Auto-darkening welding filter capable of automatically setting shade number

A technology of automatic dimming and filter mirrors, which is applied in optics, goggles, nonlinear optics, etc., can solve the problems of operator's work inconvenience, eye damage, increased working hours, etc., to protect eyes, reduce inconvenience, reduce The effect of technical barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

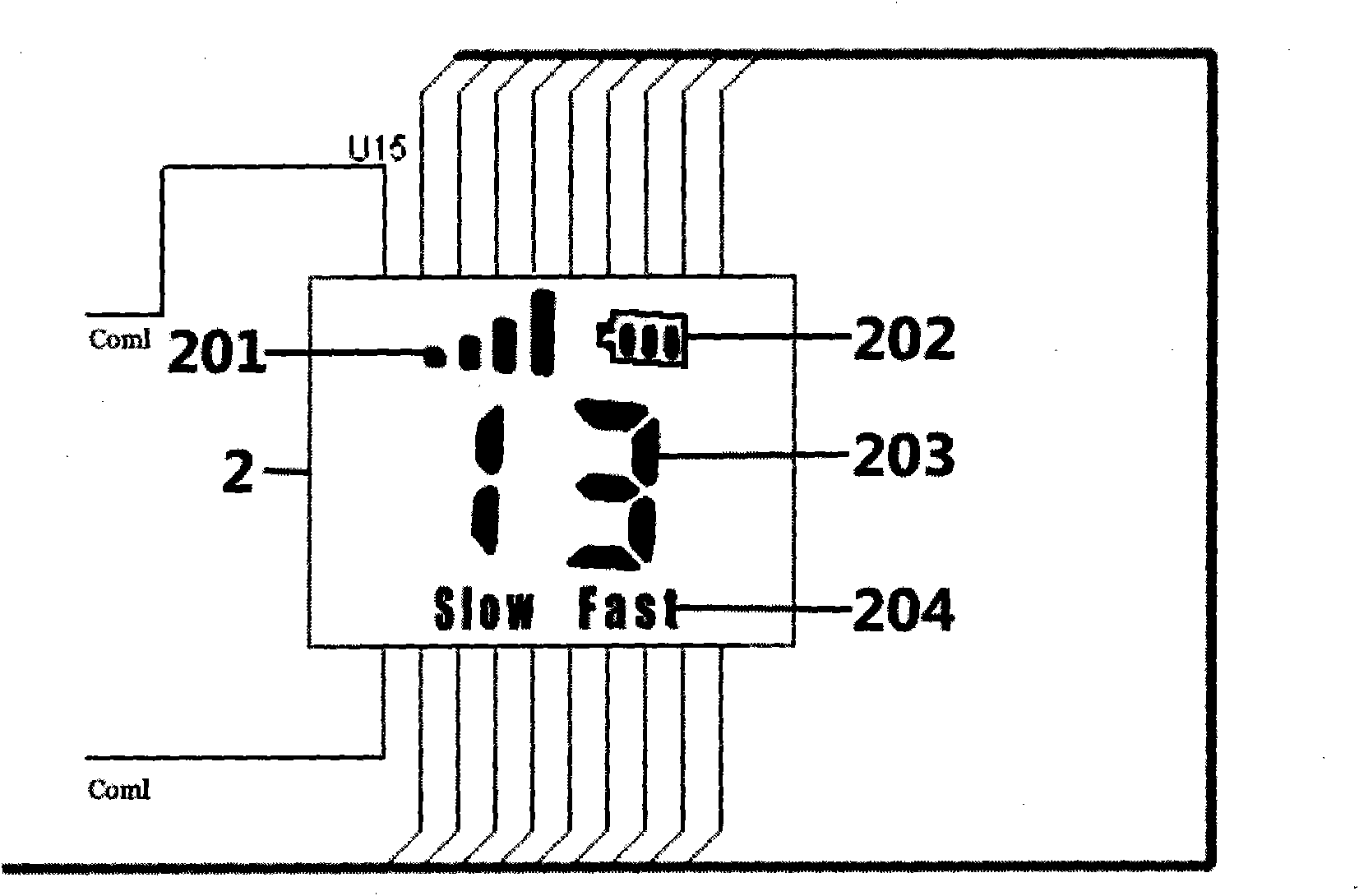

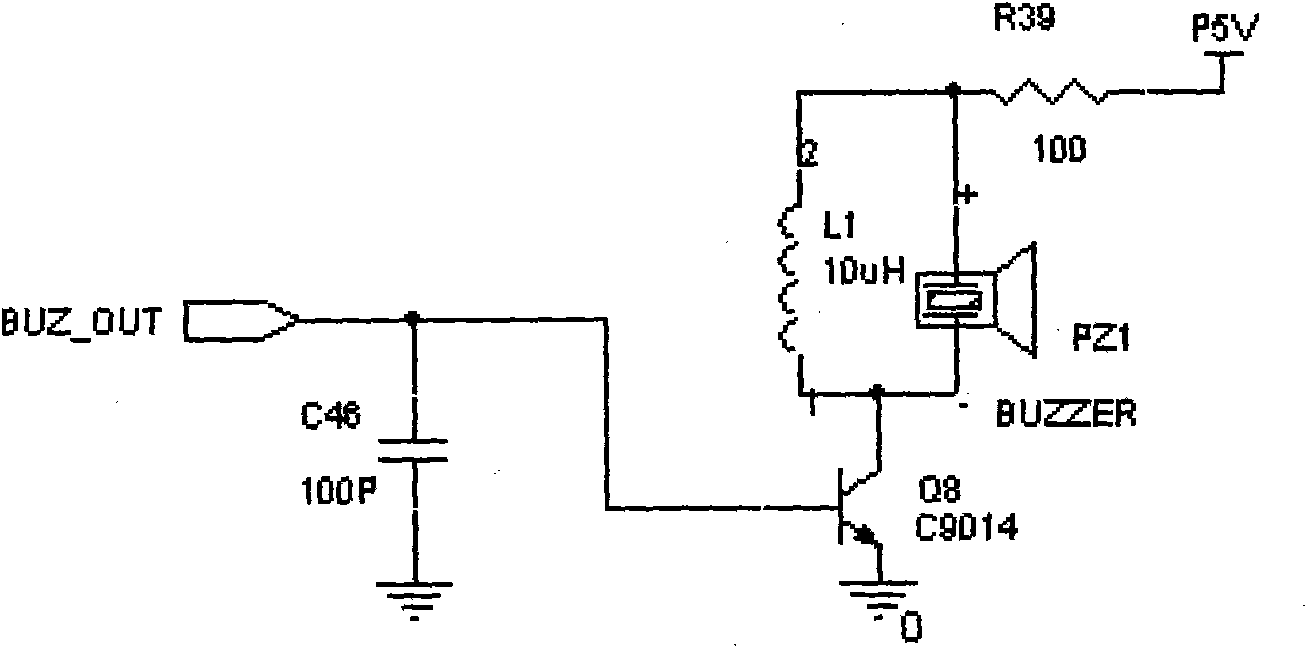

[0035] Such as figure 1 As shown in the schematic diagram of the circuit, the single chip microcomputer 1 and the sensitivity adjustment button 5, the shading number offset adjustment button 4, the delay switch adjustment button 3, the trigger circuit 10, the thermistor 11, the signal output circuit 12, the temperature compensation circuit 13, Boost circuit 14 is electrically connected with power supply voltage stabilizing chip 18; Infrared photosensitive tube 8 is electrically connected with trigger circuit 10; The compensation circuit 13 is electrically connected to the boost circuit 14; the lithium battery 17 is electrically connected to the power regulator chip 18, and the silicon photovoltaic cell 16 is electrically connected to the lithium battery 17.

[0036] The circuit is triggered to start after receiving the light intensity signal (g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com