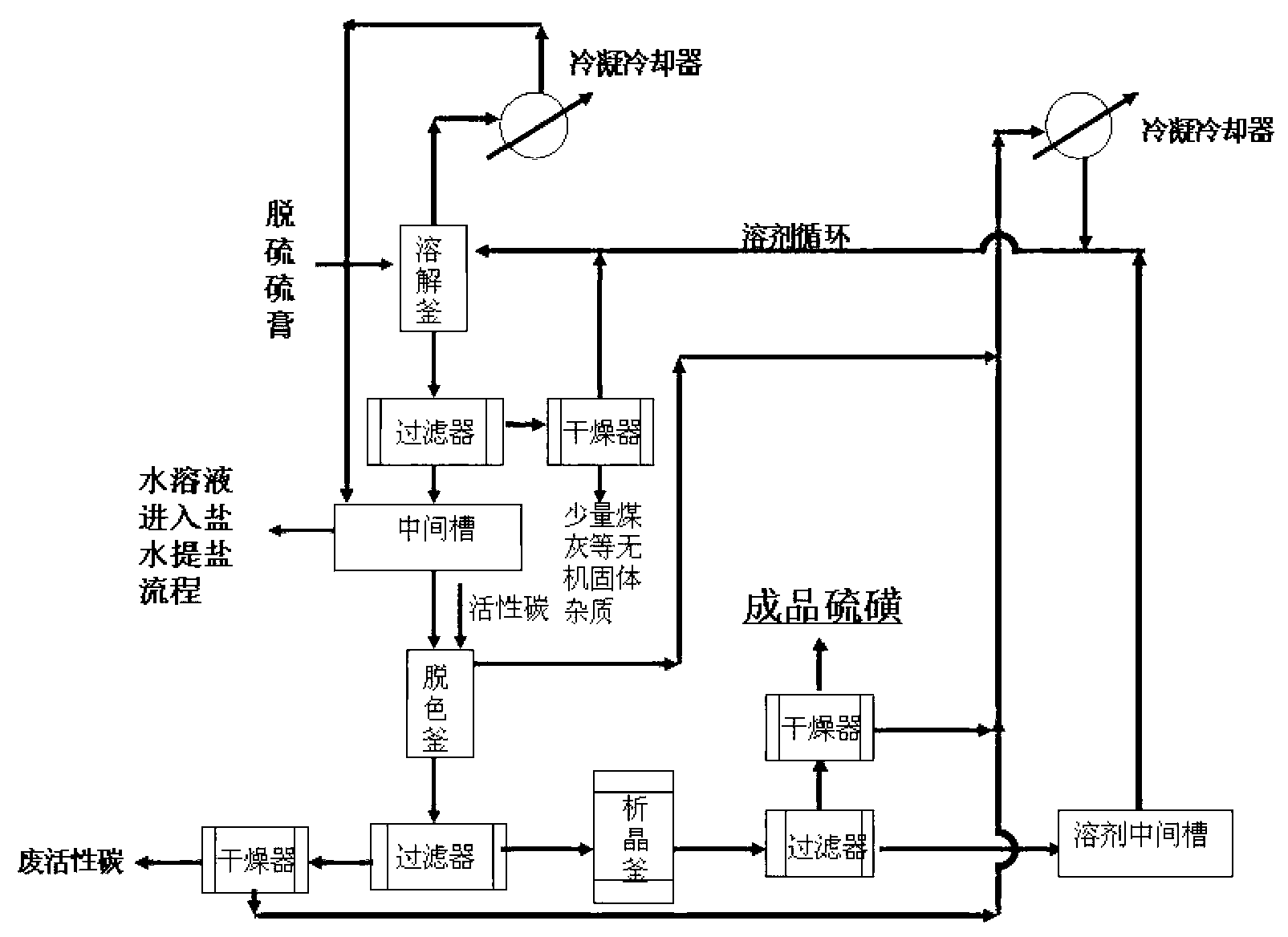

[0034] refer to figure 1 , coke oven gas desulfurization and decyanation by-product sulfur paste 1000kg (the composition content is about 42% of sulfur, 13% of sulfur salt (ammonium thiosulfate, ammonium thiocyanate, ammonium sulfate), 3% of solid impurities such as coal ash , moisture 40%, desulfurization catalyst 0.02%, a small amount of coal tar components such as naphthalene 300ppm, NH 3 1.2%)

[0035] Sulfur paste processing steps:

[0036] Step 1: Dissolving sulfur and removing impurities: 1000kg of desulfurization paste and 8000kg of tetrachlorethylene are stirred and mixed in the dissolution tank at a weight ratio of 1:8, and the temperature is raised to 110°C. After maintaining this temperature for 1 hour, the tetrachlorethylene The upper brine-containing phase is separated and introduced into the desulfurization waste liquid salt extraction process, and the remaining organic phase is subjected to heat preservation and thermal filtration to obtain sulfur-containing ...

Embodiment 2

[0041] refer to figure 1 , Coke oven gas desulfurization and decyanation by-product sulfur paste 1000kg (sulfur 39%, sulfur salt (ammonium thiosulfate, ammonium thiocyanate, ammonium sulfate) 14%, coal ash and other solid impurities 2%, moisture 43%, desulfurization catalyst 0.03%, a small amount of coal tar components such as naphthalene 400ppm, NH 3 1.5%)

[0042] Sulfur paste processing steps:

[0043] Step 1: Dissolving sulfur and removing impurities: 1000kg of desulfurization paste and 8000kg of tetrachlorethylene are stirred and mixed in the dissolution tank at a weight ratio of 1:8, and the temperature is raised to 100°C. After maintaining this temperature for 1 hour, the tetrachlorethylene The upper brine-containing phase is separated and introduced into the desulfurization waste liquid salt extraction process, and the remaining organic phase is subjected to heat preservation and thermal filtration to obtain sulfur-containing perchlorethylene filtrate and a small amo...

Embodiment 3

[0047] Embodiment 3: refer to figure 2

[0048] Waste liquid treatment:

[0049] 1000kg of waste liquid from coke oven gas desulfurization and decyanation paste (ammonium thiocyanate content 13%, ammonium thiosulfate content 9%, ammonium sulfate content 8%)

[0050] Step 1: Decolorization and impurity removal: add 1kg of 0.1% (w / w) activated carbon to the desulfurization waste liquid, keep it warm at 100°C for 30 minutes, and then filter to obtain the decolorized filtrate and activated carbon filter cake (the activated carbon filter cake will be sent to a professional recycling enterprise for regeneration treatment ).

[0051] Step 2: Concentrate the decolorized solution under reduced pressure: Concentrate the filtrate of step 1 under reduced pressure at 70°C (vacuum degree 70mmHg) until the specific gravity of the system is 1.24 (g / ml) and stop concentrating (water content is 18% (w / w) ), transfer the concentrated system to the crystallizer with heat preservation, distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com