Method for extraction of high purity sodium thiocyanate from desulfurization waste liquid or desulfurization liquid mixed salt

A technology of desulfurization waste liquid and sodium thiocyanate, applied in the direction of thiocyanate, etc., can solve the problems of low price, poor quality, meager profit, etc., and achieve significant economic benefits, low production energy consumption, fluent and short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail according to the examples below.

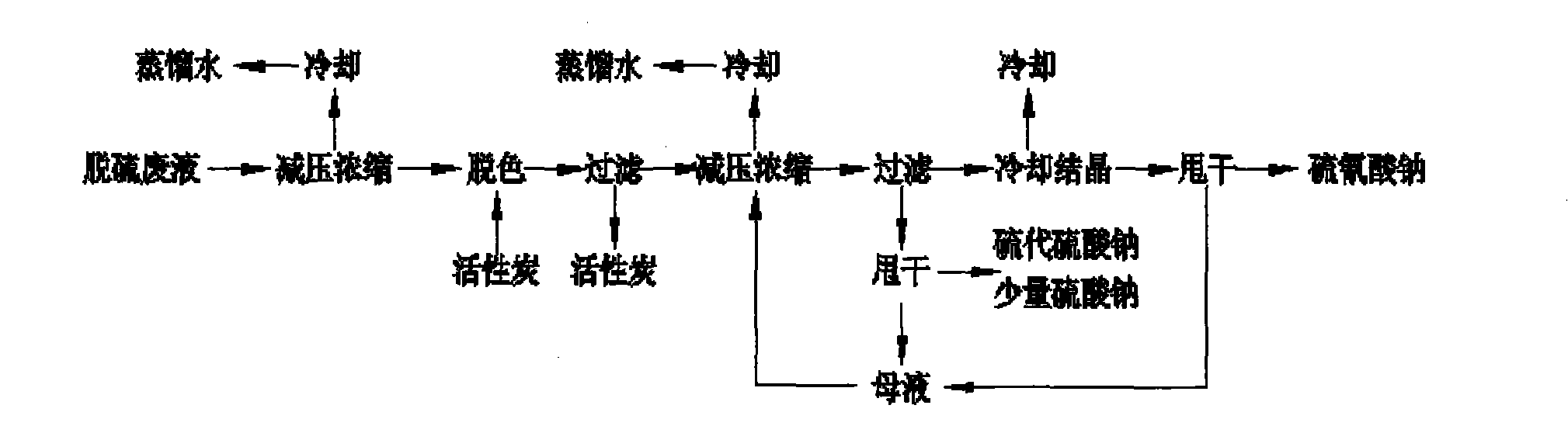

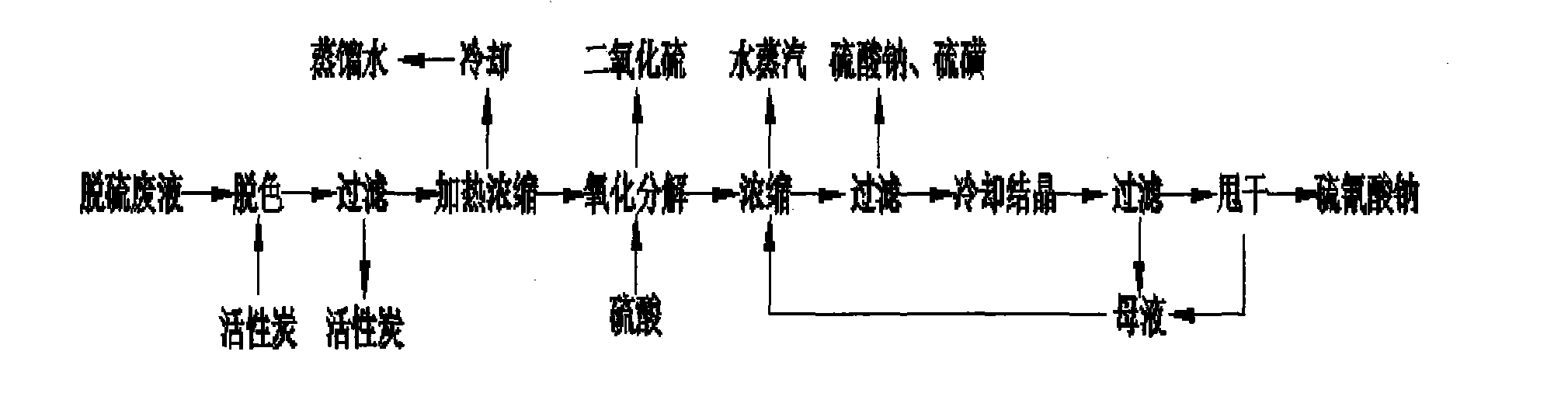

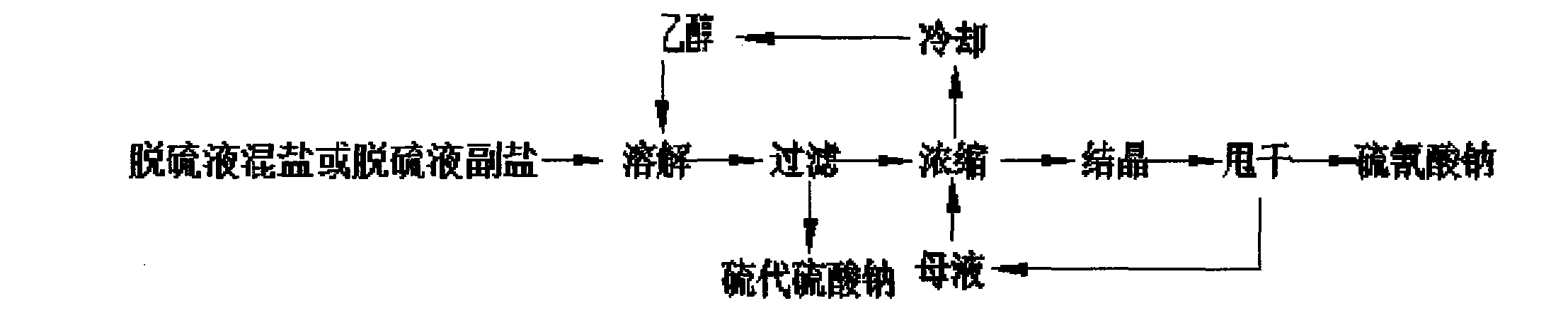

[0023] A method for extracting high-purity sodium thiocyanate from desulfurization waste liquid, that is, an alcohol extraction method.

[0024] Sodium thiocyanate is easily soluble in alcohols, and a small amount of impurities such as sodium thiosulfate, sodium sulfate, and sulfur are insoluble in alcohols, and then 1 molecule of sodium thiosulfate can easily form 5 crystals with 5 molecules of water at low temperature The characteristics of sodium thiosulfate in water, cleverly separate sodium thiosulfate, a small amount of sodium sulfate, sulfur and part of water from alcohol solution, and obtain high-purity sodium thiocyanate product.

[0025] Evaporate desulfurization waste liquid initially (or use mixed salt made from desulfurization liquid as raw material), and when it reaches a certain concentration (do not need to evaporate to dryness, a part of water is allowed), then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com