Measuring device used for measuring drop impact force of control rod

A measurement control and measurement device technology, applied in measurement devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as the inability to use conventional force sensors, save test costs and time, facilitate processing and installation, and measure Accurate and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

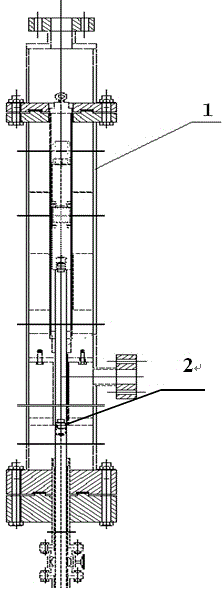

[0025] In the first embodiment, a measuring device for measuring the impact force of the falling rod of the control rod is provided, please refer to Figure 1-Figure 3 , the device includes:

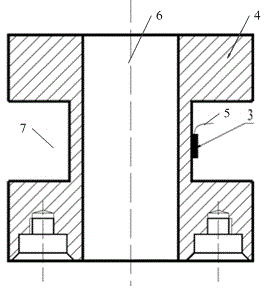

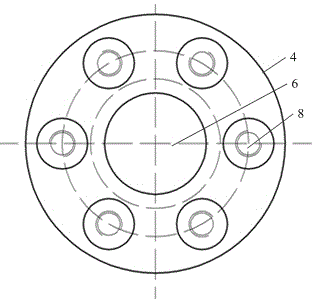

[0026] Cylinder 4, a through hole 6 is provided in the vertical direction of the cylinder 4, and a groove 7 is provided on the outer surface of the middle part of the vertical direction of the cylinder 4, and the groove 7 makes the middle part of the cylinder 4 a cylinder with a uniform wall thickness M waterproof strain gauges 3 are axially installed on the outside of the cylinder, and each waterproof strain gauge 3 is evenly installed in the middle of the cylinder at a circumferential interval of 360° / M, and the measuring device is replaced and installed on the control rod buffer At the position of the compression ring structure of the assembly.

[0027] where, in practical application, please refer to figure 1 , the measuring device 2 used to measure the impact force of the control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com