Prestressed concrete anti-corrosion pipe pile automatic assembly line operation platform

An anti-corrosion pipe pile and operating platform technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of low degree of automation, high labor intensity, and many safety hazards, and achieve a good working environment and low labor intensity. , the effect of less safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

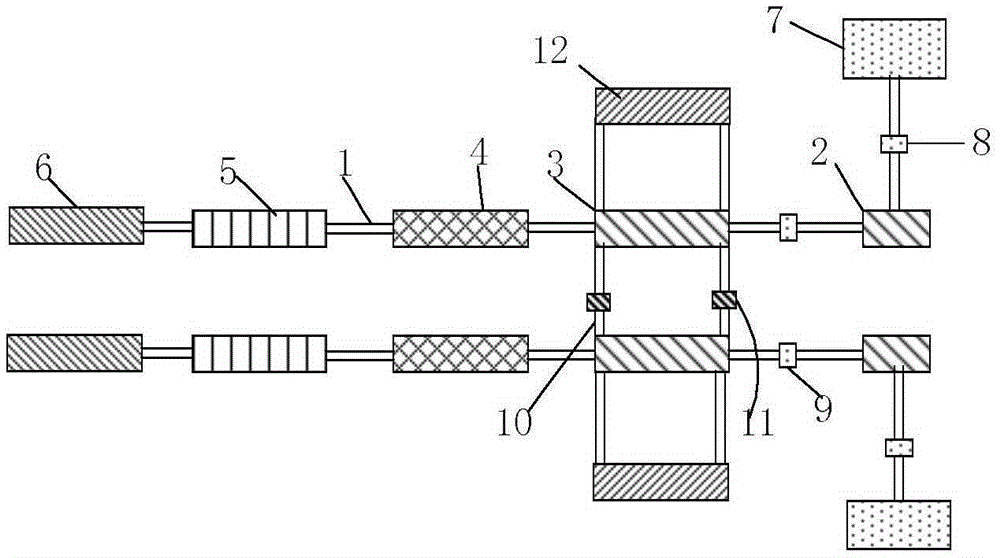

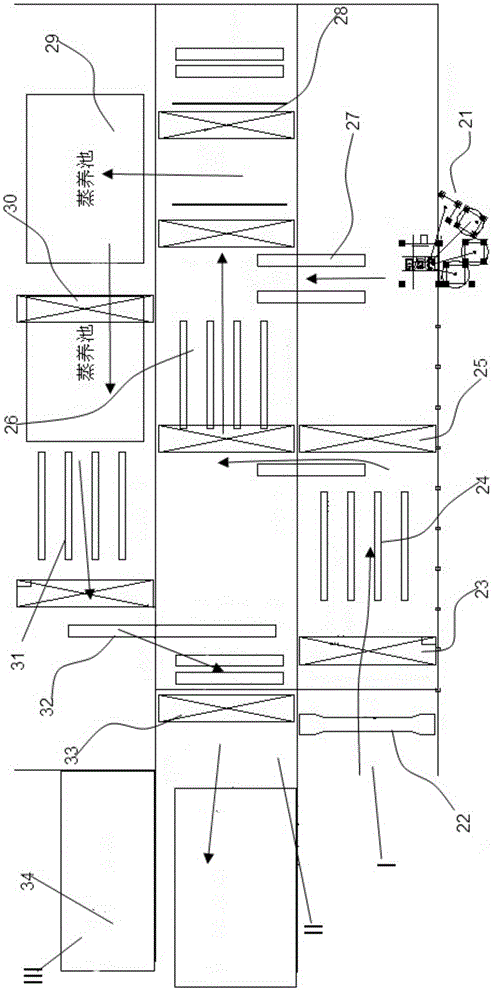

[0011] like figure 1 As shown in the figure, the prestressed concrete anti-corrosion pipe pile automatic assembly line operation platform of the present invention can adopt a linear design, which includes two parallel linear working tracks 1, and the mixing zone 2 and the centrifugal zone 3 are sequentially arranged on each working track. , normal temperature steaming area 4, high temperature steaming area 5 and pipe pile stacking area 6, and a transport vehicle running between the centrifugal area and the pipe pile stacking area, the rail is provided with a pipe mold transmission chain or crawler, the centrifugal area There is a sound-blocking wall around it, and a hoisting mechanism is arranged at the centrifugal area, which is used to hoist a plurality of pipe piles to the transport vehicle; a slurry transport trolley 9 is arranged on the track between the mixing area and the centrifugal area; two tracks There is a tensioner track 10 between the centrifugal areas above, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com