SEBS (styrenic block copolymer) thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and thermoplastic technology, applied in the field of SEBS thermoplastic elastomer and its preparation, can solve the problems of large compression set and limited SEBS application, and achieve the effects of easy operation, reduced environmental pollution and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

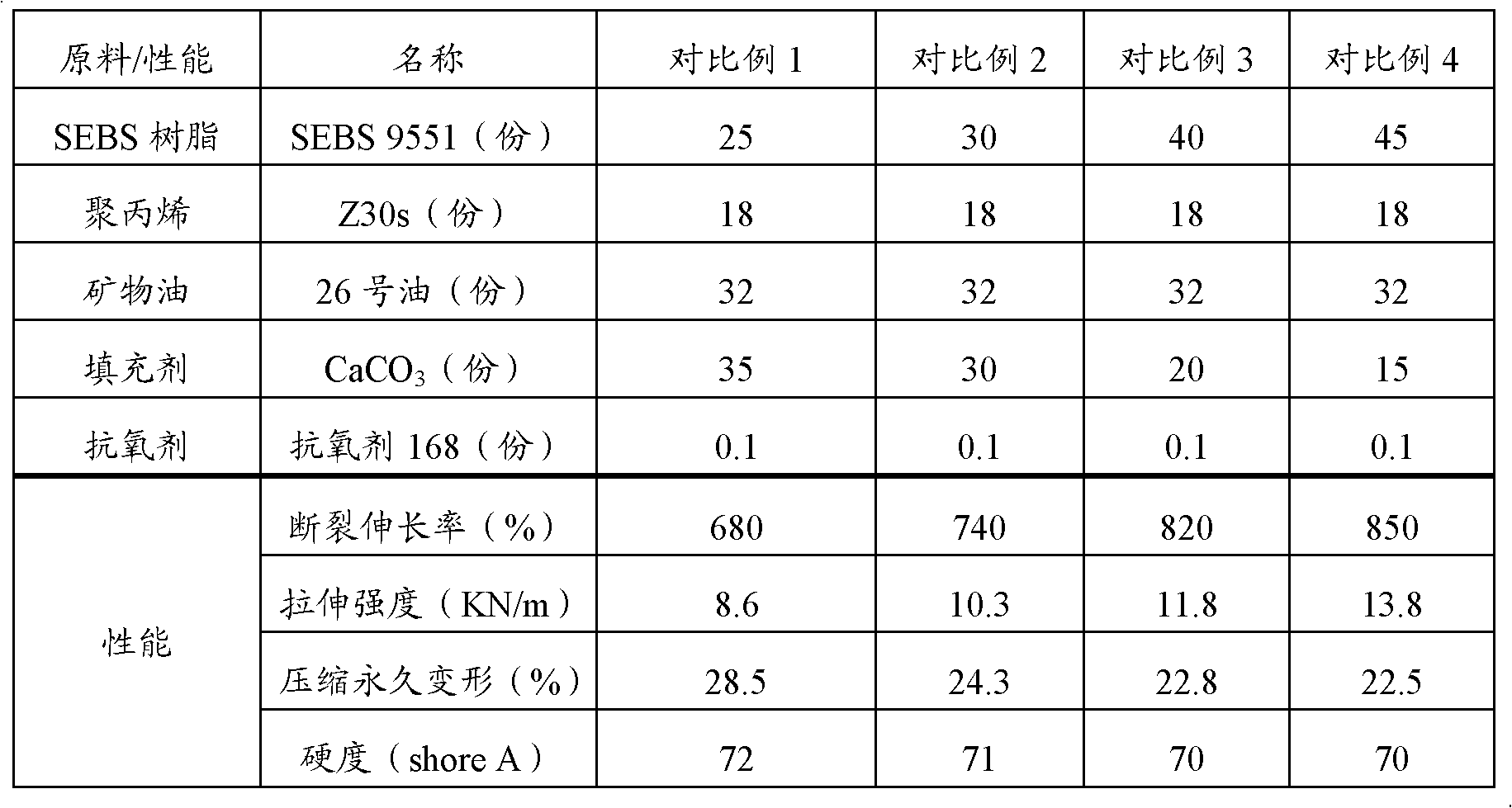

[0029] According to the formulation listed in Table 2, Examples 1-6 were carried out in the same manner as Comparative Example 1. The results are shown in Table 2.

[0030] Table 2

[0031]

[0032] From each example in Comparative Example 2 and Table 2, it is found that by adding hydrocarbon monomer resin, various mechanical properties of SEBS thermoplastic elastomer are improved, especially the compression set is significantly reduced. And within the content range of the hydrocarbon monomer resin used in the present invention, the compression set of the obtained product is good. In addition, it can be seen from Table 2 that the effect of aromatic hydrocarbon monomer resin (such as CS801) is slightly better than that of aliphatic hydrocarbon monomer resin (such as Piccotac1115).

Embodiment 7~10

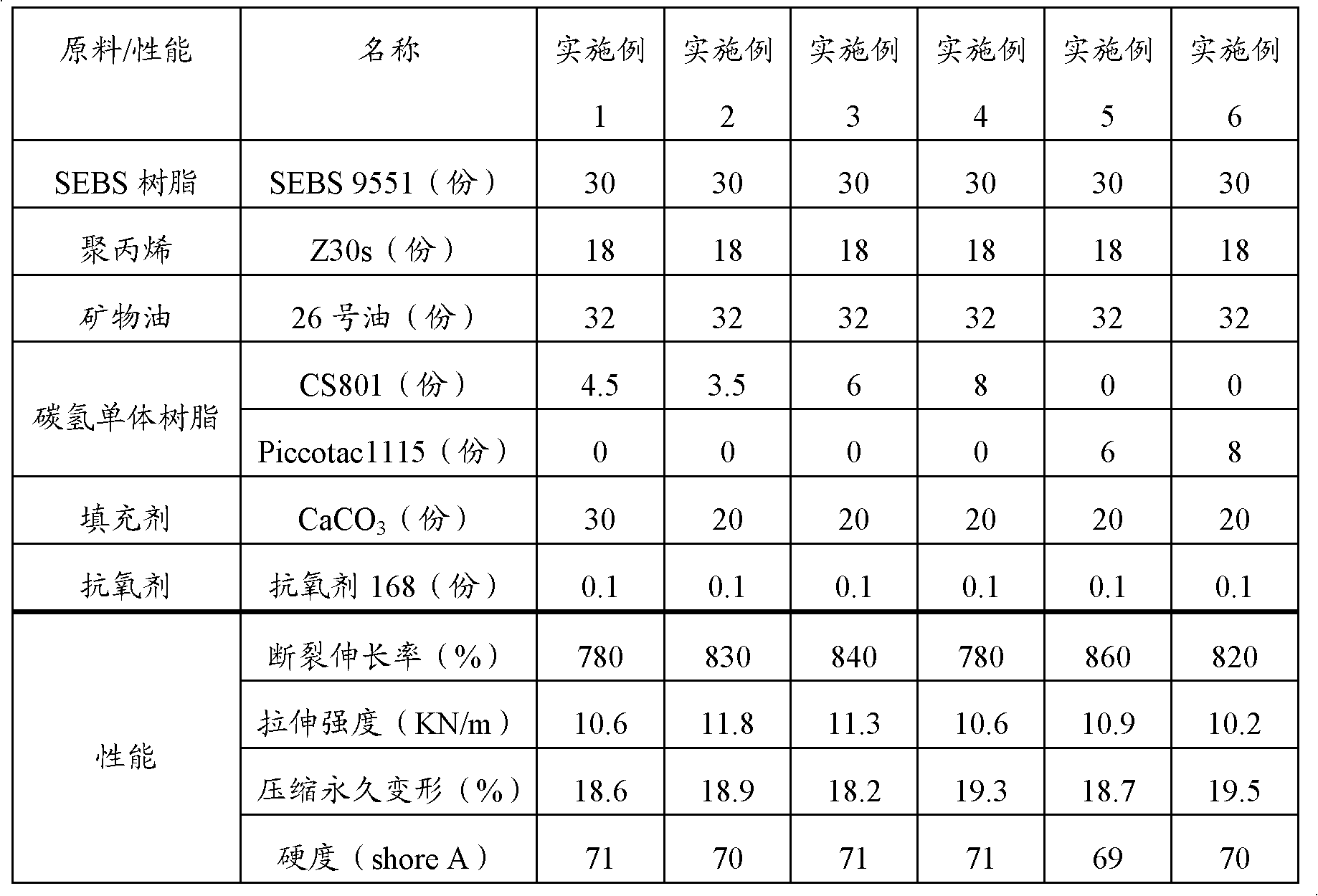

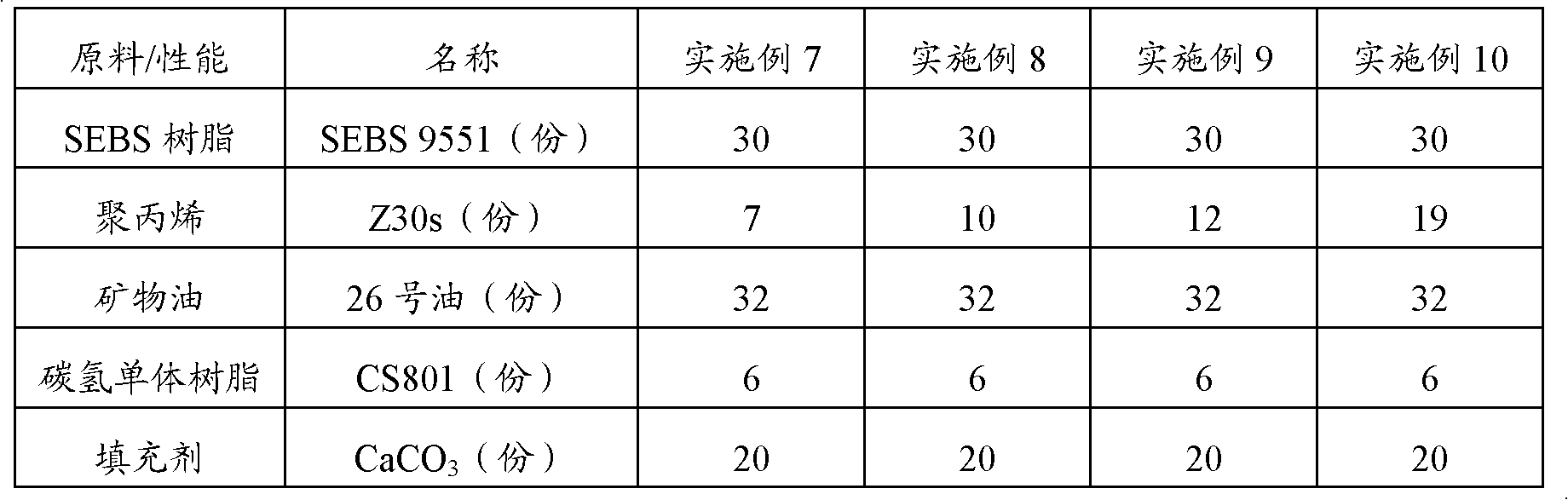

[0034] According to the formula listed in Table 3, Examples 7-10 were carried out in the same way as Comparative Example 1. The results are shown in Table 3.

[0035] table 3

[0036]

[0037]

[0038] The result of table 3 shows that the reduction of polypropylene content is beneficial to the improvement of the compression set of SEBS thermoplastic elastomer, reduces the mechanical property of thermoplastic elastomer, causes product hardness to reduce; Therefore when preparing the product of the present invention, polypropylene content should not be too low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com